The future is 3d printing

6 Predictions for the Future of 3D Printing

3D printing is quickly becoming a mature manufacturing technology. It’s useful for prototypes and offers significant benefits for small and medium-sized production runs. But just how much will 3D printing change manufacturing and supply chain — and how will the technology get there? Here are six predictions about the near future of additive manufacturing.

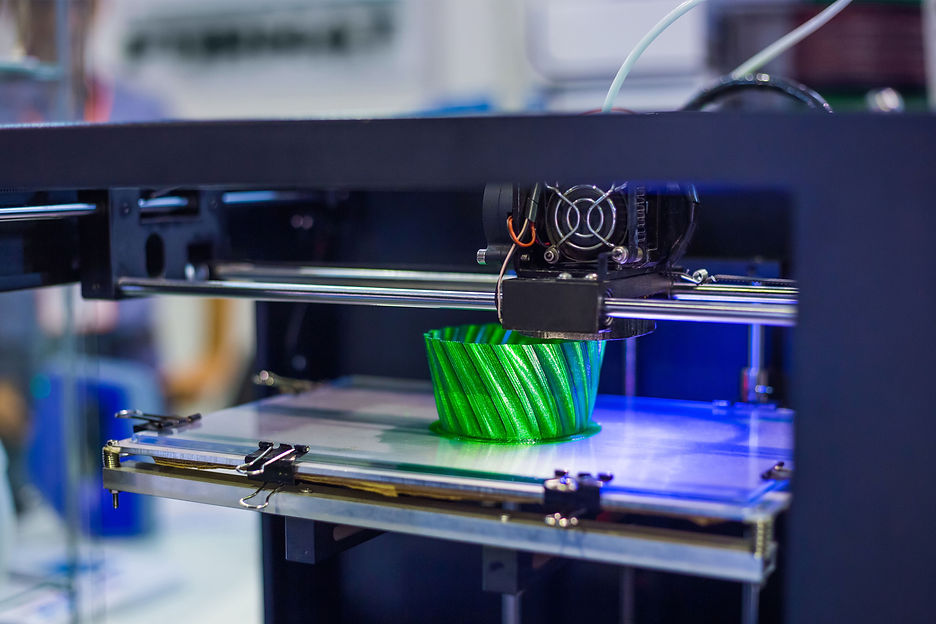

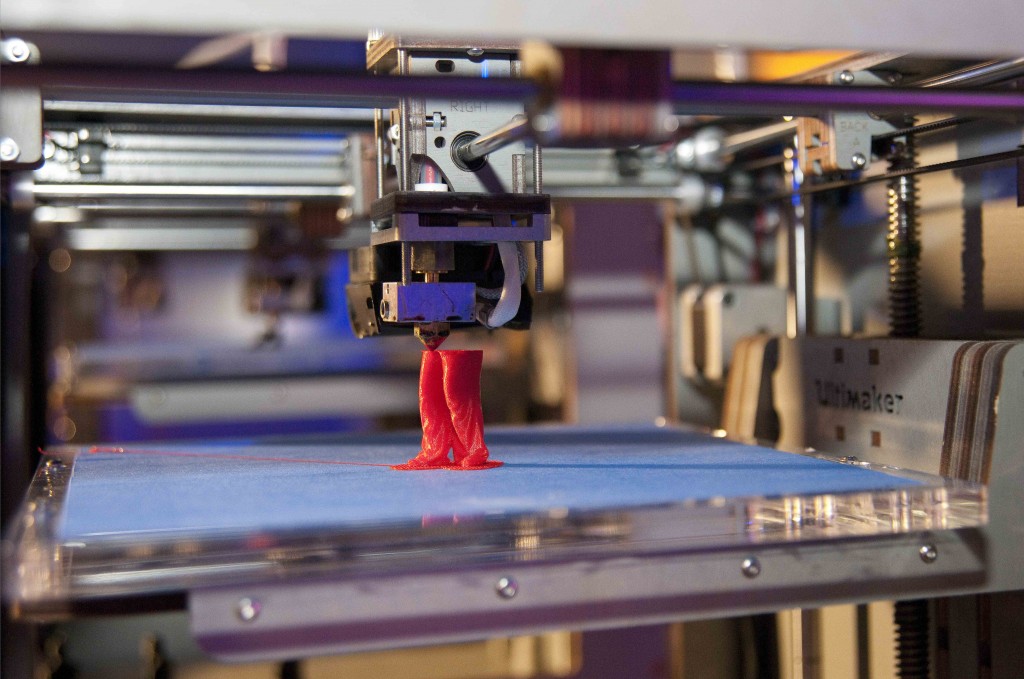

1. 3D printing will be bigger, faster and cheaper. 3D printing technologies are developing quickly. Rising demand for specialized materials to fulfil the required properties of end parts will continue to drive developments in the range and types of options available. The key for the new generation of printers, especially industrial-grade solutions, will be the ability to handle a greater range of advanced materials. This opens the door for businesses to benefit from additive manufacturing in areas where they previously could not.

Although machine costs remain high, increased print speed is pushing the price of parts down. As more and more businesses adopt 3D printing, these advancements will accelerate. With the addition of processes such as dual extrusion, the versatility of 3D printing is growing. As a result, 3D printing is being adopted in a wider range of industries. Another trend likely to significantly drive development is printing without the use of support structures, which again broadens the range of applications additive manufacturing can offer. In our eyes the potential for cost and time savings is high.

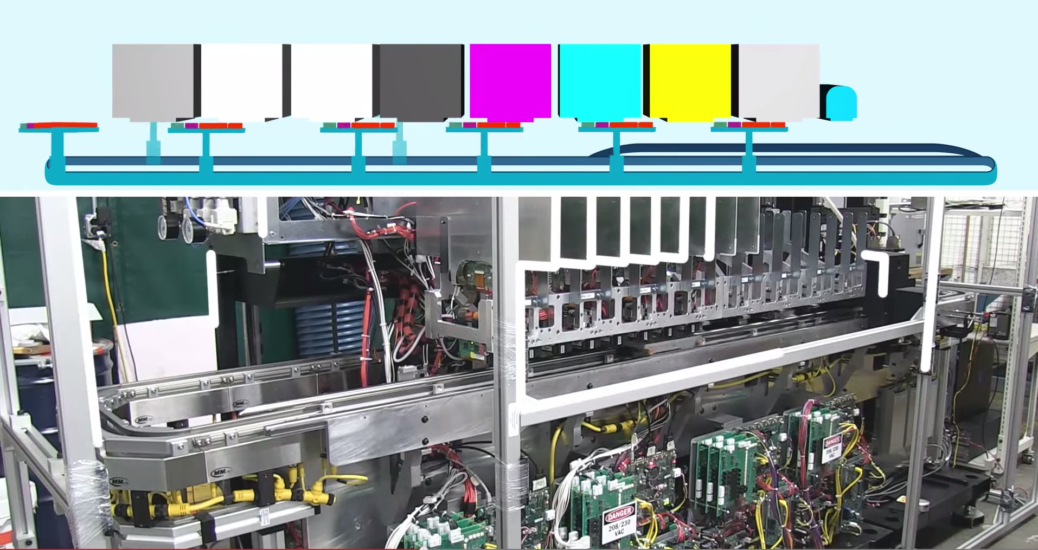

2. Additive manufacturing will become part of an integrated supply chain approach. To maximize benefits, manufacturers need a large range of printers and materials and, importantly, connections with other industry professionals. Furthermore, interoperability among different systems is becoming important to maximize the potential of 3D printing. Automation in production and post-processing as well as in integrated usability will be important trends this year and beyond. Additive manufacturing can provide a whole new supply chain approach as part of a holistic and secure platform in which the individual steps are combined into one process, from concept to materials, digital inventory, production and delivery. As manufacturers strive toward Industry 5.0, services offering a fully automated, yet secure, platform will be essential.

Additive manufacturing can provide a whole new supply chain approach as part of a holistic and secure platform in which the individual steps are combined into one process, from concept to materials, digital inventory, production and delivery. As manufacturers strive toward Industry 5.0, services offering a fully automated, yet secure, platform will be essential.

3. Working together is imperative. Partnerships can create mutual benefits and synergies that lead to a greater product for customers. In 3D printing, this has proven to be a main enabler to scale industrial production. However, to progress further, there is a need for more holistic collaboration. Standards have to be developed, and printer and post-processing systems should be able to work together. In addition, shared production data can lead to improved printers and materials for all. Likewise, close collaborations are essential to achieving the best solution. An ecosystem where service providers, material producers and print farms worldwide are connected is the next step to building a better service.

4. There must be ways to provide quality and cybersecurity assurance. 3D printing continues to transform today’s industries, with companies adopting the technology for more and more of their needs, thereby giving rise to a more integrated production environment. However, for industrial production, businesses must be assured that their 3D printed parts will meet necessary quality requirements. Moreover, data ownership will play a crucial role. Intellectual property needs to stay in the right hands. As manufacturing progresses into the digital era, data management will be critical. In terms of quality assurance, it’s important to carefully select production partners, check their capabilities and ensure repeatable fit-for-purpose parts. Further steps are required to ensure design data is kept in the right hands. In addition, organizations must enforce manufacturing parameters by encrypting the data so the parts can only be produced in the requested amount and material. By collecting manufacturing data and analyzing it, mistakes can be detected quickly, improving the process and ensuring all quality requirements are met.

By collecting manufacturing data and analyzing it, mistakes can be detected quickly, improving the process and ensuring all quality requirements are met.

5. 3D printing will boost supply chain resilience. 3D printing has been used in the past as a solution to a variety of supply chain disruptions. As the technology develops, additive manufacturing’s role in solving these problems will only increase. Because 3D printing production can be situated closer to the consumer location, manufacturing organizations leveraging this technology can build shorter, stronger and more resilient supply chains. Physical inventory is the weak point in any supply chain. But with printing on-demand capability, inventory becomes digital. Engineers and manufacturers can send the design file to the 3D printer nearest the next step in the supply chain, whether it is the manufacturer receiving the component or the consumer receiving the final product. Then, there is less need to store and incrementally move inventory. Instead, parts can be printed and shipped the shortest practical distance, thus reducing carbon dioxide emissions and boosting supply chain resilience.

Instead, parts can be printed and shipped the shortest practical distance, thus reducing carbon dioxide emissions and boosting supply chain resilience.

6. Additive manufacturing will drive sustainability forward. Demands of end-customers, official regulations and even moral duty are making sustainable production and supply chains increasingly necessary. This trend also is present in 3D printing, which can reduce waste during production. By specifically designing a part for 3D printing, engineers can drastically decrease the weight of the end part, therefore reducing the material needed for production. Moreover, when 3D printing is used as part of an on-demand and decentralized digital warehouse, it can reduce the number of parts in inventory and the associated waste. Plus, by locating production closer to the next step in the supply chain, carbon dioxide emissions during transport are reduced. Moreover, there will be growth in sustainable 3D printing materials such as recycled, reusable and biodegradable plastics.

What Does the Future of 3D Printing Look Like?

3D printing has come a long way from the early days of desktop figurines. As technology continues to evolve, the future is brighter than ever.

Once a novelty pipe dream but now an established technology, 3D printing (or additive manufacturing) is positioned for real, important growth. Remember the early days of 3D printing? We shared a collective excitement for model versions of the Brooklyn Bridge and iconic cartoon characters to adorn our desks. Now, 3D printing is tackling much larger issues and solving complex problems across industries of varying scales.

The basis of 3D printing — also called additive manufacturing — is adding layers of materials compounded to make an object. Where cutting and soldering were once required, additive manufacturing gracefully adds layers to build the same type of structures. However, these results are stronger, lighter, more temperature resistant, and require fewer parts.

Applications Showcasing What the Future Holds for 3D Printing

While there are endless examples of 3D printing being used for incredible things, here are a few examples of what the future holds:

- 3D printers have long been able to print rocket-shaped objects, but now companies in the aerospace industry are actually printing rockets.

Companies like Aerojet Rocketdyne are using additive manufacturing for rocket engine and defense system applications. These companies cite reduced lead times, affordability, and new approaches to design as factors in the decision to use additive manufacturing to deliver hypersonic flight.

Companies like Aerojet Rocketdyne are using additive manufacturing for rocket engine and defense system applications. These companies cite reduced lead times, affordability, and new approaches to design as factors in the decision to use additive manufacturing to deliver hypersonic flight.

- In healthcare, additive manufacturing is also making grand promises. 3D Systems, in partnership with CollPlant, is working on printing artificial tissues and scaffolds, advancing regenerative medicine through the use of rhCollagen as a 3D printing substrate.

- The electric vehicle industry is a similar story. Local Motors Industries, a company with only 130 employees, has already printed a 3D car that has since been discontinued. Now, they’re printing an urban electric shuttle, citing digital design advancements as a contributing factor.

At the Forefront of Evolving Technology

A generatively designed color part from the HP MJF 580 3d printer at the Autodesk Technology Center in Toronto.

Experts predict the largest industry leaps will happen in the technology facilitating additive manufacturing. Printers will likely become even faster, meaning they’ll be able to work on larger, industrial types of projects. Forbes also reports that MELD Manufacturing has designed machines that allow additive manufacturing in uncontrolled environments, which means they can operate in the field. As a result, they’re more useful in remote areas and enable a greater variety of 3D printed structures.

3D printing seeks to address efficiency problems throughout supply chains as well. Nora Toure, Founder of Women in 3D Printing, writes, “I predict there will be a countless number of companies that have adopted additive manufacturing into their supply chain commercially with a vast majority of products to be produced on-demand and locally (not necessarily through additive manufacturing, but more as a combination of manufacturing tools, including additive manufacturing).”

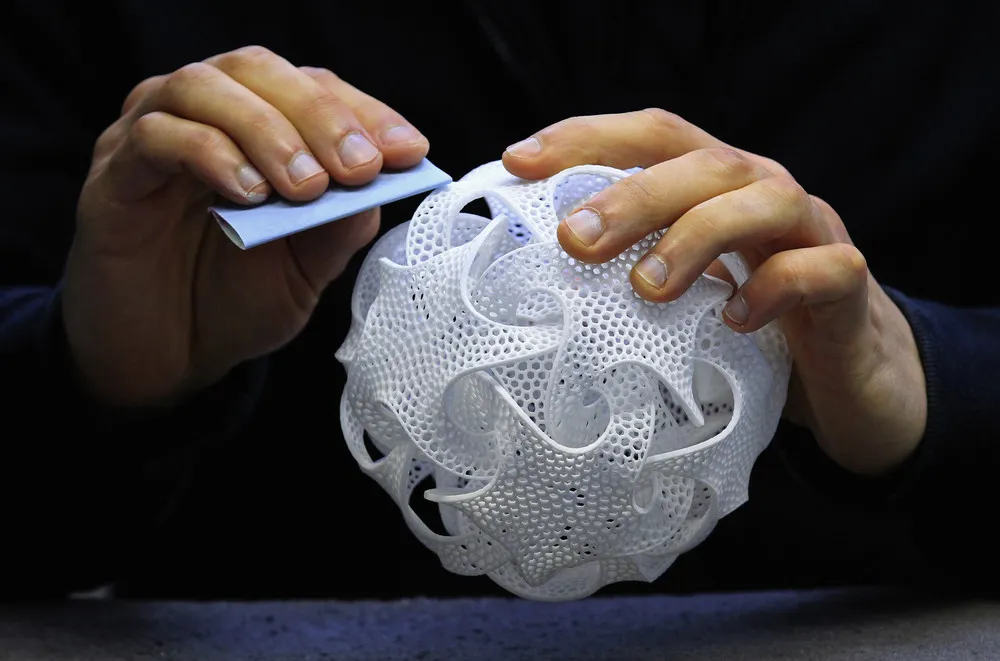

3D printers will also add versatility in other ways — using different materials, including metal and even ceramics, even within the same machine. Printers will be able to print one object containing multiple materials, paving the way for a significantly widened field of use.

Printers will be able to print one object containing multiple materials, paving the way for a significantly widened field of use.

Autodesk Fusion 360 and Additive Manufacturing

Integrated CAD + CAM software like Autodesk Fusion 360 will enable additive manufacturing to soar to entirely new levels. The Fusion 360 team is constantly thinking of ways to improve and enhance the additive manufacturing process. We recently announced a new method for generating additive manufacturing outcomes using generative design. This new method does a better job of meeting minimum thickness requirements, balancing design mass, and minimizing support material — without sacrificing shape quality to be fully self-supporting.

Many leading companies have explored the benefits of using generative design in tandem with additive manufacturing, including Hyundai, Panasonic, and more. Download Fusion 360 today to explore innovative additive manufacturing solutions.

prospects, development and future of 3d printers

3D printing is an extremely promising technology that can change the way many things are made. In addition, the use of 3D printers will significantly reduce the production time of various products and reduce their final cost. Let's consider in which areas the use of 3D printing is most promising, what is the future of this technology and how quickly it will develop.

In addition, the use of 3D printers will significantly reduce the production time of various products and reduce their final cost. Let's consider in which areas the use of 3D printing is most promising, what is the future of this technology and how quickly it will develop.

Relevance of 3D printing

3D printing technology is relevant due to its ease of use and saving time spent on the production of various types of products.

Printing of 3D objects also provides high-precision reproduction of the necessary shapes and details of a particular object. At the same time, manual labor is practically reduced to zero, which means that the cost of the operator and maintenance of the 3D printer will be minimal. Subsequently, this will reduce the cost of the finished product. nine0003

Thanks to these advantages, 3D printing is successfully used in many industries and in everyday life.

The future of 3D printers in various fields

3D printing technology has a lot of potential if applied correctly. The following areas of activity are most in need of 3D printing services:

The following areas of activity are most in need of 3D printing services:

- Construction. In the construction industry, 3D printing can be a powerful addition to traditional construction methods. Since this technology does not require the involvement of a large number of people to perform hard work. A few operators and craftsmen are enough to service the construction 3D printer. The first successful experiments in the manufacture of building parts and the construction of houses have already been carried out in China and the United Arab Emirates. nine0020

- Electronics. In the manufacture of digital devices, 3D printing will reduce the time for the manufacture of labor-intensive parts, microcircuits and hardware electronics. In particular, 3D printing is already developing the first samples of graphene batteries that have an unlimited service life.

- Mechanical engineering and automotive industry. In this area, with the help of three-dimensional printing, experimental models of future spare parts and parts are created, which later allow the production of products of perfect quality.

This is possible due to the detailed study of a three-dimensional object during its creation and printing of a finished computer model, which has a high level of detail. nine0020

This is possible due to the detailed study of a three-dimensional object during its creation and printing of a finished computer model, which has a high level of detail. nine0020 - Aerospace industry. The use of 3D printing in this industry is explained by the ability to create innovative designs of any complexity. Details of satellites, rockets and other space objects are printed from metal, polymers and other types of heavy-duty materials.

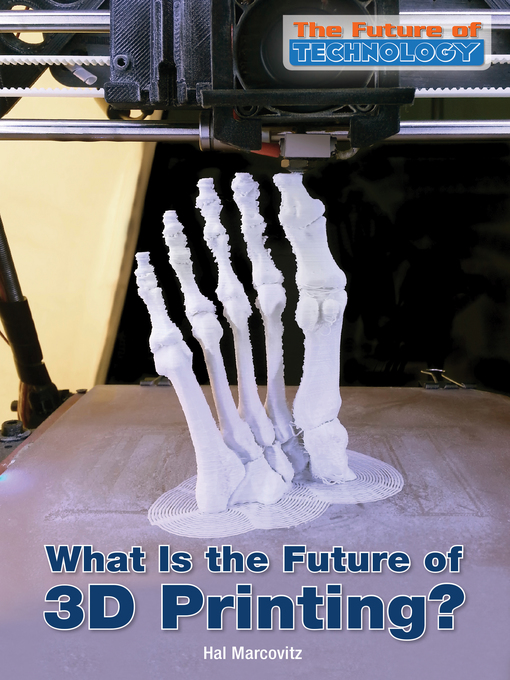

- Medicine and pharmaceuticals. In medicine, 3D printing technology is extremely important. Therefore, in this industry it is studied in great detail. With the help of a 3D printer, it is possible to print prototypes of human organs, prostheses, bone tissue implants. Even the first steps are being taken to develop and print real organs that will take root well in the human body. In the pharmaceutical industry, 3D printing is mainly used to create tablets that will gradually release active substances after ingestion. nine0020

- Advertising.

For advertising purposes, 3D printers print prototypes of various products, demonstration and handouts.

For advertising purposes, 3D printers print prototypes of various products, demonstration and handouts. - Food industry. 3D food printers are especially interesting because they allow you to create edible objects from familiar foods. 3D printing makes it possible to create unique decorations and complex multi-color objects with high detail.

The future of 3D printing

3D printing, if properly developed and explored, will be more accessible in the future. Since 3D printers will be common as a work unit in many areas. At the same time, prices for such equipment are likely to fall. Since they will be produced by various companies in large quantities to satisfy the demand of all buyers. nine0003

The growing demand for 3D printing will lead to the development of new types of 3D printers and materials for creating products.

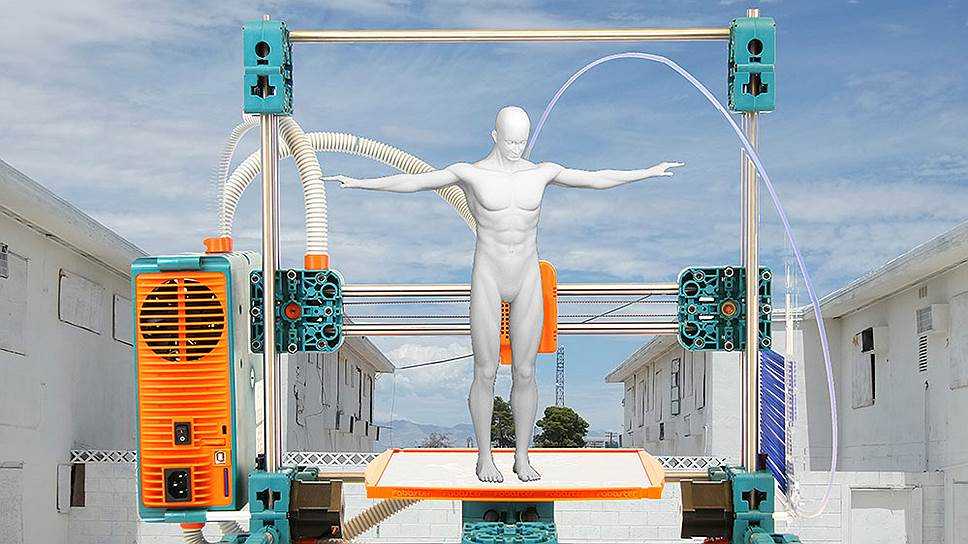

Also for larger 3D printing, large-scale equipment will be created that will allow printing very large products for construction needs, engineering and other industries.

Unexpected possibilities of 3D printing

In addition to the standard creation of three-dimensional objects, the development and 3D printing of unique and customized products is also available on a 3D printer. Their shape, structure and design features are limited only by the user's imagination. It is possible to produce unusual products. For example, non-melting ice sculptures, curly perfectly fried pancakes or fine jewelry. nine0003

Who is the future of 3D printing?

First and foremost, the future of 3D printing depends on inventors who create new types of printers and develop new printing technologies depending on the type of material used. Most often, 3D printing novelties appear in research centers, industrial enterprises and technical departments of various universities. This is due to the fact that people working in such institutions are interested in the development of new technologies. Since innovation will help to improve and improve the processes of creating products in specific areas. In addition to researchers and students, a large number of developments are carried out by children and 3D printing enthusiasts. For example, the invention of the first 3D-printed prosthesis belongs to 17-year-old Easton LaChapelle. nine0003

In addition to researchers and students, a large number of developments are carried out by children and 3D printing enthusiasts. For example, the invention of the first 3D-printed prosthesis belongs to 17-year-old Easton LaChapelle. nine0003

In addition to inventors, organizations that sponsor new developments are also responsible for the continued development and improvement of printing methods.

Help. Three companies are considered the most famous in the field of 3D printing: Shapeways, Sculpteo and Materialize. They are engaged in the professional development and release of new models of 3D printers, materials, as well as the improvement of existing technologies and the creation of new ones.

What's in store for 3D printing in the next few years? nine0005

3D printing experts in 2021 make the following forecasts for its development:

- The spread of 3D printing will be massive. Studios for creating three-dimensional objects will be distributed in much the same way as studios for photocopying and printing materials.

3D printing will be carried out both on standard models and on individual projects.

3D printing will be carried out both on standard models and on individual projects. - Small-scale production of various products will completely switch to 3D printing technology. This will help to significantly reduce the price of finished products. nine0020

- Medical scientists will master the creation of full-fledged and fully compatible organs on a 3D printer, which will be printed from dividing human cells.

- With due diligence proving the safety of 3D printing for construction purposes, many companies in the industry will start using powerful industrial printers to create the necessary building elements. At the same time, the time to build houses will be reduced and the proportion of hired workers who perform hard work will decrease. nine0020

A revolution in materials

The standard filament used in 3D printers is plastic materials. However, technology development continues at an accelerated pace. Thanks to this, innovative materials appear on the market, such as:

- Metal powder.

This material is mixed with a polymer during printing and is used in the technology of laser sintering of metals. Products printed from a mixture of polymer and metal powder have increased strength comparable to real metal. nine0020

This material is mixed with a polymer during printing and is used in the technology of laser sintering of metals. Products printed from a mixture of polymer and metal powder have increased strength comparable to real metal. nine0020 - Graphene. This carbon material is being used experimentally to develop a new composite. Ideally, a 3D-printed graphene sheet would be one molecule thick. By weight, the material will be lighter than air, but its strength properties will be very high - the sheet is ten times stronger than steel.

- Ceramic foam. Such material has flexible characteristics that can be changed depending on the purpose of use. From ceramic foam on a 3D printer, you can print both a very light figure and a heavy monument. In theory, development already exists. But it requires a series of tests and stabilization of functional properties. nine0020

What are the unusual technology projects of the future?

Among the unusual 3D technologies of the future, special attention should be paid to:

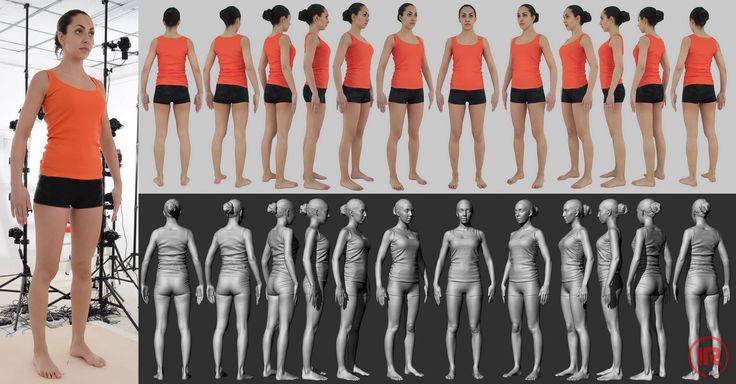

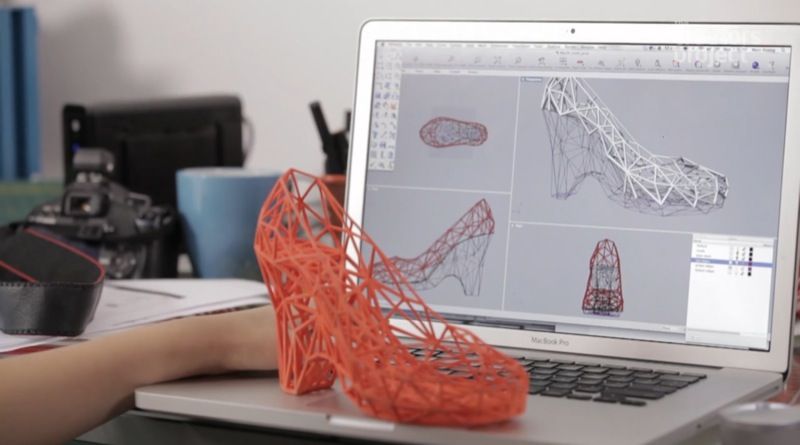

- the creation of individualized clothing and footwear, which will be produced on the basis of 3D body scanning;

- makeup created by special handheld 3D printers, which is very fast and yet very precise in fine details;

- bioprinting with living cells and creation of tissues and organs from hydrogel.

nine0020

nine0020

3D printing has very great prospects in various fields of industry and human activity. The technology will replace the hard work of people, print cheaper products with consistently high quality. However, not all areas can immediately use 3D printing. This will require many years of testing and a series of examinations.

- April 19, 2021

- 10789

Get expert advice

what's next for 3D printing

The future of 3D printing

Already, the outlook for 3D printing is very promising. Scientists are actively developing existing 3D printing techniques, developing new technologies and types of materials, and finding new areas of application. Many call 3D printing the technology of the future, and for good reason. The technique is able to completely turn the usual way of life, changing the way most things are produced. In fact, a 3D printer is a real multifunctional factory, small and compact. Due to this, the future of 3D printing can definitely be called successful. nine0003

Due to this, the future of 3D printing can definitely be called successful. nine0003

3D printers can significantly reduce production costs, thereby reducing the cost of products. Judging by the growing trend towards the popularization of 3D technologies, raw materials for 3D printing will become the main commodity unit in the future. In general, the prospects for 3D printing are defined for many areas. And now we will try to reveal them as much as possible.

The future of 3D printing

If you try to imagine the future of 3D printing, the imagination paints a rather interesting picture. Given the great interest of scientists in the 3D bioprinting technique, which is one of the most promising 3D printing technologies, the production of artificial organs on a 3D printer is not far off. It is also safe to say that the future of 3D printing will bring us dramatic changes in areas such as:

- Construction. 3D printing of houses, or contour construction, attracts many with its futurism and simplicity.

The first steps in this direction have already been taken. The pioneers in 3D printing of houses were the Chinese, followed by the government of Dubai who discovered contour building. The first 3D printed office building has already been built in this city of the future, and an entire block is planned to be printed in the near future. And just recently, the first printed house in Europe was created on a 3D printer; nine0020

The first steps in this direction have already been taken. The pioneers in 3D printing of houses were the Chinese, followed by the government of Dubai who discovered contour building. The first 3D printed office building has already been built in this city of the future, and an entire block is planned to be printed in the near future. And just recently, the first printed house in Europe was created on a 3D printer; nine0020 - Electronics. When listing the prospects for 3D printing, this point should be given special attention. Scientists believe 3D printing of electronics is the future of digital device manufacturing, and with good reason. Graphene properties and its application in additive manufacturing are currently being actively researched. A huge breakthrough in this area is the creation of a graphene battery with an unlimited service life on a 3D printer;

- Automotive and aerospace industry. The future of 3D printing is largely based on its ability to reproduce almost any element of varying complexity.

In this regard, 3D printing is already widely used in the development of aircraft, machines and satellites. The ISS even has its own 3D printer, not to mention a number of successful 3D printing of cars. nine0020

In this regard, 3D printing is already widely used in the development of aircraft, machines and satellites. The ISS even has its own 3D printer, not to mention a number of successful 3D printing of cars. nine0020 - Pharmaceutical industry. Yes, yes, you can imagine. The future of 3D printing is in the manufacture of tablets and other medicines. This is confirmed by epilepsy pills legalized in the USA, made according to a special technique. The essence of this perspective of 3D printing is the gradual release of active substances, so that instead of many tablets, you can drink just one.

- Food industry. 3D food printers are gradually gaining space in cafes and restaurants. While this is probably one of the most raw 3D printing technologies out there, it has potential. Food 3D printers are especially interesting for the possibility of making food for astronauts, as well as the freedom to display culinary talent. This is confirmed by the amazing 3D-printed desserts of our compatriot.

nine0020

nine0020

Other questions and answers about 3D printers and 3D printing:

- Finance Which 3D printer manufacturers are best?

- Finance Which 3D printer is better to buy?

The future of 3D printers

Now let's try to imagine the future of 3D printers. There are several important points to be noted here. Below we list the most likely scenarios for the future of 3D printers.

- Improving the reliability and quality of instruments. Surely, many users are looking forward to this, because most of the existing models of 3D printers cannot boast of uninterrupted operation and the absence of printing errors; nine0020

- Large-scale distribution. It is certain that the future of 3D printers will please us with their popularization. Even now, one can observe a growing trend towards the use of 3D printing in almost all areas of industry. In parallel with the fact that more and more users learn about the possibilities of technology, the demand for desktop 3D printers is also growing;

- Availability.

In continuation of the previous paragraph, it is worth noting that the growing demand for 3D printers will lead to lower prices for these devices. The use of 3D printing for domestic purposes is gaining momentum, which brings new equipment manufacturers to the market. Naturally, such a step will entail a reduction in the cost of devices; nine0020

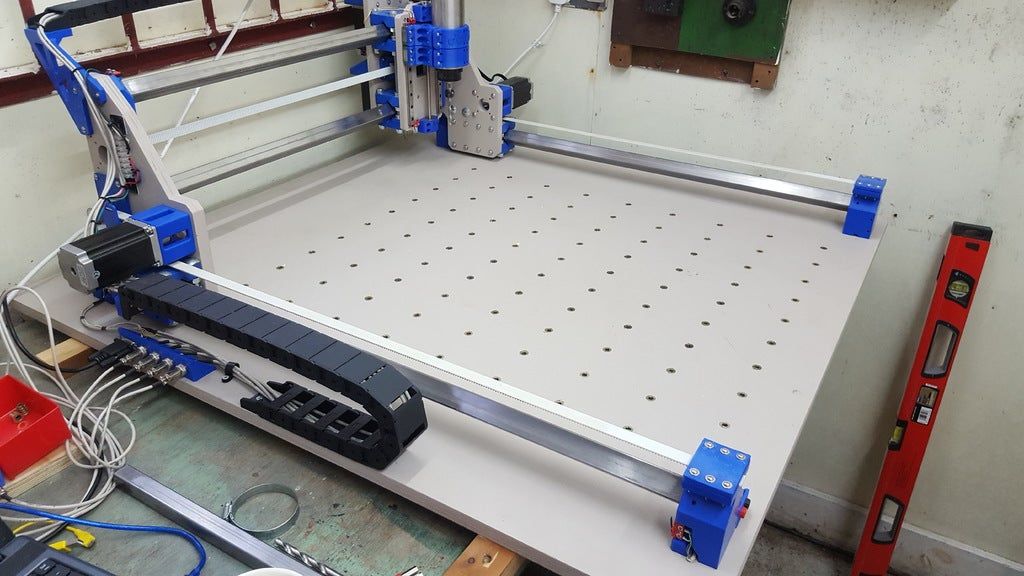

In continuation of the previous paragraph, it is worth noting that the growing demand for 3D printers will lead to lower prices for these devices. The use of 3D printing for domestic purposes is gaining momentum, which brings new equipment manufacturers to the market. Naturally, such a step will entail a reduction in the cost of devices; nine0020 - Enlargement of the construction area. 3D printing of large-sized objects has long occupied the minds of developers. Of course, this applies to industrial 3D printers, because the functionality of 3D printing at this scale will allow you to create full-fledged components, for example, cars and aircraft;

- Expanding the range of available materials. The future of 3D printers depends a lot on 3D printing materials, because more means more possibilities. The development of special equipment and related materials is being carried out by many companies, and news about the release of new polymers is constantly appearing. nine0020

3D technologies of the future

Summing up, it remains to consider only 3D technologies of the future. These include various futuristic scenarios that, to one degree or another, are already beginning to develop today. These include the technique of virtual reality, 3D scanning to create the perfect clothes and shoes, 3D printed makeup, and more. In a way, 3D technologies of the future also include bioprinting. By the way, scientists are talking about building the first 3D printed settlement on the Moon and Mars, so the prospects for 3D printing are also relevant outside the Earth. nine0003

These include various futuristic scenarios that, to one degree or another, are already beginning to develop today. These include the technique of virtual reality, 3D scanning to create the perfect clothes and shoes, 3D printed makeup, and more. In a way, 3D technologies of the future also include bioprinting. By the way, scientists are talking about building the first 3D printed settlement on the Moon and Mars, so the prospects for 3D printing are also relevant outside the Earth. nine0003

This was a list of the main scenarios for the future of 3D printing. Let's see how they are destined to come true. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

Our store offers a wide range of 3D printers, 3D scanners, 3D plastics and resins, as well as other accessories at the best prices on the Ukrainian market with delivery to all cities (Kharkiv, Nikolaev, Dnepropetrovsk, Lviv, Zaporozhye, Kherson, Donetsk, Odessa ).