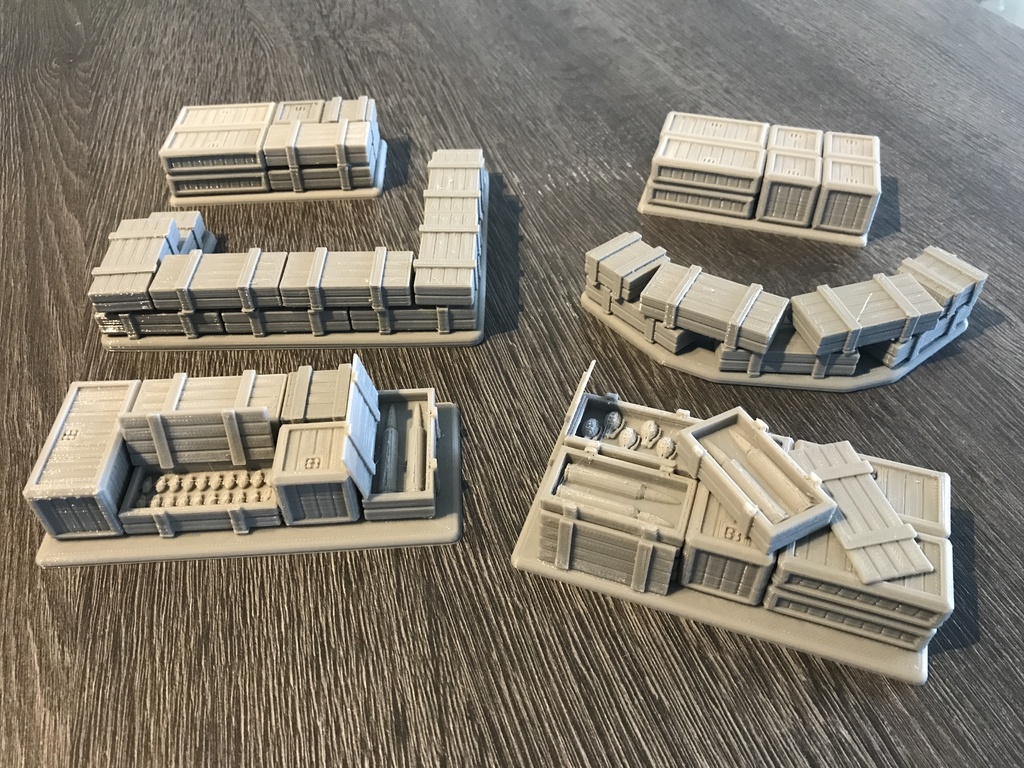

3D print terrain

3d print terrain – 3dprintterrain

STL - files for wargaming and modelling

From ancient time to modern warfare. You will find all what you need !

Happy printing !!

Sample of Medieval building

Printed and painted by Carl Schdroski

-

Happy new year

- Read more

-

6mm scale

As you know, it is sometimes very difficult to scale 1:72 or 28mm buildings down to 6mm.

Details are lost because a lot is lost at this scale. Not...

- Read more

-

Nice interpretation of my Farmbuilding from WW2 set 5

Nice. Facebook site search for Open Sights Painting

- Read more

-

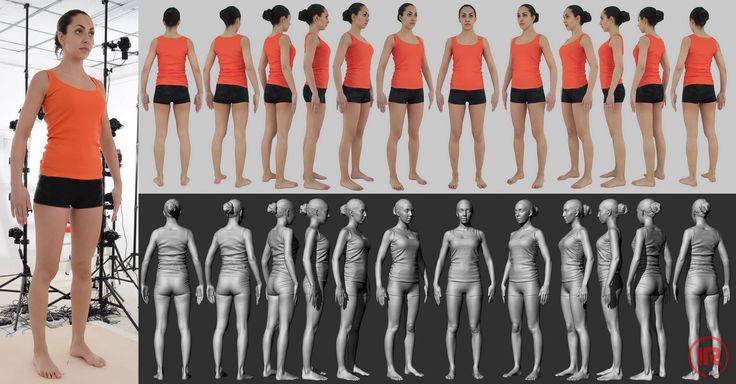

Figures from DLP printer

- Read more

-

Printing models at 10-12mm scale?

Video

- Read more

-

Medieval Saint Mère Église

Very nice setting printed and painted by Carl Schdroski.

He used the Saint Mère Église from Normandy 1944 set and the timbered houses from Medieval...

He used the Saint Mère Église from Normandy 1944 set and the timbered houses from Medieval...- Read more

-

Become a follower of my Kickstarter Campaigns

Follow my kickstarter campaigns. New, interesting projects are realized here at regular intervals. Enjoy lower entry prices for complete file sets ...

- Read more

Use left/right arrows to navigate the slideshow or swipe left/right if using a mobile device

Products – 3dprintterrain

-

Age of Pirates

Age of Pirates

- Regular price

- €65,00

- Sale price

- €65,00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

American Civil War

American Civil War

- Regular price

- €65,00

- Sale price

- €65,00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

American War of Independence / French Indian War / ACW

American War of Independence / French Indian War / ACW

- Regular price

- €65,00

- Sale price

- €65,00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

American Wild West

American Wild West

- Regular price

- €65,00

- Sale price

- €65,00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

Arabic + North Afrika

Arabic + North Afrika

- Regular price

- €65,00

- Sale price

- €65,00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

Arabic buildings modern + old

Arabic buildings modern + old

- Regular price

- €65,00

- Sale price

- €65,00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

Asian buildings Japan + China

Asian buildings Japan + China

- Regular price

- €65,00

- Sale price

- €65,00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

Cold War in Germany

Cold War in Germany

- Regular price

- €65,00

- Sale price

- €65,00

- Regular price

-

- Unit price

- /per

Sale Sold out

Use left/right arrows to navigate the slideshow or swipe left/right if using a mobile device

3D printing: the possibilities of additive technologies

Additive technologies or 3D printing is the process of creating an object that exactly corresponds to a three-dimensional model by applying material layer by layer. This innovation has become a global trend. The main advantage of the technology is resource saving. Losses of useful substance tend to zero.

This innovation has become a global trend. The main advantage of the technology is resource saving. Losses of useful substance tend to zero.

Application

3D printers have not yet penetrated into every home, but they are already present in all key areas of human life. 3D printing is in demand in the automotive industry, energy, medicine, food industry, construction/design, fashion industry. nine0003

In resource- and labour-intensive industries, the development of a product prototype costs a lot of money. With traditional casting or machining technologies, this takes weeks, months. Using the possibilities of volumetric printing, the work is done many times, and sometimes dozens of times, more quickly. At the same time, the quality does not suffer at all and the parameters of the product remain extremely accurate. By the way, the strength of the prototype is more than 20% higher than that of the classic production. nine0003

In medicine, the possibilities of 3D printing are used to design dentures, skeletons, and even internal organs. Additive technologies make it possible to create a medical instrument with certain parameters for specific patients with pathologies and anatomical features. This allows you to take a huge step forward in training and preparation for operations.

Additive technologies make it possible to create a medical instrument with certain parameters for specific patients with pathologies and anatomical features. This allows you to take a huge step forward in training and preparation for operations.

In 2011, a kidney was “drawn” on a 3D printer. Scientists have created an exoskeleton to support atrophied muscles. There are even special “pens” that “draw” living cells on injured skin areas. nine0013On 3D printers, models of premises are created with a visual study of interiors, buildings and entire residential areas with details of houses, utilities, and infrastructure facilities.

In the field of science and education, the benefits of 3D printing are expressed in the creation of visual aids with which the learning process becomes easier and more efficient.

3D printing is in demand in the fashion world. On the printer, you can create shoes, clothes, perfume bottles. While this process is expensive, therefore, it is not used in mass production.

However, piece products made on 3D printers are already presented on the catwalks. nine0003

Creative 3D Printed Sandals

The advantage of introducing AF technologies into the light industry is the ability to create products for a specific physique/foot shape. This is especially true for athletes, people with deviations of the anatomical structure. For example, designer Ross Berber introduced the world to shoes printed on a 3D machine. His collection includes 5 pairs.

3D printing allows for a breakthrough in innovation. Before a product can be mass-produced, a prototype must be tested and repeatedly tested. This is done on 3D models. You can create them in minutes. nine0003

Three-dimensional technologies are used in jewelry, when creating maps of the area, making souvenirs, customizing finished products (applying a pattern, logo).

How does a 3D printer work?

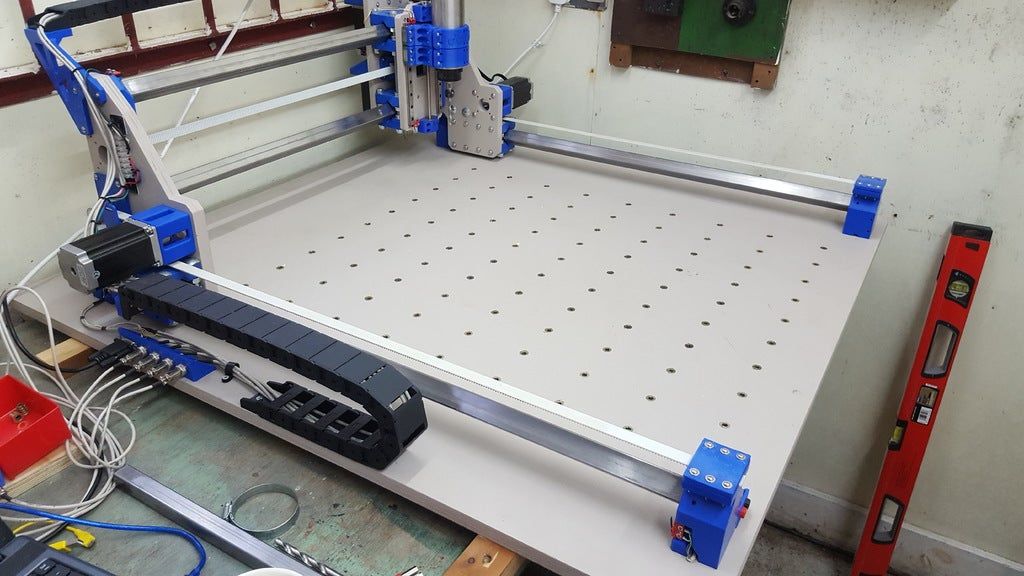

A classic 3D printer is a 3D printing device that works on the principle of FDM (Fusion Deposition Modeling).

On three-dimensional equipment, you can create an object of almost any shape, with curves, a relief surface. The product "increases" simultaneously in the horizontal and vertical directions. nine0003

Printers work with various materials: plastic, metal, and so on. With their help, you can create parts that can withstand a significant load. In order for the printer to print three-dimensional figures, it is equipped with:

- extruder - for heating and forcing plastic through the printheads;

- motors (usually linear) - set in motion the mechanisms;

- work surfaces - the platforms on which everything happens;

nine0037 sensors for fixing moving parts;- Cartesian robots - devices moving along three axes.

Printers work differently, but the classic sequence of actions can be described by a single algorithm. First, a 3D image is created. This requires specialized software. After that, the model is “cut” into horizontal layers.

A special program (G-code generator) is also provided for this. The computer converts the codes into information that the 3D printer can recognize. The next step is to recreate the model. nine0003

Smartprint HB-8 3D printer

3D printing technologies

There is monochrome and color 3D printing - more than a dozen technologies (plus their modifications). Among the most common:

- SLA - stereolithographic laser printing. The technology provides the creation of models with high detail. Its essence is the layer-by-layer application of a photopolymer material. It hardens under the influence of a laser. Then the working platform is lowered. A translucent composition is used as a photopolymer: it is easy to process, paint, glue. nine0038

- SLS - the technology is suitable for working with plastics and metals. The reagent is sintered under the laser beam. The products are very durable.

- HPM - printers work with thermoplastic, auxiliary soluble materials.

The latter are used to create complex multilevel models with cavities and functional holes. Finished products may have a different shape. They are durable, resistant to stress, mechanical and chemical stress.

- DLP is a relatively new 3D modeling technology. The printers that support it print with photopolymer resin. The material hardens when exposed to light. nine0038

The most progressive technologies are EBM and SLM. The first involves the impact on the material with an electron beam, and not with a laser, the second works with metals.Equipment for 3D printing is produced by companies from the USA, Europe, and Asia. Among the famous ones are Photocentric, 3D systems, Makerbot, Azuma Engineering Machinery Inc. other.

3D model of the ship strikes with realism

Advantages of additive technologies

The advantages of 3D printing include:

- Resource efficiency.

Products are "grown" from scratch, that is, the production is completely waste-free. For comparison: when creating a blank using traditional methods, material losses sometimes reach up to 85%.

- Efficiency. The time from the development of the layout to the receipt of the product can be reduced several times, or even tens of times, without compromising quality.

- Mobility. nine0083 The equipment is compact, layouts can be transferred online.

- Precision. Layered synthesis ensures absolute compliance with specified technical parameters.

- Strength. The indicator is 25–30% higher than that of products obtained by traditional methods (forging, casting).

- Weight. This is an important advantage for industry, aircraft and mechanical engineering. The mass of individual products is reduced by 40–50% without loss of strength. nine0038

Souvenirs and toys are successfully printed in Russia using 3D printing technology

3D printing is also used in advertising printing.

For example, for the production of souvenirs. Advertising agencies involved in cross-marketing willingly order a range of services, which includes both traditional production of business cards or flyers, as well as innovative solutions.

An overview of 5 modern 3D printers that appeared on the market in 2017, see the video: nine0003

Results

- 3D printing is in demand in almost all areas (industry, medicine, education, energy).

- In some industries, additive technologies are already actively used, in others they are just being introduced.

- Technology contributes to business development, gives competitive advantages - a layout is made in a matter of minutes, resource consumption is optimized.

- Manufacturers are constantly improving equipment for three-dimensional printing, developing new technologies. nine0038

Construction 3D printing is waiting for a breakthrough / Sudo Null IT News

3D printing technology originated in the 80s of the 20th century, but construction 3D printing appeared much later.

The first construction projects using this technology appeared only in 2014. We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed. nine0003

Construction is the world's number one market. And, if many technological innovations are being introduced in the field of high-rise construction, then little has changed in the field of low-rise construction over the past decades. The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations.

Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more. nine0003

This Internet meme shows what happened to the cost of building materials in just a year. And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development.

nine0003

Preparing to write an article, I turned to the founder of the company Arkon - Boris Kozlov cu. Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

- Construction 3D printing appeared in 2014, but no mass introduction of this technology followed in 7-8 years. Why do you think this happened, and why is there a surge of new projects right now? nine0083

- It seems to me that the reason is the snowball effect. The technology had to mature, grow from a hypothesis to a pilot implementation, and finally to commercialization and scaling (what is happening now). In addition, it should be borne in mind that construction is one of the most conservative industries, where, unlike even aviation and the automotive industry, there is still an extremely low introduction of digital solutions and automation in the field of the production process itself - the construction itself.

The issue of regulation and certification also plays an important role - this process is long and creates an additional lag. nine0149

In 2014 - 2016 the first samples of building 3D printers and prototypes of printed buildings appeared. The concepts of various form factors of construction 3D printers and types of printing materials were tested.

In 2017-2018 in the world, the first notable investments were made in a number of construction 3D printing start-ups. Further, by 2020, these investments "rolled" in the form of reaching a certain level of technology maturity - the first commercial products (3D printers and houses) appeared. nine0149

Finally, in 2020-2022 it became clear that the hypotheses of the effectiveness of construction 3D printing were justified (cheaper, faster, more environmentally friendly), and large investments began in the industry. A striking example is the investment of GE (the French division of General Electric) in the Danish COBOD or the achievement of a capitalization of $ 2 billion by the American company ICON.

In 2022-2023 over 1,000 buildings will be printed worldwide already, scaling from single buildings/pilot projects to entire villages and major infrastructure/reinforced concrete implementations. In addition, in a number of countries, by now, a regulatory framework has been created or is being actively created for the introduction of additive technologies in the construction industry. nine0149

Thus, I believe that the specified time period is a fairly natural cycle of the formation of technology, which is likely to experience exponential growth in the next decade.

According to ResearchAndMarket report, the global construction 3D printing market is valued at USD 354.3 million in 2022 and is projected to reach USD 11068.1 million by 2027, growing by 99.04%.

Various market processes affect the prices and behavior of participants in the global 3D construction printing market. They create price signals that are the result of changes in the demand and supply curves for a product or service.

They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals. nine0003

Now let's take a quick look at what is the construction 3D printer. Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers are also portal, on the basis of a flying boom, with a robotic arm.

Pictured left is a construction printer based on a boom. The figure on the right is a gantry construction 3D printer

In the figure above, a construction 3D printer in the form of a robot arm installed on a mobile platform.

Everything changed completely when, in the summer of 2021, the American company ICON, which was trying to introduce 3D printing into the construction of various auxiliary facilities, signed a contract with one of the largest American developers, Lennar, to build a village of 100 houses in Texas and immediately became a unicorn , having received 200 million dollars of investments from several investment funds.

nine0003 Pictured is a 3D printed house in Austin, Texas. A 3D printed house in Austin, Texas.

At the same time, the Danish company COBOD, created by the world's largest construction formwork company PERRI, began selling its gantry 3D construction printers and participating in construction projects around the world. In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

Few things unite developed, developing and poor countries, everywhere their problems and tasks, but The lack of affordable housing is a global agenda . If in poor countries there is an acute problem with the increase in the number of homeless people due to a lack of housing, as such, then in developing countries it is necessary to dramatically accelerate the number of new housing being built to meet the needs of a growing population. In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people.

And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse. nine0003

At the same time, the trend towards “green agenda ”, CO2 emission reduction, building with more environmentally friendly materials, etc. is developing. But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples. nine0003 3D printed walls.

Today, when we talk about 3D printing of houses, we are talking about printing walls. Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are erected as fixed formwork, which significantly saves the amount of cement used , which in turn reduces the cost of construction and reduces the environmental impact of cement production.

In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly. nine0003

Eco-concrete with the addition of polymers is currently being actively developed, the production of which reduces CO2 emissions from 30% to 100%. The Apis Cor company mentioned at the beginning of the article, which built a house in the suburbs in 2015, is now based in hot Florida, plans to start using this material in its projects.

Another startup from Russia, Mighty Buildings, headquartered in California, initially relied on a polymer with the addition of mineral chips. And while the company doesn't build entire homes, it only makes wall panels, it has won numerous design awards, as well as a $400 million valuation in several investment rounds. nine0003

As a result, with a rough calculation, we can say that the total savings on the construction of walls can reach 30%, and the total cost of the house can be reduced by 10%. This is true for houses designed for conventional construction. And if you initially design with 3D printing, you can improve this ratio by optimizing the laying of communications, the ability to immediately print interior walls, bookmark niches for bathrooms, fireplaces, built-in wardrobes and kitchens, as was done in the house built by COBOD in Germany. nine0003

"There are spots on the sun." Despite all the advantages of building 3D printing, has several significant disadvantages of .

The main one is layering, which cannot be avoided at the current level of technology development.

The photo above shows the layering of the 3D printed walls.

This task can be worked in several directions:

3D printed House Zero in the USA, built by ICON.

Ribbed walls can be plastered, painted and played with as a design element. That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards. nine0003

Use special "shutters" on the print head that allow smooth layers, as COBOD and other manufacturers do. The photo below shows that this does not ensure the complete absence of layering.

Fully sand the surface to get the usual smooth wall for plastering, painting, wallpapering or other finishing. It is possible, but it will require huge labor costs, which can reduce the overall efficiency of using 3D printing.

nine0003

Pictured above is a 3D printed wall sanded smooth.

The second problem is the required temperature. Ideally, printing should take place at temperatures between +5C° and +30C°. Humidity is also important. Using additives, you can push these boundaries, but not indefinitely. At strong sub-zero temperatures, printing will be possible in the field only if the construction site is covered with a dome and the required temperature is reached inside with the help of heat guns. In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project. nine0003

Building 3D printing can be useful not only for the construction of houses . With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop.

Learn more