3D printed gun test fire

Test-Firing The World's First Fully 3D-Printed Gun

“Alright. One…two…”

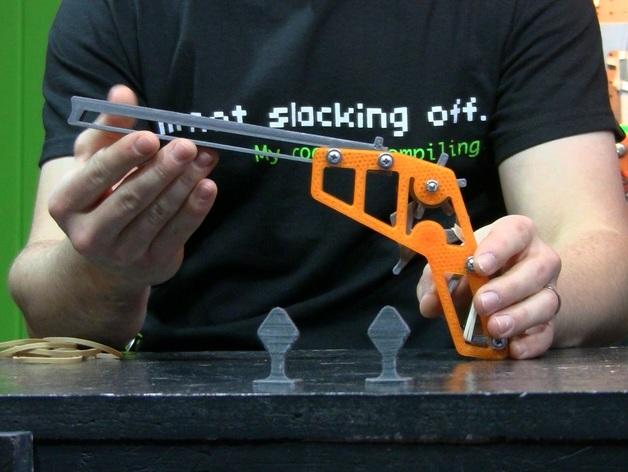

Before “three” arrives, a shot reverberates across the overcast central Texas landscape. A tall, sandy blond engineer named John has just pulled a twenty-foot length of yellow string tied to a trigger, which has successfully fired the world’s first entirely 3D-printed gun for the very first time, rocketing a .380 caliber bullet into a berm of dirt and prairie brush.

“Fuckin’ A!” yells John, who has asked me not to publish his full name. He hurries over to examine the firearm bolted to an aluminum frame. But the first to get there is Cody Wilson, a square-jawed and stubbled 25 year-old in a polo shirt and baseball cap. John may have pulled the trigger, but the gun is Wilson’s brainchild. He’s spent more than a year dreaming of its creation, and dubbed it “the Liberator” in an homage to the cheap, one-shot pistols designed to be air-dropped by the Allies over France during its Nazi occupation in World War II.

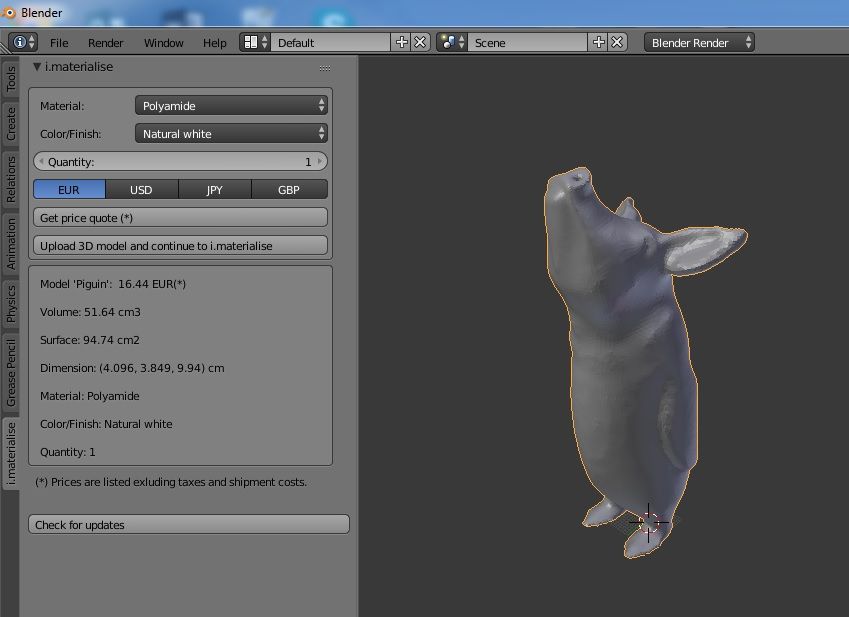

Unlike the original, steel Liberator, though, Wilson’s weapon is almost entirely plastic: Fifteen of its 16 pieces have been created inside an $8,000 second-hand Stratasys Dimension SST 3D printer, a machine that lays down threads of melted polymer that add up to precisely-shaped solid objects just as easily as a traditional printer lays ink on a page. The only non-printed piece is a common hardware store nail used as its firing pin.

Wilson crouches over the gun and pulls out the barrel, which was printed over the course of four hours earlier the same morning. Despite the explosion that just occurred inside of it, both the barrel and the body of the gun seem entirely unscathed.

Wilson scrutinizes his creation for a few more seconds, then stands up again. “I think we did it,” he says, a little incredulous.

Last August, Wilson, a law student at the University of Texas and a radical libertarian and anarchist, announced the creation of an Austin-based non-profit group called Defense Distributed, with the intention of creating a firearm anyone could fabricate using only a 3D printer. The digital blueprints for that so-called Wiki Weapon, as Wilson imagined it, could be uploaded to the Web and downloaded by anyone, anywhere in the world, hamstringing attempts at gun control and blurring the line between firearm regulation and information censorship. “You can print a lethal device. It’s kind of scary, but that’s what we’re aiming to show,” Wilson told me at the time. “Anywhere there’s a computer and an Internet connection, there would be the promise of a gun.”

The digital blueprints for that so-called Wiki Weapon, as Wilson imagined it, could be uploaded to the Web and downloaded by anyone, anywhere in the world, hamstringing attempts at gun control and blurring the line between firearm regulation and information censorship. “You can print a lethal device. It’s kind of scary, but that’s what we’re aiming to show,” Wilson told me at the time. “Anywhere there’s a computer and an Internet connection, there would be the promise of a gun.”

On May 1st, Wilson assembled the 3D-printed pieces of his Liberator for the first time, and agreed to let a Forbes photographer take pictures of the unproven device. A day later, that gun was tested on a remote private shooting range an hour's drive from Austin, Texas, whose exact location Wilson asked me not to reveal.

The verdict: it worked. The Liberator fired a standard .380 handgun round without visible damage, though it also misfired on another occasion when the firing pin failed to hit the primer cap in the loaded cartridge due a misalignment in the hammer body, resulting in an anti-climactic thunk.

The printed gun seems limited, for now, to certain calibers of ammunition. After the handgun round, Wilson switched out the Liberator’s barrel for a higher-charge 5.7x28 rifle cartridge. He and John retreated to a safe distance, and John pulled his yellow string again. This time the gun exploded, sending shards of white ABS plastic flying into the weeds and bringing the Liberator’s first field trial to an abrupt end.

Update: Defense Distributed's CAD file for the Liberator and its video introducing the gun are now online.

On the ride back to Austin after that first test-fire, Wilson seemed less than satisfied with the relative success of his 3D printed creation. He fixated on its misfiring and brooded about the tight deadline he'd given himself to work out its kinks before sharing the design on the Web. “I feel no sense of achievement," he told me. "There's a lot of work to be done."

He fixated on its misfiring and brooded about the tight deadline he'd given himself to work out its kinks before sharing the design on the Web. “I feel no sense of achievement," he told me. "There's a lot of work to be done."

And the most significant test of the Wiki Weapon was still to come, a moment of truth that may have been looming in Wilson's mind after watching his first prototype explode into plastic shrapnel: Firing the Liberator by hand.

***

By Friday at noon, photographs of the world's first 3D-printed gun published on this site set off a new round of controversy in a story that has shoved one of the most hyped trends in technology into one of the most contentious crossfires in American politics. New York Congressman Steve Israel responded to Defense Distributed's work by renewing his call for a revamp of the Undetectable Firearms Act, which bans any firearm that doesn't set off a metal detector. "Security checkpoints, background checks, and gun regulations will do little good if criminals can print plastic firearms at home and bring those firearms through metal detectors with no one the wiser," read a statement sent to me and other reporters.

Update: On Sunday, New York Senator Charles Schumer echoed Israel's call for that new legislation to ban 3D-printable guns. "A terrorist, someone who's mentally ill, a spousal abuser, a felon can essentially open a gun factory in their garage," Schumer said in a press conference.

Israel and Schumer are hardly the first to oppose Wilson's gun-printing mission. Last August, Defense Distributed's fundraising campaign was booted from the crowdfunding platform Indiegogo. In October, 3D printer maker Stratasys seized a printer leased to the group after it found out how the machine was being used. And Wilson says he's lost access to two workshop spaces after those renting to him learned about his mission. Instead, Defense Distributed has had to move its workshop to a 38-square-foot room at the southern edge of Austin that's about the size of a walk-in closet, hardly larger than the refrigerator-sized 3D printer it houses.

But at each roadblock, the group has found a detour. It's raised funds from donors through the digital payment system Bitcoin, which thanks to that crypto-currency's rising value now accounts for 99% of Defense Distributed's assets, according to Wilson. In March it received a federal license to manufacture firearms, which Wilson has framed and posted on the wall of the group's miniscule workshop. And it's complied with the Undetectable Firearms Act by inserting a six ounce cube of non-functional steel into the body of the Liberator, which makes it detectable with a metal detector--Wilson spent $400 on a walk-through model that he's installed at the workshop's door for testing. "Our strategy is overcompliance," he says. (There's no guarantee, of course, that anyone who downloads and prints the Liberator will insert the same chunk of detectable metal. )

)

The group's initial success in testing the Liberator may now silence some of its technical naysayers, too. Many skeptics (include commenters on this blog) have claimed that no plastic gun could ever handle the pressure and heat of detonating an ammunition cartridge without deforming or exploding. But Defense Distributed's design has done just that. After the test-firing I witnessed, Wilson showed me a video of an ABS plastic barrel the group printed attached to a non-printed gun body firing ten rounds of .380 ammunition before breaking on the eleventh.

Even Wilson himself says he's not sure exactly how that's possible. But one important trick may be the group's added step of treating the gun's barrel in a jar of acetone vaporized with a pan of water and a camp stove, a process that chemically melts its surface slightly and smooths the bore to avoid friction. The Dimension printer Defense Distributed used also keeps its print chamber heated to 167 degrees Fahrenheit, a method patented by Stratasys that improves the parts' resiliency.

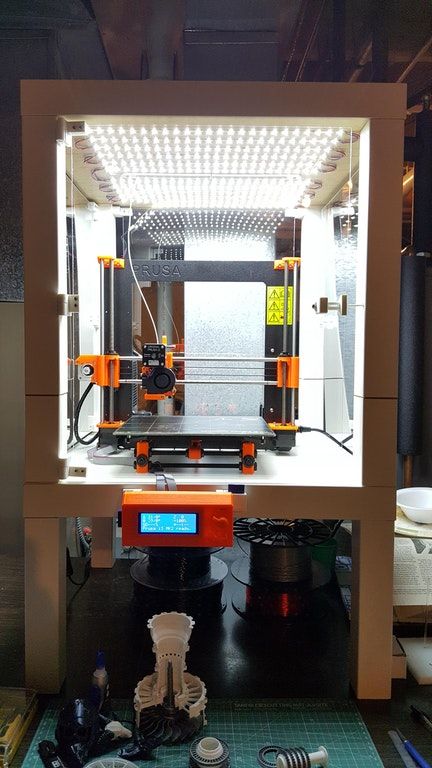

Defense Distributed's goal is to eventually adapt its method to work on cheaper printers, too, like the $2,200 Replicator sold by Makerbot or the even cheaper, open-source RepRap. Even if a barrel is deformed after firing, Defense Distributed has designed the Liberator to use removable barrels that can be swapped in and out in seconds.

Wilson hasn't shied from the growing controversy around his project. The Sandy Hook, Connecticut massacre in which a lone gunman killed twenty children and six adults only increased his sense of urgency to circumvent the anticipated wave of gun control laws. As Congress mulled limits on ammunition magazines larger than ten rounds, Defense Distributed created 3D-printable 30-round magazines for AR-15 and AK-47 rifles. In March, it released a YouTube video of a 3D-printable AR-15 lower receiver that can fire hundreds of rounds without failing. The lower receiver is the regulated body of the gun. Anyone who prints it can skirt gun laws and order the rest of the weapon's parts by mail.

Much of the criticism has focused on Wilson himself, by far the most visible figure in Defense Distributed's collection of 15 on-and-off volunteer designers and engineers spread across the world. He's received more than a dozen death threats, along with many wishes that someone would use his own 3D printed weapons to kill him. Wired included Wilson in its list of the 15 most dangerous people in the world. The Coalition To Stop Gun Violence calls him a "hardcore insurrectionist" who advocates anti-government violence. "This guy is basically saying 'print your own guns and be ready to kill government officials,'" says Ladd Everitt, a CSGV spokesperson. "The fact that we’re not talking about [him in those terms] after the Boston bombings is incredible."

But Wilson denies advocating any sort of violent revolt in America. Instead, he argues that his goal is to demonstrate how technology can circumvent laws until governments simply become irrelevant. "This is about enabling individuals to create their own sovereign space. ..The government will increasingly be on the sidelines, saying 'hey, wait,'" says Wilson. "It's about creating the new order in the crumbling shell of the old order."

..The government will increasingly be on the sidelines, saying 'hey, wait,'" says Wilson. "It's about creating the new order in the crumbling shell of the old order."

Wilson doesn't deny that his gun could be used for murder or political violence. "I recognize that this tool might be used to harm people. That's what it is: It's a gun," he says. "But I don't think that's a reason to not put it out there. I think that liberty in the end is a better interest."

He prefers to think of his Liberator in the same terms as its namesake, the one built for distribution to resistance fighters in Nazi-occupied countries in the 1940s. That plan was conceived in part as a psychological operation aimed at lowering the occupying forces' morale, Wilson says, and he believes his project will strike a similar symbolic blow against governments around the world. "The enemy took notice that weapons were being dropped from the sky," he says. "Our execution will be better. We have the Internet."

***

On a blazing Saturday afternoon, Wilson returns to the remote firing range where he first tested the Liberator. None of his Defense Distributed compatriots have joined him this time--John the engineer is away at the annual meeting of the National Rifle Association in Houston. But Wilson is accompanied by his father, Dennis, a lawyer from Little Rock, Arkansas who has flown in to witness a historic moment: His son plans to fire a fully 3D-printed weapon by hand for the first time.

None of his Defense Distributed compatriots have joined him this time--John the engineer is away at the annual meeting of the National Rifle Association in Houston. But Wilson is accompanied by his father, Dennis, a lawyer from Little Rock, Arkansas who has flown in to witness a historic moment: His son plans to fire a fully 3D-printed weapon by hand for the first time.

Wilson has spent the last few days tweaking the Liberator's CAD file and re-printing its barrel, hammer and body to realign its firing pin and solve the misfire issue. But he becomes quieter as the moment of testing approaches. His father asks how far it is to the nearest hospital: a 45 minute drive. We consider how to make a tourniquet if things go badly. "You guys are going to make me lose my nerve," says Wilson, smiling nervously.

Everyone but Wilson falls back behind him. Wilson opens the case holding the newly-printed pieces and assembles them, then loads the gun and inserts ear plugs into his ears.

He inhales sharply, aims the Liberator, fires it, and then exhales, in quick succession.

"Outstanding," says Dennis Wilson. "Congratulations, my son."

Wilson visibly relaxes. He shakes his father's hand with his own fully-intact digits. Later he'll examine the gun and find no obvious signs of damage other than a cracked pin used to hold the barrel in place.

For a few moments, Wilson seems lost for words. His expression is hidden behind his sunglasses. Then he says the first thing that comes to his mind. "Well, there are going to be some changes around here."

—

Follow me on Twitter, and check out my new book, This Machine Kills Secrets: How WikiLeakers, Cypherpunks and Hacktivists Aim To Free The World’s Information.

Related on Forbes:

Gallery: Ten Wild Things You Can 3D Print At Home

10 images

View gallery

It works! First 3D-printed gun test-fired

News

Defense Distributed also printed a 30-round magazine and AR-15 rifle parts

By Lucas Mearian

Senior Reporter, Computerworld |

Defense Distributed, the company that developed the Liberator 3D printed gun, today released a YouTube video demonstrating its first test firing of the weapon.

With dramatic orchestral music setting the tone, the video shows a man firing a single shot of a white-resin pistol that looks more like a flare gun than a modern handgun -- its only metal component is the firing pin. The video then goes on to depict some of the steps involved in making the Liberator with a 3D printer.

The video then goes on to depict some of the steps involved in making the Liberator with a 3D printer.

Defense Distributed, which makes The Liberator 3D printed gun, released this video demonstrating the first test firing of the weapon.

Cody Wilson, the 25-year-old University of Texas law student who founded Austin-based Defense Distributed, told the BBC that he understands that printed guns could be used to hurt people but said: "I don't think that's a reason to not do it -- or a reason not to put it out there."

Defense Distributed's website makes no bones about its goals: "To defend the civil liberty of popular access to arms as guaranteed by the United States Constitution and affirmed by the United States Supreme Court, through facilitating global access to, and the collaborative production of, information and knowledge related to the 3D printing of arms; and to publish and distribute, at no cost to the public, such information and knowledge in promotion of the public interest. "

"

Defense Distributed plans to publish the blueprints for making the printable gun online.

Staples plans to begin selling 3D printers next month. So it's conceivable that people could begin "printing" their own guns this year.

Along with the Liberator, Defense Distributed has also printed a 30-round magazine and the lower receiver for an AR-15 assault rifle, the semi-automatic civilian model of the U.S. military's M16 rifle.

This article, "It Works! First 3D-printed Gun Test-Fired," was originally published on Computerworld.com.

Lucas Mearian covers storage, disaster recovery and business continuity, financial services infrastructure and health care IT for Computerworld. Follow Lucas on Twitter at @lucasmearian, or subscribe to Lucas's RSS feed . His email address is [email protected].

See more by Lucas Mearian on Computerworld.com.

Related:

- Emerging Technology

- Consumer Electronics

Senior Reporter Lucas Mearian covers Windows, Future of Work issues, mobile, Apple in the enterprise, and healthcare IT.

Copyright © 2013 IDG Communications, Inc.

7 inconvenient truths about the hybrid work trend

Europol on the dangers of 3D printed weapons

According to the European Police Office, 3D printed weapons may become a serious threat in the near future due to the rapid development of technology. The first such model was made in the USA in 2013, and since then people have been dying from weapons that can be made at home. Technology is taking the problem of unaccounted weapons to a new level, experts say.

“Due to the rapid development of technology, 3D printed weapons could become a serious threat in the near future,” Europol said.

In recent months, raids and searches by European authorities have increasingly turned up firearms made in whole or in part using the aforementioned method, which is dangerous in many respects.

On the one hand, now the price of 3D printers is significant, so it is already cost-effective to produce such weapons, and on the other hand, this does not require any registrations, production numbers, so the authorities cannot track manufacturers at all.

In addition, weapons are not detected by metal detectors, so they can, for example, be easily smuggled anywhere. In one case, for example, journalists successfully entered the Israeli parliament's security system as an experiment to watch a speech by then-Israeli Prime Minister Benjamin Netanyahu with a 3D printed gun in his bag.

In September, four people were arrested in Iceland on terrorism charges, and searches revealed several semi-automatic weapons containing 3D printed parts. In Spain, too, there have been reports of the liquidation of illegal "arms factories" where 3D printers have always been found. In early October, the largest stockpile of 3D printed gun parts was discovered at a factory in London, and British authorities have warned of the growing danger this entails.

The first weapon, called the "Liberator", consisting almost entirely of 3D printed parts, except for the fuse and cartridge, was made in the USA in 2013, and its design was immediately leaked to the Internet. Since then, countless users have been creating similar weapons, blueprints, and posting them on various social media sites that anyone can download and make at home with the proper technology. At first, all this could only be achieved using industrial 3D printers, however, due to the development of technology, today a simple model is enough for this.

Since then, countless users have been creating similar weapons, blueprints, and posting them on various social media sites that anyone can download and make at home with the proper technology. At first, all this could only be achieved using industrial 3D printers, however, due to the development of technology, today a simple model is enough for this.

Social networks and Internet platforms are trying to remove these users, limit their access, but they are not keeping up.

What is known about the effectiveness of such weapons at this time? In 2019, in the German city of Halle, a man killed two people and wounded two more with homemade weapons that included 3D printed parts. The footage of the attack shows that the weapon jammed several times. In the first test, the Liberator burst after the tenth shot. Due to the plastic parts, these weapons cannot withstand the heat generated when using them, so illegal manufacturers make only parts for which this aspect is less important on a 3D printer.

While experts in Europe are unanimous that there is currently no need to fear that terrorists and criminals will turn to 3D printed weapons, this could change dramatically in the next decade. In a few years, 3D printing of metals will also become available to ordinary people, which will make homemade weapons more durable and reliable, and then this will also become a big problem.

If you find an error, please highlight the text and press Ctrl+Enter .

Is it possible to print airguns and firearms

Is it possible to make a gun on a 3D printer and is it legal?

Today's 3D printers offer enormous possibilities. They can print products of almost any complexity. Until quite recently, it was difficult to even imagine that a plastic weapon could shoot. However, it is already possible to make a pistol on a 3D printer, which, although not reliable, still fires live ammunition.

Can firearms be 3D printed?

As far back as 2013, a young American activist for the free sale and distribution of weapons proved that plastic weapons can be printed on a 3D printer. He was the first in the world to make a pistol in this way, in which only the striker was made separately from metal. All other parts were printed on an FDM printer.

He was the first in the world to make a pistol in this way, in which only the striker was made separately from metal. All other parts were printed on an FDM printer.

Today's 3D printers are capable of printing any CAD model, and these models of firearms have been available for over 10 years. If in previous years their printing required professional skills, now almost any user can master them. With a 3D printer and a finished model, it became quite possible to print a gun. Another thing is that such "creativity" is punishable by the laws of most countries.

The evolution of 3D printed weapons

Despite all the prohibitions and restrictions, the evolution of 3D printed firearms is moving at a great speed. The beginning was laid by the single-shot plastic pistol Liberator by American K. Wilson, which appeared in 2013. It had a simple design and was chambered for 380 ACP. Already after 10-12 shots, this weapon became unusable. However, the very possibility of printing firearms served as an impetus for the development of the idea. The author of the first pistol himself founded the Defense Distributed company, which began to actively improve the technology.

The author of the first pistol himself founded the Defense Distributed company, which began to actively improve the technology.

One of the ways to increase the durability of weapons was to increase the number of their barrels. At the beginning of 2014, the Japanese Y. Imura makes a 38 caliber Zig Zag pistol. He was able to fire up to 6 shots non-stop. The author of the weapon was recognized as a criminal and convicted.

The next step was the production of a six-shot revolver by J. Patrick in 2015. The PM522 Washbear has been shown in action on YouTube. The weapon was noticeably safer for the shooter compared to previous versions, but still allowed to fire only a few dozen rounds.

The first semi-automatic pistol for a 9 mm bullet appeared in 2016 under the name Shuty-MP1. It was developed by a handicraft gunsmith who hid under the pseudonym Derwood. It wasn't exactly a plastic weapon. The author used some metal parts from factory pistols - a barrel, a firing pin, a bolt and several springs. This made it possible to ensure a rate of fire of more than 46 rounds / min. However, when changing the store, the plastic case had to be cooled. In 2017, the same master proposed an improved model - Shuty AP-9.

This made it possible to ensure a rate of fire of more than 46 rounds / min. However, when changing the store, the plastic case had to be cooled. In 2017, the same master proposed an improved model - Shuty AP-9.

The main contribution to the development of 3D printed weapon printing technology was made by Defense Distributed, which brought together a group of like-minded activists. First, these enthusiasts won legal proceedings in the United States and obtained permission to 3D-print weapons, which greatly expanded their capabilities. Secondly, they were able to set up a professional business with product testing and quality control. As a result, in 2018–19 they developed numerous models of a variety of firearms - from pistols to carbines. They posted over 30 files for printing original gun parts. Most of them were plastic, and the metal parts were not made from purchased, ready-made elements, but from simple metal profiles (tubes, strips, etc.), which are sold in ordinary hardware stores. This made it possible to exclude the use of parts patented by gunsmiths.

This made it possible to exclude the use of parts patented by gunsmiths.

At the moment, the semi-automatic carbine FGC-9, developed on the basis of the Shuty AP-9, has become the pinnacle of "creativity" of Defense Distributed. At the same time, there is not a single factory part in it. The barrel for the 9 mm cartridge is made of steel pipe using electrochemical processing.

Where can I get drawings and what should I look for?

Gun manufacturing bans make it much more difficult to get blueprints and models of guns for 3D printing. The right to free placement of information was achieved only by Defense Distributed. Their website provides free access to drawings, models and technologies. Other information can be found on the Internet, but they are usually illegal.

When choosing a model, pay attention to the following information:

- material used;

- cartridge for which the model is designed;

- number of cartridges in the magazine, rate of fire;

- operating time before failure.

It is important to clarify which metal parts will need to be purchased separately, in addition to plastic for printing on a printer.

What does the law say in different countries?

The only country where firearms can be 3D printed is the United States. Gun Control Act 19 applies here68, giving Americans the right to make weapons, but only for personal use. Only one limitation is put forward: it must be determined by metal detectors, that is, it must have a metal element. In virtually all other countries, homemade manufacture and repair of weapons for any purpose is prohibited by law. In Russia, printing it on a 3D printer falls under the Criminal Code of the Russian Federation and is punishable by imprisonment.

Should we be afraid of plastic weapons?

The question of how dangerous a weapon printed on a printer is becoming increasingly important. Despite all the prohibitions, it is extremely difficult to control the spread of technology around the world. The availability of 3D printers and the increase in their functionality make it possible to master the production of plastic guns at home. How dangerous is such a weapon?

The availability of 3D printers and the increase in their functionality make it possible to master the production of plastic guns at home. How dangerous is such a weapon?

Most experts agree that currently printed weapons are more of an interesting toy. It is quite expensive and is designed to carry out only a few dozen shots. Moreover, such pistols are quite dangerous for the shooter himself with live ammunition, because they can explode in their hands.

However, the danger cannot be underestimated. It is easier and cheaper for a "serious" criminal to buy illegal military weapons than to make them on a printer. At the same time, there may be "enthusiasts" who, for their own interest, can make a pistol and try it out in action. Such inadequate people represent an undoubted danger. In addition, the temptation is great for terrorists. Metal detectors do not detect a plastic gun, which means that it is easier to carry it, for example, on an airplane.

Important! Plastic weapons have a very small resource.

At the same time, sometimes just one shot is enough to kill a person.

3D printed firearms have the following advantages:

- the ability to make military weapons at home;

- light weight;

- availability of materials;

- Ability to copy famous weapon models.

Always remember that there are significant disadvantages:

- illegal production;

- high cost of weapons;

- very small resource and limited rate of fire;

- danger to the shooter himself.

Currently, plastic weapons have more disadvantages than advantages, and most importantly, you can get a real prison term for making them.

Prospects for printing weapons

The development potential of 3D printing of firearms is far from exhausted. The expansion of equipment capabilities and the development of innovative materials indicate that in the near future such weapons may approach military weapons in terms of characteristics.