3D printed knee brace

How GRD Biomechanics Creates Custom Knee Braces With 3D Printing

While studying engineering in college, Mike Geldart suffered a significant knee injury in a racing accident. After surgery, he was given a knee brace that was stiff, didn’t properly fit, and was inadequate for a fast recovery.

Now CEO of GRD Biomechanics, Geldart is turning his frustrating recovery experience into action by creating a truly innovative knee brace. Designed with 3D printing, the knee brace enables faster recovery times and reduces surgeries for early patients. In this post, Geldart explains why 3D printing is empowering the next generation of medical applications for lower-limb recovery.

Basic care for lower limb recovery has seen little change in 50 years, with current leg braces being made of simple metal frames, foam, and plastic parts. The goal of these devices is simple: to hold the patient's leg in place until it heals. According to Geldart, this view of bone and muscle healing isn’t based on solid evidence. “These devices offer long lead times, suboptimal experience, and they are not terribly effective at healing the patient,” he said.

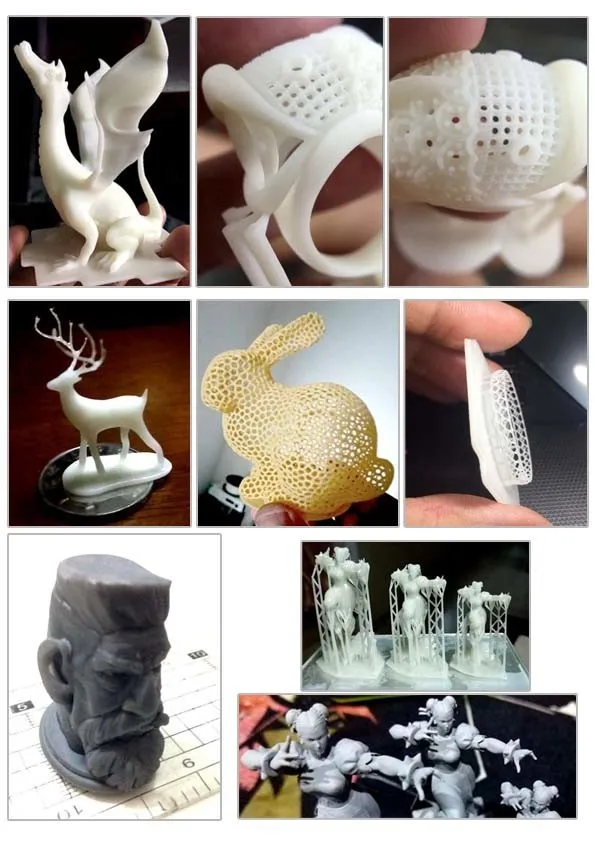

In order to change how the market thinks about leg and knee recovery, the GRD team began prototyping dozens of new devices aimed at strengthening muscles instead of reducing patient movement. Over time the team settled on combining 3D printing molds alongside 3D printing end-use parts to help create a state of the knee exoskeleton, which they are calling the Ascend Knee Brace.

The main strap that holds the Ascend onto the leg is an end-use part printed directly with Tough 2000 Resin. This part is put under constant stress, adjusted by the patient everyday, and is exposed to daily wear and tear. Due to the shape of the strap, Geldart said “it would be difficult to machine or mold this part, so we print it directly on the Form 3.”

The ability to print functional end-use parts is a significant cost and time saver for a small business. According to Geldart, “this clip would be near impossible to injection mold, and even if we could do it, it would burn through our working capital. Using the Form 3, we are making more complex geometries that suit each application, and we are doing it for less money.”

Using the Form 3, we are making more complex geometries that suit each application, and we are doing it for less money.”

Geldart’s team also prints molds for two interior hinges. This allows the team to access small-batch production with their 3D printer, guaranteeing affordability despite each patient requiring a custom brace. Using these two methods - end use production and 3D printed molds - show the versatility of in-house printing for start-ups such as GRD. For patients, this means that it is feasible, for the first time, to have access to truly customized medical solutions, accelerating recovery times.

When looking to invest in a new 3D printer, Geldart considers a couple of vital components, with material properties of the materials being most important. For Ascend, the design requirements come directly from each customer, and so there can be no compromise. The goal is for each Ascend to be a perfect fit. Parts must be durable, but not fragile, flexible, but strong. Each brace calls for parts of different material properties, meaning a 3D printer must be able to handle multiple requirements.

Each brace calls for parts of different material properties, meaning a 3D printer must be able to handle multiple requirements.

Small businesses are acutely aware of wasted time and resources, which for GRD can potentially dampen relationships with doctors and patients who are waiting for brace. That’s why the second most important trait Geldart looks for is reliability. He said, “we can’t use a printer that gets 18 or 20 hours into a print and fails. We are looking for a printer that will, in part, be used for production. So we want a reliable printer that can handle running 24 hours per day.”

The company has seen early success with Ascend. In one case, a young woman was heading toward her fifth knee surgery before being put in touch with GRD. They created a patient-specific brace, and the surgery was cancelled. The patient quickly recovered, saving her time and money by skipping the fifth surgery. Quicker recovery times also free up healthcare professionals to focus on other patients, eliminating multiple unnecessary surgeries for the same patient.

Knee braces are especially important for runners. One patient GRD worked with had suffered from runners' knees for years. After using the Ascend, he was able to run five miles without serious pain. This type of patient outcome is only possible with cutting edge customer specific medical devices.

One day, Geldart expects to see these types of stories become commonplace. “I think the market is heading toward a blend of standardized production and customization. We envision a world where we can manufacture to design instead of design to manufacture. Right now we are making more complex geometries that suit the application requirements, and we are doing it for less money than traditional manufacturing.” Until then, he expects to continue to refine his design with relentless prototyping and R&D, saying “I’ve lost count of how many prototypes we have created. 3D printing allows use, effectively, to make endless prototypes until we get the part exactly right.”

GRD used both the Form 2 and Form 3 for their parts.%20(1).jpg)

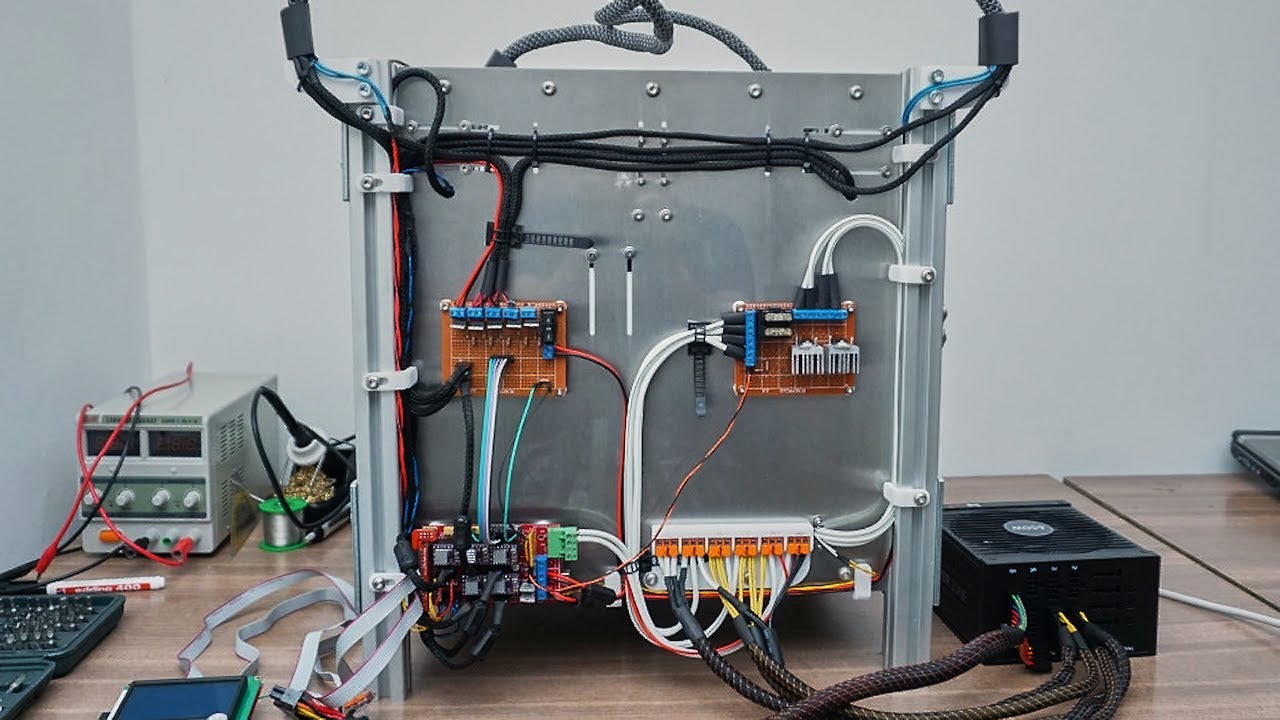

Currently, the GRD team has four Form 3s and three Form 2s. This allows for flexibility, running all seven printers at once for maximum productivity when demand is high, or to reserve a few printers for R&D. Right now, the team is happy with their fleet of SLA printers, but are always eyeing future expansion. According to Geldart, “we are interested in Nylon printing and Fuse 1. Right now they are using Nylon parts on the base of the brace, and we see room to explore and expand in that area.”

Looking to learn more about the Form 3? Request a free sample part in Tough 2000, the same material used by GRD on the Ascend.

3D Printed Knee Brace for the Elderly is Lightweight and Tailored - 3DPrint.com

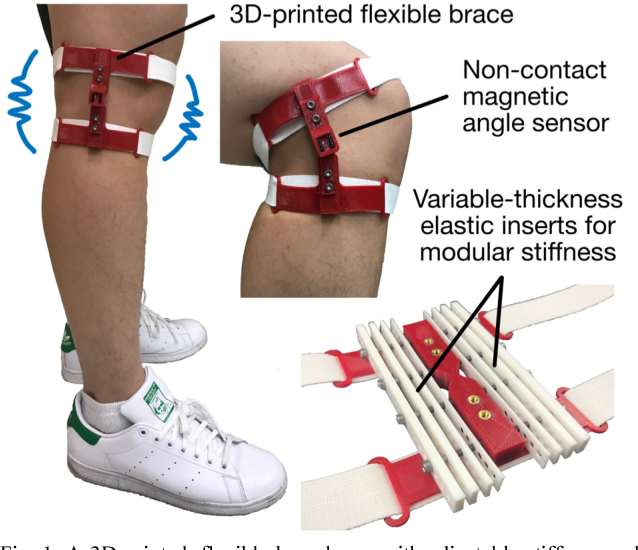

Nanyang Technological University (NTU) researchers—along with Singapore’s National Additive Manufacturing Innovation Cluster (NAMIC), material supplier Delsson and the sports medicine-focused Centre for Orthopaedics—have developed a lightweight, 3D printed knee brace. The brace weighs 720 grams, 30% lighter than traditionally made counterparts, and could help relieve the suffering of many elderly individuals afflicted with knee osteoarthritis. Moreover, the brace’s resistance for the wearer can be customised from between 6 and 32 Kilos.

The brace weighs 720 grams, 30% lighter than traditionally made counterparts, and could help relieve the suffering of many elderly individuals afflicted with knee osteoarthritis. Moreover, the brace’s resistance for the wearer can be customised from between 6 and 32 Kilos.

The team behind the X-Brace say that the device is reminiscent of one Batman uses in the Dark Night Rises. In addition to being 3D printed and lighter overall, the key advantage of the X-Brace is that the resistance can be customized to the patient. In this way, the knee can be set to stop extension of the knee beyond a certain angle. The spring tension can be adjusted to accommodate someone’s recovery, as well ,with doctors or physiotherapists changing spring tension at will according to the patent’s needs. In addition to individuals suffering from osteoarthritis, it could also aid those who have undergone knee surgeries or have issues with torn ligaments.

The brace was designed by Joel Lim, an NTU PhD Student working with NTU Assistant Professor Chan Wai Lee. Above, Professor Chan Was Lee is seated with the prototype, Joel Lim is standing and holding another prototype, as Centre for Orthopaedics Chairman Dr Jeffery Chew looks on and Delsson Executive Director Fabian Ong holds the final production knee brace.

Above, Professor Chan Was Lee is seated with the prototype, Joel Lim is standing and holding another prototype, as Centre for Orthopaedics Chairman Dr Jeffery Chew looks on and Delsson Executive Director Fabian Ong holds the final production knee brace.

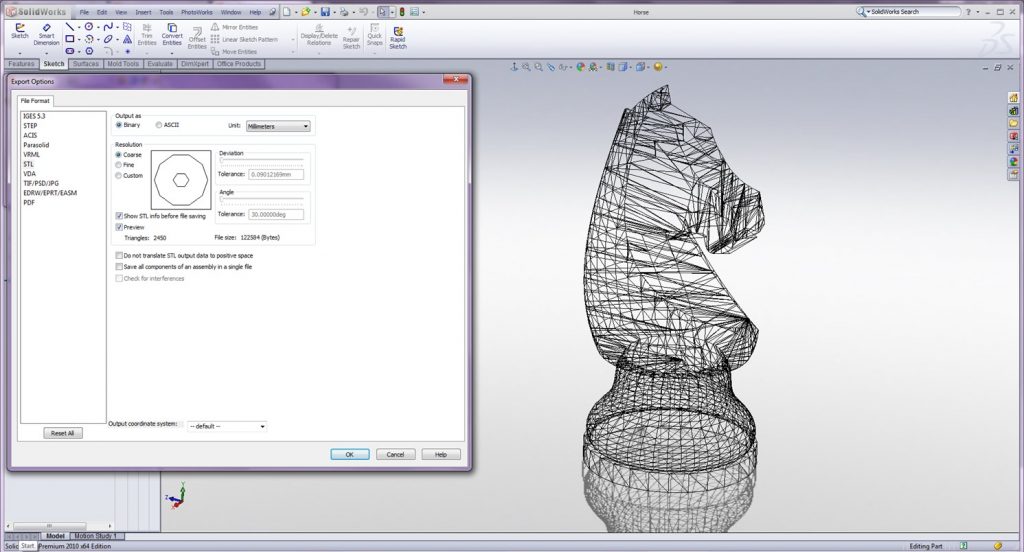

Joel Lim explained that, “Lightweight and strength are crucial to this project. We first analysed the conventional knee braces and their current bill of material. We decided to change to a plastic material with optimised structure. Using topology optimisation with a delineated stress map and 3D modelling, we then designed new structures and joints that are strong enough to withstand the flex of the knee and still assist it to move in the correct direction,”

Fabian Ong said that, “X-Brace will be revolutionary for patient recovery. It is light weight and does not slip, while its modular assistance load allows patient recovery to be individualised. NTU’s help in providing a quantitative methodology to reduce wall thickness and profile of the frame was crucial in achieving the weight reduction after several reiterations,”

Lim has made seven iterations of the X-Brace to get to the commercially available variant and now uses nylon 6 (Stanyl) as a material, while the knee can support up to 50 kg of force. Meanwhile, Lim has not stopped development but is rather advancing further still with a ninth version. Currently available for sale for SGD$1,000 (US$782), it can be purchased from Delsson subsidiary Wearable Kinetics.

Meanwhile, Lim has not stopped development but is rather advancing further still with a ninth version. Currently available for sale for SGD$1,000 (US$782), it can be purchased from Delsson subsidiary Wearable Kinetics.

Dr Ho Chaw Sing, Managing Director of NAMIC said, “With a fast-aging global population, light-weight assistive orthotics enabled by 3D printing – such as personalized knee braces, will increasingly become an essential tool in geriatrics, to achieve better elderly patient care and outcomes.”

The market for devices like the X Brace is incredibly huge. As it stands, assistive devices and braces are boring, with an aesthetic straight from the 50s. The market is stratified, slow, and set in its ways. Through lightweight, customized and innovative solutions like this, we could, as a 3D printing industry, conquer many markets, make many billions of dollars in revenue, and help millions of people worldwide improve the quality of their lives. And we can do this with a part that is relatively easy to make and well within our means.

And we can do this with a part that is relatively easy to make and well within our means.

By all means have fun negotiating with Volkswagen for the next decade of your life or try to figure out how to replicate a legacy component and beat it on cost. Those are all valuable activities. But, in the world of assistive devices, you can quickly bring to market products that are high value, as well as innovative. To me this is a lot faster, more fun, and will be more profitable as well. Best thing I’ve seen all month.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d print prototypes • 3D printed knee brace • 3d printed orthopedics • bionic • braces • Delsson • knee brace • NAMIC • Nanyang Technological University • National Additive Manufacturing Innovation Cluster • NTU • post op • post operative recovery • six millions dollar grandma • Wearable Kinetics • X-Brace

Please enable JavaScript to view the comments powered by Disqus.

News

Subscribe to the author

Subscribe

I do not want

6

BIONEEK-this is a passive bioonic exoskeleton orthicic denture developed and manufactured by Sichuan Juuan Juuan Juuan Juu AN Hui Science and Technology using an Intamsys 3D printer and high-strength polyetheretherketone (PEEK).

The knee is one of the most vulnerable and short-lived hinge joints in the human anatomy, with an average healthy lifespan of fifty years. Many older people suffer from various types of knee problems that reduce mobility and make it difficult to lead a normal life.

With a biomechanical system, the BioNEEK prosthesis enhances knee support, reduces impact, improves stability and provides maximum knee protection. The magnetorheological damper acts as a cushioning system, reducing the strain on the knee when walking while increasing patient endurance and mobility.

The BioNEEK Adjustable Hinge Prosthesis is recommended for patients with chronic knee problems as it simultaneously prevents severe sprains, speeds up recovery and relieves pain. The hinge follows the natural movement of the joint and provides lateral stability to the ligaments.

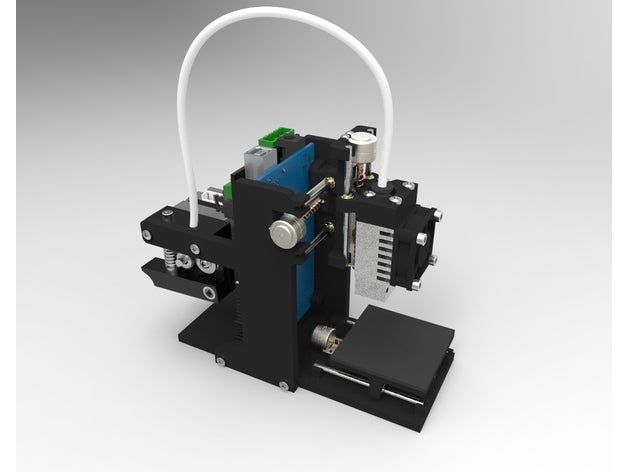

Sichuan Ju An Hui approached Intamsys to help with the additive manufacturing of BioNEEK orthoses. As a result of the joint work, the orthoses were made on a compact industrial 3D printer Funmat PRO HT, capable of efficiently printing large-sized parts from polyetheretherketone (PEEK, PEEK). The use of 3D printing technologies allows you to quickly adapt to the individual anatomy of each user of BioNEEK orthoses, which is crucial.

“Thanks to the exceptional mechanical strength and stiffness of PEEK, combined with the reliability of Intamsys additive solutions, Sichuan Ju An Hui can quickly adapt its products to individual patient sizes and produce comfortable BioNEEK knee orthoses that provide a high level of protection,” commented the company’s CEO. Intamsys Charles Khan.

Intamsys Charles Khan.

Mechanical properties of PEEK parts printed on Intamsys Funmat PRO HT 3D printer can reach 99.9 MPa in tensile strength and 3738 MPa in Young's modulus. The knee brace serves as a support structure to help prevent injury and provide an additional layer of protection. For comfortable wearing, a foam filler has been added to the design of the orthosis.

Detailed information about Funmat PRO HT 3D printers is available at this link. Z-Axis is the exclusive distributor of Intamsys solutions on the Russian market.

Press Release

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

orthosis Intamsys Funmat Pro HT BioNEEK

Follow the author

Subscribe

Don't want

6

More interesting articles

5

Follow the author

Follow

Don't want

Compared to traditional casting, 3D printed sand casting has several advantages. ..

..

Read more

four

Subscribe to the author

Subscribe

Don't want to

Jetson One is an eight-engine electric aircraft designed for one person. The design uses...

Read more

82

Subscribe to the author

Subscribe

Don't want

Collaboration 3D

We are pleased to present you our joint development with Speci...

Read more

Hip arthroplasty using a 3D printer for the first time in Israel

In recent years, a real revolution has taken place in the field of joint replacement in the world. Increasingly, scientists are talking about the possibilities of 3D technologies, which make it possible to design an accurate three-dimensional model of a human organ in accordance with its anatomy in a computer and print it from biological material. For the first time in Israel, the Soroka hospital performed a knee replacement operation using a modeled and printed joint.

For the first time in Israel, the Soroka hospital performed a knee replacement operation using a modeled and printed joint.

Author Elena Levina

When traditional treatments - physiotherapy, drug therapy - do not help, when joint pain turns into a constant, ongoing nightmare - perhaps the next step should be surgery to replace the affected joint. In recent years, a real revolution has taken place in the field of joint replacement in the world.

Medical revolution - 3D technology

Increasingly, scientists are talking about the possibilities of 3D technologies, which make it possible to design an accurate three-dimensional model of a human organ in accordance with its anatomy in a computer and print it from biological material. For the first time in Israel, the Soroka hospital performed a knee replacement surgery using simulation.

When a joint replacement is required

If joint pains are repeated, and you know that the reason for this is not physical exertion on the limbs, then most likely we are talking about one or another type of arthritis - inflammation. Most often, diseased joints are in the lower extremities, in the knees, and the hip bones. Sometimes the only solution is surgical replacement of damaged joints.

Most often, diseased joints are in the lower extremities, in the knees, and the hip bones. Sometimes the only solution is surgical replacement of damaged joints.

The average age of patients with recurrent joint pain, other than injury or accident, is approximately 60 years or older. Due to natural wear and tear and degenerative processes in the body that occur with age. Joint replacements may also be needed for younger people who have suffered fractures and injuries from sports or accidents where surgery is the only option.

Joint replacement surgery with 3D printers already in Israel!

Ami Asis, a resident of the south of the country, was the first patient in Israel and one of the few in the world whose damaged joint was replaced with a new one created using a 3D printer. Ami, who for many years suffered from pain in the hip joint and lameness, had long dreamed of replacing the damaged joint, but he knew that such operations are very difficult, require high qualification and experience from the doctor, complications are possible due to inaccurate selection of the implant . Dr. Vadim Benkovich, head of the Department of Joint Replacement at the Soroka Hospital in Beersheba, suggested that he implant a 3D-printed implant. After some hesitation, Ami agreed to the procedure. The operation was performed at Soroka hospital in Beer Sheva and took about 30 minutes.

Dr. Vadim Benkovich, head of the Department of Joint Replacement at the Soroka Hospital in Beersheba, suggested that he implant a 3D-printed implant. After some hesitation, Ami agreed to the procedure. The operation was performed at Soroka hospital in Beer Sheva and took about 30 minutes.

One-on-one model

Creating a prosthesis in accordance with the individual measurements of the patient, which would exactly repeat the anatomy of his joint, is the basis of a new method of creating an implant using 3D printers. Before the operation, the patient undergoes visual scanning procedures: MRI and CT, but not for a diagnostic examination, for which these procedures are intended, but to recreate an accurate three-dimensional model of the joint. This creates a one-on-one model of the problematic organ to be replaced. This exact copy allows doctors to plan all actions to the smallest detail, to select the adapted equipment suitable for each specific case. Orthopedics in Israel is advancing by leaps and bounds - the doctors of the country have tried various methods of surgery and materials from which implants were created. But the patient's recovery process was always very slow and painful.

Orthopedics in Israel is advancing by leaps and bounds - the doctors of the country have tried various methods of surgery and materials from which implants were created. But the patient's recovery process was always very slow and painful.

Benefits of using a 3D printer in orthopedics

The advantage of creating a joint model using a 3D printer is that it allows for a very high level of accuracy and reduces work time. This is important, first of all, because we are talking about the most precise "jewelry" operations, which are carried out in a short time and at a very high professional level. Speaking about the advantages of the method of joint replacement using "opened" organs, it is worth noting that, compared with previous methods, there are no traditional consequences of surgical intervention: tissue is less damaged, less blood loss, the patient recovers faster after surgery. In the case of Ami, we are talking about a fairly short time: only a month has passed since the surgery, he can already drive a car, move around, almost without limping, he has stopped taking analgesics for the last week.