3D print online quote

Custom Online 3D Printing Service

CapabilitiesCustom Online 3D Printing Service

Get instant online quotes on parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Our 3D Printing ServicesMaterialsApplications and BenefitsSizes and TolerancesAbout 3D Printing3D Printing GuideXometry's Online 3D Printing Services: High-Quality Rapid Prototyping and Production Parts

Xometry offers an industry-leading 3D printing service online. Whether you need prototypes or production parts, we can make them for you on demand in as fast as a day. We are your one-stop-shop for accurate, precise, custom 3D printed parts at an affordable price. Upload your 3D CAD file to get an online quote and lead time within seconds. We print everything from single prototypes to thousands of production-grade parts.

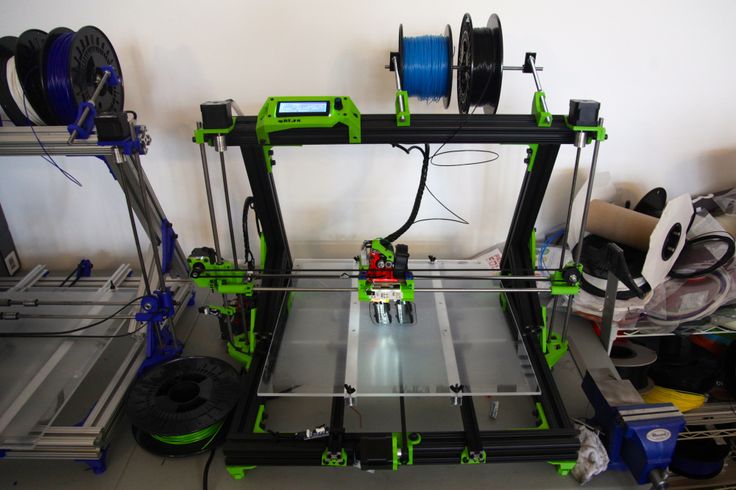

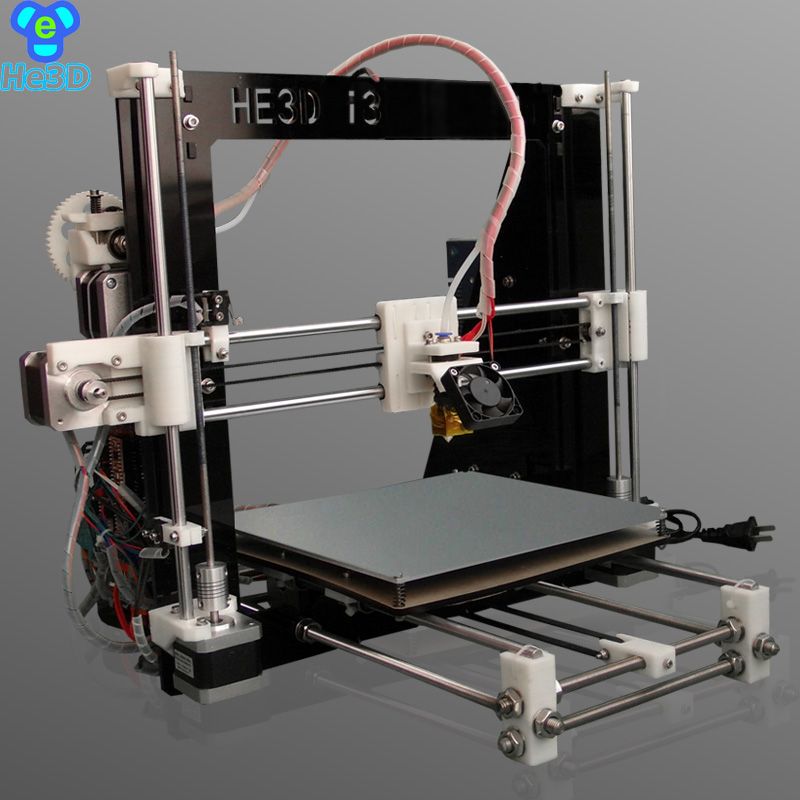

We use the latest additive manufacturing technology to build affordable functional parts in over 60 metals and plastics. Xometry offers eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more. For a great introduction to additive manufacturing, please visit our Complete Guide to 3D Printing.

Thermoplastic 3D Printing

Selective Laser Sintering (SLS) 3D Printing Service

Upload your CAD file to get instant quotes on SLS parts. Parts ship in days. Free shipping on all US orders.

Selective Laser Sintering (SLS) 3D Printing Service

HP Multi Jet Fusion (MJF) 3D Printing Service

Guaranteed quality prototypes and production parts. Free shipping on all US orders. ISO 9001:2015, ISO 13485, and AS9100D certified.

HP Multi Jet Fusion (MJF) 3D Printing Service

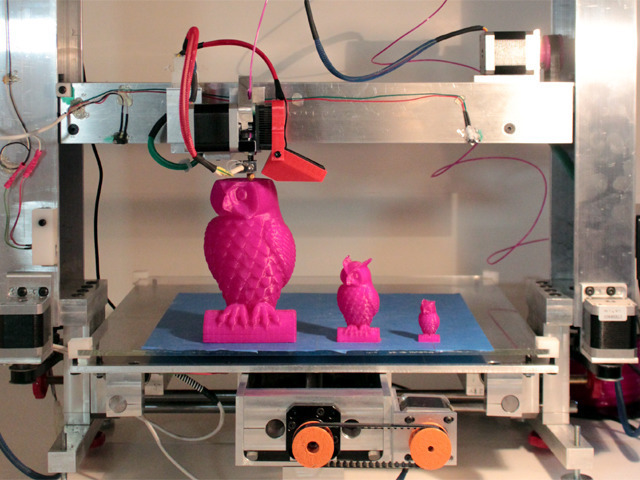

Fused Deposition Modeling (FDM) 3D Printing Service

High Quality Large Format FDM 3D Printing Free Shipping on All US Orders

Fused Deposition Modeling (FDM) 3D Printing Service

Thermoset 3D Printing

Stereolithography (SLA) 3D Printing Service

High-Resolution Prototypes in Days Free Shipping on All US Orders

Stereolithography (SLA) 3D Printing Service

Carbon Digital Light Synthesis™ (DLS™) 3D Printing Service

High-Performing Prototypes and Serialized Production Parts Free Shipping on All US Orders

Carbon Digital Light Synthesis™ (DLS™) 3D Printing Service

PolyJet 3D Printing Service

Prototypes, color concept models, and simulated overmold parts in days Free shipping on all US orders

PolyJet 3D Printing Service

Metal 3D Printing

Direct Metal Laser Sintering (DMLS) 3D Printing Service

Upload your CAD files to get an instant quote on metal prototypes and production parts. Free shipping on all US orders.

Free shipping on all US orders.

Direct Metal Laser Sintering (DMLS) 3D Printing Service

Metal Binder Jetting 3D Printing Service

Upload your CAD files to get an instant quote on parts. Free shipping on all US orders.

Metal Binder Jetting 3D Printing Service

Get flexible payment options for the parts your business needs.

The Best 3D Printing Material Selection

Durable Nylon

Nylon is one of the most versatile options for 3D printing with great feature detail and performance.

ABS and ASA

ABS and ASA 3D prints have a variety of colors and are a staple to 3D printed plastics.

ULTEM 9085 and ULTEM 1010

Tough, heat resistant, and durable ULTEM is engineered to withstand the most rigorous environments.

Elastomers and Rubber-like Materials

3D printed TPE and silicone-based elastomers give rubber parts without the need for tooling.

Metal 3D Prints

3D printed metal parts can achieve complex geometries without a sacrifice in performance.

Multi-Material Parts

PolyJet 3D can combine multiple properties in a single print for overmolds and other cosmetic features.

Materials for all Applications

Xometry has the widest variety of industrial 3D custom printing materials available for instant quoting.

New!

Flame Retardant Plastic 3D Printing

Xometry's 3D Print Service offers a variety of polymers that are flame retardant and qualify for UL-94 V-0 and FAR 25.853 60 second burn test. This includes FDM ULTEM 9085, FDM ULTEM 1010, and SLS Nylon 12, Flame Retardant. These polymers are perfect for aviation and aerospace applications. Learn more about 3D Printed Flame Retardant Plastics.

Ready to start making custom 3D printed parts?

Free shipping on all 3D printing orders!

Applications of 3D Printing

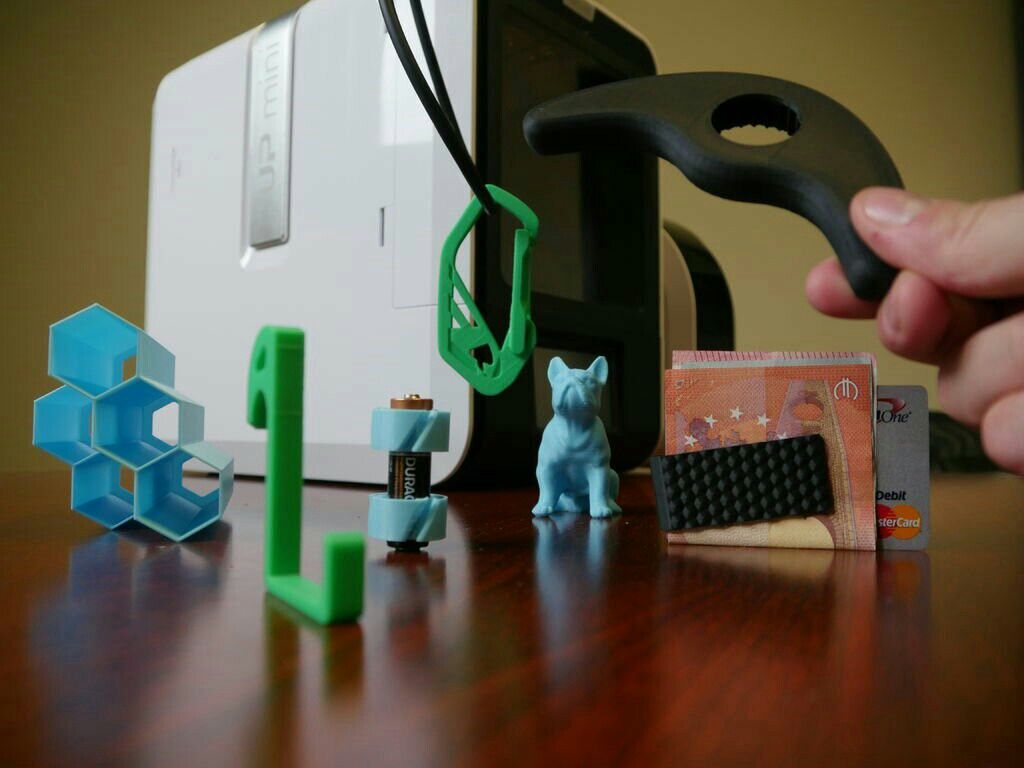

Concept Models

The speed and versatility of 3D Printing lets product developers create physical snapshots of their designs through the iterative process.

Rapid Prototyping

3D Printing can be used to create fully-functional prototypes, complete with moving parts, as well as all-in-one assemblies.

Direct Digital Manufacturing

The high accuracy and consistency of 3D printing makes it an ideal way to build production quantities of discrete or customized parts.

Advantages of 3D Printing

Rapid Turnaround

Parts can typically be shipped in as little as 1 day, allowing for faster design iterations and speed to market.

Durability

3D printing can offer great impact strength, medium flexibility, and high resistance to environmental factors.

Complex Geometry

Geometries can be built more easily due to the 3D printing process, adding complexity without additional cost.

Precision

3D printing can achieve precise parts and feature details.

Part Production

3D printing with Xometry helps you produce end-use parts on-demand, increasing throughput.

Scalability

With 3D printing, you can make a single part or component as easily as dozens of production pieces.

3D Printing General Tolerances

General Guidelines when Designing for 3D Printing

| Description | Tolerance Notes |

|---|---|

Description Part Size | Tolerance Notes Xometry can accommodate 3D printing up to 24" x 36" x 36" without the need to split and bond parts. |

Description Minimum Feature Size | Tolerance Notes 0.030" - 0.060" is typical. |

Description Minimum Wall Thickness | Tolerance Notes 0.020" - 0.060" is typical. |

Description Clearance Between Features | Tolerance Notes At least 0.030" |

General tolerances apply before secondary finishing or post-processing unless otherwise specified. Please check out Xometry's Manufacturing Standards for more information on tolerances per process.

What is 3D Printing?

What is 3D Printing?

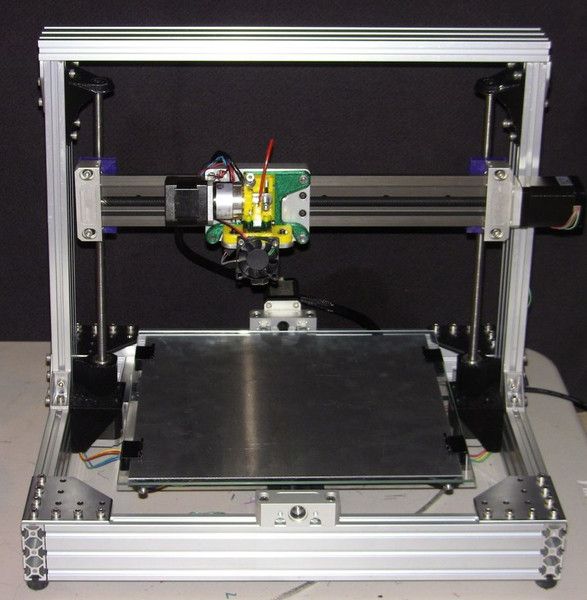

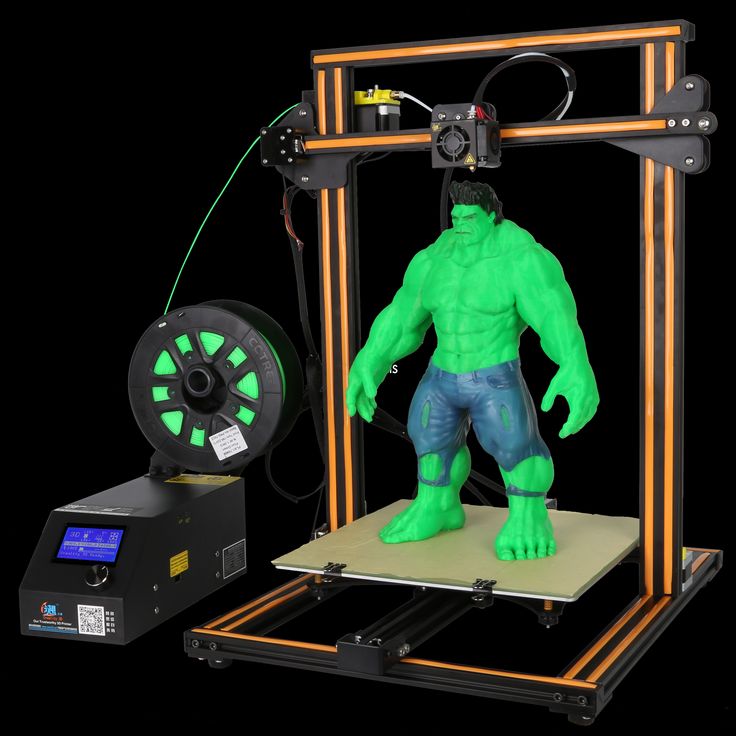

3D printing is an additive manufacturing process where materials are joined together to make objects from 3D model data (CAD). Typically, 3D printing is a layer-by-layer process where part geometries are “grown,” fusing with the previous layer. 3D printing processes can build objects in plastics, photopolymers, reaction polymers, composites, metal, glass, and other materials.

Typically, 3D printing is a layer-by-layer process where part geometries are “grown,” fusing with the previous layer. 3D printing processes can build objects in plastics, photopolymers, reaction polymers, composites, metal, glass, and other materials.

Instant Quote Demo

See how fast and simple it is to get a quote for 3D printing using the Xometry Instant Quoting Engine®.

Why Choose Xometry for 3D Printing?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

We are ISO 9001:2015, ISO 13485 and AS9100D certified.

Become an additive expert with our Complete Guide to 3D Printing

3D Printing Services Near You

AlabamaArizonaArkansasCaliforniaColoradoConnecticutDelawareFloridaGeorgiaIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaOhioOklahomaOregonPennsylvaniaRhode IslandSouth CarolinaSouth DakotaTennesseeTexasUtahVermontVirginiaWashingtonWest VirginiaWisconsinWyoming

Online 3D Printing Service | Instant 3D Printing Quotes

The easiest way to source high-quality 3D printed prototypes and production parts. Order from our network of highly experienced 3D printing shops. ISO 9001, ISO 13485 and AS9100 certified.

Order from our network of highly experienced 3D printing shops. ISO 9001, ISO 13485 and AS9100 certified.

Get an instant 3D printing quote All uploads are secure and confidential

Our 3D printing capabilities

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

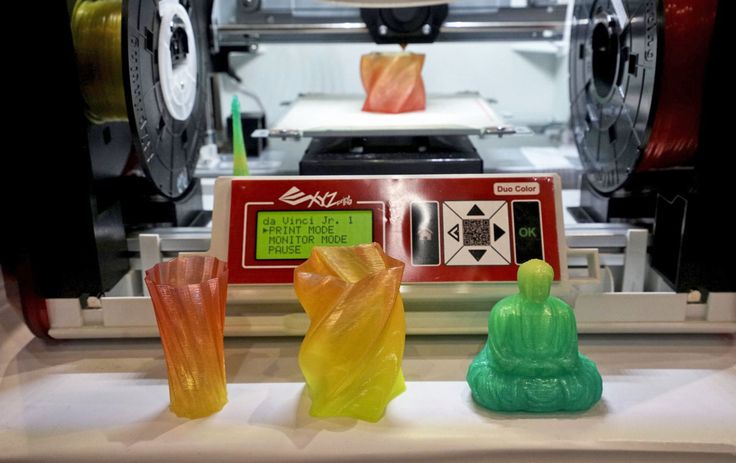

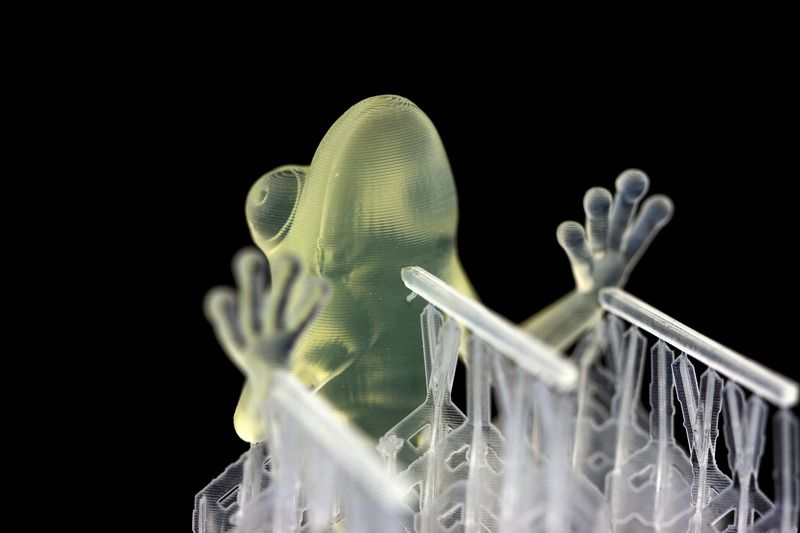

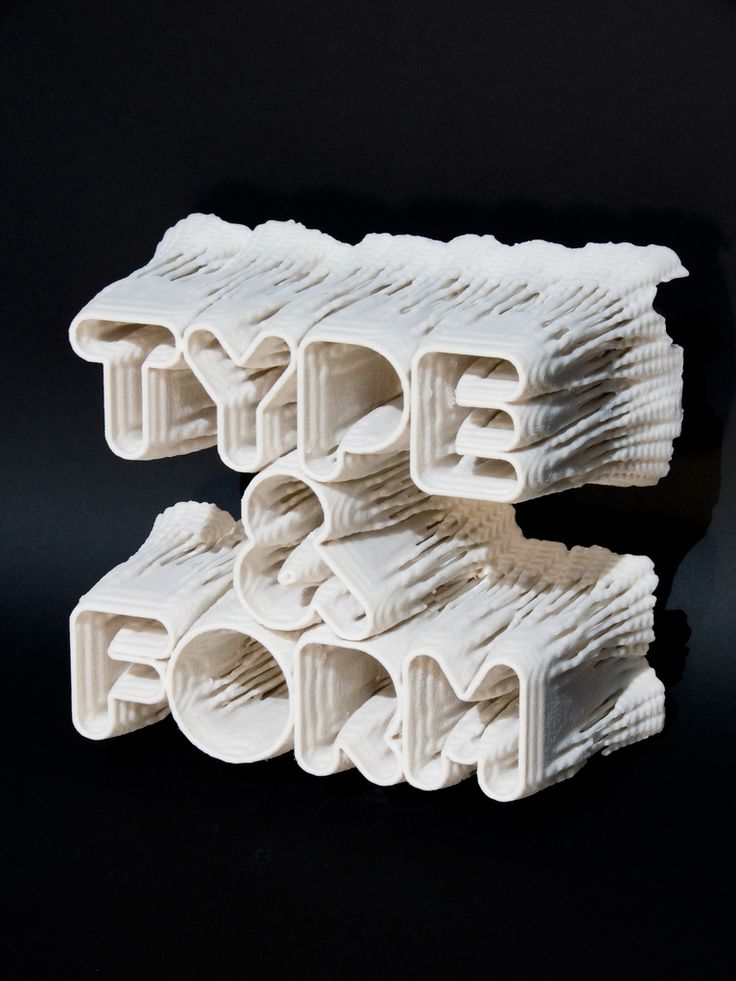

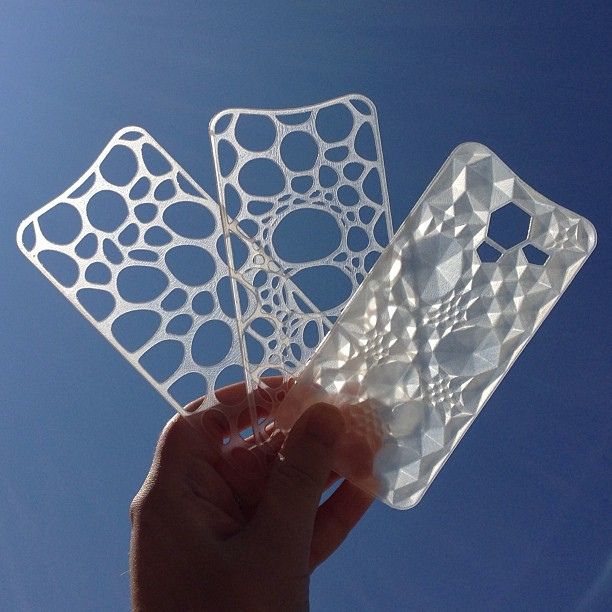

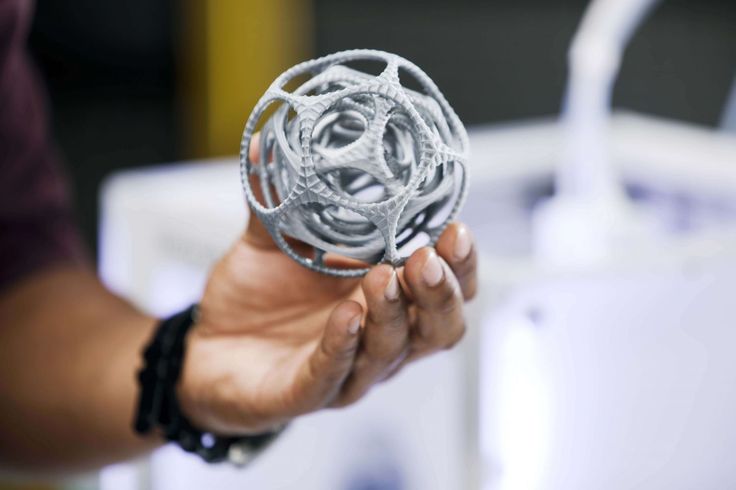

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

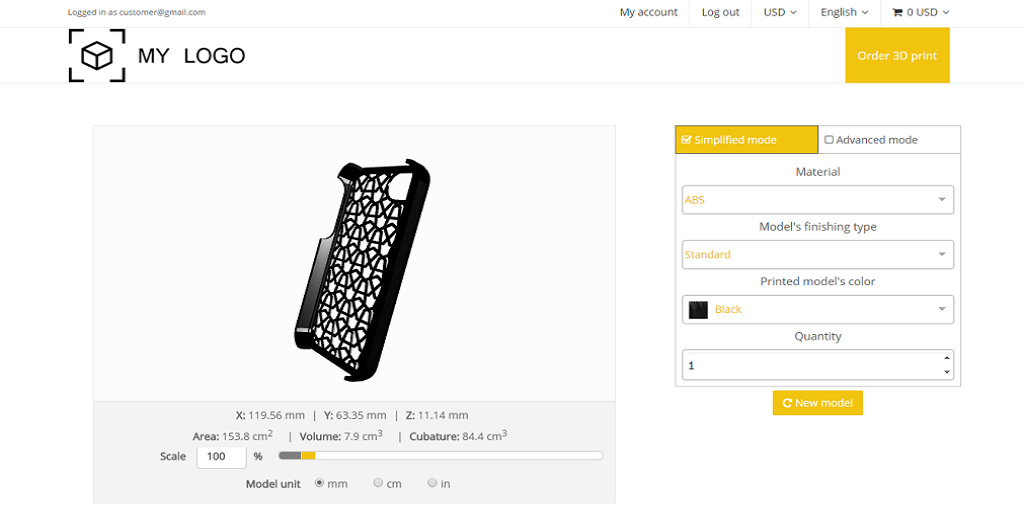

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc..

-

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

The Hubs 3D printing network

With over 90 local 3D print shops in our network we have virtually unlimited production capacity in both the EU and the US, and can always guarantee broad capabilities, immediate capacity and competitive prices. Our manufacturing partners can offer the following certificates: ISO 9001, ISO 13485 and AS9100.

Our manufacturing partners can offer the following certificates: ISO 9001, ISO 13485 and AS9100.

Learn more about our network

Some of our vetted manufacturing partners

3D printing factory in Chicago

| Established | 2013 |

| Capabilities | SLS |

| Machines | 4 EOS Machines |

| Expertise | Fast prototypes and end parts using SLS Nylon |

| Description | Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

3D printing factory in The Netherlands

| Established | 2010 |

| Capabilities | Selective Laser Sintering |

| Machines | 5 EOS Machines |

| Expertise | Range of SLS Nylons for Food and Medical |

| Description | Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Texas

| Established | 2011 |

| Capabilities | FDM & MJF |

| Machines | 60+ FDM and 3 MJF |

| Expertise | Fast turnaround prototypes and high quantity final parts. |

| Description | Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

| Established | 2018 |

| Capabilities | MJF & FDM |

| Machines | 2 MJF & 2 FDM machines |

| Expertise | Large scale FDM & multiple nylon materials using MJF |

| Description | Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in Chicago

| Established | 2013 |

| Capabilities | SLS |

| Machines | 4 EOS Machines |

| Expertise | Fast prototypes and end parts using SLS Nylon |

| Description | Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

3D printing factory in The Netherlands

| Established | 2010 |

| Capabilities | Selective Laser Sintering |

| Machines | 5 EOS Machines |

| Expertise | Range of SLS Nylons for Food and Medical |

| Description | Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Texas

| Established | 2011 |

| Capabilities | FDM & MJF |

| Machines | 60+ FDM and 3 MJF |

| Expertise | Fast turnaround prototypes and high quantity final parts. |

| Description | Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

| Established | 2018 |

| Capabilities | MJF & FDM |

| Machines | 2 MJF & 2 FDM machines |

| Expertise | Large scale FDM & multiple nylon materials using MJF |

| Description | Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in Chicago

| Established | 2013 |

| Capabilities | SLS |

| Machines | 4 EOS Machines |

| Expertise | Fast prototypes and end parts using SLS Nylon |

| Description | Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

3D printing factory in The Netherlands

| Established | 2010 |

| Capabilities | Selective Laser Sintering |

| Machines | 5 EOS Machines |

| Expertise | Range of SLS Nylons for Food and Medical |

| Description | Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Texas

| Established | 2011 |

| Capabilities | FDM & MJF |

| Machines | 60+ FDM and 3 MJF |

| Expertise | Fast turnaround prototypes and high quantity final parts. |

| Description | Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

| Established | 2018 |

| Capabilities | MJF & FDM |

| Machines | 2 MJF & 2 FDM machines |

| Expertise | Large scale FDM & multiple nylon materials using MJF |

| Description | Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in Chicago

| Established | 2013 |

| Capabilities | SLS |

| Machines | 4 EOS Machines |

| Expertise | Fast prototypes and end parts using SLS Nylon |

| Description | Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

3D printing factory in The Netherlands

| Established | 2010 |

| Capabilities | Selective Laser Sintering |

| Machines | 5 EOS Machines |

| Expertise | Range of SLS Nylons for Food and Medical |

| Description | Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Texas

| Established | 2011 |

| Capabilities | FDM & MJF |

| Machines | 60+ FDM and 3 MJF |

| Expertise | Fast turnaround prototypes and high quantity final parts. |

| Description | Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

| Established | 2018 |

| Capabilities | MJF & FDM |

| Machines | 2 MJF & 2 FDM machines |

| Expertise | Large scale FDM & multiple nylon materials using MJF |

| Description | Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in Chicago

| Established | 2013 |

| Capabilities | SLS |

| Machines | 4 EOS Machines |

| Expertise | Fast prototypes and end parts using SLS Nylon |

| Description | Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

3D printing factory in The Netherlands

| Established | 2010 |

| Capabilities | Selective Laser Sintering |

| Machines | 5 EOS Machines |

| Expertise | Range of SLS Nylons for Food and Medical |

| Description | Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Texas

| Established | 2011 |

| Capabilities | FDM & MJF |

| Machines | 60+ FDM and 3 MJF |

| Expertise | Fast turnaround prototypes and high quantity final parts. |

| Description | Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

| Established | 2018 |

| Capabilities | MJF & FDM |

| Machines | 2 MJF & 2 FDM machines |

| Expertise | Large scale FDM & multiple nylon materials using MJF |

| Description | Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in Chicago

| Established | 2013 |

| Capabilities | SLS |

| Machines | 4 EOS Machines |

| Expertise | Fast prototypes and end parts using SLS Nylon |

| Description | Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

3D printing factory in The Netherlands

| Established | 2010 |

| Capabilities | Selective Laser Sintering |

| Machines | 5 EOS Machines |

| Expertise | Range of SLS Nylons for Food and Medical |

| Description | Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Texas

| Established | 2011 |

| Capabilities | FDM & MJF |

| Machines | 60+ FDM and 3 MJF |

| Expertise | Fast turnaround prototypes and high quantity final parts. |

| Description | Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

| Established | 2018 |

| Capabilities | MJF & FDM |

| Machines | 2 MJF & 2 FDM machines |

| Expertise | Large scale FDM & multiple nylon materials using MJF |

| Description | Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in Chicago

| Established | 2013 |

| Capabilities | SLS |

| Machines | 4 EOS Machines |

| Expertise | Fast prototypes and end parts using SLS Nylon |

| Description | Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

3D printing factory in The Netherlands

| Established | 2010 |

| Capabilities | Selective Laser Sintering |

| Machines | 5 EOS Machines |

| Expertise | Range of SLS Nylons for Food and Medical |

| Description | Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Texas

| Established | 2011 |

| Capabilities | FDM & MJF |

| Machines | 60+ FDM and 3 MJF |

| Expertise | Fast turnaround prototypes and high quantity final parts. |

| Description | Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

| Established | 2018 |

| Capabilities | MJF & FDM |

| Machines | 2 MJF & 2 FDM machines |

| Expertise | Large scale FDM & multiple nylon materials using MJF |

| Description | Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in Chicago

| Established | 2013 |

| Capabilities | SLS |

| Machines | 4 EOS Machines |

| Expertise | Fast prototypes and end parts using SLS Nylon |

| Description | Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

3D printing factory in The Netherlands

| Established | 2010 |

| Capabilities | Selective Laser Sintering |

| Machines | 5 EOS Machines |

| Expertise | Range of SLS Nylons for Food and Medical |

| Description | Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Texas

| Established | 2011 |

| Capabilities | FDM & MJF |

| Machines | 60+ FDM and 3 MJF |

| Expertise | Fast turnaround prototypes and high quantity final parts. |

| Description | Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

| Established | 2018 |

| Capabilities | MJF & FDM |

| Machines | 2 MJF & 2 FDM machines |

| Expertise | Large scale FDM & multiple nylon materials using MJF |

| Description | Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in Chicago

| Established | 2013 |

| Capabilities | SLS |

| Machines | 4 EOS Machines |

| Expertise | Fast prototypes and end parts using SLS Nylon |

| Description | Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

3D printing factory in The Netherlands

| Established | 2010 |

| Capabilities | Selective Laser Sintering |

| Machines | 5 EOS Machines |

| Expertise | Range of SLS Nylons for Food and Medical |

| Description | Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Texas

| Established | 2011 |

| Capabilities | FDM & MJF |

| Machines | 60+ FDM and 3 MJF |

| Expertise | Fast turnaround prototypes and high quantity final parts. |

| Description | Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

| Established | 2018 |

| Capabilities | MJF & FDM |

| Machines | 2 MJF & 2 FDM machines |

| Expertise | Large scale FDM & multiple nylon materials using MJF |

| Description | Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in Chicago

| Established | 2013 |

| Capabilities | SLS |

| Machines | 4 EOS Machines |

| Expertise | Fast prototypes and end parts using SLS Nylon |

| Description | Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

3D printing factory in The Netherlands

| Established | 2010 |

| Capabilities | Selective Laser Sintering |

| Machines | 5 EOS Machines |

| Expertise | Range of SLS Nylons for Food and Medical |

| Description | Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Texas

| Established | 2011 |

| Capabilities | FDM & MJF |

| Machines | 60+ FDM and 3 MJF |

| Expertise | Fast turnaround prototypes and high quantity final parts. |

| Description | Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

| Established | 2018 |

| Capabilities | MJF & FDM |

| Machines | 2 MJF & 2 FDM machines |

| Expertise | Large scale FDM & multiple nylon materials using MJF |

| Description | Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

What can you create with Hubs’ custom 3D printing service?

Hubs offers a comprehensive range of additive manufacturing solutions for all applications, from single or smaller quantities of components for rapid prototypes to intricate functional parts for larger-scale production. Our online 3D printing service enables you to produce parts faster and more cost-efficiently, so you can speed up your innovation cycle and focus on making groundbreaking products.

We work with a global network of manufacturing partners operating four major technologies: Fused Deposition Modeling (FDM) , Stereolithography (SLA) , Selective Laser Sintering (SLS) and HP’s Multi Jet Fusion (MJF) . Through our vetted manufacturing network, we can produce parts using specialized 3D printers such as the Stratasys Fortus line, EOS P390, Markforged Mark 2, HP MJF 5210, 3D Systems Project and Viper line. So no matter what kinds of parts you need, we have access to the ideal technologies for your designs.

Through our vetted manufacturing network, we can produce parts using specialized 3D printers such as the Stratasys Fortus line, EOS P390, Markforged Mark 2, HP MJF 5210, 3D Systems Project and Viper line. So no matter what kinds of parts you need, we have access to the ideal technologies for your designs.

We offer a huge variety of manufacturing polymers, including PLA, PETG, ABS and Nylon, and our manufacturing partners consistently offer newer and more robust plastics. For metal 3D printing, you can speak with an account manager or explore what Protolabs has to offer. Our 3D printing capabilities make it easier to produce complex end-use components or hold your product in your hands for the very first time, all without having to wait for quotes.

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.

0008” (0.020 mm)

0008” (0.020 mm) -

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

buyers, be careful in the world of non-free 3D models / Sudo Null IT News But what about paid models? Putting a model somewhere and placing a "buy" button next to it is no longer a problem, but after spending some time buying and printing various non-free 3D models, I began to see some obvious shortcomings of this system.

The specific problems and solutions depend on how these models are marketed, but one thing is clear: Poorly designed 3D models are bad for both consumers and the future pay-per-download market.

Various ways to sell models

There are many ways to sell models online. Online stores are great for digital models because they are not physical goods, and serving a thousand customers is no different than serving ten. Technically, the user pays for a license to use the model, and its conditions vary significantly depending on the creators and intermediaries.

Online stores are great for digital models because they are not physical goods, and serving a thousand customers is no different than serving ten. Technically, the user pays for a license to use the model, and its conditions vary significantly depending on the creators and intermediaries.

Direct sales with payment per model

Direct selling is similar to downloading 3D models, only before you receive the link, you will see the price of the link. Sites like Cults3D and MyMiniFactory allow creators to set their own prices for non-free models. It is quite difficult to estimate the number of their sales, but the number of downloads for popular models is measured in hundreds or thousands.

Standing apart is the successful Hero Forge project, which allows users to create their own miniatures for board games using a web interface. Users can pay to download the STL file for the model they have created, or buy a printed version. Hero Forge is proprietary, but very successful, judging by their recent Kickstarter campaign.

Indirect sales with payment for access to models

Indirect sales mean that customers pay for access rather than buying models one by one. Successful creators make models in niche areas, and people pay to access their creator's library of work.

The usual way to manage monthly subscribers and provide access to files for 3D modelers is through Patreon. One common niche is board games, and some of the most successful creators have thousands of followers.

Another way of indirect sales is crowdfunding. Money is collected to create a certain set of models, and sponsors get access to the resulting files. Again, there are a lot of miniatures of heroes and territories for desktops.

Self-printing kits

With this approach, 3D models are sold as part of a larger product. The buyer purchases the kit and prints plastic components for it himself, while the kit may contain electronic components and other parts. The result is a set that can include fewer items, is easier to produce, cheaper to ship, and usually costs less than if the seller had to do everything themselves.

The result is a set that can include fewer items, is easier to produce, cheaper to ship, and usually costs less than if the seller had to do everything themselves.

Bulwark Blaster (NERF compliant) and OpenScan (open source 3D scanner) are examples of this business model. In both cases, the designs are based on 3D printed components and specific parts lists. The purchaser usually acquires a license to use one copy of the product.

And what's the problem?

In an ideal world, 3D printers reliably print parts of any shape without problems with overhangs, bridges, distortions or supports. You can buy a 3D model and get exactly what you expected. Unfortunately, we have not yet reached this point.

Quality 3D models need to be developed specifically for 3D printing, especially when it comes to money - because under the current system, all the risks fall on the buyers.

No test drives, no fitting rooms, no refunds

The world of non-free 3D models is like a clothing store without fitting rooms, or a car dealership without a test drive. “No money back” is a common phrase in sales and services, but when combined with the inability to try the product before buying, the result can be disappointing if the quality of the model turns out to be poor.

“No money back” is a common phrase in sales and services, but when combined with the inability to try the product before buying, the result can be disappointing if the quality of the model turns out to be poor.

Low technology models

3D printers, like any tool, are good in some situations, not bad in others, and terrible in others. This means that models intended for 3D printing need to be designed taking into account the strengths and weaknesses of 3D printers. About the model developed in this way, we can say that it is made with high manufacturability.

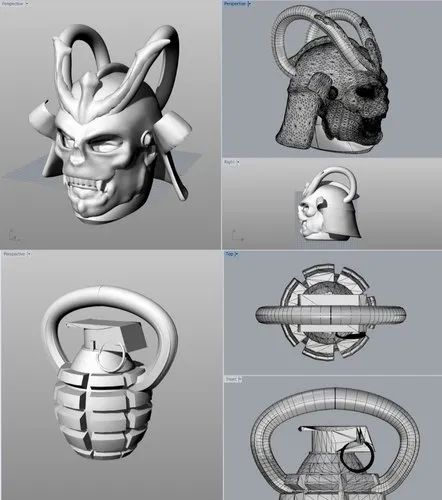

If the model was not designed with 3D printing in mind, it could create problems for the person trying to print it. The problem is that it is not always possible to identify models with which problems will arise, only by their image. Here are two examples.

For this model, supports and post-processing will be required regardless of the print orientation. The problem here is subtle: it was designed in such a way that it is almost impossible to print without props, regardless of the print orientation. She has other problems, but more on that later.

She has other problems, but more on that later.

Let's add props - and we will face the need for post-processing and poor surface in the places where they were attached. If you place them on the visible side, the detail will be ugly. If it is invisible (where the loop is), they will hardly fit there.

These problems are solved in post-processing, but the point is not that - but that it would be better to avoid these problems while developing the part.

Cut in half, colors added to contrast inner and outer layers. The model is not complete. The problem arises where there are gaps between the outer and inner layers.

Second example. This model was advertised as being compatible with SLA (Laser Stereolithography). FDM and SLA printers have very different benefits, so it was interesting to see a model specifically designed for SLA.

But disappointment awaited me. The model was not solid. There are gaps between the outer layer of the model (the clothes of the figure) and the inner layer (the body), since these layers were modeled separately - and they left it that way.

Uncured material accumulates in these gaps, and the surrounding parts of the model are very thin, which directly attracts imperfections in printing. Such a scheme of the model ensures that, most likely, its outer layers, those that are visible from the outside, will suffer during printing. And these problems were not visible until the model was paid for.

Issues like this and more show poor manufacturability that you can't see in screenshots and renders, and as I noted earlier, pay-per-download is now territory of no refunds and dangers for buyers.

Why poor quality models are a big problem

The problem with bad models is this: by the time it turns out that the model has a problem (or it cannot be made properly, or it is too wasteful to print), it turns out that the buyer has already invested much more in it than just the purchase price. A bad model only repels a person who wants to hit the "Buy" button.

Passing all the risk on the buyer, so that all his money and efforts go to waste - this should be the last thing on any platform seeking to grow.

Ways to improve the situation

It's tempting to try to solve this money-back problem with a file access control system, but then it becomes suspiciously DRM-like, and that's not likely to be a good way forward.

On the other hand, it is possible to increase confidence in the quality of models and purchases without changing too much in current platforms. Here's what you can do.

Demonstrate the quality of models with photographs and documentation

Documentation and a photo of the printed results, rather than just rendering models on a computer, is an effective way to provide the buyer with additional information about the model. The documentation does not have to be extensive, but it should list design elements, assemblies, or areas that require special control. An example is a printable vise model by Christoph Leimer. This is a free model, but its excellent documentation inspires confidence in its quality.

Models that require additional components must clearly list them in the description, along with specifications and sources. The latch model I used as an example of poor manufacturability requires some sort of arcane spring, with no dimensions or where to find it. This is another problem that comes to light too late.

If the developer has not clearly and clearly demonstrated that he successfully printed his own development, do not buy it.

Provide test drive parts

Designers of kits and other prefabricated structures can give free access to some components, as if to say, "if you can print and assemble these models, then you will succeed, because the principles for developing my product were the same." If customers cannot return purchases, then this approach will at least give them a semblance of a test drive.

Run automatic quality check on models

Professional print studios like 3D Hubs analyze uploaded items as part of the approval process and warn of features such as thin walls, small parts that can get lost, and potential issues with prop removal. Model hosting and selling services could improve customer confidence by doing similar checks on the models they sell, and displaying the results of that analysis along with the model and price.

Model hosting and selling services could improve customer confidence by doing similar checks on the models they sell, and displaying the results of that analysis along with the model and price.

What was your experience with paid models?

Have you bought models online, or do you sell your own? What was your experience and what would you change about this system?

3D printing | 3D printing services | 3D printing online

3D printingREC2022-05-20T15:05:44+08:00

Get instant online 3D printing prices for over 70 metal and plastic parts. Delivery time from 1 day. ISO 9001:2015 and AS9 certified100D.

GET INSTANT PRICE

CERTIFICATES

ISO 9001:2015 | AS9100D | ITARS is registered

100,000+

Parts printed every month

30,000+

Services were served products

9014 130+

9000 9000 9000 print 3D printing, or additive manufacturing, is a manufacturing process in which materials (such as plastics, photopolymers, reactive polymers, composites, metal, glass, and other materials) are added layer by layer to create objects from a CAD model or digital 3D -models.

With our professional manufacturing capabilities, we can reliably deliver parts within days. In addition to a wide choice of materials, we also offer a variety of post-treatment options to improve the surface or improve the mechanical properties.

Stereolithography (SLA)

Stereolithography (SLA) uses an ultraviolet laser that draws on the surface of a liquid thermosetting resin to create thousands of thin layers until the final details are formed.

GET INSTANT PRICE

Fused Deposition Modeling (FDM)

High Quality FDM Large Format 3D Printing

GET INSTANT PRICE

Binder Inkjet

PolyJet uses a spray process where small droplets of liquid photopolymer are sprayed from multiple jets onto the build platform and cure in layers to form elastomeric parts.

GET INSTANT QUOTE

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is a 3D metal printing technology used to create metal parts with exceptional mechanical properties and precision.

GET INSTANT QUOTE

Metal 3D Printing

Direct Metal Laser Sintering (DMLS) uses a fiber laser system that draws on the surface of sprayed metal powder, welding the powder into completely dense metal parts.

GET AN INSTANT QUOTE

Available 3D Printing Materials

New to our 3D printing services and not sure which additive technology is right for your 3D projects? Below each material, see which ones fit your application's requirements.

Our 3D printing service includes individual decoration

Clean coat

Transparent cosmetic coating, which can be applied to translucent/transparent materials, similar to ABS (Watershed XC 11122) and translucent/translucent/translucent/transparents similar PCs (Accura 60).

Painting

After sanding and polishing, parts can be painted with automotive paint. Specify the pantone color in your request for a quote. We also offer soft-touch painting.

Specify the pantone color in your request for a quote. We also offer soft-touch painting.

Plating

Chemical nickel plating can be used to produce parts similar to cast aluminum or magnesium.

dyeing

Staining is another method of adding color to 3D prints. This is a faster option with limited color options, so it's more cost effective than painting.

Sticker

The sticker can be used to add a logo or other graphics to enhance appearance or functionality.

Polishing

We can polish parts to a mirror finish. If this is a requirement, we ask that you provide a drawing or image that reflects your expectations for the finish.

Heat Treat

Harden and strengthen 3D metal prints with multiple heat treatments: NADCAP heat treatment, Hot Isostatic Pressing (HIP), solution annealing and aging.

Machining

Machining metal 3D prints for exceptional surface finishes or tight tolerances.

Why choose RJC for 3D printing?

Reduce your cost

Although 3D printers require electricity to operate, there is usually no material loss. On the other hand, subtractive processes such as machining produce waste. Because 3D printing uses only the material needed and no tools are required, it is one of the most affordable manufacturing processes for single parts or small batches. The speed and versatility of 3D printing allows product designers to create physical snapshots of their designs through iterative processes. process.

Wide choice of materials

In our six 3D printing technologies, we use a range of commercial thermoset resins and thermoplastic and metal powders to 3D print parts suitable for a variety of applications and industries. If your parts require it, we offer a variety of post-processing options such as heat treatment, secondary processing, electroplating, painting and painting to further improve the mechanical properties and cosmetic properties.

Advisory Quote

Get design feedback from our experienced and professional RJC engineering team who have helped thousands of customers bring their products to market with high quality 3D printed parts. We will also work with you to determine the best part orientation for your needs.

Flexible Manufacturing

RJC has 3D printing machines that produce metal and plastic parts for your projects, whether it's low volume or mass production. Once a part has been designed with CAD software, it can be printed in hours without a lengthy setup procedure for your rapid prototypes. 3D printing can be used to create fully functional prototypes with moving parts as well as all-in-one assemblies. Since 3D printed parts do not require tools, there is less risk involved in manufacturing the part. If a defect is found after printing, it can be digitally corrected without changing expensive tools.

Accurate and professional

Our industry leading tolerances and surface finish quality are the result of a dedicated team of process engineers and quality specialists for each 3D printing technology or exciting production technology.