Subtractive 3d printer

Additive vs. Subtractive Manufacturing

Additive manufacturing processes build objects by adding material layer by layer, while subtractive manufacturing removes material to create parts. Though these approaches are fundamentally different, subtractive and additive manufacturing processes are often used side by side due to their overlapping range of applications.

It can initially be difficult to understand how to make the most of each type of technology to optimize product development and manufacturing. Both have cases where it makes sense to use one approach over the other, for example, one process can be more useful for a certain production volume, or at a specific stage of product development.

In this guide, we’ll be taking a closer look at the various additive and subtractive manufacturing techniques and applications to help you decide how to leverage them for your own processes.

Subtractive manufacturing is an umbrella term for various controlled machining and material removal processes that start with solid blocks, bars, rods of plastic, metal, or other materials that are shaped by removing material through cutting, boring, drilling, and grinding.

These processes are either performed manually or more commonly, driven by computer numerical control (CNC).

In CNC, a virtual model designed in CAD software serves as input for the fabrication tool. Software simulation is combined with user input to generate toolpaths that guide the cutting tool through the part geometry. These instructions tell the machine how to make necessary cuts, channels, holes, and any other features that require material removal, taking into account speed of the cutting tool and feed rate of the material. CNC tools manufacture parts based on this computer-aided manufacturing (CAM) data, with little or no human assistance or interaction.

Subtractive manufacturing processes are typically used to create parts in plastics or metals for prototyping, manufacturing tooling, and end-use parts. They’re ideal for applications that require tight tolerances and geometries that are difficult to mold, cast, or produce with other traditional manufacturing methods.

Subtractive manufacturing offers a variety of material and processing methods. Softer materials are much easier to machine to their desired shape, but will wear more quickly.

| Process | Materials |

|---|---|

| CNC machining (turning, drilling, boring, milling, reaming) | Hard thermoplastics, thermoset plastics, soft metals, hard metals (industrial machines) |

| Electrical discharge machining (EDM) | Hard metals |

| Laser cutting | Thermoplastics, wood, acrylic, fabrics, metals (industrial machines) |

| Water jet cutting | Plastics, hard and soft metals, stone, glass, composites |

In contrast to the subtractive process of removing material from a larger piece, additive manufacturing or 3D printing processes build objects by adding material one layer at a time, with each successive layer bonding to the preceding layer until the part is complete.

Just like subtractive CNC tools, additive manufacturing technologies create parts from CAD models. Preparing models for 3D printing with print preparation or slicer software is mostly automated, making job setup substantially easier and faster than with CNC tools. Depending on the technology, the 3D printer deposits material, selectively melts and fuses powder, or cures liquid photopolymer materials to create parts based on the CAM data. The 3D printed parts often require some form of cleaning and finishing to achieve their final properties and appearance before they’re ready to use.

Additive manufacturing is ideal for a range of engineering and manufacturing applications including prototyping, manufacturing tooling, and casting patterns, as well as short-run, bridge production, and custom manufacturing of final parts. 3D printers offer a very high degree of design freedom and can produce complex designs that would be impossible or excessively costly to create with any other manufacturing method.

The most common materials used in additive manufacturing are plastics and metals. Desktop and benchtop 3D printers offer an affordable solution to create plastics parts, while metals are currently limited to industrial systems.

| Process | Materials |

|---|---|

| Stereolithography (SLA) | Varieties of resin (thermoset plastics), high-strength, rigid, flexible, elastic, heat-resistant, castable (wax-like) |

| Selective laser sintering (SLS) | Engineering thermoplastics, such as nylon |

| Fused deposition modeling (FDM) | Standard thermoplastics, such as ABS, PLA, and their various blends |

| Material jetting | Varieties of resin (thermosetting plastics) |

| Binder jetting | Gypsum (full color), metals |

| Selective laser melting (SLM) or direct metal laser sintering (DMLS) | Soft and hard metals |

| Electron beam melting (EBM) | Soft and hard metals |

Video Guide

Having trouble finding the best 3D printing technology for your needs? In this video guide, we compare FDM, SLA, and SLS technologies across popular buying considerations.

Watch the Videos

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

White Paper

Looking for a 3D printer to create strong, functional parts? Download our white paper to learn how SLS printing works and why it's a popular 3D printing process for functional prototyping and end-use production.

Download the White Paper

While there are key differences, subtractive and additive manufacturing are not mutually exclusive. In fact, they are quite often used side by side and at different stages of product development and in manufacturing.

The prototyping process, for example, often relies on both additive and subtractive tools. Early concept models and prototypes are generally more economical and faster to produce with plastic additive manufacturing processes, such as stereolithography (SLA) or selective laser sintering (SLS). 3D printing offers a wide variety of material options for the functional prototyping of plastic parts. Additive technologies are also typically better suited for small parts and highly complex or intricate designs.

Early concept models and prototypes are generally more economical and faster to produce with plastic additive manufacturing processes, such as stereolithography (SLA) or selective laser sintering (SLS). 3D printing offers a wide variety of material options for the functional prototyping of plastic parts. Additive technologies are also typically better suited for small parts and highly complex or intricate designs.

When later stages of the development process require larger batches, subtractive processes become more competitive. Larger, less complex objects also lend themselves more to subtractive manufacturing. Due to the myriad choices in surface finishes and the speed of the process, subtractive manufacturing is most often the choice for fabricating finished parts. As metal 3D printed parts can be cost-prohibitive, subtractive processes are a better choice for metals parts for all but the most complex designs.

In manufacturing, subtractive and additive processes often complement each other in the production of tooling, jigs, fixtures, brackets, molds, and patterns. Manufacturers often use plastic 3D printed parts for fast, custom, low-volume, or replacement parts and opt for subtractive metal processes for higher volumes or parts that are subject to more extreme mechanical stress and strain.

Manufacturers often use plastic 3D printed parts for fast, custom, low-volume, or replacement parts and opt for subtractive metal processes for higher volumes or parts that are subject to more extreme mechanical stress and strain.

Utilizing both additive and subtractive manufacturing results in a hybrid process. This allows product designers and manufacturers to combine the versatility and quick turnaround times of additive manufacturing with the strength of subtractively produced parts.

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

Additive and subtractive technologies come in many form factors, with a range of cost and capabilities, from desktop machines to large industrial equipment. Ultimately, you should choose the technology that makes the most sense for your business needs and applications.

| Additive Manufacturing | Subtractive Manufacturing | |

|---|---|---|

| Equipment Costs | Professional desktop printers start at $3,500 for plastics. Large-scale industrial machines for metals start from ~$400,000. | Small CNC machines for workshops start around $2,000. More advanced workshop tools go well beyond that depending on the number of axes, features, part size, and tooling needed for specific materials. |

| Training | Desktop printers are practically plug and play, requiring minor training on build setup, maintenance, machine operation, and finishing. Industrial additive manufacturing systems require dedicated staff and extensive training. | Small CNC machines require moderate training for software, job setup, maintenance, machine operation, and finishing. Larger, industrial subtractive systems require dedicated staff and extensive training. |

| Facility Requirements | Desktop machines are suitable for the office and benchtop systems for a workshop environment with moderate space. Industrial 3D printers often require a dedicated space or room with HVAC control. Industrial 3D printers often require a dedicated space or room with HVAC control. | Small CNC machines are suitable for workshops. Industrial systems require a larger, dedicated space. |

| Ancillary Equipment | Tools and (some automated) systems for cleaning, washing, post-curing, and finishing, depending on the process. | Various tooling. More advanced systems automate some processes like tool changing, chip clearing and handling, and coolant management. |

Learn more about the most common subtractive and additive fabrication tools suitable for professional workspaces, machine shops, and workshops.

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

Prices have dropped significantly in recent years and compact, easy-to-use desktop additive and subtractive manufacturing tools are available today professional workspaces, machine shops, and workshops.

Learn more about 3D printing and see quality firsthand by requesting a complimentary sample part printed on a Formlabs SLA 3D printer.

Request a Free Sample Part

Additive vs Subtractive Manufacturing: Difference

What is additive manufacturing? How does it work? What is subtractive technology? What are the advantages of additive manufacturing?

Over the years, both additive and subtractive manufacturing processes have drastically shaken up the world. With their cutting edge technologies, they continue to create and parts that several industries can benefit from. But what is the difference between the two.

Additive Manufacturing vs Subtractive Manufacturing: Advantages and Disadvantages

Additive manufacturing refers to the process that creates an object by adding multiple layers. On the other hand, subtractive manufacturing removes or cuts away material to create parts. Both processes have different fundamentals, however, it’s interesting to note that they are often used together due to the fact that some of their applications overlap one another.

The below table compares and contrasts a few differences between additive manufacturing and subtractive manufacturing.

Now that you have a better understanding between the two, let us now take a closer look at both processes in more depth.

Additive Manufacturing

As discussed in previous blog posts, additive manufacturing is mostly used in the world of 3D printing. Objects are built by adding materials layer by layer, until an object or part is created.

In this case, the technologies that are embedded in these additive manufacturing processes are used to create parts from virtual CAD models. Depending on the type of printer, this technology deposits material, melts and fuses powder and finally cures liquid photopolymer to create parts. In the end, these would require some finishing touches before they are ready to use, including a good polish and finishing.

Subtractive Manufacturing

Subtractive Manufacturing is used in several controlled machining and material processes such as metal, solid blocks, bars etc. Eventually these are all shaped by removing the material through cutting, drilling, milling or grinding.

Eventually these are all shaped by removing the material through cutting, drilling, milling or grinding.

All processes can be manually set or are else driven by what is more commonly known as Computer Numerical Control (CNC). In this case, a virtual model designed in CAD software acts like an input for the fabrication tool. Coupled with the user input, the software simulation is the used to trigger the tool paths that aid the cutting tools to make the necessary removals, holes, channels etc.

When to use Additive and Subtractive Manufacturing

As discussed previously, while both processes are entirely different from one an another, they more or less work well side by side.

For starters, you are required to use both processes for concept models and prototypes. This makes sense because on the one hand, additive manufacturing helps with the production of small parts and their details, while on the other, you can adjust things accordingly since you’re at an early stage of the process. Additionally, subtractive manufacturing is more ideal for bigger parts, since they are available in more surface finishes.

Additionally, subtractive manufacturing is more ideal for bigger parts, since they are available in more surface finishes.

Ultimately, both processes complement each other well. Together, you can create so many different things, according to the demand and what’s needed. So to answer your question, it’s best to look at this from an economical point of view as explained in the table above.

Discover our products in the shop section:

Differences between additive and subtractive manufacturing

Contents of the article:

Additive and subtractive manufacturing work with CAD (Computer Aided Design) software. Both molds can be very precise and can be used to make complex designs for a variety of industries and applications. Both have their own niches and benefits for specific purposes, which we will explore below.

Comparison: Additive Manufacturing (3D Printer) vs. Subtractive Manufacturing (Lathe)

- Additive manufacturing

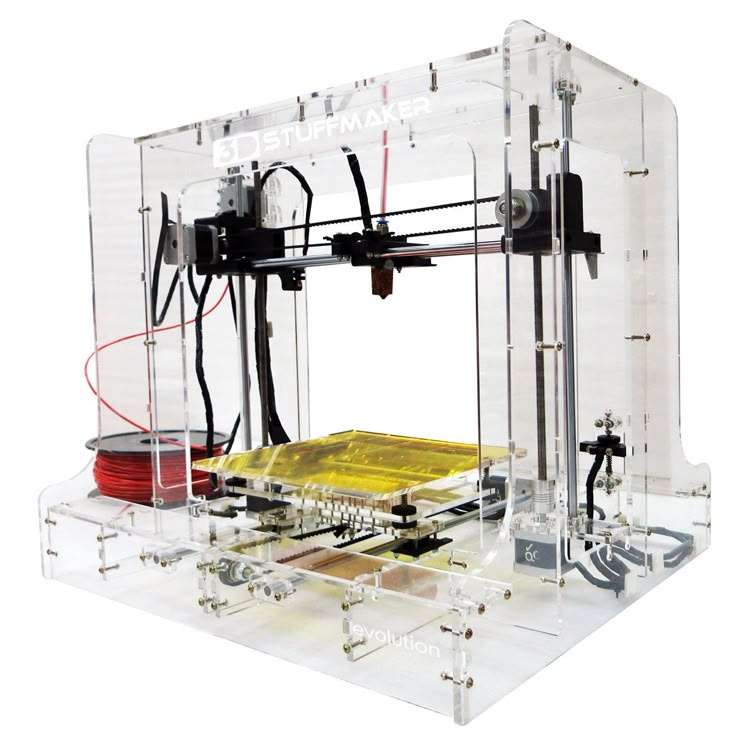

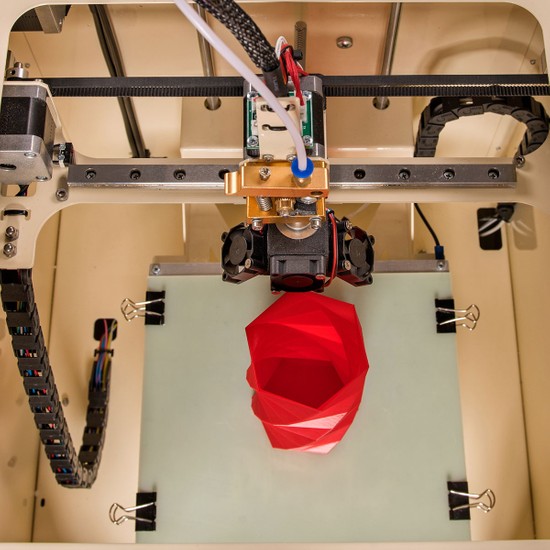

3D printers rule the world of additive manufacturing. 3D, as the name suggests, works by printing layers of material. This feature is called fused deposition modeling and is done with a machine repeatedly depositing the same area to build up from the base to create the final model. So, although it is called a 3D printer, it actually prints each layer in 2D cross-sectional layers overlapping each other until the desired result is achieved.

3D, as the name suggests, works by printing layers of material. This feature is called fused deposition modeling and is done with a machine repeatedly depositing the same area to build up from the base to create the final model. So, although it is called a 3D printer, it actually prints each layer in 2D cross-sectional layers overlapping each other until the desired result is achieved.

Conventional printers use powder or ink to apply to paper, but of course these substances would not be enough to create 3D products. In most 3D printing, each layer is created from molten thermoplastic and then fused together using glue or UV light. Thermoplastics are a type of plastic whose shape depends on their temperature: when heated, they become liquid, and when cooled, they return to a solid form. This means that during the 3D printing process, the machine must wait for each layer to cool before applying the next one in order to maintain the strength and integrity of the mold.

While the most common material used in 3D printers is plastic, some also function using metal. These printers still work with the same layered 2D sectioning process; however, they use metal blend layers instead of their plastic counterparts.

These printers still work with the same layered 2D sectioning process; however, they use metal blend layers instead of their plastic counterparts.

- Subtractive manufacturing

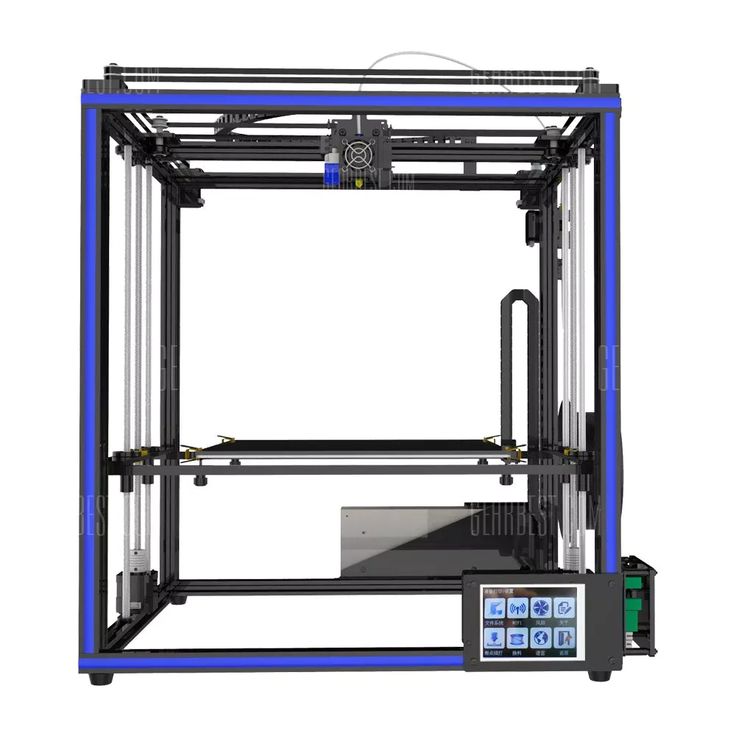

Subtractive manufacturing starts with a solid block of material. The machine gradually cuts off the necessary parts to create the desired part. CNC machines dominate the subtractive manufacturing industry and come in myriad forms to suit a myriad of requirements. Like 3D manufacturing, CNC machining can be used for the industrial production of plastic and metal products.

CNC machines can work in many different ways, they can either have maneuvering and rotating tools inserted into a stationary material held firmly in place, or the workpiece can be rotated by the machine itself. Again, it depends on the project. CNC machines can work with a variety of materials, from metal and plastic to wood, and come in all shapes and sizes.

Which is better?

Subtractive and additive manufacturing are great for different purposes, but when it comes to industrial manufacturing, there is no point in using a 3D printer for CNC jobs. For example, 3D machines need a rather specific type of metal to achieve optimal functionality, resulting in less versatility and limited freedom in the choice of materials you can use for metal-based projects.

For example, 3D machines need a rather specific type of metal to achieve optimal functionality, resulting in less versatility and limited freedom in the choice of materials you can use for metal-based projects.

They also offer a difference in value for money when it comes to large scale production, because having to wait for each layer of material to dry causes a delay in work time. Modern CNC machines can perform several functions at the same time, if necessary. Thus, if you are looking for the best value for money while maintaining integrity, detail, quantity, quality, speed and variety of material possibilities, you are best off ordering industrial processing on CNC machines in Togliatti.

Artel is proud to offer a wide range of machining services, including milling and turning. Contact us to discuss your project and start cooperation.

What is additive technology? The most important thing about 3D printing

Basics of 3D

Author: Semyon Popadyuk

Author: Semyon Popadyuk

What is additive manufacturing | Processes | 3D printing technologies | Consumables | Applications | Additive manufacturing in Russia

Additive manufacturing is the process of combining materials to create objects based on 3D model data, usually in layers, as opposed to the subtractive method and the molding method. Terms such as additive manufacturing, additive processes, additive methods, additive layer-by-layer manufacturing, layer-by-layer manufacturing, freeform solids manufacturing, and freeform manufacturing have been used at various times.

Terms such as additive manufacturing, additive processes, additive methods, additive layer-by-layer manufacturing, layer-by-layer manufacturing, freeform solids manufacturing, and freeform manufacturing have been used at various times.

In this dynamic industry, new terms are rapidly emerging. 3D printing, according to the ISO/ASTM 52900 standard, is the production of objects by applying material with a printhead, nozzle, or other printing technology. In the past, the term was associated with low cost, low productivity machines. However, this is no longer the case: the terms "additive manufacturing" and "3D printing" mean the same thing.

"Additive Manufacturing" is an official industry term approved by the ASTM and ISO standards bodies, but "3D printing" is more common and has become the de facto standard. It is especially widely used in the media, the terminology of startups, investors and other communities.

Can 3D technology help you optimize production in your organization? Order iQB Technologies services: expert consultation, training, test 3D printing/3D scanning, equipment demonstration, site visits and others:

One of the advantages of additive technologies is the ability to create objects of complex shape and structure with high accuracy.

Processes

Additive manufacturing (AM) includes seven different processes. Products can be created in layers by:

- extrusion,

- spray (jet spray),

- UV Curing,

- lamination,

- fusion materials.

3D printing technology

Modern FDM installations, such as the Discovery 3D Printer, allow you to print one-piece large-sized products up to 2.5 m

The main technologies used in the creation of products on additive installations:

- SLM (Selective Laser Melting) - selective laser melting of metal powder according to mathematical CAD models using an ytterbium laser;

- FDM (Fused Deposition Modeling) - a method of layer-by-layer deposition using a plastic thread or granules;

- SLA (Laser Stereolithography) - laser stereolithography, based on the layer-by-layer curing of a liquid material under the action of a laser;

- DLP (Digital Light Processing) - a stereolithographic 3D printing method using digital LED projectors;

- LCD (Liquid Crystal Display) - another type of photopolymer printing, when the photopolymer resin is illuminated by an LED UV matrix through an LCD screen mask;

- SLS (Selective Laser Sintering) - selective laser sintering under laser beams of particles of powdered material until a physical object is formed according to a given CAD model;

- Binder Jetting - layer-by-layer bonding of a composite powder (sand, polymer, metal, etc.

) with a binder;

) with a binder; - MJP (MultiJet Printing) - multi-jet modeling with photopolymer or wax;

- CJP (ColorJet Printing) is a full-color 3D printing technology by gluing a special gypsum-based powder.

Consumables

The main materials used in additive processes are:

- thermoplastics in the form of filaments or granules;

- UV and photocurable liquid photopolymers;

- ceramic-filled liquid photopolymers;

- polystyrene powder;

- glass-filled, carbon-filled and metal-filled polyamides in powder form;

- wax;

- gypsum powder;

- sand in powder form;

- metal alloys in powder form, etc.

iQB Technologies experts recommend article Russian manufacturer of SLM machines dispels myths about technology

Applications of additive technologies

Additive technologies are used to create physical models, prototypes, samples, tooling and production of plastic, metal, ceramic, glass, composite and biomaterial components. The principle of operation of additive installations is based on the construction of thin horizontal layers from 3D models created using computer-aided design (CAD) systems and 3D scanners.

The principle of operation of additive installations is based on the construction of thin horizontal layers from 3D models created using computer-aided design (CAD) systems and 3D scanners.

Design and manufacturing enterprises use AP for the manufacture of consumer, industrial, medical and military products, and that's not all. Cameras, mobile phones, engine parts, car interiors, aircraft parts and components, machine tools and medical implants are just the beginning of the vast list of additive manufacturing products.

AM simplifies and speeds up the product development process. Companies are turning to additive technologies to reduce production time, improve product quality and reduce costs. As a visualization tool, 3D printing helps businesses determine the likelihood of creating defective or unsatisfactory products. In addition, methods, processes and systems for tooling are being developed.

3D printing is actively used in the aerospace, automotive, oil and gas industries, shipbuilding, medicine, jewelry and many other industries.

3D printing is actively used to improve the quality of injection molding tooling. In some areas, AM is used to obtain results that are unattainable using conventional machines. In other industries, AM is being used to create fabrication and assembly tools such as fixtures, fixtures, templates, and guides for drilling and cutting.

3D printing has a big impact on the production of many products. Enterprises, large and small, successfully apply technology to the production of finished products. According to experts, direct manufacturing will become the largest application area for additive technologies. This technology can affect production more than other traditional methods.

The industry continues to evolve with new methods, technologies, materials, applications and business models emerging. The geography and scope of industrial application of AP is expanding. Additive technologies have already had a huge impact on the development of design and manufacturing; in the future, their role will increase more and more.

Additive manufacturing in Russia

The laboratory of additive technologies of Samara University performs unique metal 3D printing projects using the SLM Solutions installation / Photo: Ekaterina Vinokurova

In Russia, the 3D technology market is quite young, but it is already showing dynamic growth (according to Rosnano, about 30% per year). More and more companies are realizing the need to apply additive methods in manufacturing and research. There are organizations that are actively involved in the certification of materials and are already testing 3D printers of their own production. At the enterprises there are laboratories for the development and implementation of 3D solutions in certain sections of the technological cycle.

Today, we are not talking about a complete transition to additive technologies - so far they are able to effectively complement classical processes or replace them at some particular stage of the cycle. However, industry experts argue that in the near future, additive manufacturing will become an integral part of the technological processes in the enterprise.