3D print bike

🚲 Best STL files 3D printed for Bike・Cults

🚲 Best STL files 3D printed for Bike

Download free Bike Accessories 3D files

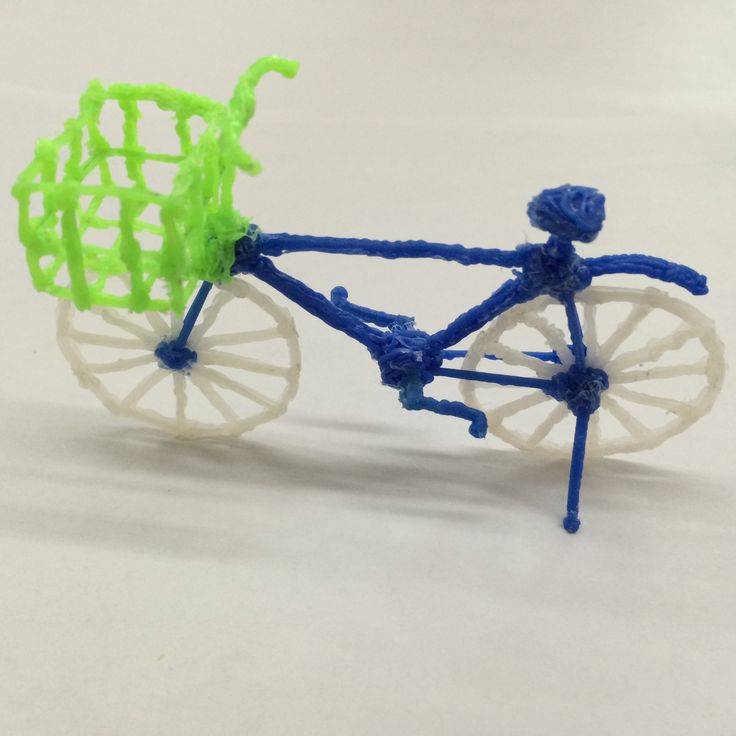

Find out a selection of valve cap, mounts, holders and racks for your bike to make with a 3D printer. There are so many accessories for bikes and they can be really expensive, 3D printing is a great way to reduce the cost! 3D printing is also a great solution to invent ideas to make daily live on your bike easier.

Customizable Bike Mount for Modular Mounting System

Free

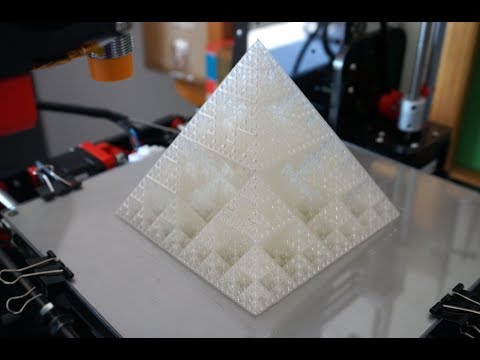

3D Printed Bike

Free

Wall Rack

Free

mountain bike wall mount

Free

GoPro bike mount

Free

Bicycle Water Bottle Cage

Free

Stand Phone For Bike

Free

Water Bottle Holder

Free

Pizza Valve Cap

Free

Stormtrooper Valve Cap

Free

Coffee Cup Holder

Free

Brompton logo tap

Free

Presta valve cap with thread _ Presta Cap valve with thread

Free

Smartphone Support Magnetic Bike

€0. 50

GoPro Handlebar Mount (customizable)

Free

bike flashlight mount

Free

MOUSQUETON

Free

SR Suntour fork top cap socket (FAA122 replacement)

Free

Handelbar mount for Samsung S5 with wireless Qi charging - weather proof

Free

bike support go pro diameter 32 mm

Free

Bike Light

Free

Triathlon extension

Free

Smartphone bike holder

Free

Bar-End bike Plugs

Free

Saddle mount for "Smart LED / Planet Bike" lights

Free

Bike FlashLight Quick Release Mount

Free

iPhone 6 Holder

Free

Draisienne bike (IKEA hack collection) by Andreas Bhend and Samuel N.

Bernier

BernierFree

The Bicycle Bubble Machine

Free

iPhone XS/6s Holder for GARMIN Mount (eTrex/Oregon/Colorado Series)

Free

bike holder

Free

Mud Bike

Free

Pinces pantalon pour le velo - Cycling Trouser Clips

Free

TUTUGO | Coffee Cup Valve Caps

Free

Fizik ICS Integrated Clip System Saddle adapter for Planet Bike / SMART Led Lights

Free

Clamping Knob For M8 Nut

Free

Deer Bike Rack

Free

Bead buddy for bicycle tire installation

Free

iPhone 6 Plus Holder

Free

bike cleaning wheel

Free

Bicycle Stand - 2 Part for use on the Road

Free

Graziella Back Light Mount

Free

Lightweight press-fit MTB handlebar plugs

Free

Yet Another Bicycle Flashlight Holder

Free

Beach umbrella holder for your bike

Free

Bike Attachment for iPhone 5, 4 and 4S

Free

GoPro clamp mount

Free

Bike Handlebar Cup Holder - Pint Glass or Coffee

Free

Here is our selection of the best STL files for Bike, all these accessories are from the 3D file library Cults and are perfectly 3D printable.

This collection includes free 3D files of Bike accessories. The numerous 3D models will adapt perfectly to all types of bike: Mountain bike, city bike or racing bike. No restriction on the type of bike so you can even modify the size or shape of the 3D files to fit the shape of your bike or its frame.

The 3D designers who propose their creations on the 3D file download platform Cults have therefore competed in ingenuity to facilitate your daily life on a bike. For example you can easily hook your phone to the handlebars, carry your water bottles or attach a GoPro on your bike. Once you get home, there are printable 3D solutions that will allow you to store your bike. You can even stand out by 3D printing customizations for your bike such as valve caps 3D printed in the shape of a pizza or a Lego man's head!

The Top Bicycles Made With 3D Printing

Published on September 22, 2020 by Aysha M.

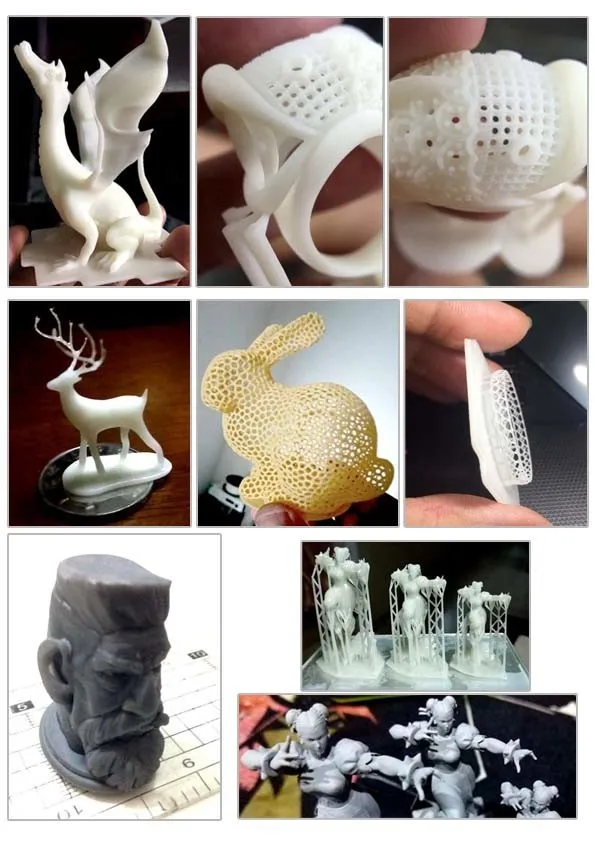

As you know, additive manufacturing is starting to play an important role in the world of sports, where it allows to design custom-made equipment, more adapted to the morphology of each athlete: while focusing on increasing comfort, it also offers better performance. Cycling is undoubtedly one of the sports where 3D technologies are most widely used. The goal is to imagine a bike that is lighter, faster, more comfortable, while reducing manufacturing time and costs. At the moment, there is no such thing as a bike 3D printed in its entirety – it’s more a matter of certain components, such as the saddle, frame, pedals, etc. So today, we present 12 bikes that have been made using 3D printing, be it commercialized products available on the market or just unique projects that demonstrate the advantages of the technology. The bikes are listed in alphabetical order.

The Bikes Available on the Market

Bike frame by Arevo

A startup from Silicon Valley, Arevo, has developed a six-axis robotic 3D printing platform capable of designing composite parts. In order to demonstrate the advantages of its solution, it has imagined a 3D printed frame from carbon fibers. The part was produced in a single run and took only a few days to manufacture – the process normally takes 18 months from design to production. In particular, Arevo worked with Emery Bikes to create Emery One, the first electric bicycle with a 3D printed carbon fiber frame.

In order to demonstrate the advantages of its solution, it has imagined a 3D printed frame from carbon fibers. The part was produced in a single run and took only a few days to manufacture – the process normally takes 18 months from design to production. In particular, Arevo worked with Emery Bikes to create Emery One, the first electric bicycle with a 3D printed carbon fiber frame.

Atherton Bikes

Specializing in mountain bike production, Atherton worked with UK metal 3D printer manufacturer Renishaw to produce the titanium sleeves for its bike frames. These are connectors that connect the cylindrical tubes that form the frame of the two-wheeler. They were printed on the RenAM 500Q machine with four lasers. This saves Atherton time, but also allows the company to change the sleeve design if necessary – simply by modifying the CAD file and testing different designs.

Empire Cycles & Renishaw: 3D printed bike frame

Empire Cycles is a bike designing and manufacturing company from the North-West of England that offers innovative designs to mountain bikers and downhillers. Working with UK metal AM manufacturer Renishaw, it optimized the design of its mountain bike using additive manufacturing technologies. By using topology optimization software, Renishaw was able to determine the most efficient place for material, removing it from areas of low stress until a design optimized for load bearing was generated. Therefore, the mountain bike frame’s weight was reduced by 33%. The resulting mountain bike is lighter yet stronger, showcasing a 3D printed titanium alloy frame and seat post bracket. The frame was additively manufactured in sections using Renishaw’s AM250 machine.

Working with UK metal AM manufacturer Renishaw, it optimized the design of its mountain bike using additive manufacturing technologies. By using topology optimization software, Renishaw was able to determine the most efficient place for material, removing it from areas of low stress until a design optimized for load bearing was generated. Therefore, the mountain bike frame’s weight was reduced by 33%. The resulting mountain bike is lighter yet stronger, showcasing a 3D printed titanium alloy frame and seat post bracket. The frame was additively manufactured in sections using Renishaw’s AM250 machine.

Specialized 3D printed bike saddles

Specialized Bicycles, based in the US, manufactures fitness, mountain and road bikes. In a recent collaboration with 3D printer manufacturer Carbon, the company redesigned the saddle, which it considers one of the most important parts of a bike’s body. The challenge when it comes to the saddle is designing a part that can maximize rider performance while providing comfort and stability. Using Carbon’s technology, the company replaced the traditional foam saddle with an intricate elastomeric lattice structure that overcomes the limits of foam. Therefore the new design, in hand with the Carbon Digital Light Synthesis technology – which relies on a process of photopolymerization – allows riders to rebound quickly, disperse pressure and improve breathability.

Using Carbon’s technology, the company replaced the traditional foam saddle with an intricate elastomeric lattice structure that overcomes the limits of foam. Therefore the new design, in hand with the Carbon Digital Light Synthesis technology – which relies on a process of photopolymerization – allows riders to rebound quickly, disperse pressure and improve breathability.

Superstrata

Superstrata partnered with Arevo to design its 3D printed unibody bicycle, which the two companies jointly unveiled this summer. Typically, 3D printed bike frames consisted of several elements that are glued and welded together. The biggest disadvantage of that conventional manufacturing technique is that such frames can quite easily fall apart under pressure. Therefore, Superstrata decided to additively manufacture unibody bikes, using continuous carbon fiber technology. By using carbon fiber reinforced thermoplastics, Superstrata managed to achieve high impact-resistance and light weight – according to the company, one bike weighs less than 2 water bottles or 1,3 kg! Since Directed Energy Deposition (DED) 3D printing technology enables a perfect customization, each frame can be custom produced to fit the individual’s body type.

Urwahn Bikes

The German bike manufacturer, Urwahn Bikes partnered with Schmolke Carbon, specialized in the fabrication of carbon fiber bike parts, to develop a 3D printed frame for its racing bike. The first thing you notice on this bike is the copper plating on the 3D printed steel frame. Besides its shiny exterior, this racing bike has a geometric advantage over other bikes: the elastic suspension of the rear wheel gives the rider additional riding comfort without sacrificing bottom bracket stiffness. This effect is especially noticeable on longer rides and uneven surfaces.

Volkswagen x Kinazo electric bike

The Slovak company Kinazo worked with the automotive manufacturer Volkswagen to design its 3D printed electric bike, the Kinazo e1, which was first released in 2017. Kinazo aimed to create an electric bike with an integrated battery in the frame and its own system of controlling the electronics through a mobile application. They also wanted it to be customizable. 3D printing was a perfect solution, as it would allow not only customization but also for the frame to be produced in one piece! Therefore, Kinazo turned to Volkswagen, which, at the time, had one of the largest metal 3D printers in the world: a Concept Laser X LINE 2000R. With a build area of 800 x 400 x 500 mm, the machine was big enough to 3D print the bike’s frame. The bike was prototyped in aluminum and weighed about 20 kilograms.

3D printing was a perfect solution, as it would allow not only customization but also for the frame to be produced in one piece! Therefore, Kinazo turned to Volkswagen, which, at the time, had one of the largest metal 3D printers in the world: a Concept Laser X LINE 2000R. With a build area of 800 x 400 x 500 mm, the machine was big enough to 3D print the bike’s frame. The bike was prototyped in aluminum and weighed about 20 kilograms.

WX-R Vorteq

The British company Vorteq developed the WX-R track bike in collaboration with engineers from the bike manufacturer Worx. The aim of the project was to overcome air resistance. For the realization of the bike, they used the portable 3D scanning technology, Artec Leo, a CFD analysis and a CAD program. This enabled them to develop a high-performance carbon fiber bike that has already won two medals, three personal records, two national records and a new Asian record at the UCI Track World Championships in early 2020. In the future, the WX-R track bike will be used in sprint events at the Olympic Games!

The 3D printed bike projects

3D printed Arc Bike II

The Amsterdam-based company MX3D, which specializes in RAM (Robotic Additive Manufacturing) technology, has developed its own bike called the Arc Bike II. It was 3D printed in 24 hours using WAAM (Wire Arc Additive Manufacturing) technology. Unlike its predecessor, which was made of stainless steel, this one is much lighter because it is made of aluminum. It should also be easier to customize since the design of the bike can be adapted to the proportions of the cyclist’s body using generative design software. The bike is not intended to be commercially available, but is currently being used as a demonstrator of the benefits of WAAM technology.

It was 3D printed in 24 hours using WAAM (Wire Arc Additive Manufacturing) technology. Unlike its predecessor, which was made of stainless steel, this one is much lighter because it is made of aluminum. It should also be easier to customize since the design of the bike can be adapted to the proportions of the cyclist’s body using generative design software. The bike is not intended to be commercially available, but is currently being used as a demonstrator of the benefits of WAAM technology.

BMW Balance Bike

A balance bicycle is a bike without pedals, chains or gears that helps children learn balance and steering. Dutch designer Roel van Heur has designed a model inspired by a BMW luxury motorcycle. The frame and forks of the Balance Bike were made of stainless steel, cut and welded into shape, and then hand brushed for an authentic finish. The Balance Bike also contains 3D printed parts, such as the fake fuel tank and fork sleeves. This small 3D printed bike is a personal project and shows the capabilities of 3D printing.

Freicycle

Developed by Dr. Dennis Freiburg, the Freicycle broke the Guinness record for the world’s lightest electric bicycle in 2019. Weighing less than 7 kg, this bicycle features 3D printed parts, which helped to significantly reduced the final weight. The German mechanical engineer started with a model whose chassis weighed less than 1 kg and whose brakes were mounted on the rim. Pedals and brake calipers were an example of lightweight parts that could be integrated through additive manufacturing. The engine part often adds a lot of weight to a bike, so Dennis converted the main engine to a friction motor supported by the rear wheel. Being able to reach a speed of 48 km/h, the Freicycle is certainly an incredibly efficient solution.

3D printed bike by Sculpteo

Sculpteo has once again proven that it is capable of providing solutions to all obstacles that may arise by optimizing manufacturing processes. This time, they proposed one of the most visionary and original products: the first 3D printed bicycle that moves thanks to digital functions. Sculpteo’s engineers and managers took this bike on a trip from Las Vegas to San Francisco. The goal? To demonstrate the strength of the product as well as the advantages of the technology used. Their Agile Metal Technology was a key point of the project. It is a very complete software suite designed to facilitate and accelerate metal 3D printing projects. It can be considered today as the first 3D printing artificial intelligence application, created to help evaluate and anticipate all the problems that a project like this can encounter during the manufacturing process.

Sculpteo’s engineers and managers took this bike on a trip from Las Vegas to San Francisco. The goal? To demonstrate the strength of the product as well as the advantages of the technology used. Their Agile Metal Technology was a key point of the project. It is a very complete software suite designed to facilitate and accelerate metal 3D printing projects. It can be considered today as the first 3D printing artificial intelligence application, created to help evaluate and anticipate all the problems that a project like this can encounter during the manufacturing process.

What do you think about this ranking of 3D printed bikes? Let us know in a comment down below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

🚲 Best Bicycle 3D Printable STL Files・Cults

🚲 Best Bicycle 3D Printable STL Files

Free Download Bicycle Accessories 3D Files

A selection of valve covers, mounts, holders and racks for your bike that you can make with 3D printer. There are so many bike accessories out there and they can be very expensive, 3D printing is a great way to cut costs! 3D printing is also a great solution for inventing ideas that will make everyday life on your bike easier.

There are so many bike accessories out there and they can be very expensive, 3D printing is a great way to cut costs! 3D printing is also a great solution for inventing ideas that will make everyday life on your bike easier.

Customizable Bike Mount for Modular Mounting System

Free

3D Printed Bike

Free

Wall Rack

Free

mountain bike wall mount

Free

GoPro bike mount

Free

Bicycle Water Bottle Cage

Free

Stand Phone For Bike

Free

Water Bottle Holder

Free

Pizza Valve Cap

Free

Stormtrooper Valve Cap

Free

Coffee Cup Holder

Free

Brompton logo tap

Free

Presta valve cap with thread _ Presta Cap valve with thread

Free

Smartphone Support Magnetic Bike

0,50 €

GoPro Handlebar Mount (customizable)

Free

bike flashlight mount

Free

MOUSQUETON

Free

SR Suntour fork top cap socket (FAA122 replacement)

Free

Handelbar mount for Samsung S5 with wireless Qi charging - weather proof

Free

bike support go pro diameter 32 mm

free

Bike Light

Free

Triathlon extension

Free

Smartphone bike holder

Free

Bar-End bike Plugs

Free

Saddle mount for "Smart LED / Planet Bike" lights

Free

Bike FlashLight Quick Release Mount

Free

iPhone 6 Holder

Free

Draisienne bike (IKEA hack collection) by Andreas Bhend and Samuel N.

Bernier

Bernier Free

The Bicycle Bubble Machine

Free

iPhone XS/6s Holder for GARMIN Mount (eTrex/Oregon/Colorado Series)

Free

bike holder

Free

Mud Bike

Free

Pinces pantalon pour le velo - Cycling Trouser Clips

Free

TUTUGO | Coffee Cup Valve Caps

Free

Fizik ICS Integrated Clip System Saddle adapter for Planet Bike / SMART Led Lights

Free

Clamping Knob For M8 Nut

Free

Deer Bike Rack

Free

Bead buddy for bicycle tire installation

Free

iPhone 6 Plus Holder

Free

bike cleaning wheel

Free

Bicycle Stand - 2 Part for use on the Road

Free

Graziella Back Light Mount

Free

Lightweight press-fit MTB handlebar plugs

Free

Yet Another Bicycle Flashlight Holder

Free

Beach umbrella holder for your bike

Free

Bike Attachment for iPhone 5, 4 and 4S

Free

GoPro clamp mount

Free

Bike Handlebar Cup Holder - Pint Glass or Coffee

Free

Here is our selection of best stl files for bike, all these accessories are taken from 3D Cults library files and 3D printed beautifully .

This collection includes free 3D files of bicycle accessories. Numerous 3D models of are perfect for all types of bikes: mountain, city or racing bike . There are no restrictions on the type of bike, so you can even resize or reshape the 3D files to match the shape of your bike or frame.

So 3D designers offering their creations on the Cults 3D file upload platform compete in ingenuity to make your everyday life on a bike . For example, you can easily attach your phone to the handlebar, carry water bottles, or attach your GoPro to the bike. Once you get home, there are 3D printable solutions that will allow you to store your bike. You can even stand out by 3D printing custom decorations for your bike, like 3D printed valve caps in the shape of a pizza or a Lego man head!

how the world's lightest bicycle pulley was created

3D printing

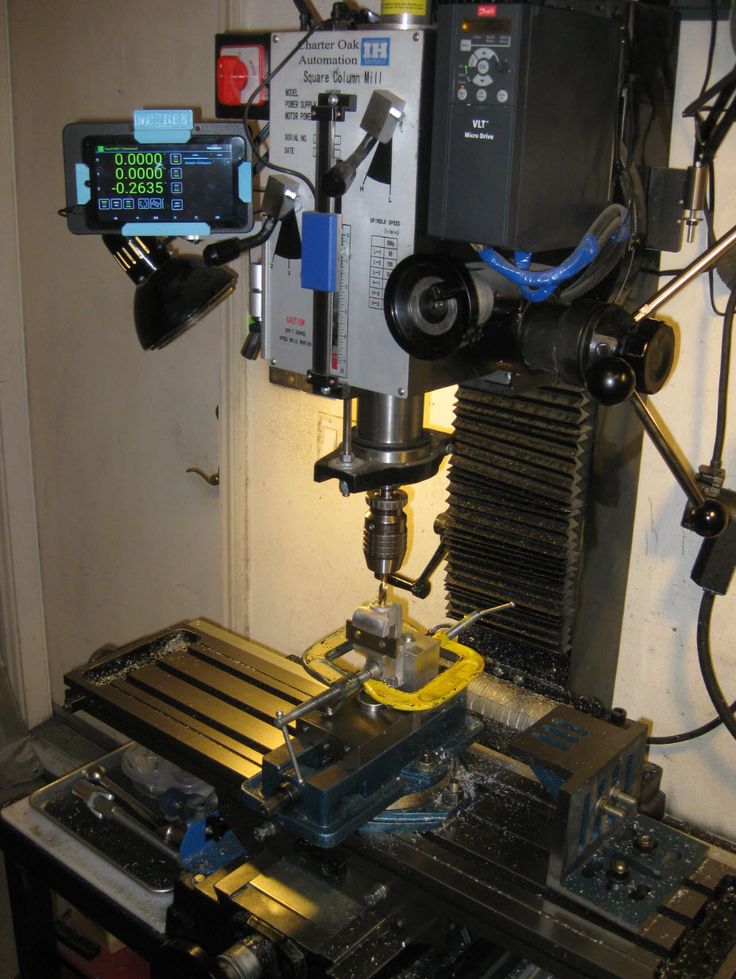

in general, and races such as the 3,460 km Tour de France present unique engineering challenges for optimizing weight while maintaining stability throughout the race.

In collaboration with selective laser melting experts at the Danish Institute of Technology (DTI), cycling pioneer CeramicSpeed has developed a lightweight and durable pulley that allows professional cyclists to improve their performance.

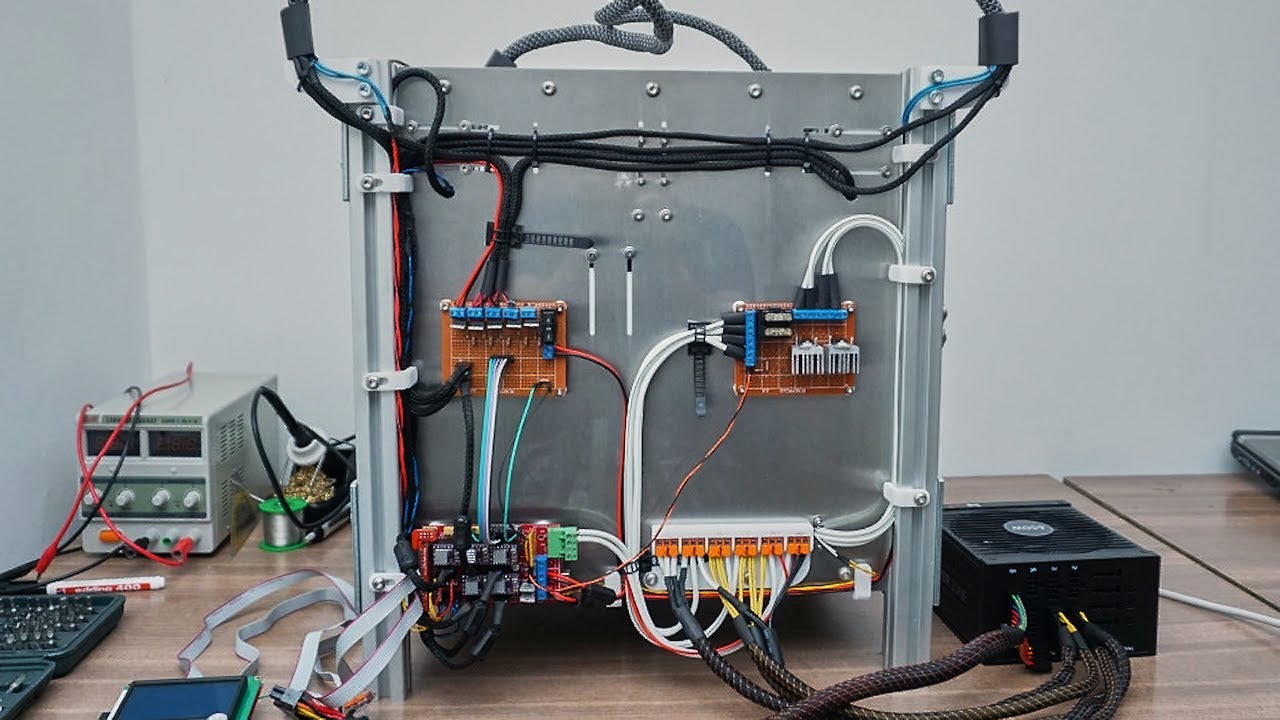

In collaboration with selective laser melting experts at the Danish Institute of Technology (DTI), cycling pioneer CeramicSpeed has developed a lightweight and durable pulley that allows professional cyclists to improve their performance. The global bicycle market is driven by innovation. Committed to being at the forefront of the industry, CeramicSpeed has partnered with DTI to revolutionize the world of professional cycling with the introduction of ceramic bearings. With the SLM 500 (four lasers) and SLM 280 (two lasers) metal additive printing machines, the institute has been successfully implementing selective laser melting for many years, being the ideal partner for development optimization.

The result of the collaboration is the world's lightest gear wheel, the so-called titanium pulley, developed by two partners together with professional riders who have tested the new solution in the conditions of the Tour de France.

Photo: Dansk Teknologisk Institut / dti.

dk

dk Part data

- Name: drive pulley

- Application: cycling

- Material: titanium

- Layer thickness: 60 microns

- Production time: 21.5 hours (full load, 120 elements)

- Equipment: SLM 500 3D printer

What did design optimization and SLM printing yield?

- Improved quality: 3-5 times longer service life.

- Significant weight reduction due to the hollow shape of the product.

- Process optimization: mass production despite design complexity.

High productivity through additive manufacturing

Pulleys made of titanium, equipped with 17 spokes, each 2 mm in diameter with a wall thickness of only 0.4 mm. Due to the hollow design, it was possible to reduce the total weight of the sprocket to 8.4 grams. The overall energy savings in the system reach 30-60%, and in some cases even more, compared to the standard configuration. The service life of optimized pulleys is 3 to 5 times longer than standard pulleys on the market.

Thor Bramsen, director of industrialization at the Danish Institute of Technology, is enthusiastic about the possibilities of SLM technology: “The hollow geometry of objects cannot be realized with conventional methods, but 3D printing, combined with subsequent specialized processes, makes it possible to obtain a unique innovative product” . Despite complex geometries, DTI can consistently produce parts of the same quality in series production.

“3D printing technology has given us a lot of freedom to experiment creatively in design while at the same time optimizing the function of the product, ,” says Carsten Ebbesen, Director of R&D CeramicSpeed. “ The collaboration with DTI has allowed us to develop and produce completely new gear designs that can only be realized through 3D printing.”

SLM gears have also been subjected to rigorous testing. The pulleys are mounted on the outer gears of the gear mechanism and are tested for wear. CeramicSpeed's R&D department tested the wear of printed titanium parts, which proved to be more durable and resistant to corrosion and provide higher strength at a lower density than traditional aluminum parts.

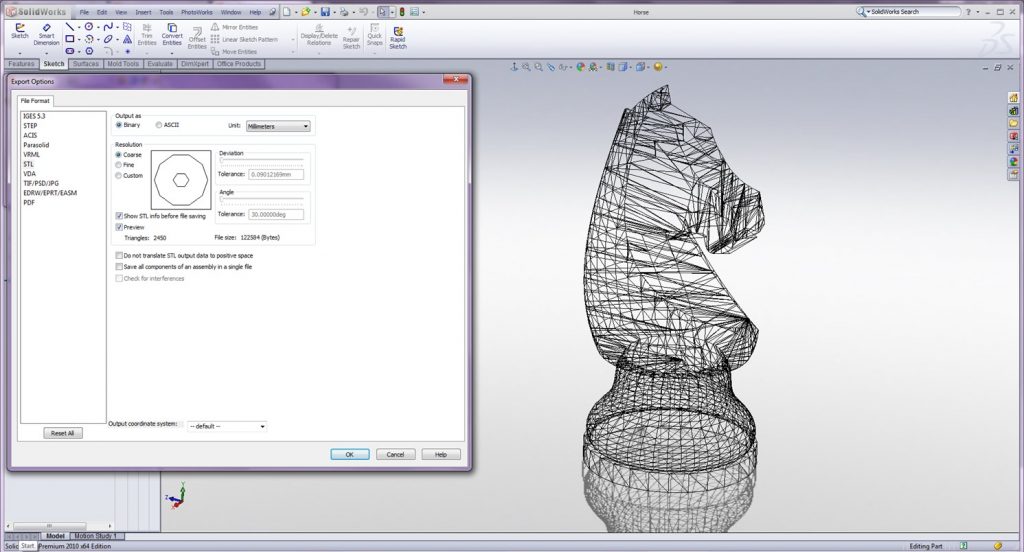

To organize serial additive manufacturing of high quality products, it is necessary to coordinate the entire technological process. This includes choosing reliable AM equipment, but the process starts with redesigning the AM components. DTI used design principles for additive manufacturing (DfAM) to optimize CeramicSpeed's original product design for mass production based on selective laser melting technology. This required a careful approach to maintain the customer's original design, add material for CNC-machined post-print surfaces, optimize supports, and minimize wall thickness and weight.

Successful production is followed by equally complex and equally important post-processing steps, where DTI specialists apply all their manufacturing experience, ensuring that only assembly is required when the finished product is delivered.

The first ceramic bearings from CeramicSpeed were introduced at the Tour de France less than 20 years ago. Innovative engineering enabled by SLM technology and collaboration with experts from the Danish Institute of Technology help the company push the boundaries of cycling technology and set new standards as riders test the latest advances in training to present new developments in future competitions.