3D printed green wall

This 3D printed green wall comes with an embedded irrigation system

This 3D printed green wall comes with an embedded irrigation system - Tech Skip to main contentTech

3D printing brings previously unthinkable designs to life.

By Maria Dermentzi

> Tech

Remember that 3D printed e-bike? How about those airless bicycle tires? Both of these were built by NOWLAB, the innovation lab of German 3D printer manufacturer BigRep, which is back with a new project, the BANYAN Eco Wall.

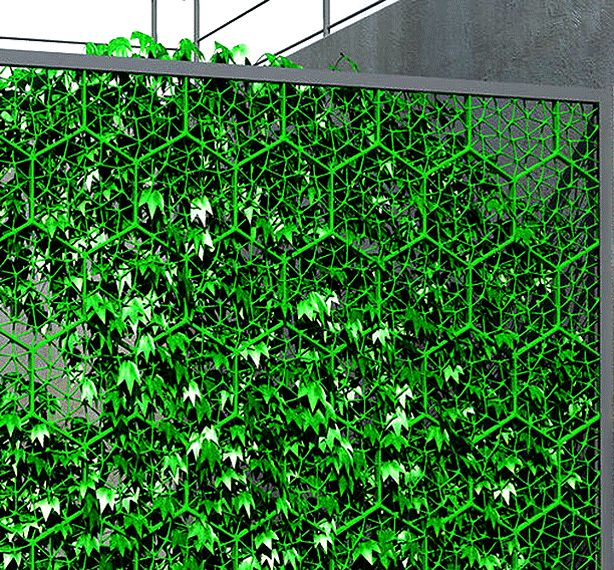

BANYAN is a fully 3D printed green wall that comes with an embedded irrigation and drainage system, and it is yet another example that 3D printing can bring previously unthinkable designs to life.

Topics: Tech, Tech, Design, 3d printing, Innovations, 3D Printers

Recommended For You

-

Here's how to make the best of The Prime Early Access Sale on Amazon Singapore

Christmas is coming!

-

You can now get this WiFi-controllable essential oil diffuser at a bargain

You can even tell it to change color.

-

This car absorbs CO2 from the air & can travel nearly 320km before needing to 'refuel'

It even acts as an external battery.

-

Google's new Pixel 7 line is here. Is it worth the upgrade?

What's new and what's stayed the same.

-

Google Pixel 7's new photo features seem like the real deal

You got "Star Trek" in my Pixel 7 phone.

-

Robot companies pledge they're not going to let the robots kill you

Alrighty then, worries over.

-

TikTok adds a 2,200 character limit to video descriptions for wordy people

Giving video essay new meaning.

Trending on Mashable

-

This car absorbs CO2 from the air & can travel nearly 320km before needing to 'refuel'

It even acts as an external battery.

-

'Werewolf by Night' is a classic horror-style addition to the MCU that works surprisingly well

The spooky and odd underbelly of the MCU has finally laid itself bare.

-

2 men stranded on highway get free food & drinks thanks to helpful Facebook group

The power of social media.

-

I worked at a call center. Here are 5 steps to fix common internet connection problems.

Half of these problems can be solved by a reliable internet service provider such as Unifi.

-

Factory turns disgusting cigarette butts into beautiful, soft toys & pillows

Turning something crappy into something sweet.

University of Virginia 3D-prints living soil walls that sprout greenery

Rima Sabina Aouf | Leave a comment

University of Virginia researchers have invented a method of 3D printing with seed-impregnated soil, which could be used to create walls and roofs teeming with plant life.

Prototypes built by the researchers start off looking like ordinary raw-earth structures. But over the course of a few days, they sprout and become covered in greenery, leading the University of Virginia (UVA) to compare them to "oversized Chia Pets".

Building elements such as green walls and roofs could be constructed using this method, bringing benefits like natural insulation, flood prevention and green spaces for people, pollinators and other animals, according to UVA.

UVA researchers have 3D-printed living walls that sprout greeneryBy combining soil and seeds into 3D-printable "soil inks", greenery could be built into the very fabric of architectural features rather than just layered on top.

This has the potential to reduce the need for more emissions-intensive building materials and replace them with a circular alternative, which the researchers say can be can be reused again and again.

"We are working with local soils and plants mixed with water," said Ehsan Baharlou, an assistant professor at UVA's School of Architecture. "The only electricity we need is to move the material and run a pump during printing."

"The only electricity we need is to move the material and run a pump during printing."

"If we don't need a printed piece or if it isn't the right quality, we can recycle and reuse the material in the next batch of inks."

Ehsan Baharlou is one member of the research team. Photo by Tom DalyBuildings made with this technique have the potential to be carbon neutral or even carbon negative, as their plant covering would draw down carbon dioxide from the atmosphere.

"This method hypothesises to create an active ecological system that might store emitted carbon in 3D-printed soil structures through the process of photosynthesis," Baharlou told Dezeen.

Initially, the UVA researchers used their method to create a series of small, self-supporting structures that resemble beehives and published them in the journal Additive Manufacturing.

The team developed 3D-printable "soil inks" made from raw earth and seedsAt that stage, their goal was to create structures that were solid enough to stand by themselves while also providing enough moisture and nutrients to support seed germination and seedling growth.

For the seeds, they chose to use stonecrop – a succulent plant that can survive with little water – as the extrusion process makes the soil compact and dry.

Blast Studio 3D prints column from mycelium to make "architecture that could feed people"

The researchers have since started printing larger objects such as low walls about a metre in height. Next, they will look at mounting the 3D-printing system on a moving robot that could enable the production of taller, more complex structures with multiple sides.

For this upcoming stage, the researchers will have to further develop the formula for their "soil inks" as they predict that the extra height will exacerbate problems such as soil cracking.

Plant life begins to grow on the structures in a matter of daysThe researchers also plan to experiment with using multiple material layers within a wall panel, allowing the dry inner wall to be insulated from the moist outer wall.

Other efforts to create living architecture through 3D printing have come from London-based Blast Studio, which has mixed mycelium with paper pulp to create an architectural column that can sprout mushrooms.

The photos are by Ehsan Baharlou unless otherwise stated.

Project credits

Research team: Ji Ma, David Carr, Ehsan Baharlou, Spencer Barnes, Leah Kirssin and Lizzie Needham.

Subscribe to our newsletters

Your email addressDezeen Debate

Our most popular newsletter, formerly known as Dezeen Weekly. Sent every Thursday and featuring a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

New! Dezeen AgendaSent every Tuesday and containing a selection of the most important news highlights. Plus occasional updates on Dezeen’s services and breaking news.

Dezeen DailyA daily newsletter containing the latest stories from Dezeen.

Dezeen JobsDaily updates on the latest design and architecture vacancies advertised on Dezeen Jobs. Plus occasional news.

Plus occasional news.

News about our Dezeen Awards programme, including entry deadlines and announcements. Plus occasional updates.

Dezeen Events GuideNews from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Plus occasional updates.

We will only use your email address to send you the newsletters you have requested. We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected].

For more details, please see our privacy notice.

Thank you!

You will shortly receive a welcome email so please check your inbox.

You can unsubscribe at any time by clicking the link at the bottom of every newsletter.

More images

Executive Director Magazine

The world's first fully 3D printed irrigated green wall with integrated water supply and sanitation was presented by BigRep Innovation Consultancy. The difference between BANYON ECO WALL and other products is that its drainage system is built-in and created during the printing process.

The difference between BANYON ECO WALL and other products is that its drainage system is built-in and created during the printing process.

The structure's miniature internal channels are designed for optimum water flow and feature a micro-shower mechanism to precisely irrigate plants where needed.

“Our BANYAN ECO WALL is inspired by nature's principles with a sophisticated, smart and elegant design. Traditional technologies such as milling or injection molding cannot provide this level of sophistication and functionality,” explains BigRep CEO Stefan Beyer, Ph.D.

Irrigation systems, designed to provide a controlled supply of water at regular intervals, meet the unique needs of plants and crops without human intervention. The innovators hope systems like these will inspire designers and architects to create a greener future – whether at work or these days, from the home office.

Source archello.com

Subscribe to news

We are in social networks

Video materials

Conference materials Transformation of workspace management processes. Operation of the office in modern conditions” (27.05.21)

Operation of the office in modern conditions” (27.05.21)

Video recordings of the conference “Care for employees. Yours sincerely, Administrative Director»

Corporate Happiness. Presentations and photos

Video: Materials of the online seminar “Contract. How to avoid risks”

Subscribe to the mailing list

The winners of the Administrative Project Management Award have been announced!

Get trial number

Events

-

IX Annual PA Forum

10/22/2022

-

Postponement of events of the Administrative Project Management Award

25.10.2022 /08:00 - 18.11.2022 /17:00

-

MICE Excellence Forum will bring together business event industry players

10/27/2022 - 10/29/2022

-

Exhibition and business forum "Safety and labor protection - 2022" (BIOT)

06.12.2022 /10:00 - 09.

12.2022 /17:00

12.2022 /17:00

View all Events

Magazine announcements

Expert articles

Video

Previous Next

Supplier News

All supplier news

Archives

Archives Select month September 2022 (24) August 2022 (21) July 2022 (41) June 2022 (27) May 2022 (22) April 2022 (23) March 2022 (22) February 2022 (32) January 2022 (302) December (2 36) November 2021 (20) October 2021 (31) September 2021 (19)) August 2021 (18) July 2021 (40) June 2021 (25) May 2021 (13) April 2021 (36) March 2021 (9) February 2021 (22) January 2021 (29) December 2020 (26) November 2020 ) October 2020 (19) September 2020 (22) August 2020 (25) July 2020 (25) June 2020 (20) May 2020 (31) April 2020 (55) March 2020 (35) February 2020 (21) January 2020 (2020) ) December 2019 (65) November 2019 (11) October 2019 (38) September 2019 (11) August 2019 (13) July 2019 (13) June 2019 (16) May 2019 (27) April 2019(15) March 2019 (25) February 2019 (11) January 2019 (15) December 2018 (25) November 2018 (34) October 2018 (4) September 2018 (28) August 2018 (13) July 2018 (201) June 2018 (17) May 2018 (29) April 2018 (16) March 2018 (26) February 2018 (58) January 2018 (22) December 2017 (43) November 2017 (43) October 2017 (22) September 2017 (2017) (35) July 2017 (26) June 2017 (19) May 2017 (31) April 2017 (11) March 2017 (41) February 2017 (17) January 2017 (12) December 2016 (30) November 2016 (46) (18) September 2016 (38) August 2016 (15) July 2016 (22) June 2016 (11) May 2016 (26) April 2016 (13) March 2016 (19)) February 2016 (8) January 2016 (14) December 2015 (31) November 2015 (17) October 2015 (29) September 2015 (21) August 2015 (27) July 2015 (19) June 2015 2015 (40) May ) April 2015 (32) March 2015 (22) February 2015 (26) January 2015 (16) December 2014 (35) November 2014 (17) October 2014 (50) September 2014 (56) August 2014 (201) June ) April 2014 (17) February 2014 (15) December 2013 (15) October 2013 (11) August 2013 (17) June 2013 (17) April 2013 (15) February 2013 (37) January 2013 (12) December 2013 (2) December 2013 (2) ) November 2012 (27) October 2012 (14) September 2012 (20) August 2012 (10) May 2012 (1) January 2012 (8) April 201 (1)Get a trial number

3D applications in landscaping

News

Subscribe to the author

Subscribe

Don't want

4

. Let's talk about how this technology helps to save resources and reduce the carbon footprint, save ecosystems and create greenery.

Let's talk about how this technology helps to save resources and reduce the carbon footprint, save ecosystems and create greenery.

How does 3D printing work? She creates three-dimensional objects using a special printer that applies the material in layers. In order to print an object, you first need to create its digital model. The technology was developed back in the early 80s, but for a long time 3D printers were too expensive for everyday use. The first affordable models appeared in the mid-2000s, and since the early 1910s, 3D printing has become more common: a 3D printer costs about the same as a home computer and does not take up much space.

Almost anything can now be printed with 3D printers, from aircraft parts, houses and bridges to food and, in the near future, human organs. This technology saves resources: 3D printing consumes up to 100% of the material used, while carbon dioxide emissions are quite large compared to, for example, casting technology.

On the other hand, 3D printing helps to reduce the weight of the final product, and for example, reducing the weight of an aircraft by 100 kg saves up to 1.3 million tons of carbon dioxide throughout its life cycle.

3D printing can not only reduce your carbon footprint, but also save entire ecosystems. Coral reefs are dying due to the climate crisis, and this in turn causes an imbalance of life in the ocean, which could eventually lead to the extinction of most life on earth. Scientists partner with 3D printing companies to create tiles that mimic coral reefs and allow new corals to grow while keeping organisms associated with the ecosystem alive.

3D printing is also used in landscaping, which is also important for the improvement of ecosystems: for example, in China, in the city of Shenzhen, a huge park was created using this technology. Of course, the plants there are real, but all the benches, borders and flower beds are printed on a 3D printer. This approach reduced construction costs and shortened the project time: it took only two and a half months.

This approach reduced construction costs and shortened the project time: it took only two and a half months.

Development on printing the environment for the plants themselves is also underway: back in 2014, the programmer Yushiro Takeuchi proposed the technology of printing a "lawn" with seeds that then germinated. Such a technology would make it possible to create vertical gardens of any shape, easy to operate and with significant water savings, but the project was put on hold.

3D printed planters, plant care tools and imitation trees. Until recently, the value for money of such products was not suitable for large-scale landscaping projects, but the situation is changing. Work is currently underway on several vertical gardens that grow in 3D printed planters.

3D printing can also be useful at the stage of preparing a landscaping project. An example is the work of the Ficus company for the airport in Simferopol in 2017-2018. The terms of reference included the creation of the largest green wall in Europe: 15 meters high and consisting of 30,000 plants. Especially for the project, Ficus developed a new system with automatic watering, which reduces the risk of plant death in the event of unforeseen events.

Especially for the project, Ficus developed a new system with automatic watering, which reduces the risk of plant death in the event of unforeseen events.

However, before investing the customer's resources in the construction of such a complex and expensive facility, it was decided to test the prototype. 3D printing helped: with its help, glass modules were quickly made, a plywood wall structure with an area of two square meters was mounted, and the functionality of the new development was tested on it. Six months later, the prototype turned into a real vertical garden, which became the main distinguishing feature of the airport.

Yes, the 3D printing process is often still energy intensive, which contributes to increased emissions. Therefore, it cannot be argued that its role in sustainable development is decisive at the moment, but now the industry is using 3D printing from recycled materials, including plastic found in the ocean or wood waste, and the prospects for technology are huge.