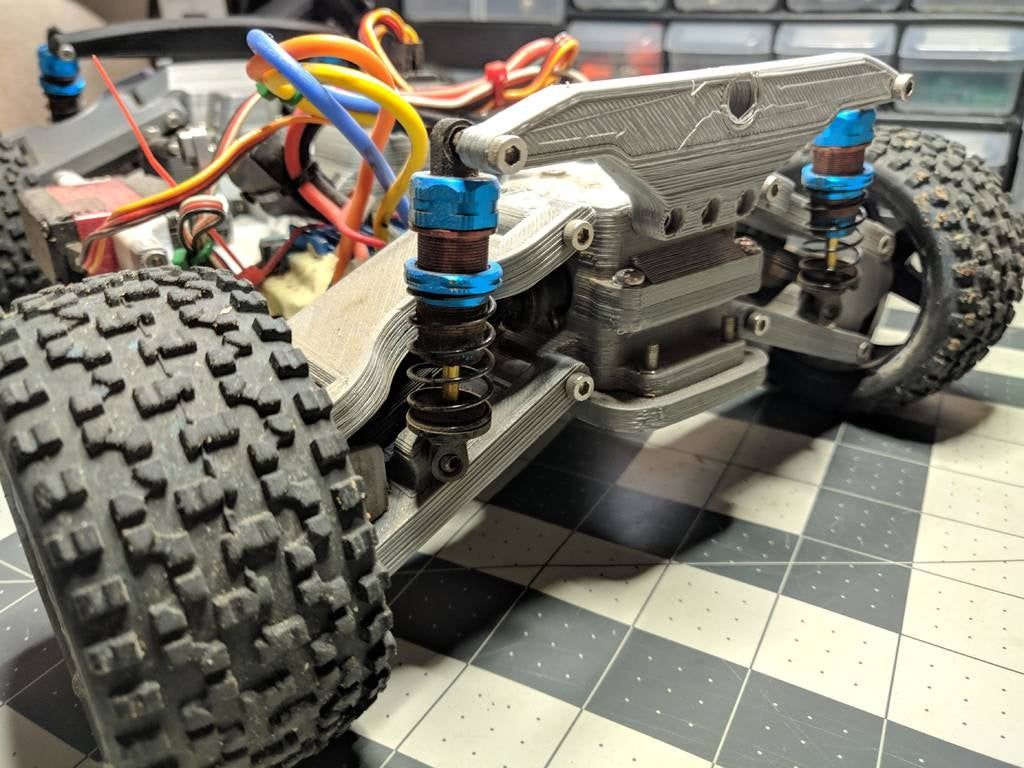

Car printed with 3d printer

Father and son 3D print Lamborghini in their garage

Published on July 12, 2019 by Filippos Voulpiotis

When a few days ago the giant automaker, BMW, presented to the world its new model of its 3D printable at home concept car, a father and a son had already started working on their very own project, making a full sized 3D printed Lamborghini Aventador. The duo decided to create the majority of the supercar’s parts with small office 3D printers they own, and it must be said, the results are impressive! The father, Sterling Backus, a physicist, decided to turn the ambitious idea of 3D printing a life-size car in his garage into reality to show his son what technology is capable of. This example, seems to be one of many that evolve the term of large format 3D printing.

When it comes to the relationship between cars and 3D printing, it’s important to highlight that most vehicles have a few if any 3D printed parts. As of today (July 12th 2019) the available technologies are not enough to produce a whole car model. However, that does not prevent us from saluting the initiatives taken in the industry that enable the development of car production. Thanks to additive manufacturing, many components can be optimized and therefore weigh less, thus increasing the vehicle’s capabilities whilst reducing the overall cost as fewer materials are needed. In the case of Sterling Backus, such technological developments, have allowed him to own the supercar he wished to have without spending hundreds of thousands of dollars.

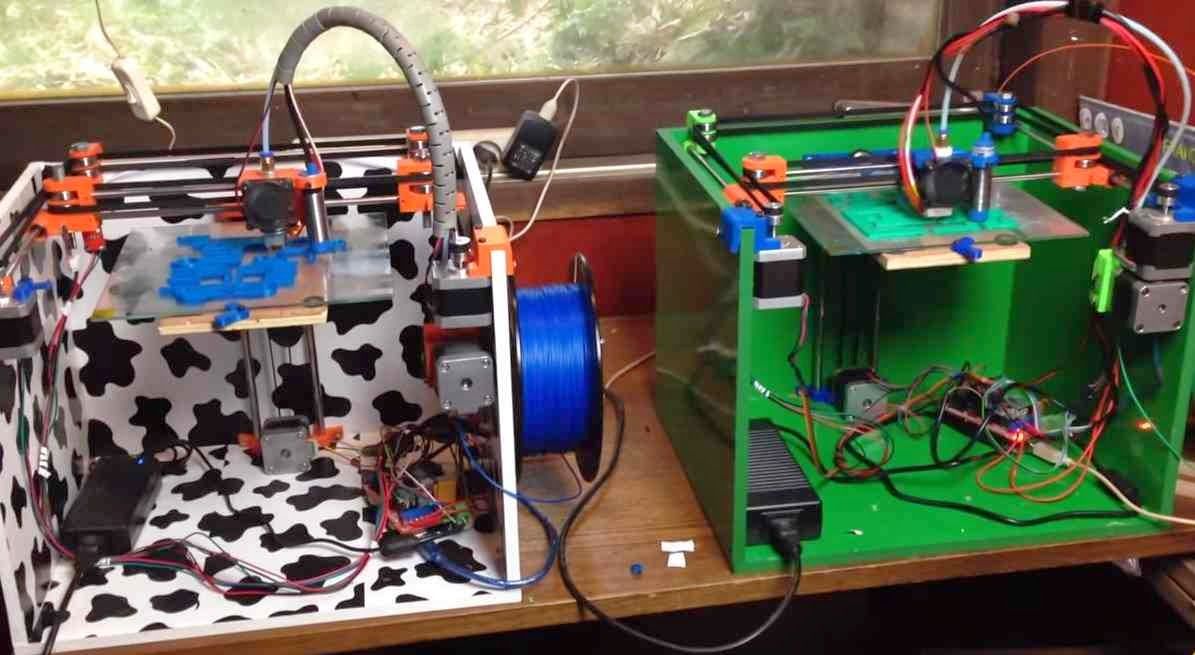

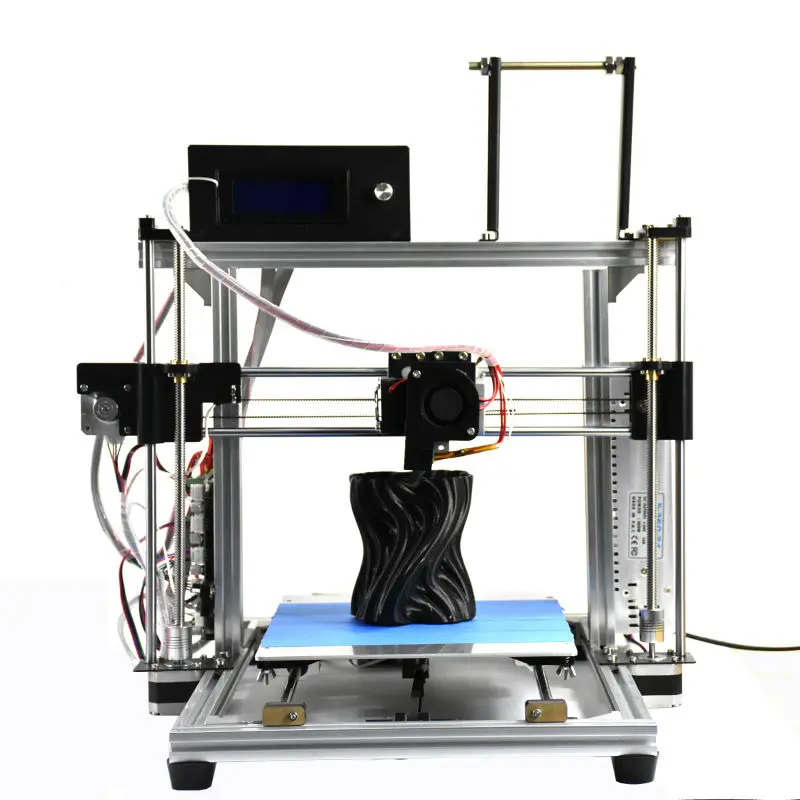

The physicist already had a rich history with 3D printing, having used several FDM printers before. For this project, the CR-10S, CR-105S and QIDI Xpro machines were used. Sterling also explains that in total, 220 spools of thermoplastic filaments were used to make the entire body. PLA was used for the body panels due to its good dimensional stability, ASA and ABS were used for rear light housings and headlights, whilst carbon fiber filled nylon was used for interior parts requiring high strength. The printing process was by no means executed perfectly from start to finish, as about 50 spools were used for several tests and failures.

The printing process was by no means executed perfectly from start to finish, as about 50 spools were used for several tests and failures.

In addition to 3D printing, the father and son have used other traditional manufacturing processes such as CNC machining, waterjet cutting, vacuum infusion and carbon fiber encapsulation. The physicist said: “We decided to use advanced technologies to build the car. However, we wanted to use low cost options. This led us to researching different techniques of automobile construction. After choosing to use 3D printing for most of the car body, we needed solidity. Very few choices of heat stress resistant materials were compatible with our 3D printers; so we turned to encapsulation of 3D printed parts with carbon fiber.”

Sterling wants to show his large format project to everyone, including local schools as part of their STEM project. He hopes to interest children in science, technology, engineering, art and mathematics, and what’s better at attracting children’s attention than a life-size partially 3D printed Lamborghini? The physicist recalls how ambitious the idea was 1 year and months ago, when he started working on it with his son. They spent at least an hour per day, whilst over $20,000 were invested in total for the project, a relatively low price considering the cheapest version of the official Aventador retails at over $300,000! The physicist concluded by saying that he is not planning on selling the car, not to compete with the car manufacturer. Sterling describes his entire project on his Facebook page HERE.

They spent at least an hour per day, whilst over $20,000 were invested in total for the project, a relatively low price considering the cheapest version of the official Aventador retails at over $300,000! The physicist concluded by saying that he is not planning on selling the car, not to compete with the car manufacturer. Sterling describes his entire project on his Facebook page HERE.

What do you think of this 3D printed Lamborghini project? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Does the Czinger 21C Supercar Herald the 3D-Printed Future of Car Making?

- The Czinger 21C supercar is fast and a little revolutionary, but the manufacturing process that went into it could change the world.

- Czinger uses additive manufacturing, or what we call 3D printing, to make parts that are then glued together by robots.

- The Czinger manufacturing method is being exported around the world.

At first glance, it was just another supercar being hyped by its millionaire maker as the fastest thing since Warp Factor 6. Granted, the Czinger 21C was fast—the tandem-seated carbon-fiber-over-aluminum-spaceframe hybrid superbeast had lapped Laguna Seca in 1:25.446 seconds. There was no disputing that, it said so right there in the press release:

“Czinger, the trailblazing company that uses revolutionary design and manufacturing technologies to build state-of-the-art, homologated high-performance vehicles, has set a new lap record at WeatherTech Laguna Seca Raceway, smashing the old record by an astonishing two seconds!”

Note the exclamation mark! True, the 21C had a proprietary 2.88-liter twin-turbo V8 located right behind its two tandem seats, aided and abetted by an 800-volt electric drive system with one motor for each front wheel making a total of 1233 bhp. So it could do it.

So it could do it.

Having seen so many such releases, however, we were skeptical. For instance, the release said, “lap record.”

“We don’t record lap records outside of sanctioned race laps,” said the WeatherTech Raceway track spokesman we called.

This content is imported from YouTube. You may be able to find the same content in another format, or you may be able to find more information, at their web site.

The lap record at WeatherTech Raceway Laguna Seca is held by Helio Castroneves, who turned a 1:07.722 in a Penske Indy car during the CART race in 2000. That’s quicker than 1:25.446, isn’t it? Well, this record is for production cars, see, and the Czinger beat the Randy Pobst-driven McLaren Senna by two seconds. The difference is that McLaren actually manufactured 500 Sennas and sold them to customers. Czinger hasn’t made any 21Cs that you can buy and won’t before 2023 or so. We could nitpick semantics like “lap record” and “production” all day.

But it would be a mistake to dismiss the Czinger 21C supercar just because of some over-anxious publicity stunt.

The biggest news about the Czinger is not how fast it’ll go, but how it and its maker will change the way cars are manufactured. For the last 118 years, since Henry Ford built the first assembly line in Highland Park, Michigan, cars rolled down a line and had parts added to them by human workers. Those parts were cast, stamped, extruded, sintered, or machined. Then all the parts were bolted, riveted, welded, or even glued together. Once you did enough of that, you had a car.

Kevin Czinger, for whom the lap-record supercar is named, has a different idea, making him potentially the Henry Ford of the new millennium.

Instead of all that extruding, stamping, bolting, and riveting, Czinger has developed a system based around additive manufacturing, or additive-layer manufacturing, which is the industrial production name for 3D printing. AM is a computer-controlled process that creates three-dimensional objects by depositing materials in layers in whatever shape they’ve been computer-programmed to become. In the case of car making, the material is usually some kind of aluminum alloy, but there are many, many materials that can be used.

In the case of car making, the material is usually some kind of aluminum alloy, but there are many, many materials that can be used.

Czinger didn’t invent additive manufacturing, 3D printing, or robots, of course, but he has a new way of bringing them all together.

"Most of the system is newly invented with ~500 patent filings," Czinger said. "It is a new system architecture, in-house purpose-built software and hardware for the three subsystems, and there is a new vehicle architecture.”

Wait, who’s Czinger? Kevin Czinger is something of a manufacturing revolutionary. He has a manufacturing facility in Torrance, California, unlike any you may have seen. In one huge room are a number of large, industrial AM machines printing parts, or adding layers until they’ve printed a part. In another room is a circle of robots centered around whatever it is they’re manufacturing. As the parts are printed and then delivered to the robots, the robots grab them in their computer-controlled hands and glue them together. Glue enough of them together and you have a car.

Glue enough of them together and you have a car.

“That’s taking almost 50% of the mass out of a combined subsystem.”

Czinger is putting together not only the manufacturing process and facility I saw in Torrance, but has plans to set up similar, custom-built facilities all over the world. In most applications, you get a much more efficient part in terms of increased strength and decreased weight. In the conference room where we were talking there were a number of automotive assemblies, all looking a little like the creature in the Alien movies. I said that I like the look of a brake assembly, for instance.

“That’s taking almost 50% of the mass out of a combined subsystem,” Czinger said.

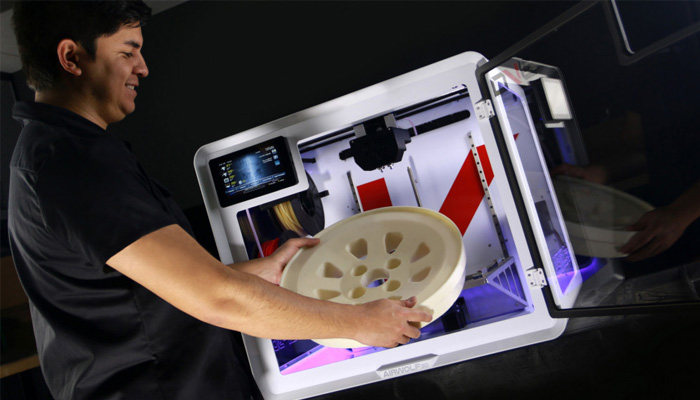

On the end of the conference table was an entire rear assembly of a car. Czinger walked over and picked the whole thing up. By designing everything through CAD, then downloading the design to the AM printer, the part can be made much lighter, with less material, and in a truly optimized shape.

“This is digital manufacturing, as it will be in the future,” Czinger said. “Today, we’re printing at a rate that if you took the very fastest machine on the planet, we’re printing 15x faster than that.”

He worked with the makers of AM machines to get the speed and accuracy he wanted. He sees what he’s doing as a revolution akin to the move from typewriters to computers—specifically, the first IBM Selectric typewriters that had two lines of memory.

“IBM said they’re going to digitalize the typewriter,” Czinger said, picking an analogy a writer/reporter could grasp. “I’m 62, so I remember when they had the IBM Selectric, and they’re like, ‘We’re digitalizing! We’re adding two lines of memory!’ Right? No, you have to architect desktop computing and desktop publishing if you want to have an actual digital system. We have 150 engineers and scientists here under one roof, like an old-school, Cold War skunk works, like the original Kelly Johnson skunk works. We architected an entire system for design, print, assembly, with what that really means, which is that all of the constraints are computer generated, including how you manufacture and how you assemble equipment that prints at the right rate and quality with the right materials. And then (we have) an automated assembly system that’s completely fixtureless, the assembly system can go from doing a full-scale large drone to a battery electric SUV with zero switchover time. None of the hardware ever changes.”

And then (we have) an automated assembly system that’s completely fixtureless, the assembly system can go from doing a full-scale large drone to a battery electric SUV with zero switchover time. None of the hardware ever changes.”

I got to see the system, but much of it is proprietary, so I can’t discuss a lot of details. But he had me sold. Sure looked like the future to me.

“We had a first principle idea which was to remove all of the hard tooling from the (manufacturing) process so that we could have a hardware base that adapted to any design,” said Kevin Czinger’s son Lukas Czinger, a Yale graduate in electrical engineering. “We can do that rear frame, do a customer rear frame, do a full chassis, just by changing the software, no hardware changes.”

About a year ago, in October 2020, the Czingers birthed a beta version of this new process. And it seems to do what it was designed to do.

“You could take that entire complex form and just 3D-print that as one solid metal piece.

”

“For our OEMs, we were able to show a print rate 50% faster than they needed for value production and an assembly rate about 35% faster than they need for full-volume production,” Kevin said. “We have a dozen programs for multi component structures,” said Kevin. “Our first production programs are going to be in vehicles on the road in early 2022. And these are with brands that are within groups that are in the top five global automotive groups by annual volume.”

So, just to review, it’s: computer-designed parts, 3D printers making those parts, which are assembled by robots, in a much smaller space than typical assembly lines.

So no more River Rouge. The Czingers say that carmakers could replace assembly lines that had been a mile long with assembly stations like the one I saw, greatly reducing the lead time, cost, and complexity of car making. And you can switch the car model that you’re building with every new assembly. No more downtime during model-year changeover. And all those spare parts carmakers have to keep in warehouses for 10 years? They will be replaced by instant 3D printing of whatever spare part you need.

And all those spare parts carmakers have to keep in warehouses for 10 years? They will be replaced by instant 3D printing of whatever spare part you need.

So is this really a brave new world that has such robots in it?

“3D printing offers the chance to pretty dramatically reduce how much effort you have to put into assembly,” said Peter Zelinski, editor-in-chief of additivemanufacturing.media. “So something like a car’s chassis or even just a component like the assembly around the wheel, the wheel carrier, you think about all of the little parts from many different places that are riveted together or welded together or held with fasteners, and you could take that entire complex form and just 3D-print that as one solid metal piece.”

While carmakers have used additive manufacturing or just plain old 3D printing for years, it’s never been optimized on such a large scale.

“Additive Manufacturing has been used in the auto industry for some time, but the last few years we have really seen accelerated growth in the technology,” said Ali Shabbir, GM engineering group manager for additive design and manufacturing, via email. “General Motors sees value in three key areas. Prototype parts allow for rapid, iterative development of components and greatly reduces tooling costs while increasing agility in providing functional pre-production parts. Manufacturing tools can be printed to be lighter and more ergonomically designed for assembly operators, all while significantly reducing lead times. Localized printing is also promising technique, as additive manufacturing engineers in Warren, Michigan, could design a part and then send the designs to be printed at assembly plants around the world. Production parts are the latest application of additive manufacturing we have implemented. Based on volume, cost, and build complexity, a business case for each production part needs to be made.”

“General Motors sees value in three key areas. Prototype parts allow for rapid, iterative development of components and greatly reduces tooling costs while increasing agility in providing functional pre-production parts. Manufacturing tools can be printed to be lighter and more ergonomically designed for assembly operators, all while significantly reducing lead times. Localized printing is also promising technique, as additive manufacturing engineers in Warren, Michigan, could design a part and then send the designs to be printed at assembly plants around the world. Production parts are the latest application of additive manufacturing we have implemented. Based on volume, cost, and build complexity, a business case for each production part needs to be made.”

Toyota doesn't use AM very much.

"Very little for in-line production," Toyota said in response to a question about AM's presence in production. "Most of 3DP applications are proto parts, proto tools, proof of concepts, occasionally spare part manufacturing. The largest utilization of 3DP is for prototyping and pre-production purpose."

The largest utilization of 3DP is for prototyping and pre-production purpose."

Toyota doesn't see it as a major contributor to mass-production yet, either.

"Not with the current technology – 3DP cycle times are very long – unless we batch production of 3DP parts or use it for low option manufacturing."

“For our prototyping and prove-out we use it a lot,” said Andre Hudson, head of product design at INDI EV. “But in the production, there’s just so many challenges, it’s a whole different thing—the materials, the thicknesses of materials, the process—to make it durable enough to actually be to put in a product that you’re going to sell to somebody to use. I still think we’re quite a ways off.”

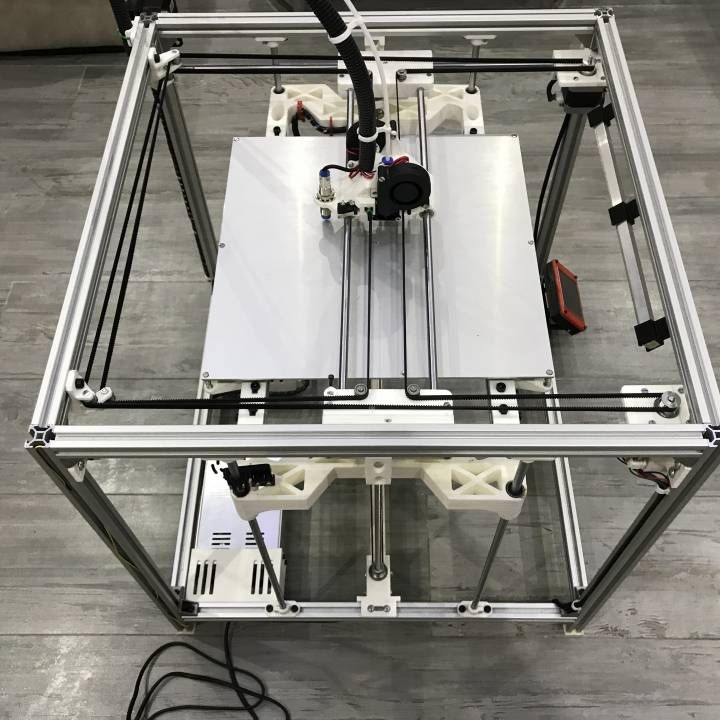

Limitations of AM include the size of AM machines right now, which limit the size of parts that can be made. You can’t AM and entire automotive space frame, for instance.

Kevin Czinger agrees that massive adoption of a system like his in the global auto market is still in the future.

“3D printing today is not even a baby step,” he said. “It’s not even born. We had to design the materials and the machines to actually do it at an industrial level.”

I asked Zelinski if he thinks we’re in the middle of a revolution in manufacturing.

“I think we are, actually. We are in the middle of the beginning of it,” Zelinski said. “But the revolution won’t be a change in the types of parts we see today and how they’re made. It’s an utter rethinking of A) part designs and B) manufacturing enterprises. So the part designs change because, as you saw how he lifted up that component (the big rear subframe). There’s all kinds of design freedoms now to use way less material, far fewer fasteners, to have lattice structures on the inside instead of a solid form, to make things lighter and to utterly rethink how manufactured parts are designed and what they look like.”

So expect to see lighter cars made from less material at what could be a lower cost. But maybe not this week.

Do you think we’ll see 3D-printed cars in any real volume in the near future? Or will it remain a niche manufacturing process? Share your thoughts in the comments below.

Mark Vaughn Mark Vaughn grew up in a Ford family and spent many hours holding a trouble light over a straight-six miraculously fed by a single-barrel carburetor while his father cursed Ford, all its products and everyone who ever worked there.

We got to the S-class. How car parts are already being created on a 3D printer

Innovative technologies have penetrated into all areas of our lives. Cars, the favorite toys of men, did not stand aside either. In about 100 years of its existence, the car has evolved from self-running carriages into a vehicle that will soon be… printable at home.

How did it all start?

No matter how surprising it may sound, but work on the creation of a 3D printer has been going on since 1980s, and despite the fact that the usual black and white 2D printer appeared in 1985. The first 3D printer was the Actua 2100 from 3D Systems, released in 1996.

The first 3D printer was the Actua 2100 from 3D Systems, released in 1996.

The first 3D printers were extremely slow due to lack of power, and as the speed increased, they gave a large error. Only in 2005 did printers appear capable of producing high quality products. And since 2008, printers have gained the ability to print products made up of more than 100 materials, including concrete, ice, metal powder, and even chocolate. nine0003

In the automotive industry, the first mention of 3D printing is associated with Ford and dates back to 2009. The company calculated that products printed on a 3D printer reduce the cost of production and in the future are able to compare in reliability with traditional ones. Ford's experience was instantly adopted ... by Chinese automakers - and away we go! The Chinese began to print not only plastic elements, but also turbochargers, even individual parts of the engine. Of course, at first, the parts deformed faster than usual due to exposure to high temperatures, but gradually the problem was solved, and now even such giants of the auto industry as BMW, Mercedes, Cadillac and others are preparing to introduce 3D printed components into production. nine0003

nine0003

Automotive 3D printing in 2016

3D printing has changed many industries, giving designers a unique tool for creating complex structural elements. The introduction of additive technologies (the principle of operation of a 3D printer, which consists in the sequential application of layers of material) in the automotive industry has been gradual. At first, functional prototypes were made on a 3D printer, then suitable materials and technologies for printing structural elements were created, and everything grew into the production of finished 3D printed car models. The production of prototypes using additive technologies allowed not only to make the work several times faster, but also to significantly save money. nine0003

Initially, the automotive industry used mainly metals for printing, but this year a new material has appeared - polymer polyether ether ketone, or PEEK. It has a polycrystalline structure, which determines its heat resistance, strength, wear resistance and chemical inertness. By replacing metal components with parts made from PEEK, the weight of the vehicle will be reduced, resulting in a noticeable reduction in fuel consumption and emissions.

By replacing metal components with parts made from PEEK, the weight of the vehicle will be reduced, resulting in a noticeable reduction in fuel consumption and emissions.

Which vehicles already use 3D printing?

This year, Daimler's management announced the transition to digital production methods, and now spare parts for trucks will be printed on a 3D printer. The concern is going to use additive technologies for finishing passenger models, in particular the Mercedes S-class sedan, which will be released in 2018.

Rolls-Royce presented its concept car of the future in the middle of the year. The 103EX limousine is equipped with an autopilot and two electric motors, has an extraordinary futuristic design, but most importantly, many details of the luxury concept are made using a 3D printer. nine0003

While other major car brands are 3D printed parts, Local Motors is printing complete cars. The company has already printed two cars - the unmanned Strati, which is planned to introduce the Fly-Mode flight mode, and the unmanned Olli minibus.

Strati

Olli at the implementation stage. But the Olli self-driving minibus with an electric motor has already been printed. Moreover, they were able to create a unique vehicle for 12 people in just half a day. Olli developers said that the company has mastered the technology of 3D printing of minibuses and is going to promote such vehicles in the US, Europe and Australia. nine0003

4ekolka

A new generation urban vehicle was created in Prague. Local specialists presented the car 4ekolka, which was completely printed on a 3D printer. A compact, inexpensive and environmentally friendly electric car with two seats is already being tested in the Czech capital, so perhaps soon such models will become an absolutely familiar means of transportation.

Slightly aside is an art masterpiece presented by Nissan, about which it would be a sin to remain silent. This spectacular PR move demonstrated that, with a 3Doodler 3D pen at hand, you can create a full-size replica of the Nissan Qashqai model. nine0003

nine0003

Artist Grace du Pres and her team created this unique urban SUV sculpture in a matter of weeks. And it is worth saying that the object turned out really amazing.

Editor's note

Not all vehicles that have been 3D printed are shown here. Technology is gradually becoming one of the most popular tools for designing and building vehicles and components. This year Moscow will host the international conference 3D Print Expo, which will present advanced technologies in the field of 3D printing. The organizers promise a large number of participants, many of which are ready to offer printing of automotive parts, components and all kinds of decorative elements for cars. An ABW.BY correspondent will visit the exhibition to find out how soon these technologies will be applied in mass production, see the printing process with their own eyes, and if they are lucky, they will look / touch / smell the car printed on a 3D printer. The event will take place on November 17-18 at the Sokolniki Exhibition and Convention Center. Following the results of the exhibition, a report with photos and video materials is planned. Follow the site! Well, if someone wants to take part, you can register using the link. nine0003

Following the results of the exhibition, a report with photos and video materials is planned. Follow the site! Well, if someone wants to take part, you can register using the link. nine0003

Roman SAVINICH

Photo uae.yallamotor.com, rolls-roycemotorcars.com, ucarecdn.com, 3dprintingindustry.com, hybrid.cz, tech.co, the3doodler.com

ABW.BY

Source

printer, car parts, Ford, 3D printing, additive technologies, PEEK, Daimler, Mercedes S-class, Rolls-Royce, Local Motors, 3D printed parts, Olli driverless van, 4ekolka car

10 Benefits of 3D printer: save time and money

Until quite recently, 3D printing was seen as something completely new. The technology was underdeveloped, the hardware was too expensive for widespread use. But only a few years have passed, and the situation has changed radically. Not only did more and more 3D printers begin to appear in stores, but also some enthusiasts began to assemble this equipment themselves.

1.

Cost-Effective

Cost-Effective While large-scale projects with thousands of 3D printed parts are not cheap, they are still much more cost effective than other technologies. Many manufacturers use 3D printing for small runs or for prototyping. Plastic can also be used for injection molding, but casting small batches can require expensive equipment. But even in this case, manufacturers can produce cast 3D parts several times cheaper than using aluminum. nine0003

Prototype parts printed on Prusa i3 Bizon 3D printer, layer height 0.1mm, PLA material

Compared to traditional production methods, the entire process can take weeks or days, and most products are printed in hours. Some manufacturers have even begun to make parts to order, which has also allowed them to optimize their warehouse capacity and resource management scheme, making them more flexible. With this new approach, the manufacturer does not need to store every single part or component, they can simply be printed as needed and immediately put into action.

nine0003

nine0003

Miniature parts printed by Wanhao Duplicator 7 photopolymer 3D printer, layer height 0.5mm, photopolymer resin material

It not only affects the reputation of the company in its industry, insufficient technical control can lead to injury to employees and customers. Since 3D printing uses a completely different production method than most machine tool operations, the process has significantly fewer weaknesses and flaws overall. nine0003

Model printed on Picaso Designer X PRO 3D printer, 0.2 mm layer, ABS materials, HIPS

4. Less waste

The press is gaining more and more support in the form of supporters of the "green" movement. Because 3D printing produces significantly less waste than traditional processing, the technology is more environmentally friendly while reducing costs. 3D printing has even made its way into the textile industry, allowing clothing and prototypes to be printed. nine0003

Hercules Strong 3D printed yacht steering parts. Details printed in 15 hours with a 0.5 mm nozzle and a layer height of 0.3 mm at a speed of 60 mm/s.

Details printed in 15 hours with a 0.5 mm nozzle and a layer height of 0.3 mm at a speed of 60 mm/s.

5. Greater customization

3D printed products are also highly customizable. Parts can be printed not only with light plastic, some next-generation models may also have a metal coating. As a result, objects are not only aesthetic, but also functional. In addition, they can acquire thermal and chemical resistance. The existing metallization method can also be used for plastic. nine0003

Functional parts printed on Hercules. Material ABS, nozzle diameter 0.5 mm, layer height 150 µm, filling 100%. The model consists of 3 parts: the body and 2 halves of the latch, after printing and processing, the parts were glued together with acetone.

6. Customer Availability

If some craftsmen set up small mechanical workshops, for example, in garages, then most of us cannot afford such a luxury. 3D printing allows you to bring a significant part of the manufacturing process directly into the home, made possible by the availability of user-grade 3D technology. While it turns out to be quite expensive for one-off projects, the price of 3D printers and consumables is dropping rapidly. nine0003

3D printing allows you to bring a significant part of the manufacturing process directly into the home, made possible by the availability of user-grade 3D technology. While it turns out to be quite expensive for one-off projects, the price of 3D printers and consumables is dropping rapidly. nine0003

Technical wing caps in REC RUBBER or REC FLEX. The models are printed on a Prusa i3 Steel 3D printer.

7. High complexity

In most cases, when it comes to complex parts and elements, the manufacturing process imposes certain limitations. Techniques used in casting and finishing objects may not be subtle enough for sophisticated design details. 3D manufacturing processes make it possible to realize almost any design solution, regardless of its complexity, and in a reasonable time. This not only eliminates the extra assembly steps required by traditional methods, but also provides more freedom to create future-proof designs. nine0003

Printing large parts from engine mock-ups on a Zenit 3D printer

8.

Less risk

Less risk While there are inherent risks associated with these new technologies, in terms of day-to-day business, 3D printing risks are significantly lower than with traditional manufacturing methods. Not only is 3D printing much cheaper when it comes to testing a new design or product, the printed prototypes themselves can stir up investor and customer interest and get them to decide whether to proceed with mass production of a product, whether it is worth the time and effort required. nine0003

Wanhao Duplicator i3

9. Variety of materials 3D printing also provides the ability to mix different substances, a luxury that is not always available with conventional methods. Although many 3D printer manufacturers offer their own, very limited set of sources, 3D printers can work not only with original materials, allowing you to simulate ceramics, metal, glass and more. nine0003

Wanhao D6 3D Printer PEGT, ABS-PC, PLA, SBS

The manufacturer not only needs to clearly understand what the customer wants, the manufacturer must also be able to explain what he himself can.