Artisan keycaps 3d print

3D Printed Keycaps vs. Artisan Keycaps

Like Tenkeyless mechanical keyboards, Custom keycaps are a natural progression for many mechanical keyboard enthusiasts.

Sites such as Massdrop often sell standard Cherry MX keycaps, but with a unique color, theme applied. But just changing the color or font of the keys isn’t what we’re talking about today. Instead, we’re talking about custom keycaps, which completely change the form of the standard keycap you’re used to.

There are two main custom keycap categories out there today – Artisan and 3D Printed. Let’s dive into the two and look at the differences, advantages, and disadvantages of each.

Artisan KeycapsArtisan keycaps are what their name suggests – works of art! There are several steps to making an artisan keycap. The typical design process goes like this – first, the artist sculpts some sort of design out of clay (or some similar material) onto a standard keycap. Once satisfied with their design, they make a two-part silicone mold of their sculpt.

Once the mold is complete, they can begin the next step – casting resin (or some similar plastic material) into the mold, which is a process that has many points of failure. The artist must make sure any dyes are mixed completely and that no air bubbles remain in the casting material, for starters.

Some keycaps also require two different casting pours timed properly to pull off a multi-color keycap. Further embellishments can be added as needed, for example, KeyKollectiv‘s Snackeys seen on the left which look like fruit.

Below is an artisan keycap of mine by Hot Keys Project called “Raven” complete with green eyes and movable visor. This keycap is on a CODE mechanical keyboard with Cherry MX Brown switches.

3 Artisan keycaps on a backlit mechanical keyboard.

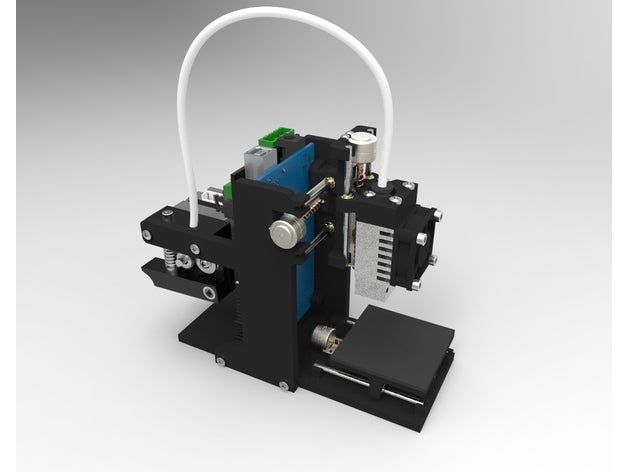

3D Printed Keycaps3D printed keycaps are a newer entrant to the custom keycap market. Using 3D printer technology, a designer can now design their keycap on a computer and have their design printed without having to touch any physical materials. The results can be very detailed and precise keycap designs that might be difficult to capture with clay. However, 3D printing technology itself isn’t perfect in terms of precision or smoothness.

The results can be very detailed and precise keycap designs that might be difficult to capture with clay. However, 3D printing technology itself isn’t perfect in terms of precision or smoothness.

Here’s an example of one such 3D printed keycap that you may recognize, which is a two-piece model –

Now that you’ve got a little background on artisan and 3D printed keycaps, let’s run down pros and cons.

Note: All 3D printed keycaps displayed in this article came from Tasker’s Gizmo Bazaar. You can purchase any of these models from his store as well as many others.

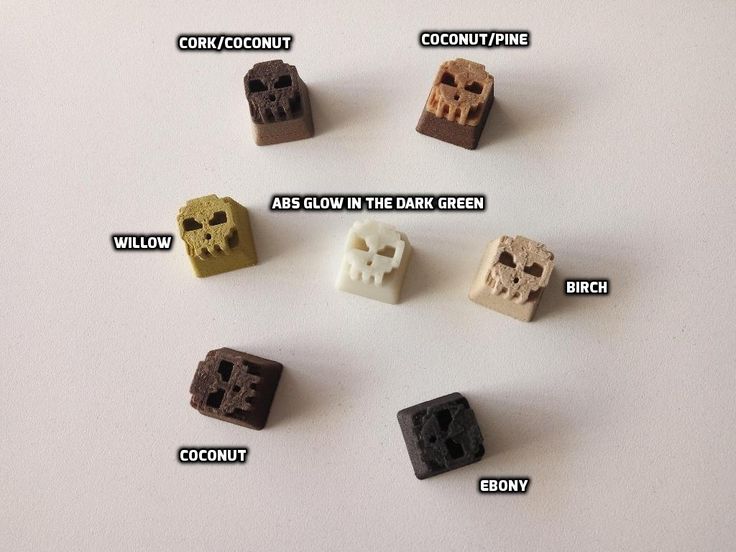

Advantages of 3D Printed Custom KeycapsMore Color/Material Choices

When it comes to artisan keycaps, the original artist has complete control over the finished product. Unless you’re crazy enough to try altering it or painting it (and ruining its value), every keycap is going to look exactly how the artist intended.

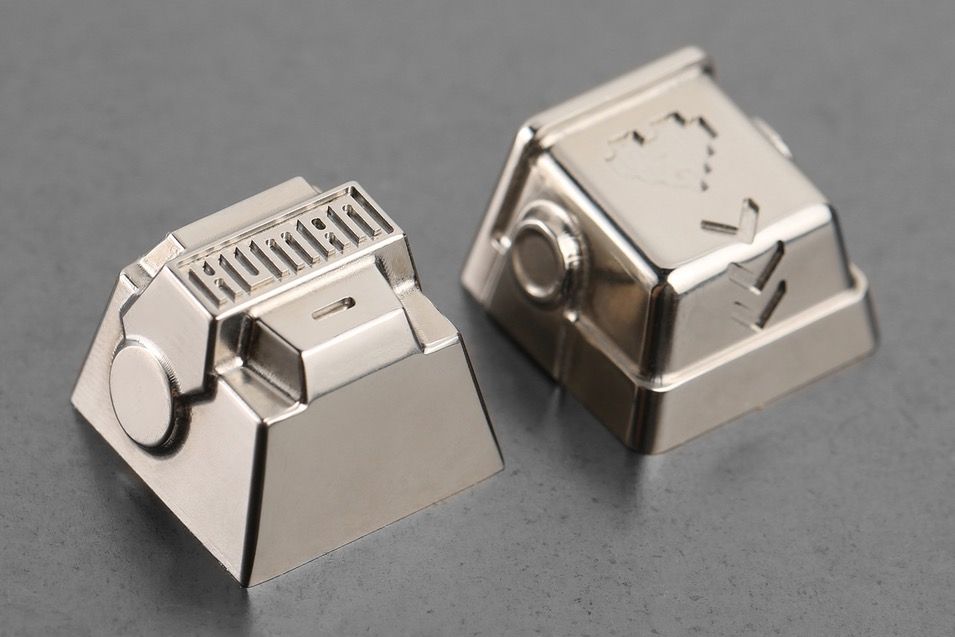

When it comes to 3D printer keycaps, this isn’t the case. The designer puts the model out there, and the buyer gets to choose the material and color. Shapeways has numerous material choices – metals like gold and silver, at least 10 colors of plastic, and even weird things you wouldn’t think you could 3D print like porcelain, sandstone, and wax.

The designer puts the model out there, and the buyer gets to choose the material and color. Shapeways has numerous material choices – metals like gold and silver, at least 10 colors of plastic, and even weird things you wouldn’t think you could 3D print like porcelain, sandstone, and wax.

As you can see below, I selected a traditional red and green Petey Piranha – probably the way the designer intended – as well as a unique orange and purple Petey.

No Limits to Production

When it comes to artisan keycaps, the artist must physically make every batch, which means making multiple molds, mixing the casting materials and dye many times, injecting the dye as needed, waiting hours for it to harden, removing the finished product, and repeating the process. It’s very labor-intensive, which means there’s a limit to how many they can produce.

With 3D printed keycaps, there is (in theory at least) no limit to the number of keycaps that can be produced. If you notice your friend has a cool 3D printed keycap you like, you won’t need to sift through classified listings on forums hoping to find one, and you won’t be paying a huge markup because you missed the initial sale. Below I have two identical monster designs in two different colors.

If you notice your friend has a cool 3D printed keycap you like, you won’t need to sift through classified listings on forums hoping to find one, and you won’t be paying a huge markup because you missed the initial sale. Below I have two identical monster designs in two different colors.

Much More Affordable

One of the greatest advantages of 3D printed keycaps is the price! Since the cost of materials is lower, and there’s no manual labor that goes into the crafting, you’ll get a keycap for only 20-50% of what you would pay for an artisan keycap brand new. The two monsters above? Less than $6 each. Petey Piranha is less than $10 for the body/head combo.

Artisan keycaps, on the other hand, will cost you $20-40 if you can get it brand-new from the artist. If you miss the initial sale, you might be paying 2x that or more in the aftermarket.

More Intricate Designs

Since 3D printed caps are designed using software that have precise, calculated units of measure, it’s possible to pull off some pretty cool multi-piece tricks that would be much harder with an artisan keycap. You can also get some pretty thin pieces, which would be very difficult to mold and cast.

You can also get some pretty thin pieces, which would be very difficult to mold and cast.

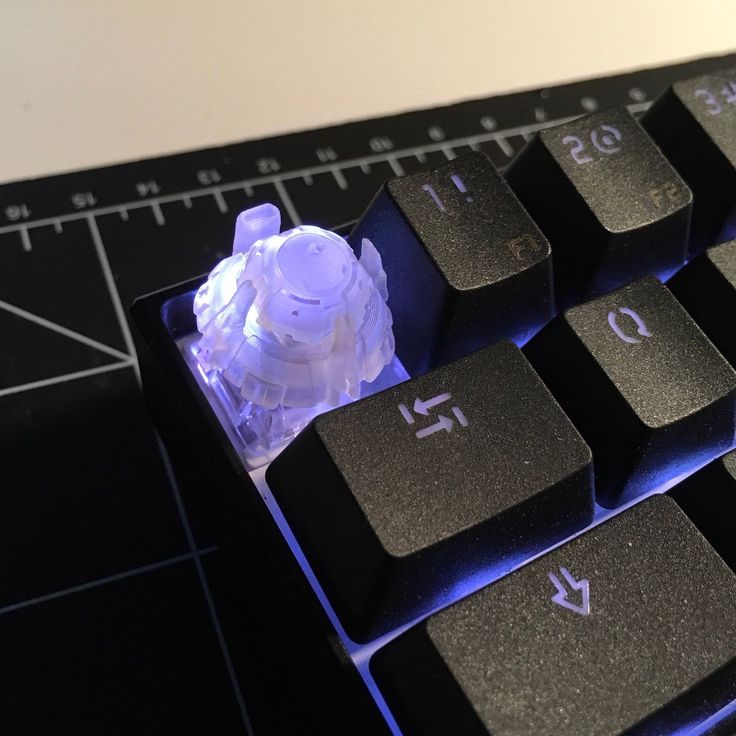

In Tasker’s Astronaut, you can see he executes a 3-piece design that would be extremely difficult if not impossible to do as an artisan keycap.

The keycap uses an astronaut helmet shell (I tried one in matte metal coated with some sort of gold sheen – the gold didn’t stick to 100% of the surface), inner skull, and cracked visor.

Here you can see the set with all frosted plastic pieces and the visor in place.

And here, you can see them with a white LED backlighting from a CODE keyboard applied. It should be noted that the current visor design is still in “beta”, and if you want to make the skull show more obviously you can polish the visor before assembling. Also seen below – the unspeakable 3D printed Cthulhu!

Disadvantages of 3D Printed KeysMost of the disadvantages of 3D printed keys are just viewing their advantages through a different lens. I’ll explain –

I’ll explain –

Less Artistic Touch

When you get an artisan keycap, you can really view it as a work of art from top to bottom. You know that the colors were exactly what the artist intended, and the design was hand-crafted. It can give artisan keycaps more of living feeling to them. Also, artisan keycaps can be multiple colors, which mass-production 3D printers just can’t do right yet.

Less Rare/Collectible

Many people make a hobby out of collecting artisan keys. For them, hunting down the keycap they want and finding a reasonable deal on it is much of the fun. Many people also trade artisan keycaps within the community.

Since 3D printed keycaps can be purchased for a cheap price by anyone, this takes away the “limited edition” feel of artisans and it doesn’t feel like something you would feel as strong of an urge to collect since they can always make more.

3D Printing Plastic Quality Not as Nice

I think the 3D printing market still has a bit further to go before they catch the quality of plastic that resins create. The 3D printed plastics from Shapeways has a bit of a “powdery” feel to it. Granted, the keycaps are only around $5 each, but it would be nice if they offered a more premium plastic option in the future.

The 3D printed plastics from Shapeways has a bit of a “powdery” feel to it. Granted, the keycaps are only around $5 each, but it would be nice if they offered a more premium plastic option in the future.

Due to the less “solid” feeling of the 3D printed keycaps, you likely wouldn’t want to use them on any keys that get heavy use, especially not on a gaming keyboard. The plastic likely wouldn’t hold up over the long haul, so it’s best to use them on lesser used keys.

Final Thought on 3D Printer Keycaps

I think 3D Printed keycaps occupy a different market from artisan keycaps, and the two don’t really compete as much as you may think. For people who just want an interesting or different looking keycap but don’t want to spend the money on artisan, they will love going the 3D printed route. For others, they’ll rather pay a premium for something they feel is more of a collectible work of art. It’s really just a matter of preference at this point.

Where Can I Get Custom Keycaps?For 3D Printed keycaps, you can find many options on Shapeways, and Tasker’s shop has all the keycaps you saw on this page.

For artisan keycaps, you’ll need to do more hunting. Reddit has /r/mechmarket and geekhack has its own marketplace for aftermarket sales. To catch sales as they come up, I would browse geekhack forums often or follow us on Twitter and we’ll do our best to keep you updated. MassDrop also occasionally has some artisan sales.

That concludes our comprehensive comparison between the differences of artisan and 3D printed keycaps.

For more mechanical keyboard related stuff, check out our buying guides:

- Top Mechanical Keyboards Under $50

- Absolute Best Mac Keyboard Alternatives

- Best White Mechanical Keyboards

3d Printed Keycaps - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(516 relevant results)

Best Files for 3D Printing Keycap・Cults

X-keyboard

2 € -fifty% 1 €

Chubby- Artisan Keycap for keyboard

4 €

Naruto Key Holder

1. 92 €

92 €

Space between Goku and Broly keys

5.50 €

Strawberry meowko

5 €

key cap Pterodactyl

5 €

Iron Man Keyboard

2 €

keyboard trolley

5 €

medieval trunk

5 €

keyboard car of the future

5 €

Ankylosaurus

5 €

Key holder pokemon seel

5 €

Sharingan-Naruto-inspired handmade key cover

0,70 €

One piece esc key luffy, artisan keycap

0,70 €

Solid esc key Trafalgar Law, craft keyboard

0. 70 €

70 €

Housekeeper Inosuke Kimetsu no Yaiba

2 €

keyboard Deadpool

0.50 €

dragon ball esc keycap - Turtle hermit's school kanji

€0.70

Empty Keycap Bottom Row 1.25u

Free

Artisan Keycap Pokemon - Lechonk - Mechanical Keyboard

2.88 €

Key holder Wheatley Portal 2

5 €

Pokemon with key x6

8.14 €

Housekeeper Courage the Cowardly Dog Courage, the Cowardly Dog

2.91 €

Key holder Wall-e

3.78 €

Key Holder Sign of Sacrifice Berserk

3. 78 €

78 €

Key holder PEPE THE FROG

3,49 €

Valorant logo

3.78 €

PRINTSCR BLANK KEYBOARD INSERTS PERFECT FOR CHERRY MX, GATERONS, KAILH

Free

Mario Bros keyboard cube

1.92 €

Key set Bulbasaur/ Ivysaur/ Venusaur

0,80 €

Housekeeper Gudetama

1,50 €

Housekeeper Meduza

€2.50

Mechanical Keyboard Sharingan Keycap Tray

3 €

Neko Keycap Artisan

3 €

Poke balls for keys

2 €

Pokemon Gengar

Free

Mario Keycap piranha plant

€2. 90

90

Pochita Chainsaw Man Artisan Keycap (longer chainsaw version)

4 €

Housekeeper Spiderman

0,50 €

keyboard Morty

0.50 €

Magnetic key holder Thor Mjolnir

4 €

Pikachu with key

0,50 €

Key Holder Coffing

0,50 €

Enchantress with a key

0,50 €

starwars housekeeper

Free

Housekeeper Weasling Alola

3,97 €

keycap (gamecube keyboard key)

€0.50

BLANK BACKSPACE PERFECT FOR CHERRY MX, GATERONS, KAILH

Free

What is 3D printing in 2021

3D printing technology has changed the manufacturing process of everything that surrounds us. From children's toys and clothes to prostheses, implants, etc.

From children's toys and clothes to prostheses, implants, etc.

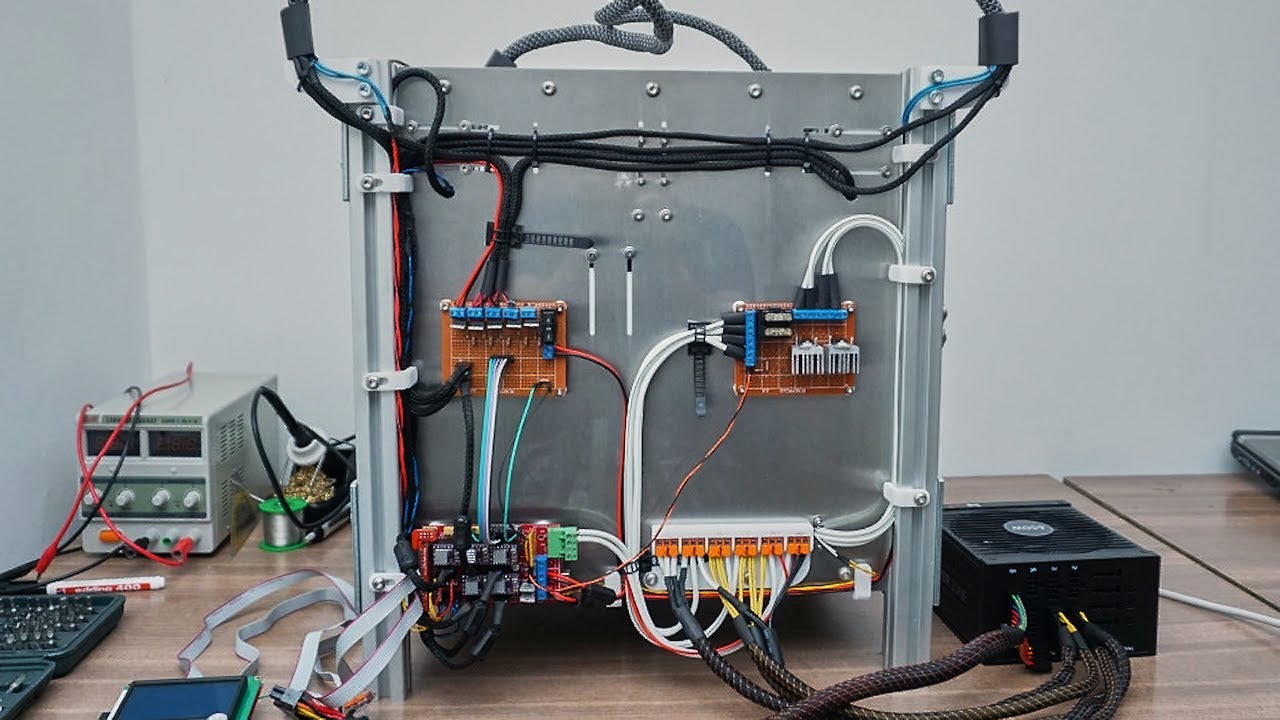

The 3D printing process is also known as additive manufacturing. In simple terms, a computer program tells the printer where to lay thin layers of material that gradually turn into a solid object.

Types and processes of 3D printing technologies

The first mention of 3D printing technology appeared in the late 1980s. They were called rapid prototyping technologies. The name refers to a process that was conceived as a faster and more cost-effective method of prototyping in product development. The very first patent application for this technology was filed by Dr. Hideo Kodama in May 1980. But, unfortunately for the inventor, the full patent specification was not submitted until one year after the application was filed. Kodama used ultraviolet light to cure plastic and create an AM object.

Years later, the American Scott Crumb developed the most common type of 3D printing today - FDM (Fused deposition modeling). This technology stands for deposition modeling. This type is characterized by the fact that the thermoplastic material is heated to a liquid state and extruded through the nozzle layer by layer.

This technology stands for deposition modeling. This type is characterized by the fact that the thermoplastic material is heated to a liquid state and extruded through the nozzle layer by layer.

Charles Hull, co-founder of 3D Systems, was one of the inventors of the 3D printing technology known as stereolithography. The technology is based on photochemical processes.

But Kodama, Crump, and Hull weren't the only ones to develop 3D printing techniques.

WINBO 3D printer at Art-Up Design Studio

Here are some other types of 3D printing that are in use today:

- FDM (Fused Deposition Modeling) is by far the most common method for producing thermoplastic parts and prototypes today. Based on the melting of the filament in the nozzle with its subsequent laying in layers. It is also the most economical way of 3D printing due to the availability of a wide range of thermoplastic materials with different technical characteristics, which allow generating both functional parts of mechanism prototypes and volumetric cases, as well as any free spatial decorative forms.

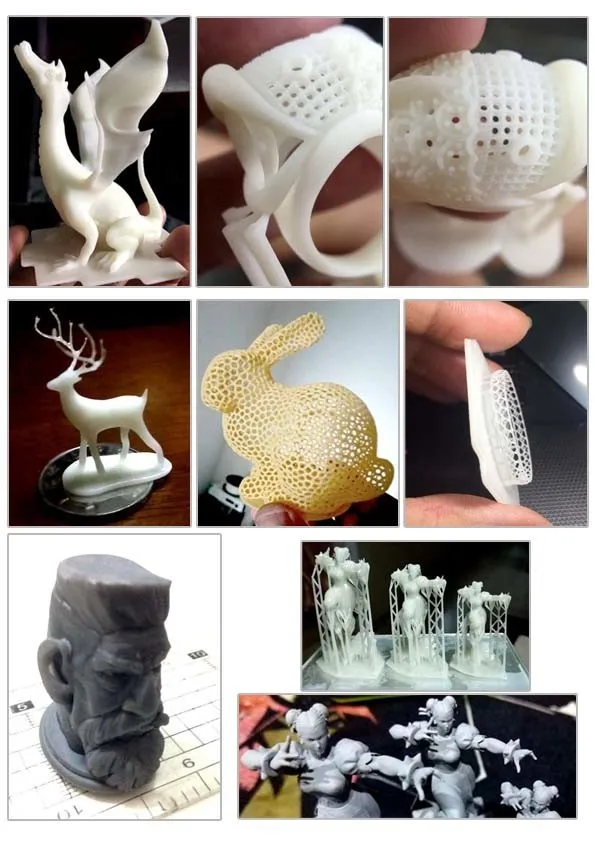

- SLA (Stereo Lithography Apparatus) is based on the layer-by-layer curing of a liquid photopolymer material under the influence of UV study. Can print objects in multiple colors and materials with different physical properties, including rubber-like parts. The high printing accuracy of this method makes it more expensive and not optimal for simple plastic structures.

- DLP (Digital Light Processing) cures polymers using a light projector rather than an ultraviolet laser. This allows you to create a whole layer in one exposure, thus increasing the speed of production.

Metals too have their own 3D printing techniques. The type of technology is selected depending on the features of the object.

- SLS (Selective Laser Sintering) is based on layer-by-layer sintering of polymer powder particles using laser radiation. The nylon powder melts into a strong, hard plastic. Due to the peculiarity of the technology, the surface of the part is not ideal, but very functional for use in prototypes with hinges and latches.

- SLM (Selective Laser Melting) is based on layer-by-layer sintering of metal powder under the action of a laser beam. Used in the manufacture of decorative items. Therefore, it is useful for applications in medicine and lightweight structures. Often this method is used in conjunction with traditional metal casting technology to create prototypes or final products.

- EBM (Electron Beam Melting) is based on layer-by-layer melting using an electron beam. The printing uses electromagnetic coils to superheat the metal powder in a vacuum.

How 3D printing works

3D printing is the process of layering one on top of another. Every 3D printed object starts life as a 3D model in a computer program.

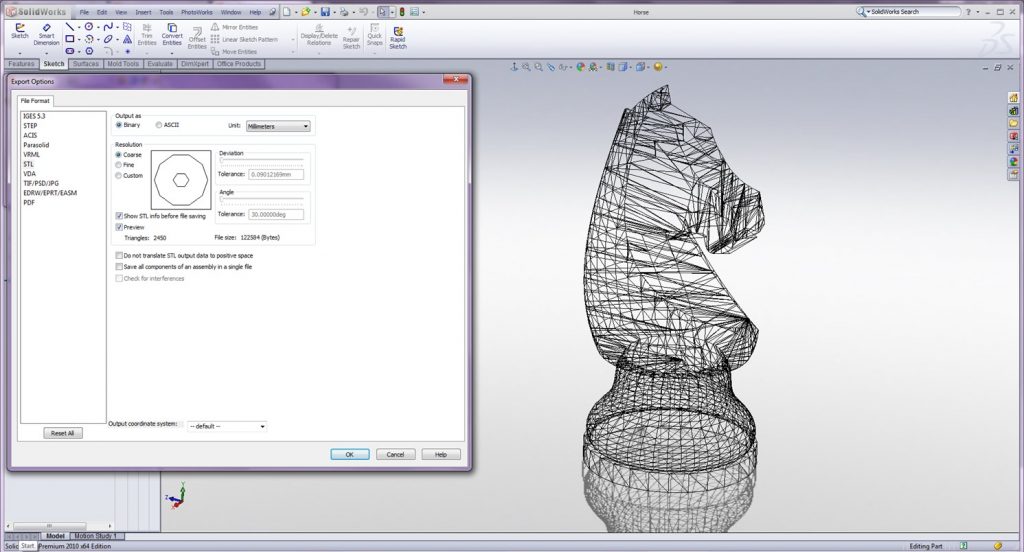

You can create your own design in programs such as Maya, Blender, ZBrush, CATIA, Solidworks. In addition, ready-made 3D models of parts can be downloaded from sites such as Thingiverse or CGTrader.

When you have a 3D model obtained in one way or another, you “run” it through the “slicer” program (from the English word “to slice”), which converts the original 3D model in STL format into print layers. The information received is eventually converted into a special data format called G-code for further printing on a 3D printer.

The information received is eventually converted into a special data format called G-code for further printing on a 3D printer.

Such programs usually come with the 3D printer, or they can be freely downloaded, such as the Cura program. What these softwares have in common is that they create thousands of lines of code for layers. This code tells the printer how to print.

Next, you need to set up your 3D printer, select the print quality and the correct material settings. To start printing, you load your "sliced" part into the printer via a USB stick, SD card, or send directly from your computer. And the printer starts a slow additive layering process.

Photo of Christian Reil from Pixabay

Materials used in 3D printing

The materials available for 3D printing have come a long way. Currently, there is a wide range of materials that differ both in properties, types, and in the states supplied (powder, threads, granules, resins, etc. ).

).

Some materials are developed for specific applications to perform special tasks. For example, the medical sector, where special photopolymer resins (SLA 3D printing technology) are used, the properties of which make it possible to print implants, casts, and so on.

Some of the most commonly used materials:

- Plastics. Sintering (SLS) typically uses polyamides or nylon supplied in powder form. It is a strong, flexible and durable material. It is white in color, so it needs to be tinted before or after printing. The most common 3D printing technology today is FDM, which uses ABS or PLA plastic filaments. These plastics are available in a wide range of colors. Compared to PLA, ABS plastic has higher strength characteristics. But PLA is biodegradable, so it's as widespread as ABS.

- Metals. More and more metals and metal composites are finding their way into industrial 3D printing. The most common of them are derivatives of aluminum and cobalt.

Due to its strength characteristics, stainless steel is often used in powder form in 3D printing technologies such as sintering, melting, EBM. In the last couple of years, silver and gold have been added to the list of metals suitable for printing. This made it possible to significantly expand the possibilities of jewelry production.

Due to its strength characteristics, stainless steel is often used in powder form in 3D printing technologies such as sintering, melting, EBM. In the last couple of years, silver and gold have been added to the list of metals suitable for printing. This made it possible to significantly expand the possibilities of jewelry production. - Ceramics. A relatively new group of materials used in 3D printing. The peculiarity of printing with these materials is that the printed ceramic parts must go through the same processes as ceramic products made by traditional methods - firing and glazing.

- Biomaterials. Currently, a large number of studies are being conducted aimed at exploring the possibility of 3D printing from biomaterials for the needs of medicine. This includes the printing of human organs for transplantation, external tissues for replacement of body parts. To do this, leading institutions research living tissues.

- Food. Over the past few years, there has been an increase in experimentation with food 3D printing extruders.

Chocolate printing is the most widely used. There are 3D printers that use sugar, pasta, meat, dough.

Chocolate printing is the most widely used. There are 3D printers that use sugar, pasta, meat, dough.

Photo of mebner1 from Pixabay

What 3D printing is used for

If you can think of an item, then most likely you can print it. Children's toys, jewelry, phone cases and much more are already being printed by enthusiasts on 3D printers. Some use 3D printing for fun. Fun projects already exist: a printed guitar, a loom, and an intricate sculpture created from a combination of laser-fused glass and nylon. 3D printing has already moved beyond its origins in plastic printing and has moved into the use of metal, rubber, wood, synthetic fabrics, and ceramic resins. Functional 3D-printed human organs have not yet been created, but scientists say that this is a matter of the near future.

Because additive manufacturing of complex objects is faster and cheaper than traditional molding and casting methods, it has found its way into industry and the arts. The possibilities of this technology are almost limitless, but 3D printers are not perfect machines. In addition to all the advantages, there are also reasons for concern.

The possibilities of this technology are almost limitless, but 3D printers are not perfect machines. In addition to all the advantages, there are also reasons for concern.

Ethical issues in 3D printers

3D printers consume a lot of energy and emit ultra-light plastic particles into the air, which are then inhaled by humans. These harmful emissions can be compared to a cigarette lit indoors.

While humanity is trying to reduce the use and consumption of plastic, 3D printers are another technology heavily dependent on it. This presents a problem for all ecosystems, in particular for the already suffering oceans with their floating islands of plastic.

A few years ago, the news of the first 3D printed firearm caused a media frenzy. The creation of untraceable weapons by a private individual remains a modern security problem.

From a legal point of view, there is no clear answer to the question of who is responsible in the event of harm to health caused by a printed object. Indeed, in most cases, the developer of a 3D model, the manufacturer of a 3D printer, and the one who printed it are different people or organizations. Determining liability for potential injury and death is a new challenge.

Indeed, in most cases, the developer of a 3D model, the manufacturer of a 3D printer, and the one who printed it are different people or organizations. Determining liability for potential injury and death is a new challenge.

At the same time, the use of 3D printing technology in the medical field to print tissue raises a number of ethical and moral questions. These issues are similar to the talk of stem cell research and gene editing that has been going on for decades.

On the other hand, we have a powerful tool in our hands that is changing the way we create and produce things. We still don't fully understand what this means for our future.

Potential effect on the global economy

If 3D printing continues to develop at the same pace as it is now, then its use could potentially affect the global economy. The transition of production and distribution from the current model to localized custom manufacturing can reduce the imbalance between exporting and importing countries.

3D printing is creating new industries and new professions. Professions related to the production of 3D printers or, for example, a vacancy for a rapid prototyping technician at the Cartier jewelry house. New professional services are emerging, such as supply of materials, printer operator, legal services in dispute resolution and intellectual property issues. With the development of 3D printing technology, the issue of "piracy" becomes an urgent problem.

The impact of 3D printing on developing countries is a double-edged sword. The positive effect for such countries is the reduction in the cost of production through the use of recycled and other local materials. But the loss of manufacturing jobs could hit these economies hard, and it will take time to find a balance.

Where can I use a 3D printer

Owning a 3D printer with the necessary software and materials can still be expensive for individual needs, so public 3D printers are becoming more common.

There are places like labs and 3D printing shops. You can send your design and pick up the finished part in a couple of days. Some companies, such as ART AP Design Studio, also do 3D printing.

If you are a student or student, 3D printing services may be available at your school.

Art-Up Design Studio

Where can I learn how to use a 3D printer

For those who already have the specialty of an engineer, there are advanced training programs (Additional education) from the Russian Academy of Crafts, designed for 36 or 72 academic hours.

The training course in an accessible lecture form reveals the theoretical and practical foundations of design, three-dimensional modeling, design of plastic products. It provides for the performance of work and tests within the framework of the design tasks of the course and the final exam.

As a result of mastering the program, the trainee receives a certificate "Specialist in Additive Technologies".