3D printed clockwork

Clockwork best STL files for 3D printing・Cults

Movie Coaster/ClockWork Orange Coaster (A Clockwork Orange)

€0.99

15mm Clockwork Daddy on Mobile Obeying Platform

€11.32

Spider Ball Clockwork Robot Miniature Artificer Construct for Tabletop Games

€1.90

Rush Clockwork Angels Clock Face and Hands -Remix

€2.85

15mm Clockwork Soldiers. Separate, Supported and Builder

€11.32

Clockwork Horror

€2.90

CLOCKWORK ORANGE STENCIL

Free

Motorized Star Wars AT-AT

Free

Alex

€4.49

Malakai Makaisonn's Goblin Hewer - Dwarf Slayers

€1. 13

Xavier Valden Irwin - XVI

€4.15

Angel Clockwork Wall Art 2 versions

€16.98

Angel Clockwork Wall Art 2

€13.58

Mechanic Orange Jesus Figure

€12.29

Robot Tiger Steel Defender for DnD Artificer

€2.85

The Little Man Clock

Free

A Clockwork Orange 3D print model

€28.42

Clockwork Frogs and Flies

€3.80

Walking Robot Eldritch Cannon for DnD Artificer

€1.90

Clockwork

€3

*BETA*Creality Compatible Afterburner with undermounted belt and front MGN12H Linear Rail v1

Free

220 Clock Model

Free

Clockwork Orange - Alex

€2. 83

83

Wall Clock, Ball Clock Replic (Design: George Nelson)

Free

Aeropic's magnetico-mechanical 7 segment display

Free

Clockwork Scarab Dice Vault - SUPPORT FREE!

€4.74

Voron Clockwork TPU

Free

DND ARTIFICER Steel Defender pack (golem)

€1.90

Root + All Expansions Organizer

€2.10

Bandit Cannon Wagon

€11

Wind up key (scaled up to fit 17HD40005)

Free

Mashup Walker Shell

Free

Windup Walker Negative

Free

Netherforge Vaulthammer (28mm/Heroic scale)

Free

Netherforge Siege Maul (28mm/Heroic scale)

Free

Netherforge Hammergonne (28mm/Heroic scale)

Free

Netherforge Miner King (28mm/Heroic scale)

Free

Netherforged Bombardier (28mm/Heroic scale)

Free

KEYCHAIN clockwork orange

€0. 53

53

Clockwork Orange Wall Mount

Free

miniclock_ver2 [two-tone color available]

Free

miniclock_ver1

Free

Windup Walker Teardown

Free

Electronic box for Real Tower Clock

Free

Real Tower Clock

Free

DCF 77 module for real tower clock

Free

Metal Warforged Clockwork Sorcerer

Free

Clockwork-Steampunk cosplay articulated fingers

€5.94

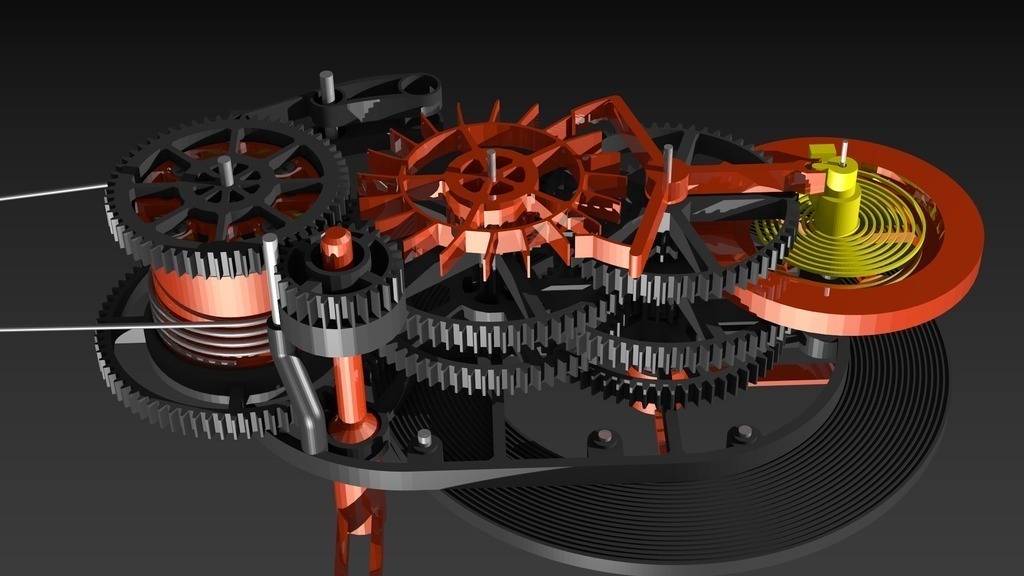

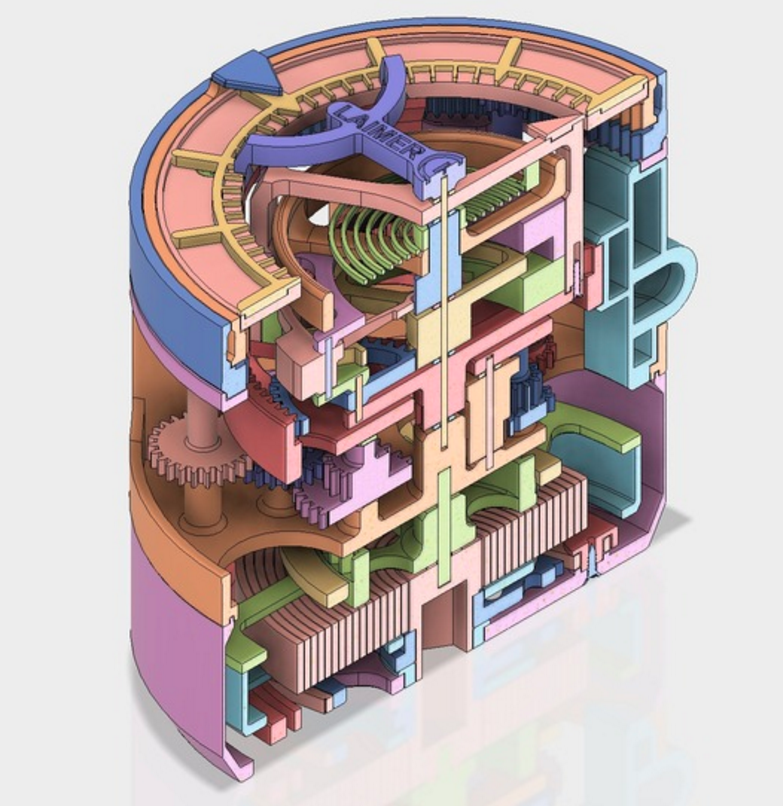

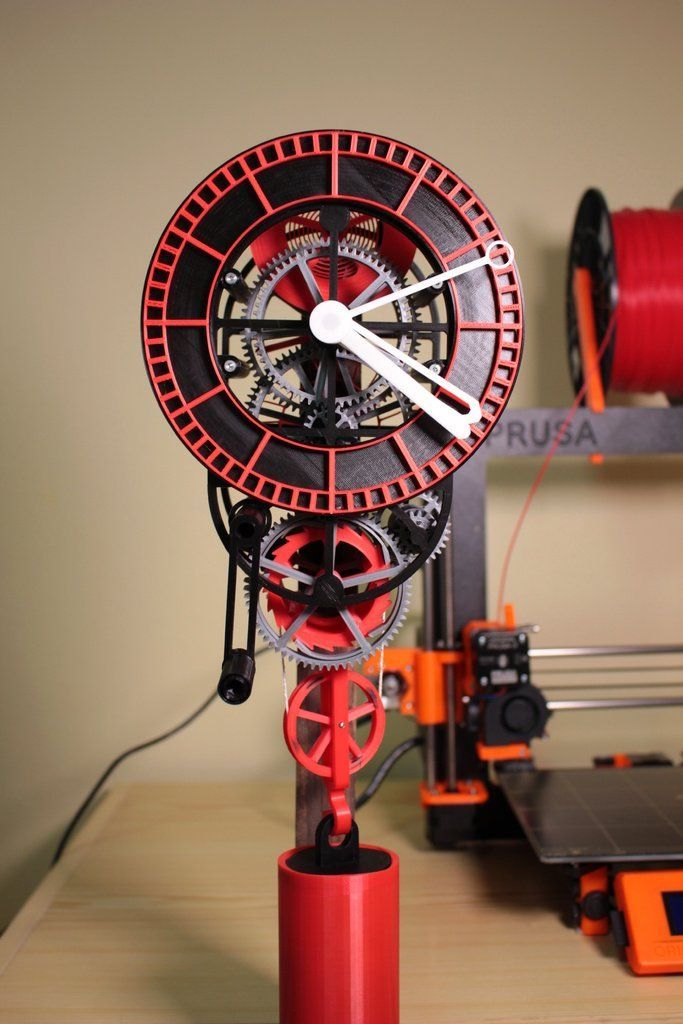

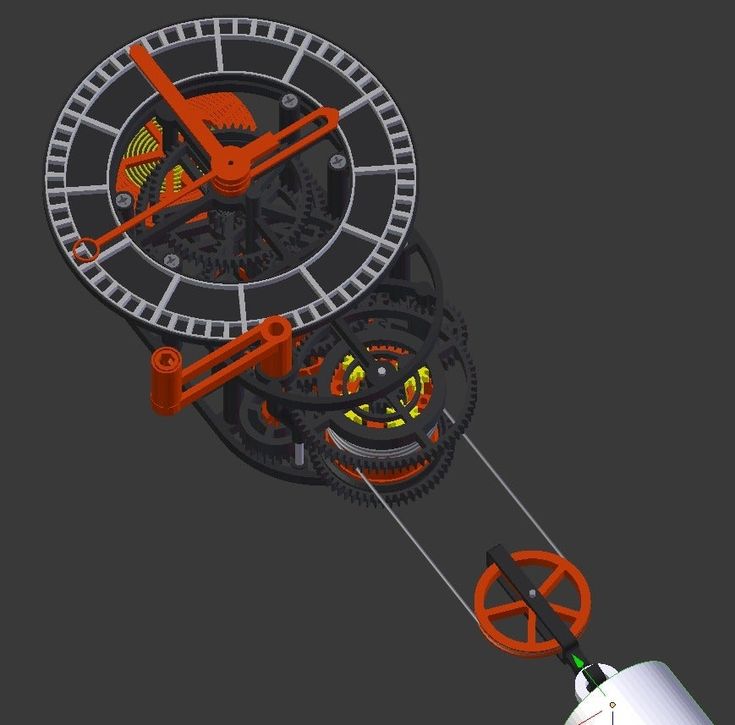

3D printing application example of a mechanical clockwork

- Home

- Industrial sectors

- Model building

- 3D printing application example of a mechanical clockwork

- What was needed: components for mechanical clockwork

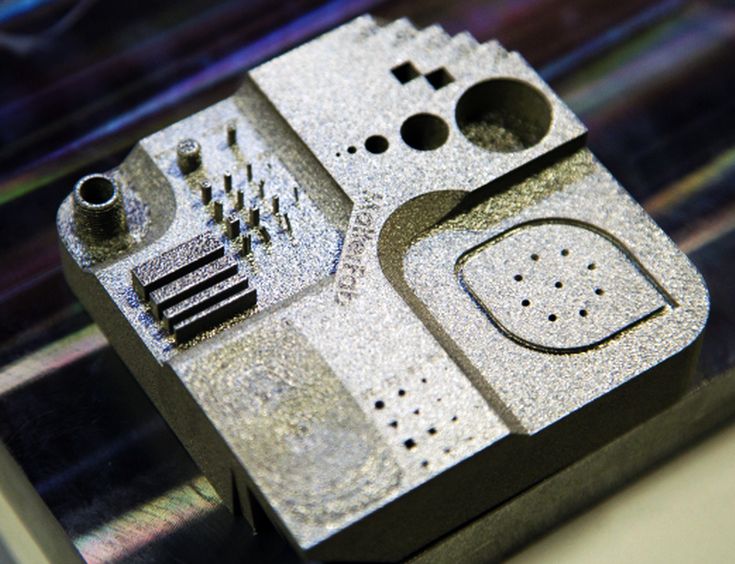

- Manufacturing method: filament extrusion (FDM)

- Requirements: high abrasion resistance, good mechanical properties, detail accuracy

- Material: iglidur i150

- Industry: model making

- Success for the customer: improved wear resistance, significantly longer component service life, more regular running of the escapement and thus of the clockwork as a whole

The application at a glance:

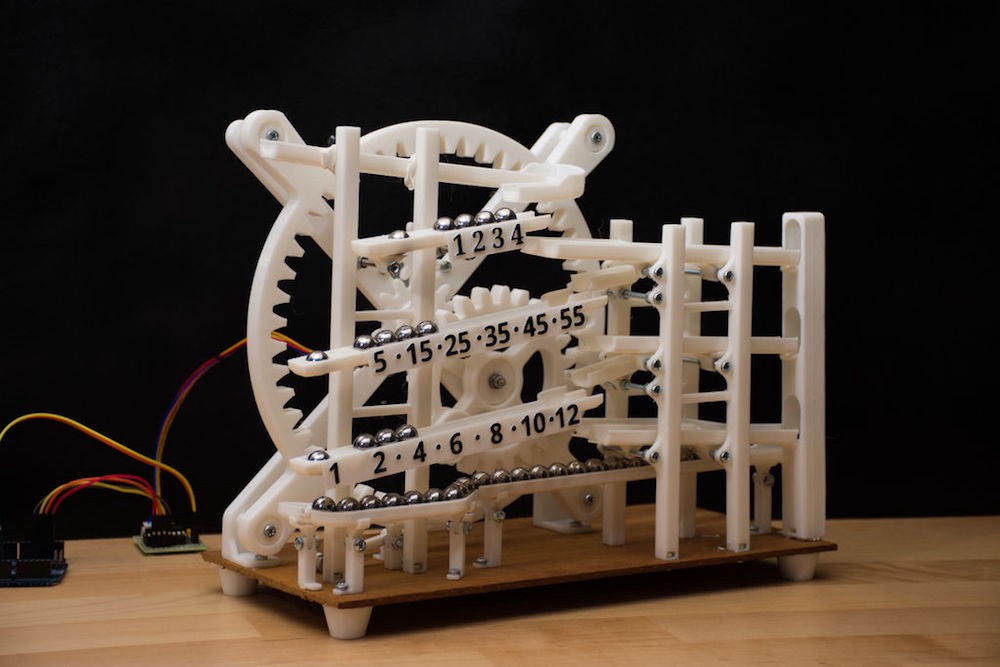

As part of a Jugend Forscht project, Kai Schmidt-Brauns constructed a completely 3D-printable clockwork and compared a mathematically calculated profile curve of a mechanical clockwork escapement with an empirically determined profile curve. To test each profile curve, he printed the mechanical clockwork based on his mathematical model. In addition to the experiments with components made of conventional PLA, Schmidt-Brauns tested the different profile curves with components made of the iglidur i150 tribofilament. This confirmed that the escapement with the igus material performed better. Due to the tribologically optimised filament, components that are subjected to particularly high mechanical loads were able to achieve a significantly longer service life and a more regular run than parts made of conventional PLA.

To test each profile curve, he printed the mechanical clockwork based on his mathematical model. In addition to the experiments with components made of conventional PLA, Schmidt-Brauns tested the different profile curves with components made of the iglidur i150 tribofilament. This confirmed that the escapement with the igus material performed better. Due to the tribologically optimised filament, components that are subjected to particularly high mechanical loads were able to achieve a significantly longer service life and a more regular run than parts made of conventional PLA.

More about iglidur i150

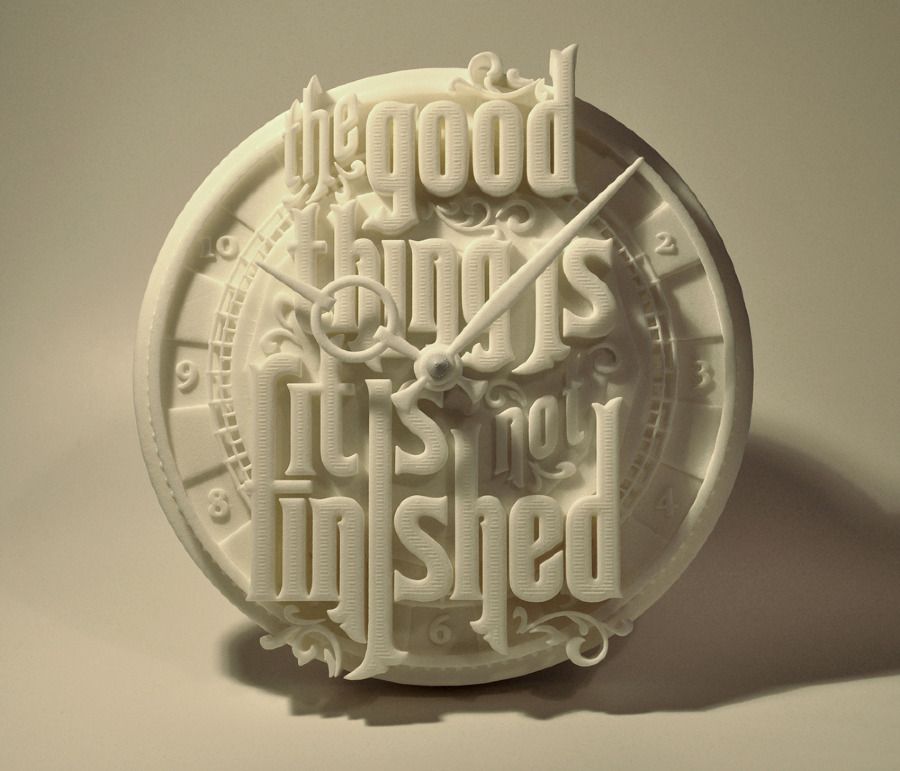

The mechanical clockwork from the front: energy is stored in the winding mechanismProblem

In order for a mechanical clockwork to run accurately, the geometry of all components of the mechanism must be precisely determined and the friction between moving parts must be kept as low as possible. The aim of Kai Schmidt-Brauns' project was to design an escapement mechanism for the 3D printable clockwork and subsequently determine its geometry with a mathematical model. Although the mathematical model led to a more regular movement of the clockwork, the question arose as to other ways of making the clockwork even more accurate. In addition, in the tests with 3D-printed components made of conventional PLA, the heavily stressed parts, such as the ratchet (consisting of ratchet wheel and ratchet rim) in the lift, did not have a particularly long service life.

Although the mathematical model led to a more regular movement of the clockwork, the question arose as to other ways of making the clockwork even more accurate. In addition, in the tests with 3D-printed components made of conventional PLA, the heavily stressed parts, such as the ratchet (consisting of ratchet wheel and ratchet rim) in the lift, did not have a particularly long service life.

Solution

After the tests with the clockwork made of conventional PLA, Kai Schmidt-Brauns replaced critical components with specimens printed from the igus iglidur i150 tribofilament. In the comparison, it was noticeable that the sliding and static friction between the components made of iglidur i150 is significantly reduced. In addition, thanks to the high wear resistance of the igus material, the service life of the ratchet could be increased, as well as a more regular movement of the escapement.

A precise clockwork completely from the 3D printer

Jugend Forscht is a German competition for young researchers from the 4th grade up to the age of 21. Participants can work on and submit problems of their own choice in the fields of mathematics, computer science and natural sciences. As part of this competition, Kai Schmidt-Brauns from Wolfsburg first set up a mathematical model to determine the exact geometry of the components of a 3D printable escapement mechanism. This involved in particular the profile curve of the profile wheel, which he was able to calculate from well-defined parameters. The escapement of a watch is the part that determines the accuracy of the watch. The escapement mechanism "inhibits" the gear train at regular intervals, for example with the help of a pellet fork, and ensures that one minute in the clock also corresponds to one minute and does not last sometimes 61 and sometimes 55 seconds. In the next step of the project, Kai Schmidt-Brauns compared the calculated profile curve with an empirically determined profile curve. He found that the movement with the calculated profile curve had a more regular rate than the empirically determined profile curve.

Participants can work on and submit problems of their own choice in the fields of mathematics, computer science and natural sciences. As part of this competition, Kai Schmidt-Brauns from Wolfsburg first set up a mathematical model to determine the exact geometry of the components of a 3D printable escapement mechanism. This involved in particular the profile curve of the profile wheel, which he was able to calculate from well-defined parameters. The escapement of a watch is the part that determines the accuracy of the watch. The escapement mechanism "inhibits" the gear train at regular intervals, for example with the help of a pellet fork, and ensures that one minute in the clock also corresponds to one minute and does not last sometimes 61 and sometimes 55 seconds. In the next step of the project, Kai Schmidt-Brauns compared the calculated profile curve with an empirically determined profile curve. He found that the movement with the calculated profile curve had a more regular rate than the empirically determined profile curve.

More precise motion with iglidur i150

In addition to comparing the mathematical formula and the empirically determined profile curve, Kai Schmidt-Brauns tested the escapements with different material. The choice fell on the iglidur i150 tribofilament. With a bed temperature of 40°C, a printing speed of 30mm/s at a layer height of 0.1mm and an extruder temperature of 250°C, the student achieved the best results with the filament from igus. Compared to the conventional PLA, he was also able to detect a much more regular escapement during a test run. In addition to the results in the escapement, the tribologically optimised filament was able to provide an improvement in heavily stressed components with its wear resistance. The ratchet rim of the ratchet (see picture), which is located in the winding mechanism of the clockwork, had to be replaced significantly more often when using conventional PLA than with iglidur i150. Furthermore, through tests with a spiral spring printed from iglidur i150, he was able to record a higher toughness and pliability compared to the one made from conventional PLA.

Furthermore, through tests with a spiral spring printed from iglidur i150, he was able to record a higher toughness and pliability compared to the one made from conventional PLA.

igus tribofilaments for more service life of the applications

Besides iglidur i150, igus offers many other tribologically optimised filaments for 3D printing. All have in common their high abrasion resistance for gliding applications. iglidur i150 can be processed very easily, just like PLA and PETG filaments. In the wear test from igus' in-house test laboratory, the igus tribofilaments perform up to 50 times better than conventional plastics such as PLA and ABS (see picture). It is also food compliant according to EU Regulation 10/2011 and therefore suitable for appropriate applications in the food and packaging industry. The all-rounder filament is particularly suitable for novice printers due to its easy processing. The 3D printing service is also available at any time with a delivery time of 1-3 days if expert help is needed.

The 3D printing service is also available at any time with a delivery time of 1-3 days if expert help is needed.

Go to 3D printing service

iglidur i150 wear test: Y-axis = wear rate [μm/km] 1. iglidur i150 2. iglidur i180 3. PLA 4. ABS test parameters (linear motion): v = 0.1m/s; p = 1MPa; shaft materials: hardened steel (Cf53/1.1213) and stainless steel (V2A/1.4301)Other application examples for 3D printed components can be found here:

All customer applications at a glance

3D Printed Illuminated Wall Clock

You Are Here

Home

One of the problems with 3D printing is the large amount of plastic waste. Let's face it, all makers fill their trash cans with failed prints and empty spools. This is a real huge graveyard of worn plastic.

Original clock + light: 2 in 1

There are many ways to get creative and recycle plastic waste. Here we will consider the possibility of reusing spools for plastic threads. This idea belongs to the maker under the nickname dominofreak. We found it on Thingiverse. It consists in making a wall clock out of a used coil.

Here we will consider the possibility of reusing spools for plastic threads. This idea belongs to the maker under the nickname dominofreak. We found it on Thingiverse. It consists in making a wall clock out of a used coil.

This is a relatively simple project that uses 3D printing and LED lighting. Stop throwing plastic spools in the bin and turn them into color changing wall clocks. nine0005

In addition to the blank spool, you will need to print some watch parts. For example, it will be necessary to make a diffuser and a clockwork using a 3D printer. We suggest downloading the STL files necessary for this on Thingiverse.

What do you need to know to implement the project?

Before jumping into this idea, it's important to understand that not all filament spools are the same physical size. You may need to measure the coil and adjust the 3D model settings accordingly. The author of the project used a plastic spool from the German manufacturer of 3D printing filament Janbex (the exact dimensions of this spool can be found on Thingiverse). nine0005

nine0005

In addition to the coil and 3D printed parts, you will need an LED strip and a clockwork. According to dominofreak, the 3D model is meant to be printed with support structures. To ensure that the light emits properly through the clock panel, the designer used white PLA to print a thin wall (only one layer thick).

Now a question about the LED strip. The author suggests using a battery power supply so as not to mess around with cables and wires. The battery compartment is safely hidden in the inside of the coil. nine0005

Source

Other materials:

- Fillamentum offers material for FDM 3D printers based on PVC

- Space meatballs: 3D Bioprinting Solutions will conduct experiments on 3D printing of meat in orbit

- Scientists have developed a SEAM system for accelerated 3D printing of plastic

- New methods of analysis will help improve metal laser 3D printing

- Autodesk opens generative design lab in Chicago

Attention!

We accept news, articles or press releases

with links and images. [email protected]

[email protected]

STL file Clock mechanism・3D printer model for download・Cults

Kunkka

3 €

nine0065 Invoker Torso15 €

Best 3D printer files in Game category

WINGMAN // Legends of Apex

18.27 €

Big Eyed Dragon

1,50 €

Pokémon - Charmander pull-back car toy

Free

nine0065 Speedy the SnailFree

Baby Groot Sculpture 3D Print Model - STL Files for 3D Printing

24.99 €

Anubis Flexi (Egyptian Gods 1/6)

3. 07 €

07 €

Ratchet & Clank Rivet's Hammer

14.95 €

Tom Nook Animal Crossing

4.74 €

Bestsellers in the Game category

WARFORGED VOIDWALKER EXOSUIT UPGRADE KIT

9,50 €

Batman Crossbow / Seal in Place

€2.50 -25% 1.88 €

1.77 €

Chopper motorcycle print-in-place

1 €

Beaky Boyz Builder: PF_MK-Six

12.36 €

GIANT CROCODILE HINGED

4. 18 €

18 €

Octopus 2.0

3.79 €

nine0065 Bicycle1.40 €

Voidwalker Exosuits Truescale

14.83 €

Enourmous Imperial heavy tank

10 €

Non-chronic melee kit

7 €

USS EnterSurprise - printable game container for tiny F14 9 jet fighters0066

3.79 €

Cute flexi unicorn

1.77 €

Articulated dragon

3.79 €

Flexy Pangolin

€3.66 -thirty% 2.56 €

Do you want to support Cults? nine0003

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy.