3D printing gearbox

Gearbox 3D Printer - 3DXTECH

Gearbox™ HT2 prints a broad array of materials including PEEK, PEKK, Ultem PEI.

- tab-1

- tab-2

- tab-3

- tab-4

- tab-5

- tab-6

Large Heated Build Chamber

Precisely controlled for printing ultra-polymers

- Actively heated chamber reaches up to 225ºC

- Ideal for printing material such as Ultem™ PEI, PPSU, and PEEK

- Improved part strength and dimensional stability

- Huge 18″ x 18″ x 32″ [10,368in³ volume]

- Print large parts or multiple small parts

Dual High Temp Extruders

Ideal for multi-material complex parts [Model + Support]

- Extruder temperature up to 500º C for printing ultra-polymers

- Infinitely variable nozzle lift system for printing model & support

- Hardened system designed for carbon and glass fibers

- Model and support nozzles deliver complex parts

- Print with truly water-soluble supports – no harsh chemicals

Easy to use HMI

Large touch screen interface with simple to use navigation

- Intuitive 7″ touch screen interface

- Easy to use and interpret functions

- Simple navigation step-by-step to print

- Monitor all major systems with ease

- Adjust as needed to help save prints and downtime

Large Vacuum Secured Build Platform

Time Proven System – Reliable and Repeatable Results

- Touch-free automatic bed leveling

- Durable vacuum secured build sheets

- Build platform heated up to 225°C

- Simple swap of build sheets between prints

- Excellent adhesion of print to build sheets

Heated & Actively Dried Filament Bays

Fully integrated Materials Management System

- Large filament capacity up to 16kg [≈ 900in³]

- Actively heated filament bays to pre-heat materials assist in drying

- Desiccant drying system to continuously dehumidify filament bays

- Auto filament loader for ease of starting new prints

- Continuous unattended builds with auto-reel switching

High Speed Servo System

Precision engineered for fast and accurate builds

- Speed – capable of +300mm/s printing speeds

- Precision – exacting specifications and integration

- Reliability – proven industrial-grade motion system

- Repeatable – maximize productivity and uptime

- Continuous – unattended printing for long builds

Get Your Quote now

Get Your Quote now

Take your printing to the next level

Please fill out the form today to order your Gearbox™ HT2 and learn more information.

Name *

Business / Organization *

Email *

Phone *

State

Country

Industry Sector *Select your IndustryAerospace/DefenseMilitaryAdditive Manufacturing / Machine ShopAutomotiveConsumerEducationOil/Gas/EnergyEngineering/Management/Research FirmEntertainmentGovernmentIndustrialIT/ElectronicsMedicalOther

Select which industry you would utilize the HT2

Timeline for Purchase *Select timeline< 3 Months3-6 Months6-12 Months> 12 Months

When would you like to potentially purchase an HT2

Request *

Newsletter Signup

- Sign me up for Gearbox Email updates!

Gearbox best 3D printing models・Cults

Airsoft AEG Gearbox anti-reverse clip

Free

TRANSFER LEVER BUSHING MITSUBISHI L200 '06-'14 (TRANSMISSION)

€4

Dual Shaft DC Gear Motor

€1. 93

93

Airsoft Gear Support

€0.50

Peugeot 307, Peugeot 407,Citroen C4 GEARBOX REPAIR KIT 3D PRINT MODEL

€7

Kitchen Aid Turntable Gadget, Turntable for KitchenAid

€7.50

Engine - Gearbox POLOLU 137:1

€2.43

Gear Fidget Spinner

€14.95

Gear Fidget Spinner

€14.95

Pro Mod Reid Rossler with Bellhousing N Gear Vendors N Rife Sensors

€5.65

Gearbox and housing from a dough sheeter

€20

Herringbone Double Helical Gear Set

€12.95

Spur Gear Set

€12. 95

95

Osmo Pocket Accessories Storage Block

Free

Helical Gear Set (Module 1.5 - Z5-Z100)

€12.95

Controlli MVB56 Valve Actuator gears

€5

Mushroom jewelry box and mushroom piggy bank

€3

Volkswagen Sharan / Ford Galaxy / Seat alhambra GEARBOX REPAIR KIT 3D PRINT MODEL

€10

Bushing Opel for gearbox F23

€6.25

Gearbox bushing Opel Astra H F17

€6.25

Plastic ring inside the gear lever bellows Fiat Tipo 2 356 (from 2015) + clips

€1.88

Fishing

€40

ICS MA-62 split gearbox lower

€8

27 to 1 reduction gearset

Free

Turntable

Free

Outboard Engine Clutch

€4. 95

95

STEP FILE Strainwave Gearbox 3D Printed 35:1 / 34:1

€4.50

Saeco Royal Professional - gearses for gearbox

€19

2-speed gearbox

€4.95

Rear Gearbox for AYK Radiant

€5

Front Gearbox Modified for AYK Radiant

€10

Outboard Engine GearBox Gear Case

€10.95

Gearbox for Kyosho Scorpion Tomahawk Turbo Scorpion

€10

BMW ball joint repair bushing

€6

Gearbox Shift Knob - Peugeot 205

Free

Mercedes Benz Vito balancer repair kit 638

€8

GEARBOX REPAIR KITBMW E23 E28 E30 E32 E34 E36

€6. 25

25

3D Printed Universal Planetary Gearbox remixed

Free

Chevy Th450 Transmission 1/24

€4.49

Harmonic Drive

Free

Gearbox Cover compatible with John Deere pedal tractor

Free

BMW gearbox bushing (original)

€8

Sage / Breville Dose Control Pro worm gear

Free

Airsoft Thompson gearbox centering clip

€4

CyBot - 6 axis Robot Arm Cycloidal gearbox drive actuator <In Progress>

Free

Marui Hunter & Galaxy special gearbox cover

€10

COMPLETE SET OF SKODA, VOLKSWAGEN GEARBOX BUSHINGS (without gearbox joint)

€10

Stackable planetary gear - High torque

Free

planetary for children's typewriter, stl printable model

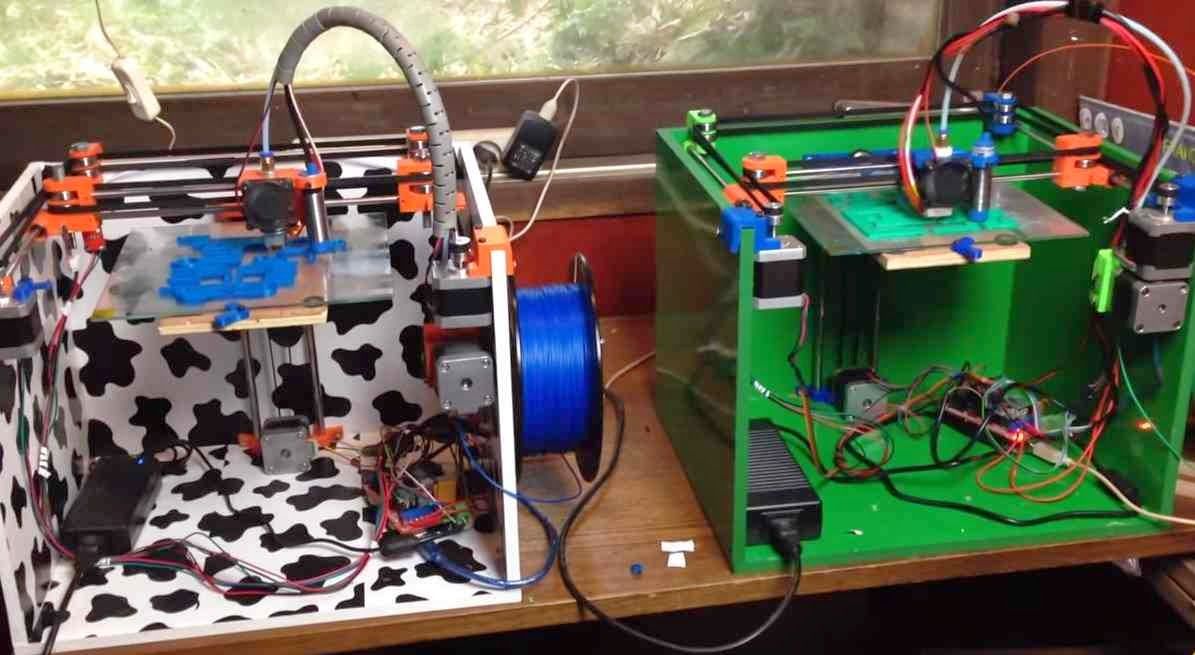

3D printing technology allows you to successfully model and print a variety of products, including those with increased complexity. Printing a gearbox on a 3D printer at home has some features and requires preparation, but it is quite possible.

Printing a gearbox on a 3D printer at home has some features and requires preparation, but it is quite possible.

Reducer on a 3D printer

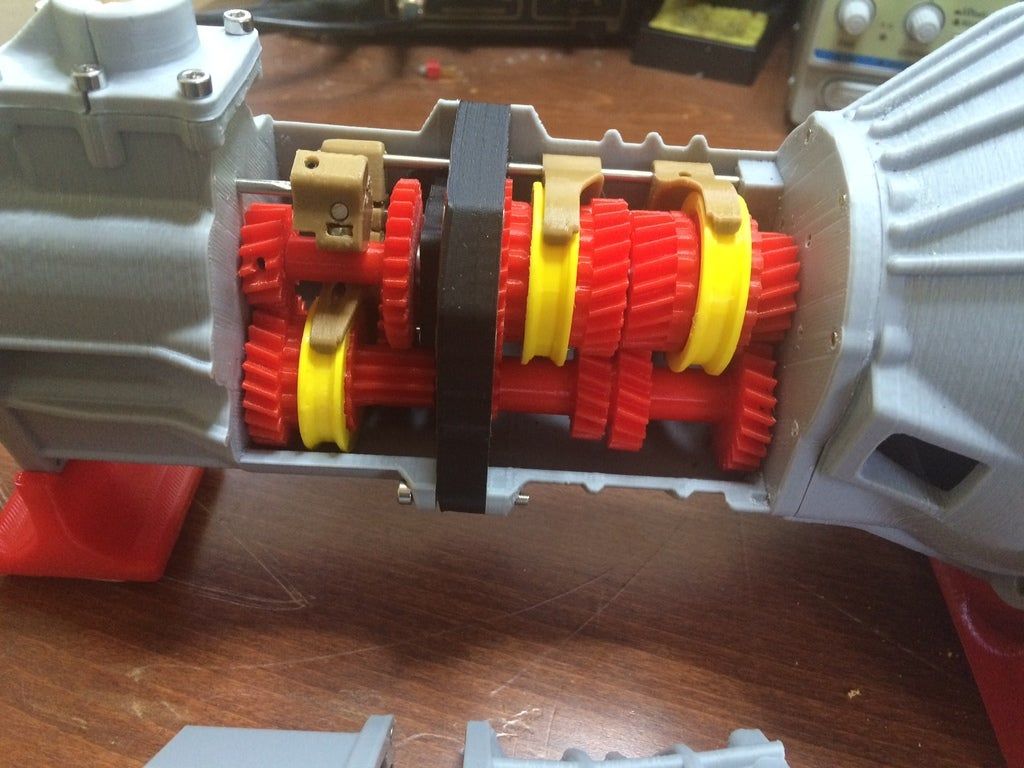

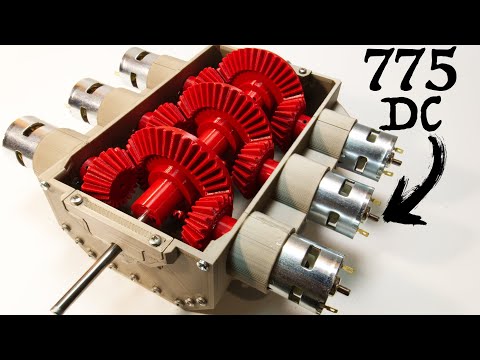

The reducer is a mechanism that converts the torque and power of the engine. This element is present in almost any machine tool, car or other mechanical device. From a technical point of view, a gearbox is a set of gears that interact with each other and in a given way reduce the number of engine revolutions to the required rotation speed of the executing unit. nine0003

In the simplest version, the gear unit includes a main gear mesh and a toothed wheel. At the moment of contact of the parts, torque is transmitted. The number of rotations of the parts is different, this indicator depends on the diameter of the parts and the number of teeth on them.

Gears and wheels must be permanently mounted on the shafts or be made together with them. The device consists of:

- body;

- covers;

- hook pair; nine0014

- shafts;

- bearings;

- o-rings.

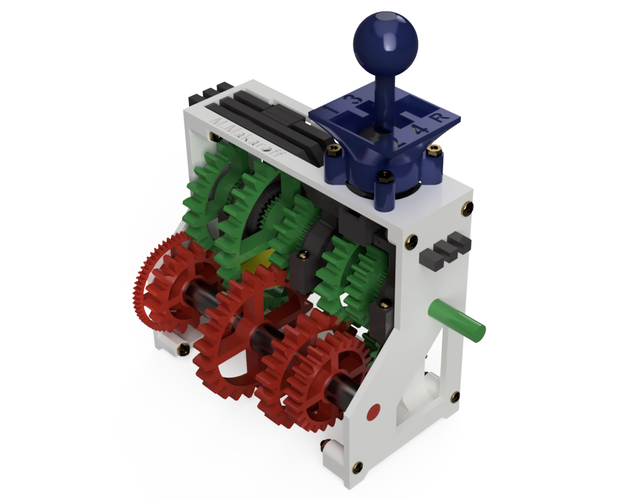

Planetary gear - a subspecies of these devices, a mechanism in which one or more planetary gears are placed.

The planetary gear consists of the following elements:

- the sun gear, which is located in the central part of the mechanism;

- planet gears are gears which are placed in such a way as to be in constant contact with the central gear; nine0014

- epicycle - a wheel with external teeth and one internal tooth, which is engaged with the satellites;

- planet carrier - connector for satellites.

The principle of the gearbox is based on the sequential transfer of torque from one shaft to another through the interaction of gear parts statically fixed inside the housing.

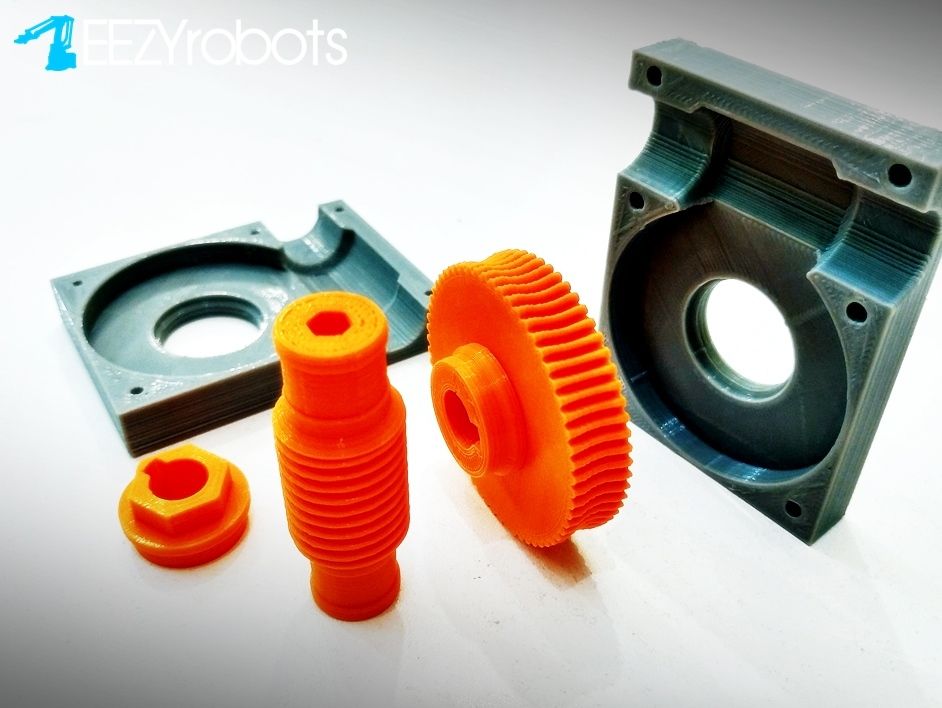

Printing the gearbox on a home 3D printer has its advantages and disadvantages. Benefits include:

- The ability to create a part that is ideal for a given situation. The user can take into account all the necessary dimensions and develop a model according to his needs.

- Relatively lower cost than when buying ready-made.

- Ability to quickly create a replacement for a failed part. No need to look for a similar one on sale and order delivery.

- A self-made part will have less weight and dimensions.

- The design can be optimized for a specific project. nine0014

Disadvantages include:

- the need to create an accurate model of the gearbox;

- Comparatively lower part accuracy than industrially produced products.

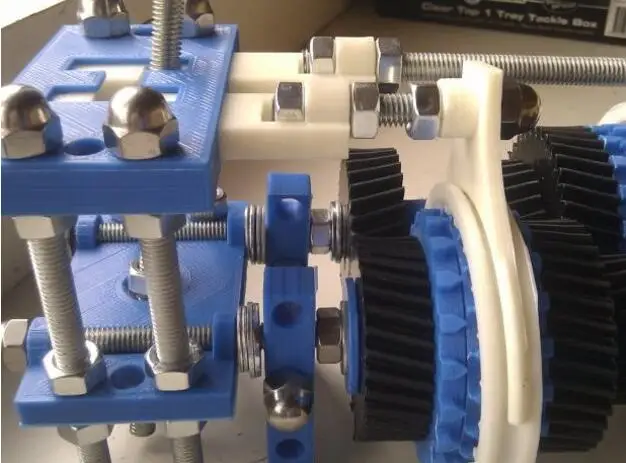

How to choose a model for a gearbox on a 3D printer?

Most modern 3D printers use files saved in the STL format. They describe the geometric features of a given object in a three-dimensional coordinate system, without paying attention to color, texture, and other attributes of the model. nine0003

You can create such a file in any engineering program, including CAD, Compass, etc.

IMPORTANT! For the development of gear models, it is necessary that the selected program has the appropriate module.

When developing models, the following parameters of the part must be taken into account:

- desired diameter;

- number of gear teeth;

- drive wheel diameter and number of teeth;

- rotation speed; nine0014

- district force;

- rotor load;

- gap and offset factors.

The model for the gearbox must be selected to best suit its intended use.

How to print a planetary gearbox on a 3D printer: step by step instructions

Printing a planetary gearbox on a 3D printer should begin with the development of a model. To do this, you will need:

- open one of the applications in which the gear simulation function is available; nine0014

- run the calculation of the model parameters and specify the number of teeth in the gears;

- indicate the module by calculating the index based on the diameter of the teeth and the diameter of the model;

- Specify a gap factor (0.

4%) to avoid biting during operation;

4%) to avoid biting during operation; - specify the offset factor;

- form a gear model;

- build the part body model;

- export the model and save it in a printer-readable format.

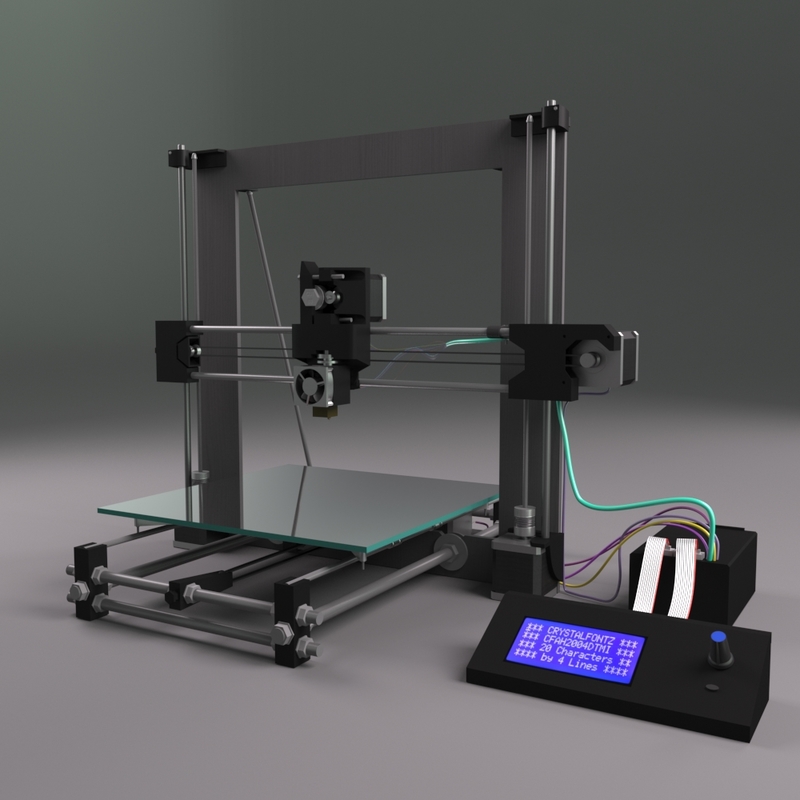

Next, you will need to configure the 3D printer print settings. To do this, follow:

- Set the printer's print settings, taking into account the material used. It is recommended that the product be printed using support structures printed in straight lines.

- Save the model and move it to the printer's memory.

- Adjust the table before printing to avoid deformation of the part.

- When the table is adjusted, start printing and wait for the extruder to reach the optimum temperature. nine0014

- Before printing, you should also increase the adhesion of the desktop surface by coating it with a special compound or film. This must be done immediately before printing, otherwise the adhesion of the part to the surface will be insufficient.

- During printing, protect the part from possible drafts by closing the printer chamber.

- After printing is completed, the product must be removed from the table surface and cleaned, removing the supporting structures.

- When all the details of the product are printed, the design must be assembled and checked, post-processing if necessary. nine0014

Mistakes and how to avoid them

The most common printing errors are incorrect print temperature, layer speed, and poor first coat adhesion.

In order for the gearbox to print as planned, you need to:

- Adjust the printer to avoid jamming and jerky motion.

- Achieve the optimum room temperature or cover the printer with a special cover to avoid drafts. If the temperature regime fails, the product may be deformed. nine0014

- Choose the right filament. The gearbox will be subjected to severe stress during operation, so the plastic chosen must be durable and impact resistant.

It is also recommended to choose a plastic that is less prone to shrinkage, such as ABS.

It is also recommended to choose a plastic that is less prone to shrinkage, such as ABS. - Adjust the filament feed speed to the extruder and its heating temperature. Too much heat can create webs that will ruin the product and require you to start printing again.

- The performance of the printed product is directly related to how well the support structures are removed. For the best effect, it is recommended to wash the product in ultrasonic baths with a special composition. nine0014

Printing a gearbox on a home 3D printer is a procedure that requires careful preparation. But at the same time, a product printed according to individual parameters will be much more efficient in operation and will enable its owner to significantly save both money and time.

- April 19, 2021

- 2562

Get expert advice

Reducer on 3D printer

A 3D printer will help you print a part, regardless of its complexity. 3D printing is suitable for home use. But the process and preparation for it can take some time.

3D printing is suitable for home use. But the process and preparation for it can take some time.

Contents

- 1 Gearbox

- 2 Selecting a 3D model

- 3 Step-by-step instructions for printing on a 3D printer

- 4 Common mistakes Externally, the part is a few connected gears. Characteristics allows you to get the speed you need for work at the output node. You can meet a similar mechanism in various devices: machines, vehicles or various tools. You can buy geared motors here. nine0003

Parts are engaged with each other by teeth, the number of revolutions is different for elements of different diameters. The simplest mechanism may consist of a wheel connected to one gear. The resulting rotation speed depends on the characteristics of a particular element: the number of teeth and the diameter of the gear.

When creating a mechanism, you should consider how the gears and shafts are attached. The interaction of the elements allows you to transfer the rotation of the engine to the actuator. Inside, some of the elements are stationary, others consistently transmit the moment of rotation. nine0003

Inside, some of the elements are stationary, others consistently transmit the moment of rotation. nine0003 The planetary gearbox often allows more than one gear to be used. It is a subspecies of the mechanism, it contains:

- sun gear - the central element of the design;

- satellites - several gears located around the main one;

- carrier - a part fixing the position of satellites;

- epicycle (ring gear) - pinion gears touch the inner teeth of this part.

3D printing at home has advantages and disadvantages to be aware of. The advantages of self-manufacturing the part are:

- You can work out the dimensions and weight, choosing the parameters suitable for the project.

- Printing takes less time than searching for ready-made prints in stores.

- The cost of your own part will be lower than that of a purchased part.

- The model can be optimized and modified if required.

The disadvantages of this method include:

- The complexity of creating a well-developed model.

- The accuracy of the resulting gearbox will be inferior to those produced by industrial machines.

Selecting a 3D model

In order for the printer to print the part, you need a file saved in a suitable format. STL is often used, which is suitable for describing the geometric features of 3D models. Colors, textures and other parameters in such files are not important.

There are many programs for creating three-dimensional models. Among the well-known ones are CAD and Compass, but there are also others. If you need to develop or modify the model, then it is important that the module for working with gears is installed. nine0003

The gearbox has several parameters. Some can be traced externally by examining the model and drawings, such as the diameter of gears and teeth. It is necessary to check the compliance of the parameters critical for operation. In order for the gears to interact correctly, the clearance and offset coefficients are indicated.

The number of teeth on each gear is important. Also, when creating a model, the maximum speed and load should be calculated.

The number of teeth on each gear is important. Also, when creating a model, the maximum speed and load should be calculated. When choosing a model, consider the purpose of the gearbox. Then the model will not require significant refinement for the device in which it will be used. nine0003

Step by step instructions for 3D printing

The first step is to create a suitable model. In a convenient program, you need to create gears, be sure to specify the number of teeth for the gear. You will need to calculate the module, it depends on the diameters of the teeth and the model. You must also set the offset and clearance factors. If the value of the latter is incorrect, biting may occur during operation. Thus, the creation of all parts of the gearbox should be completed. At the end, be sure to save the file in a format that the printer can work with. nine0003

The next step is to set the print parameters:

- Set up the printer to work with the selected material, and also prepare the supports.

- Load part into memory.

- Prepare the work surface.

- Warm up the extruder and cover the table with film to improve adhesion.

- Protect the working area from drafts, close the chamber if necessary.

- Wait for the end of printing and clean the part from the supports.

- Assemble and check the movement if necessary. nine0014

Common Errors

In the process, you may encounter problems that will negatively affect the quality of the part. Pay attention to:

- Printer adjustment. There should be no interruptions during the printing process.

- Preparing the room. Drafts should be excluded, the temperature in the room should not change during the operation of the printer.

- Filament selection.

- Feed rate and heating temperature of the filament when printing. nine0014

- Removal of supports and cleaning of the resulting product.

The quality of the plastic affects the performance of the gearbox.

Learn more