3D printed house nantes

A French family is the first to move into a 3D printed house

0Shares

The Ramdani family has become the world’s first inhabitants of a 3D printed four-bedroom house located in Nantes, France.

This house is part of the social housing project, Yhnova, which aims to construct affordable, adaptable, and energy efficient housing in a time and cost-effective manner.

Led by the University of Nantes (IUT), the Yhnova project was completed under a consortium of scientists, manufacturers, and public and socio-economic actors who are now planning to create a suburban neighborhood using the same building principles.

The 3D printed house in Nantes. Photo via BBC.The success of project Yhnova

Last year, the Yhnova project began breaking ground in a deprived neighbourhood in the north of the Nantes to prepare for the construction of the 3D printed house. IUT Professor and Project Manager, Benoit Furet’s concept for this house was to fully realise an architect’s vision using innovative and disruptive manufacturing technology.

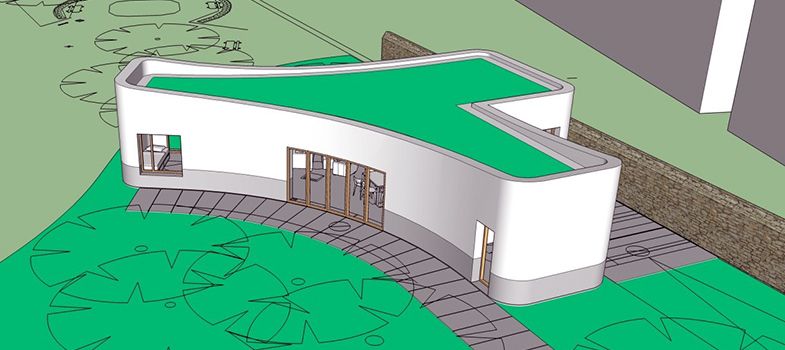

“The advantage of 3D printing is that it enables us to have far richer solutions in terms of the shape of the house. It’s much more interesting to architects than the traditional building of straight walls.”

With the freedom allowed by their patented 3D printing technology, BatiPrint3D, the arched walls designs were able to improve thermal resistance, air circulation, and create a wheelchair accessible layout within the house. The 3D printed house was also built to curve around 100-year-old protected trees on the plot.

Overall the 95 metre house took 54 hours to print, excluding the four months taken for contractors to fit windows, doors and roof fixtures. The building cost of the house totalled an estimated £176,000, which is 20% cheaper than an identical construction with traditional methods.

“It’s a big honour to be a part of this project,” stated Nordine and Nouria Ramdani, the chosen family that will be living in the 3D printed house along with their three children.

“We lived in a block of council flats from the 60s, so it’s a big change for us. It’s really something amazing to be able to live in a place where there is a garden, and to have a detached house.”

Nordine and Nouria Ramdani, residents of the 3D printed house. Photo via BBC.The Batiprint3D process

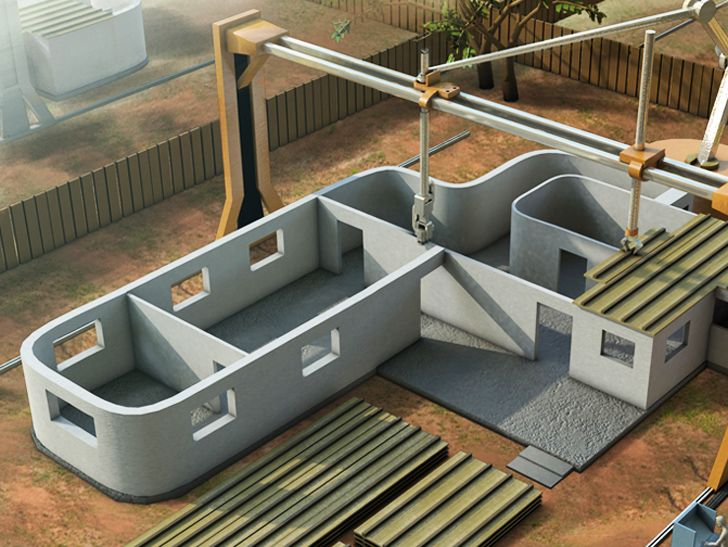

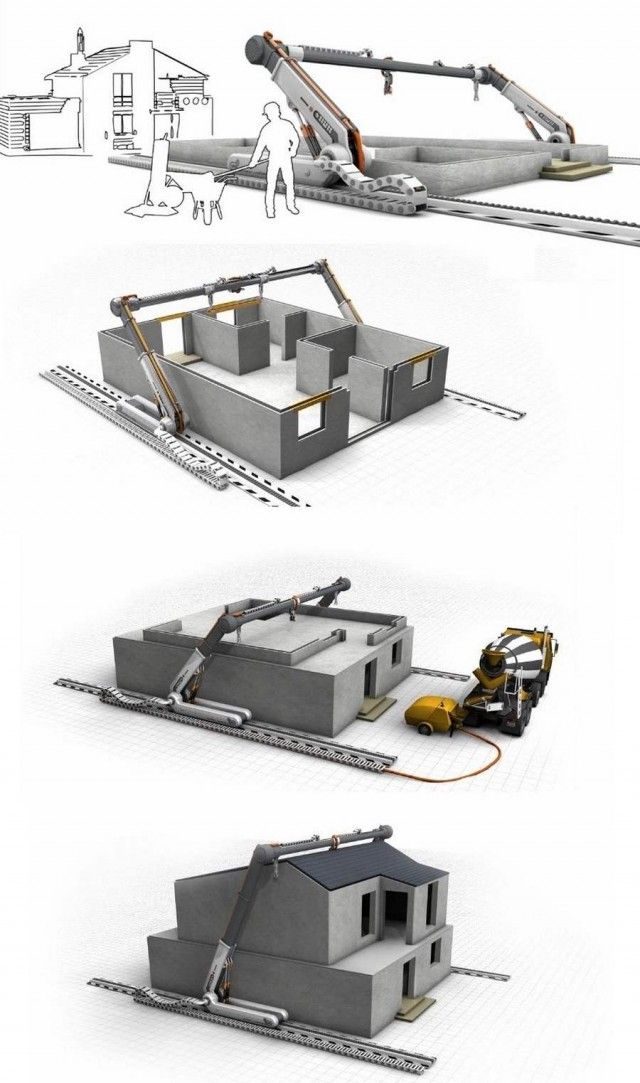

3D printing for construction and building continues to be used in various ways to create unique houses and structures. Construction companies are using methods that directly deposit cement onto the desired foundation to create building structures, as seen with Contour Crafting. However, the BatiPrint3D method, developed by researchers at IUT, prints parallel layers of insulator polyurethane that is then filled in the middle with cement.

The robotic arm constructs the thick, insulated, and fully-durable walls in the predetermined shape for the house.

Stage 1 of construction for the 3D printed house. The space in-between the two printer blocks is filled with cement to form the wall. Photo via BBC.

Photo via BBC.A 3D printed suburban neighbourhood

With the successful completion of the Yhnova project, Professor Furet is now planning to 3D print 18 houses in the north of Paris to further improve the social housing conditions of residents within the area.

“Social housing is something that touches me personally,” said Professor Furet. “I was born in a working-class town and lived in a little house. My parents – who are very old now – still live in the same house [where] the street is a row of little houses, one next to the other, all identical.”

Due to the advancements in their BatiPrint3D technology, Professor Furet also believes that his team can reduce the cost of the construction of such houses by 25% in five years and by 40% in 10 to 15 years. Franky Trichet, the Deputy Mayor of the City of Nantes has confidence in the application of this technology for the economical future of French cities.

“The future of the project from the perspective of the town is two-fold. The first is to see whether we can mainstream this type of construction. The second objective for us is to see if we can apply these construction principles for other types of public buildings – like sports halls or communal buildings.”

The first is to see whether we can mainstream this type of construction. The second objective for us is to see if we can apply these construction principles for other types of public buildings – like sports halls or communal buildings.”

The team now believe they could print the same house again in 33 hours.

Keep up with the latest in 3D printing by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Need a change of pace? Seeking new talent for your business? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the 3D printed house in Nantes. Photo via BBC.

Tags Batiprint3D Benoit Furet Franky Trichet Ramdani family University of Nantes

Tia Vialva

Tia holds a BA in journalism, and has a background in writing news and features and is a senior journalist at 3D printing industry.

French Family Is First to Live in 3D-Printed Home

French Family Is First to Live in 3D-Printed Home Search iconA magnifying glass. It indicates, "Click to perform a search". Insider logoThe word "Insider".US Markets Loading... H M S In the news

Chevron iconIt indicates an expandable section or menu, or sometimes previous / next navigation options.HOMEPAGEScience

Save Article IconA bookmarkShare iconAn curved arrow pointing right.Download the app

Nantes MetropoleEngineers and manufacturers have been working to automate the homebuilding process for years, and some startups have already released prototypes of their designs. Until this year, however, nobody has lived in any of these prototypes.

Until this year, however, nobody has lived in any of these prototypes.

This summer, a five-person family in France became the first to permanently live in a 3D-printed home. The 1,022-square-foot home, part of the "Yhnova" project, is located in Nantes.

Below, take a look at the building's construction process and photos of other startups' designs for 3D-printed homes.

Yhnova was printed in 54 hours, and contractors spent the next four months adding windows, doors, and the roof.

People walk past a placard showing the construction site of a 3D printed social housing building called "Yhnova," in Nantes, France, on September 19, 2017. Stephane Mahe/ReutersThe home was developed by University of Nantes researchers. According to BBC, they believe the next 3D-printed home could be built in 33 hours.

According to BBC, they believe the next 3D-printed home could be built in 33 hours.

Construction of the building cost about $232,000, which is 20% cheaper than a similarly sized building would usually cost, BBC reported.

The University of Nantes teamed up with the city council and a local housing association to create the house.

An employee works to build a 3D printed social housing building in Nantes, France, on September 19, 2017. Stephane Mahe/ReutersFrancky Trichet, technology and innovation lead at the Nantes city council, told BBC that he is interested in 3D-printing more than just homes. For example, the technology could be applied to sports halls, he said.

For example, the technology could be applied to sports halls, he said.

Yhnova was partly funded by the Nantes city council.

University of Nantes professor Benoit Furet, who is leading the project, told BBC he expects the 3D printing process to become much less expensive in a few years.

Polyurethane and concrete are pictured as an employee works to build Yhnova on September 19, 2017. Stephane Mahe/ReutersIn five years, Furet said, building 3D homes will be 25% cheaper. As more houses are built and the technology improves, he expects the cost to be 40% cheaper a decade from now, all while adhering to building codes.

As more houses are built and the technology improves, he expects the cost to be 40% cheaper a decade from now, all while adhering to building codes.

Furet said 3D printing is environmentally friendly and allows architects to be creative.

An employee works to build a 3D printed social housing building called "Yhnova", using a construction 3D printing technique known as BatiPrint3D and developed by researchers from the University of Nantes, in Nantes, France, September 19, 2017. Stephane Mahe/ReutersArchitects can adjust a 3D-printed house's shape to the surrounding area. In Nantes, for instance, the house was built to curve around century-old trees on the property.

In Nantes, for instance, the house was built to curve around century-old trees on the property.

In addition, the home is equipped with sensors that monitor humidity, air quality, and temperature, all of which help reduce energy costs.

Furet said he hopes to build an entire neighborhood of 3D-printed homes next. According to BBC, Furet is working on an 18-house project in Paris and a roughly 7,500-square-foot commercial building.

Another group of developers is working on bringing 3D-printed homes to the Netherlands.

Houben / Van MierloIn a project led by Eindhoven University of Technology and its partners, five concrete houses are set to be built in the Dutch city of Eindhoven.

Project Milestone's first goal is to build a single-story house, after which the developers will focus on building homes as tall as three stories.

Business Insider previously reported that the Project Milestone team said 3D printing allows houses to be customized and reduces waste, as it requires fewer building materials.

A Nevada-based company is also printing houses, with plans for Bay Area customers to begin living in them in a few months.

PassivDomThe homebuilding startup PassivDom uses a robot to print the walls, floor, and roof of a new home, after which a human worker adds the windows, doors, plumbing, and electrical systems.

PassivDom will offer a few different models that vary in size and technical features. The houses do not need to connect to external plumbing or electrical systems, as solar energy is stored in a battery connected to the house. Water is collected from humidity in the air.

The company initially intended to deliver the first 100 homes to customers in January 2018, but founder and CEO Max Gerbut told Business Insider that production and development took longer than anticipated.

Gerbut said customers worldwide have requested more than 10,000 PassivDom units, and the company aims to be the first autonomous, self-sustainable home in the United States.

And in Chattanooga, Tennessee, architectural company Branch Technology is building its own prototype of a 3D-printed home.

Branch TechnologyBranch Technology uses machines to print the walls and roof of its model, which is called Curve Appeal. A construction crew then assembles the parts on-site.

A construction crew then assembles the parts on-site.

Curve Appeal, designed to span 1,000 square feet, will include a bedroom, living room, and bathroom. The project is still in the research and development phase.

Branch's machines, unlike many 3D printers, do not build layer-by-layer. Instead, the robots create lattices that are filled with liquid foam and concrete. David Fuehrer, Branch's director of sales, said the the homes will be three or four times stronger than wood buildings because of this method.

After finishing the project, Branch plans on donating the home to Chattanooga State Community College, which will hold classes inside.

Read next

LoadingSomething is loading.

Thanks for signing up!

Access your favorite topics in a personalized feed while you're on the go.

Features BI Innovation 3D PrintingMore...

How the Nantes team's 3D printing can change the shape of a house

3D construction is the most promising direction in contemporary architecture. A new 3D printed house from France proves this claim.

Within a few months, a 3D printed house being built in the city of Nantes attracted a lot of attention, not only because a 3D printer was involved, but also because the construction took 54 hours, plus a little more time for windows and roofs.

3D printed house in Nantes

A robot printer was used to print floor-to-ceiling layers to form the walls, and the videos show a beautiful result of five rooms with rounded walls.

The latest news is that the first family in the world will live in a 3D printed house, it will be the Ramdani family, consisting of two parents and their 3 children, who will enjoy life in a 4 bedroom house in Nantes, France.

Costs

Project leader Benoît Furet, professor at the University of Nantes, presented the costs of a house in his report. “He believes that in five years they will be able to reduce the cost of building such houses by 25% while complying with building codes and by 40% in 10-15 years.” The reasons why prices for 3D printed houses will decrease is the systematic evolution of technology.

House 95 m 2 was built so as not to affect the 100-year-old protected trees on the site. This points to a key benefit of using 3D printing to build unusual architectural forms, and the creative experience opens up a lot of possibilities for architects outside of the straight-walled box of traditional designs.

Contemporary creative limitations are especially evident in traditional housing. High-rise buildings are more like prison cells, blocking the natural environment.

The project leader said that 3D printing allows for more interesting solutions for new house shapes. Curved walls are not only pleasing to the eye, but also have practical advantages. The curved shape also improves air circulation in the home, reducing humidity and improving heat resistance.

How the house was built

Each wall of the 3D house consists of two layers of insulating polyurethane with an intermediate layer filled with cement. Then the windows, doors and roof are installed. The house has an IoT system with which residents can control the temperature and other functions through a tablet.

Nantes officials are interested in 3D printing houses - can the same construction principles be applied to other public buildings such as sports halls? Can such technologies affect the construction industry?

Only time will tell. In the meantime, a robot printer prints 18 houses and a commercial building in the north of Paris. published by econet.ru

In the meantime, a robot printer prints 18 houses and a commercial building in the north of Paris. published by econet.ru

If you have any questions on this topic, ask them to specialists and readers of our project here.

P.S. And remember, just by changing your consumption, we are changing the world together! © econet

Read an article about the first 3D printed houses?

3D printing has been used in construction for several years now. In this article, you will learn about the first real houses printed on 3D printers.

3D printing of houses is still quite new to the layman. While construction 3D printing technologies have been developed for many years, only a few "real" projects have already seen the light of day. We are still far from technology taking over conventional construction methods. But with each new project, she is getting closer to becoming mainstream.

But with each new project, she is getting closer to becoming mainstream.

3D printing has many advantages. For example, the cost of a 3D printed house can be much lower. And it will take much less time to build.

In order to draw a line under what has already been achieved in this area and show some interesting projects, we have devoted an article to the "first" and the best. These projects will always remain milestones in the 3D construction printing industry as they set the stage for future advances in the field.

Germany's first 3D printed house

Germany is a country often associated with cutting edge engineering, so let's start our list with Germany's first ever 3D printed house.

The house itself is located in Beckum, a city that is partly located in North Rhine-Westphalia, next to Holland and Belgium. This is the first 3D printed house to be fully certified to official building codes. This project will give way to many other 3D printed construction projects in Germany as well as the rest of Europe.

The project is the result of a collaboration between German construction company Peri and Danish construction 3D printing firm COBOD. Peri is a large corporation that operates not only in Germany, but throughout the EU. Its portfolio includes many products, including scaffolding and formwork solutions that every construction site needs.

Peri followed the construction 3D printing segment for years before acquiring a stake in COBOD in 2018. Now they are pushing the technology together and further. The construction of the house in Beckum began two years after the acquisition of the share.

For 3D printing at home, a BOD2 modular 3D printer from COBOD was used. The printing itself took just over 100 hours.

• Built: (started) September 17, 2020

• Commissioned: summer 2021

• Where: Beckum, North Rhine-Westphalia, Germany

• By: Peri, COBOD

First occupied 3D printed home in the US

Several homes have been printed in the US, but this home is the first officially occupied home, according to CNN. Its creators: the construction company Alquist and the humanitarian organization Habitat for Humanity Peninsula.

Its creators: the construction company Alquist and the humanitarian organization Habitat for Humanity Peninsula.

From afar, you might think that this is an ordinary house. However, when approaching it, the layered structure of the concrete walls becomes noticeable. After all, 3D printing creates an object in layers.

Surprisingly, the 111.5 square meter concrete structure of the house (was printed in about 12 hours, significantly faster than traditional construction methods would allow.

The house was reportedly bought by April Springfield, who lives there with her son and dog She bought the house through Habitat for Humanity's housing program, and given that the nonprofit's goal is to help solve the global housing crisis, it makes sense to use 3D printing to create affordable homes that will make many people's dreams of home ownership come true.0003

• Built: 2021

• Commissioned: December 22, 2021

• Where: Williamsburg, Virginia, USA

• By: Alquist 3D, Habitat for Humanity Peninsula, Greater Williamsburg

The first five-story 3D printed house

This project, made by the Chinese company WinSun, is a real record holder. It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

The house is located in Suzhou Industrial Park in Jiangsu province in eastern China. It stands next to a mansion that was also built by WinSun using a concrete 3D printer.

Looking at WinSun designs, you can't help but notice that they don't look like they've been 3D printed. Usually 3D printed structures are gray in color, the layer lines are clearly visible. But WinSun adds color and makes walls smoother. Nowhere is it stated how the company achieves the smoothness of the walls, but we assume that the workers smooth them by hand. WinSun projects are not like the ones we're used to.

• Built: Winter 2014

• Commissioned: Not specified

• Where: Suzhou, Jiangsu, China

• By: WinSun

First 3D printed biodegradable house

Can you guess that there is rice in the walls of this house?

Most 3D printed buildings are made from concrete mix. But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste.

But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste.

WASP developed the sustainable blend in collaboration with Ricehouse, a company that specializes in using natural and agricultural materials such as clay and rice in construction.

The house is named Gaia in honor of the ancient Greek goddess of the earth. In fact, 25% of the mixture contains local soil, 10% hydraulic lime, 25% rice husks and 40% crushed rice straw (a by-product of rice production at harvest).

An innovative solution not only in terms of material, but also in the design of the walls themselves. The specific corrugated structure was used to provide ventilation on warm days as well as insulation on cold periods, virtually eliminating the need for air conditioning.

Gay's house is small - about 20 square meters. The wall printing took only 10 days, while the estimated materials cost is just under $1,000.

• Built: not specified

• Commissioned: October 7, 2018

• Where: Massa Lombarda, Ravenna, Italy

• By: WASP, Ricehouse

AirBnB's first 3D printed home

The perfect weekend getaway.

You can find many different types of accommodation on AirBnB, but what about a 3D printed home?

The so-called Fibonacci house is the first 3D printed house to be offered for booking through AirBnB. Considering that it is located in rural British Columbia, it will be a wonderful place to stay.

Although the Fibonacci house looks small, it has a lot to offer vacationers. About 35 square meters is enough to accommodate up to four people.

The concrete walls of the house were designed and printed by Dutch 3D printing firm Twente. 20 concrete parts were produced offsite in just 11 days. The material was produced by Laticrete. The parts were later transported and assembled at their current location.

• Built: 2020

• Commissioned: Not specified

• Where: Kootenays, British Columbia, Canada

• By: Twente Additive Manufacturing

First 3D printed houseboat

Prvok is not only the first 3D printed house in the Czech Republic, but the world's first floating 3D printed house on a pontoon.

The project was implemented by the start-up company Scoolpt. The concrete structure of the houseboat took only 22 hours to print.

Approximately 43 square meters of living space divided into bathroom, bedroom and living room with kitchen. Weight isn't usually discussed in the context of houses, but given that this one is on water, it's interesting to note that Prvok weighs 43 tons.

The house is equipped with a built-in recirculating shower and tanks for drinking and municipal water and has a service life of at least 100 years.

• Built: June 2020

• Commissioned: August 18, 2020

• Where: Prague, Czech Republic

• By: Scoolpt

Europe's first 3D printed residential house

Not every 3D printed house has visible line layers.

More often than not, 3D printed houses are demos made to show what the technology can do. For most of them there is no information about the actual residents. But in 2017, the couple did move to live in a 3D printed house located in Nantes, France. Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe.

Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe.

The house is a project of the University and the Laboratory of Digital Sciences of Nantes. An interesting aspect of the project is the special technique used in its construction by BatiPrint3D. Instead of 3D printing a concrete structure, the robotic arm created wall shells using polyurethane, a material used for insulation. Later, these membranes were filled with concrete.

It took a total of 54 hours to print. It took a little over 4 months to complete the construction. Mainly due to the fact that the rest of the components were created using conventional means. House area - 95 square meters.

• Built: 2017

• Commissioned: March 2018

• Where: Nantes, France

• By: University of Nantes, Nantes Digital Science Lab

India's first 3D printed house

This building was built in a couple of days.

India's first ever 3D printed house was completed back in 2020. The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building.

The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building.

The significance of this project lies in its possible impact on the solution of the housing crisis worldwide and in India in particular. The ability to build such a house within a few days and at a low cost cannot be underestimated.

House 55.7 sq.m. with a spacious layout, one bedroom, combined kitchen and living room.

The concrete structure of the house was 3D printed off site and the parts were later transported and assembled on campus. The foundation, meanwhile, was built using the conventional method of pouring concrete into the ground.

• Built: 2020

• Commissioned: Not specified

• Where: Chennai, India

• By: Tvasta Construction

Africa's first 3D printed house

Back in 2019, in the Moroccan city of Ben Guerir, Spanish firm Be More 3D created Africa's first 3D printed house. The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses.

The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses.

Be More 3D printed house 32 sq.m. in about 12 hours, took first place and received the title of the most innovative startup.

Be More 3D didn't stop building in Africa and later created the first 3D printed house in Spain and developed its own concrete 3D printer in partnership with several corporations from the automation and materials industries.

• Built: 2019

• Commissioned: Not specified

• Where: Ben Guerir, Morocco

• By: Be More 3D

First 3D printed home for sale in the US

Last on our list is the first 3D printed home for sale in the US.

This house was printed in the same place by SQ4D, a company specializing in the development of robotic building systems. The building was printed with SQ4D's Arcs concrete extrusion system and has a 50-year warranty on the printed structure.