Home 3d printer kickstarter

This ceramic 3D printer on Kickstarter can print big things with waste products

Audio player loading…3D printing is one of the coolest futuristic techs that can live in the modern home of the present day. Being able to download a digital file and with some time and patience turn that into a real world 3D object is absolutely mind blowing. We can print accessible controller mods to help more people play games, or our own fans for cooling PCs , or just a straight up Steam Deck shell . We are steps away from Star Trek's replicators in my mind's eye. Perhaps many many steps. But one of the biggest steps to jump over has to be the materials we use.

Most 3D printing, especially in the home, uses some kind of plastic filament. There are a lot of great initiatives being taken to cut down on the waste but it's still a lot of plastic. You can get other filaments, made from things like wood. However, it's still often buying a new resource to make things, using a printer that requires very specific inputs, with a fair amount of waste.

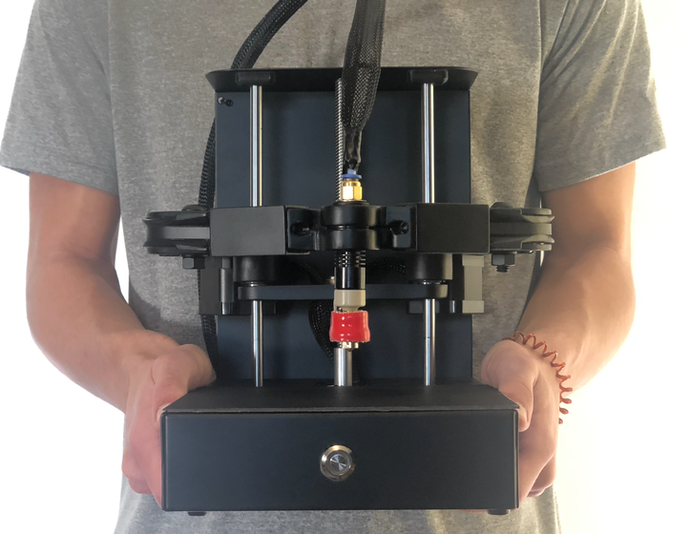

Ceramic printers are one of the logical next steps in integrating more materials, but are fairly uncommon compared to their filament brothers. There are difficulties with the printing process thanks to air bubble build ups, and are often fairly niche and expensive. Still they can often use a wider range of materials, and that's why the Matrix 3D printer on Kickstarter has caught my attention.

The Kickstarter page proudly states "In addition to ceramic materials, Matrix can print using a wide range of viscous fluids, especially environmental and ecological restoration materials, to help you realize your creative ideas." While this sounds deeply disturbing, what it means is you can print with things you likely have around your home already. Things like paper pulp, ground up eggshells, and waste coffee grounds can be used to print new things.

Cooling off

(Image credit: Cooler Master, EKWB)Best AIO cooler for CPUs : All-in-one, and one for all. .. components.

.. components.

Best CPU air coolers : CPU fans that don't go brrr.

The other big benefit this Matrix printer boasts is an increased capacity for builds. Often printers can be fairly limited in size, but this one can print objects up to 500 x 500 x 700mm on the largest model. They also come with up to 20L cartridge sizes, which can be swapped out mid print. This allows for some fairly large single prints, plus printing in ceramics or other malleable materials means it should be easy to piece multiple prints together, or add your own flairs by hand.

Of course, being a Kickstarter means it's good to keep your wits about you when making decisions. Thankfully, the maker Cerambot has a decent track record, producing two ceramic printers on the platform in the past, and the Matrix is already more than fully backed. So hopefully this one is a safer bet than some of the vapourware around.

Right now there are still some spots left on the early bird backings, which can get you a Matrix M500 for $799 USD, or 47% off the RRP. The larger options are also available at discounted prices, but are all looking fairly limited. If you're hoping to be an early adopter of this multi-printing machine, you might want to get in fast.

The larger options are also available at discounted prices, but are all looking fairly limited. If you're hoping to be an early adopter of this multi-printing machine, you might want to get in fast.

Hope’s been writing about games for about a decade, starting out way back when on the Australian Nintendo fan site Vooks.net. Since then, she’s talked far too much about games and tech for publications such as Techlife, Byteside, IGN, and GameSpot. Of course there’s also here at PC Gamer, where she gets to indulge her inner hardware nerd with news and reviews. You can usually find Hope fawning over some art, tech, or likely a wonderful combination of them both and where relevant she’ll share them with you here. When she’s not writing about the amazing creations of others, she’s working on what she hopes will one day be her own. You can find her fictional chill out ambient far future sci-fi radio show/album/listening experience podcast right here.

No, she’s not kidding.

Geeetech THUNDER Coming to Kickstarter

FDM printers aren’t always the fastest things in the world, often taking hours upon hours to deliver prints.

Geeetech has a new printer coming to Kickstarter, and it’s not your average snail’s pace FDM printer, no it isn’t.

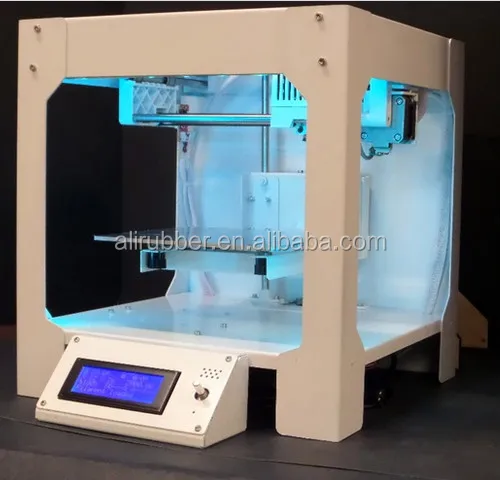

In early September, Geeetech will be launching a new high-speed 3D printer named THUNDER on Kickstarter. THUNDER will come with high printing speed, all-metal body, a super strong cooling system and big printing volume.

Thundering Along

After 2 years of development, Geeetech has matured the technology on THUNDER to print at high speeds with no loss of print quality.

How fast?

The printing speed of the Geeetech THUNDER can reach up to 300mm/s, with accelerations of 5000mm/s² for the X-axis and 4000mm/s² for the Y-axis.

When compared against the same model and same print quality, these speed gains result in a saving of between 30%-70% in printing time.

Watch the video below to see the Geeetech THUNDER print a Benchy in super fast time, and with no loss in quality.

The THUNDER runs at the accuracy of 0.1mm, with no compromise to the printing quality even when you print at fast speed. The resulting printed model comes with a fine finish, smooth curves, clear angles and a solid structure.

Features

THUNDER offers a printing volume of 250 x 250 x 260 mm and come with 5 different printing modes for different printing needs.

In addition, the printer includes a dual drive gear extruder, high power heating module, large volume nozzle for extrusion, and 5 cooling fans for hotend and model cooling.

From the melting of filament, to extrusion, to cooling, the THUNDER remains stable thanks to its combination of rigid hardware including the all-metal body with dual Z axis design.

This ensures stability of the machine when printing at high speed.

And if that’s not enough, there are a lot of features to ensure the printer outputs the best prints. Such features include quick adjusting belts, Y-axis damping, closed-loop stepper drive, and a multitude of cooling features.

Heat dissipation is one of the bottlenecks in high-speed printing. The Geeetech THUNDER has been designed with two high-volume heat dissipation fans on the hot end. What’s more, to achieve high-speed single-layer printing, THUNDER also added two larger auxiliary part cooling fans.

All four of these 4 fans can be turned on at the same time with the “One-button Strong Cooling Mode” function.

Availability

Geeetech will launch THUNDER on Kickstarter in early September 2022.

The price starts from $399 for early birds.

In the meantime, Geeetech is holding a bunch of THUNDER-related giveaways on their official website.

Visit their website to find out more about the Geeetech THUNDER.

Learn More

90,000 conveyor 3D printer from Creality enters the KickstarterNews

Subscribe to

Subscribe

Z. The desktop additive system can be used for both oversized 3D printing and small-scale additive manufacturing.

The desktop additive system can be used for both oversized 3D printing and small-scale additive manufacturing.

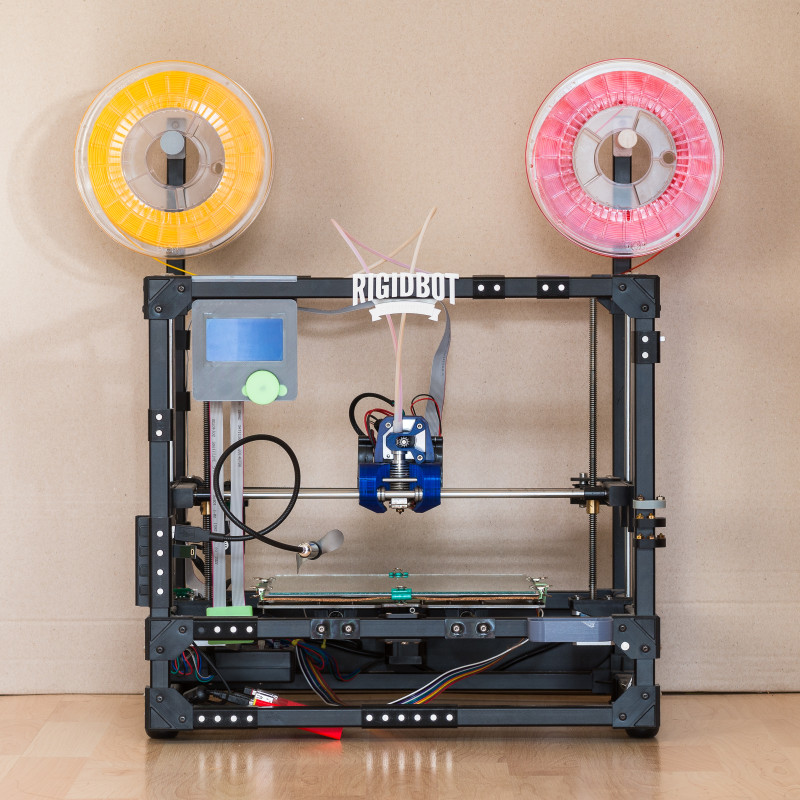

This 3D printer has already been featured in several reviews under the designation CR-30. In the additive community, the idea of conveyor 3D printers has been floating around for a long time, at least twelve years, but commercial versions have only recently begun to appear: Blackbelt in 2017, Powerbelt Zero in 2019, from the open source versions, the White Knight project can be mentioned. Another promising option called Printrbelt was never brought to market due to the untimely demise of Printrbot.

It was only a matter of time before an analogue appeared in the assortment of leading Chinese manufacturers of 3D printers, and already on November 18, everyone will be able to apply for Creality's system, called 3DPrintMill. The development of our own version of a conveyor 3D printer was promoted by Naomi Wu (a.k.a. SexyCyborg), a DIYer familiar to our community members, who has been collaborating with Creality for a long time. Perhaps the main factor was the cost: the price range among the above offers is wide, reaching up to €12,500, and Creality offers a very affordable option: early Kickstarter campaign participants can place orders for as low as $538.

Perhaps the main factor was the cost: the price range among the above offers is wide, reaching up to €12,500, and Creality offers a very affordable option: early Kickstarter campaign participants can place orders for as low as $538.

As you can see in the illustrations, the distinguishing features of these 3D printers are the guides mounted at an angle of 45 ° to the surface along the X and Y axes, as well as the conveyor belt. You can get confused with the coordinate system, but imagine that a slightly skewed 3D printer is lying on its back - then the CoreXY kinematics are mounted on the portal with the appropriate coordinates, and the belt moves along the Z axis. The tilt of the portal, coupled with the translational movement of the belt, provides the ability to build parts in height without the need to rollback the entire model. In other words, this scheme allows you to print parts of theoretically unlimited length - just remember to attach the roller table and open the window.

Alternatively, this 3D printer can be used for in-line production, printing one part after another and allowing the models to separate themselves from the tape at the end and fall into a container. From an economic point of view, serial 3D printing will be justified as long as we are talking about relatively small batches of products, measured in hundreds or thousands of pieces.

Polylactide, PET-G, and TPU are listed as consumables, but there is a heated platform in the work area under the belt. The wear-resistant conveyor belt is made on a nylon base, apparently with the addition of carbon fibers. The system is calibrated at the factory, equipped with quiet drivers, a massive airflow with three fans is installed on the head. Additional features include a filament sensor, save and resume function, plus a card capture reader for offline operation. Frame made of aluminum profiles with V-shaped rollers and guides reinforced with corners. Given the unusual coordinate system, the preparation of machine code requires special software - for this purpose, the company offers a specialized slicer CrealityBelt.

Specifications of 3DPrintMill 3D Printer (CR-30):

- Print technology: FDM

- Number of extruders: 1

- Construction area size: 200x170x∞ mm

- Printing accuracy: ±0.1 mm

- Nozzle diameter: 0.4 mm

- Layer thickness: 0.1-0.4 mm

- Hot end temperature: ≤240°C

- Heating temperature: ≤100°C

- Power consumption: 350W

- Power supply: AC 100-120V / 200-240V, DC 24V

- Consumables: PLA, PET-G, TPU

- Filament diameter: 1.75 mm

- Interface language: English

- Data transfer: USB, SD card

- Software: CrealityBelt Slicer

- Dimensions: 535x656x410 mm

- Weight: 16.5 kg (net), 20.5 kg (gross)

The start of accepting orders is scheduled for November 18, 19:00 Moscow time.

You can subscribe to the notification about the start of the campaign here.

FFF fdm CREALITY 3DPrintMill CR-30 conveyor

Follow author

Follow

Don't want

11

More interesting articles

6

Subscribe author

Subscribe

Don't want

REC offers a set of 1.8 mm filaments, primarily for 3D printer operators...

Read more

5

Follow the author

Subscribe

Don't want

Time to switch from sanctioned Volkswagen Tiguan to advanced 3D printed vehicles. ...

...

Read more

59

Subscribe to the author

Subscribe to the author

Don't want to

3Dtoday portal, supported by Creality and Bestfilament, invites everyone to participate in the contest...

Read more0001

Miscellaneous

Subscribe author

Subscribe

Don't want

1

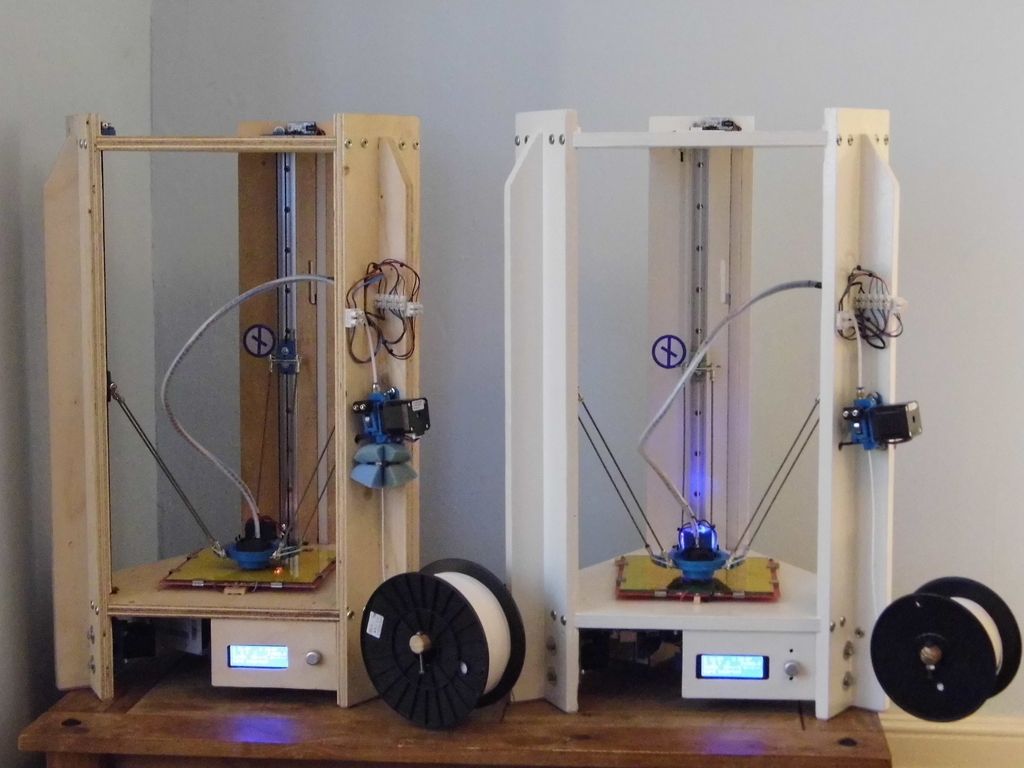

German manufacturer of 4-in-1 conveyor belt 3D printer, iFactory3D, won the hearts of 434 supporters from the US, Canada, to a community of non-professional 3D printing enthusiasts who appreciated the open source code for its hardware and software.

The 3D printing industry has evolved over the past decade. According to the 3D printing trends 2020 report prepared by the 3D Hubs network, the average annual market growth will be 24% over the next 5 years. It will double every three years and reach $35. 0 billion by 2024. However, the industrial use of 3D printing is perceived as the main driver of market growth.

0 billion by 2024. However, the industrial use of 3D printing is perceived as the main driver of market growth.

With the unpredictable onset of the COVID-19 pandemic, the need to restructure global supply chains has given a huge boost to the 3D printing industry. Especially in the field of medical technology: European government health agencies and the FDA have made a strategic bet on 3D printing in the fight against the COVID-19 outbreak.

A less obvious and less widely discussed trend is the growing demand for 3D printers for business and home use. Self-isolation during the lockdown has contributed to this: the need for individual accessories for everyday life has increased significantly (look at how people use 3D printers to improve masks!). To put it simply, an already existing “maker” culture has been spurred on by the boredom of self-isolation, resulting in a new wave of “home” 3D printer evangelists. Interest in a 3D printer from China confirms the trend.

iFactory3D, unlike the Chinese manufacturer, gives more freedom and opportunities for those involved in 3D printing, involving the community in the joint creation of the product. The iFactory3D team, led by Arthur Steffen, open source iFactory One and the community is involved in the development of iFactory3D. The ability to customize and upgrade was built into the 3D printer from the very beginning.

The iFactory3D team, led by Arthur Steffen, open source iFactory One and the community is involved in the development of iFactory3D. The ability to customize and upgrade was built into the 3D printer from the very beginning.

Designed for home users and businesses alike, the iFactory3D printer will rely on "collective wisdom" to create and execute a product roadmap.

This approach allowed the iFactory3D team to develop an ecosystem of services built into the printer. It currently includes built-in error detection software as well as features related to automatic printing. But in the future, it can be expanded through collaboration with software services.

“We just ran a successful Kickstarter campaign and hit about 186% of our funding target,” says Arthur Steffen, CEO of iFactory3D. - The project was supported by 434 sponsors, discussed in the community and presented in various media. This means good prospects for technology in general and for our company in particular. We are proud to receive support from the community, and we are grateful to everyone who gave their opinion about our product and contributed to it. Thanks to the feedback, we have the opportunity to improve the printer's feature set to meet current user needs.”

We are proud to receive support from the community, and we are grateful to everyone who gave their opinion about our product and contributed to it. Thanks to the feedback, we have the opportunity to improve the printer's feature set to meet current user needs.”

The start of sales of the 3D printer is scheduled for April 2021, the company's partners with verified distributors must meet the delivery time. In 2021, iFactory3D plans to launch a new line of 3D printers in both the B2C and B2B markets, relying on both crowdfunding and traditional venture capital investments as funding sources.

iFactory

Subscribe author

Subscribe

Don't want

1

More interesting articles

2

Follow author

Follow

Don't want

Yesterday, October 26, 2022, was the first day of Formlabs User Summit 2022, where Fo.