Pla 3d print

Ultimate Materials Guide - Tips for 3D Printing with PLA

Overview

Polylactic Acid, commonly known as PLA, is one of the most popular materials used in desktop 3D printing. It is the default filament of choice for most extrusion-based 3D printers because it can be printed at a low temperature and does not require a heated bed. PLA is a great first material to use as you are learning about 3D printing because it is easy to print, very inexpensive, and creates parts that can be used for a wide variety of applications. It is also one of the most environmentally friendly filaments on the market today. Derived from crops such as corn and sugarcane, PLA is renewable and most importantly biodegradable. As a bonus, this also allows the plastic to give off a sweet aroma during printing.

- Low Cost

- Stiff and good strength

- Good dimensional accuracy

- Good shelf life

- Low heat resistance

- Can ooze and may need cooling fans

- Filament can get brittle and break

- Not suitable for outdoors (sunlight exposure)

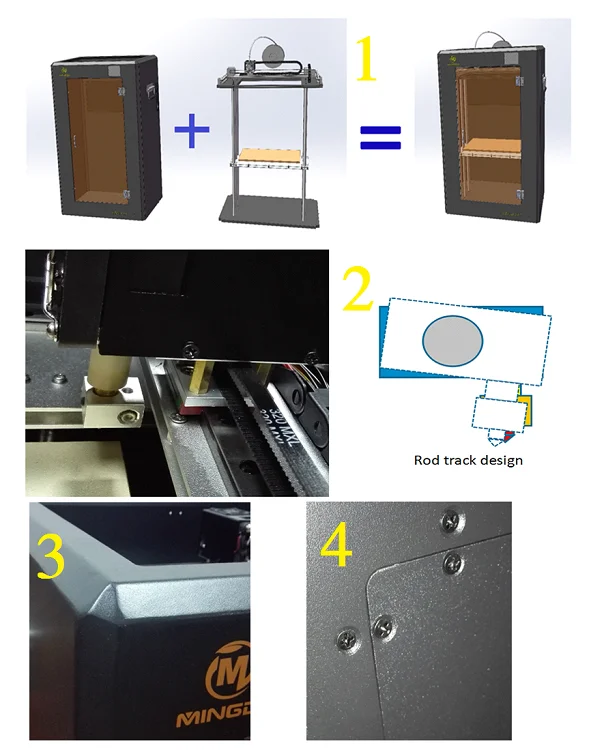

Hardware Requirements

Before 3D printing with PLA make sure your 3D Printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 45-60 °C

Heated Bed Optional

Enclosure not required

Build Surface

Painter’s tape

PEI

Glass plate

Glue stick

Extruder

Temperature: 190-220 °C

No special hot-end required

Cooling

Part Cooling Fan Required

Fan Speed: 100%

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with PLA such as stringing, oozing, or under-extrusion.

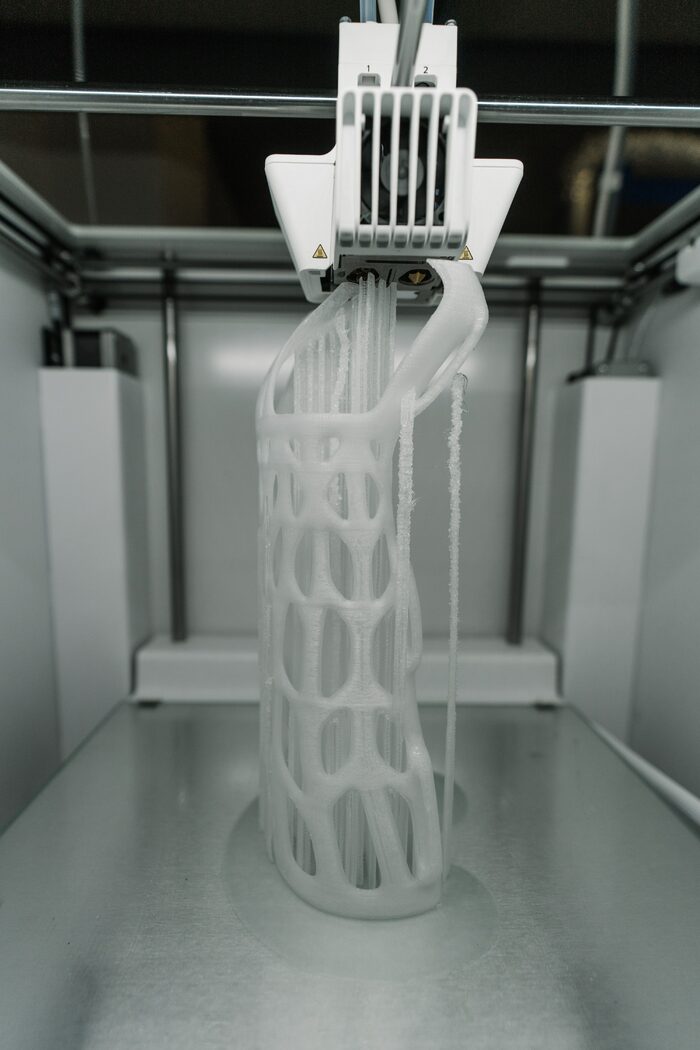

Fine Tune the Retractions to Prevent Oozing

One of the most common problems with PLA is oozing. Since the filament flows relatively easily when compared to the other materials, it has a tendency to continue flowing during travel movements at the end of a segment. This creates strings or hairs on your part, and dialing in your retraction settings is the best way to combat this behavior! Different brands of PLA and different printers may need slightly different retraction settings, so you may need to experiment to find the best value for your printer. Simplify3D added a very useful feature in Version 4.0 that can help with this, by allowing you to quickly try dozens of different settings, and then look at the final part to determine which one worked the best on your specific setup. For example, you could setup two vertical pillars which are printed side-by-side to evaluate stringing when moving back-and-forth between each pillar. Then go to Tools > Variable Settings Wizard and choose how you want to adjust your settings during the print. For example, you could try a different retraction distance for each 20mm section of the print and then pick the value that works best in the end. For more tips on how to reduce stringing and oozing, be sure to check out our Print Quality Guide which contains an entire section dedicated to this issue: How to Reduce Stringing and Oozing.

Simplify3D added a very useful feature in Version 4.0 that can help with this, by allowing you to quickly try dozens of different settings, and then look at the final part to determine which one worked the best on your specific setup. For example, you could setup two vertical pillars which are printed side-by-side to evaluate stringing when moving back-and-forth between each pillar. Then go to Tools > Variable Settings Wizard and choose how you want to adjust your settings during the print. For example, you could try a different retraction distance for each 20mm section of the print and then pick the value that works best in the end. For more tips on how to reduce stringing and oozing, be sure to check out our Print Quality Guide which contains an entire section dedicated to this issue: How to Reduce Stringing and Oozing.

Optimize Your Cooling Settings

Cooling is one of the most important aspects of printing with PLA. Having a dedicated part cooling fan makes a huge difference in the quality of the printed parts. The freshly extruded plastic needs to cool down below the glass transition temperature as quickly as possible. This will prevent the plastic from stringing and producing other artifacts. We recommend setting the fan to 100% throughout the print, except for the first 1-2 layers where you want to form a strong bond with the print bed. Simplify3D also includes a useful option on the Cooling tab of your process settings that can automatically reduce the print speed for small parts, ensuring that the layers have sufficient time to cool. This can greatly improve the print quality by allowing the layer to solidify before printing the next layer on top of it. This setting can be found on the Speeds tab of your process settings.

The freshly extruded plastic needs to cool down below the glass transition temperature as quickly as possible. This will prevent the plastic from stringing and producing other artifacts. We recommend setting the fan to 100% throughout the print, except for the first 1-2 layers where you want to form a strong bond with the print bed. Simplify3D also includes a useful option on the Cooling tab of your process settings that can automatically reduce the print speed for small parts, ensuring that the layers have sufficient time to cool. This can greatly improve the print quality by allowing the layer to solidify before printing the next layer on top of it. This setting can be found on the Speeds tab of your process settings.

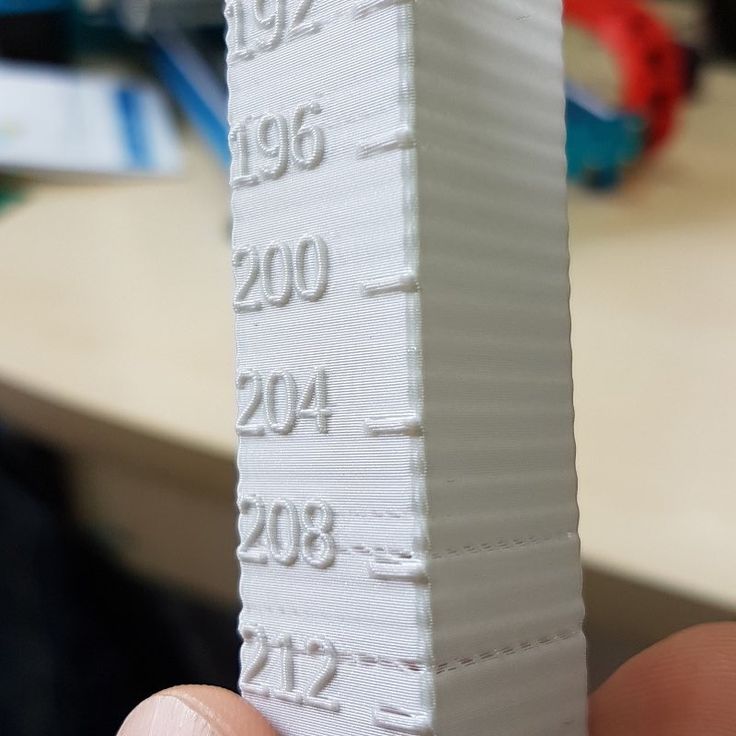

Choose the Correct Extruder Temperature

This is a great tip for any filament, but is especially useful for PLA which often contains different combinations of additives depending on the manufacturer. These different additives can lead to variations in printing temperature between 190-230 degrees Celsius. If you are not printing at the right temperature this can lead to several print quality issues including oozing, stringing, and under-extrusion. PLA can also be combined with different fills like metal, wood, and fiber that give it different characteristics than a standard homogeneous PLA. These may require different settings or even different hardware. Be sure to check with the manufacturer of your filament to verify the optimal temperature to use for your specific filament. If you have trouble with stringing, try reducing this temperature by 5-10 degrees, which will help prevent the excess oozing. If you’re struggling with under-extrusion, try increasing the temperature by 10 degrees so that the material flows more easily through the nozzle.

If you are not printing at the right temperature this can lead to several print quality issues including oozing, stringing, and under-extrusion. PLA can also be combined with different fills like metal, wood, and fiber that give it different characteristics than a standard homogeneous PLA. These may require different settings or even different hardware. Be sure to check with the manufacturer of your filament to verify the optimal temperature to use for your specific filament. If you have trouble with stringing, try reducing this temperature by 5-10 degrees, which will help prevent the excess oozing. If you’re struggling with under-extrusion, try increasing the temperature by 10 degrees so that the material flows more easily through the nozzle.

Pro-Tips

- Using a fan that cools the 3D printed part from all directions is highly recommended. Many popular 3D printers have community-designed attachments that can be printed and retrofitted onto your machine to improve the cooling airflow.

- Increasing the number of perimeter outlines for your PLA prints will create a strong bond between each layer, creating stronger parts that are less prone to breaking.

Get Started with PLA

Now that you are ready to start printing with PLA, here’s a bit more information to help you get started. Start thinking of project ideas by reviewing our common applications, try out one of the provided sample projects, or find a new filament to try from our list of popular material brands.

Common Applications

- Test and calibration items

- Dimensionally accurate assemblies

- Decorative Parts

- Cosplay Props

Sample Projects

- LA Spring Motor, Rolling Chassis

- G – Clamp

- Storm Trooper Helmet

Popular Brands

- Polymaker PLA, PolyMax, PolyPlus

- ColorFabb PLA/PHA

- Hatchbox PLA

- eSun PLA

- Filamentum PLA

MH Build Series PLA | MatterHackers

Technical Specifications

- PLA Filament Temperature: 205±15°C

- 3D Printing Speed: 50mm/s

- Heated Bed: 50°C (A heated bed is not necessary to print PLA, but if your 3D Printer has a heated bed, MatterHackers recommends using it)

- 1.

75mm PLA Filament True Diameter: 1.75 ±0.05mm

75mm PLA Filament True Diameter: 1.75 ±0.05mm - 2.85mm PLA Filament True Diameter: 2.85 ±0.05mm

- Spool Dimensions (Approx.): 200mm Total Diameter x 50mm Inner Hole Diameter x 65mm Height

- Chemical Identification: Polylactic Acid

- 3D Printer Compatibality: Ultimaker, LulzBot, MAKEiT, Raise3D, Prusa i3, and more! The ease of 3D printing in PLA makes it compatible with all the best 3D printers.

MH Build Series Filament

MH Build Series ABS

An affordable 3D printing filament meant for every maker with projects that require durable and temperature resistant parts.

MH Build Series PLA

An affordable, low-cost PLA filament intended for producing quality, 3D printed parts.

MH Build Series PETG

An affordable, low-cost PETG filament intended for producing tough and sturdy 3D printed parts.

MH Build Series TPU

An affordable, low-cost TPU filament intended for producing quality, 3D printed parts.

MH Build Series Silky PLA

An affordable, low-cost silky PLA filament intended for producing high quality beautiful 3D prints

MH Build Series PVA Filament

An affordable, low cost PVA filament intended for producing supports when printing complex 3D prints

Guides & Articles

How To Succeed When 3D Printing With PLA Filament

Discover the best practices for 3D printing with PLA filament - from finding the right temperature, to which surfaces to 3D print on, this step-by-step guide will help you succeed with 3D printing PLA.

How To: Smooth and Finish Your PLA Prints - Part 1

Making your 3D prints look fresh off the assembly line isn't as hard as you think. Follow these simple techniques to finish your 3D prints and make them shine.

How To: Smooth and Finish Your PLA Prints - Part 2

3D printing is a wonderful process, but for convention and show ready prints, some post-processing may be necessary. Learn some helpful techniques from our resident cosplayer to turn even the most polygonal model into a smooth masterpiece.

Learn some helpful techniques from our resident cosplayer to turn even the most polygonal model into a smooth masterpiece.

3D Printer Filament Comparison Guide

There are many different kinds of 3D printer filament, and each one has it's own strengths for different projects. Knowing these differences is key to a successful 3D printing experience and so we have created a Filament Comparison Guide with everything you need to know about every type of filament available.

3D Printer Troubleshooting Guide

Use this guide to help you identify and solve the most common issues that may occur while 3D printing.

Retraction: Just say "No" to oozing

By understanding a little more about the 3D printing process, and how settings in MatterControl affect extrusion, we can help you reduce and even eliminate oozing and stringing from your 3D prints. This should be a part of the regular maintenance and calibration program for your 3d printer.

How To Clear and Prevent Jams on Your 3D Printer

At some point you may encounter a filament jam or a clogged nozzle where your 3D printer is not extruding. This guide is intended to help you prevent such jams, or fix with them as painlessly as possible.

Extruders 101: A crash course on an essential component of your 3D printer

The extruder, a piece that could determine the success or failure of your print. Shoot for success with this simple guide that can improve your print quality.

PLA print settings | How to choose modes for PLA filament

PLA plastic filament is used in FDM 3D printers. This is a truly amazing material that is environmentally friendly and non-toxic. During printing, it does not “stink”, but emits a light aroma of popcorn. The thing is that it is made on the basis of natural plant materials - corn, potatoes, cane, etc.

If you compare PLA with ABS, it turns out that the former is harder, and therefore the process of applying the next layer will be slower. But this has a positive effect on the result of printing, because the products are smoother. However, this imposes its own characteristics on the print settings, the choice of which should be guided by the characteristics of the material.

But this has a positive effect on the result of printing, because the products are smoother. However, this imposes its own characteristics on the print settings, the choice of which should be guided by the characteristics of the material.

PLA plastic specifications

PLA plastic for 3D printers has a number of key characteristics. Depending on the brand, the properties may vary slightly. However, this material is characterized by:

- strength and rigidity;

- translucency and even transparency;

- wide range of colors;

- smooth, detailed finished models and shiny surface.

PLA turns out to be easier to work with, ideal for those new to 3D printing as it doesn't warp or shrink like ABS. But it is less heat-resistant and already at 70 degrees it can begin to deform.

8%

8% The most important layer in FDM 3D printing will always be the first layer. It must be fixed on the desktop to avoid further deformation. In this regard, PLA plastic is less demanding in comparison with ABS. But many use special substrates, blue tape or glue stick. You can print simply on glass, especially if the 3D printer is equipped with a heated table. The optimum temperature in this case will be 70 degrees, although in some cases, it has been experimentally established that the best results are achieved on a cold table.

The second point - it is important to correctly set the height of the extruder. The nozzle should be at such a height that a standard sheet can easily pass between it and the work table.

Next, you need to decide on the standard set of settings:

- temperature;

- layer thickness;

- table temperature (if heated).

Another important point to get the best print result from PLA is to use the blower at full power. So the plastic will be cooled in time and not deformed.

As with ABS, print performance will be derived empirically. For example, the temperature will be set to 200 degrees and then raised or lowered by 5 degrees until the best option is found, in which the layers will perfectly hold together, have time to freeze and not swim.

And the average print settings for PLA are as follows:0026

, nevertheless, is still guided by the recommendations . Add to this experienced developments and the best printing result will not be long in coming.

Material comparison:

Poor +

Satisfactory + +

normal + +

Good + + +

excellent + + + +

|

| ABS HIPS FLEX | + + + + | + + + + + | + + | + + | + + + | + + | + + + + | ||

| Light fur. Processing | + + + + | + + | + + | + | + | + + | + + + | |||

| Durability on the street | + + | + | + + | + + + 9003 | + + + | + + + | + + | + | Thermal resistance | + + + | + + | + + + | + + + + | + + | + 9002 + | + + + + | + + + + | + | + + | + + + | + 9,0000033 |

| Proceeds | + + + | + + | + | + + + | + + + + + . | + + | ||||

| Oil resistance | + + + | + + + | + + | -40°С to +70°С | -40°С to +100С | -35°С to +85°С | ~190°С fusion temperature -10°C to +30°C |

Simplify3D PLA print settings

Below are the recommended print settings for PLA plastic and job preparation in the Simplify3D slicer.

Main parameters: printer print area - 200x200x210 mm, nozzle diameter - 0.3 mm. *These values need to be changed for your printer.

Translation of tabs and parameters of the Simplify3D slice is submitted by the link - go

9000 9000 9000 9000 9000

Printe Print 3D

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with.