3D printer chainmail

The Best Way To 3D Print Chainmail – Props And Armor

3D printed chainmail is a good alternative to metal, especially for costuming purposes. It’s lighter, easier to produce, and can even be made in a multitude of colors. When I say that it’s easier to produce than metal chainmail, I mean that you don’t need to assemble it one ring at a time. You can print out large sections of it at once, and then piece those together. As long as your print settings are good, then you can just leave it to print while you work on other things.

This article will go over all of the things that I’ve learned about how to optimally 3D print chainmail, so that you can avoid the problems that I had in the beginning. I’ll also go over the different styles of 3D printed chainmail, and what kind might be best for you. There will also be some explanation of different colors of plastic and paint.

Choosing A Style

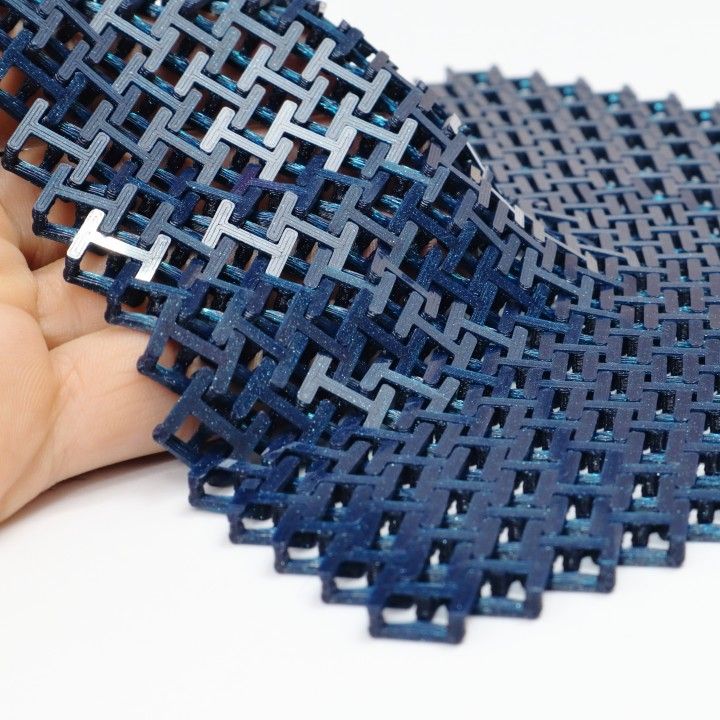

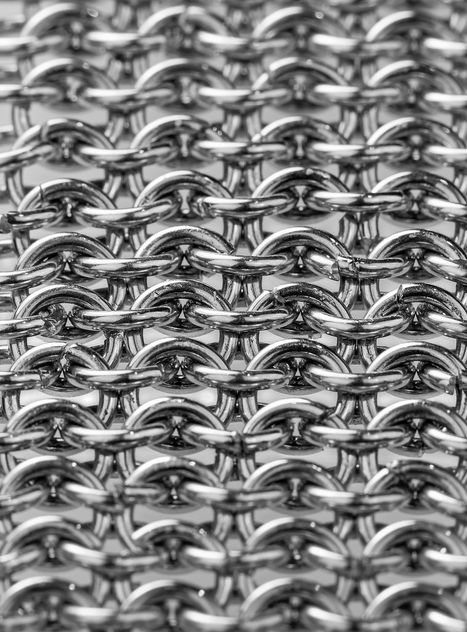

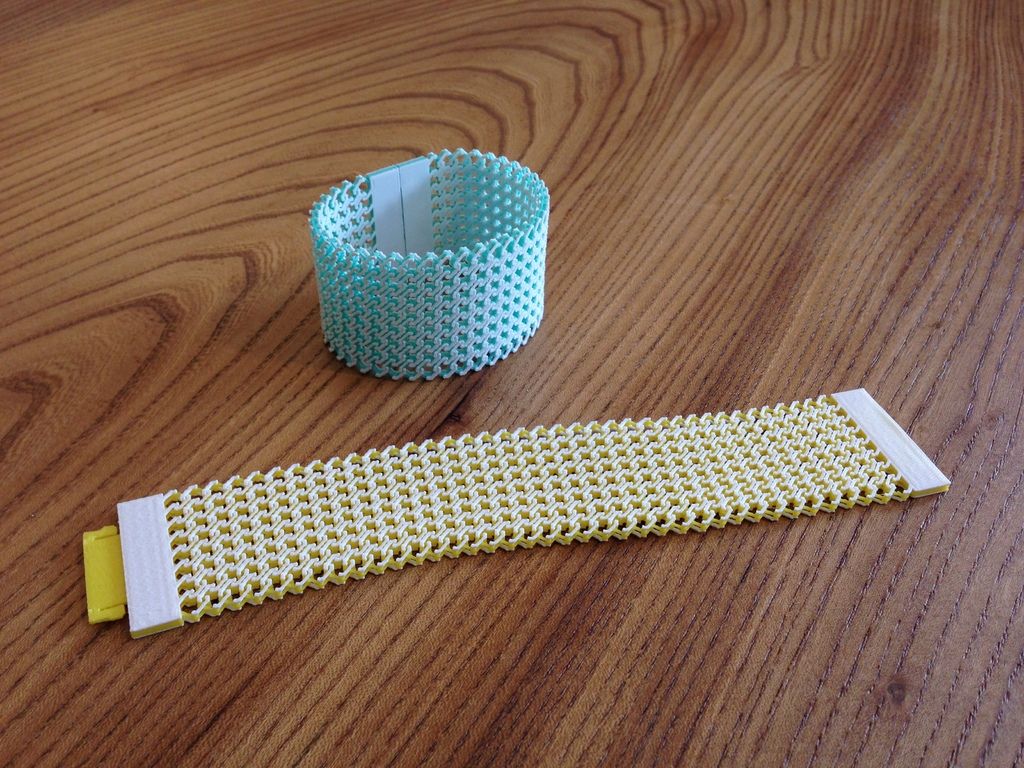

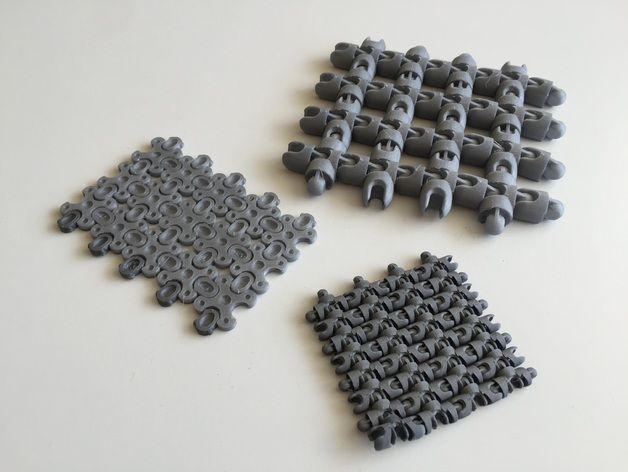

If you look online for 3D printed chainmail, you’ll find that there are many different designs to choose from. A lot of them look futuristic and angular. Some look more like traditional chainmail. If you’re trying to make a medieval fantasy themed costume, you probably want to use a design that uses round rings, unless it specifically calls for something different. For some costumes, are more distinct style like square rings might be more appropriate.

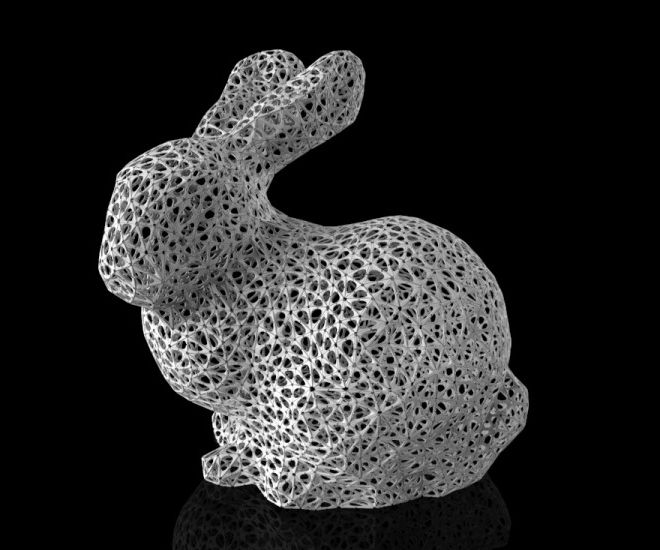

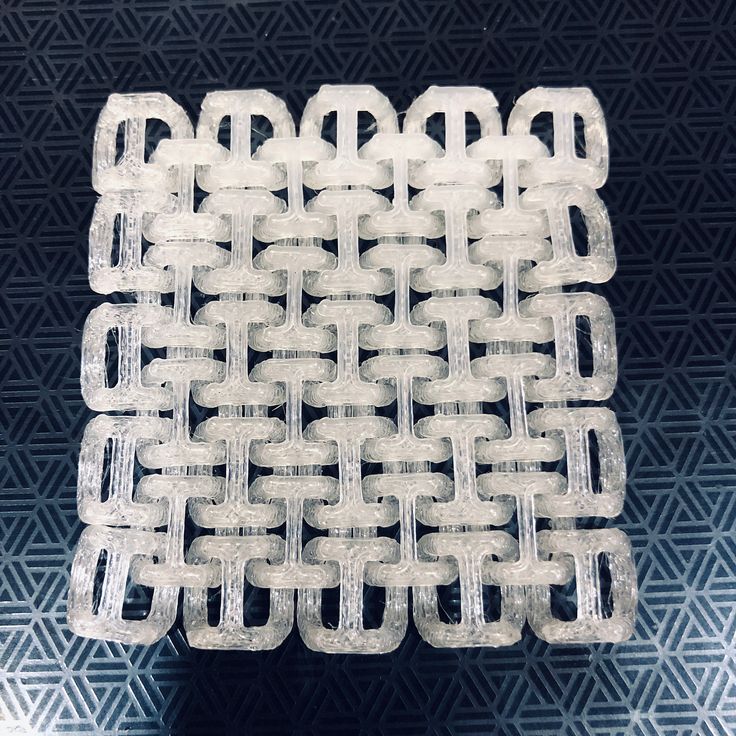

There are some designs that are even more advanced, and it’s almost difficult to call them chainmail anymore. The links are much more complex than just rings. Some of them are designed to have multiple holes in each link. These would be good for sci-fi costumes, because they have kind of a space age look. I haven’t really done much with this type of 3D printed chainmail, so this article will focus more on the simple ring designs.

Plain Ring Chainmail

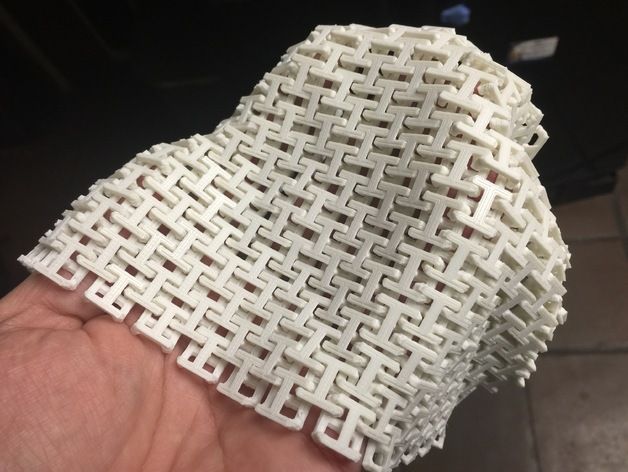

Even for plain ring chainmail, there are different designs that people have come up with to make them easier to 3D print. The simplest form is to have the rings be flat and circular. However, that requires the rings to be printed at an angle instead of flat on the bed. This causes issues with the rings becoming dislodged from the print bed, because they only have a little bit of surface area touching the bed.

However, that requires the rings to be printed at an angle instead of flat on the bed. This causes issues with the rings becoming dislodged from the print bed, because they only have a little bit of surface area touching the bed.

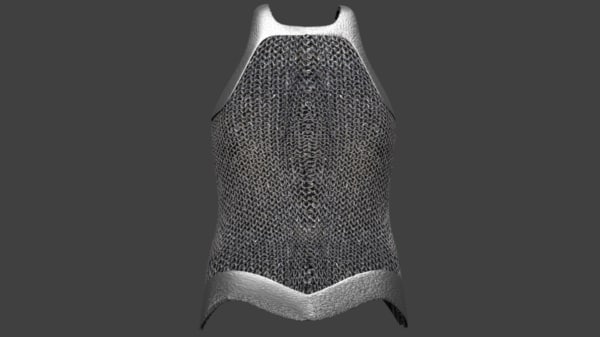

Some designs get around this by putting some extra curvature into the rings, giving them a compound curved shape. Others have built in grooves to allow for the space of the other rings. This allows the rings to be printed in more of flat configuration, and still be interwoven together. The only down side to these designs is that they lose a bit of authenticity by changing the shape of the rings. Aside from that, they’re much easier to print.

If you just want some 3D printed chainmail with simple circular rings, don’t worry. Those designs exist, but they’re just a bit tricky to print. I’ll have a link here to the thingiverse page of the design that I use. The rings on this design are a bit large at just over ¾ of an inch for the external diameter, or about 2 centimeters.

Benefits Of Using Larger Rings

A sheet made of larger rings will have fewer rings per sheet than one made up of smaller rings. This means that you will have fewer rings to join together when you connect the sheets, which will save you time. Making chainmail can be quite a long and tedious process, so it’s nice to speed it up a bit.

Larger rings are also more noticeable than smaller rings. In other words, the pattern of the chainmail will stand out more than if you used small rings. A lot of chainmail designs that you see in video games and movies have large rings, probably to exaggerate the detail and make it easier to see. It will also help it to stand out in photos.

Problems With Printing Chainmail

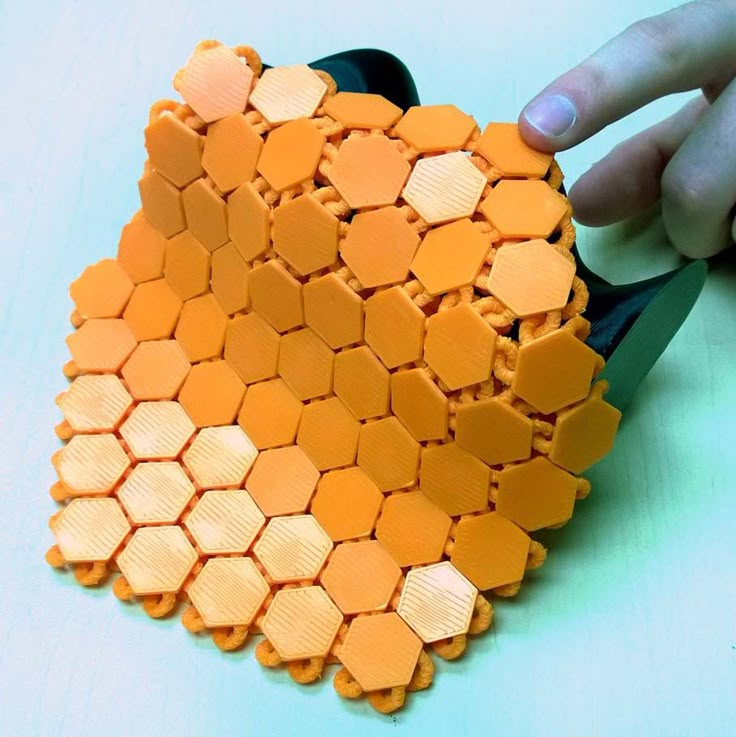

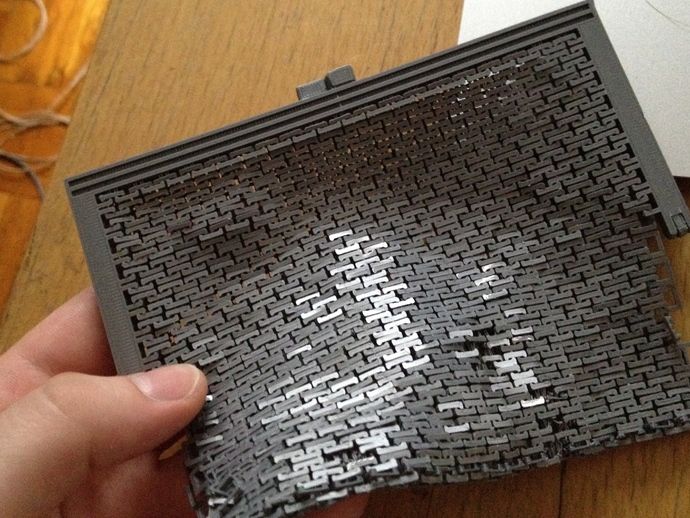

In order for the rings to be printed in one interconnected sheet of chainmail, they’re set at angles. If you look at the picture above you can see what I mean. This orientation makes for some problems though.

The main issue is the overhang on some of the layers. Because of the angle that the rings need to be printed at, some of the layers overhang pretty far, and that causes them to curl up as they cool. Once they’re sticking up, it becomes very easy for the print head to run into them and dislodge them from the print bed.

Because of the angle that the rings need to be printed at, some of the layers overhang pretty far, and that causes them to curl up as they cool. Once they’re sticking up, it becomes very easy for the print head to run into them and dislodge them from the print bed.

Once they’ve been knocked out of place, they can interfere with the other rings, causing a chain reaction that dislodges other rings. If it was just a few rings missing from one sheet it wouldn’t be too bad, but after a certain point it isn’t really worth letting it continue. The printer will keep depositing plastic where the rings used to be, which will end up getting stuck on the other rings. It really just becomes a mess.

This is why so many designs focus on making it so that the rings can print flat. However, like I said earlier, the only way to print these simple round rings is in this angled configuration. Luckily, with just some minor modifications to the print settings, these designs can be printed successfully without losing a single ring.

Print Settings

To make sure that the rings stay on the print bed, you have a few different options. One way is to increase the amount of plastic at the base of the rings so that they have more surface area attached to the print bed. The designer of the chainmail suggests that you print it on a raft. This will put a layer of support material underneath the whole sheet, which the rings will sit on top of. It’s a good option, but it uses a bit more plastic.

If you want to save filament, you can tell your slicer to add a brim to the object. This will create a little pad of plastic around the bottom of each ring, to help it stick to the bed better. You can adjust the brims to be any width you want. The problem with adding brims is that you have to peel them off later, which can take a while with so many rings. The advantage of using a raft instead of brims is that the raft can be peeled off in one big piece. However, if you make the brims wide enough, they will join together, making them easier to remove.

The designer also recommends that you raise the print head a very small amount, so that it will be less likely to hit the pieces of plastic that curl up. This isn’t a bad idea, but I found that my rings were curling up a lot higher than the amount he recommends raising it by. Some slicers have the option to raise the print head every time a retraction occurs, or if the print head moves a certain distance. If you have options like that, they might help, but they will also increase the print time significantly.

Filament Colors And Painting

Because the rings are interwoven, they’re very difficult to paint with spray paint, which is normally a good way to paint 3D printed objects. The normal thing to do is spray the piece with a coat of primer first, because otherwise paint won’t stick very well to PLA plastic. But because the rings are overlapping, there will be a lot of spots where the paint won’t reach. You would have to adjust the rings after one coat has dried and try to maneuver the rings so that any unpainted spot are exposed.

To avoid all that hassle, you can just print the rings in the base color that you want the rings to be. If you want your chainmail to be silver, print it with a silver or gray filament. If you’re going for a darker looking chainmail, then maybe print it with black filament.

You can still apply paint directly on the plastic if you want, and I have done that. A coat of silver paint helps to make the rings look more metallic. You could also mix up some reddish brown paint and apply it in places to give the appearance of rust. Just be aware that the paint will probably start to flake off after a while, especially as the rings move and scrape against each other.

3D printed “chain mail” paves way for next-generation smart fabrics

0Shares

Nominations for the 2021 3D Printing Industry Awards are now open, have your say who is leading the industry now.

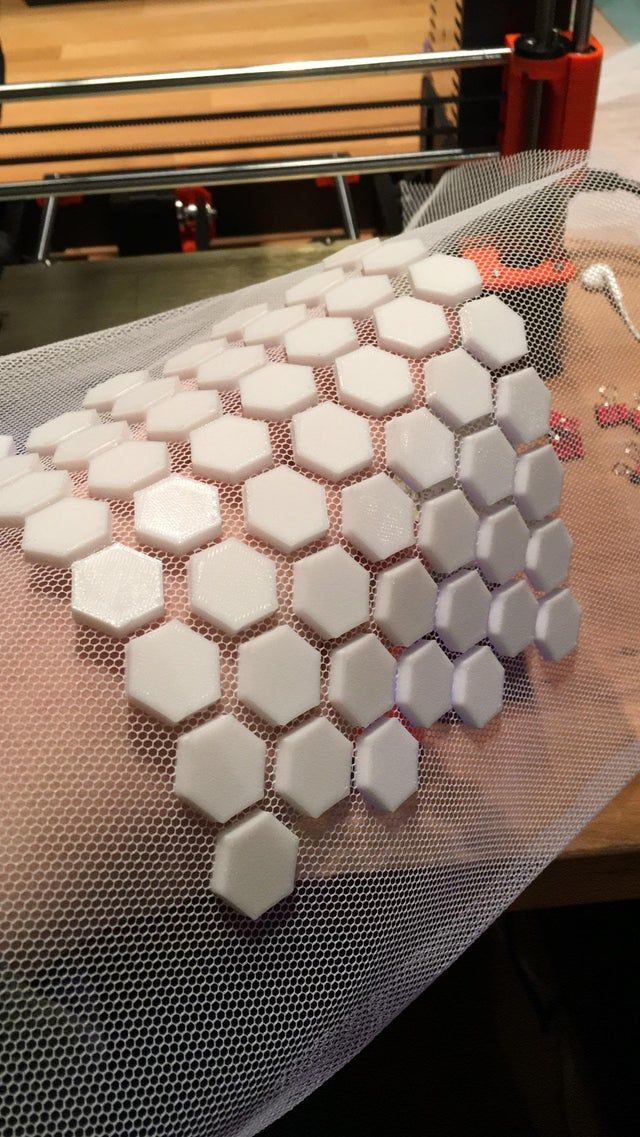

Scientists from Nanyang Technological University (NTU) Singapore and the California Institute of Technology (Caltech) have 3D printed a flexible chain mail-inspired fabric that can stiffen on demand.

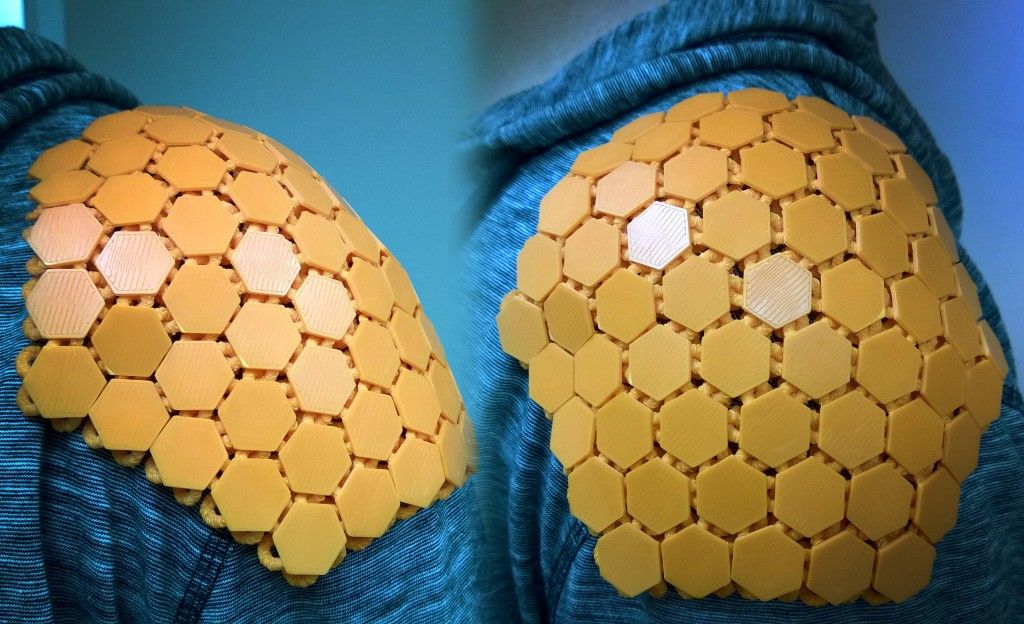

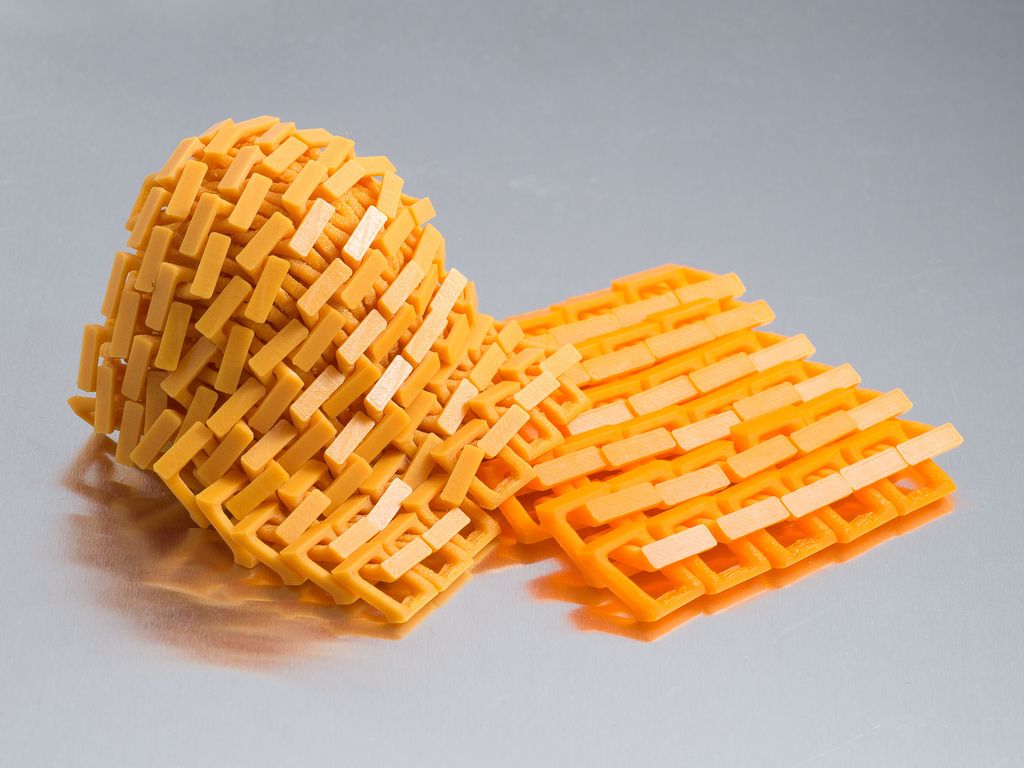

3D printed from nylon plastic polymer octahedrons that interlock with each other, the fabric can turn into a rigid structure that is 25 times stiffer than its relaxed form. Classed as a wearable structural fabric, the development could pave the way for next-generation fabrics that are capable of hardening to protect a wearer against impacts or for additional load bearing requirements.

The fabric could potentially be used for bullet-proof or stab-proof vests, medical support, and protective exoskeletons for high-impact sports or workplaces, like construction sites.

“With an engineered fabric that is lightweight and tuneable – easily changeable from soft to rigid – we can use it to address the needs of patients and the aging population, for instance, to create exoskeletons that can help them stand, carry loads and assist them with their daily tasks,” said Wang Yifan, Assistant Professor at NTU’s School of Mechanical and Aerospace Engineering and Lead Author of the paper.

Hardening fabric via jamming transition

The scientists’ hardening fabric is inspired by ancient chain mail armor, and consists of 3D printed hollow nylon plastic polymer octahedrons – a shape with eight equal triangular faces – that interlock with each other. Based on the scientific concept of ‘jamming transition’, the soft fabric turns into a hard, rigid structure when wrapped within a flexible plastic envelope and vacuum packed.

During this transition, particles switch from a fluid-like soft state to a solid-like rigid state with increased packing density, however typically solid particles are too heavy for wearable applications.

To address this issue, the researchers designed structured nylon polymer particles, each made of hollow frames, in the shape of rings, ovals, squares, cubes, pyramids, and other shapes made up of octahedrons, that could be interlocked. These structures were then 3D printed as a single piece to form a low density chain mail-style fabric with a high tensile stiffness.

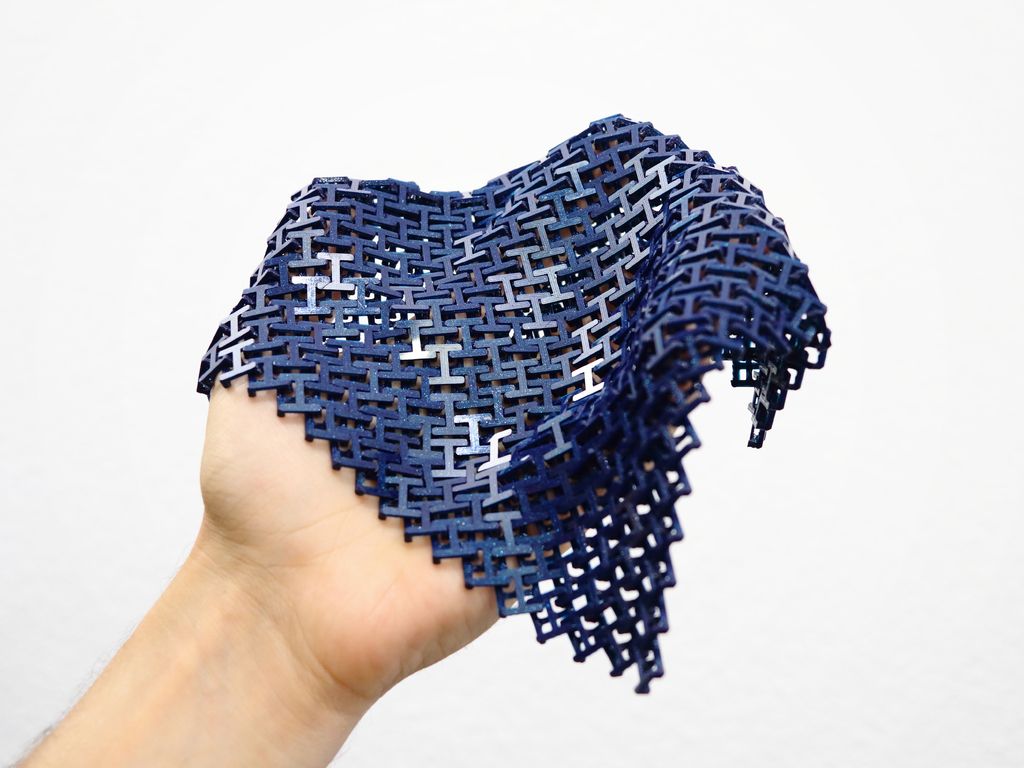

To strike the ideal balance between the fabric’s weight and flexibility, the scientists modelled the number of average contact points per particle and investigated how much each structure bent in response to applied stress. To control the stiffness of the fabric, they then encapsulated it within a flexible plastic envelope and compacted it using a vacuum. This pressure increased the packing density of the fabric, causing each particle to have more contact with its neighbor and resulting in a structure that is 25 times more rigid than its ‘soft’ form.

“We wanted to make materials that can change stiffness on command,” said Chiara Daraio, Caltech’s G. Bradford Jones Professor of Mechanical Engineering and Applied Physics. “We’d like to create a fabric that goes from soft and foldable to rigid and load-bearing in a controllable way.”

Bradford Jones Professor of Mechanical Engineering and Applied Physics. “We’d like to create a fabric that goes from soft and foldable to rigid and load-bearing in a controllable way.”

The 3D printed fabric is able to hold a load of 1.5kg, more than fifty times its own weight. To test the material’s stiffness and strength, the scientists dropped a steel ball weighing 30g onto the chain mail at a speed of three meters per second. When rigid, the impact deformed the fabric by just 3mm, reducing penetration depth by six times in comparison to the 26mm of deformation observed when the fabric was relaxed.

When stiffened, the chain mail fabric can withstand up to 50 times its own weight. Photo via NTU Singapore.Further development with metals

Having demonstrated their concept with plastic polymer octahedrons, the scientists are also looking to replicate the wearable structured fabric using various metals.

“Inspired by ancient chain mail armor, we used plastic hollow particles that are interlocked to enhance our tuneable fabric’s stiffness,” said Wang. “To further increase the material’s stiffness and strength, we are now working on fabrics made from various metals including aluminum, which could be used for larger-scale industrial applications requiring higher load capacity, such as bridges or buildings.”

“To further increase the material’s stiffness and strength, we are now working on fabrics made from various metals including aluminum, which could be used for larger-scale industrial applications requiring higher load capacity, such as bridges or buildings.”

To achieve this, the team has already 3D printed the chain mail using aluminum, and has successfully demonstrated that, while maintaining the same flexibility and soft performance of nylon, it can be jammed into structures that are much stiffer.

Such 3D printed metallic chain mails could potentially be used in applications such as body armor to protect against hard and high-speed impacts from sharp objects. For these scenarios, the envelope material could be made from aramid fibers, also known as Kevlar, which is commonly used in bulletproof vests.

Going forward, the scientists will seek to improve the performance of their chain mail fabric and explore further ways of stiffening it, such as through magnetism, electricity, or temperature.

Further information can be found in the study titled: “Structured fabrics with tunable mechanical properties”, published in the Nature journal. The study was co-authored by Y. Wang, L. Li, D. Hofmann, J. Andrade, and C. Daraio.

The researchers have also 3D printed the chain mail in aluminum that has more tensile strength. Photo via NTU Singapore.3D printing wearable fabrics

3D printing has been deployed for the creation of fabrics for a variety of different purposes. For instance, researchers from MIT have previously developed a flexible, 3D printable mesh fabric claimed to be “as soft as skin”, which could potentially be used to create medical devices, wearable supports and implantable devices.

Meanwhile, polymer specialists Polymaker and Covestro have jointly developed 3D printable fabrics from a TPU-based polymer as a more environmentally-friendly alternative to traditional weaving techniques. The 3D printed fabrics are designed for use in conventional production lines and can be attached to other articles of clothing such as shoes, bags, and hats.

3D printing has also been utilized elsewhere in the fashion industry thanks to the creative freedom it offers, and has even made catwalk appearances at global events such as New York City’s Met Gala and Paris Fashion Week. Esteemed fashion designers Ganit Goldstein and Julia Koerner have recently leveraged Stratasys’ PolyJet technology to directly 3D print designs onto their garments, while Chiara Giusti has partnered with Superforma Fablab to create a 3D printed clothing line called TECHNĒ.

The use of 3D printing in fashion and textile design has also been explored for some time by fashion designer and researcher Mingjing Lin, whose thesis investigated the relationship between 3D printed design and the human body, and how fluidity within 3D printed textiles can be accomplished.

NTU Singapore Assistant Professor Wang Yifan bending the wearable structured fabric. Photo via NTU Singapore.Nominations for the 2021 3D Printing Industry Awards are now open, have your say who is leading the industry now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows when stiffened, the chain mail fabric can withstand up to 50 times its own weight. Photo via NTU Singapore.

Tags Caltech Chiara Daraio Chiara Giusti Covestro D. Hofmann Ganit Goldstein J. Andrade Julia Koerner L. Li MIT New York City Met Gala NTU Singapore Paris Fashion Week Polymaker Stratasys Superforma Fablab Wang Yifan

Hayley Everett

Hayley is a Technology Journalist for 3DPI and has a background in B2B publications spanning manufacturing, tools and cycling. Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in.

Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in.

3D printer prints Kolchuga variable stiffness

September 11, 2021 (Saturday) 17307

Scientists of the Nanyan Technological University, NTU) and the California Technological Institute published in the NATRU journal. which details research into a new "smart fabric" like chain mail that changes stiffness when compressed.

The chain mail itself is 3D printed from nylon, and each chain link is shaped like an octahedron. The hollowness of single particles provides a low density and at the same time high tensile rigidity of the fabric.

Separate "single particles" are topologically linked like chain mail, forming the form of a continuous loose fabric. Despite the clearly three-dimensional single particles, the fabric as a whole is more like a 2-dimensional structure

To control the rigidity of the structure, the researchers soldered the chain mail into a transparent plastic bag from which air can be pumped out. The vacuum squeezed the single particles together, causing the octahedrons to "cling" and thus limiting the movement of each chain mail link, and therefore increasing the rigidity of the overall structure. The mechanism by which particles adhere to each other is called "transitional seizing" or "transitional seizing".

The vacuum squeezed the single particles together, causing the octahedrons to "cling" and thus limiting the movement of each chain mail link, and therefore increasing the rigidity of the overall structure. The mechanism by which particles adhere to each other is called "transitional seizing" or "transitional seizing".

Pressure increases the density of the packet, as a result, each particle has more contact with its neighbors, as a result of which the fabric of octahedral structures becomes 25 times more rigid. Formed into a flat structure, this “vacuum-fixed” fabric can withstand a load of 1.5 kg, which is more than 50 times the weight of the fabric itself.

Due to the fact that the fabric is built using octahedrons, the finished structure can be fixed in quite arbitrary shapes, for example, like this bridge shape in the illustration.

In another experiment, the researchers dropped a small 30-gram steel ball onto the chain mail. The impact deformed the tissue up to 26 mm when it was “relaxed”, but only 3 mm when it was stiff, which reduced the penetration depth by a factor of six.

“We wanted to create materials that can change stiffness on command. We would like to create a fabric that transitions from being soft and foldable to being a rigid load-bearing structure in a controlled manner,” said Prof. Chiara Darayo, Professor of Mechanical Engineering and Applied Physics at the California Institute of Technology.

“With lightweight and customizable fabric that is easy to change from soft to firm, we can help patients, for example, create exoskeletons, help them stand, carry loads, and perform daily tasks,” said Asst. Professor Yifan Wang from NTU Singapore School of Mechanical and Aerospace Engineering.

"Inspired by ancient chain mail armor, we used plastic hollow particles that interlock with each other to increase the stiffness of our customizable fabrics," said Asst. Professor Wang from the NTU School of Mechanical and Aerospace Engineering.

“To further increase the stiffness and strength of the material, we are working on fabrics made from various metals, including aluminum. Such a material would already be suitable for large-scale industrial applications requiring higher load capacities, such as bridges or buildings.”

Variable Stiffness Metal Structures (Photo: Caltech)

In the future, the team at Caltech and NTU Singapore intends to expand into other materials as well as explore new (non-vacuum) means of controlling tissue structure stiffness, such as magnetism, electricity or temperature.

Learn more about chain mail (and maybe even design and print your own) with the help of the scientific article at the link.

Soft bulletproof chain mail hardens when hit by a bullet

August 13, 2021 12:54 Natalia Teryaeva

A fabric similar to chain mail can, when "hardened", hold a weight of 50 times its own.

Photo of Nanyang Technological University.

The fabric consists of octahedrons - figures with eight faces, each of which is a triangle.

Photo by Caltech.

Flexible fabric such as chain mail can "harden" if necessary

Photo of Nanyang Technological University.

Study author Wang Yifan demonstrates his fabric in a "hardened" state - it looks like a board.

Photo of Nanyang Technological University.

3D printed material resembling chain mail. And he has already demonstrated outstanding performance.

Materials that can change their properties in response to external influences are of great value in many applications. A new example of such technology was shown by scientists from Singapore's Nanyang Technological University and the California Institute of Technology in the United States.

They created a light and durable "fabric" made up of links similar to chain mail armor. Thanks to this combination of elements, the fabric can quickly turn from flexible to solid.

Scientists describe their fabric as "a wearable structured fabric".

Its ability to harden is easiest to compare with how a vacuum bag filled with rice or ground coffee can harden into a stone if all the air is taken out of the bag without leaving gaps between the grains, Singaporean researchers note. Their American colleagues add that the properties of the "fabric" are based on the ability of its elastic elements to jam each other in close contact.

Their American colleagues add that the properties of the "fabric" are based on the ability of its elastic elements to jam each other in close contact.

This design was inspired by Batman's cape, which could transform into a solid glider.

A 3D printed nylon cloth made of octahedral "skeletal" elements connected like chain mail. It was printed on one canvas at once.

Her scientists explored how structured but hollow elements can be connected to each other to form a web with a stiffness that can be changed as needed.

"Inspired by ancient mail armor, we used plastic hollow elements that are interlocked with each other to increase the stiffness of our controllable fabric," explains study author Wang Yifan.

The web was then placed in a plastic bag and sealed with a vacuum (the device sucks all the air out of the bag). This increased the packing density of the material, pulling the web elements towards each other and increasing the number of points of contact between them. As a result, the structure became 25 times more rigid.

As a result, the structure became 25 times more rigid.

After transformation, this "fabric" is capable of holding a load of 1.5 kg, which is 50 times its own weight.

In another experiment, to test the strength of the fabric obtained, a small steel ball was first dropped onto the fabric while it was in a "relaxed", flexible state. The fabric eventually sagged due to the ball falling on it by 26 millimeters. Then the ball was dropped onto the canvas in a "hardened" state (the elements of the fabric were forced to jam each other even without vacuum packaging), and then the ball was able to bend the canvas that had become rigid by only 3 mm.

The scientists then 3D printed an aluminum version of their chain mail fabric. The softness of the aluminum thread is comparable to nylon. But the aluminum web turned out to be much stiffer than nylon due to the greater strength of aluminum compared to nylon.

To seal the nylon webbing, as we said, a plastic vacuum bag was used. And for the aluminum version, the inventors are going to create a "robe" of Kevlar to form a protective fabric for bulletproof vests.

And for the aluminum version, the inventors are going to create a "robe" of Kevlar to form a protective fabric for bulletproof vests.

Other potential applications for both versions of the impact-hardened mail web include exoskeletons that change stiffness as the patient recovers, and even bridges that can be deployed for fast crossings.

The team is currently working on improving the characteristics of the material and exploring new ways to strengthen it, including magnetism, temperature and electricity.

An article on chain mail was published in the journal Nature.

Earlier we talked about creating the world's strongest glass that scratches diamond and conducts electricity. Chemists have also created nanoribbons that are stronger than steel. In addition, we wrote about the amazing armor of gardening ants and the most durable biomaterial in the world.

More interesting science and technology news can be found in the "Science" section of the "Looking" media platform.