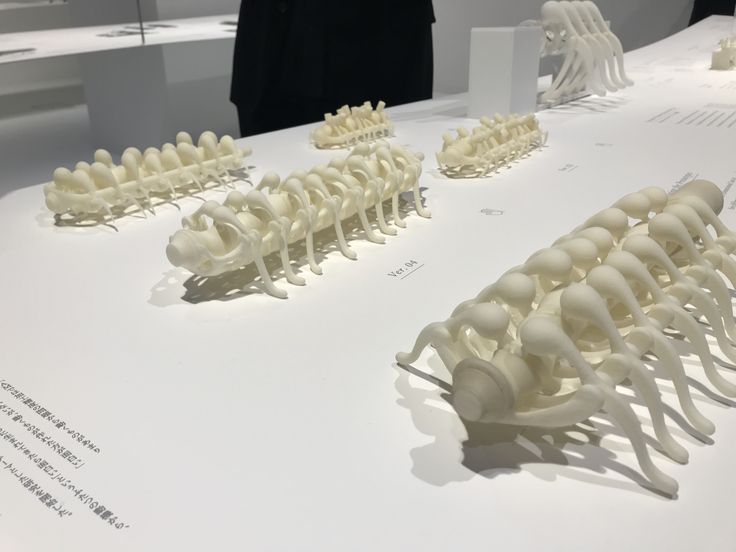

3D printing science fair ideas

Top 10 STEM Designs for Your 3D Printer

Science, Technology, Engineering, and Math or STEM is the new buzzword in education as all levels of educators press to refocus curriculum suited for tomorrow’s emerging technological workforce. A 3D printer enables teachers to span the entire STEM spectrum with one device. Here are 10 designs that demonstrate one or more letters in S.T.E.M. The links to each design include the .STL file download that is needed to create them with your 3D Printer!

Math

1) Geometry Connectors – Add some excitement to your Geometry lesson! Use these geometric connectors with quarter-inch dowel rods to make shapes like a icosahedron, tetrahedron, and cube come to life.

Source: Thingiverse – fozzy13, published Nov 28, 2015

2) Fraction learning kit – What child has not struggled with fractions in some form or another? And what teacher has not used the proverbial slices of pie example to clear those glassy eyes? Well, these slices of pie can be used over and over again without getting pie filling all over the classroom! Let’s Learn Fractions is a short video that fully discusses fractional concepts. It is animated and done well!

Source: Thingiverse – Fraction learning kit by tuempl, published May 6, 2013

3) Customizable Convex Polyhedra – This webpage offers 110 different polyhedra solids and cutouts. The customizer alone makes this page worth a venture just to see the names and shapes together…it’s incredible! Make sure to visit the customizer and play around viewing the different shapes. This Polyhedra video is a discussion explaining what they are, how they are named, and how they are classified.

Source: Thingiverse – pdragy, published Mar 4, 2014

4) Sterographic Projection – defined by Dictionary.com stereographic projection is a “one-to-one correspondence between the points on a sphere and the extended complex plane where the north pole on the sphere corresponds to the point at infinity of the plane.” In other words, it’s a map from the sphere to the plane. Also, included on the Thingiverse page linked below is a great video discussion of stereo projection!

Source: Thingiverse – henryseg, published Dec 13, 2013

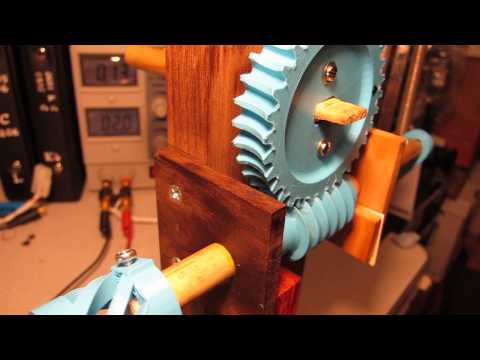

Math & Engineering

Math Gears – This design is easily used with overhead projectors and demonstrates ratios and mechanical engineering. Home Science Tools has this short discussion explaining types of machines and various aspects of gears and their uses. You can also refer to this video that illustrates and explains gear speed, direction, circumference, diameter, and radius concepts.

Home Science Tools has this short discussion explaining types of machines and various aspects of gears and their uses. You can also refer to this video that illustrates and explains gear speed, direction, circumference, diameter, and radius concepts.

Source: Thingiverse – SSW, published Nov 18, 2013

Engineering

1) Modified Howe Bridge – Engineering Project (STEM) – WongZCMS designed this bridge as one of three designs to discuss and demonstrate bridge concepts with his class. As a set, they demonstrate the characteristics of various bridge designs. Additionally, this link lists 8 videos discussing building bridges concepts. Additionally, the How Stuff Works website published this How Bridges Work article discussing everything from the basics of bridge design to living bridges.

Source: Thingiverse – WongZCMS, published Aug 11, 2013

2) Archimedes Trammel – is a mechanical device which produces the shape of an ellipse by using 2 shuttles which move in the x and y direction. In other words, it is a device used to draw a near perfect ellipse using mechanical means. Here is a fun video from a young boy who built a trammel with his father from Legos, and he gives a simple explanation to its use. This video demonstrates that even today Archimedes Trammel is useful in a real world situation!

In other words, it is a device used to draw a near perfect ellipse using mechanical means. Here is a fun video from a young boy who built a trammel with his father from Legos, and he gives a simple explanation to its use. This video demonstrates that even today Archimedes Trammel is useful in a real world situation!

Source: Thingiverse – EXO2, published Jun 8, 2015

Science

Rocket Car Race Chassis and Wheels – Thrust, mass, and acceleration can be explained by stepping through the basic rocket principles. This is a non explosive principles demonstration and is environmentally friendly. Students can learn about science and re-purpose those old soda bottles! This video called Build Your Own Rocket Car demonstrates how to make a homemade bottle rocket car and how to charge and release it…watch it go! Another great resource is NASA which provides this complete lesson guide for Pre-K-2 which focuses on activities about the International Space Station and the role of rockets.

Source: Thingiverse – ralphmcneill, published Nov 5, 2014

Science, Technology, Engineering, Math

Windmills and wind turbines seem to encompass the whole gambit of STEM! Blade design and lift characteristics can be examined as well as electrical technologies and circuit design. When electronic experimentation is exhausted the windmill can then be transformed into a mechanical water pump for more mechanical engineering examples and experimentation! How Do Wind Turbines Work is a great video explaining how full scale wind turbines operate today and includes discussion about blade aerodynamics. This video animation demonstrates how windmills can be used to pump water or grind wheat.

Source: Thingiverse – Wind Turbine by AtomKemp, published Jun 28, 2013

Source: Thingiverse, Mini – Wind Turbine by larsonmattr, published Nov 27, 2010

Science, Technology, Engineering

Ultrasonic 3D Scanner – Although this project is ambitious, it has room to grow. This nifty little device uses sound to create a low resolution 3D picture of its surroundings! The software is in its infancy and refinement could be a project unto itself.

This nifty little device uses sound to create a low resolution 3D picture of its surroundings! The software is in its infancy and refinement could be a project unto itself.

Source: Thingiverse – Pyromaniac, published Jun 22, 2015

STEM is important because it is vital to our children’s future and our country’s. 3D printers are poised to be the all in one package for S.T.E.M. educators. This article only scrapes the surface of possible classroom learning opportunities. The real power is problem solving scenarios which can be developed, designed, and then brought to life; an idea brought forth from conception into an actual object. Imagine tasking your class with a real problem solving opportunity, such as a local handicap community member struggling with a certain daily task like grasping a credit card with their hands. Having students conceive and produce a device which will aid this person in their daily life can be a powerful motivator. Your class collaborates, conceives, designs, and prints their object, and then they get the wonderful feeling of seeing that person benefit from their work. They get to see an idea actually materialize from a mental picture to an actual hands on object. The sky is the limit…

They get to see an idea actually materialize from a mental picture to an actual hands on object. The sky is the limit…

Author: David Weas, Tech Support Director at RNK Distributing

Check out our Imaginator 3D Printer at S&S Worldwide!

Ideas for Your Classroom, Science Fair, or Home [Book]

Book description

3D Printed Science Projects describes how to create 3D printable models that can help students from kindergarten through grad school learn math, physics, botany, chemistry, engineering and more. Each of the eight topics is designed to be customized by the reader to create a wide range of projects suitable for science fairs, extra credit, or classroom demonstrations. Science fair project suggestions and extensive "where to learn more" resources are included, too. You will add another dimension to your textbook understanding of science.

Table of contents

- Cover

- Title

- Copyright

- Dedication

- Contents at a Glance

- Contents

- About the Authors

- Acknowledgments

- Introduction

- Chapter 1: 3D Math Functions

- Math Modeling for 3D Printing

- 3D Printing

- Math Background

- Creating Surfaces Entirely in OpenSCAD

- Making a Smooth Surface with a Flat Bottom

- Making a Two-Sided Smoothed Surface

- Very Simple Model to Make a “Blocky” One-Sided Surface

- Creating Surfaces from an External Data File

- Example: Using a Python Program to Generate Data for a Thin Surface

- Constraints

- Where to Learn More

- Teacher Tips

- Science Fair Project Ideas

- Summary

- Math Modeling for 3D Printing

- Chapter 2: Light and Other Waves

- Physics and Math Background

- Coordinate System and Conventions

- Principle of Superposition

- Some Basic Examples

- Point Sources and Plane Waves

- Two Interacting Sources

- More Complex Examples: Diffraction

- The Double-Slit Experiment

- One-Slit Examples

- Printing Considerations

- Where to Learn More

- Teacher Tips

- Science Fair Project Ideas

- More Wave Interaction Models

- Magnetism Explorations

- Summary

- Physics and Math Background

- Chapter 3: Gravity

- Universal Gravitation

- Gravitational Potential Wells

- Earth-Moon System Model

- Algol Model

- Orbits

- Halley’s Comet Orbit Model

- Inner Solar System Model

- Printing Tips

- Where to Learn More

- Teacher Tips

- Science Fair Project Ideas

- Summary

- Chapter 4: Airfoils

- How Airfoils Work

- Flight Forces: Lift, Drag, Gravity, and Thrust

- Chord, Camber, and Thickness

- NACA Airfoils

- Classic Airplanes Using NACA Airfoils

- Using the 3D-Printed Airfoil Models

- Measuring Lift

- Printing Suggestions

- Where to Learn More

- Building a Student Wind Tunnel

- Visualizing Flow

- Scaling a Model

- Teacher Tips

- Science Fair Project Ideas

- Summary

- How Airfoils Work

- Chapter 5: Simple Machines

- Physics Background

- The Machines

- Inclined Plane and Wedge

- Lever

- Screw

- Wheel, Axle, and Pulley

- Printing Suggestions

- Where to Learn More

- Teacher Tips

- Science Fair Project Ideas

- Summary

- Chapter 6: Plants and Their Ecosystems

- Botany Background

- Water

- Sunlight

- Nutrients

- Plant Communities

- The Mathematics of Plant Growth

- The Golden Ratio

- The Golden Angle

- Fibonacci Sequence

- Phyllotaxis

- The Models

- Desert Plants

- Tropical Jungle Plants

- Flowers

- Printing the Models

- Plant and Flower Models

- Jungle Plant Leaf Model

- Printing Suggestions

- Where to Learn More

- Teacher Tips

- Science Fair Project Ideas

- Summary

- Botany Background

- Chapter 7: Molecules

- Chemistry Background

- Valence Electrons and the Periodic Table

- Basic Orbital Shapes

- Carbon Atom Model

- Printing the Carbon Atom

- How to Assemble the Carbon Atom Model

- Water Molecules

- The Water Molecule Model

- The Carbon vs.

Water Molecule Model

Water Molecule Model

- Crystals

- Water Ice

- Diamond

- Printing Suggestions

- Where to Learn More

- Teacher Tips

- Science Fair Project Ideas

- Summary

- Chemistry Background

- Chapter 8: Trusses

- Engineering Background

- Why Triangular Structures?

- Forces on Planar (“2D”) Truss Members

- The Space (3D) Truss

- Tensegrity Structures

- The Models

- 2D Truss Model

- Tensegrity Structure Model

- Assembling the 3-Rod Tensegrity Prism

- Printing These Models

- Where to Learn More

- Teacher Tips

- Science Fair Project Ideas

- A Few Last Words About Making Things

- Summary

- Engineering Background

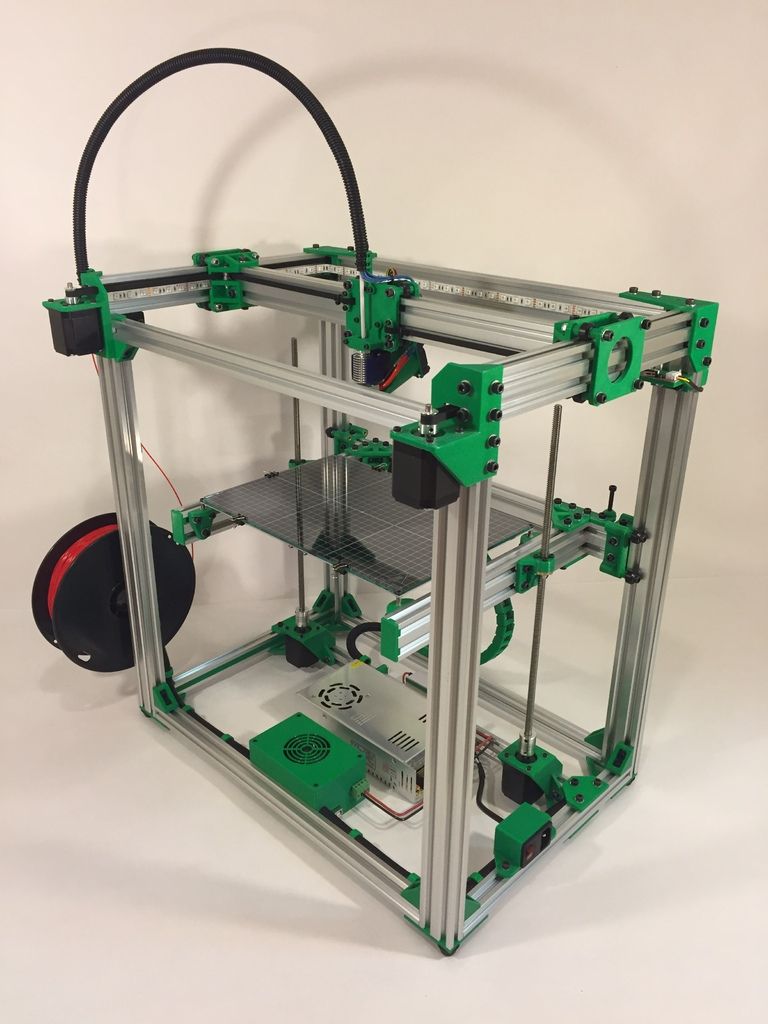

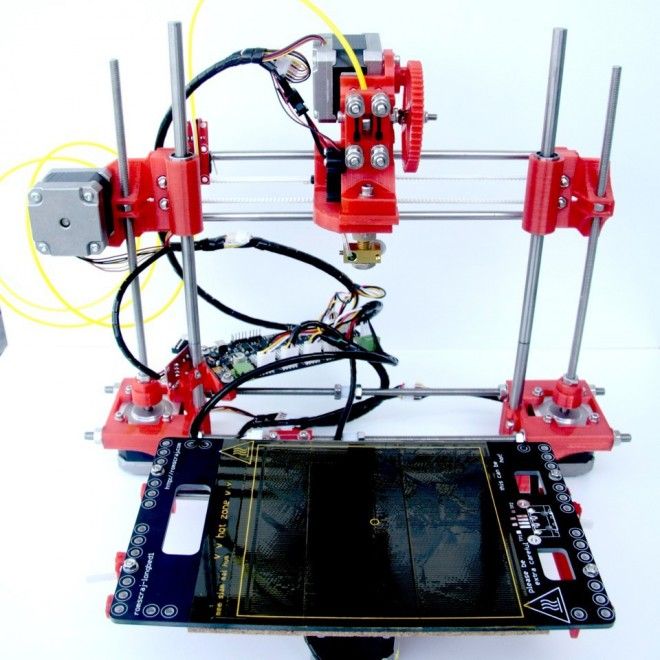

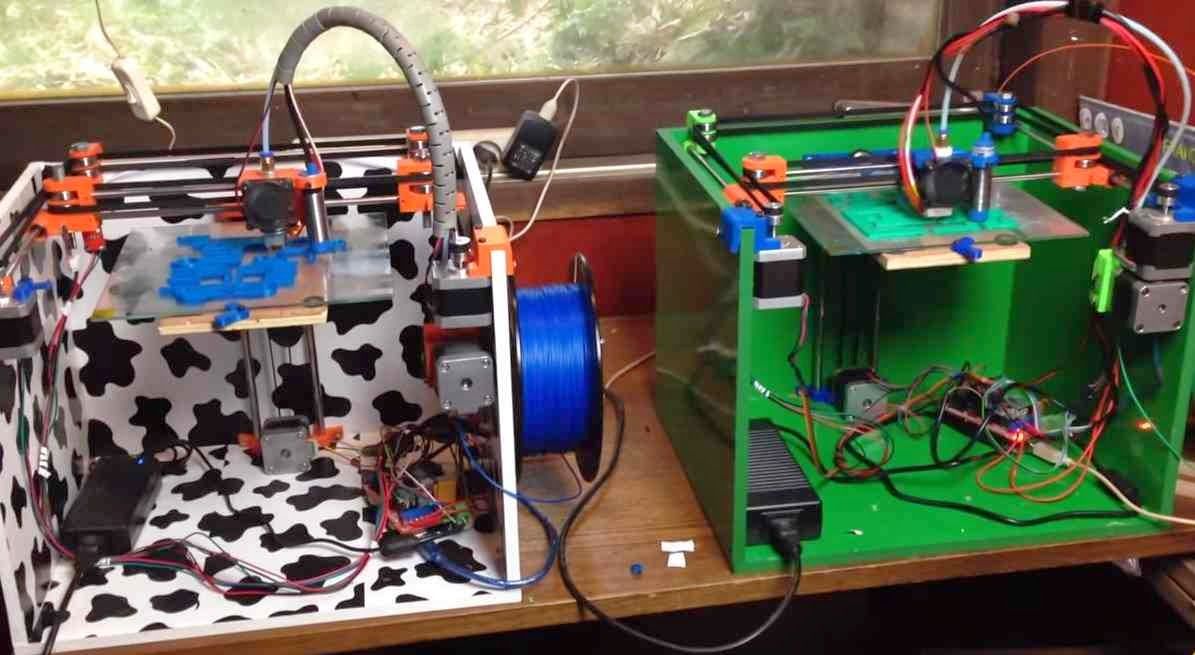

- Appendix A: 3D Printing

- The 3D Printing Process

- Filament-based 3D Printing

- File Types

- OpenSCAD

- Downloading OpenSCAD

- Editing the Models

- Ideosyncracies of OpenSCAD

- MatterControl

- Printers MatterControl Supports

- Downloading and Installing MatterControl

- Using MatterControl

- Settings

- Archives and Repositories

- The 3D Printing Process

- Appendix B: Links

- About the Authors

- Chapter 1: 3D Math Functions

- Chapter 2: Light and Other Waves

- Chapter 3: Gravity

- Chapter 4: Airfoils

- Chapter 5: Simple Machines

- Chapter 6: Plants and Their Ecosystems

- Chapter 7: Molecules

- Chapter 8: Trusses

- Appendix A: 3D Printing

- Index

World achievements of chemists KBSU - TsPMAT

- 10/22/2020

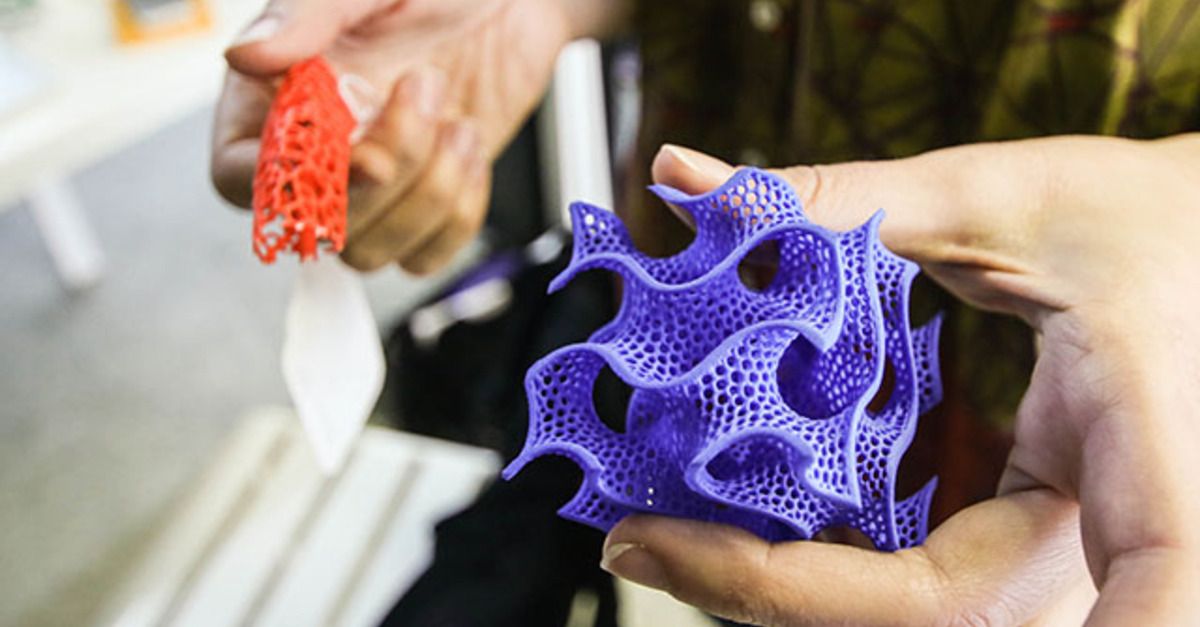

3D printing is one of the top 10 technologies that are rapidly changing the world. This process can be carried out in different ways, using different materials, but any of them is based on the principle of layer-by-layer creation (“growing”) of a solid object. With the help of 3D printers (computer numerical control machines) using additive technologies, products of complex shape are created in a short time, the manufacture of which using traditional technologies requires a number of labor-intensive operations. nine0008

This process can be carried out in different ways, using different materials, but any of them is based on the principle of layer-by-layer creation (“growing”) of a solid object. With the help of 3D printers (computer numerical control machines) using additive technologies, products of complex shape are created in a short time, the manufacture of which using traditional technologies requires a number of labor-intensive operations. nine0008

Unique technologies for obtaining superstructural polymers for 3D printing, developed at the Kabardino-Balkarian State University named after. HM. Berbekov, have no analogues in Russia and surpass foreign models in most characteristics.

At the Center for Advanced Materials and Additive Technologies of the KBSU, samples of such products were presented to the Minister of Science and Higher Education of the Russian Federation Mikhail Kotyukov during his working visit to our republic this fall. nine0012 Professor Svetlana Khashirova, Doctor of Chemistry, Professor Svetlana Khashirova, spoke about the activities and achievements of this structural unit of the university.

Joint project

Nowadays it is difficult to find a person who has not heard anything about 3D printing. However, in 2014, when we decided to implement a joint project of the Advanced Research Foundation and the Ministry of Education and Science of the Russian Federation, only a few people in our country knew about such technologies. nine0008

In Russia, there was practically no scientific and technical groundwork in the field of creating domestic new generation materials and equipment for 3D printing. The implementation of scientific research and development in this direction was associated with a high degree of risk of achieving qualitatively new results. It is these high-risk breakthrough studies that are supported by the State Advanced Research Fund, which promotes the creation of innovative technologies and the production of high-tech military, special and dual-use products. nine0008

In 2014, we submitted an ambitious application for a competition at the FPI for the creation of

domestic superconstruction polymers specialized for 3D printing, the development of the first additive machine in Russia and technological modes of 3D printing. Not a single metropolitan university and institute undertook to solve so many problems in three years.

Not a single metropolitan university and institute undertook to solve so many problems in three years.

The Foundation for Advanced Study and the Ministry of Education and Science of Russia supported our application, and in 2014 KBSU was among the first five universities in the Russian Federation that were selected to solve the breakthrough tasks facing our country. In KBSU, together with the FPI, a laboratory of progressive polymers was created. nine0008

Mikitaev School

Ambitions to solve such difficult tasks at KBSU, of course, did not arise by chance. Behind him was the strongest scientific polymer school in the Russian Federation, Honored Scientist of the Russian Federation, Doctor of Chemical Sciences, Professor of KBSU Abdulakh Mikitaev.

The Laboratory of Progressive Polymers, established in 2014 to implement the scientific and technical project "Development of 3D Printing Technology for New Generation Superstructural Polymers", was equipped with modern research and pilot equipment to carry out a full cycle of work - from the formation of a scientific idea to its implementation into reality. nine0012 Abdulakh Kasbulatovich is no longer with us, but his scientific school is growing and developing. In 2014, the laboratory had 27 employees, and now it has grown into a center for advanced materials and additive technologies, where 42 researchers work, more than half of them have an advanced degree. The average age of the members of the labor collective is 37 years old, all of them are graduates of the Faculty of Chemistry of the KBSU.

Doctor of Chemistry, Professor Aues Beev, Candidates of Chemistry, Senior Researchers Azamat Zhansitov, Igor Dolbin and Albert Shabaev, Candidates of Technical Sciences, Senior Researchers Ismel Musov, Azamat Slonov, Amina Vindizheva and other scientists successfully work here. Zhanna Kurdanova, Diana Khakulova, Kamilla Shakhmurzova defended the first Ph.D. theses in our country in the development of domestic superstructural polymers and composites for additive technologies, four more young scientists are preparing for their defense. nine0008

Materials developed

The laboratory achieved a number of original scientific results in the field of polycondensation polymers of various classes, which received international recognition and support within the framework of the federal target program "Research and development in priority areas of development of the scientific and technological complex of Russia" and other state programs.

Materials developed include high barrier films with high barrier properties for packaging and storage of food and beverages. Composites have been created for the production of cable products with high fire-resistant properties, large impact-resistant containers for fruit storage. Polymer gels and solutions have been developed that can be used in medicine and agriculture. nine0012 Over the past five years, more than 500 scientific articles have been published by the laboratory staff, more than 30 patents have been received, a project of the Advanced Research Foundation has been successfully completed, two projects of the Ministry of Education and Science of the Russian Federation are being carried out jointly with Composite JSC of the Roscosmos Corporation (Korolev).

Special for 3D printing

Additive technologies are used in the creation of space and aviation equipment, marine vessels and cars, in construction, oil and gas and infrastructure sectors. Also, 3D printing is used where unique details or a relatively small number of them are needed (architectural elements, parts of robots, jewelry, etc.), it is in great demand in medicine (prosthetics). nine0008

Any polymer is not suitable for additive manufacturing. It must have a special unique structure that will allow you to get better characteristics than materials made in the casting process.

We solve the problem of obtaining special polymers, including those for 3D printing, which, unfortunately, are not produced by the domestic industry. They are produced by only two or three firms in the world, and the total production is very small - about 100 thousand tons per year.

Foreign technologies for obtaining such polymers are closed, so our projects are aimed at developing domestic technology, studying the possibility of modification to create high-strength composites and ensuring flexibility of application, manufacturability for use in additive technologies. nine0012 At present, we have already developed a number of technologies for obtaining superconstructive polymers and a line of domestic materials for 3D printing (more than 30 formulations), but, despite the successes achieved, we continue to work in this direction, setting ourselves increasingly ambitious tasks.

The unique technologies for obtaining superstructural polymers for 3D printing developed by the laboratory team have no analogues in Russia and surpass foreign samples in most characteristics. A great achievement is the creation of the first in the Russian Federation demonstration sample of additive equipment for laser sintering of polyether ether ketones (high-temperature polymers with unique performance characteristics that are maintained when the material is heated to 310°C). Such equipment is planned to be produced jointly with the industrial partner JSC Composite (Roscosmos). nine0008

Training of scientific personnel

Our center is included in the comprehensive plan for the development and implementation of additive technologies in the Russian Federation until 2025 as a performer of the event to develop a line of domestic superconstruction polymers and composites for 3D printing and educational programs in this area. Under the guidance of laboratory staff, scientific personnel are trained.

So, in the spring of this year, in the coworking center of KBSU "Boiling Point", the department for supporting projects of the "National Technology Initiative" program and public events held the final presentation of student innovative projects of the educational intensive "Digital Height". One of the most promising experts recognized the project “Development of a biocomposite polyetheretherketone of a new generation for 3D printing of implants with programmable properties” to replace metal plates implanted in complex bone injuries with plastic analogs made using a 3D printer. nine0008

In the leading positions

The activities of the Center for Advanced Materials and Additive Technologies of KBSU are aimed at developing such advanced production technologies as the development of new domestic polymer and composite materials, digital design and modeling of structures made of polymer materials and composites, additive technologies, equipment for additive technologies.

Advanced polymer materials developed at the center are promising for most NTI markets, high-tech industries. nine0008

Parts for space technology, air ducts for the MS-21 mainline aircraft, the first sample of additive equipment in the Russian Federation for selective laser sintering of high-temperature-resistant polymers ... In many ways, the Center for Advanced Materials and Additive Technologies KBSU occupies a leading position in the Russian Federation, holds a priority, is a pioneer.

Implant manufacturing

Among the recent projects of the Center for Advanced Materials and Additive Technologies of KBSU is the solution of a problem related to neurosurgery. At the pre-congress of the international symposium of neurosurgeons, held in September in Nalchik, the country's leading neurosurgeons recognized the achievements of KBSU in the development of superstructural materials and their 3D printing technology as advanced and emphasized the high demand of domestic medicine for such materials for the manufacture of implants. nine0008

Within the framework of the pre-congress, Zhanna Semyonova, Doctor of Medical Sciences, Chief Freelance Pediatric Specialist - Neurosurgeon of Moscow, Head of the Department of Neurosurgery and Neurotrauma of the Research Institute of Emergency Pediatric Surgery and Traumatology of the Moscow Health Department, demonstrated the first results of successful joint research on the reconstruction of the skull of rats using implants from superstructural polymers developed at the Center for Advanced Materials and Additive Technologies of KBSU. It was noted that tests on laboratory animals were successful, the rats feel great. In the near future, after certification, the developed materials can be used as implants, while printing them individually for each patient in a much shorter time. nine0008

The staff of the center has repeatedly assisted surgeons in 3D printing of surgical templates for operations. Based on the images provided by the doctors, 3D models of damaged fragments of the skull, maxillofacial region of a number of patients were created. 3D printing completely recreates the damaged parts of the human skeleton. The use of such templates helps surgeons to improve the accuracy of operations, reduce the risk of complications and reduce rehabilitation time.

Awards

Works carried out at KBSU within the framework of projects of the Ministry of Education and Science of the Russian Federation were awarded with diplomas and medals at the international level: 47th International Exhibition of Inventions in Geneva - silver medal; International Exhibition of Intellectual Property, Inventions, Innovations and Technologies in Bangkok (IPITEx-2019) - silver medal; Seoul International Invention Fair (SIIF-2018) - bronze medal and special award; 69th International Exhibition "Ideas - Innovations - New Developments" IENA - two gold medals; international exhibition in Paris, competition "LEPINE" - gold medal, silver medal, bronze medal; international salon in Geneva - two silver medals and a bronze medal; the international exhibition in Brussels "Eureka" - two gold medals, the 57th World Exhibition of Research and Inventions in Brussels - a gold medal. nine0012 Recorded by Irina Bogacheva

Source: http://gazeta.kbpravda.ru/node/25537

REPORT: Robots, 3D printers, solar concentrator

Smart Patent'17 Innovative Ideas Fair opened in Minsk today. The event, which has established itself as a good platform for launching promising developments, is being held in the city for the seventh time. The exposition includes 50 projects in the field of medicine, education, energy, industry, and robotics. Traditionally, the forum brings together representatives of leading scientific and innovation laboratories, investment funds, technology parks interested in partnership contacts and technology promotion. BelTA correspondents looked at the know-how offered by the exhibitors. nine0102

One of the most memorable exhibits was a design made of mirrors, presented by Dmitry Povargo, an inventor from Lida. This is a solar concentrator and a system for storing thermal energy to it. The installation demonstrates the technical possibilities of using solar energy for heating and hot water supply in the conditions of the republic. “The problem is that we have too few sunny days. As a rule, there is partly cloudy weather,” says the young man. “The concentrator allows you to collect the full spectrum of radiation in a short time and convert it into thermal energy. A prototype is being tested. The competitive advantages of the device are ease of manufacture and the absence of expensive materials." nine0008

Another promising development is the Pulse collaborative robotic arm, which can be used in industries where it is required to ensure high-quality performance of constant manipulations, such as moving objects, storing them, packaging raw materials, applying material. At the exhibition, the "mechanical hand" famously rearranged checkers on the board.

"Our robotic arm is absolutely safe," explains Evgeny Kovalenko, head of the marketing department of the Belarusian company Rozum Robotics. "Sensor sensors and systems immediately stop the equipment at the slightest contact with a person. associations and in the first quarter of next year we will start installing the first production model in Belarus. The main areas of application of the novelty are the automotive industry, metalworking, medicine, footwear production. nine0008

Also presented at the fair were a microbiological method for cleaning pipes of heating networks and waste water, energy-efficient heat exchange units for housing and communal services, energy, chemical, oil refining, food industries, technology for the production of radioprotective glass, an automated watering system for indoor plants.

A large number of projects - know-how in the health sector. In particular, the Republican Scientific and Practical Center of Traumatology and Orthopedics, together with NPO Medbiotech, presented an innovative spinal implant - a universal fixator with a biologically inert coating that increases its strength, color coding. “This development has every prospect of being used not only in Belarus, but also entering the markets of foreign countries. The project should be completed in mid-2018, after which the novelty will be put into production. Prototypes have been created,” said a researcher at the Laboratory of Traumatic Spinal Injuries and spinal cord of the Republican Scientific and Practical Center, neurosurgeon Sergey Zalepugin. nine0008

The joint booth of the Republican Scientific and Practical Center for Pediatric Surgery and TTF-Group introduces the technology of 3D printing of organs for diagnostic purposes. "This technology allows the surgeon to be better prepared. About 30 operations have already been performed using 3D printing, and there are plans to further develop the project. We intend to create a printer that can print samples not only from polymers, but also from soft materials. The better the surgeon is prepared for operations, the better the result," says Ruslan Kruglyakov, director of TTF-Group.