3D printers buying guide

Best 3D Printer 2022 - The Ultimate Buying Guide [WINNERS]

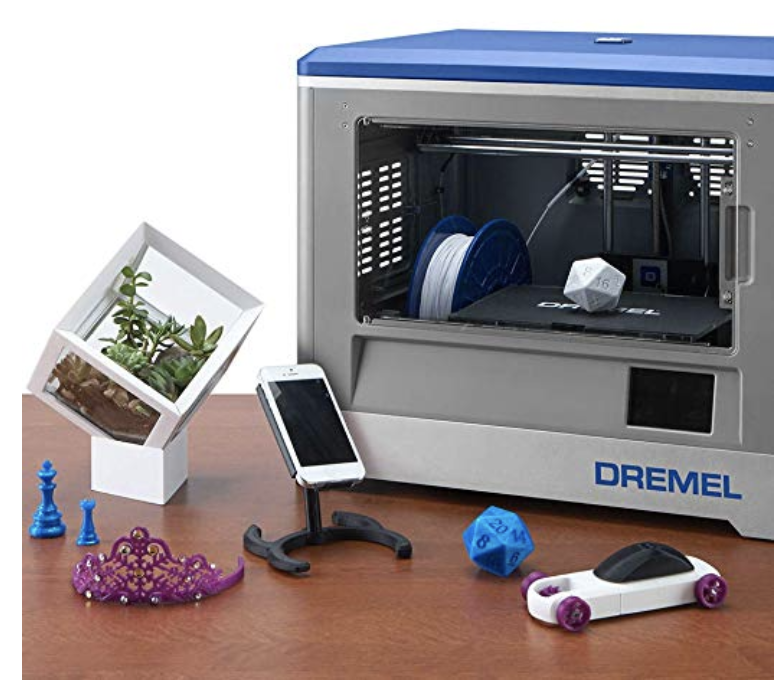

]3D printers grant you the ability to generate anything you can possibly dream of. However, as they’re fairly complex pieces of kit it’s often hard to decide which one is best for your needs.

That’s where we come in. We’ve researched some of the best 3D printers on the market and broken them down by category. No matter your needs or budget, we’re positive that there’s a 3D printer right here for you!

Table of ContentsShow

Zoom Out: The 15 Best 3D Printers For 2022

In the short buyer’s guide below we’ll explain a few things to look out for. This will help ensure that you find a printer that fits your needs and prevents you from feeling ripped off or otherwise disappointed in your new product. Now, before you spend any money, it’s important to know what the 3D printer’s specifications mean.

We know, we know, it’s a little boring but it CAN save you hundreds of dollars and a whole lot of buyer’s remorse, so taking a little extra time to compare different products is of grand importance.

Build Area

This one is really simple. The build area of a 3D printer refers to the maximum size of an object you can create.

Now, 3D printers come in all shapes and sizes, so some might have a taller or wider build area than others. You can still use most of the templates you’ll find online but you might have to rotate them first.

Generally speaking, bigger is better when it comes to the build area. Unfortunately, larger areas usually mean a higher price tag, so you should try and strike a balance between creating huge items and saving money in the long term.

Materials

Essentially, 3D printing works by heating a filament until it’s malleable and remolding it in the shape you need. However, there are several different filament materials on offer and not every printer can use every type.

The most commonly used filaments are ABS and PLA. These make durable, temperature resistant items, but there are many other types available. If you want to use one, in particular, make sure the printer supports it before buying.

There are even 3D printers that can use other materials, like clay or Sugru. The problem with these printers is that they’re usually less reliable than standard filament-based models. If you’re an artist or want to use a printer for experimental use then have at it, but most people will be better suited towards a standard printer.

Print Speed

Here’s the bad news: 3D printing is still very slow despite its many advancements.

Generally, most low-budget printers go at a rate of around 50mm per second. This means that larger models can take a long time to create. There’s another problem: very fast printers create thicker, more obvious layers in the final product. This proves that usually, slow and steady is the better option.

Some printers allow you to add an additional extruder (essentially a nozzle) to speed up the printing process. These have another upside too – you may even be able to use multiple materials at the same time. If this is something that you think you’d like, consider purchasing a dual-extruder model.

Best Budget 3D Printers

While 3D printers still aren’t particularly cheap, there are several that come with a relatively low price tag. We’ve located and thoroughly researched three of the best budget 3D printers on the market so that you don’t have to.

Take a look!

Monoprice Select Mini

Our first recommendation is the Monoprice Select Mini. At a little over $200, this model is an excellent choice for people looking to dip their toes into the world of 3D printing.

It has a 4.7” build area. This isn’t huge, but it’s still large enough to create models or little things for around the home. With a printing speed of 55mm/s, it’s slightly faster than others in this price range. Need a bracket for that cupboard door? No problem, just wait a few hours.

With its WiFi capability, MicroSD slot, and simple, intuitive interface, this product offers far more than you expect. Also, its price makes it an absolute bargain.

New Matter MOD-t

Next, let’s take a look at the New Matter MOD-t. This is a futuristic looking printer that comes with lifetime tech support and wireless printing functionality.

It uses PLA filament and can print at up 80mm/s, although its speed is adjustable. This allows you to spend a little longer to create a smoother, more professional looking product or just get the job done quickly depending on the situation. Good, right?

It has a slightly larger build area than the Monoprice, and accordingly, costs a little more money. That said, we believe that the versatility of this product more than offsets the increase in price.

XYZprinting da Vinci Jr.

Lastly, in this category, we have the XYZprinting da Vinci Jr. This model has a 5.9” build area and a maximum printing speed of 100mm/s, making it larger and faster than the two others we’ve seen.

So what’s the catch?

Well, this printer uses a uniquely sized filament. It’s a little less expensive than you might think, but your options for buying filament are very restricted. This can, in turn, lead to slightly more expensive refills.

It’s a little less expensive than you might think, but your options for buying filament are very restricted. This can, in turn, lead to slightly more expensive refills.

That said, in terms of performance, this product far outshines the others we’ve seen so far. It’s unfortunate that you can’t use standard filament with this model, but if this doesn’t bother you then the da Vinci Jr. would be an excellent choice.

Best Commercial 3D Printers

At some point, a standard 3D printer just isn’t going to meet your needs. Maybe you’re considering starting a printing business or just have exceptionally high demand. Whatever you need, we’re positive that one of the two following models will fit the bill.

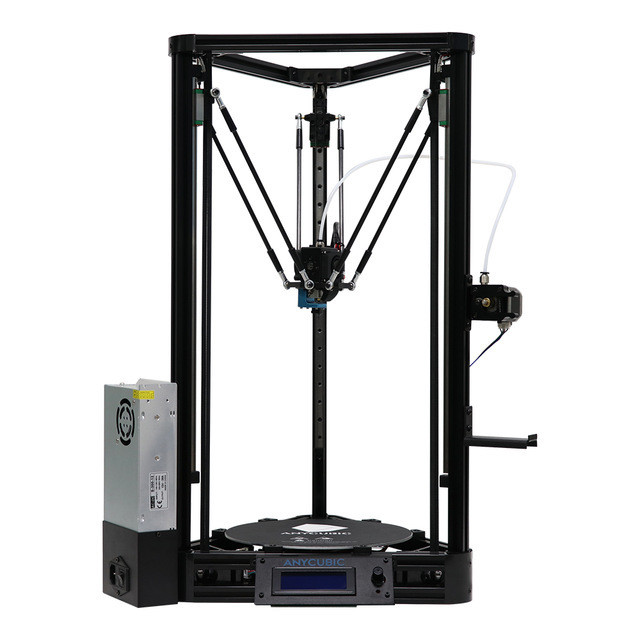

Lulzbot TAZ 6

The Lulzbot TAZ 6 is very well-known in the 3D printing community, but it comes with a substantial $2500 price tag. So what does this product do to justify it?

Well, keep reading to find out.

Firstly, it has a massive build area of almost 11 square inches. Secondly, with the TAZ 6, you aren’t limited to just the standard materials. In fact, it can handle more than 30 different types of filament including wood, metal, and stone composites.

Secondly, with the TAZ 6, you aren’t limited to just the standard materials. In fact, it can handle more than 30 different types of filament including wood, metal, and stone composites.

Not only that but this model has a self-leveling and self-cleaning print head. This takes the hard work away and leaves you free to enjoy the design and printing process.

So is it still as slow as all the rest? Well, it’s dual extruder compatible. This means that you can hypothetically halve the time it takes to complete a model, although of course, as we’ve mentioned above, this will affect the overall look of the finished result.

All things considered, we think that this printer will likely be too expensive and too high-tech for most people’s needs, but for commercial printers or organizations who plan to use it a lot, it’s actually very reasonably priced.

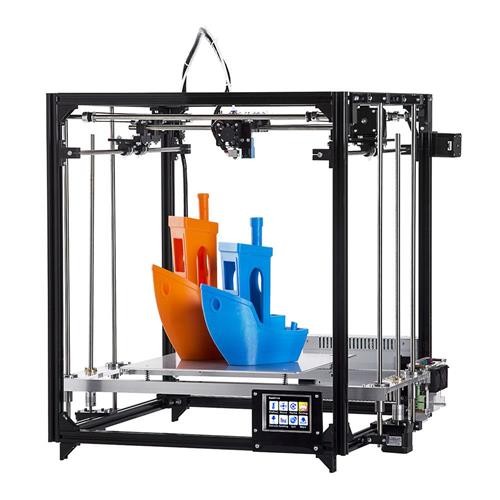

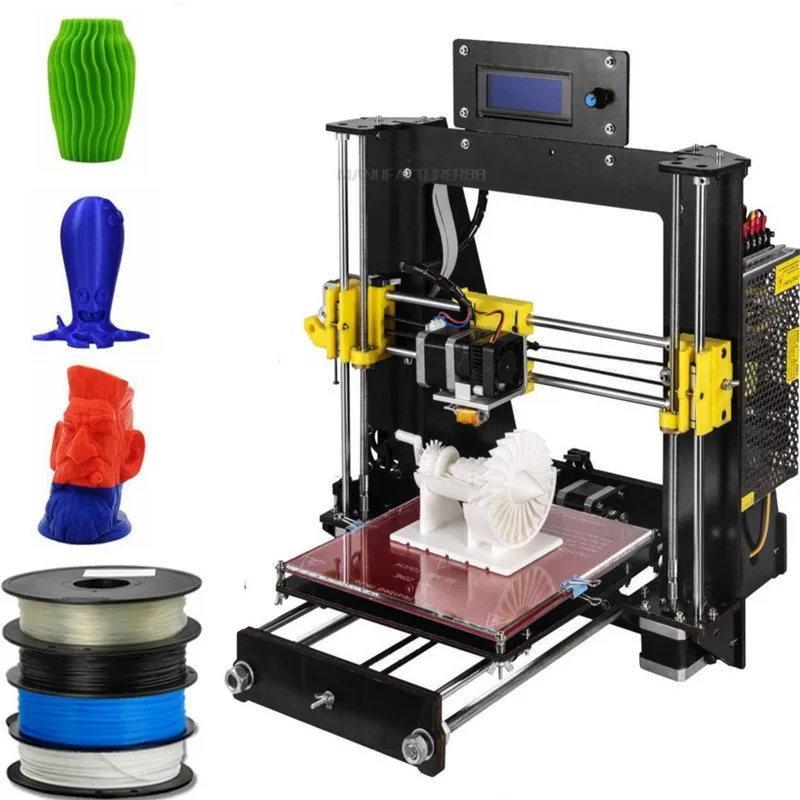

HICTOP Creality CR-10

The second commercial printer we’ve found is the HICTOP Creality CR-10. This is far less expensive than the TAZ, at around $500, yet provides an even larger build area.

This is far less expensive than the TAZ, at around $500, yet provides an even larger build area.

This is due to this printer’s open design. It’s not constrained by the same hardware and can freely create things much larger than most of its rivals could handle. This simple design means that this printer can be broken down into just three parts for easy assembly. What else is good?

This printer has a variable printing speed. At its base rate, it can run at 80mm/s but this can be boosted as high as 200mm/s if you’re in a hurry. Layers can be as thick as 0.4mm or as thin as 0.5mm so there’s a good degree of creative freedom with the CR-10.

You might expect the CR-10 to be a compromise considering its far more palatable price. However, nothing could be farther from the truth. It’s a solid, fast 3D printer that can handle anything you throw at it.

Ultimately, if you don’t care about using anything except PLA then there’s no reason to spend any extra money on a fancy printer. Simply put, this model has everything you need.

Simply put, this model has everything you need.

If you work in a creative field, you’ll probably have been asked to create a rapid prototype of something. What if you could remove the hassle from this and create an even higher quality item while you were away doing other things?

Well, you can. The following 3D printers are packed full of features that make them invaluable to designers and we’re confident that you’ll find one you like.

FlashForge Creator Pro

First up we have the FlashForge Creator Pro. This is a pretty pricey printer but it supports printing with a huge range of different materials including wood and nylon. So how is it to use?

It does have a fairly small build area, but this is offset by its high speed. This means that you can create several smaller items and combine them later at the same time that creating a larger object would have taken.

This printer supports tetherless printing via SD card, but there’s no WiFI functionality. Considering it’s the kind of product that would be best suited to a computer lab, this really isn’t as big of an issue as it appears at first.

Considering it’s the kind of product that would be best suited to a computer lab, this really isn’t as big of an issue as it appears at first.

Overall, while the FlashForge can seem a little overpriced considering its small build area, it’s actually pretty good at what it does. We particularly liked its wide material support – this is something usually only found in far more expensive models and something we’re sure will come in handy.

QIDI TECHNOLOGY

There’s also a reasonably priced 3D printer from QIDI TECHNOLOGY. It costs around $400 and has a 5.5” build area. This is a pretty small chamber but considering this is a mid-budget pick, that’s to be expected.

So what is this printer’s best feature?

One of the things we really liked about this printer is its ultra-simple interface. 3D printing can get pretty technical so having something that’s easy to understand is a breath of fresh air and will help less experienced users feel more at home.

This printer supports both simple and advanced materials, although there are limits. You won’t be able to print with wood, for example, but less common plastic composites will work just fine.

All in all, the QIDI printer is a decent middle ground between the functionality of an advanced model and the price of a budget one. For that reason alone, it’s a strong choice, but when you take the versatility into account, this printer becomes a no-brainer for any designer.

Best 3D Printer For Hobbyists

Maybe the products we’ve seen thus far are way more than you’re looking for. Maybe you only want a 3D printer for occasional use or to help facilitate another one of your hobbies.

That’s okay too!

However, since you’re not going to be a heavy user, it doesn’t make sense to spend a lot of money. Below, you’ll find two 3D printers that are as versatile as they are inexpensive.

XYZPrinting Mini

First up is another entry in XYZPrinting’s da Vinci line. The XYZPrinting Mini is, as you might expect, a tiny little printer. It stands just 24” tall, 18” wide, and 15.5” deep. This makes it nice and easy to put away in a closet when you aren’t using it.

The XYZPrinting Mini is, as you might expect, a tiny little printer. It stands just 24” tall, 18” wide, and 15.5” deep. This makes it nice and easy to put away in a closet when you aren’t using it.

It has a build area that’s a reasonable size given this model’s sub-$200 price and 5.9” is plenty of space to create most of the things you’ll want, plus you can always combine components if you want to make something larger. So, let’s talk filament.

Like the da Vinci Jr., the Mini only uses a proprietary XYZPrinting filament. This is fairly standard PLA material but it’s a little narrower than other brands’. This does mean that filament is slightly more cost-intensive, but infrequent users will find that they don’t have to buy extra filament all that often anyway.

There’s a lot to like here. This product has an incredibly simple interface: it’s a single button with LED lights to indicate print status. This helps make the Mini an excellent choice for people looking to experiment with 3D printing for the first time.

This printer takes the stress out of setup by automatically calibrating itself and with a maximum speed of 120mm/s, it’s more than capable of getting things done quickly when necessary.

So it’s perfect, right? Well, not exactly.

We did find that the Mini is a little loud, but that’s to be expected at this price range. If you’re planning to print overnight, we’d recommend placing this product as far from the bedroom as possible because even if it seems quiet at first, it can quickly become distracting enough to keep you awake.

Apart from its noisy operation, the da Vinci Jr. is an exemplary little 3D printer. It comes with everything you need to get started and is unhampered by the extensive setup and configuration process that more advanced printers are.

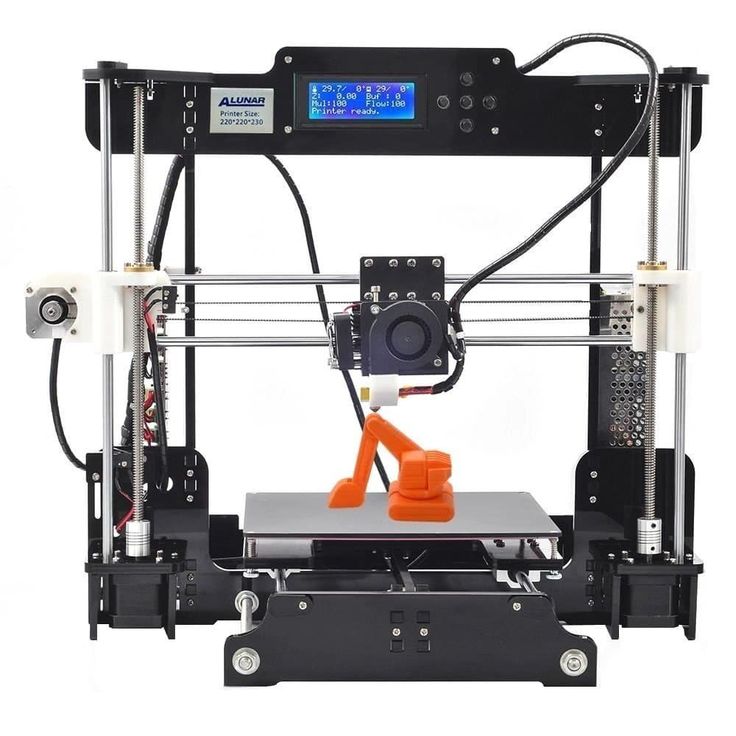

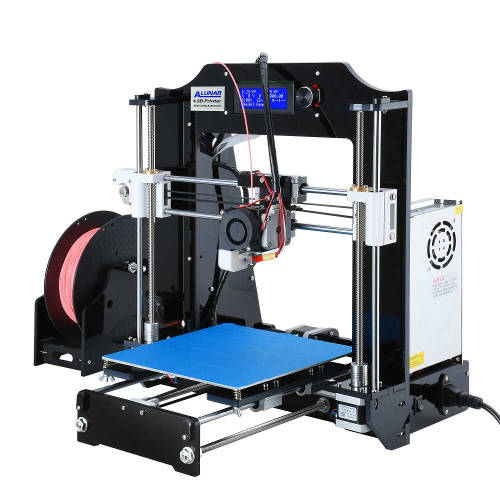

ALUNAR 3D Printer

If the Mini’s reliance on specific materials annoys you, you might be better suited to the ALUNAR 3D printer. It’s capable of using any standard filament plus some more advanced ones like wood or conductive materials.

This printer is a touch more expensive at around $210. That said, it comes with a 1000 hour motor guarantee, so you can expect it to work for a long time. So far, so good.

Now, a word of warning. This printer requires some assembly. For the most part, this is very simple but it does require some degree of common sense. For example, you’ll have to switch the voltage to either 100V or 220V depending on your input.

We really liked that this printer lets you pause your work at any time. This allows you to quiet it down after hours or catch any mistakes before they’re set in stone (possibly literally). You’ll have to be quick, though: this printer can go as high as 100mm/s.

Again, the ALUNAR has a slightly more complex user interface than the Mini. It has five buttons and an LCD display for navigating its menu system. Rather than complicating things, this actually makes the user feel like they have more control, and with this new wave of tech, that’s a benefit that can’t be understated.

This is a printer that provides the best of both worlds. On one hand, it offers far more creative freedom than its rivals, and on the other, it does require some construction. Nonetheless, we still recommend it.

Best Mid-Budget 3D Printers

The products above are great but let’s say you don’t fit neatly into any of our categories and just want to know what’s available. Well, you’re in luck! We’ve created a list of the best all-around 3D printers in the mid-budget range to help you out.

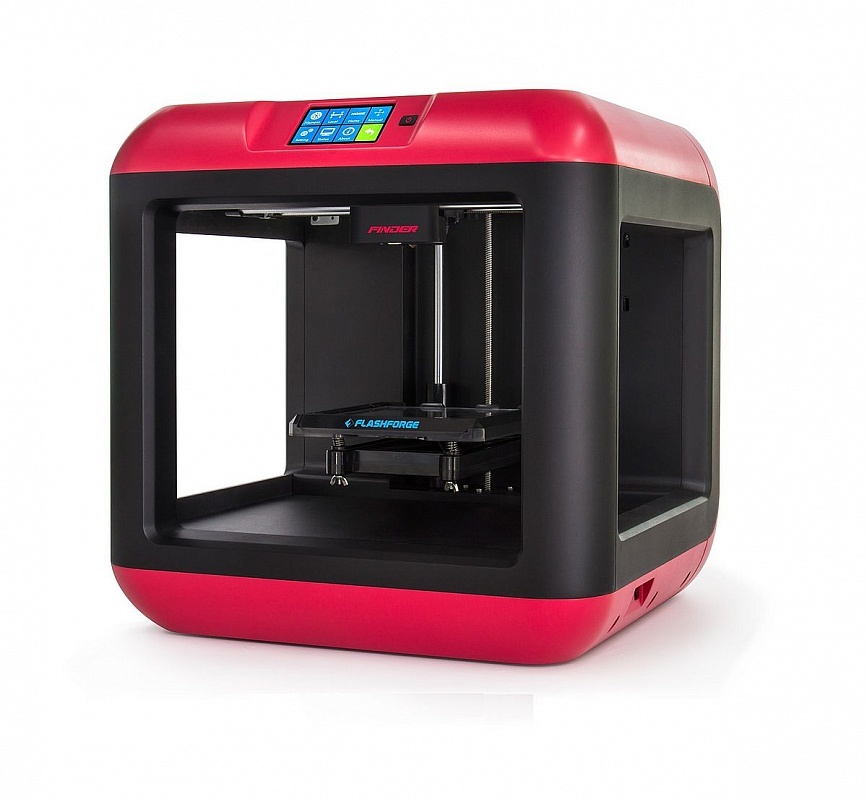

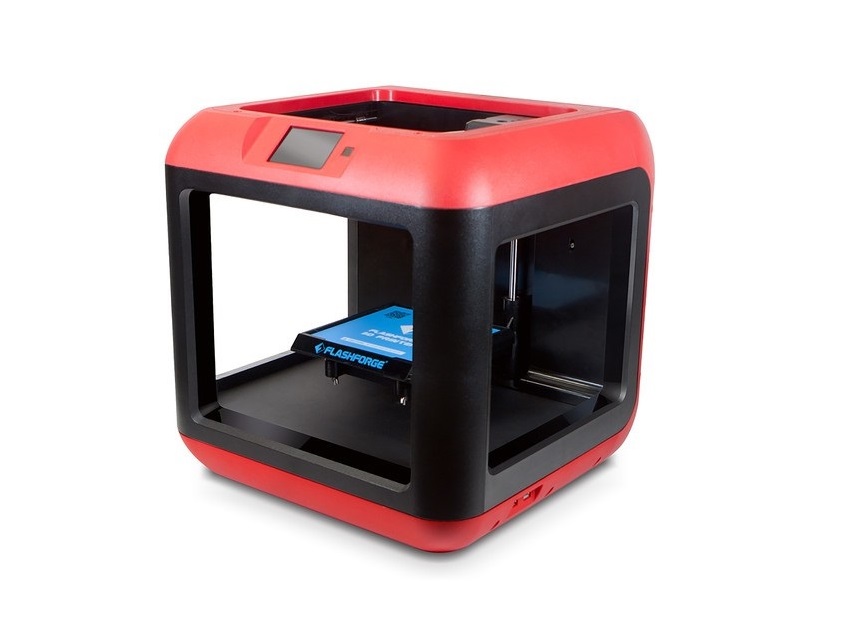

FlashForge Finder

Let’s take a look at the FlashForge Finder. It costs around $400 and has a 5.5”3 build area. But that’s far from all this product has to offer.

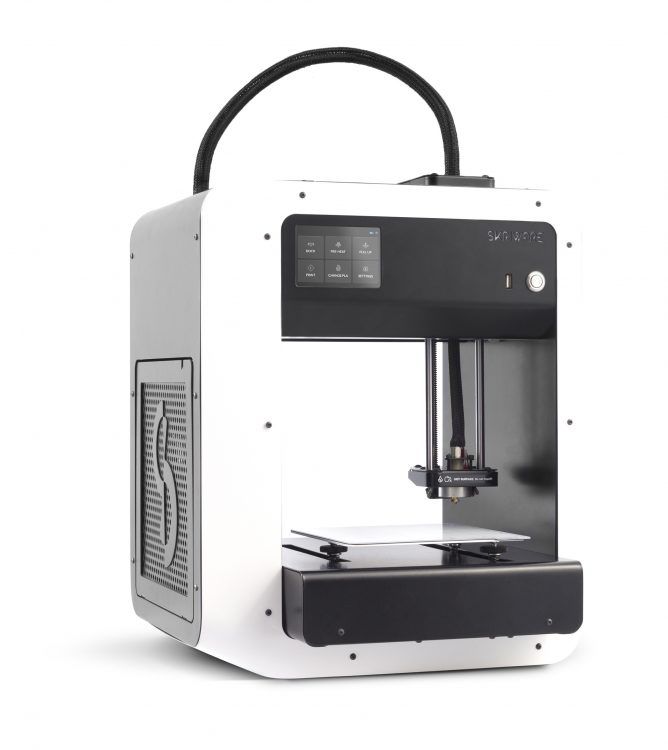

This printer is exactly what you imagine when someone says “3D printer”. It looks futuristic and sleek, featuring a small 3.5” LCD touchscreen interface. This keeps operation nice and simple while providing enough flexibility to navigate menus with ease.

The Finder offers two ways to import files. The first is the standard SD care and flash drive support, but it also features WiFi functionality for tetherless printing. This can be especially useful if your computer is somewhere out of the way and you don’t fancy running cables through your home.

The first is the standard SD care and flash drive support, but it also features WiFi functionality for tetherless printing. This can be especially useful if your computer is somewhere out of the way and you don’t fancy running cables through your home.

The only issue with this printer is that it’s designed to work only with FlashForge PLA filament. That said, it’s also possible to use Hatchbox filament if you run it in from outside. Either way, your filament options are limited which may lead to slightly increased costs down the line.

One of the things we really liked about this model is its filament refill alert. It automatically detects when you’re running low so you never find yourself halfway through a print and having to buy extra filament.

QIDI TECHNOLOGY 3DP-QDA16-01

Our second pick is the QIDI TECHNOLOGY 3DP-QDA16-01. What it lacks in a catchy name, it makes up for in terms of functionality.

First up, it has a slightly wider than average build area at 8. 8”. This gives you the freedom to create ever larger items and given its price (around $650) this size is excellent. So what else does it offer?

8”. This gives you the freedom to create ever larger items and given its price (around $650) this size is excellent. So what else does it offer?

Well, it’s almost entirely metal. This not only looks good but lends the printer added stability and structure. This is more important than you might think – with temperatures up to 280° you need all the stability you can get.

It features a dual-extruder setup. This means that you can print models up to twice as fast as other models. There is very little range in terms of layer size, however. It ranges from 0.1-.2mm and while you might think that this makes layers noticeable, it’s actually not that bad.

We really liked that this model comes with 24-hour tech support and a turbofan cooling function to let you grab your items as soon as possible after it’s done.

Files can be transferred either via SD card or USB stick, and while there’s no WiFi capability, this is just a bonus and isn’t all that necessary.

Robo R1+

Lastly, in this category, we have the Robo R1+. Sounds fancy, right? Well, you’ll be pleased to hear that its functionality lives up to its futuristic name.

Sounds fancy, right? Well, you’ll be pleased to hear that its functionality lives up to its futuristic name.

This printer has a quick-change extruder system and fast-feed filament setup. Finally – a printer that can keep up with the fastest print speeds, In many ways, it’s designed for professionals – with maintenance this simple, it’s no longer a chore.

Believe it or not, it gets better. This printer has an absolutely huge build area. For around $500 you can create items up to 10” x 9” x 8” in size. That’s incredible, but wait, there’s more.

Let’s say you run into trouble using the R1+. No problem – just use the free 24-hour tech support. Ah but wait, what if the problem is your hardware itself? Relax! The R1+ is covered by a six-month parts warranty, so you can have it fixed at no additional cost. Good, right?

Our last point is a big one: this printer can use more than 30 different materials including carbon fiber PLA, rubber, and stainless steel. This provides unparalleled flexibility in terms of what you can create and frankly at this price range, that’s amazing.

Best High-End 3D Printers

Okay, we’ve covered most of the popular basic 3D printers but what if you have a little more money to spend? You’ll likely want printers with functionality that you can’t find in lower price brackets, right? The printers below offer extra features, both in terms of ease of use and printing capability.

Robo R2 3D Printer

Our first high-budget pick is the Robo R2 3D printer. This is priced at around $1500 so it’s not going to be for everyone. Those that can afford it, however, will find that it offers a lot of bang for your buck.

Did you know that this printer can print very thin layers? They range from 0.02mm to 0.3mm which is frankly crazy. This is far finer than any other printer we’ve seen and will result in a much more professional looking finished piece.

The build area is large but not as big as some due to the closed nature of the printer. Still, there’s plenty of space available for those who like to create larger items. This printer can actually save you time: models that would have to be done in parts on other printers can be done in one go with the R2.

This printer can actually save you time: models that would have to be done in parts on other printers can be done in one go with the R2.

More than 30 different materials are supported and because you can add a second extruder, you can even print two at once for a more attractive end product. If you’re not impressed yet, maybe this final point will change your mind.

The R2 comes with a year’s subscription to a professional level printing program, and there’s even 24/7 customer support, as well as a year’s warranty on parts. What’s not to like?

JGAURORA Printer

Next, we have the JGAURORA printer. It’s still considered a high-budget printer but costs about half as much as the R2. If you found the R2’s high price tag too hard to justify, perhaps this would be a better choice.

Let’s start with the basics. This printer works with any 1.75mm printing filament. That’s it – there are no other restrictions. This makes it an excellent choice for those who want to build complex, multi-material pieces without spending over a thousand dollars.

It also features a switchable voltage so be sure to alter this based on your power source. The frame is made of metal for added stability, plus the temperature can be controlled either by changing it directly or by using the built-in fan. So how is it for printing?

In a word: excellent. The layer thickness can be adjusted from 0.1-0.4mm which allows for some exceptionally high-quality models. These can be pretty large too since the build area is 11” wide, 7.9” tall and deep.

While this printer can’t connect via WiFi it does come with an 8GB SD card and reader. To be honest, WiFi connectivity would have been a bonus, but it’s hardly essential. The only difference is that files have to be transferred across. On the plus side, an SD card can load data faster than WiFi so you can get started sooner.

Sindoh 3DWOX DP200

Our final recommendation is the Sindoh 3DWOX DP200. Now, you might be thinking “how can I justify spending all this money on a product with a 7. 9×7.9×7.3” build area. Well, this printer has a number of features that make it a strong contender, and we’ll outline these below.

9×7.9×7.3” build area. Well, this printer has a number of features that make it a strong contender, and we’ll outline these below.

Take connectivity, for example. It can use Ethernet, USB, WiFi, or SD cards. Better still, it has an internal camera that can be viewed remotely. Want to check on its progress while at work? No problem!

This model makes it easier to begin printing, too. It can automatically load and unload filament and uses specialized technology to assist you during the bed-leveling process. The only way this printer could make your life even easier is if it sprouted legs and plugged itself in.

Now, this printer supports fewer material types than some of the others we’ve seen. That said, it still accepts the standard PLA and ABS filaments so the most commonly used types will work. Considering the layers can be as fine as 0.05mm, you’ll be able to create truly stunning, professional looking items.

Overall, we believe this printer to offer a good middle ground between performance and affordability. Although it has only basic material support, no other product on this list offers a camera or as many connectivity options.

Although it has only basic material support, no other product on this list offers a camera or as many connectivity options.

What 3D Printer Should You Buy? A Simple Buying Guide – 3D Printerly

Buying a 3D printer is an important step to getting optimal results and making sure you don’t experience many issues that might stop you from getting into 3D printing with enthusiasm. There are some important factors you’ll want to know before buying a 3D printer, so I decided to write an article about it.

What to Look For in 3D Printers – Key Features

- Printing Technology

- Resolution or Quality

- Printing Speed

- Build Plate Size

Printing Technology

There are two main 3D printing technologies that people use:

- FDM (Fused Deposition Modeling)

- SLA (Stereolithography)

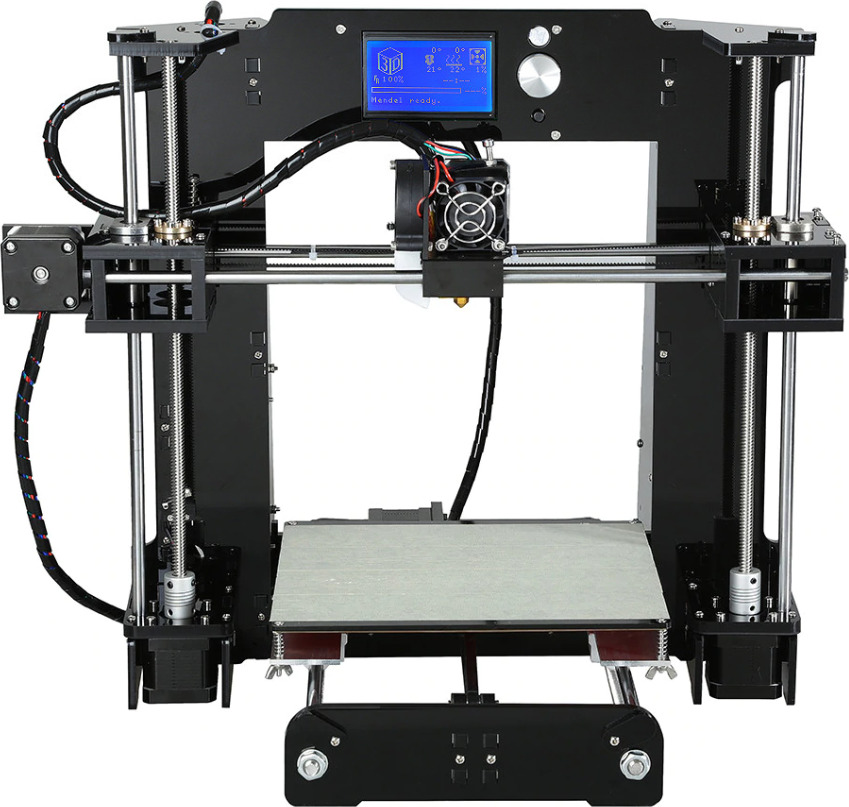

FDM (Fused Deposition Modeling)

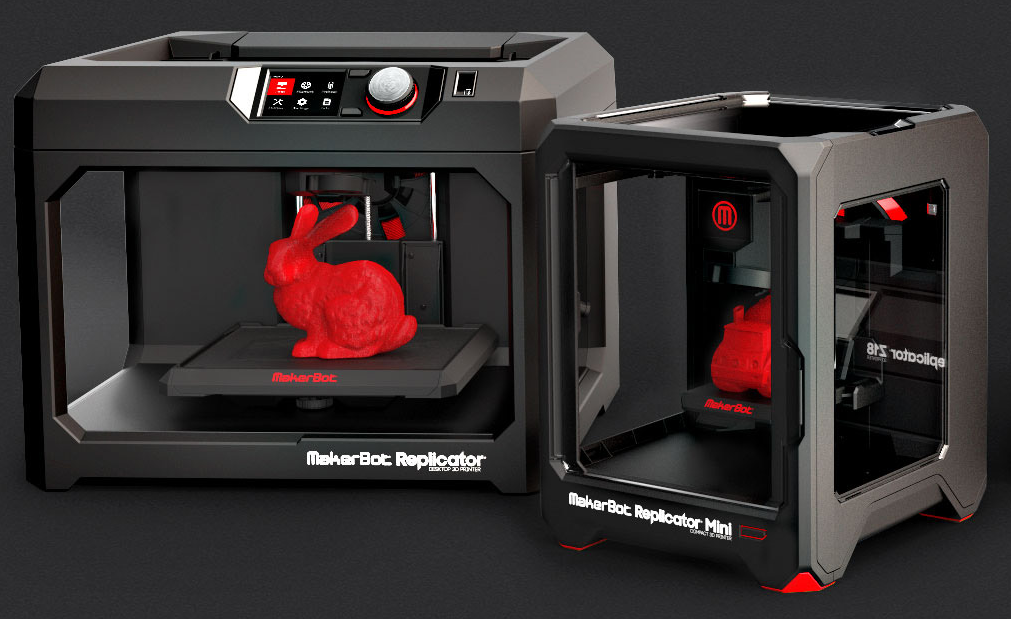

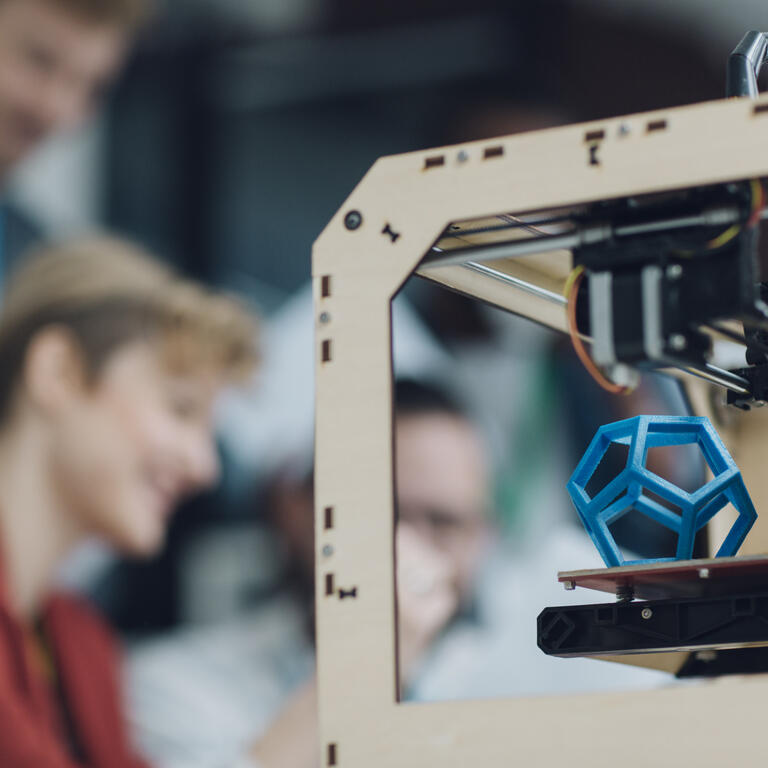

The most popular 3D printing technology today is FDM 3D printing. It’s very suitable for beginners, up to experts for creating 3D prints. When you are choosing a 3D printer most people will start with an FDM 3D printer, then decide to branch out with more experience.

When you are choosing a 3D printer most people will start with an FDM 3D printer, then decide to branch out with more experience.

This is personally how I got into the 3D printing field, with the Ender 3 (Amazon), priced at around $200.

The best thing about FDM 3D printers is the cheaper cost, ease of use, larger build size for models, wide range of materials to use, and overall durability.

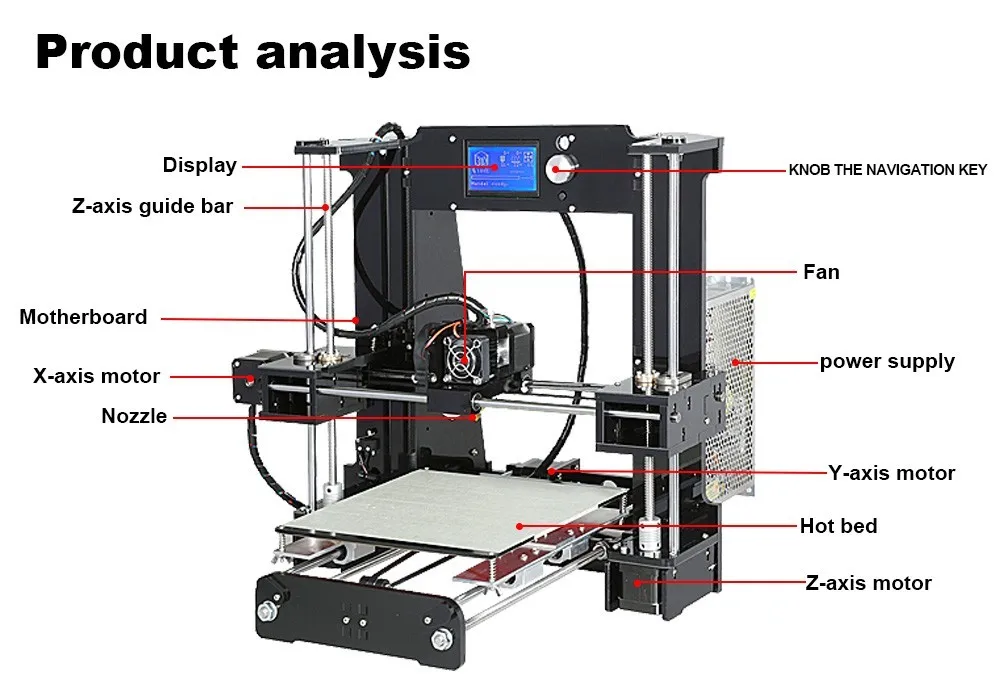

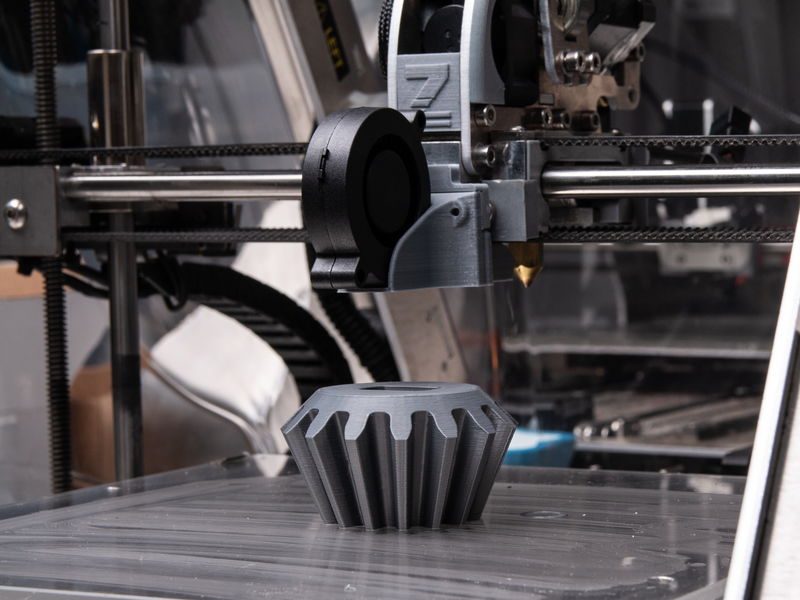

It works mainly with a spool or roll of plastic which gets pushed through an extrusion system, down into a hotend that melts the plastic through a nozzle (0.4mm standard), and gets placed down onto a build surface, layer by layer to form your 3D printed model.

It does require some basic knowledge to get things right, but as things have developed, it’s very easy to set an FDM 3D printer up and get some models 3D printed within the hour.

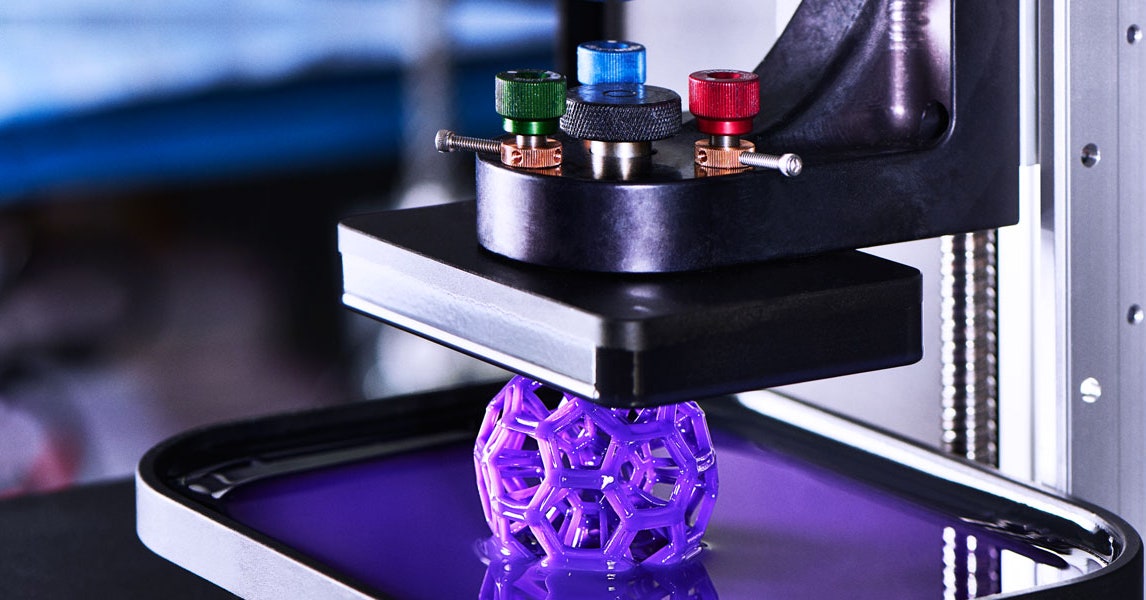

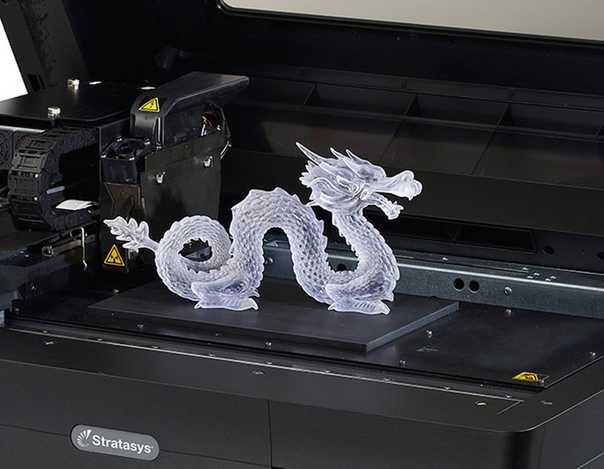

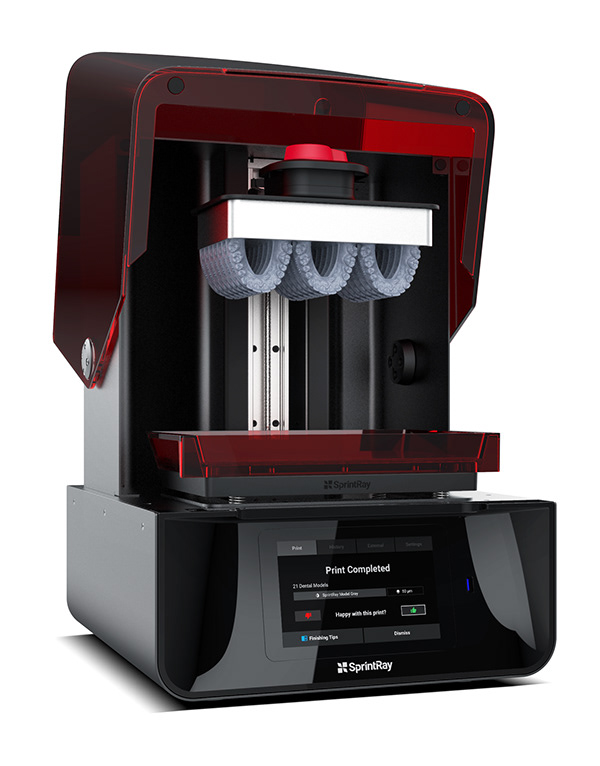

SLA (Stereolithography)

The second most popular 3D printing technology is SLA 3D printing. Beginners can still start with this, but it will be a little more challenging than FDM 3D printers.

This 3D printing technology works with a photosensitive liquid called resin. In other words, it’s a liquid that reacts and hardens to a certain wavelength of light. A popular SLA 3D printer would be something like the Elegoo Mars 2 Pro (Amazon), or the Anycubic Photon Mono, both around $300.

The best thing about SLA 3D printers is the high quality/resolution, speed of printing multiple models, and ability to make unique models that manufacturing methods can’t produce.

It works with a vat of resin placed on the main machine, which sits on top of an LCD screen. The screen shines a UV light beam (405nm wavelength) in specific patterns to produce a layer of hardened resin.

This hardened resin sticks to a plastic film at the bottom of the resin vat, and peels off onto a build plate above due to the suction force from the build plate lowering down into the resin vat.

It does this layer-by-layer until your 3D model has completed, similar to FDM 3D printers, but it creates models upside down.

You can create really high quality models with this technology. This type of 3D printing is growing quickly, with many 3D printer manufacturers starting to build resin 3D printers for cheaper, with higher quality and more durable features.

Working with this technology is known to be more difficult as compared to FDM because it requires more post-processing to finish off 3D models.

It’s also known to be quite messy since it works with liquids and plastic sheets which can sometimes pierce and leak if a mistake is made with not cleaning out the resin vat properly. It used to be more expensive to work with resin 3D printers, but the prices are starting to match up.

Resolution or Quality

The resolution or quality that your 3D printer can reach is usually limited to a level, detailed in the 3D printer’s specifications. It’s common to see 3D printers that can reach a 0.1mm, 0.05mm, down to 0.01mm.

The lower the number, the higher the resolution since it refers to the height of each layer the 3D printers will produce. Think of it like a staircase for your models. Each model is a series of steps, so the smaller the steps, the more details you’ll see in the model and vice versa.

Think of it like a staircase for your models. Each model is a series of steps, so the smaller the steps, the more details you’ll see in the model and vice versa.

When it comes to resolution/quality, SLA 3D printing that uses the photopolymer resin can get much higher resolutions. These resin 3D printers usually start off with a resolution of 0.05mm or 50 microns, and reach up to either 0.025mm (25 microns) or 0.01mm (10 microns.

For FDM 3D printers that use filament, you’ll usually see resolutions of 0.1mm or 100 microns, down to 0.05mm or 50 microns. Although the resolution is the same, I find that resin 3D printers that use 0.05mm layer heights produce better quality than filament 3D printers that use the same layer height.

This is because of the method of extrusion for filament 3D printers have a lot more movements and weight that reflect imperfections on the models. Another factor is with the small nozzle where the filament comes out from.

It can get slightly clogged or not melt fast enough, leading to small blemishes.

But don’t get me wrong, filament 3D printers can produce really high quality models when calibrated and optimized properly, quite comparable to SLA 3D prints. 3D printers from Prusa & Ultimaker are known to be very high quality for FDM, but costly.

Printing Speed

There are differences in printing speed between 3D printers and 3D printing technologies. When you look at the specifications of a 3D printer, they will usually detail a specific printing speed maximum and an average speed that they recommend.

We can see a key difference of printing speeds between FDM and SLA 3D printers due to the way they create 3D models. FDM 3D printers are great for creating models with a lot of height and lower quality models quickly.

The way SLA 3D printers work, their speed is actually determined by the height of the model, even if you use the whole build plate.

This means that if you have one small model that you want to replicate many times, you can create as many as you can fit on the build plate, at the same time that you can create one.

FDM 3D printers don’t have this same luxury, so the speed would be slower in that case. For models like a vase, and other tall models, FDM works very well.

You can even change your nozzle diameter for a larger one (1mm+ vs 0.4mm standard) and create 3D prints a lot quicker, but at the sacrifice of quality.

An FDM 3D printer like the Ender 3 has a maximum printing speed of around 200mm/s of extruded material, which would create a much lower quality 3D print.. An SLA 3D printer like the Elegoo Mars 2 Pro has a printing speed of 30-50mm/h, in terms of height.

Build Plate Size

The size of the build plate for your 3D printer is important, depending on what your project goals are. If you are looking to do some basic models as a hobbyist and don’t have specific projects, then a standard build plate should work well.

If you plan to do something like cosplay, where you’re creating outfits, helmets, weapons like swords and axes, you’ll want a larger build plate.

FDM 3D printers are known to have a significantly larger build volume compared to SLA 3D printers. An example of a common build plate size for FDM 3D printers would be the Ender 3 with a 235 x 235 x 250mm build volume.

A common build plate size for an SLA 3D printer would be the Elegoo Mars 2 Pro with a build volume of 192 x 80 x 160mm, at a similar price. Larger build volumes are possible with SLA 3D printers, but these can get pricey, and harder to operate.

A larger build plate in 3D printing can save you a lot of time and money in the long run if you are looking to 3D print large objects. It’s possible to 3D print objects on a smaller build plate and stick them together, but that can be tedious.

Below is the list of some essential things to consider whether you are buying an FDM or SLA 3D printer.

How to Choose a 3D Printer to Buy

As mentioned in the previous section, there are a couple of different 3D printing technologies and you need to first decide on whether you are going to buy an FDM or an SLA 3D printer.

Once this has been sorted, it’s time to look for the features that should be in your desired 3D printer to perform your task efficiently and get 3D models of your desires.

Below are the major features according to the 3D printing technologies you are going with. Let’s start from FDM and then move on to SLA.

Key Features to Look For in FDM 3D Printers

- Bowden or Direct Drive Extruder

- Build Plate Material

- Control Screen

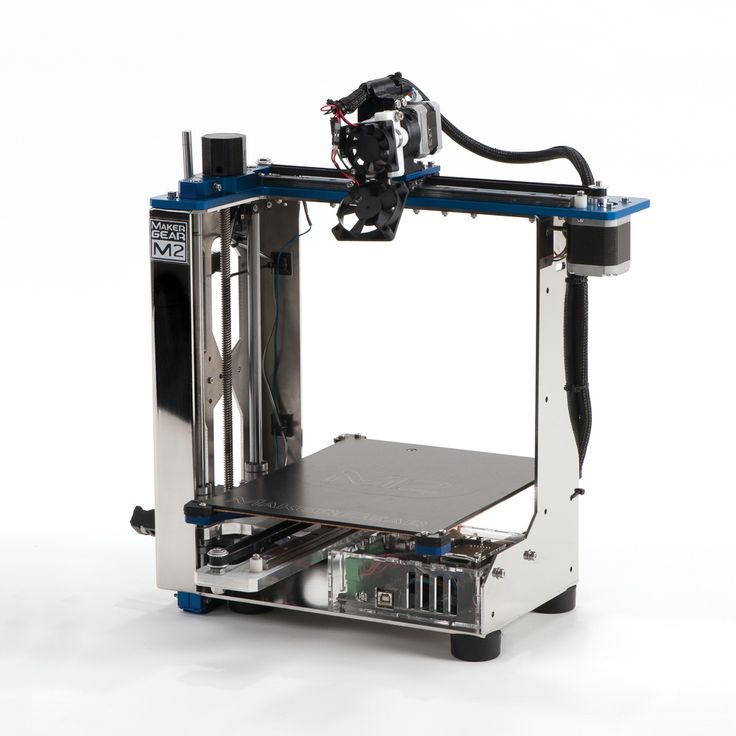

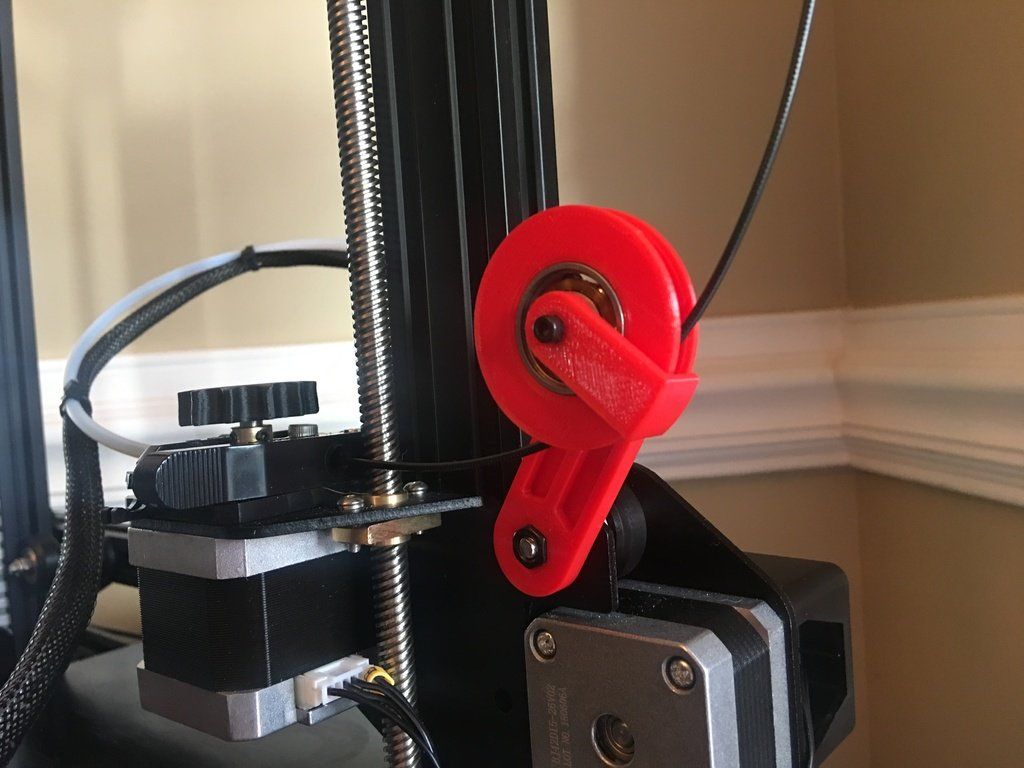

Bowden or Direct Drive Extruder

There are two main types of extruders with 3D printers, Bowden or Direct Drive. They can both produce 3D models to a great standard but there are a few differences between the two.

A Bowden extruder will be more than enough if you are going to print 3D models using standard FDM printing materials while requiring a high level of speed and accuracy in details.

- Faster

- Lighter

- High Precision

You should go for a direct drive extruder setup if you have plans to print abrasive and tough filaments on your 3D printers.

- Better retraction and extrusion

- Suitable for a wide range of filaments

- Small size motors

- Easier to change filament

Build Plate Material

There are a range of build plate materials that 3D printers use in order for filament to adhere to the surface nicely. Some of the most common build plate materials are tempered or borosilicate glass, a magnetic flex surface, and PEI.

It’s a good idea to choose a 3D printer with a build surface that works well with the filament you’ll be using.

They all are usually good in their own ways, but I think PEI build surfaces work the best with a range of materials. You can always choose to upgrade your existing 3D printer bed by purchasing the new bed surface and attaching it to your 3D printer.

Most 3D printers won’t have this advanced surface, but I’d recommend getting the HICTOP Flexible Steel Platform with PEI Surface from Amazon.

Another option you have is to simply apply an external printing surface like Blue Painter’s Tape or Kapton Tape across your build surface. This is a great way to improve adhesion of the filament so your first layer sticks well.

Control Screen

The control screen is fairly important for having a good control over your 3D prints. You can either get a touch screen or a screen with a separate dial to scroll through options. They both work pretty well, but having a touch screen makes things a little easier.

Another thing about the control screen is the firmware of the 3D printer. Some 3D printers will improve the amount of control and options you can access, so ensuring you have a fairly modern firmware can make things easier.

Key Features to Look For in SLA 3D Printers

- Type of Printing Screen

- Build Plate Size

Type of Printing Screen

For resin or SLA 3D printers, there are a few types of printing screens that you can get. They make a significant different on the level of quality you can get in your 3D prints, as well as how long your 3D prints will take, based on the UV light strength.

They make a significant different on the level of quality you can get in your 3D prints, as well as how long your 3D prints will take, based on the UV light strength.

There are two factors you want to look into.

Monochrome Vs RGB Screen

Monochrome screens are the better option because they provide a stronger UV light, so the exposure times that are required for each layer are significantly shorter (2 seconds vs 6 seconds+).

They also have a longer durability and can last around 2,000 hours, versus RGB screens which last for around 500 hours of 3D printing.

Check out the video below for a full explanation on the differences.

2K Vs 4K

There are two main screen resolutions with resin 3D printers, a 2K screen and a 4K screen. There is a pretty significant different between the two when it comes to the final quality of your 3D printed part. They are both in the monochrome screen category, but provide a further option to choose from.

There is a pretty significant different between the two when it comes to the final quality of your 3D printed part. They are both in the monochrome screen category, but provide a further option to choose from.

I’d highly recommend going with a 4K monochrome screen if you want the best quality, but if you are balancing out the price of your model and don’t need anything too high quality, a 2K screen can work just fine.

Do keep in mind, the main measure to look at is the XY and Z resolution. A larger build plate size will require more pixels, so a 2K and a 4K 3D printer could still produce similar quality.

When you have a higher XY & Z resolution (lower number is higher resolution), then you can produce higher quality 3D models.

Check out the video below by Uncle Jessy detailing the difference between a 2K and a 4K monochrome screen.

Build Plate Size

The build plate size in resin 3D printers were always known to be smaller than filament 3D printers, but they are definitely getting bigger as time goes on. You want to identify what kind of projects and goals you might have for your resin 3D printer and select a build plate size based on that.

You want to identify what kind of projects and goals you might have for your resin 3D printer and select a build plate size based on that.

If you are only 3D printing miniatures for tabletop gaming like D&D, a smaller build plate size can still work well. A larger build plate would be the optimal option since you could fit more miniatures on the build plate at a time though.

A standard build plate size for something like the Elegoo Mars 2 Pro is 129 x 80 x 160mm, while a larger 3D printer like the Anycubic Photon Mono X has a build plate size of 192 x 120 x 245mm, comparable to a small FDM 3D printer.

What 3D Printer Should You Buy?

- For a solid FDM 3D printer, I’d recommend getting something like the modern Ender 3 S1.

- For a solid SLA 3D printer, I’d recommend getting something like the Elegoo Mars 2 Pro.

- If you want a more premium FDM 3D printer, I’d go with the Prusa i3 MK3S+.

- If you want a more premium SLA 3D printer, I’d go with the Elegoo Saturn.

Let’s go through the two standard options for an FDM & SLA 3D printer.

Creality Ender 3 S1

The Ender 3 series is very well known for its popularity and high quality output. They’ve created the Ender 3 S1 which is a version that incorporates many desired upgrades from users. I have one of these myself and it performs very well right out the box.

The assembly is simple, the operation is easy, and the print quality is excellent.

Features of the Ender 3 S1

- Dual Gear Direct Drive Extruder

- CR-Touch Automatic Bed Leveling

- High Precision Dual Z-Axis

- 32-Bit Silent Mainboard

- Quick 6-Step Assembling – 96% Pre-Installed

- PC Spring Steel Print Sheet

- 4.3-Inch LCD Screen

- Filament Runout Sensor

- Power Loss Print Recovery

- XY Knob Belt Tensioners

- International Certification & Quality Assurance

Specifications of the Ender 3 S1

- Build Size: 220 x 220 x 270mm

- Supported Filament: PLA/ABS/PETG/TPU

- Max.

Printing Speed: 150mm/s

Printing Speed: 150mm/s - Extruder Type: “Sprite” Direct Extruder

- Display Screen: 4.3-Inch Color Screen

- Layer Resolution: 0.05 – 0.35mm

- Max. Nozzle Temperature: 260°C

- Max. Heatbed Temperature: 100°C

- Printing Platform: PC Spring Steel Sheet

Pros of the Ender 3 S1

- Print quality is fantastic for FDM printing from the first print without tuning, with a 0.05mm maximum resolution.

- Assembly is very quick compared to most 3D printers, only requiring 6 steps

- Leveling is automatic which makes operation a lot easier to handle

- Has compatibility with many filaments including flexibles due to the direct drive extruder

- Belt tensioning is made easier with the tensioner knobs for the X & Y axis

- The integrated toolbox clears up space by allowing you to keep your tools within the 3D printer

- Dual Z-axis with the connected belt increases stability for better print quality

Cons of the Ender 3 S1

- Doesn’t have a touchscreen display, but it’s still really easy to operate

- The fan duct blocks the front view of the printing process, so you’ll have to look at the nozzle from the sides.

- The cable at the back of the bed has a long rubber guard which gives it less space for bed clearance

- Doesn’t let you mute the beeping sound for the display screen

Get yourself the Creality Ender 3 S1 from Amazon for your 3D printing projects.

Elegoo Mars 2 Pro

The Elegoo Mars 2 Pro is a respected SLA 3D printer in the community, known for its reliability and great printing quality. Although it’s a 2K 3D printer, the XY resolution is at a respectable 0.05mm or 50 microns.

I also have an Elegoo Mars 2 Pro and it has been working very well since I started using it. Models always stick securely to the build plate and you don’t need to re-level the machine. The quality output is really good, though it’s not the largest build plate size.

Features of the Elegoo Mars 2 Pro

- 6.08″ 2K Monochrome LCD

- CNC-Machined Aluminum Body

- Sanded Aluminum Build Plate

- Light & Compact Resin Vat

- Built-In Active Carbon

- COB UV LED Light Source

- ChiTuBox Slicer

- Multi-Language Interface

Specifications of the Elegoo Mars 2 Pro

- Layer Thickness: 0.

01-0.2mm

01-0.2mm - Printing Speed: 30-50mm/h

- Z Axis Positioning Accuracy: 0.00125mm

- XY Resolution: 0.05mm (1620 x 2560)

- Build Volume: 129 x 80 x 160mm

- Operation: 3.5-Inch Touch Screen

- Printer Dimensions: 200 x 200 x 410mm

Pros of the Elegoo Mars 2 Pro

- Offers high-resolution prints

- Cures a single layer at an average speed of just 2.5 seconds

- Satisfactory build area

- High level of precision, quality, and accuracy

- Easy to operate

- Integrated filtration system

- Minimum maintenance required

- Durability and Longevity

Cons of the Elegoo Mars 2 Pro

- Side-mounted resin vat

- Noisy fans

- No protective sheet or glass on the LCD screen

- Less pixel density as compared to its simple Mars and Pro versions

You can get yourself the Elegoo Mars 2 Pro from Amazon today.

3D Printer Buyer's Guide

Think It Right

Start-up Costs

Consumables Costs

Operating Costs and Savings

Service and Maintenance Costs

The Toughest Economics Survive

Conclusions Choosing the right 3D printer is important now more than ever. A wisely chosen 3D printer will greatly speed up the iterative development process.

A wisely chosen 3D printer will greatly speed up the iterative development process.

Think things through

Hard times are the strongest argument for investing in 3D printing and its opportunities. Money spent on a 3D printer will provide strategic benefits not only in the long term: it will increase the efficiency of development, accelerate the time to market for new products, and this will immediately lead to lower costs. The mainstream trend in 3D CAD technology is to use more and more models in the early stages of development - this increases the level of collaboration on the project, and the detected errors are eliminated long before production begins. In large-scale developments that require gradual fine-tuning (the so-called iterative developments), 3D printers, at quite reasonable costs, can reduce the overall cost of the model.

Wherever 3D printers appear, they revolutionize the world. Designers can bring their concepts to life in full color realistic models. Marketers begin to promote a product even before its production begins. In some cases, 3D modeling technology can be used for small-scale production of samples. But in order not to make a mistake in the choice, the decision maker must evaluate not only the direct costs of acquiring a 3D printer, but also all the others - often they can decide the fate of the purchase. It is even more important to find out in advance how 3D printers differ from each other and by what parameters you can compare devices from different manufacturers.

Marketers begin to promote a product even before its production begins. In some cases, 3D modeling technology can be used for small-scale production of samples. But in order not to make a mistake in the choice, the decision maker must evaluate not only the direct costs of acquiring a 3D printer, but also all the others - often they can decide the fate of the purchase. It is even more important to find out in advance how 3D printers differ from each other and by what parameters you can compare devices from different manufacturers.

Start-up costs

Factors to consider include the cost of the device, maintenance during the first year of operation, the cost of post-treatment equipment, and possible additional equipment. Add to this the starter kit of consumables, installation and training costs, maintenance during the second year of operation and beyond.

These costs are not always obvious. Beware of "basic" kits. What does such a kit actually include? Some manufacturers limit it to the main device, and in order to get a fully functional system (or, in some cases, implement certain functions), you will have to invest in additional equipment for pre- or post-processing. Moreover, the devices of some manufacturers have increased requirements for energy consumption and operating conditions (for example, their operation is associated with the release of toxic fumes and the formation of chemical waste).

Beware of "basic" kits. What does such a kit actually include? Some manufacturers limit it to the main device, and in order to get a fully functional system (or, in some cases, implement certain functions), you will have to invest in additional equipment for pre- or post-processing. Moreover, the devices of some manufacturers have increased requirements for energy consumption and operating conditions (for example, their operation is associated with the release of toxic fumes and the formation of chemical waste).

Some kind of post-processing is required for any 3D printer product, but the methods of this processing are extremely diverse, including in complexity. It is one thing when the product is enough, for example, to blow it with compressed air or immerse it in water to wash off the dust, and quite another when it comes to special devices and special cutters for removing mechanical supports. Depending on the manufacturer of the machine and its features, you may need additional ventilation equipment or special stands just to install the 3D printer in a convenient position for work.

Consumables costs

Another factor is the cost of consumables. It varies greatly depending on the type of processing, the specific geometry of the components and the specific application. For example, the use of a 3D printer for conceptual modeling requires that many parts be created in a short time during the development of a new product. Since some materials are objectively more expensive than others, the use of expensive materials will be too costly. In addition to the cost of materials, there may be others related to the manufacturing process and at first not manifested in any way. Some machines use simple, commercially available interchangeable printheads. Others require critical components only from the manufacturer. Moreover, in this case, additional materials are used for the structures supporting the protruding elements and the solvent containers. The starter kit is often supplied with the device, and its size and composition significantly affect the costs during the first year of operation.

When estimating the cost of consumables, identify the various components of these costs. The objective comparison parameter is the cost per unit volume of the simulated part - this is more reliable than comparing the cost per unit weight of the manufactured product. Be realistic about future work: the consumable requirements for modeling mobile phone components may be different than when modeling an exhaust pipe or pump housing.

All types of 3D printers use more material when working than what is left in the finished part - the material is taken with a margin. Some systems provide for the reuse of some or all of the consumables, others do not allow any reuse. These differences in process organization can lead to significant differences in material costs over time.

Some used consumables are difficult to dispose of or reuse, while others can be downright dangerous. All these are additional costs.

Operating costs and savings

The time factor contributes greatly to the overall cost picture. On different devices, the execution time of the same process can vary by more than five times. The same applies to individual operations: some operations require more actions than others (including the setting of parameters, which affects the scheduling of tasks and the need to involve qualified personnel).

On different devices, the execution time of the same process can vary by more than five times. The same applies to individual operations: some operations require more actions than others (including the setting of parameters, which affects the scheduling of tasks and the need to involve qualified personnel).

Similar printers from two different manufacturers can form comparable products, but differ significantly in speed and cost of production. For example, let's take a model of a pulley with a diameter of 6 inches (see figure). The average cost of making a multi-color part on a machine from manufacturer A is $3.41 per cubic inch of production, while it is $5.56 per cubic inch for making single-color components on a printer from manufacturer B, which is almost twice as much. . Manufacturer A's printer takes (including setup time) 5.17 hours to produce one part; the material cost would be less than $47. Manufacturer B's printer takes 21.63 hours to complete the same job for $80 supplies, and the model will need to be repainted later.

The next article of potential time and money savings is device performance. This term refers to the total amount of output that can be produced in a certain time. Using reference parts with different geometries (see graph), manufacturer A's printer is producing 120-220 cubic inches of product in 24 hours, and manufacturer B's printer is only 15-25 cubic inches in the same time, so in terms of overall productivity, The performance of the first device is almost an order of magnitude better.

Some printers can make multiple copies of a sample (or different samples) in a single pass, allowing multiple users to work. Thus, productivity can also be calculated based on the number of copies of reference samples that can be made in a given time. This factor is very important when an entire engineering department or a group of students share the same 3D printer. What kind of time savings and productive work can we talk about, for example, when an engineer is tenth in line and waits a week for a part to be manufactured according to his project . ..

..

Considering all relevant factors, including purchase, service, and shipping costs, as well as the performance that comparable 3D printers can deliver, there is a significant difference in part cost and lead time. Some of the results of comparing printers from the two leading companies are shown in the graphs.

Service and maintenance costs

Finally, you need to evaluate how much general and routine maintenance will cost, whether there is a guarantee and for how long it will be provided, what exactly is covered by the guarantee and what is not.

Conclusions

In short, just as when choosing a car, you look not only at its cost, but also at convenience, appearance, evaluate its reliability, take into account fuel consumption, so buying a 3D printer requires the same careful approach. Investing wisely in a 3D printer can help you reduce your product development costs and get your product to market faster, which is a huge advantage in a highly competitive environment.

We must pay tribute, in the English-speaking segment, then there was an active development of this technology and interesting articles such as “Selection of the type of notches of the extruder feed gear for a specific type of plastic” or “Determination of the optimal printing temperature using a strain gauge installed on the extruder” came across. Since then, 7 years have passed. I managed to master modeling, assemble a printer from scratch, be a moderator of “3D Today” for a while, work as a freelancer in the field of modeling and printing, organize a prototyping circle for children and bring it to the Russian level. Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

We must pay tribute, in the English-speaking segment, then there was an active development of this technology and interesting articles such as “Selection of the type of notches of the extruder feed gear for a specific type of plastic” or “Determination of the optimal printing temperature using a strain gauge installed on the extruder” came across. Since then, 7 years have passed. I managed to master modeling, assemble a printer from scratch, be a moderator of “3D Today” for a while, work as a freelancer in the field of modeling and printing, organize a prototyping circle for children and bring it to the Russian level. Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".  FDM technology is more common, due to the lower cost of equipment and consumables, but in recent years, the prices of LCD printers and printing resins have decreased significantly and photopolymer printing has almost caught up with FDM printing in terms of cost and entry level.

FDM technology is more common, due to the lower cost of equipment and consumables, but in recent years, the prices of LCD printers and printing resins have decreased significantly and photopolymer printing has almost caught up with FDM printing in terms of cost and entry level.

It is recommended to take models that have already formed a large community around them. This means that most of the shortcomings have already been identified and there are standard inexpensive methods to solve them.

It is recommended to take models that have already formed a large community around them. This means that most of the shortcomings have already been identified and there are standard inexpensive methods to solve them.

Some are demanding on the quality of plastic, there are models that work only on chipped coils.

Some are demanding on the quality of plastic, there are models that work only on chipped coils.  Therefore, I want a printer that will do everything for me - in this case it is better to look at semi-professional printers. If the budget is not enough, you can look at used ones or order an assembly of a domestic set - usually manufacturers offer this service through intermediaries. When ordering an assembly - look for experience and positive reviews, there are nuances.

Therefore, I want a printer that will do everything for me - in this case it is better to look at semi-professional printers. If the budget is not enough, you can look at used ones or order an assembly of a domestic set - usually manufacturers offer this service through intermediaries. When ordering an assembly - look for experience and positive reviews, there are nuances.

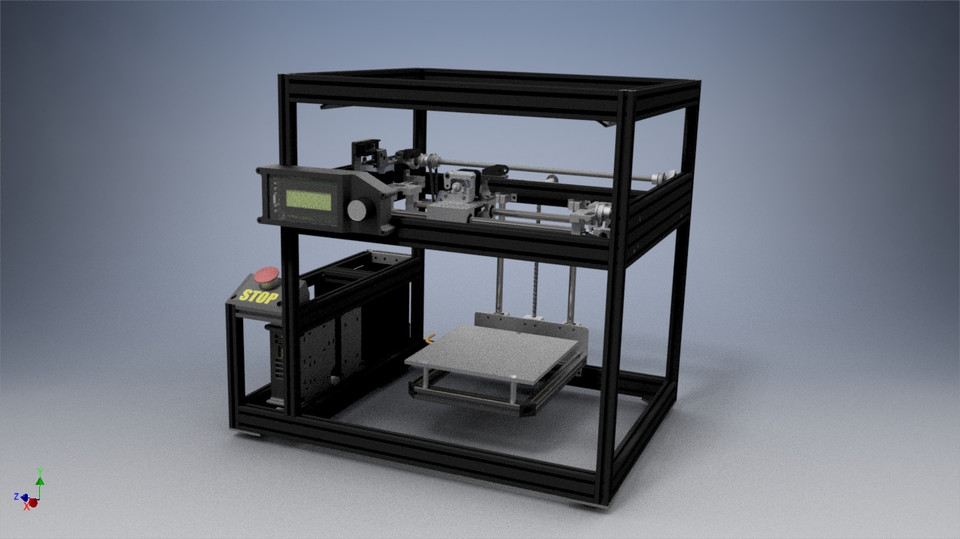

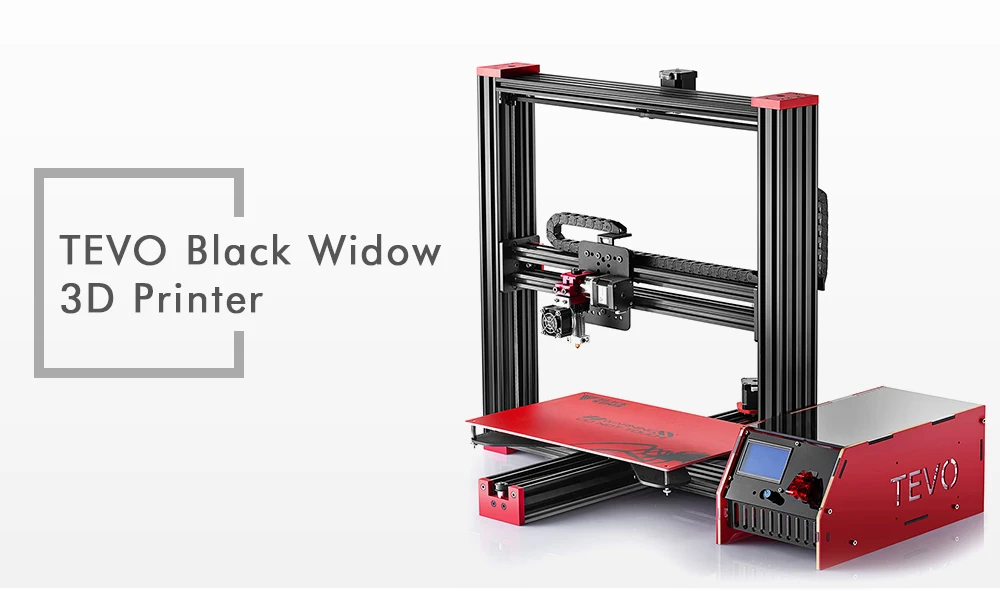

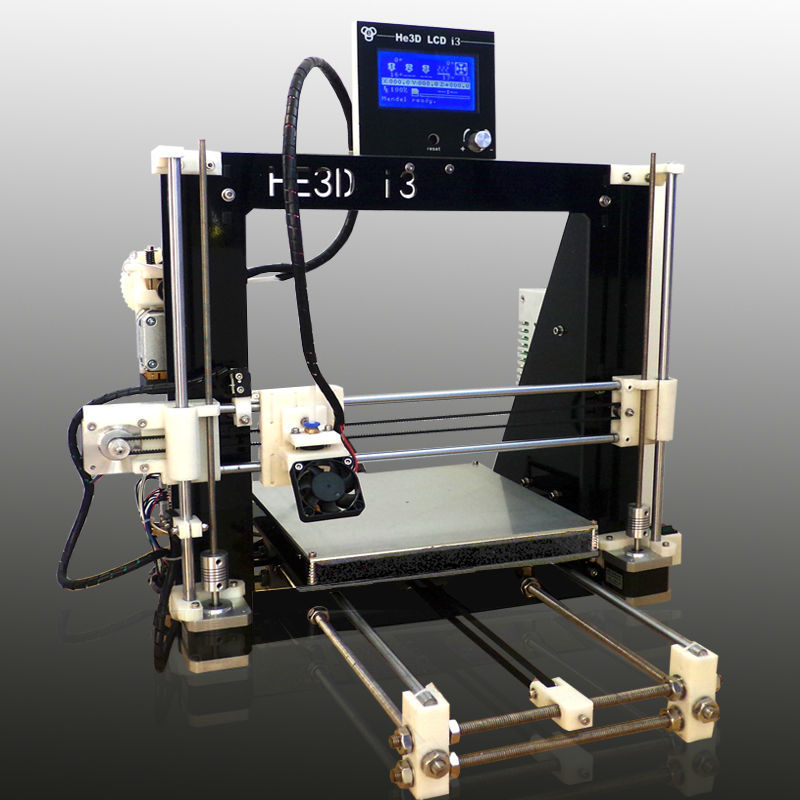

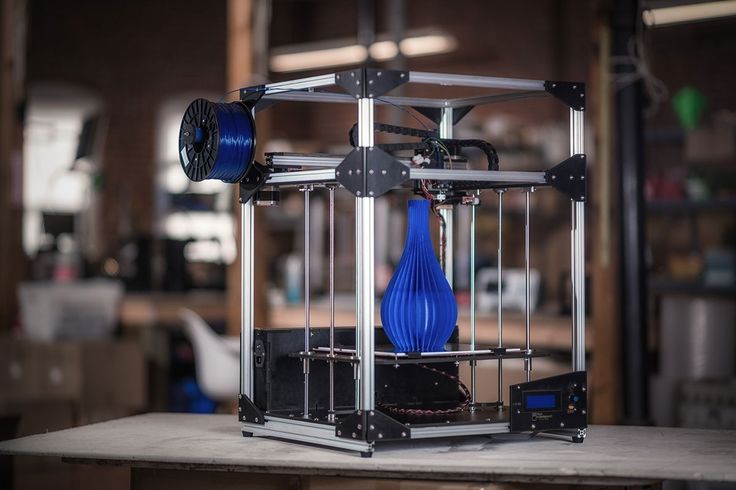

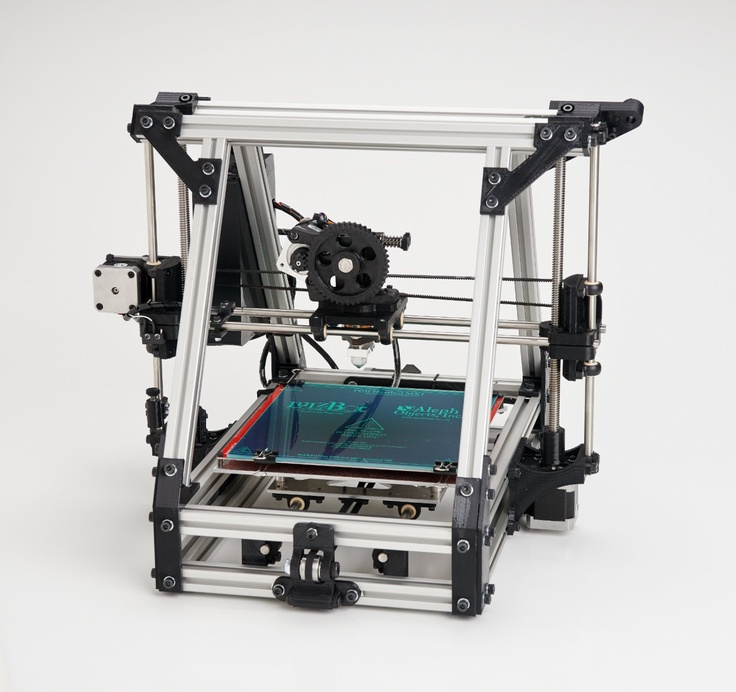

For example, the construction of the printer shown below cost its author 80-9, according to him.0 dollars.

For example, the construction of the printer shown below cost its author 80-9, according to him.0 dollars.