3D printer brighton

3D Printing in Brighton, Colorado

Easily transforming your concept into a printed masterpiece. We want to help bring our clients ideas to life. Bring your blueprints and enthusiasm- we’ll provide you with the 3D model, the genuine customer support, and together we’ll create custom prototypes, models, or replicas.

Where concepts come to life

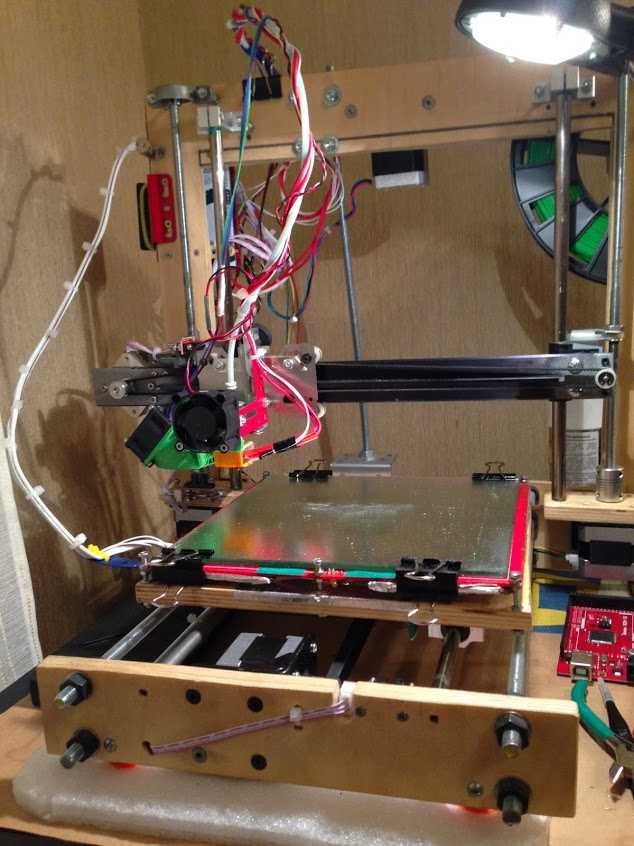

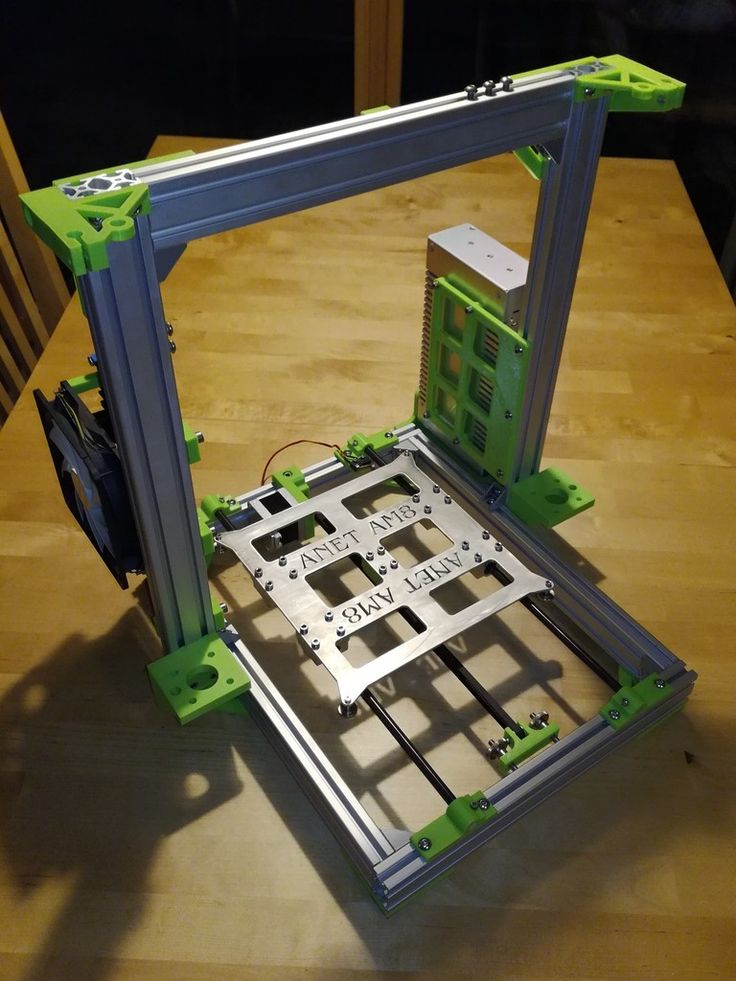

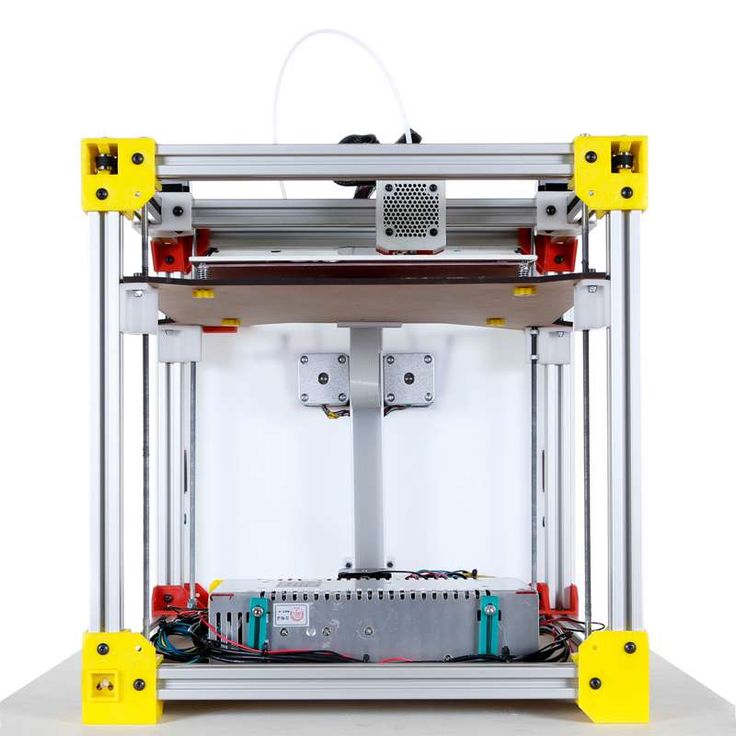

With 13 unique machines and excellent service, we provide unparalleled solutions.

Whether for beginning entrepreneurs, or large corporations, 3D Cubed Printing provides optimized prints aimed specifically for your organization’s growth and innovation.

Helping you to scale and innovate

In a day and age where most innovators are set up for failure, 3D Cubed Printing leverages our technology and experience to improve production and keep processes moving efficiently to help you with your scaling and innovation needs.

Honest pricing is our priority

Where there is ambiguity, there is confusion. Too often companies provide ambiguous pricing, conceal fees, and skip over investing in customer and organizational needs.

3D Cubed Printing prioritizes transparency and provides the ultimate service for your innovation. Our passion and understanding of 3D Printing allows us to provide transparent pricing.

Industry leading-3D printing

Our industry-leading 3D Printing is powered by quality machines and people who are passionate about innovation and design.

We select the best machines and materials to effortlessly bring your design concept to life.

Getting started with us

3D Cubed Printing shares a deep passion for innovation and an all-encompassing love for creativity. Driven by the success of our customers, we have made getting started with us an easy step-by-step process.

3d printing in brighton, coloradoStep One

Connect with us

Get in touch with us so we can assist with your 3D printing needs. We leverage our expertise to efficiently bring your design to fruition and provide ultimate value.

Step Two

Provide a blueprint

As your designated 3D Printing company, provide us an existing or custom blueprint. In doing so, we take the blueprint, input it into our machines, and get to work. In certain cases we may be able to provide blueprints depending on the complexity of the design. Get in touch to learn more.

Step Three

3d printing in brighton, coloradoConfirm material

Do you already know what print material you need? Perfect, just let us know. Not sure what material your 3D print needs to be created with? That's fine too. Get connected so we can help decide on the best material for your project.

Step Three

3d printing in brighton, coloradoStep Four

Let us go to work

After you have had a consultation, provided us with a blueprint, and confirmed a material, we get to work. During this phase, we will keep you updated with detailed status reports.

Gun Enthusiasts

Prototyping using 3D printing allows firearms manufacturers to cut down lead time in product development. 3D printing also reduces trial and error since prototypes are more cost-effective and product revisions are quickly made and printed with adjustments to the master design file.

3D printing also reduces trial and error since prototypes are more cost-effective and product revisions are quickly made and printed with adjustments to the master design file.

Game Nerds

3D printing allows you to design and scale games of any kind. Provide blueprints to assemble an arcade-sized prototype or have small characters printed for your game. We can also can create game pieces for Dungeons and Dragons, board games, escape rooms, etc.

Car Enthusiasts

We can produce low cost prototypes, jigs, fixtures, and tools. We can also print pieces to complete an assembly such as a full-sized car, a shelf model car, or parts to a vehicle such as a handles or dashboard.

Aerospace Engineers

If you need low cost prototypes, jigs, fixtures, or tools for planes we can produce those as well! Pieces can be printed to complete an assembly such as a full-sized plane, a shelf model plane, or parts to a plane such as handles or dashboards.

Arts and Crafts

Our 3D printers can print custom cake toppers, ornamental pieces, cookie cutters, cake molds, stencils, paint and brush holders, and organizers.

The Sky's the Limit

3D Printing is being used by innovators in the robotics, manufacturing, construction, and health care industry.

An adventure with 3D-printing in Brighton

In one form or another, 3D-printing has been around since the 1980’s, but it is only now maturing from its industrial heartland into a plethora of applications and through to our homes.

Of all the technologies coming our way this one has the potential to challenge the world we live in.

Inspired after reading online about advances in 3D-printing, I’d remembered I had something that needed fixing: a LOCK; ceiling lamp.[image type=”circle” float=”left” src=”http://thebadgeronline.com/wp-content/uploads/2015/03/Lamp.jpg” info=”none” info_place=”top” info_trigger=”hover”]

A piece of Swedish design I’m not really too keen on but nonetheless one that’s not mine to dislike.

The lamp had broken about a month after moving in. One of its plastic clips become brittle with age, and snapped in the process of changing a light bulb.

I imagined this must happen quite often and presumed there must be spare parts available. I envisaged reams of plastic clips at hand to replace their broken counterparts, but this turned out not to be the case.

Replacing the entire unit was the only option. Though the cost would be small, out of principle it wasn’t replaced; I mean, what a waste of mostly functioning lighting unit.

When searching for a replacement I’d stumbled across a 3D Design of the clip I needed which seemed useless at the time.

I began to rummage through the internet in hopes of finding the design again as I wasn’t sure how well I could design it myself.

I eventually found the design on Thingiverse, a website that primarily hosts open-source 3D designs for 3D-printing.

It had 8 likes and someone claimed they’d made one and hadn’t posted a disparaging comment about it. Marvellous I thought, now to find someone with a 3D-printer.

Marvellous I thought, now to find someone with a 3D-printer.

Aware of the maker movement that has grown in recent years and the rise of hackerspaces and Fab Labs that have appeared worldwide, I found it wasn’t really a problem.

Another hunt through the internet and I came across the website 3dhubs.com, a website that allowed me to get in contact with local printers.

I uploaded the design of the clip from Thingiverse and was presented with a choice of manufacturers, the materials, colours, delivery options and the cost.

Wanting to see the product being printed, I didn’t go through with the online order. I chose the cheapest option which was by Solutions Inc in Hove, and cycled out to their shop.

Arriving with the design on a USB stick, it wasn’t long before I was stood in front of the printer choosing a colour, watching it heat up and print a clip, layer by layer. The process took around 16 minutes.

I had the part I required; no fuss, no postage costs and it didn’t come with 99% of a lighting unit that wasn’t needed, so with a lot less waste as well.

Upon arriving home I proceeded to fit the clip into the light and put it all together, it all worked exactly as I wanted it to.

Admittedly though, printing a part to fix a flimsy piece of Scandinavian design is not the most exciting thing that has been 3D-printed.

The articles that inspired me to finally fix the light were far more interesting. One was of a 3D-printed jet engine, another about complete houses being printed in China.

These are, of course, printed using more advanced printers with differing technologies that enable them to print with metal or other substances.

Interestingly, 3D-printing has found a use in regenerative medicine. We already have 3D-printed implants: from jawbones and vertebrate to partial skull replacements.

The development of bioprinting is an area developing rapidly that will endow us with the ability to print working organs, and other body-parts that patients need.

So whilst the type of commercial 3D-printers aimed at hobbyists and the home might not yet be able to print your own organs, they do have a massive (positive) disruptive potential.

For example, NASA has recently emailed a spanner to the International Space Station which was then printed onboard.

This raises the question, how much of what we need could we print? If this technology enables us to print the items we need at home there will be less need for us to shop, meaning less tax income for government.

It could empower us all to become makers and menders of the things we own.

This could disrupt the capitalist mode of production as we know it, potentially ushering in a new decentralised-libertarian-paradigm of production, empowering people whilst challenging businesses and governments.

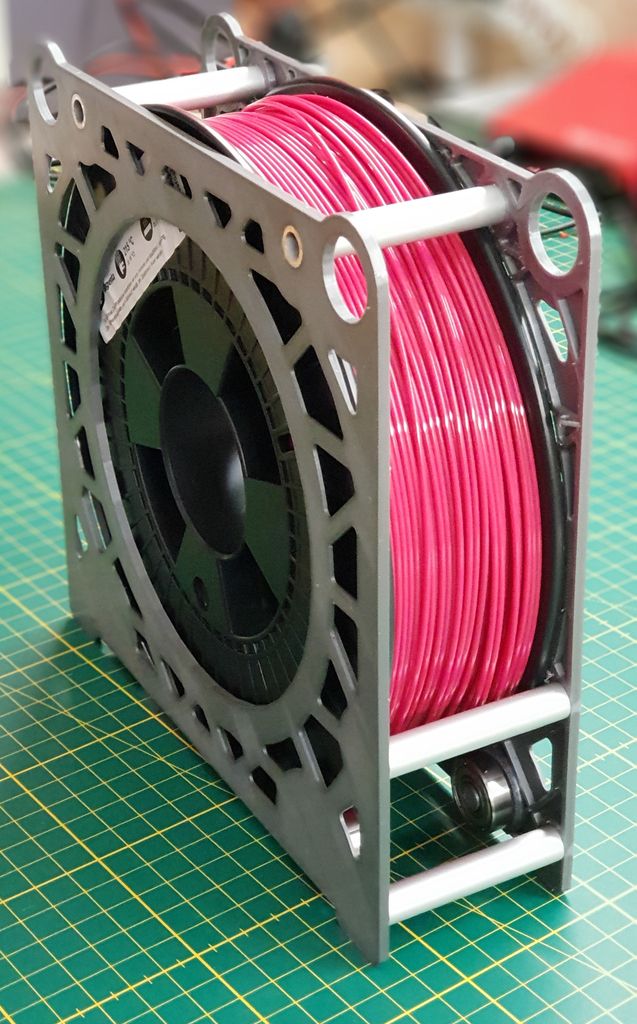

There are downsides, however. The machines use lots of energy, and usually a plastic-filament.

There are also regulatory (or lack of) problems such as the fact people seem hell-bent on producing 3D-printed guns.

It can also be a little costly depending on what you need, though the price will come down as it becomes more ubiquitous. The technology is coming, and coming fast.

Last week I attended a talk by Professor Helga Nowotny who claimed that science/technology brings the future into the present.

When my plastic clip was printing, I did feel a little bit like I was actually in the future.

Luke Richards

I’d like to thank Solutions Inc in Hove for printing my clip. They 3D-print from here.

Tags: 3d printing Brighton tech

Categories: Science & Technology

3D printers are being used to create living structures out of mud

A design team in Jerusalem intends to replace heavy materials such as concrete and reinforced steel with 3D printed residential structures made entirely from natural resources.

3D printing has come a long way in the last 20 years and should be a $56 billion market by 2027. In the last year alone, we've written about sustainable printed fashion, home product designs made from food waste, and even printed vegan steaks.

A recent little-known use of the technology involves printing layers of vertical living 3D soil. As part of Jerusalem Design Week, an installation called "Grow a Building" featured dozens of mud structures, each containing dense green roots and even an edible radish.

As part of Jerusalem Design Week, an installation called "Grow a Building" featured dozens of mud structures, each containing dense green roots and even an edible radish.

Resembling a concrete pump, a specially designed machine was loaded with seeded soil and used to form several geometric shapes of various sizes. From there, fertilization and regular watering ensured that the natural plantation would bloom and strengthen each structure.

This may sound experimental, but it's far from just a demonstration of the technology. The installation is based on very pragmatic and relevant concerns; mainly that the constant use of concrete and steel in the construction industry is responsible for approximately 22% of all global emissions.

“We wanted to create an architecture made from completely organic and local materials so that you don't have to ship materials from the other side of the world,” he says. Nof Natanson, an architect who worked on this project with a group of seven other designers.

If you've been following Thred for a while, you probably know that this isn't the first time sustainable materials have been printed in layers to create habitable structures. However, it is definitely the first company to offer pickled vegetables.

Credit: Dor KedmiBricks can already be molded from agave pulp, for example, and cast walls can be molded from compacted natural material such as chalk or earth.

The only problem with these methods is that they are often limiting when it comes to creating complex shapes such as curved walls or domes. They are also time-consuming and require a rare specialist skill set. As Nathanson says, "architects and designers are basically limited by the machines available."

That's why the team turned to 3D printing with their groundbreaking idea (pun intended). By modifying an existing printer, they developed a special nozzle capable of holding a textured mixture of wheat, soil, and vegetable seeds. After shaping, six weeks of watering turned each creation into a solid column.

“There is a lot of mathematical work on the fractals of plants and trees, so integrating how different plants grow into the design process and the geometry of those walls can make the material more durable and efficient,” explains Natanson.

As it stands, there is no real clarity as to whether natural flora and fauna can ever replicate the stability of, say, reinforced steel, but we must try to create alternatives that are not as harmful to the environment.

The tallest earth structure at the show stands at 4.9 feet, but the team is aiming for more next year. “We could go higher and build a real pavilion,” she says.

Jamie Watts

Technical editor London, UK

I'm Jamie (He/He), Associate Editor and Senior Writer at Thred. Keeping up to date with social media updates and revolutionary technology is my forte, but when I'm not typing, you'll probably find myself wrapped in a big, icy Tango explosion in the latest horror movie. Follow me on Twitter , LinkedIn and send me some ideas/feedback via Email address.

Follow me on Twitter , LinkedIn and send me some ideas/feedback via Email address.

Amazing things that can be printed on a 3D printer - Articles - Arrivo

"What we need to build a house - draw, we will live" - today this phrase has become a reality. Everyone is happy with the progress in 3D printing: archaeologists are copying mummies, NASA specialists are growing artificial meat, birds are moving into high-tech birdhouses, and designers are bringing to life the most daring shoes that girls have ever worn. We offer you to get acquainted with the latest innovations and trends in 3D printing.

Pistol

Owners of 3D printers can get their hands on a weapon by downloading a few files from the Defense Distributed website. The printed pistols look like weapons from science fiction films, but are not yet as reliable as real ones. However, progress does not stand still - last year, Solid Concepts printed the world's first 3D metal gun.

SLR camera

French designer Leo Marius managed to print a SLR camera. The author of the invention did not fail to share it with the world - today anyone who does not spare $30 to download files from Marius' website and 15 hours to assemble the camera can become the owner of the unique Open Reflex "reflex camera".

Marius did not dare to create a 3D printed lens, and the Japanese Yuki Suzuki was not afraid of this either. He made the lens out of clear acrylic. The pictures taken on this camera can hardly be called high-quality, but Suzuki did not seek to please the capricious fans of Canons and Nikons - he was primarily guided by scientific interest.

Waterproof bikini and futuristic shoes

Advanced designers have also learned how to customize the 3D printer to suit their needs. Special software today allows you to quickly make clothes, taking into account the individual parameters of a person. Using new technologies, designers from Continuum, for example, have already managed to create a waterproof nylon bikini.

It is quite possible that 3D outfits will soon become a trend, but so far only celebrities risk flaunting futuristic dresses, and even then very extravagant ones.

Lady Gaga went public last year wearing a black 3D printed dress by Materialize. Flashed in a printed dress and "Queen of Burlesque" Dita Von Teese. At the same time, the dress for Dita was made according to the drawings of the medieval mathematician Fibonacci and consisted of 17 different parts.

Designers have not forgotten about the part of the wardrobe so beloved by women, like shoes - in this genre, a 3D printer can work real miracles. For example, Sebastian Errazuriz printed a unique collection called "12 Shoes for 12 Lovers", dedicated to his apparently difficult relationships with women. Among the gems of the collection are shoes called "Gold Digger Allison", "Snow Queen Sofia", "Soldier Jane Barbara" and "Crybaby Alexander".

Sweets

Replacing the traditional plastic in the cartridge with melted chocolate, you can get endless possibilities for creating desserts. Chocedge has created exclusive 3D printers that can print any pattern in chocolate, including your own photo. If chocolate is too traditional for you, you can try unusual sweets from Cubify.

Chocedge has created exclusive 3D printers that can print any pattern in chocolate, including your own photo. If chocolate is too traditional for you, you can try unusual sweets from Cubify.

Meanwhile, Modern Meadow is hard at work building a printer that can print a steak. To do this, scientists use sophisticated technology, including the cultivation of stem cells.

The 3D printed food project is being funded by the space agency NASA, which believes it will be possible to feed astronauts in this way in the near future.

Researchers also assure that the day is not far off when modern technologies will allow even pizza to be printed. To do this, they say, it is simply necessary to increase the number of cartridges in the printer by adding dough, cheese and other necessary ingredients.

The rights to this article belong to arrivo.ru.

Acoustic guitar

The world's first 3D-printed acoustic guitar was Scott Summit, who claims that his creation even surpasses hand-assembled instruments. New Zealander Olaf Digel followed in his footsteps, creating a whole line of so-called ODD guitars, among which there is even an instrument in the form of a web with spiders crawling inside.

New Zealander Olaf Digel followed in his footsteps, creating a whole line of so-called ODD guitars, among which there is even an instrument in the form of a web with spiders crawling inside.

3D printing is not limited to guitars. So, an employee of the MIT Media Lab, Amit Zoran, managed to print a real flute, and the German company EOS created a 3D model of a violin based on a polymer. But innovative instruments still sound much worse than traditional ones.

James Bond car

The creators of the latest James Bond film, Skyfall Coordinates, regretted really blowing up the legendary 1960 Aston Martin DB5 special agent car, and printed out a 1:3 scaled down copy of it on a 3D printer.

It is the 3D printed version that explodes on the screen at the climax of the film.

A complete car can also be printed on a 3D printer. This is how all 50 parts of Urbee 2 were created, which is capable of accelerating to 112 km / h and driving up to 64 km on electric power alone. At the same time, the streamlined body of the machine significantly reduces fuel consumption. In 2015, the creators of the hybrid are going to drive more than 4,000 km on it, spending only 38 liters of fuel.

At the same time, the streamlined body of the machine significantly reduces fuel consumption. In 2015, the creators of the hybrid are going to drive more than 4,000 km on it, spending only 38 liters of fuel.

Prostheses and human organs

In 2011, Richard Wang, who lost 4 fingers while working in his workshop, 3D printed his own prosthesis. Subsequently, Richard began to design prosthetic hands called Robohand and even created the world's first 3D prosthetic laboratory in Sudan, where he helps disabled children.

The use of 3D printers in medicine promises to become even more useful over time - Chinese scientists have already learned how to print prototypes of human organs. True, they “live” for no more than 4 months and are devoid of blood vessels. However, according to researchers, it will be possible to “print” full-fledged organs in 15-20 years.

Turntable

Amanda Gassey created a turntable using a 3D printer. You can't listen to classic vinyl records on it, but Amanda also came up with a special program that converts any sound file into 3D format. The sound quality of such records leaves much to be desired, so the creation can be considered rather as a design refinement.

The sound quality of such records leaves much to be desired, so the creation can be considered rather as a design refinement.

Bicycle

Why reinvent the wheel? It's better to print it on a 3D printer, EADS decided. The AirBike created in this way impresses with its characteristics. Firstly, it is 65% lighter than its classic aluminum counterparts, and secondly, it is no less durable than them.

Birdhouse

Coming into contact with such a brilliant creation of our time as a 3D printer, one cannot but share it with the smaller brothers. Recently, MakerBot held a competition for the best printed birdhouse. The owners of 3D printers did not stint on ideas for birdhouses: many creations were sent to the competition in all possible styles - from classic to high-tech. The winner was Eric Darwoodle, who built a real cozy villa for some lucky bird.

Lamp

Thanks to the development of Materialize, everyone can create their own unique lamp. If you do not believe in your design abilities, you can simply choose one of the copies available on the Internet and print it on your own 3D printer or order it for home delivery. Such lamps are able to turn any room into a forest from Avatar, casting the thinnest shadows on the ceiling. Designers from Nervous system assure that each lamp they create with a leaf pattern is unique, just like plants in nature.

Such lamps are able to turn any room into a forest from Avatar, casting the thinnest shadows on the ceiling. Designers from Nervous system assure that each lamp they create with a leaf pattern is unique, just like plants in nature.

Mummy

While the real mummy of the Egyptian emperor Tutankhamun rests in his homeland, in New York they recreated its exact copy using a 3D printer. Materialize, which created the reproduction, used CT scan data. The copy is made from photopolymer resin applied layer by layer. Makeup artists helped to fully match its counterpart to the 3D printed version of Tutankhamen.

The rights to this article belong to arrivo.ru.

3D children's drawings

Crayon creatures offers everyone the opportunity to bring children's drawings to life by printing them out in 3D. The idea is good because it makes getting a new toy dependent on the development of children's artistic skills. Who knows, maybe, having such a motivation, one day your child will learn to draw no worse than Van Gogh or Picasso.

Toys for adults

Using a 3D printer, you can create toys not only for children, but also for adults. So, the site Maker love offers a free and quite diverse design of sex products. If you have a 3D printer, you can download and print any copy you like here, and do it in a size that is limited only by your imagination.

Gadget Accessories

Gadget fans will love 3D printed accessories too. Printers today can print a case for an iPhone or iPad. If you want something extraordinary, you can turn to designer creations. So, SaGa design has developed an unusual stand for a tablet, which is an atlas supporting the gadget.

Art objects and sculptures

A lacy skull, a puppet horse or a futuristic bouquet of flowers - the possibilities of 3D printing are limited only by the imagination of the author of the art object. Many designers have already turned to this genre, and some of them have managed to create real masterpieces of our time with the help of a 3D printer.

For example, Josh Hacker is making headway towards lace skulls. According to him, he sets as his task "the embodiment of the architecture of the imagination." And Mikaella Janse van Vuuren printed out a three-dimensional image of her drawing of a puppet horse with movable wings and functional joints.

Jewelry

Jewelry created using the power of 3D printing, although not precious, is undeniably unique. The American design studio Nervous System has 3D printed flexible jewelry, consisting of hundreds of small fragments connected by miniature hinges. To create such decorations, fragments are combined in a special graphic editor into the final three-dimensional model, which is then compressed to a small size and sent to print.

Building

Dutch architect Janjap Reissenaars from Universe Architecture is going to build an entire building using a 3D printer. As conceived by the author, the printer will create sections of the building (6 by 9 meters in size) from sand and a binder. The final material promises to be stronger than cement. Although the building will still need to be reinforced with concrete, this is the world's first project to build an entire building using a 3D printer.

Furniture

By 3D printing a house, you can create furniture for it in the same way. There are already tables, chairs and even beds that have been made using 3D printing. Basically, such furniture is created from individual parts, but recently BigRep created a printer that can print whole furniture. The dimensions of such furniture are quite standard.

The machine can work with nylon, plastic and Laywood, which looks like real wood.

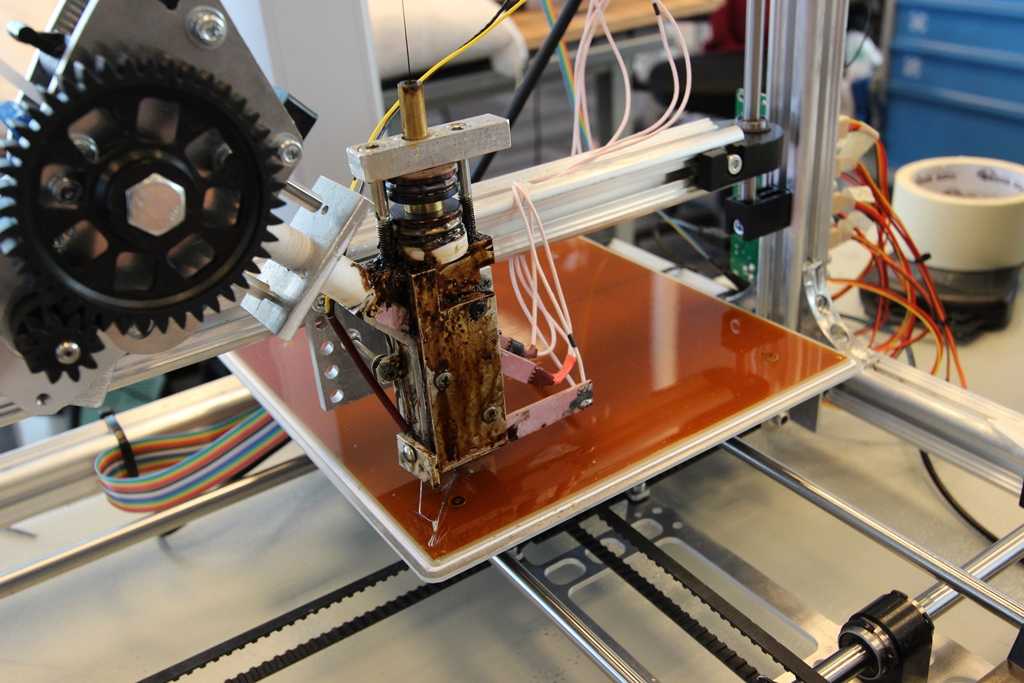

3D printer

The RepRap 3D printer is unique in that it can print itself. Nevertheless, it still does not reproduce all of its own parts, and the final assembly must still be carried out by a person. The creators of RepRap believe that the universal self-replicating 3D printer can eventually be used in the production of small household items.