3D printers perth

3D Printing Parts selling in perth WA for your 3D Printer online – 3D Printing Perth

Add to wishlistSALE 33%

$6.00$4.00

White

Add to wishlist Add to wishlistSALE 33%

$6.00$4.00

Add to wishlist Add to wishlistSALE 31%

$6.50$4.50

Add to wishlist Add to wishlistSALE 33%

$6.00$4.00

Add to wishlist Add to wishlistSALE 30%

$5. 00$3.50

SALE 30%

$2.00

DuPont Terminal Open Wire Terminal Xh3.54 Terminal

- 1 Meter

SALE 30%

$1.60

0.2mm 0.3mm 0.4mm 0.5mm 0.6mm 0.8mm 1. 0mm

0mm

- 1.75mm Filament

SALE 30%

$1.60

0.2mm 0.3mm 0.4mm 0.5mm 0.6mm 0.8mm 1.0mm

- 1.

75mm Filament

75mm Filament - 3.00mm Filament

SALE 30%

$7.50

0.2mm 0.3mm 0.4mm 0.5mm 0.6mm 0.8mm 1.0mm

- 1.

75mm Filament

75mm Filament

SALE 30%SOLD OUT

Add to wishlistSALE 30%

$5.00

M6 X 15mm M6 X 20mm M6 X 30mm

- 40W

- 1000mm (1M)

SALE 25%

$8.00$6.00

145mm X 145mm 200mm X 300mm 214mm X 214mm

Add to wishlistShow more

BACK TO TOPAdded to cart successfully!

x

There are itemsin your cart

Total:

View CartPROCEED TO CHECKOUT

Please login and you will add product to your wishlist

Sign In Register

Printing Filament selling in perth WA for your 3D Printer online – 3D Printing Perth

Add to wishlistSALE

$25. 00

00

SALE

$24.00

Add to wishlist Add to wishlistSALE

$23.00

1KG

- Standard Colour

SALE

$30.00

Add to wishlist Add to wishlistSALE

$26.00

Add to wishlist Add to wishlistSALE

$30.00

Add to wishlist Add to wishlistSALE

$30. 00

00

SALE 15%SOLD OUT

$52.00$44.00

Add to wishlistSALE 15%

$40.00

Add to wishlist Add to wishlistSALE 15%

$36.00

Add to wishlist Add to wishlistSALE 15%

$30.00

Add to wishlist Add to wishlistSALE 15%

$24.00

Add to wishlistShow more

BACK TO TOPAdded to cart successfully!

x

There are itemsin your cart

Total:

View CartPROCEED TO CHECKOUT

Please login and you will add product to your wishlist

Sign In Register

New, dynamic Rapide One 3D printer project launches soon on Indiegogo

Archive

Subscribe author

Subscribe

Don't want

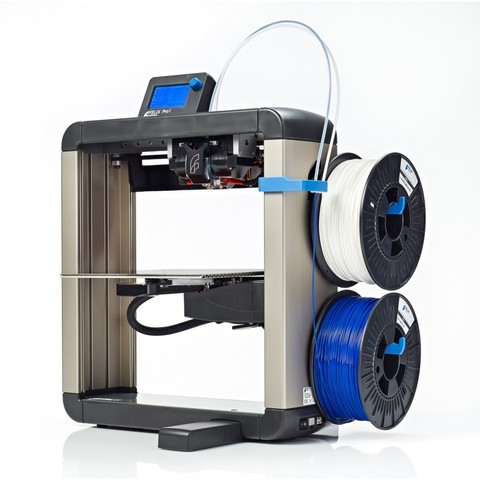

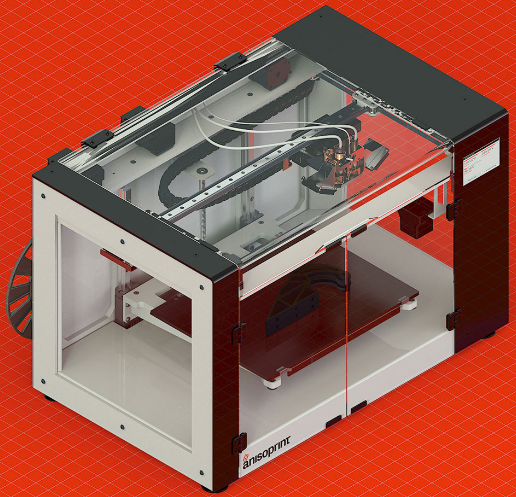

A team of Australian and Chinese designers and engineers developed the 3D printer able to completely redefine what 3D printing is all about.

"When designing the Rapide One, we researched all the current 3D printers on the market...and what we found in our research is that there is a huge gap between consumer grade 3D printers and professional 3D printers," says the Rapide 3D team

This is how Rapide One was born. Rapide One is a 3D printer that uses deposition modeling technology to bring 3D printed designs to life. "We believe we've created a 3D printer that's fairly easy to use while still competing in performance with high-end printers - but at a fraction of the cost of the latter," says Rapide 3D.

The Rapide One project is innovative, dynamic and bold. It comes with a unique fully enclosed body that resembles a gaming computer and an easy to use cartridge system. Through the large glass front and rear walls of the printer, you can easily observe the printing process. The interchangeable cartridge system located on the top of the printer not only saves space, but also makes it easy to change colors on the fly. All you need is just to load up to 500 grams of filament into a special tray.

All you need is just to load up to 500 grams of filament into a special tray.

For strength, the Rapide One body is made from aircraft-grade aluminum. The heated platform made of polished aluminum is not only completely flat and even, but also stable, which minimizes possible deformations and inaccuracies during the printing process.

Rapide One is capable of printing 100µm (0.1mm) layers with individual parts as small as 300µm (0.3mm) in a total printable area of 160 x 160 x 160mm. The dimensions of the entire Rapide One 3D printer are 532 x 449x 345 mm when closed.

The Rapide One software has been designed with a simple and intuitive interface. A key advantage of the Rapide One software is the ability to create 3D models with high accuracy.

Simultaneously with Rapide One, ABS, PLA and PVA filaments developed specifically for Rapide One will be on sale.

Specifications:

- Base: Aircraft aluminum

- Housing: aluminium, glass, PVC

- Platform: heated, polished aluminum 356F

- XYZ bearings : wear resistant plain bearings K

- Stepper motors: 1.

8 degree step angle, 1/16 micro stepping

8 degree step angle, 1/16 micro stepping - Layer resolution settings: high: 100 microns [0.1 mm] / standard: 200 microns [0.2 mm] / low: 300 microns [0.3 mm]

- Positioning accuracy : XY : 11 microns [0.001 cm] ; Z: 2.5 microns [0.00025 cm]

- Filament diameter: 1.75 mm

- Nozzle diameter: 0.4 mm

- Software compatible with: Windows (XP 32bit/7+) , Ubuntu Linux (+12.04), Mac OS X (10.6+64bit/10.7)

- Weight: 21 kg

Initially, the Rapide One was designed so that future models could be resized to include an additional extruder. In addition, the Rapide 3D team plans to develop printers in the future that, in addition to printing with standard materials, will also print with sugar and chocolate.

Rapide S

Rapide 3D has more than 11 years of experience in the design and development of advanced technologies. The company has offices in Perth, Melbourne, Hong Kong, Shenzhen and Guangzhou, and also has a design department in China. The company started working on the Rapide project in 2012 and after 18 months they have developed 3 generations of prototypes, started mass production of Alpha devices and are testing Beta devices. At present, the base and all components, as well as industrial design, are already completely ready, and the Rapide 3D team is testing the software on prototypes.

The company started working on the Rapide project in 2012 and after 18 months they have developed 3 generations of prototypes, started mass production of Alpha devices and are testing Beta devices. At present, the base and all components, as well as industrial design, are already completely ready, and the Rapide 3D team is testing the software on prototypes.

Rapide One is getting ready to launch on IndieGoGo (crowdfunding site). The single-extruder Rapide One retails at $2,499, but there are discounts for those who support the project on IndieGoGo: $1,499 for a printer or $1,649 for a printer with a single cartridge filled with ABS or PLA filament.

The first delivery is planned for January 2014 for early investors, and February 2014 for the remaining participants. Internal components will be manufactured in Wuhu, China, and final assembly and testing will be done in Shenzhen, China.

"We didn't invent the 3D printer, but we believe we've pushed the boundaries that define the concept of 3D printers and, in the process, have made professional-quality 3D printing accessible to many," says the Rapide 3D team.

Article prepared for 3dtoday.ru

Subscribe to the author

Subscribe

Don't want

More interesting articles

6

Follow author

Follow

Don't want to

One of the latest developments in 3D printing devices is the introduction of extruders. No, it's not...

Read more

four

Subscribe to the author

Subscribe

Don't want

If yesterday 3D printing was the lot of boys of different age groups trying to adapt new...

Read more

3

Follow author

Subscribe

Don't want

Recently, we talked about an interesting engineering and architectural project that is directly related to the . ..

..

Read more

Amazing things that can be printed on a 3D printer - Articles - Arrivo

“What does it cost us to build a house - we will draw, we will live” - today this phrase has become a reality. Everyone is happy with the progress in 3D printing: archaeologists are copying mummies, NASA specialists are growing artificial meat, birds are moving into high-tech birdhouses, and designers are bringing to life the most daring shoes that girls have ever worn. We offer you to get acquainted with the latest innovations and trends in 3D printing.

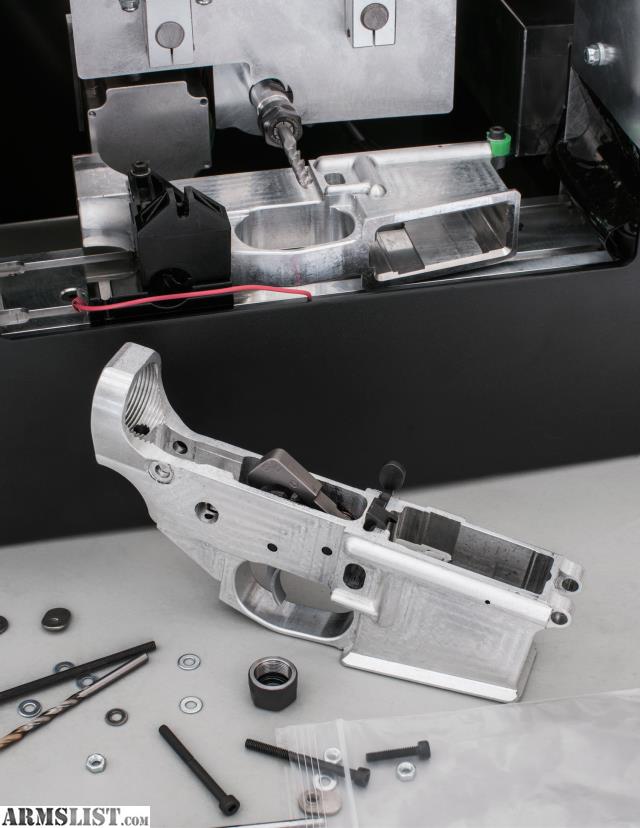

Pistol

Owners of 3D printers can get their hands on a weapon by downloading a few files from the Defense Distributed website. The printed pistols look like weapons from science fiction films, but are not yet as reliable as real ones. However, progress does not stand still - last year, Solid Concepts printed the world's first 3D metal gun.

SLR camera

French designer Leo Marius managed to print a SLR camera. The author of the invention did not fail to share it with the world - today anyone who does not spare $30 to download files from Marius' website and 15 hours to assemble the camera can become the owner of the unique Open Reflex "reflex camera".

The author of the invention did not fail to share it with the world - today anyone who does not spare $30 to download files from Marius' website and 15 hours to assemble the camera can become the owner of the unique Open Reflex "reflex camera".

Marius did not dare to create a 3D printed lens, and the Japanese Yuki Suzuki was not afraid of this either. He made the lens out of clear acrylic. The pictures taken on this camera can hardly be called high-quality, but Suzuki did not seek to please the capricious fans of Canons and Nikons - he was primarily guided by scientific interest.

Waterproof bikini and futuristic shoes

Advanced designers have also learned how to customize the 3D printer to suit their needs. Special software today allows you to quickly make clothes, taking into account the individual parameters of a person. Using new technologies, designers from Continuum, for example, have already managed to create a waterproof nylon bikini.

It is quite possible that 3D outfits will soon become a trend, but so far only celebrities risk flaunting futuristic dresses, and even then very extravagant ones.

Last year, Lady Gaga appeared in public in a black dress printed on a 3D printer by Materialize. Flashed in a printed dress and "Queen of Burlesque" Dita Von Teese. At the same time, the dress for Dita was made according to the drawings of the medieval mathematician Fibonacci and consisted of 17 different parts.

Designers have not forgotten about the part of the wardrobe so beloved by women, like shoes - in this genre, a 3D printer can work real miracles. For example, Sebastian Errazuriz printed a unique collection called "12 Shoes for 12 Lovers", dedicated to his apparently difficult relationships with women. Among the gems of the collection are shoes called "Gold Digger Allison", "Snow Queen Sofia", "Soldier Jane Barbara" and "Crybaby Alexander".

Sweets

Replacing traditional plastic cartridges with melted chocolate, you can create endless possibilities for creating desserts. Chocedge has created exclusive 3D printers that can print any pattern in chocolate, including your own photo. If chocolate is too traditional for you, you can try unusual sweets from Cubify.

If chocolate is too traditional for you, you can try unusual sweets from Cubify.

Meanwhile, Modern Meadow is hard at work building a printer that can print a steak. To do this, scientists use sophisticated technology, including the cultivation of stem cells.

The 3D printed food project is being funded by the space agency NASA, which believes it will be possible to feed astronauts in this way in the near future.

Researchers also assure that the day is not far off when modern technologies will allow even pizza to be printed. To do this, they say, it is simply necessary to increase the number of cartridges in the printer by adding dough, cheese and other necessary ingredients.

The rights to this article belong to arrivo.ru.

Acoustic guitar

The world's first 3D printed acoustic guitar was Scott Summit, who claims that his creation is even superior to hand-assembled instruments. New Zealander Olaf Digel followed in his footsteps, creating a whole line of so-called ODD guitars, among which there is even an instrument in the form of a web with spiders crawling inside.

3D printing is not limited to guitars. So, an employee of the MIT Media Lab, Amit Zoran, managed to print a real flute, and the German company EOS created a 3D model of a violin based on a polymer. But innovative instruments still sound much worse than traditional ones.

James Bond car

The creators of the latest James Bond film, Skyfall Coordinates, regretted actually blowing up the legendary 1960 Aston Martin DB5 special agent car, and printed a 1:3 scaled down version of it on a 3D printer.

It is the 3D printed version that explodes on the screen at the climax of the film.

A complete car can also be printed on a 3D printer. This is how all 50 parts of Urbee 2 were created, which is capable of accelerating to 112 km / h and driving up to 64 km on electric power alone. At the same time, the streamlined body of the machine significantly reduces fuel consumption. In 2015, the creators of the hybrid are going to drive more than 4,000 km on it, spending only 38 liters of fuel.

Prostheses and human organs

In 2011, Richard Wang, who lost 4 fingers while working in the workshop, 3D printed his own prosthesis. Subsequently, Richard began to design prosthetic hands called Robohand and even created the world's first 3D prosthetic laboratory in Sudan, where he helps disabled children.

The use of 3D printers in medicine promises to become even more useful over time - Chinese scientists have already learned how to print prototypes of human organs. True, they “live” for no more than 4 months and are devoid of blood vessels. However, according to researchers, it will be possible to “print” full-fledged organs in 15-20 years.

Turntable

Amanda Gassey created a turntable using a 3D printer. You can't listen to classic vinyl records on it, but Amanda also came up with a special program that converts any sound file into 3D format. The sound quality of such records leaves much to be desired, so the creation can be considered rather as a design refinement.

Bicycle

Why reinvent the wheel - it's better to print it on a 3D printer, EADS decided. The AirBike created in this way impresses with its characteristics. Firstly, it is 65% lighter than its classic aluminum counterparts, and secondly, it is no less durable than them.

Birdhouse

Coming into contact with such a brilliant creation of our time as a 3D printer, one cannot help but share it with the smaller brothers. Recently, MakerBot held a competition for the best printed birdhouse. The owners of 3D printers did not stint on ideas for birdhouses: many creations were sent to the competition in all possible styles - from classic to high-tech. The winner was Eric Darwoodle, who built a real cozy villa for some lucky bird.

Lamp

Thanks to the development of Materialize, everyone can create their own unique lamp. If you do not believe in your design abilities, you can simply choose one of the copies available on the Internet and print it on your own 3D printer or order it for home delivery. Such lamps are able to turn any room into a forest from Avatar, casting the thinnest shadows on the ceiling. Designers from Nervous system assure that each lamp they create with a leaf pattern is unique, just like plants in nature.

Such lamps are able to turn any room into a forest from Avatar, casting the thinnest shadows on the ceiling. Designers from Nervous system assure that each lamp they create with a leaf pattern is unique, just like plants in nature.

Mummy

While the real mummy of the Egyptian emperor Tutankhamen rests in his homeland, in New York they recreated its exact copy using a 3D printer. Materialize, which created the reproduction, used CT scan data. The copy is made from photopolymer resin applied layer by layer. Makeup artists helped to fully match its counterpart to the 3D printed version of Tutankhamen.

The rights to this article belong to arrivo.ru.

3D children's drawings

The Crayon creatures site offers everyone the opportunity to bring children's drawings to life by printing them out in 3D. The idea is good because it makes getting a new toy dependent on the development of children's artistic skills. Who knows, maybe, having such a motivation, one day your child will learn to draw no worse than Van Gogh or Picasso.

Toys for adults

Using a 3D printer, you can create toys not only for children, but also for adults. So, the site Maker love offers a free and quite diverse design of sex products. If you have a 3D printer, you can download and print any copy you like here, and do it in a size that is limited only by your imagination.

Gadget Accessories

Gadget fans will love 3D printed accessories too. Printers today can print a case for an iPhone or iPad. If you want something extraordinary, you can turn to designer creations. So, SaGa design has developed an unusual stand for a tablet, which is an atlas supporting the gadget.

Art objects and sculptures

A lacy skull, a puppet horse or a futuristic bouquet of flowers - the possibilities of 3D printing are limited only by the imagination of the author of the art object. Many designers have already turned to this genre, and some of them have managed to create real masterpieces of our time with the help of a 3D printer.

For example, Josh Hacker is making headway towards lace skulls. According to him, he sets as his task "the embodiment of the architecture of the imagination." And Mikaella Janse van Vuuren printed out a three-dimensional image of her drawing of a puppet horse with movable wings and functional joints.

Jewelry

Jewelry created using the possibilities of 3D printing, although not precious, is undeniably unique. The American design studio Nervous System has 3D printed flexible jewelry, consisting of hundreds of small fragments connected by miniature hinges. To create such decorations, fragments are combined in a special graphic editor into the final three-dimensional model, which is then compressed to a small size and sent to print.

House

Dutch architect Janjap Reissenaars from Universe Architecture is going to build an entire building using a 3D printer. As conceived by the author, the printer will create sections of the building (6 by 9 meters in size) from sand and a binder. The final material promises to be stronger than cement. Although the building will still need to be reinforced with concrete, this is the world's first project to build an entire building using a 3D printer.

The final material promises to be stronger than cement. Although the building will still need to be reinforced with concrete, this is the world's first project to build an entire building using a 3D printer.

Furniture

By 3D printing a house, you can create furniture for it in the same way. There are already tables, chairs and even beds that have been made using 3D printing. Basically, such furniture is created from individual parts, but recently BigRep created a printer that can print whole furniture. The dimensions of such furniture are quite standard.

The machine can work with nylon, plastic and Laywood, which looks like real wood.

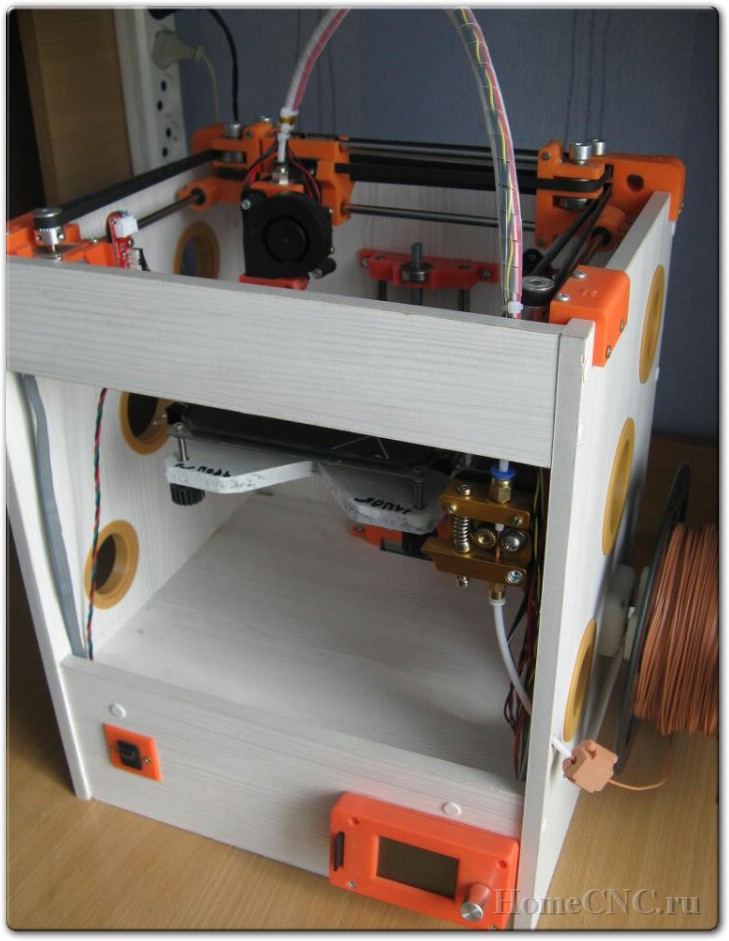

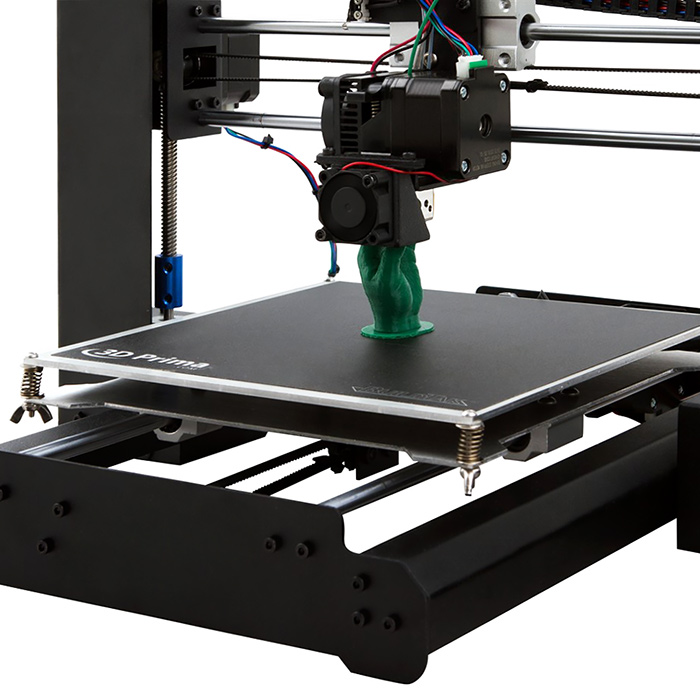

3D printer

The RepRap 3D printer is unique in that it can print itself. Nevertheless, it still does not reproduce all of its own parts, and the final assembly must still be carried out by a person. The creators of RepRap believe that the universal self-replicating 3D printer can eventually be used in the production of small household items.