3D printer filament weight

The densities of all 3D printing materials

Today at Bitfab we’re going to talk about a subject that every good maker ends up wondering about: what is the density of a filament, how much is the weight of each meter, and how many meters of it are in a one kilo coil.

At first glance, it might seem silly to you; how many objects in our daily life do we need to know this data from? Practically none, but in this point it is essential, because with this data we can know exactly the amount of spent filament or if really 1kg of a material from one coil compensates us more than another.

How? We’ll tell you, so keep reading this because you’ re going to like it 🙂

📖 What do you want to read?

The density chart of all 3D materials

Here’s a list of different materials taken from this article on 3D printer filaments to give you an idea of what’s on the market.

In grams per cubic centimeter so you can see for yourself!

| Material | Density [g/cm3] |

| PLA | 1. |

| ABS | 1.04 |

| PETG | 1.27 |

| NYLON | 1.52 |

| Flexible (TPU) | 1.21 |

| Polycarbonate (PC) | 1.3 |

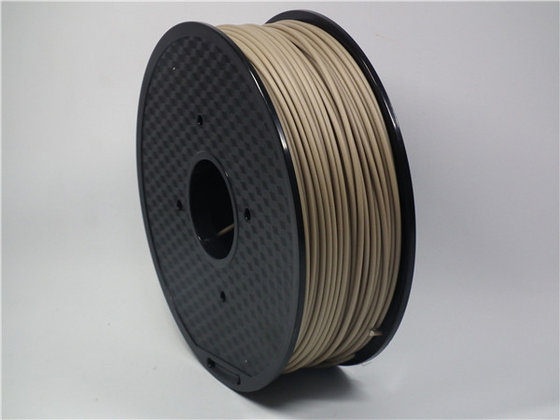

| Wood | 1.28 |

| Carbon FIber | 1.3 |

| PC/ABS | 1.19 |

| HIPS | 1.03 |

| PVA | 1.23 |

| ASA | 1.05 |

| Polypropylene (PP) | 0.9 |

| Acetal (POM) | 1.4 |

| PMMA | 1.18 |

| Semi flexible (FPE) | 2.16 |

🥁🥁🥁 Here’s also… a graphic, so you can compare!

Here there are plenty of materials such as PLA, ABS, Polypropylene (PP), PETG, flexible filaments (TPU) or filaments with carbon fibre.

The lightest material for printing

Do you want to print the lightest pieces? A drone, a part for a radio-controlled plane… The lightest material used in 3D printing is Polypropylene, with only 0. 9 grams per cubic centimeter. Although we warn you: PP warping makes it quite difficult to print for large parts!

9 grams per cubic centimeter. Although we warn you: PP warping makes it quite difficult to print for large parts!

The heaviest 3D printing material

The heaviest materials on our chart are semi-flexible FPE and nylon (Polyamide), so they can affect you in applications where you are looking for lightness.

Apart from these, there are other heavier materials that we have not yet considered: metal-filled materials. There are materials filled with bronze, brass, copper, iron… which considerably increase the density of the material. These filaments usually have an aesthetic purpose and that is why we have left them out of our list of materials.

How many meters of material are there in a kilo of filament? (with chart)

The chart you were looking for to go from kilos to meters of material, to know how many meters there are in a coil, both for 1.75mm and 3mm filament.

| Material | How many meters in 1kg of material (3mm)? | How many meters in 1kg of material (1. 75mm)? 75mm)? |

| PLA | 114 | 335 |

| ABS | 136 | 400 |

| PETG | 111 | 328 |

| Nylon | 93 | 274 |

| Flexible (TPU) | 117 | 344 |

| Polycarbonate (PC) | 109 | 320 |

| Wood | 111 | 325 |

| Carbon Fiber | 109 | 320 |

| PC/ABS | 119 | 350 |

| HIPS | 137 | 404 |

| PVA | 115 | 338 |

| ASA | 135 | 396 |

| Polypropylene (PP) | 157 | 462 |

| Acetal (POM) | 101 | 297 |

| PMMA | 120 | 353 |

| Semi flexible (FPE) | 66 | 193 |

Do you want to know how we calculated this chart? This is the formula we have used. Let’s take an example of a 1.75mm coil weighing 1kg. You could do the same calculation for a 3mm coil.

How many grams are in a meter of filament? (with chart)

The question asked the other way around: how much does a meter of 3D printing filament weighs. We have also generated a chart with all the information so that you can consult it comfortably.

| Material | How much does 1 meter of 1.75mm filament weighs? [grams] | How much does 1 meter of 3mm filament weighs? [grams] |

| PLA | 2.98 | 8.76 |

| ABS | 2.50 | 7.35 |

| PETG | 3.05 | 8.97 |

| Nylon | 3.65 | 10.74 |

| Flexible (TPU) | 2.91 | 8.55 |

| Polycarbonate (PC) | 3.13 | 9.18 |

| Wood | 3.08 | 9.04 |

| Carbon Fiber | 3.13 | 9.18 |

| PC/ABS | 2.86 | 8.41 |

| HIPS | 2.48 | 7.28 |

| PVA | 2. 96 96 | 8.69 |

| ASA | 2.52 | 7.42 |

| Polypropylene (PP) | 2.16 | 6.36 |

| Acetal (POM) | 3.37 | 9.89 |

| PMMA | 2.84 | 8.34 |

| Semi flexible (FPE) | 5.19 | 15.26 |

How much does my 3D printed part weigh?

As a curiosity, in Cura you can also see the length of filament you spend per piece in the lower part of the program.

How to calculate the density of a filament with all formulas

As we have mentioned, density is the relationship between mass and volume of something; in this case our 3D filament.

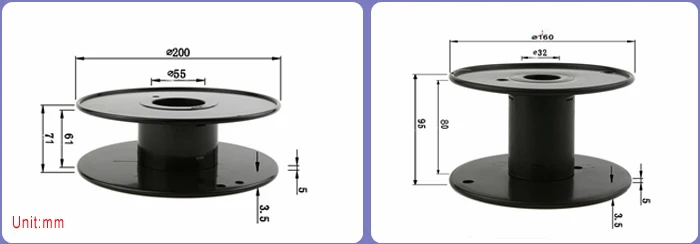

We already have the mass of the filaments, since they usually come in coils of 1[kg] of weight (minus the weight of the support). We only have to know the volume, and here comes the problem.

If we consider the filament as if it were completely stretched, it would be a very long cylinder tube, like this, where we are going to define the main measurements.

To calculate the volume of that cylindrical tube, we have the following procedure:

We have the filament radius, and we understand that it is 1.75[mm]/2. If we wanted to do a more precise calculation, we would take into account that the diameter of a filament has a tolerance of ±0.05[mm] and there are even manufacturers that reach ±0.02[mm].

The fact is that in order to do this analysis, you don’t have to take this into account, but it’s always good to know it (so you can look at it in the product specifications when you buy it).

Only length would remain and this is the one that does not normally come in the manufacturer’s specifications. However, it is usually between 335[m], although this value can vary between companies.

Finally, to calculate the density of a 1[kg] filament:

What did you think of our article on densities of 3D materials?

And this is as far as the article goes. We hope you liked it. Now you only need to read it a couple more times, and practice.

We would love if you could comment on the meters of the new filament you buy, and if the formula has really hit the nail on the head (when you finish it clearly).

Greetings and see you in the next article. Meanwhile, if you need something, you know you can count on our online 3D printing service.

Quick Tip: Using Filament Weight to Avoid 3D Print Failures

Running out of filament in the middle of a print is so unfortunate, but with this quick tip that hopefully never happens again!

Posted on January 29, 2020

by

Alec Richter

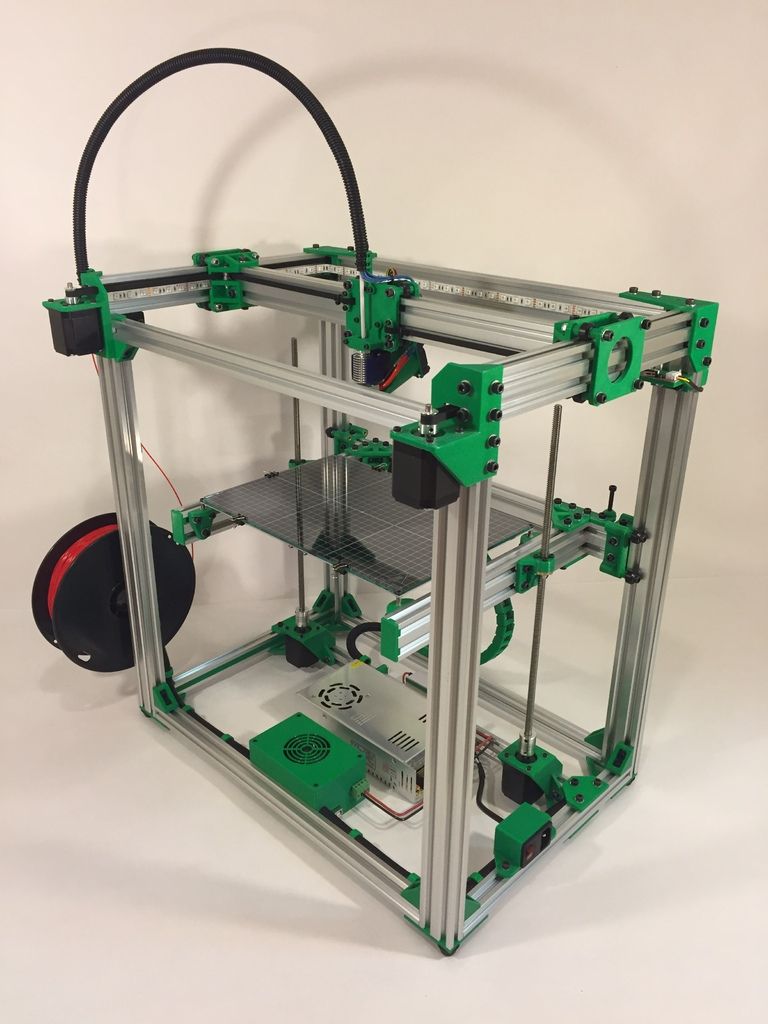

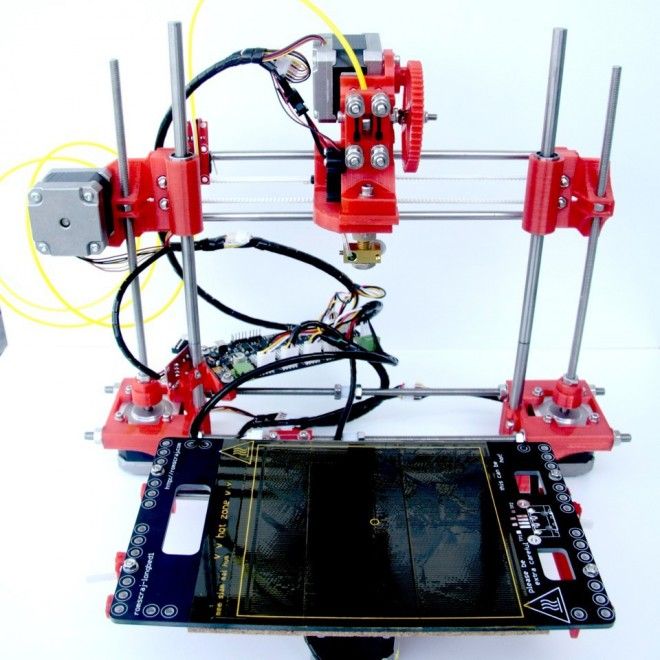

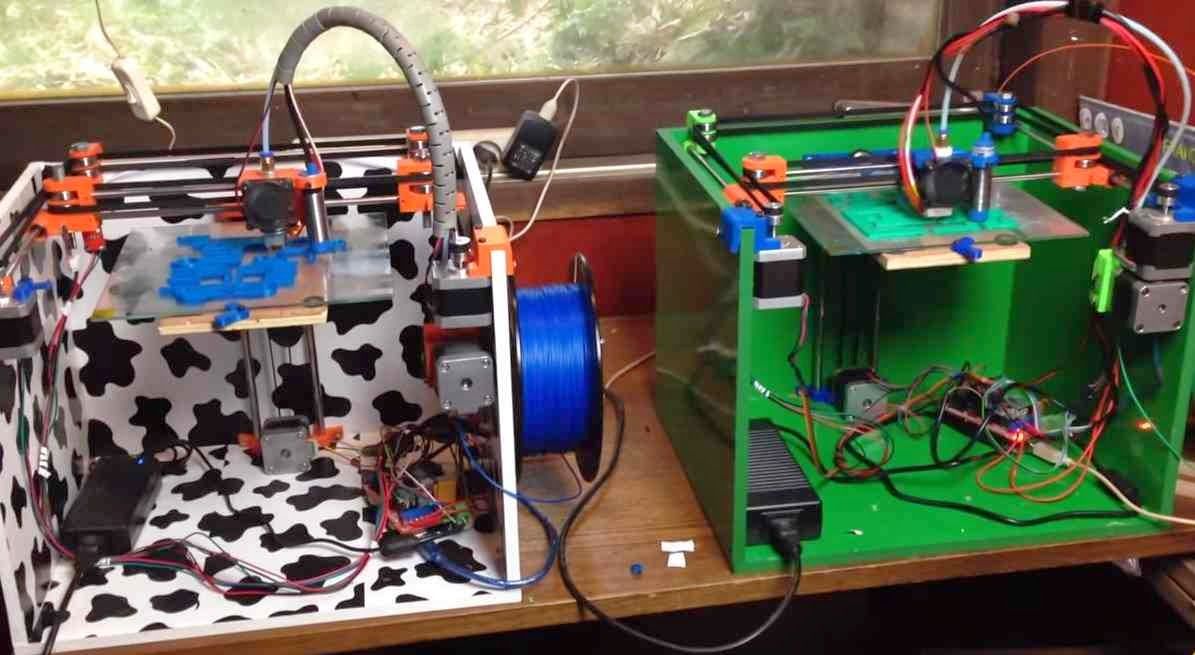

You hate to see it happen; you look at a spool before starting a print and think “this should hopefully be enough to finish this print” and as luck would have it, it wasn’t - you come back to find your 3D printer air printing because it ran out of filament before the job finished. I have a quick tip that can help you avoid these problems in the future, all you need is a digital scale. Let’s get started.

Let’s get started.

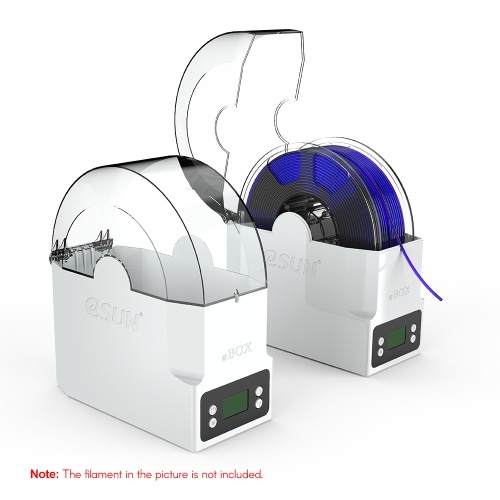

As soon as you unpackage a new spool, grab your scale and find the mass of the full spool in grams. After you tare the scale to make sure it reads zero with nothing on it, place your spool onto it and subtract the filament weight (this should be listed on the spool or on its product page online), this is the weight of the spool. You can now come back later with your spool and measure again to find how much filament you have left. This isn’t 100% perfect, as there are a lot of variables affecting the weight measured, so leave yourself some margin of error when you are printing with it: if you need 50g of filament to finish a print but you have 51g, either don’t use that filament, use a runout sensor, or keep a careful eye on it near the end of the print to make sure it doesn’t run out.

Before you do any 3D printing, be sure to weigh everything out.

Your slicer will usually calculate the mass of the filament that will be used for a finished print, but that is reliant on you making sure that the density of the material you are printing is entered into the field within the slicer, otherwise its prediction can be significantly off. ABS is around 1g/cm3 and PLA is around 1.25 g/cm3 which means if you leave in one value and meant for the other to be entered, your filament estimate will be 25% off.

ABS is around 1g/cm3 and PLA is around 1.25 g/cm3 which means if you leave in one value and meant for the other to be entered, your filament estimate will be 25% off.

Almost every slicer features a way to estimate material consumption of a given gcode.

I would suggest keeping a spreadsheet of all the different brands of filament you have used and the weight of the spools that the manufacturer uses, including an average spool weight as they tend to fluctuate. A good habit to have is to weigh your empty spools as well so you have a more concrete measure of the spool weight rather than just an estimate.

You don't need to get fancy with it, just having a document you can always come back to and confirm spool weights is enough diligence.

Another thing, make sure you maintain control of your filament. We have another article where I talk about how to avoid getting tangles in your filament, which is a possibility if you aren’t careful when handling your spools and let the end of the filament pass under a loop, which will over time tighten and tighten until it snags and ruins a print. Thankfully it is easily fixable!

Thankfully it is easily fixable!

Getting a tangle can ruin your prints, so be sure to take care of them before they become a problem.

I hope this gives you a better shot at success with your 3D printer, whether it’s trying to use that last bit of filament on some small print or if you’re questioning if you have just enough for a long one. And if you know you’re going to run out, MatterHackers fast and free shipping makes it really easy to restock.

Happy printing!

Article Tags

- 3D Printing

- Firmware

- 3D Design

- MatterControl

- Press Releases

- Small Business

- Automotive

- E3D

- Jewelry Making

- Engineering

- Entertainment Industry

- MatterControl Touch

- ESD Materials

- NylonX

- BCN3D

- Open Source

- Crafty Pen

- Digital Fabrication Anatomy

- How To

- Hardware and Upgrades

- Tips and Tricks

- Weekend Builds

- Top Ten

- Education

- Tech Breakdown

- Women in 3D Printing

- Project Ideas

- Advanced Materials

- Reference

- Pulse Dual Extrusion

- Product Spotlight

- Aerospace

- Jobs

- Military & Government

- Multi-Tool Machines

- Getting Started

- Healthcare

- How To Succeed With Any 3D Printing Material

- Creality3D

- Architecture

- 3D Printer Reviews

- Hacker of the Month

Related Products

View all related productsEngineering plastic for 3D printer

Cart is empty

Site search

Home / Catalog / Consumables / Engineering plastic for 3D printer

Materials for 3D printing on a 3D printer of functional products. High-strength polymers and plastics based on various plasticizers and functional additives. Products printed from these materials have increased strength and hardness. wear resistance. They have wide temperature ranges of application, good resistance to fats and mineral acids. Various weather and impact resistant plastics based on ASA, PET-G, NYLON. The materials have high strength and resistance to external factors, have a wide operating temperature range for a long time, are resistant to ultraviolet radiation and are practically unaffected by lubricants, dilute acids and diesel fuel. They have increased adhesion and less shrinkage effect. The materials are suitable for printing device cases, outdoor equipment, automotive, marine and air equipment elements (both external and internal elements) and objects that are exposed to the environment during operation. Various thermoplastic polyurethanes, polymeric materials that combine the hardness of strong plastics and the elasticity of natural rubber.

High-strength polymers and plastics based on various plasticizers and functional additives. Products printed from these materials have increased strength and hardness. wear resistance. They have wide temperature ranges of application, good resistance to fats and mineral acids. Various weather and impact resistant plastics based on ASA, PET-G, NYLON. The materials have high strength and resistance to external factors, have a wide operating temperature range for a long time, are resistant to ultraviolet radiation and are practically unaffected by lubricants, dilute acids and diesel fuel. They have increased adhesion and less shrinkage effect. The materials are suitable for printing device cases, outdoor equipment, automotive, marine and air equipment elements (both external and internal elements) and objects that are exposed to the environment during operation. Various thermoplastic polyurethanes, polymeric materials that combine the hardness of strong plastics and the elasticity of natural rubber. Materials for 3D printers hold their shape well, have high flexural and tensile strength, excellent sound absorption and vibration damping properties, and a high degree of wear resistance. Polymers for 3D printing are resistant to sea water, fats, and are not affected by microbes or bacteria. Materials for 3D printers have a high level of resistance to natural aging and can be recycled. You can buy plastic for a 3D printer in Arkhangelsuk, Severodvinsk, Novodvinsk at 3DELO. nine0003

Materials for 3D printers hold their shape well, have high flexural and tensile strength, excellent sound absorption and vibration damping properties, and a high degree of wear resistance. Polymers for 3D printing are resistant to sea water, fats, and are not affected by microbes or bacteria. Materials for 3D printers have a high level of resistance to natural aging and can be recycled. You can buy plastic for a 3D printer in Arkhangelsuk, Severodvinsk, Novodvinsk at 3DELO. nine0003

-

Plastic for 3D printer PET-G

Material type: PET-G

Manufacturer: ABS Maker

Thread diameter: 1.75 mm

Thread weight: 1000 g -

Plastic for 3D printer PLA High Performance nine0003

Material type: PHA / PLA

Manufacturer: U3PRINT

Filament diameter: 1.75 mm

Filament weight: 1000 g -

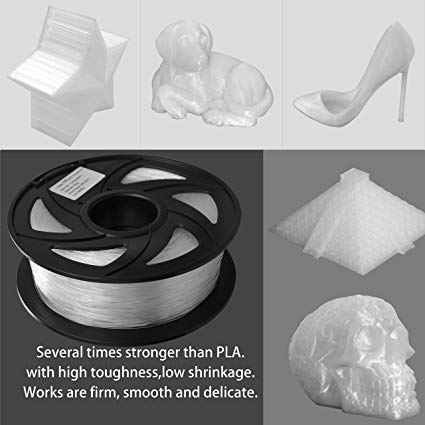

Plastic for 3D printer PLA Extra Strength

Material type: PHA / PLA

Manufacturer: U3PRINT

Thread diameter: 1. 75 mm

75 mm

Thread weight: 1000 g -

Plastic for 3d printer PETG

Material type: PET-G

Manufacturer: U3PRINT

Thread diameter: 1.75 mm

Thread weight: 1000 g - nine0002 Plastic for 3d printer NYLON SUPER CARBON

Material type: CARBON / NYLON

Manufacturer: U3PRINT

Thread diameter: 1.75 mm

Thread weight: 500 g -

Plastic for 3d printer NYLON REGULAR

Material Type: NYLON

Manufacturer: U3PRINT

Thread diameter: 1.75 mm

Thread weight: 500 g -

Plastic for 3d printer CARBON FIBER

Material type: CARBON

Manufacturer: FIBER FORCE

Thread diameter: 1.75 mm

Thread weight: 750 g nine0081

Best 3D Printer Filaments (Review 2021)

Once you've chosen your 3D printer, you need to select the type of filament for your project. Filament is a raw material used in 3D printers that will be heated to a high temperature to turn it into a semi-solid state. At this point, the printer can easily create the appropriate design layers and print the entire 3D CAD model onto a plate.

At this point, the printer can easily create the appropriate design layers and print the entire 3D CAD model onto a plate.

However, as you research the various 3D printer filaments, you will hear of numerous materials that can only make it harder to choose the right one for you. This is especially true for people who are just starting to explore the world of the 3D printing process. nine0003

While most of us are not new to PLA and ABS, there are other fiber materials you should be aware of such as HIPS, PET, PETG, TPE, TPU, TPC and a few others. And to get a better idea of them, here are some of the more typical types of 3D printer filaments available on the market.

3D Printer Filament Types

PLA Filament

Polylactic acid (PLA) reigns supreme in the industrial 3D printing world. 3D printing with PLA is so easy. It has a lower plate temperature, so it doesn't need a heating bed and therefore has fewer warping issues. nine0003

nine0003

It is widely used in prototyping, such as printing low-wear toys, prototype parts and containers. Please note that it cannot be used for anything that has a temperature rating of 60°C or higher as it warps at 60°C. For all other purposes, PLA is suitable for a general 3D printer.

ABS Filament

ABS (also known as Acrylonitrile Butadiene Styrene) is the second most popular 3D printing filament. In general, ABS withstands high loads and high temperatures. Thus, it is suitable for most applications. It is great for items that are frequently handled, dropped or heated. For example, mobile phone cases, high-wear items, automotive trim parts, and electronic houses. nine0003

Nylon filament

Nylon is the preferred family of synthetic polymers for many industries, professional 3D printing being one of them. As for other forms of filament, they have better performance, efficiency, versatility and durability. Given the strength and versatility of nylon, this type of 3D printer filament can be used to make loops, buckles or gears, as well as working prototypes.

Given the strength and versatility of nylon, this type of 3D printer filament can be used to make loops, buckles or gears, as well as working prototypes.

PET (G) thread

The most widely used plastic in the world is polyethylene terephthalate (PET). It is best known as water bottle thread, but it is also used in clothing fibers as well as food containers. Although PET is commonly used in 3D printing, its modified version PETG is becoming more common.

The G in PET stands for glycol, resulting in a more transparent filament that is less prone to cracking and easier to use. PETG is versatile but surpasses many forms of 3D printer filament in its strength and inability to reach high temperatures or withstand strong impacts. The fulfillment of the following conditions makes it an excellent choice for 3D printing filament for practical parts such as mechanical parts, printer parts, and protective materials. nine0003

TPE, TPU, TPC filament

Thermoplastic polyurethane (TPE) is a flexible and durable plastic similar to rubber. In addition, TPE is mainly used for the production of auto parts and household appliances.

In addition, TPE is mainly used for the production of auto parts and household appliances.

TPU (Thermoplastic Polyester E) is a special form of TPE that is very common among high end 3D printers. Compared to conventional TPE, TPU is significantly more flexible, hence allowing more control during printing.

Moreover, TPC (thermoplastic copolyester) is also another form of TPE that is not as widely used as TPU. The key advantage of TPC over TPE is its greater resistance to chemical and UV attack, as well as heat (up to 150°C).

If you need to create items that require a lot of wear, use TPE or TPU because these filaments use 3D printed filaments that are vulnerable to deformation. Products such as toys, mobile phone cases, or wearable items such as wristbands can be some examples of its application. On the other hand, TPC performs well for comparable applications, but outperforms it in harsher environments, including outdoors. nine0003

Wood filament

Technically not wood because it contains wood fiber in enhanced PLA. Generally speaking, wood products are valued for their natural beauty rather than their practical utility. When printing items for tables, tables or shelves, it is recommended to use wood 3D printing media. Any of the application examples include chalices, figurines, and trophies. What's more, it's a truly innovative application for 3D printers, which are often used to model real buildings, structures, or trees. nine0003

Generally speaking, wood products are valued for their natural beauty rather than their practical utility. When printing items for tables, tables or shelves, it is recommended to use wood 3D printing media. Any of the application examples include chalices, figurines, and trophies. What's more, it's a truly innovative application for 3D printers, which are often used to model real buildings, structures, or trees. nine0003

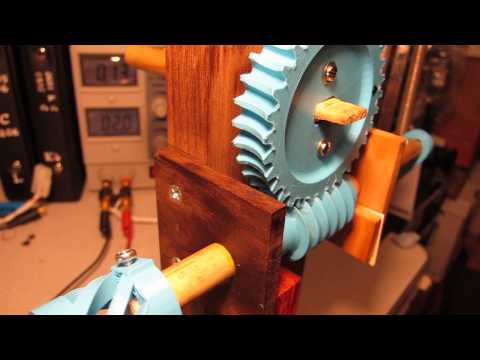

Metal thread

Like wood thread, it is not 100% metal. Specifically, it is composed of metal powder, and one of the following materials is PLA or ABS. However, the effects also have a metal-like aesthetic appeal. Metal Infused can be printed for both decorative and practical purposes. Figures, prototypes, toys, including tokens, can be 3D printed from metal and give them a great look. You can also use metallic 3D printer filament to make parts such as tools or finishing components in light applications. nine0003

Biodegradable (biophila) filament

This biodegradable 3D printer filament aims to reduce the impact of all plastic waste into the atmosphere. Although biodegradable 3D filament was originally environmentally friendly, it can still produce quality printed products. Choose this biophile if you don't have special requirements for strength, versatility or endurance. For projects that require prototyping, you can also benefit from these flawless fiber prints that can be biodegraded responsibly. nine0003

Although biodegradable 3D filament was originally environmentally friendly, it can still produce quality printed products. Choose this biophile if you don't have special requirements for strength, versatility or endurance. For projects that require prototyping, you can also benefit from these flawless fiber prints that can be biodegraded responsibly. nine0003

Conductive thread

This is a kind of three-dimensional material with conductive carbon particles in it. It is ideal for Arduino-based open source businesses. You'll want to look into this filament if you want to make circuits, LEDs, sensors, and other low voltage projects.

Magnetic filament

Magnetic PLA iron filament is as magnetic as the name suggests. This one-of-a-kind filament is made from PLA material impregnated with powdered iron. It is ideal for making fridge magnets and other custom-made decorative items. Also, it can be used to create multiple DIY structures, sensors, educational resources, etc.