3D printing company australia

Popular 3D Printing Companies In Australia

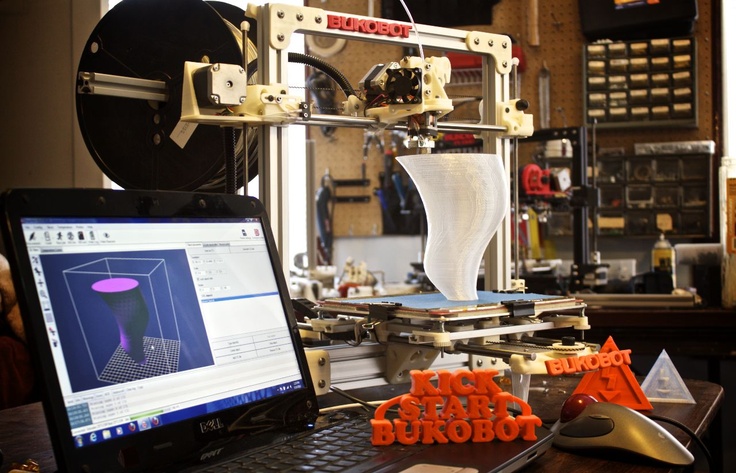

3D printing is rapidly gaining popularity, and almost every country now has a number of 3D printing companies offering 3D printers, materials, components, and services. This article looks at some of the most popular 3D printing companies in Australia.

Contents

- 1 3D Printing Companies in Australia

- 1.1 Titomic

- 1.2 SPEE3D

- 1.3 Aurora Labs

- 1.4 Objective3D

- 1.5 Inventia Life Science

- 1.6 Conflux Technology

- 1.7 3D MEDiTech

- 1.8 Additive Assurance

- 1.9 Monocure3D

- 1.10 FreeForm Composites

- 2 A Few More 3D Printing Companies

- 2.1 Luyten3D

- 2.2 Evok3D

- 2.3 GoProto

- 2.4 WYSIWYG 3D

- 2.5 Zeal 3D Printing

3D Printing Companies in Australia

Titomic

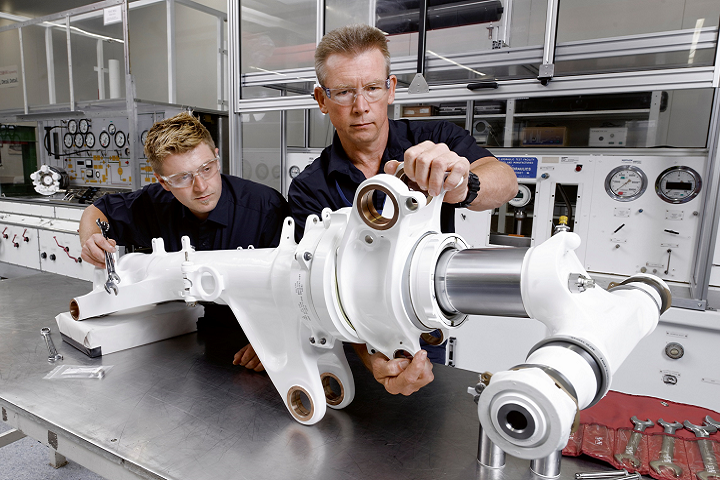

Above: Titomic Kinetic Fusion 3D Printer/Source: TitomicTitomic is the prominent 3D printing company in Australia. It focuses on advanced materials and a new additive manufacturing technology – Titomic Kinetic Fusion™. Titomic aims to reinvent manufacturing to build a better, safer and more sustainable world.

With its expertise, it can create products in new materials using proprietary machines and a patented process to achieve unique functionality. Metal-composite fusion produces hybrid materials with revolutionary properties.

Titomic has exclusive rights to commercialise Titomic Kinetic Fusion™, which is a Commonwealth Science and Industrial Research Organisation’s (CSIRO) proprietary and patented technology. It is a process for cold-gas spraying titanium or titanium alloy particles on a scaffold to create a load-bearing structure. It can be easily integrated into clients’ manufacturing supply chains to produce components with no shape or size limitations.

SPEE3D

Above: WarpSPEE3D World’s Fastest Metal 3D Printer/Image Source: SPEE3DSPEE3D is one of the most popular 3D printing companies in Australia. It is the world’s first metal 3D printer leveraging supersonic 3D deposition (SP3D) technology to deliver manufacturing grade printing at production speeds. SPEE3D is designed for scalable, just-in-time production, and it prints metal parts in minutes rather than hours or days, as is the industry standard.

SPEE3D is designed for scalable, just-in-time production, and it prints metal parts in minutes rather than hours or days, as is the industry standard.

SPEE3D addresses cost, speed, and repeatability in manufacturing. Its patented technology produces fast, low-cost casting-grade parts for commercial and industrial applications. SPEE3D manufactures brackets, manifolds, and engine components on-demand and 100 to 1,000 times faster than traditional metal 3D printing.

Its industrial printers give manufacturers control by speeding up and simplifying metal 3D printing. SPEE3D focuses on aluminium and copper, and its innovative mindset allows for industry growth.

Aurora Labs

Aurora Labs is working on a suite of market-leading technologies, with its flagship high-power, multi-laser printing package set to hit the market soon. The package is ready to serve the market for an affordable, industrial grade, high productivity, high accuracy 3D metal printer that is cost-effectively competitive with traditional metal manufacturing.

Aurora Labs is actively seeking technology partners in Perth and worldwide.

Objective3D

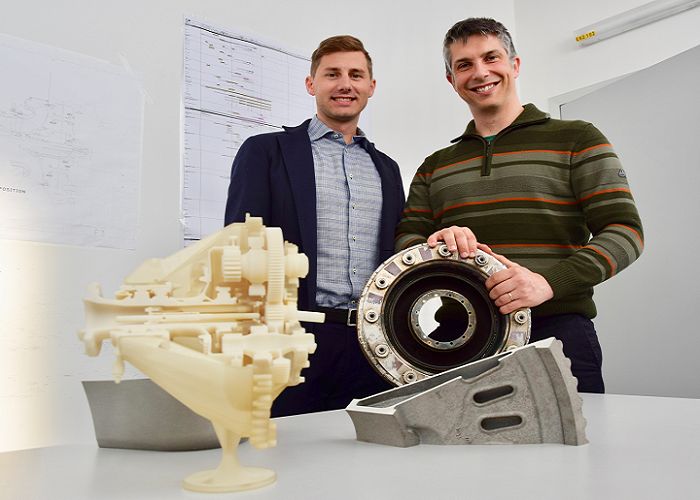

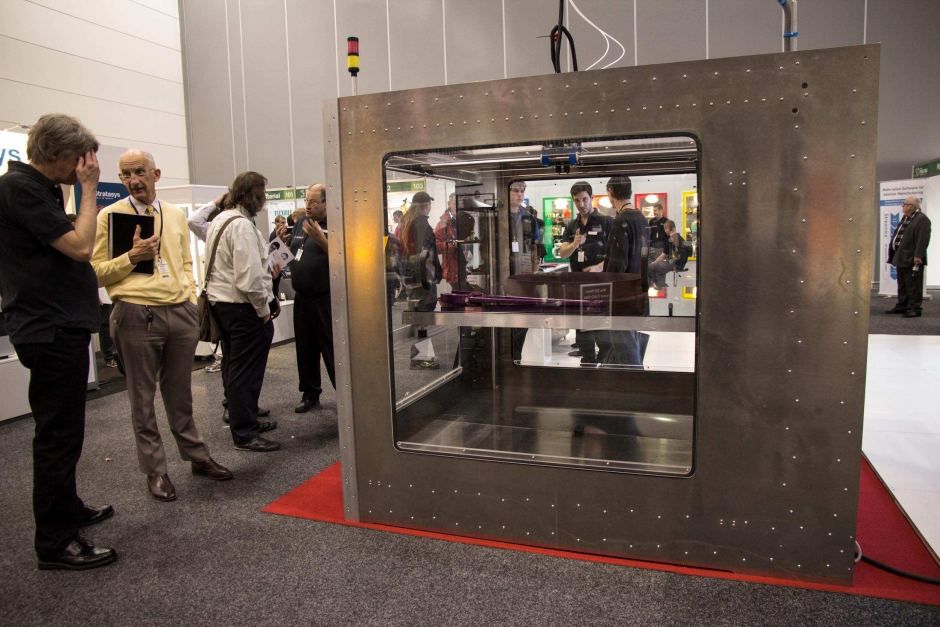

Objective3D is a well-known 3D printing company in Australia and New Zealand. It is a leading provider of 3D Printer and 3D Scanner Solutions from Stratasys, GE Additive, Lithoz, and Artec for designers, educators, and manufacturers. Objective3D, as the preferred Stratasys Partner, offers both 3D Printer Solutions and 3D Printing Bureau Service through a state-of-the-art Additive Manufacturing Centre that houses the most extensive range of Fused Deposition Modelling (FDM), PolyJet, SLS, DMLS, and BMD Machines, as well as consumables and spare parts.

Its 3D printer solutions range from low-cost desktop 3D printers to large, advanced 3D production systems, making 3D printing more accessible than ever. FDM, Polyjet, SLS, and Metal technologies are used by our manufacturing customers to create models and prototypes for new product design and testing, as well as to build low-volume end-use parts. Its customers range from hobbyists and educators to industry professionals who create models and prototypes for new product design and testing as well as to build end-use parts in low volume.

Its customers range from hobbyists and educators to industry professionals who create models and prototypes for new product design and testing as well as to build end-use parts in low volume.

It services more than 1500 orders with over 100,000 parts produced annually for clients across Australia and New Zealand.

Inventia Life Science

Above: Inventia Life Science RASTRUM™ Bioprinter/Source: Inventia Life ScienceInventia Life Science is a biotech company based in Sydney, Australia that was founded in 2013. It is one of the few biotech 3D printing companies in Australia. It creates machines to bioprint human cells in 3D and assists forward-thinking pioneers in drug discovery and biomedical research in the creation of human tissue for research and therapy.

Bioprinters generate cell models that most closely and predictably mimic real human tissue structure and behaviour across a wide range of disease states. This physiological complexity provides an environment for world-class research and discovery to take place right in its own lab.

Conflux Technology

Above: Conflux Technology advances toward Aerospace Certification AS9100D with Design/Source: Conflux TechnologyConflux Technology has its origins in European F1 motorsport, where the founder Michael Fuller worked as a senior engineer for more than 15 years, designing championship-winning Formula One, World Rally, and Le Mans prototype race cars.

Working in such a competitive environment, as well as witnessing the limitations of heat exchanger performance, pushed Michael to think outside the traditional boundaries of thermal technology.

Conflux now works across many industries and applications, pushing the limits of heat transfer and additive manufacturing, and creating part geometries that are unique to this technology. Conflux Technology creates game-changing solutions for customers in aerospace, defence, industrial, energy, automotive, and microelectronics.

3D MEDiTech

Above: 3DMEDiTech Covid-19 swabs/Source: 3DMEDiTech3DMEDiTech™ has established a cutting-edge 3D printing facility, which is transforming the personalised medical device industry. In 2016, it was founded in Melbourne, Australia, with advanced manufacturing technologies that dramatically reduce waiting times for customised devices and maximise supply chain efficiencies for governments, hospitals, and clinics.

In 2016, it was founded in Melbourne, Australia, with advanced manufacturing technologies that dramatically reduce waiting times for customised devices and maximise supply chain efficiencies for governments, hospitals, and clinics.

It is one of Australia’s first 3D printing companies and the country’s only large-scale manufacturer of custom 3D printed medical and healthcare devices. 3DMEDiTech™ has developed 3D printing technologies, know-how, and engineering over the years to produce lighter, stronger, and customised devices.

3DMEDiTech™ is able to provide a full end-to-end manufacturing solutions approach by combining these unique capabilities with the expertise of its world-leading research institution partners, 3D engineering specialists, software engineers, and process engineers.

Additive Assurance

Additive Assurance is a unique quality assurance company that operate sin the additive space. It has created a laser powder bed fusion additive manufacturing process monitoring and quality assurance solution. Additive Assurance provides full process traceability by combining high-fidelity process data with powerful machine learning algorithms. Additive Assurance, inspired and developed by users, understands how to take quality assurance to the next level.

Additive Assurance provides full process traceability by combining high-fidelity process data with powerful machine learning algorithms. Additive Assurance, inspired and developed by users, understands how to take quality assurance to the next level.

Its mission is to help unlock the potential of metal additive manufacturing by providing a comprehensive solution for laser powder bed fusion quality assurance. Expertise in additive manufacturing, aerospace engineering, physical metallurgy, computational materials science, industrial design, computer vision, machine learning and artificial intelligence, and software development is shared by the team. We are also supported by a diverse board of directors, as well as industry advisors and mentors with strong business acumen.

Monocure3D

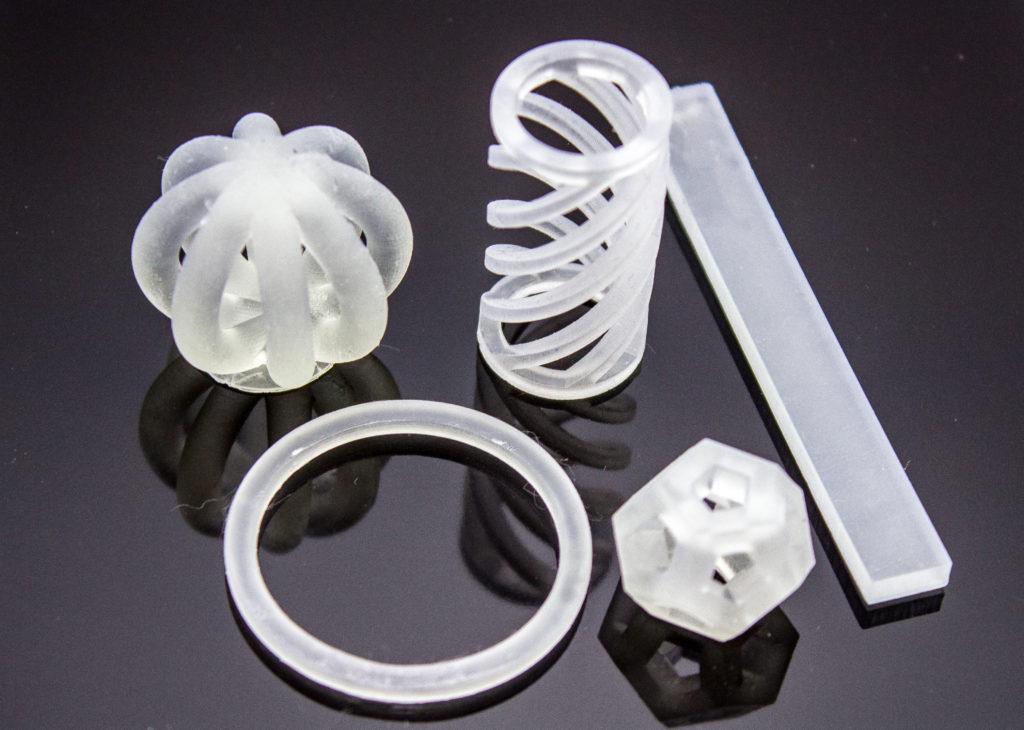

Above: Monocure3D premium resins/Source: Monocure3DMonocure3D develops, manufactures and supplies the highest quality 3D printing resins to consumers, businesses and resellers. Till date, the company has developed over 30 different product lines that cater to SLA/DLP/mSLA 3D printers. They have customers spread across 30 countries.

They have customers spread across 30 countries.

Monocure is a market leader in high-quality resins and all their resins all manufactured in-house in their Sydney facility.

FreeForm Composites

Above: Chain Link Epoxy Composite/Source: FreeForm CompositesAs the name suggests, Freeform Composites is a Melbourne-based company focused on developing composites for 3D printing technology. They have developed an entirely new material and process for binder jet 3D printing of ultra-lightweight, mechanically strong carbon composite products for high-end industrial applications (International Patents Pending).

With their materials, they offer 3D printer manufacturers the ability to quickly and efficiently provide an early stage entry into the carbon composites market through licensing our materials and technology developed for binder jet 3D printing of carbon composite products.

FreeForm composites is among the newest 3D printing companies in Australia but has aims to broaden the scope of commercial applications of carbon composite products with markets geographically located in Americas, Europe and Asia-Pacific.

Related Read: Popular 3D Printing Companies in New Zealand

A Few More 3D Printing Companies

Luyten3D

Luyten3D was founded with the goal of closing the technological gap in the large-scale construction and manufacturing industries by introducing robust cutting-edge 3D printing/Additive technologies.

It designs and manufactures custom large-scale three-dimensional concrete printers that cater for all project needs on site from conceptual design through to the final product. The business offers 3D concrete printing solutions for the incorporation of three-dimensional membranes on traditional construction sites, as well as on-site concrete printing consultations, operational assistance, and rental service offerings.

Evok3D

EVOK3D offers professional services as well as the manufacture of 3D printing solutions such as machines, materials, and professional support. EVOK3D offers the broadest range of applications of any 3D printing solutions company in Australia, with additive manufacturing systems suited to design concept modelling all the way through to production of end use parts. It has numerous partnerships with industry leaders such as HP, 3DGence, Asiga, and others.

It has numerous partnerships with industry leaders such as HP, 3DGence, Asiga, and others.

The EVOK3D team has extensive experience in 3D design, engineering, manufacturing, logistics, information technology, and customer service. EVOK3D services all capital cities and regional areas across Australia and New Zealand from offices in Melbourne, Sydney, and Auckland.

GoProto

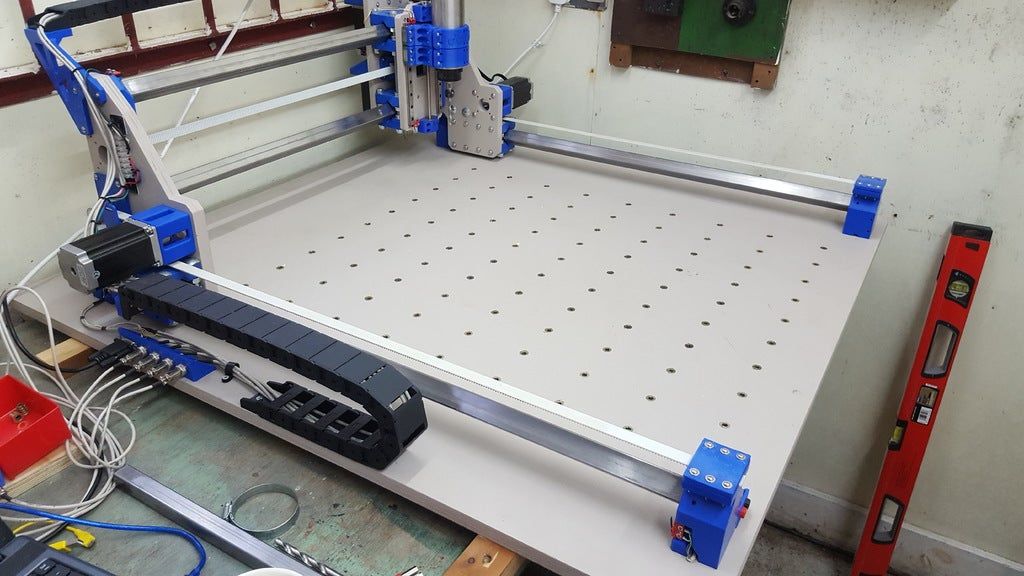

GoProto delivers turnkey manufacturing solutions including 3D scanning, rapid prototyping, additive manufacturing, cast urethane, CNC machining, sheet metal, injection tooling & moulding, die-casting, and sheet metal, and part finishing to complete your product.

It has Australia’s largest in-house 3D scanning, 3D printing & additive manufacturing facility in addition to facilities outside the country

WYSIWYG 3D

Wysiwyg 3D or ‘What You See Is What You Get 3D’ is an innovative Sydney-based engineering firm that specialises in 3D Measurement Services. It has over 10 years of experience in 3D scanning and are at the forefront of applying cutting-edge measurement technology to a wide range of markets.

Our highly skilled and passionate team of engineers and surveyors, based in Sydney SW but operating globally, provides accurate bespoke solutions for individual client requirements.

Zeal 3D Printing

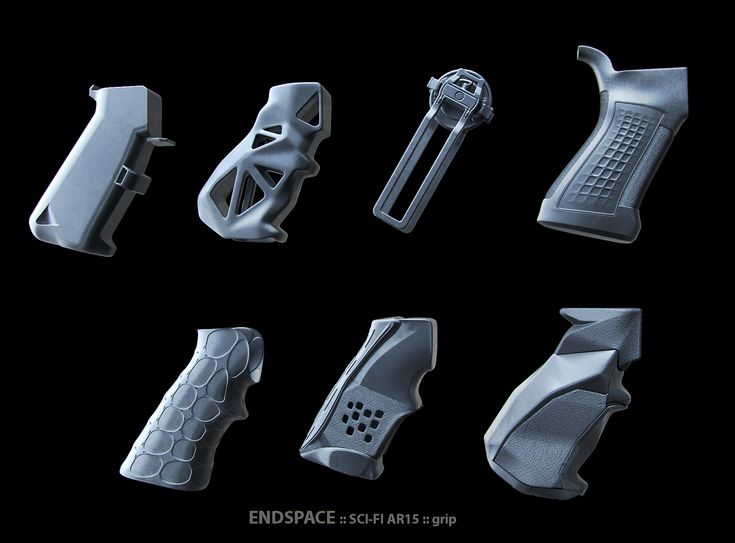

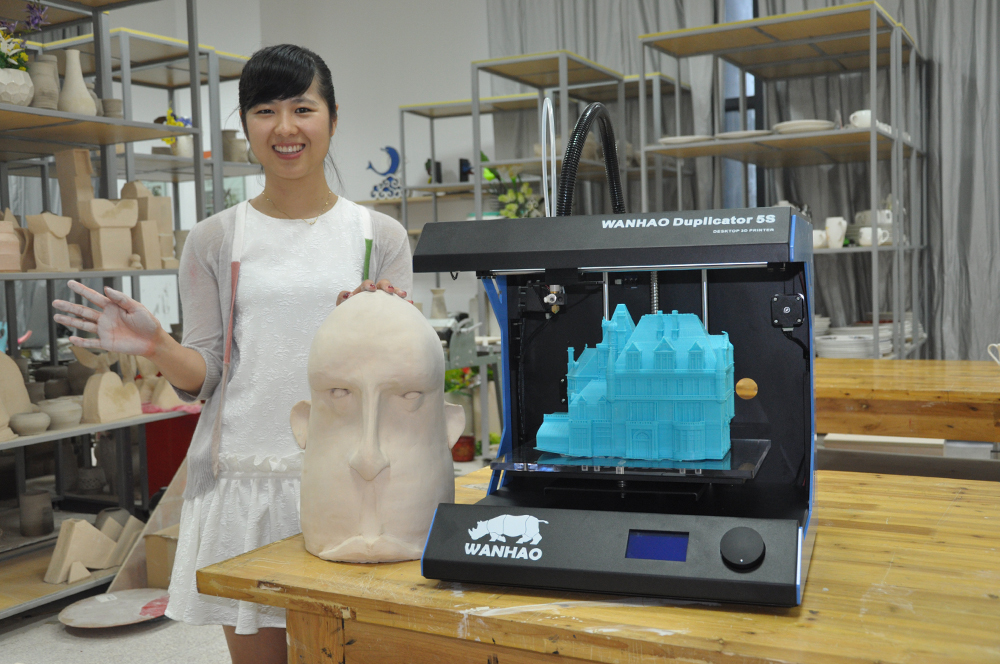

Zeal 3D, founded in 2014, is an ISO 9001-2015 certified digital manufacturing company that provides services throughout Australia. It is one of the popular 3D printing companies in Australia and provides on-demand Industry 4.0 services.

Zeal 3D works with businesses to assist them in streamlining their complex design and manufacturing goals by utilising modern technologies such as 3D printing and other manufacturing services. Zeal’s workshops are fully equipped with high-end equipment and software, allowing our team to design, test, and build a bespoke product in a shorter time frame.

Related Read: Popular 3D Printing Companies in New Zealand

Note: This list is based on the popularity of 3D printing companies in the country based on their online presence, ease of online search, metrics as obtained from SEO software, etc.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.

Professional 3D Printing Services available in Australia from Thinglab

Professional 3D Printing Services.

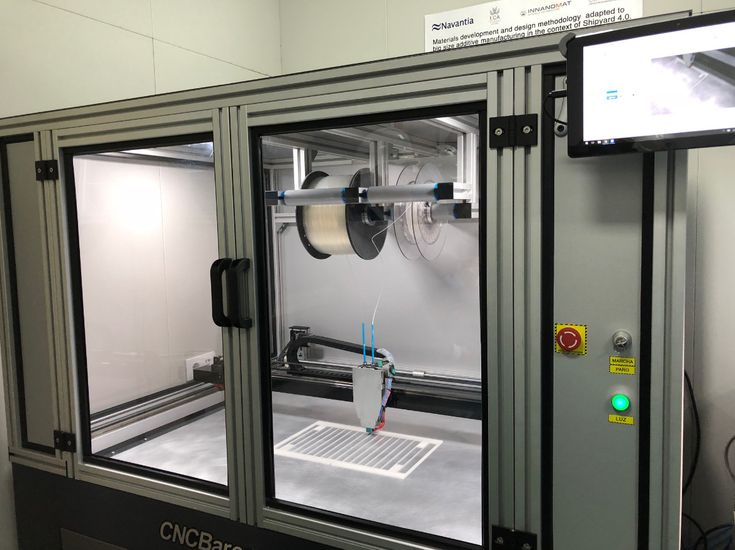

We provide professional 3D printing services out of our studio in Melbourne and can deliver Australia wide. With decades of combined experience in 3D printing services, and a large range of 3D printers in house, no one is better equipped to print your models.

We offer

- quick turnaround

- express service (available on request)

- affordable prices

- large build volumes

- a wide range of technologies and materials

- one off prints to large volume production runs

- expertise that will save you time and money

- NDA’s for sensitive projects

Instant Quote FAQs Contact Us

We Provide 3D Printing Services Across All Industries

Aerospace

Architecture

Arts

Engineering

Entertainment

Fashion

Forensics

Heritage

Medical

Product Design

Schools

Universities

We print to your needs

Low Cost Rapid Prototyping Through to Professional Quality Production Prints

A Wide Variety of 3D Printers to Choose From

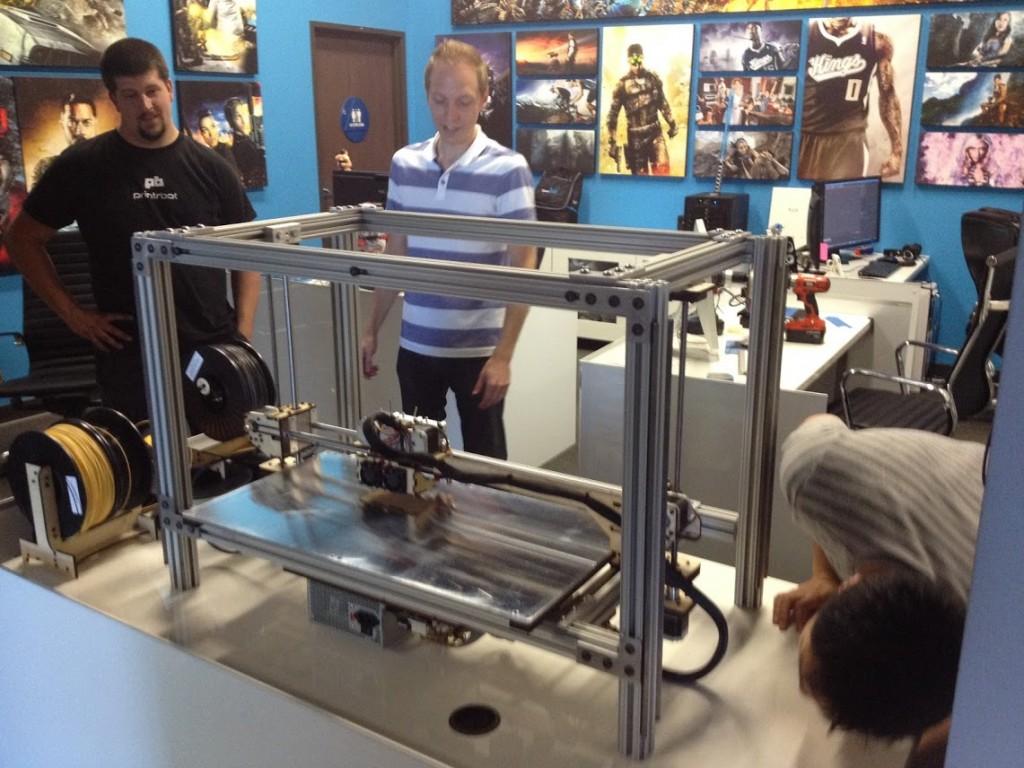

Large Build Volume

Build Your Parts Up to 1m³

Instant Quote

Having trouble with our instant quote?

Contact one of our team directly who will assist with your 3D printing needs.

Contact Us

Frequently Asked Questions

+How much does it cost to print a 3D model?

Our 3D printing services team are able to produce 3D prints in a range of different materials across a variety of 3D printing technologies to a maximum print volume of 1m³.

The minimum charge for a 3D print service is $150 and lead times range from overnight to several weeks dependent on size of print and machine availability.

We charge for 3D printed models based on a formula that takes into consideration build time, setup and labour time. For data that contains errors there may be an additional charge for the time required to repair the file for printing.

You can request an official quotation by sending us a STL (Stereolithography) file to [email protected] so that we can identify your requirements and check the suitability of the parts for 3D printing.

+What can I print?

You can print almost any 3D object using 3D printing technology, but some techniques are more suited to some shapes than others. Not all parts are suitable for printing. If you are unsure, send us an stl file and we will be happy to assess it for you. There are some important things to take into consideration when 3D printing:

Not all parts are suitable for printing. If you are unsure, send us an stl file and we will be happy to assess it for you. There are some important things to take into consideration when 3D printing:

- What is the end use of the prototype?

- Do you require specific material properties/characteristics?

- Does the part(s) need support structures for overhanging surfaces?

- What orientation is required for the part you’re building?

+What services do Thinglab provide?

We can provide prototyping services in a range of materials and 3D printing technologies, as well as 3D printing consultancy to determine the best technology and materials for your application. If you need a prototype not suited to FFF or SLA let us know and we can help with other 3D print technologies.

+How big can I print a part?

Depending on the material required we can provide printed prototypes up to a size of 1m³ (in FFF) or 140 x 140 x 170 mm (in SLA). *Multiple parts can be bonded together post production, but this is not a service we currently provide.

+How long does it take?

3D printing is one of the fastest ways to prototype physical objects, but it is not instant. Build times can take days to print for larger models, plus additional time for pre and post processing. Specifying your deadline is one of the best ways for our 3D printing services team to prioritise your work and ensure delivery for a time suited to you.

+What do I need to 3D print a part?

All you need is a CAD model of your part and this will need to be saved as a *.stl file, which is the standard file format for 3D printing.

Want To Know More?

Our team of 3D printing services professionals are just an email or a phone call away.

contact us

Australian 3D printing company wants to build houses on the moon (VIDEO)

Image of what a 3D printed model on the moon might look like. (Luyten) An Australian construction company has partnered with the University of New South Wales (UNSW) to accelerate the development of a 3D printer to build houses on the moon.

Luyten's co-founder and CEO, Ahmed Mahil, said he was delighted with the collaboration.

pidrimatiGreat Epoch (The Epoch Times) - tse independent international vision without a splash of any political or economic structures. Sob pratsyuvati far, we need your support. nine0003

"We are thrilled and honored to be partnering with UNSW to make building on the Moon possible. UNSW is renowned for its world-class academic leadership and research, and we are thrilled to be working together," Mahil said in a press release.

The partnership will put Australia at the forefront of the space race, he said.

"Our combined expertise and passion for innovative and exceptional building results across a range of interrelated disciplines will help humanity accelerate the colonization of the Moon and other planets," Mahil said. nine0003

Construction on the Moon was not originally planned.

"When we developed our revolutionary 3D concrete printers, we thought we would be solving building and structure problems around the world, but now, after discussions with the space industry, we are considering solving the problems of building and structures on the Moon " Mahil said.

3D printer designed for construction on the Moon, lightweight and durable.

"We have developed a compact printer using lightweight composite materials for its structure and robotic transformation technology, making it ideal for space transportation purposes," Mahil said. "[It] can be installed in less than 30 minutes." nine0003

According to UNSW Associate Professor Matthias Hank Heusler, their main task will be to develop a habitat with a shell that protects people from radiation.

"Computational design puts the scientific knowledge of how to protect humans from solar and cosmic radiation into a scenario that creates a shelter from the required 80 centimeters of solid material," Hausler said.

The need for the architecture to be strong enough to withstand meteorites and lunar earthquakes also makes the mission very complex, requiring significant technology. nine0003

The rovers will first assess the structural possibilities of the site. During this time, other rovers will collect local building materials to evaluate their mechanical properties. Then the robots will transfer the information received directly to the 3D printer.

Then the robots will transfer the information received directly to the 3D printer.

"Lunar regolith will be the main building material for printed structures because of its abundance," Mahil said. "Once the materials are available for 3D printing, the printer will start printing on the lunar surface. The materials will then be run through the printer and form layers of structures." nine0003

Hausler said the project could help them create homes for indigenous communities.

"The knowledge we generate to build on the Moon can be directly used to build housing for extreme climates like heat or to solve housing problems in remote indigenous communities," Hausler said.

Based on The Epoch Times USA

AUSTRALIAN LUYTEN 3D INTRODUCED PLATYPUS X12 CONSTRUCTION PRINTER

You are here

Home

The

IS "THE WORLD'S LARGEST MOBILE AI 3D PRINTER FOR THE CONSTRUCTION INDUSTRY".

The name of the Platypus X12 printer reflects the Australian roots of the company - platypus in translation means platypus. The main feature of this device is the possibility of its automatic transformation from the transport position to the working one. nine0003

According to Ahmed Mahil, co-founder and CEO of Luyten, “This is the most advanced mobile 3D concrete printer in the world. We have focused on cutting-edge technology and user-friendliness in designing the printer to ensure that the printer delivers the most complex and accurate results and The Platypus X12 is equipped with Luyten Tursiops [Tursiops australis - a species of bottlenose dolphin] extruder with an optional 3D-compatible contour nozzle. with robust artificial intelligence algorithms for use in expeditionary conditions." nine0003

"Flexible in scale, the printer can transform into a 12 x 6 mobile crane in 20 minutes, expanding its ability to print large-scale structures. It literally expands to 12 meters wide, 6 meters high and [this process] thanks to its robotic nature, it takes only a few minutes to unfold to full size - Mahil adds - Despite its size and robotic ability to unfold to any size, it is very light, but at the same time durable and mobile.