Off book 3d printing

The 8 Best 3D Printing Books in 2021 (Including Introductions to 3D Printing)

Welcome to the Thomas guide to the best 3D printing books 2021. Thomas has been connecting North American industrial buyers and suppliers for more than 120 years. When you purchase products through our independent recommendations, we may earn an affiliate commission.

The best place to really dig in deep about a subject is a book. If 3D printing has piqued your interest, our lineup of the best 3D printing books will help wrap your head around this concept, teach you to apply it to everyday work, and learn helpful hints, tips, and tricks.

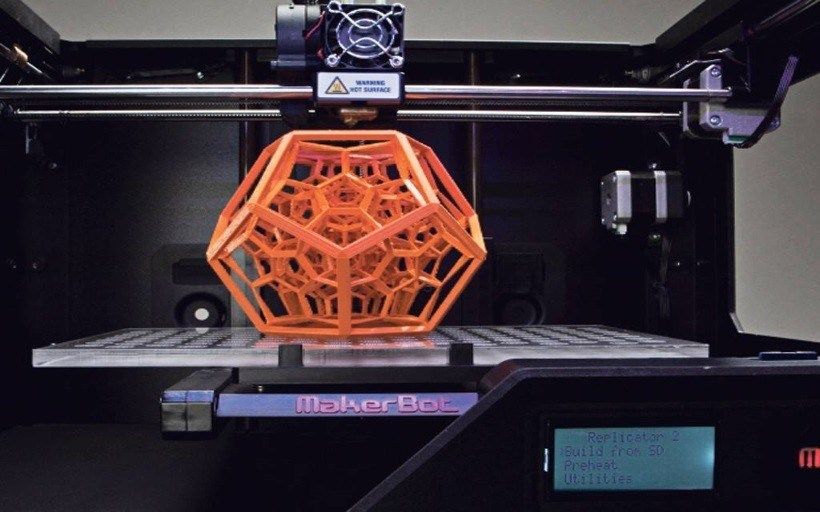

Books on 3D printing are an excellent foray into the world of additive manufacturingAt first glance, 3D printing (or additive manufacturing) can be an intimidating field to get into. The intersection of science, technology, and mathematics may appear to be overwhelming, but with the right resources and tools, anyone who’s serious about learning the inner workings of 3D printing can.

What is 3D printing?

It may sound like a futuristic practice, but 3D printing has been around since the ’80s. In essence, 3D printing is the art and science of producing tangible materials, models, and objects out of digital files on a 3D printer. There are a lot of moving parts that go into it between the creation of the files, the uploading of them, and the actual printing and implementing of the object.

This method can be used in numerous applications, from at-home science projects or creating a jamb for a door to constructing artificial organs in the medical field or building parts for the aircraft industry. The beauty of additive manufacturing is that it can be adapted for both minuscule projects and large-scale inventions, and many industries are beginning to understand this. In fact, one survey found that nearly 75% of those who participated are looking to invest in 3D printing in 2021. If you’re curious about how things work in this sector, these books are a great place for getting started or brushing up on your knowledge about all-things printers, filaments, software, and uses.

Thomas’ Top Picks for the Best 3D Printing Books

Whether you’re just starting out in the world of 3D printing or are familiar with the processes and endless breadth of projects, these books will provide inspiration, instructions, and important details.

- Best 3D Printing Book for Troubleshooting: 3D Printing Failures

- Best General 3D Printing Guide: The 3D Printing Handbook

- Best 3D Printing Book for Everyday Objects: Functional Design for 3D Printing

- Best 3D Printing Book for Kids: 3D Printing Projects

- Best 3D Printing Book for Beginners: Getting Started with 3D Printing

- Best 3D Printing Book for Essentials: The Zombie Apocalypse Guide to 3D Printing

- Best Introductory 3D Printing Book: 3D Printing: An Introduction

- Best 3D Printing Book for Learning Software: Fusion 360 for Makers

Browse through our selection of the best 3D printing books to kickstart your journey to learning about this fascinating science.

1. Best 3D Printing Book for Troubleshooting—

3D Printing FailuresThe best way to learn is through mistakes, whether you’re the one making them or you have the privilege to learn from someone else’s. In 3D Printing Failures: How to Diagnose and Repair All Desktop 3D Printing Issues, the author, Sean Aranda, delves into problems you may run into with materials or the machinery itself. This is an update from the original version and includes seven new chapters that are more relevant to today’s 3D printing processes and conundrums. “While it is geared primarily to newbies to 3D printing, I found material helpful to me and my three years of experience,” wrote one happy reviewer.

BUY NOW:

$18.99, Amazon2. Best General 3D Printing Guide—

The 3D Printing HandbookThe pages of The 3D Printing Handbook: Technologies, Design and Applications by Ben Redwood, Filemon Schöffer, and Brian Garret pulls insight from additive manufacturing experts and forms it into digestible chapters. It goes into detail about how the equipment works, how to choose the right technology for your specified sector or projects, and outlines industry standards. It’s a great read for those who have a background in 3D printing, but with a bit of dedicated attention, beginners can utilize this book, too. “If you need an all-in-one guide on 3D printing as a whole, this is an invaluable resource,” described one customer.

It goes into detail about how the equipment works, how to choose the right technology for your specified sector or projects, and outlines industry standards. It’s a great read for those who have a background in 3D printing, but with a bit of dedicated attention, beginners can utilize this book, too. “If you need an all-in-one guide on 3D printing as a whole, this is an invaluable resource,” described one customer.

BUY NOW:

$32, Amazon3. Best 3D Printing Book for Everyday Objects—

Functional Design for 3D PrintingFor knowledgable hobbyists, or those further along in their additive manufacturing careers, there is plenty of useful information in Clifford T Smyth’s Functional Design for 3D Printing: Designing 3D Printed Things for Everyday Use. It provides readers with techniques and guidance on how to configure different materials, set up proper support structures, improve workflow, and handle concerns surrounding problems like warping and adhesion. This third edition has not only expanded textually, but it has included additional instructive illustrations. “This book hits the middle ground just right,” explained one buyer. “It focuses on pragmatic advice for designing useful parts that are strong enough to work in real-world applications.”

This third edition has not only expanded textually, but it has included additional instructive illustrations. “This book hits the middle ground just right,” explained one buyer. “It focuses on pragmatic advice for designing useful parts that are strong enough to work in real-world applications.”

BUY NOW:

$22.95, Amazon4. Best 3D Printing Books for Kids—

3D Printing ProjectsIf you have the equipment at the ready but are unsure where to start, the compilation of ideas and tutorials in 3D Printing Projects by DK is the perfect place to start. While it’s ideal for kids and teens who are testing the waters with 3D printing, it’s a fantastic resource for adults who are just breaking in, too. Of the projects listed, you’ll find guidance on how to make desk caddies, phone stands, and even fridge magnets to try your hand at 3D printing. The book also offers a nice overview of the topic, a glossary of terms, and some light reading on troubleshooting. “My teen boys and I are working our way through the projects and having so much fun,” wrote one customer. “There is plenty of room for adding your own artistic flair to each project and my boys are really proud of their creations.”

“My teen boys and I are working our way through the projects and having so much fun,” wrote one customer. “There is plenty of room for adding your own artistic flair to each project and my boys are really proud of their creations.”

BUY NOW:

$12.73, Amazon5. Best 3D Printing Book for Beginners—

Getting Started with 3D PrintingGetting Started with 3D Printing: A Hands-on Guide to the Hardware, Software, and Services Behind the New Manufacturing Revolution provides a basic yet comprehensive blueprint for people who are easing their way into this science. In the book, authors Liza Wallach Kloski and Nick Kloski discuss the history as well as the supplies and tools needed. It also offers guidance on how to select the right materials and technology (i.e. the printers and filaments) that’ll suit you and your needs best. The book also contains a few project tutorials to start out with. “This book covers everything and helped me a lot when I couldn't figure out how to fix my prints,” wrote one beginner. “I'm not very tech-savvy and found other books harder to follow. I found this book the easiest to understand.”

“I'm not very tech-savvy and found other books harder to follow. I found this book the easiest to understand.”

BUY NOW:

$13.99, Amazon6. Best 3D Printing Book for Essentials—

The Zombie Apocalypse Guide to 3D PrintingIt’s hard not to be intrigued by the title of this guide to 3D printing, another book written by Clifford T Smyth. While the subjects may seem incongruent, the context of The Zombie Apocalypse Guide to 3D Printing: Designing and Printing Practical Objects makes sense; it gives an in-depth guide to being as self-sufficient as possible with a 3D printer. While you’ll learn how to make certain objects, it takes a more interesting angle. It’ll teach you how to make replacement parts, items, and hardware that fit in certain spaces (like bolts and jambs), and integrate 3D printed prototypes into already existing objects. “It covers expert topics… and the ‘Appendices’ are actually full-blown chapters, with more examples of how to meet your design constraints,” wrote one reviewer. “It's a solid handbook to mark up and keep by your printer.”

“It's a solid handbook to mark up and keep by your printer.”

BUY NOW:

from $14.99, Amazon7. Best Introductory 3D Printing Book—

3D Printing: An IntroductionTo stay on track and set yourself up for success, you’ll want to turn to 3D Printing: An Introduction by Stephanie and Jonathan Torta. Not only does it present you with the history and basic parts of a 3D printing configuration, but it’ll lead you in setting up your printer and how to get started without relying solely on beginner’s luck. The chapters also contain tips on avoiding mistakes and fixing mishaps, how to follow safety protocols, and how to start the actual printing procedure. “I found the book so helpful that I marked off several pages for quick reference,” wrote one customer. “I was able to follow the steps in the book to start printing some real decent quality models.”

BUY NOW:

$34.04, Amazon8. Best 3D Printing Book for Learning Software—

Fusion 360 for MakersFusion 360 for Makers: Design Your Own Digital Models for 3D Printing and CNC Fabrication gifts readers with a detailed look at this popular program that many turn to for their 3D printers and other computer numerical control machinery. The author, Lydia Sloan Cline, is a teacher on the subject and has authored eight other books in a similar vein, and many reviewers found her writing to be easy to implement. Aside from the projects in the book, readers will be educated on how to solve problems, apply this tech in a real-life work environment, and get a well-rounded grasp on understanding the software. “Excellent primer on getting up to speed with Fusion 360,” wrote one happy consumer. “Combined with the many online tutorials, it makes the program approachable.”

The author, Lydia Sloan Cline, is a teacher on the subject and has authored eight other books in a similar vein, and many reviewers found her writing to be easy to implement. Aside from the projects in the book, readers will be educated on how to solve problems, apply this tech in a real-life work environment, and get a well-rounded grasp on understanding the software. “Excellent primer on getting up to speed with Fusion 360,” wrote one happy consumer. “Combined with the many online tutorials, it makes the program approachable.”

BUY NOW:

$18.59, AmazonBest 3D printing Books 2021—Summary

No matter where you are in your 3D printing career or passion project, there’s a book out there to help. Beginners will enjoy Getting Started with 3D Printing while those further along will appreciate the brush up that Functional Design for 3D Printing provides. We hope our review of the best 3D printing books has been helpful. For more similar suppliers, including suppliers of plastic filaments, direct energy deposition additive manufacturing, and 3D photographic printing, consult our additional guides or visit the Thomas Supplier Discovery Platform.

*Prices listed in this article were as shown on Amazon.com as of April, 2021.

Sources

- https://amfg.ai/industrial-applications-of-3d-printing-the-ultimate-guide/

- https://3dinsider.com/3d-printing-history/

- https://www.designnews.com/automation/predictions-future-3d-printing

Other 3D Printing Articles

- The 7 Best 3D Printers for Miniatures

- The 7 Best 3D Printers for Cosplay

- The 10 Best 3D Printers under $200

- The 9 Best 3D Printers under $300

- The Best 3D Printers under $500

- The 8 Best 3D Printers under $1000

- The 11 Best 3D Printer Filament Spools in 2021

Other Best Product Articles

- The Best Cordless Impact Wrenches

- The Best Portable Generators

- The Best Portable Band Saws

- The Best Electric Space Heaters

- The Best Mini Milling Machine

- The Best Attic Ladders

- The Best Air Purifiers for Smoke

- The Best Circuit Breaker Locator

- The Best Engine Hoists and Accessories

- The Best Drywall Lifts

- The Best Whole-House Generators

- The Best Home Automation Systems

- The Best Quietest Portable Generators

- The Best Uninterruptible Power Supply Systems

- The Best Commercial Patio Heaters

- The Best Electric Bikes

- The Best Electric Pressure Washers

- The Best Keyless Door Locks

- The Best Electric Lawnmowers

- The Best Electric Hand Warmers

More from Custom Manufacturing & Fabricating

3D printing is tackling what may be its biggest challenge yet: the humble book

Thirty-four years ago, Chuck Hull developed stereolithography, the grandfather of additive manufacturing systems that rests under the now broad umbrella of 3D printing. In the intervening years, thousands of people have poured their creativity and ingenuity into 3D-printed body parts, bridges, and even a car.

In the intervening years, thousands of people have poured their creativity and ingenuity into 3D-printed body parts, bridges, and even a car.

But Ron Arad, a London based Israeli Industrial designer, is taking on a seemingly more banal challenge. He’s 3D printing a book.

“3D printing stole the word ‘printing’ from the written word,” Arad told PopSci from his London studio. “We’re just returning it.”

On the internet, Arad is perhaps best known for his two nuns bicycle, a steel single gear bicycle with wheels made from swirls of thin flexible steel bound together into a rough circle that resemble the petals of a daisy. The bicycle looks incapable of being ridden. But despite deceptive appearances, it is functional. Pedal fast enough and the wheels disappear—the bicycle floats.

3D printing a book seems simple compared to creating a floating bicycle. After all, humans have been mass printing books since before the colonialization of the Americas. But even as 3D printing has expanded what’s possible, 3D printing a book—especially one crafted as a solid piece (including the binding)—is hard.

After all, humans have been mass printing books since before the colonialization of the Americas. But even as 3D printing has expanded what’s possible, 3D printing a book—especially one crafted as a solid piece (including the binding)—is hard.

That it’s hard, says Arad with a grin, is the point. Arad thinks it will be the first-ever book made from a single 3D printing. In 2014, Tom Burtonwood, in conjunction with the Art institute of Chicago, produced a 3D-printed book of Bas Relief art from the museum’s collections. But each of that book’s pages are printed separately and then bound. Each of Arad’s books will be printed and bound in one shot. And at least one of Arad’s books will be printed in space. It will be printed on the International Space Station through a collaboration with NASA, the Japanese Space Agency, and the European Space Agency.

The pages in this 3D-printed book of bas-relief carvings were each printed separately and then bound together. Arad’s book will be printed all in a single piece. Tom Burtonwood

Tom BurtonwoodThe Albert Einstein Foundation commissioned the book as part of their legacy project, a year-long celebration commemorating not only Einstein’s theory of general relativity but also what Einstein has come to symbolize: creativity, ingenuity, and humanity. Their original idea, however, was not for a book at all. It was for a bust of Einstein’s head.

“We are not very good at doing what we’re asked to do,” said Arad. “We always want to change it.”

The idea that it should be in the shape of Einstein’s iconic head—that hair—remained. As did the idea of getting some of the world’s most dexterous creators in science, the arts, and social justice to weigh in. But instead of their signatures, they would lend the same thing that Einstein is best known for—their most visionary ideas in the form of a poem, perhaps, or an essay, or maybe even a sketch. There will be a total of 100 contributors spread out among 10 categories—from science to literature to leadership, technology, and space—with the idea that the book will me more than just a book. It’ll be a time capsule, embodied in its limited-edition run of just 300 to be unveiled this fall in Montreal at what the Einstein Legacy Project is calling the “Dinner of the Century.” So far, Nobel physicist Steven Chu. architect Frank Gehry, and authors Chimamanda Ngozi Adichie and Paulo Coelho are among those who have committed to the project.

It’ll be a time capsule, embodied in its limited-edition run of just 300 to be unveiled this fall in Montreal at what the Einstein Legacy Project is calling the “Dinner of the Century.” So far, Nobel physicist Steven Chu. architect Frank Gehry, and authors Chimamanda Ngozi Adichie and Paulo Coelho are among those who have committed to the project.

Each visionary will get a single page, meaning Arad will make 100 3D-printed sheets in total. Yes, the book will contain 100 sheets, not 50. Unlike traditionally printed books, which are typically double sided, the nature of the 3D printing technique Arad is using, called selective laser sintering, means the words exist in negative space- like a stencil.

“For us, it was and still is a technical challenge,” said Marcus Hirst the head of design at Ron Arad Studio, who you can see cycling on the two nuns bicycle. One of the big challenges is that we want this to be one single piece, not a bunch of pieces. And to do that you run into the limitations of 3D printing. We couldn’t get what we needed from an injection mold process.”

One of the big challenges is that we want this to be one single piece, not a bunch of pieces. And to do that you run into the limitations of 3D printing. We couldn’t get what we needed from an injection mold process.”

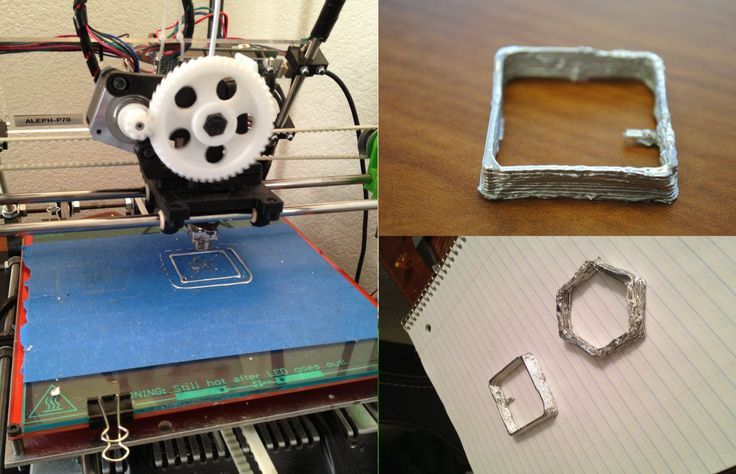

That process is what most people think of 3D printing. It’s additive—you use molten to “build up” a structure kind of like Legos. Selective sintering works by fusing together substances. It’s a technique originally developed to do fine-scale metal soldering. It’s the kind of fine work that joins the blades of a typical razor to the handle, but the technique has been expanded for a host of other uses, including art.

The book will be printed with the letters in negative space the way the letters are stenciled cut into this chair. [Jenny Downing via Flickr](https://www.flickr.com/photos/jenny-pics/3534826309/in/photolist-6omUHc-7M3YPC-BiPGXM-ujjrKL-BWyYZT-6EUUmE-dm852i-7xtYDy-bzMhum-2Cp5Gq-FLbeR4-GFyALk-6EUTWm-5MWUCe-2kKzub-9Mzcqa-8u2Qqg-mf9F1D-5HH8kY-7Tj7Jf-ef5hqb-boX1Vt-4TbPb1-hw“Imagine you have a bed of sand,” says Nicholas Fang an associate professor in the department of mechanical engineering at the Massachusetts Institute of Technology (MIT). “And you have a glue pen that you can trace on the sand to form the page.” Wherever you glue will fuse together, and the page will only be as deep as the glue can reach into the bed of sand.

“And you have a glue pen that you can trace on the sand to form the page.” Wherever you glue will fuse together, and the page will only be as deep as the glue can reach into the bed of sand.

In the case of the selective laser sintering, the laser is the glue pen, and the sand can be one of a host of powders. “Nylon, polystyrene, and sometimes a green sand that contains a mixture of silicon glass and some kind of molten polymer coating, could all be used in selective laser sintering,” says Fang.

The laser traces out the shape of the page, and the outside of the letters, waits for the layer to cool, and builds another page. According to Fang, on the lab scale selective laser sintering can print layers as thin as 10 micrometers, basically one-tenth the thickness of a strand of hair.

Arad’s pages are thicker since the pages need to be able to have holes in the forms of letter, and because he’s building each book from the same printing process he has to deal with the pages sticking together. And he said, “we’re relying on the flexibility of the material for the binding.”

And he said, “we’re relying on the flexibility of the material for the binding.”

It’s easy to frame science and art as opposites on a continuum, with the former being hard, the latter being soft, and everything else residing somewhere along the middle. The book is art, but it pushes the limits of existing technologies. In a way, it feels in line with Einstein’s whole deal. He did say, after all, that “science will stagnate if it is made to serve practical goals.”

Open University: books, money, 3D printers

On September 26, the second “Open University” was held in the Northern capital - an urban educational project that includes lectures where St. Petersburg residents can learn about the latest research and topical issues in the world of science. The program of the event was divided into three sections, devoting the September Open University to the topics of 3D printing, literature in the digital age and electronic money.

A factory in a garage, or a new technological order

The first section dedicated to 3D printing technologies was opened by Andrey Gribovsky, head of ITMO University's Center for Prototyping and Industrial Design . He spoke about the fact that humanity is now, in fact, on the verge of the fourth industrial revolution: if the first three occurred due to the taming of the energy of steam, electricity, and then the use of electronics, now we are moving to the era of digital production.

He spoke about the fact that humanity is now, in fact, on the verge of the fourth industrial revolution: if the first three occurred due to the taming of the energy of steam, electricity, and then the use of electronics, now we are moving to the era of digital production.

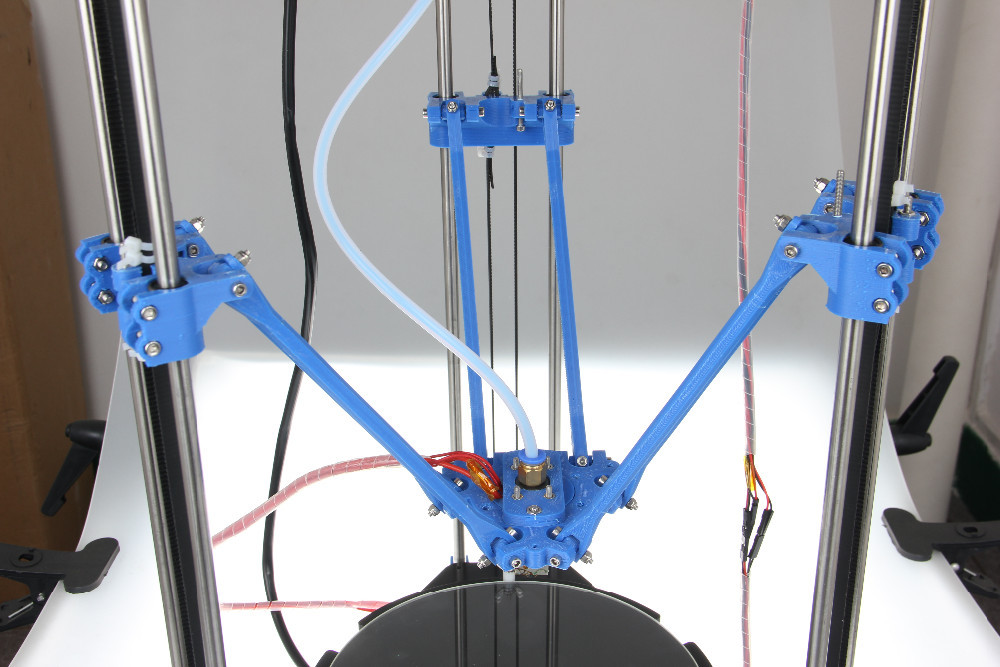

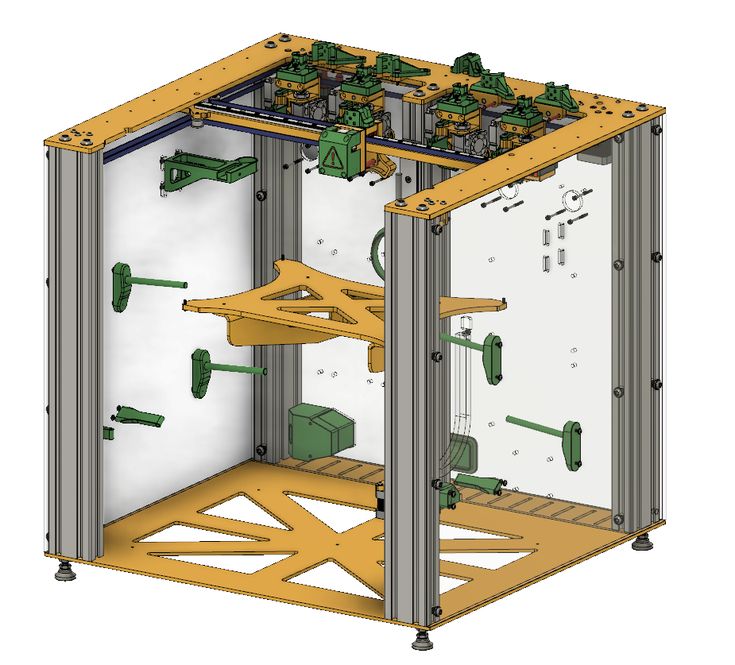

“This was made possible by the combination of open electronics, intelligent robotics and 3D printing, ,” explains Andrey Gribovsky. – All nodes of production interact with each other: this approach allows you to move away from mass production to one that can be reconfigured and changed at any time to suit your needs. In small workshops, which are called fab labs at universities, with the help of simple and versatile equipment, we can carry out a project from an idea to a finished product, produce them in a single and small-scale form and meet the needs of the city in our products” .

ITMO University. Andrey Gribovsky. "Open University".

Andrey Gribovsky's colleague, head of the Institute of Laser and Welding Technologies of Peter the Great St. Petersburg Polytechnic University (SPbPU) Gleb Turichin is of the opinion that the change in the technological structure is due to the development of computer technology. Once upon a time, the profession of a printer was an honorable and highly paid one, but today a small computer replaces large staffs of casters and compositors. Almost the same processes are taking place in industry, so factories will gradually begin to give way to individual production.

Petersburg Polytechnic University (SPbPU) Gleb Turichin is of the opinion that the change in the technological structure is due to the development of computer technology. Once upon a time, the profession of a printer was an honorable and highly paid one, but today a small computer replaces large staffs of casters and compositors. Almost the same processes are taking place in industry, so factories will gradually begin to give way to individual production.

“A significant part of what we call industry is turning into computer peripherals. A small 3D printer can be bought for seven hundred dollars, and if you have basic drawing skills, then soon you will start producing what you need, often just for self-realization, - says Gleb Turichin. - Then it turns out that you have a machine in your hands that allows you to earn money, it becomes possible to create network enterprises. Someone will guess: you have an SLA machine, you will grow a plastic case, those three will buy an SLM machine and make something iron, and we also have a friend who is an economist girl who will write a business model.

This is a completely new form of activity. Sure, big machines can cost millions of dollars now, but computers were once expensive.” .

ITMO University. Maxim Odnoblyudov. "Open University".

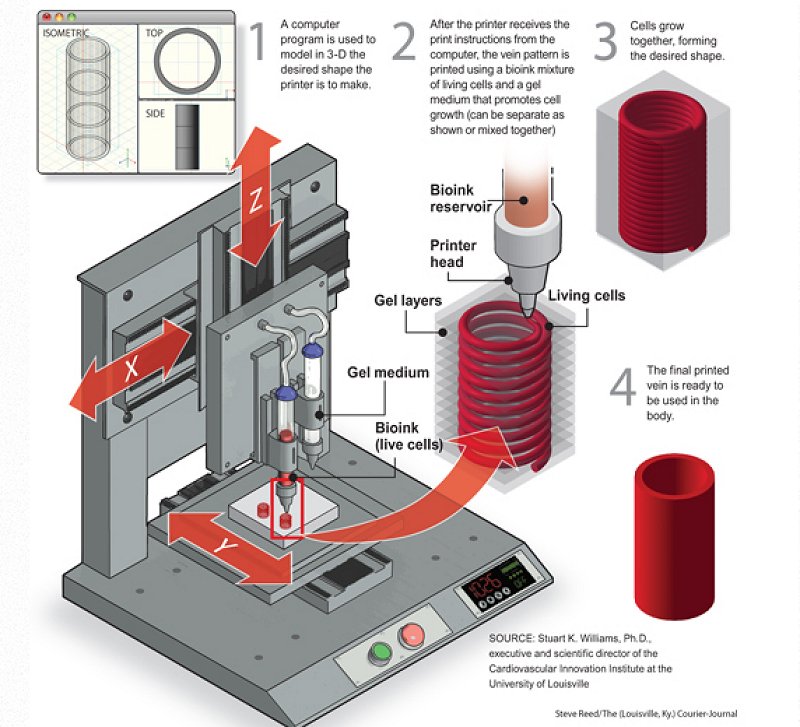

In turn, Maxim Odnoblyudov, Director of the Joint Scientific and Technological Institute of SPbPU , explains that 3D printing already today helps to introduce an individual approach where it is most needed - in medicine. If a joint in a patient with arthrosis is so destroyed that it cannot be replaced with a prosthesis, a model printed on the basis of a tomogram allows you to design a titanium “patch” that exactly repeats the profile of bone destruction.

“Digital and additive technologies make it possible to abandon the disadvantages of mass production and move towards customization. In medicine, the use of typical elements is very often the cause of complications and health problems, and personification eliminates these problems, - says Maxim Odnoblyudov.

– In addition, production can be located near the consumer: such a site for the design and manufacture of endoprostheses can be located in every hospital. Doctors do not have to maintain a warehouse and wait for a patient to appear, and when a patient arrives within a few weeks, it will be possible to manufacture a prosthesis that is optimized directly for the patient.”

Gutenberg 2.0

The organizers devoted the next section to the changes in reading culture with the advent of Google and Wikipedia. According to the moderator of the section, St. Petersburg philologist and writer Andrey Astvatsaturov , the text becomes a set of information, and a detailed narrative is no longer perceived in the same way as in pre-digital times. A web user is much more likely to pay attention to a picture with a caption than to a voluminous text.

ITMO University. Andrey Astvatsaturov. "Open University".“As a teacher of literature at a university, I see that it is becoming increasingly difficult for students to read European and Russian classics, they use sites with brief retellings.

Classics required rocking chairs and a blanket, leisure. But we don’t have it, and we don’t want to have it, we rather perceive everything as fragmentary information, - Andrey Astvatsaturov comments. – Literature is beginning to resemble the texts we read in the blogosphere, as writers adapt to write more clip-like, fragmented. The nature of the perception of prose has changed fundamentally” .

Kirill Martynov Associate Professor of the HSE School of Philosophy , on the contrary, notes that in our time the value of a classic book is only increasing. This is due to the fact that books stand in stark contrast to the "usual" redundant information that appears on the Internet every day.

ITMO University. Kirill Martynov. "Open University".“What is happening now with the text is a return to its normal functioning. The letters of Cicero or the letters of the Apostle Paul were also “reposted” and “liked”, only in analog form, and there was no centralized publishing house that would print them until the 15th century, - says Kirill Martynov.

– We simply abandon the old industrial production of the book and separate the text itself, which can be copied indefinitely, and the book as a physical object. This is a return to the pre-Gutenberg era, and the advantage here is that each of us can contribute to the process of the functioning of the text” .

Money and security

The final discussion of the Open University was devoted to the role of electronic and paper money in the economy of the 21st century. Professor, Faculty of Economics, European University at St. Petersburg Yulia Vymyatina explained that it is incorrect to equate cryptocurrencies with non-cash and electronic money. Their common feature is that they can be issued by private organizations, unlike cash. So, when issuing a loan, the bank may not have the required amount. However, cryptocurrencies differ sharply in the decentralized mechanism for confirming transactions, as well as in the fact that they cannot be a means of storing the value of goods.

ITMO University. Arthur Glame. "Open University".

Professor of the Tallinn Technical University (Estonia) Kuldar Taveter spoke about how the most popular cryptocurrency in the world, Bitcoin, was arranged, and Artur Gleim , head of the Laboratory of Quantum Informatics at the International Institute of Photonics and Optoinformatics of ITMO University , dwelled on the new needs of digital society. According to him, with the complication of the data exchange process, new technological risks appear, and the issue of security becomes critical. Therefore, it is necessary not only to increase the resistance of systems to hacking, but to build such an infrastructure where the question of greater or lesser security is not at all. For example, a small innovative enterprise at ITMO University, led by Arthur Gleim, develops devices that transmit data in such a way that hacking a communication line is contrary to the laws of nature.

ITMO University Small Innovative Enterprise Quantum Communications.“The criteria and values of the information society are changing and we must offer something new.

Mankind has come up with a way to generate money outside the boundaries and strict requirements, but, as a result, the problem of permissiveness has arisen, - Arthur Gleim notes. – There is a need to build a universal environment that does not carry risks, which we can trust day in and day out and know that our funds and personal data are safe. Technologies that enable a new technological paradigm to take this path are possible: an example of such an environment can be a quantum information infrastructure” .

Recall that the first "Open University" was held on June 12, 2015 on the New Stage of the Alexandrinsky Theater and was dedicated to the development of a modern city, diseases of the XXI century, linguistics and scientific ideas that may be of interest to people of completely different professions. Read the report here.

Alexander Pushkash ,

ITMO News Portal

Photo: Andrey Kulikov, Anton Malkov.

Top

Nikita Chen-Yun-Tai - Irkutsk citizen who printed a two-story house on a 3D printer

Habitat | Book of Records

October 19, 2020

The information portal "Verb. Irkutsk Review" is a partner of the "Book of Records of the Irkutsk Region" project and publishes on its pages excerpts from a new edition that has recently appeared in our region. The book has been published for the fifteenth year, and on its pages are published both the achievements of Irkutsk people in social, cultural and sports life, as well as a large amount of local history information.

The 30-year-old founder of Apis Cor, Nikita Chen-Yun-Tai, was born in Irkutsk. From childhood, he was fond of robotics - in a school circle he assembled CNC machines. Immediately after school, he got a job as a salesman in an auto parts store. Then, after serving in the army, in 2009 he opened a bureau for the production of advertising signs. At first, the clients of his Plasma Systems company were the owners of shops and beauty salons. In 2013, he was able to win the tender of the Irkutsk cemetery for the production of concrete signs. The ritual client was followed by the organizers of the Olympics in Sochi - "Plasma Systems" made 5000 navigation signs on a CNC machine of its own production. Nikita invested the money he earned in the development and creation of the Apis Cor mobile 3D printer.

At first, the clients of his Plasma Systems company were the owners of shops and beauty salons. In 2013, he was able to win the tender of the Irkutsk cemetery for the production of concrete signs. The ritual client was followed by the organizers of the Olympics in Sochi - "Plasma Systems" made 5000 navigation signs on a CNC machine of its own production. Nikita invested the money he earned in the development and creation of the Apis Cor mobile 3D printer.

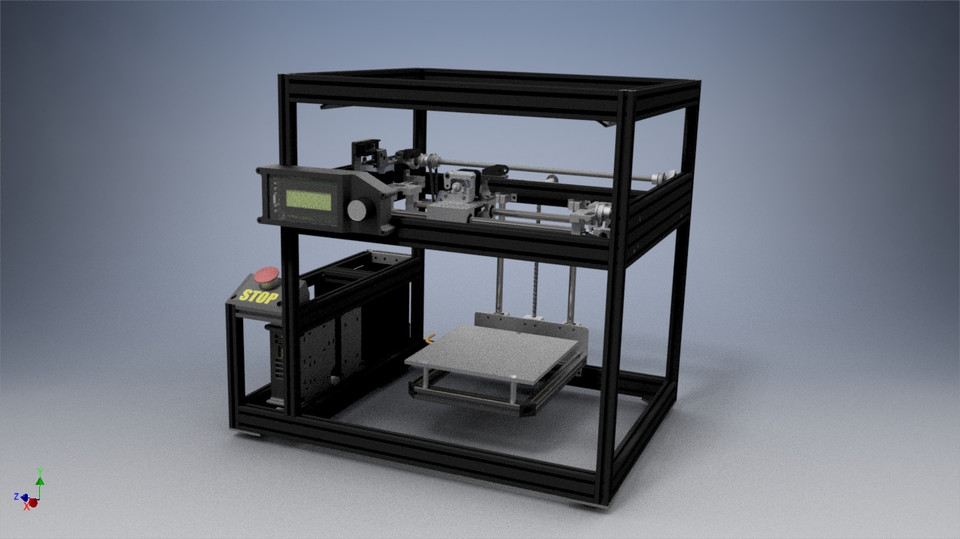

There are many companies in the construction market that print structural elements on 3D printers in the shops and offer assembly on site. Chen-Yun-Tai has developed a unique mobile 3D printer that prints entire buildings on site.

“Our printer is fundamentally different from existing construction printers,” says Nikita. “Their gantry structure runs on rails that require a perfectly flat surface. Otherwise, the entire structure of the equipment will jam or lose accuracy, and the geometry of the building will be violated. Commissioning of such a printer at the construction site can take up to three weeks. Our model works in polar coordinates. She prints the building, being in its center. At the same time, it has a rather large print area from one point - 132 sq. m. The printer is easily transported using a conventional truck-based crane, its commissioning takes no more than an hour, and the most important advantage is the automatic mixture preparation and supply system. We can say that our printer is a new generation printer.”

Our model works in polar coordinates. She prints the building, being in its center. At the same time, it has a rather large print area from one point - 132 sq. m. The printer is easily transported using a conventional truck-based crane, its commissioning takes no more than an hour, and the most important advantage is the automatic mixture preparation and supply system. We can say that our printer is a new generation printer.”

The first construction experience took place in February 2017, when Apis Cor printed its first 3D concrete-based house in Stupino near Moscow. The insulated building with an area of 37 square meters was erected in 24 hours. Along the way, another advantage of 3D printing was proven: such buildings, regardless of geometry, do not have cold bridges. The project received a lot of media attention.

An invitation from the municipality of Dubai fell into the mail of Nikita Chen-Yun-Tai in the spring of 2017. The city authorities became interested in his project and offered to get to know him better.