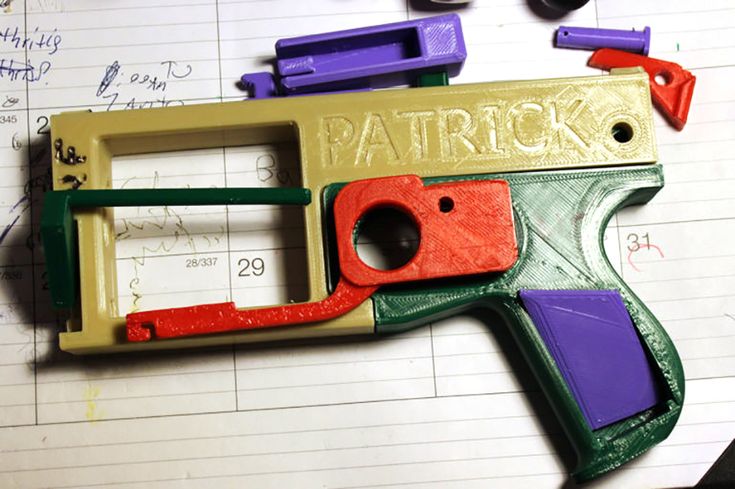

3D printed sten gun

3D file STEN MKII (non-firing replica)・3D print model to download・Cults

Volcanic pistol (non-firing replica)

€14.90

MAS 36 (non-firing replica)

€16.76

BAR rifle (non-firing replica)

€23.28

Webley MKVI (non-firing replica)

€14.90

Mondragon rifle (non-firing replica)

€18.62

Martini Henry (non-firing replica)

€16.76

Best 3D printer files of the Various category

GPS Mount - TomTom XXL 540 TM

Free

Guitar chord kit

€5

articulated geometry - Print in place - geométrie articulée

€0. 50

Enormous Heavy Tank Alternate Turret (Kitbash/Remix)

Free

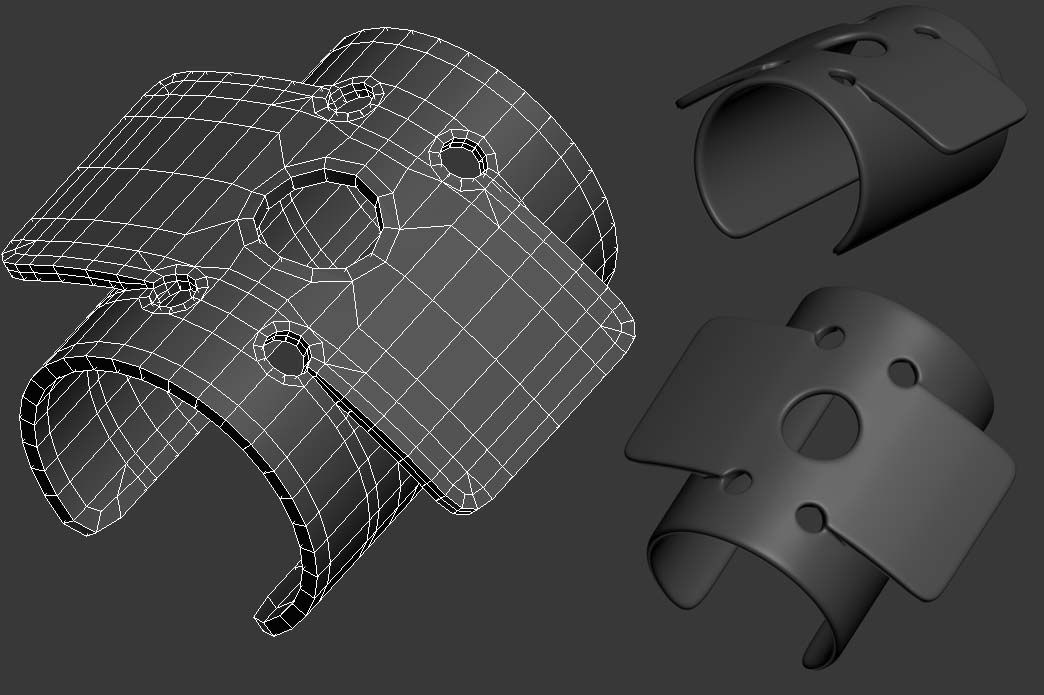

Autonomous Drone - Quadcopter (Silent Might) APM 2.5

Free

Airsoft - Supressor 2

€3

AMONG US - COLOSSAL TITAN half body (ATTACK ON TITAN)

€1.06

Best sellers of the category Various

Gengar Pen holder

€1.50

Gomu Gomu Fruit | Gomu Gomu Gomu no Mi | Hito Hito No Mi Nika Sun God |One Piece Grinder Grinder

€20

Charizard - Flexi Articulated Pokémon (print in place, no supports)

€3

flexi snail

€2

Polestar 2 center console accessories

€6. 69

69

The Thing Addams

€1.99

Charmander - Flexi Articulated Pokémon (print in place, no supports)

€2

STREET BUGGY FULL MODELKIT 1/24

€14.90

Articulated Rayquaza Flexible Pokemon Dragon

€1

THE THING-WEDNESDAY COMPANIONON-HD PRINT

€1.30

5 Gnomes ( Supportless )

€2.49

4th Planet Battleduke Pre-Olympian God

€12

SlingHAMMER - repeating Crossbow Pistol for 6mm 8mm 10mm or 12mm Steel Balls

€12.50

STREET Kart

€7.34

Hrabis - Caricature of Czech premier

€5. -50% €2.68 36

36

American Football Snack Dome (Snack Stadium, Snack Arena)

€20 -25% €15

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your banner blocker (AdBlock, …) and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via Ko-Fi 💜.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

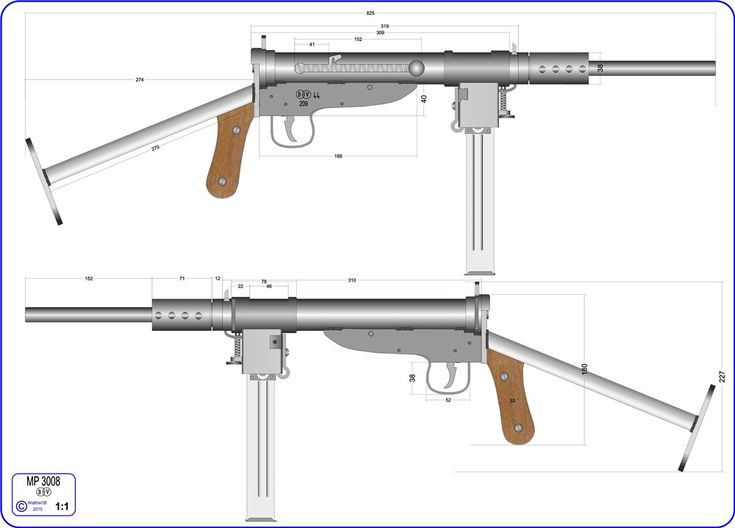

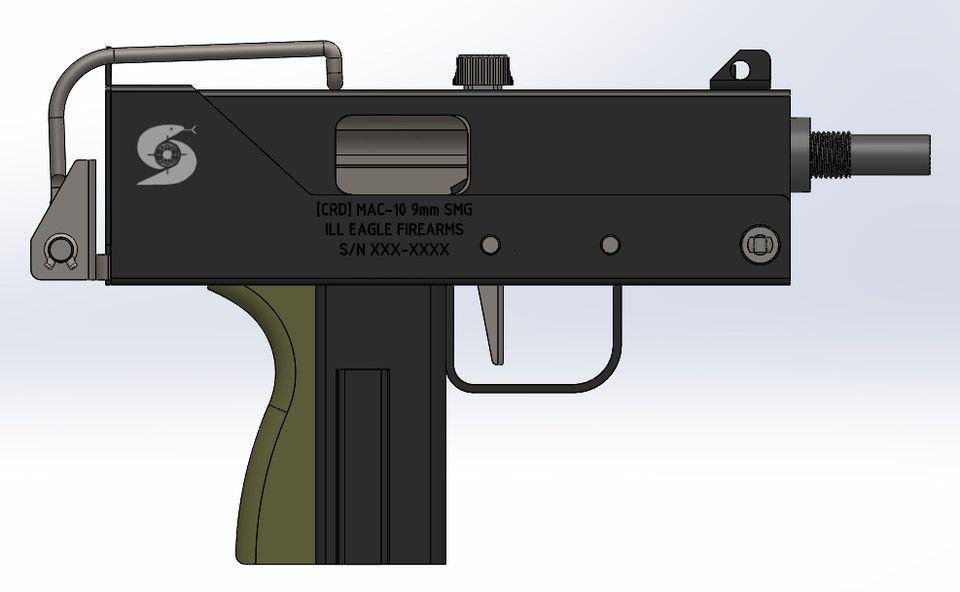

3D file Sten Gun (3D PRINT MODEL)・3D printable model to download・Cults

Mauser C96 (711) (3D PRINT MODEL)

€9.09 -10% €8.18

Glock 17 Soild prop model

€3.25

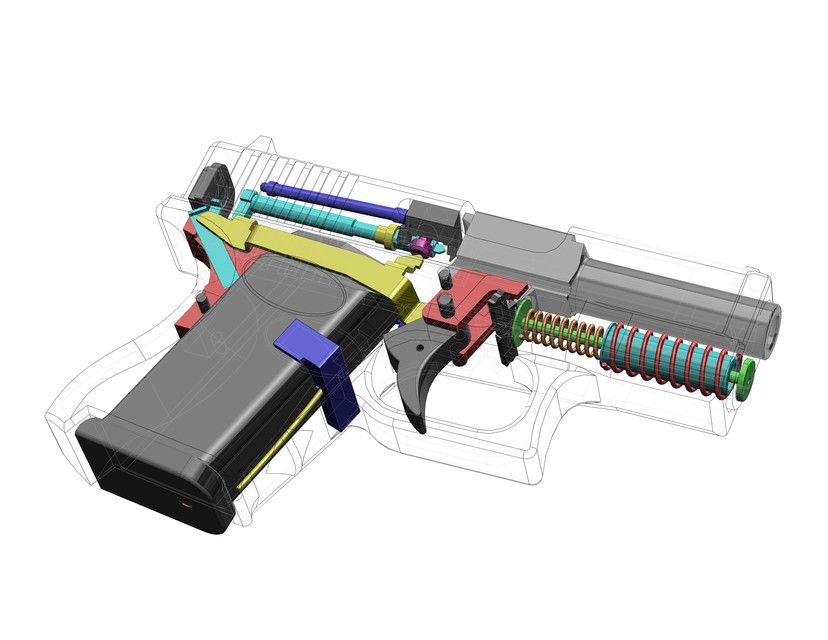

1911 Cutaway model (3D printable)

€2.60

PPSH-41 (3d print model)

€12.99

Desert Eagle 50AE (3D print model)

€11.97 -38% €7.42

EP-1 (3D print model)

€8. 09

09

1911 Commander (3d print model)

€6.43

STG-44 (3d print model)

€13.47

1911 Cutaway model (3D printable)

€2.60

Steyr Pistol 1912 (3d print model)

€6.43

PPSH-41 (3d print model)

€12.99

TT-33 (3d print model)

€6.43

Best 3D printer files of the Gadget category

DUAL GYRO WINDER / WATCH WINDER / WATCH WINDER

€2.50

Surprise Egg #14 - Tiny Dump Truck

Free

Hidden box for Tardis (box)

€0.93

Gameboy Button Faceplate For iPhone | GBA4iOS

Free

Tilt free GoPro

Free

Fish automaton

€2. 30

30

apple pencil holder

€1.40

Best sellers of the category Gadget

Air Vent Phone Holder for Car PRINT-IN-PLACE

€2.50

Range Cable

€0.50

Geared Box Print in Place

€3.50 -25% €2.62

FoldaBox Container - Print in Place

€1.36

App to turn your photo into 10 types of decoration

€3.50

PiPBOT 1 - Print in Place ROBOT

€4.66

Samsung Galaxy s23 ultra case set (3in1)

€2.30

Flexi Duck Print in place Multiparts

€2. 79

79

VALENTINE'S DAY FLEXI DUCK HEART GIFT BOX

€2.79

FLSUN V400 BELT GAUGE

€1

Italian hand

€1

App to create dual text illusion

€3.50

2-STROKE CYLINDER/PISTON WALL HANGER

€1.20

Bambu AMS Colour 2 Tier Stand (for 2 AMS Units 1 Above 1 Below)

€2.26

skeeride 2 dual spur gear transmission

€8.74

Chainsaw Man keychain - Pochita

€4

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

Here are 4 solutions accessible to all:

ADVERTISING: Disable your banner blocker (AdBlock, …) and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via Ko-Fi 💜.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

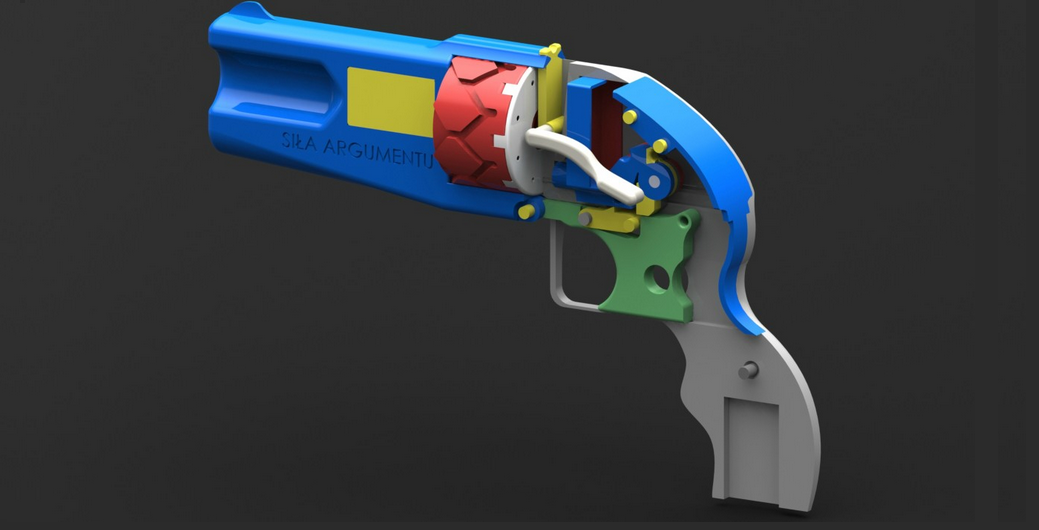

Deadly number: what the inventor of the world's first 3D gun is fighting for

Radical libertarian Cody Wilson 3D printed a full-fledged model of a pistol and was the first to test an innovative weapon. What threatens the world with his invention?

Order. One…two…” On the count of “three”, a gunshot shakes the peaceful Texas landscape. Tall, blond-haired engineer John has just pulled the end of a 6-meter yellow rope that has pulled the trigger for the world's first 3D printed gun. Bullet from 9 caliber ammunitionx17 mm flies into thickets of low dense bushes.

Tall, blond-haired engineer John has just pulled the end of a 6-meter yellow rope that has pulled the trigger for the world's first 3D printed gun. Bullet from 9 caliber ammunitionx17 mm flies into thickets of low dense bushes.

"First off!" shouts John, who asked me not to publish his full name. He hurries to check the weapon, mounted on an aluminum frame. But the tester is ahead of Cody Wilson, a tall, bristly man in a polo shirt and a baseball cap. John just pulled the trigger, while 25-year-old Wilson is the father and mastermind behind the breakthrough project. He spent more than a year perfecting his brainchild, which he named the Liberator after the cheap single-shot pistols of the Second World War. The "ancestor" of the innovative weapon was developed by the Allies specifically for dropping large batches from the air in the territory of occupied France.

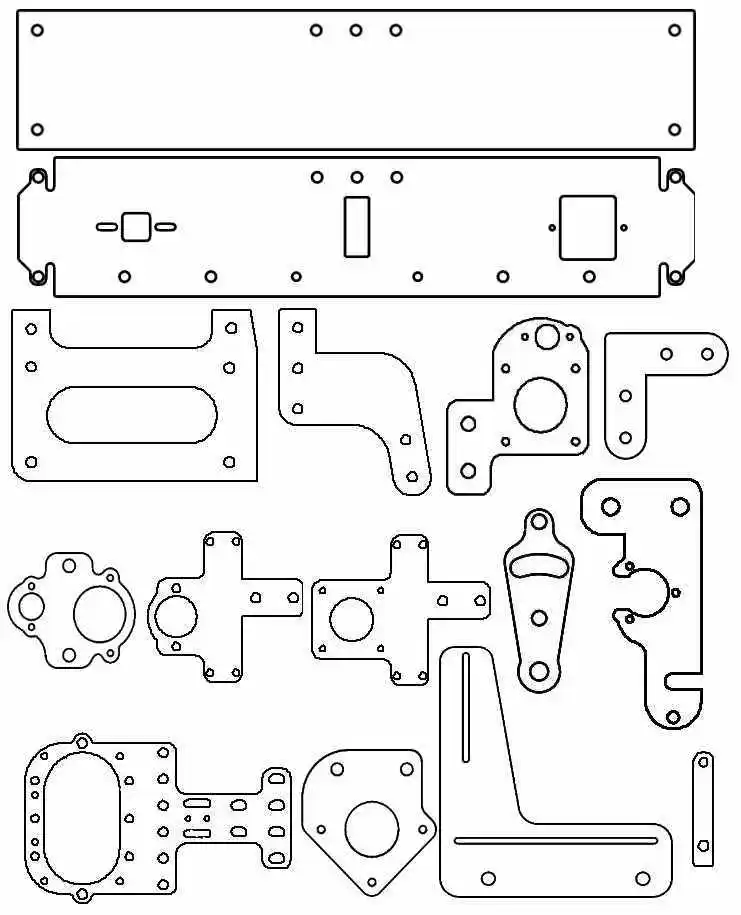

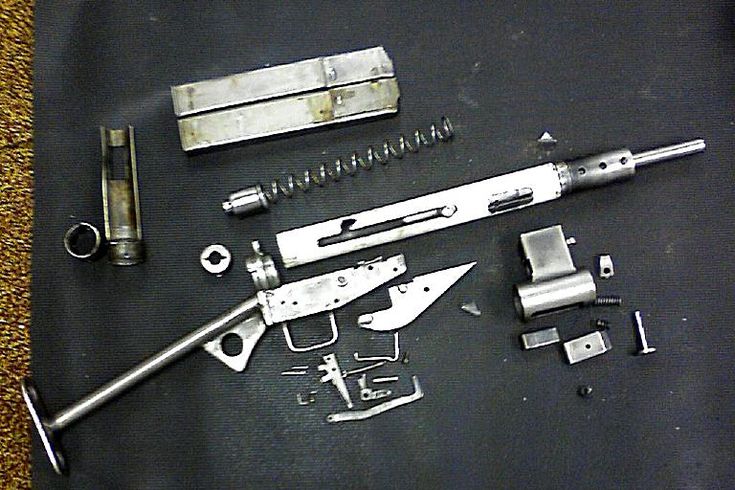

In contrast to the steel "original", the Wilson pistol is almost entirely made of thermoplastic: 15 of the 16 parts of the weapon are made of this material. They are all printed on a used $8,000 Stratasys Dimension industrial 3D printer. The developer made an exception for the striker, which was used as an ordinary nail.

They are all printed on a used $8,000 Stratasys Dimension industrial 3D printer. The developer made an exception for the striker, which was used as an ordinary nail.

Wilson leans over the gun and carefully examines the barrel. It took four hours to print the largest part. After the shot, both the barrel and the body of the pistol appear intact. After a few more seconds of visual analysis, the inventor states: “I think we did it.” There is a hint of skepticism in his voice.

In August 2012, Wilson, a University of Texas student and radical libertarian anarchist, cobbled together Defense Distributed, a non-profit organization in Austin, to develop a 3D weapon project available to anyone. Digital drawings of the pistol, which the creator called the Wiki Weapon in the drafts, can be found on the net and downloaded by every Internet user. This not only calls into question the existing parameters of the regulation of the arms market, but also exacerbates the conflict between the state and supporters of a free society. “You can print a deadly device. Sounds scary, but that's our goal. Wherever there is a computer and the Internet, users will have access to weapons,” explains Wilson.

“You can print a deadly device. Sounds scary, but that's our goal. Wherever there is a computer and the Internet, users will have access to weapons,” explains Wilson.

On May 1, 2013, he assembled the Liberator parts for the first time and agreed to have a Forbes photographer capture the components on camera. A day later, the pistol passed its first marksmanship test at a private property about an hour from Austin. I was also asked not to disclose the exact coordinates of the improvised training ground.

The verdict is this thing works. The pistol fired a standard 9x17 cartridge without any visible technical flaws. True, the first misfire also happened: the striker did not hit the primer and instead of a shot, only a dull thud was heard.

So far, the technology of weapons allows the use of only cartridges of a certain caliber. When Wilson tried to load a 5.7x28 mm caliber into the pistol, when the trigger was pressed, the Liberator simply blew up. So the debut tests of the invention ended “lethally”.

When Wilson tried to load a 5.7x28 mm caliber into the pistol, when the trigger was pressed, the Liberator simply blew up. So the debut tests of the invention ended “lethally”.

On the way home, Wilson did not look overly satisfied with the results of the tests, despite the relative success of the event. He preferred to focus on problems. The inventor himself set a deadline for himself by which he would have to bring to mind the drawings for the Internet. “I'm not quite happy yet,” he said. “We have a lot of work ahead of us.”

The most important Wiki Weapon test was days away. The "moment of truth" for the project in Wilson's understanding was to be a shot from the hand. After the prototype was torn to pieces before our eyes, this prospect looked really frightening.

When we published photos of the Liberator on Forbes on Friday, a real political battle unfolded around the project. Instead of debating the most promising 3D printing technology, the debaters focused on the terrorist potential of Wilson's invention. Congressman Steve Israel responded to the news from Defense Distributed with a legislative initiative to expand the Undetectable Firearm Act, which prohibits the circulation of firearms that cannot be detected by metal detectors. “Security departments, document checks and market regulation will do little to help us if criminals get the functionality to print plastic guns at home and smuggle them through frames,” the congressman said in a statement. Israel was supported by Senator Charles Schumer: "A terrorist, a mentally ill person or an adherent of radical ideas now has everything to equip a small arms factory in his garage."

Instead of debating the most promising 3D printing technology, the debaters focused on the terrorist potential of Wilson's invention. Congressman Steve Israel responded to the news from Defense Distributed with a legislative initiative to expand the Undetectable Firearm Act, which prohibits the circulation of firearms that cannot be detected by metal detectors. “Security departments, document checks and market regulation will do little to help us if criminals get the functionality to print plastic guns at home and smuggle them through frames,” the congressman said in a statement. Israel was supported by Senator Charles Schumer: "A terrorist, a mentally ill person or an adherent of radical ideas now has everything to equip a small arms factory in his garage."

Israel and Schumer are not the first opponents of Wilson's project. Back in August, the Defense Distributed fundraising campaign was curtailed by the administration of the crowdsourcing portal Indiegogo due to the odious nature of the startup. In October, 3D printer maker Stratasys confiscated a model leased by Wilson's team after learning of the lease's purpose. Twice inventors were kicked out of workshops where they worked on weapon designs. As a result, they had to huddle in a closet with an area of 3.5 square meters. m in a workshop on the southern outskirts of Austin. And this is without taking into account the fact that most of the space was taken up by a 3D printer resembling a modern refrigerator in size.

In October, 3D printer maker Stratasys confiscated a model leased by Wilson's team after learning of the lease's purpose. Twice inventors were kicked out of workshops where they worked on weapon designs. As a result, they had to huddle in a closet with an area of 3.5 square meters. m in a workshop on the southern outskirts of Austin. And this is without taking into account the fact that most of the space was taken up by a 3D printer resembling a modern refrigerator in size.

However, each new obstacle only spurred Wilson's enthusiasm. He raised funds for the implementation of the project using the digital currency Bitcoin, in which 99% of the assets of Defense Distributed are accumulated today. In March, the group received a federal license to manufacture weapons. The framed document now hangs on the wall of the miniature workshop. The inventor circumvented the dilemma with the Stealth Weapons Act by implanting a 170-gram steel cube into the case of the Liberator. A non-functional part does not burden the owner of the gun too much, and at the same time allows the metal detector to fix it. Wilson installed the $400 frame right at the entrance to the workshop. “Our strategy is to fully comply with all the requirements of the law,” he says (however, no one can give guarantees that users of Wilson’s instructions will also be able to install a metal die in their “liberators”).

A non-functional part does not burden the owner of the gun too much, and at the same time allows the metal detector to fix it. Wilson installed the $400 frame right at the entrance to the workshop. “Our strategy is to fully comply with all the requirements of the law,” he says (however, no one can give guarantees that users of Wilson’s instructions will also be able to install a metal die in their “liberators”).

The success of the first tests of the pistol will also silence the critics of the technical solution chosen by the inventor. Many skeptics have argued that plastic weapons will not withstand the pressure and temperature of cartridge case release and will deform or explode when fired. But Defense Distributed figured out how to solve a difficult problem. After testing at the test site, Wilson showed me a video in which a printed plastic barrel, mounted on a conventional body, fires ten rounds of 9 rounds in a row. x17 and only breaks on the eleventh lap.

x17 and only breaks on the eleventh lap.

The inventor admits that he himself does not fully understand how such an effect became possible. An important role could be played by the decision to first lower the barrel into a vessel with acetone. The chemical treatment of the weapon makes the terrain smoother and avoids additional friction. The printer model used by Defense Distributed also allows printing at 75 degrees Celsius. Stratasys' patented thermal technology gives the Liberator greater mechanical strength.

The goal of Defense Distributed is to adapt the technology to more affordable printer models, like Makerbot's $2200 Replicator and the even cheaper RepRap, built by enthusiasts and using free software. In case of damage to the barrel, Wilson has a way out: his pistol uses a removable barrel that can be changed within a few seconds.

The author of a deadly project does not care too much about the discussions around his invention. Last year's Massachusetts Sandy Hook massacre, when 20-year-old Adam Lanza single-handedly shot 12 children and 6 adults, only hastened Wilson's initiatives to circumvent federal gun bans. While Congress vetoed magazines with a capacity of more than 10 rounds, Defense Distributed introduced a 3D-printed 30-round magazine for AR-15 and Kalashnikov semi-automatic rifles. In March, Wilson and his associates posted a video on YouTube in which they proudly showed off a printed AR-15 receiver with a potential of several hundred shots. It is the turnover of receivers that is limited by American laws. It turns out that, using the advice of Defense Distributed, any owner of a 3D printer received instructions on how to get around the bans. All other parts of the rifle are easy to order by mail.

Last year's Massachusetts Sandy Hook massacre, when 20-year-old Adam Lanza single-handedly shot 12 children and 6 adults, only hastened Wilson's initiatives to circumvent federal gun bans. While Congress vetoed magazines with a capacity of more than 10 rounds, Defense Distributed introduced a 3D-printed 30-round magazine for AR-15 and Kalashnikov semi-automatic rifles. In March, Wilson and his associates posted a video on YouTube in which they proudly showed off a printed AR-15 receiver with a potential of several hundred shots. It is the turnover of receivers that is limited by American laws. It turns out that, using the advice of Defense Distributed, any owner of a 3D printer received instructions on how to get around the bans. All other parts of the rifle are easy to order by mail.

The figure of Wilson in connection with the growing arsenal of his inventions is increasingly criticized. Many opponents focus on the enthusiasm of the leader of the group, which today brings together about 15 volunteers - designers and engineers - around the world. The ambitious libertarian has already received a dozen death threats, and often anonymous spiteful critics promise to shoot the demiurge of a 3D weapon from his own brainchild. Wired magazine even included Wilson in the list of the 15 most dangerous people in the world. The Coalition to Stop Gun Violence labeled the inventor as an "ardent rebel" and advocate for anti-state violence. “This guy is actually sending the message ‘print your own guns and be prepared to kill civil servants,’” organization spokesman Ladd Everitt was categorical. “The fact that we still don’t talk about it in those terms even after the Boston bombing is unimaginable.”

The ambitious libertarian has already received a dozen death threats, and often anonymous spiteful critics promise to shoot the demiurge of a 3D weapon from his own brainchild. Wired magazine even included Wilson in the list of the 15 most dangerous people in the world. The Coalition to Stop Gun Violence labeled the inventor as an "ardent rebel" and advocate for anti-state violence. “This guy is actually sending the message ‘print your own guns and be prepared to kill civil servants,’” organization spokesman Ladd Everitt was categorical. “The fact that we still don’t talk about it in those terms even after the Boston bombing is unimaginable.”

Wilson dismisses suspicions of a desire to organize a rebellion. He sees the global goal of his activity in demonstrating the advantages of technology over the desire of the state to regulate the circulation of weapons. Ultimately, people must realize the helplessness and uselessness of the authorities in their current form. “We need to inspire the population to build their own independent space. The government will increasingly find itself overboard in private life and babble there: “Hey, wait a minute,” the inventor argues. “This is the beginning of a new order on the ruins of the old order.”

“We need to inspire the population to build their own independent space. The government will increasingly find itself overboard in private life and babble there: “Hey, wait a minute,” the inventor argues. “This is the beginning of a new order on the ruins of the old order.”

He does not deny that the 3D weapon could potentially be used for assassination or political violence: “I understand that the device can harm people. But listen, we are talking about weapons. I just don't think that's a strong enough reason to abandon our developments. Freedom is what really matters in this case.”

Wilson likes to think of his "Liberator" in the discourse of the history of the "ancestor" of the pistol. In the 1940s, American craftsmen created elementary weapons that were massively dropped from the air on the territories of the countries occupied by the Nazis. Partly in the plans of the allies at that time there was an idea not so much to arm the resistance as to demoralize the occupiers, to force them to be more careful. The ideologue of Defense Distributed hopes to do the same trick with modern state machines: “Then the enemy just watched the weapons drop from the air. Our possibilities are even wider. We have internet."

The ideologue of Defense Distributed hopes to do the same trick with modern state machines: “Then the enemy just watched the weapons drop from the air. Our possibilities are even wider. We have internet."

On a hot Sunday afternoon, Wilson returns to the Texas test site where he tested the Liberator prototype a couple of days ago. None of the Defense Distributed associates joined their leader this time, even engineer John left for a meeting of National Rifle Association activists in Houston at a historic moment. But next to the founder of the group is his father Dennis Wilson, a lawyer from Little Rock, who decided to become the only witness to the triumph of his son - the first ever shot from a 3D handgun.

The last couple of days the inventor spent on finalizing the Liberator's systems and printing out a new barrel and body to adjust the striker and minimize the threat of a second explosion. At the most crucial moment, Wilson becomes as focused as possible. His father asks how far it is from here to the nearest hospital: it turns out 45 minutes by car. We're learning how to apply a tourniquet in case things go wrong. “You guys want me to completely lose my nerves,” the protagonist of the day jokes in response.

At the most crucial moment, Wilson becomes as focused as possible. His father asks how far it is from here to the nearest hospital: it turns out 45 minutes by car. We're learning how to apply a tourniquet in case things go wrong. “You guys want me to completely lose my nerves,” the protagonist of the day jokes in response.

Gradually conversations recede into the background. Wilson opens the case with the printed parts and collects them, then loads the gun and puts earplugs in his ears. He holds his breath, aims, fires, and exhales sharply in relief.

“Awesome,” says Dennis. “Congratulations, son.”

Wilson feels much better. First of all, he shakes hands with his father, the shooter has no injuries. Then he studies the pistol, which passed the test with a single blot in the form of a crack on the firing pin.

For a few seconds, Wilson feels speechless. He hides his emotions behind sunglasses. Finally, he utters the phrase that first came to his mind: “Well, it seems that some changes are coming here.”

3D printing is becoming in demand in various fields

Fresh number

RG-Nedela

Rodina

thematic applications

Union

Fresh number

08/12/2013 12:09 9000

Category:

Society

3D printing promises a third industrial revolution

Yuri Medvedev

3D films have become a global event. But in fact, the real sensation today is ripening in a completely different area. So far, only narrow specialists know about it. It takes a few high-profile sensations to hit the masses. And recently, the first signs appeared: the American gunsmith Cody Wilson demonstrated a pistol, the main elements of which were printed on a 3D printer. The pistol is named "Liberator" in honor of the single-shot weapon used by the French resistance fighters during the Second World War.

The pistol is named "Liberator" in honor of the single-shot weapon used by the French resistance fighters during the Second World War.

Only the head of the pistol is made of metal, everything else is plastic. Several trial shots were fired from the weapon. American politicians have become alarmed and are already sounding the alarm, demanding a ban on the manufacture of weapons on 3D printers. After all, Wilson showed that, in principle, anyone can easily stamp such pistols, it is enough to buy a "printing" apparatus and a computer program that he developed.

Enthusiasts generally predict a fantastic future for 3D printing: the technology promises a revolution in many sectors of the economy, will lead to the third industrial revolution, profound changes in the entire life of society. Isn't it surprising that any person can make any thing at home according to his own taste.

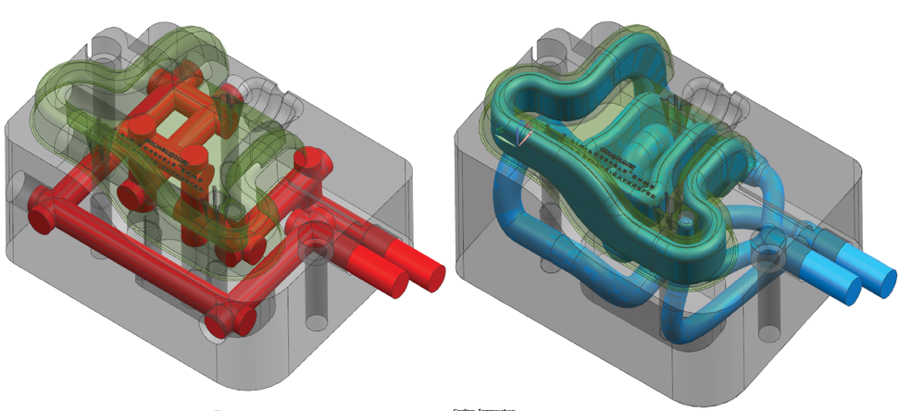

What is the essence of 3D printing? Today, the main method of manufacturing products is mechanical processing: everything superfluous is cut off, knocked out, drilled, etc. Up to 80-90 percent of materials go into shavings, a large amount of energy is consumed. The creation of a three-dimensional product is quite another matter, when with the help of a "printing" head, executing the commands of a computer program, the material is built up layer by layer until the structure acquires a given shape. This is somewhat reminiscent of squeezing the gel out of a tube or cream with a syringe. When the layer hardens, the next one is applied. Moreover, the product is immediately ready, it does not need to be assembled, all the details are in place. The material for such a printer can be polymers, metal powders, cement, sand, glass, ceramics, rubber, non-ferrous metals, composites, etc.

Up to 80-90 percent of materials go into shavings, a large amount of energy is consumed. The creation of a three-dimensional product is quite another matter, when with the help of a "printing" head, executing the commands of a computer program, the material is built up layer by layer until the structure acquires a given shape. This is somewhat reminiscent of squeezing the gel out of a tube or cream with a syringe. When the layer hardens, the next one is applied. Moreover, the product is immediately ready, it does not need to be assembled, all the details are in place. The material for such a printer can be polymers, metal powders, cement, sand, glass, ceramics, rubber, non-ferrous metals, composites, etc.

The advantages of the new technology are obvious: no waste, efficiency, speed, the ability to make the most complex parts in hours. But that is in the future as technology improves. So far, it has a number of disadvantages, in particular, it has low productivity, it cannot be used to create products with built-in electronic circuits, since the use of high temperature to solidify the layers burns out the electronics.

These problems are currently being tackled in the world's leading laboratories. And progress is fast. With the help of 3D printing, unique jewelry is already being made, shoes are being modeled, it has found its way into architecture and construction, in the automotive, aerospace and medical industries. For example, the famous companies Boeing and General Electric have already begun to use 3D printing in a number of their industries. This is especially true for parts for unmanned aircraft. And British scientists have already tested the world's first printed drone. European aerospace concern EADS has created a nylon bike that you can ride.

But, perhaps, this method is most widely used today in dentistry and orthopedics to create implants. By the way, such "prostheses" are already much cheaper than those made using traditional methods. So, an 83-year-old resident of Holland was implanted with a titanium jaw printed on a printer, and in Germany, surgeons replaced 75 percent of the skull with a plastic prosthesis made on a 3D printer.

Princeton University scientists 3D printed an ear out of calf cells, a polymer gel and silver nanoparticles. It is able to perceive radio waves that are outside the range of human hearing. The ear can be directly connected to the neurons of the brain. But science goes further. A 3D bioprinter has already been created that can print human tissues from stem cells, and in the future, scientists intend to grow whole organs in this way.

3D printing has also entered the fashion world. At this year's Paris Fashion Week, the main sensation was dresses of stunning complexity made from a new experimental material. The accuracy of the lace seamless structure can only be ensured by 3D printing.

The world's first 3D printed violin has become a real sensation. It was created by American Alex Davis. Of course, this is not a Stradivarius, but for a homemade musical instrument it is quite good. And enthusiasts of new technology are looking forward to another sensation, which this time should happen in construction. Already by the end of this year, scientists intend to print a building about three meters high in Holland. To do this, a huge 3D printer is created, resembling an overhead crane. The walls will be built with the help of a machine from ceramic material in layers, and immediately taking into account all communications: electrical wiring, ventilation, sewerage. Estimates show that the cost of the house will be 30-50 percent lower than with the manual version, and it is built four times faster.

Already by the end of this year, scientists intend to print a building about three meters high in Holland. To do this, a huge 3D printer is created, resembling an overhead crane. The walls will be built with the help of a machine from ceramic material in layers, and immediately taking into account all communications: electrical wiring, ventilation, sewerage. Estimates show that the cost of the house will be 30-50 percent lower than with the manual version, and it is built four times faster.

Of course, this is a breakthrough. This means that in the near future, in order to build a house, a person will not need to call workers and construction equipment. All you need is a robot that will print the building according to the program that you have chosen on the Internet. Moreover, you can furnish the house with furniture that also came out of a 3D printer. All this will be on the shoulder of any person.

For a long time, the cost of 3D printing "bited", so this technology was available only to the "chosen ones".