3D print mechanical clock

⌚ Best STL files 3D printed for clocks and watches・Cults

⌚ Best STL files 3D printed for clocks and watches

Download free clocks and watches 3D files

Discover our selection of 3D files of beautiful watches and clocks perfectly 3D printable to add a touch of 3D printing to your interior or on your wrist. You will find in this collection all the 3D models you need to always be on time, no more excuses!

Clock One

Free

Gyro Winder / Watch Winder

€2.50

Gyrotourbillon

Free

Christian Huygens 3D printed clock

Free

Reloj Simpsons

Free

Reloj Spiderman

Free

Reloj gato v3

Free

Structure Clock

Free

Reloj Dragon Ball Z

Free

Reloj The Beatles

Free

7-Segments

€7. 45

Clock Games

Free

Reloj vinilo The Lord of the Rings

Free

Reloj Beatles

Free

Clock Game of Thrones

Free

Triaxial Motorized

Free

Kitchen clock "Coffee time"

Free

Mechanical clock to go up

Free

Triaxial Quartz Movement Upgrade

Free

Reloj Rick y Morty

Free

Reloj spiderman V2

Free

Galileo Escapement Design

Free

Clock with decorative mechanism.

Free

Spiral exhaust movement

Free

Round Clock

Free

Reloj Star Wars

Free

Drip Clock

Free

Reloj Astérix

Free

Reloj Jasmine (X3 VERSIONES)

Free

3D Printed Galileo Escapement Clock with Hands

Free

Reloj Queen Freddie Mercury

Free

The First Clock

Free

Extra large roman wall clock

Free

Batman logo Wall Clock Ikea STOMMA

Free

Alien Clock 3D

Free

Modular Wristwatch - 3D Printing Build

Free

Reloj cubo RUBIK

Free

Game of Thrones Clock

Free

Reloj de pared

Free

STAR WARS LOGO STENCIL

Free

Clock with decorative mechanism 2

Free

pink floyd clock 350 mm diameter

Free

MICHAEL JACKSON WATCH

Free

Mario 3D Clock

Free

Table Clock

€2. 49

49

Reloj Walking Dead

Free

Darth Vader Clock

Free

Reloj Chewbacca

Free

Sunburst Tabletop Clock

Galileo Escapement clock spring driven and hands

Galileo Escapement Design

Gyro Watch Winder | Gimbal Watch Winder | Watch Winder with ESP32 and Wifi

Here is our selection of the best 3D files of clock and watch for 3D printers, all these creations are from the STL file library Cults and are perfectly 3D printable.

This collection includes free or paid STL files of superb clocks created by the designers of our community. 3D printing allows you to create an extreme variety of shapes to enhance your interior decoration in the best way. All you need to do is add a classic clock mechanism to transform your print into a beautiful clock. In this selection you will also find 3D models allowing you to print your watch in 3D. In the same way as for els clocks, it will obviously be necessary to complete with a classical mechanism such as a Casio or Swatch for example.

All you need to do is add a classic clock mechanism to transform your print into a beautiful clock. In this selection you will also find 3D models allowing you to print your watch in 3D. In the same way as for els clocks, it will obviously be necessary to complete with a classical mechanism such as a Casio or Swatch for example.

The 3D designers who propose their creations on the 3D file download platform Cults have really competed in ingenuity to make all these objects, if you download them, don't forget to post pictures of the result! It's also a great gift idea for your friends who are always late!

Mechanical Wall Clock « Fabbaloo

By Kerry Stevenson on June 21st, 2021 in Design, news

Tags: clock, designoftheweek, mechanical

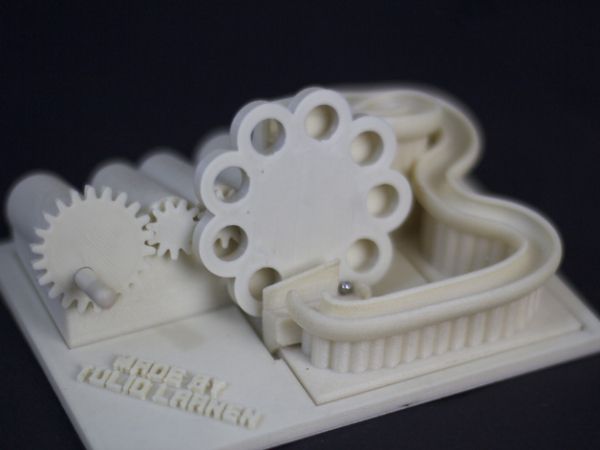

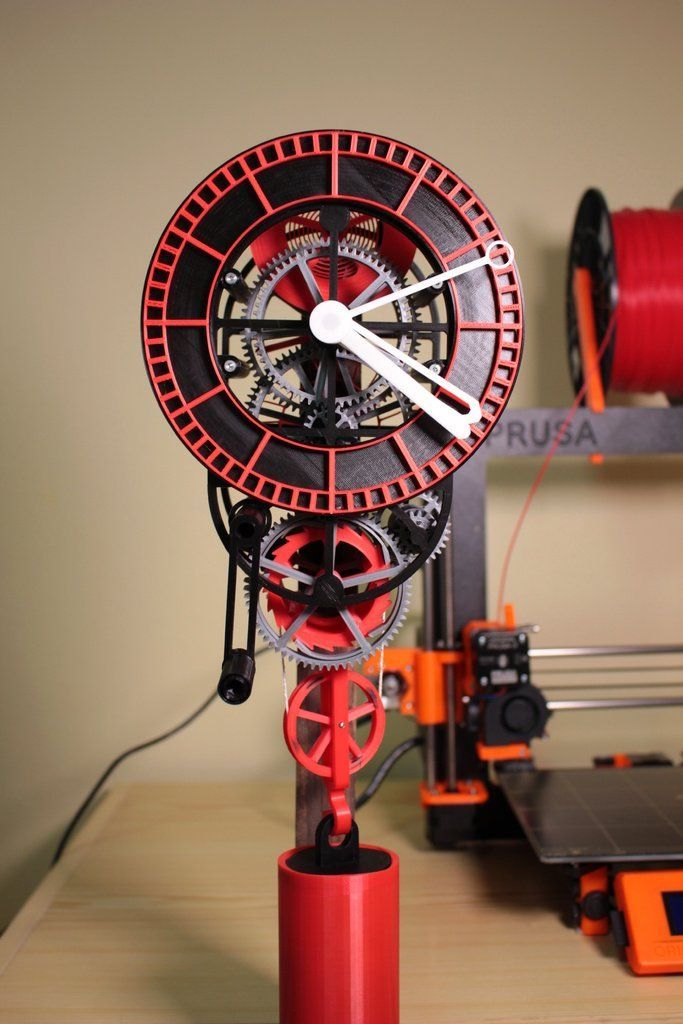

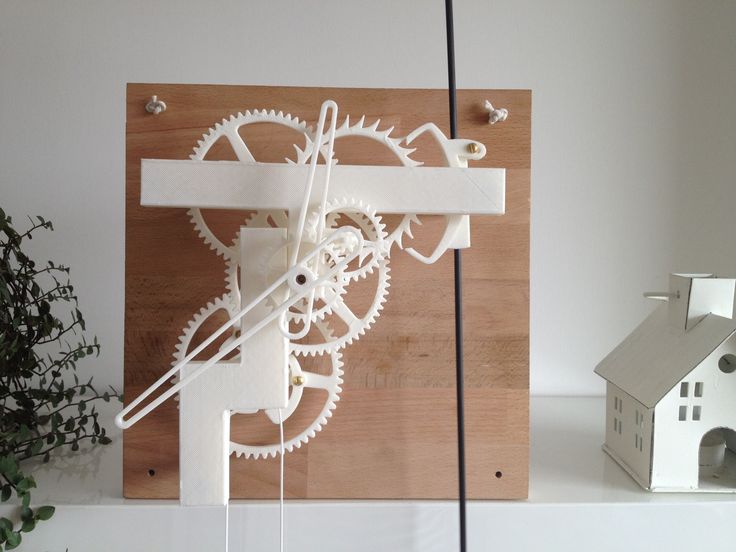

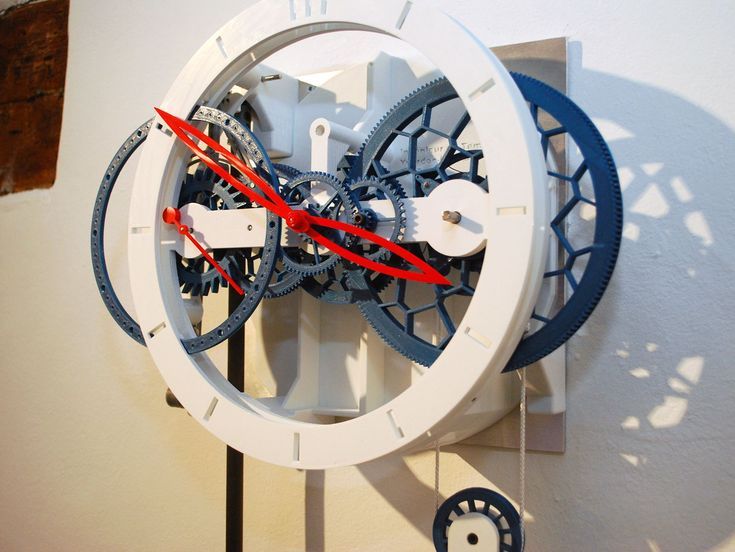

The 3D printed Mechanical Wall Clock project [Source: Prusa Printers]This week’s selection is the Mechanical Wall Clock by designer Harald Andersson.

This item is, as it seems, a fully 3D printed wall clock in the shape of a bird. I’d like to emphasize “fully 3D printed”, because that’s precisely the case here: there are no motors or electronics in this project.

The clock operates in the historical manner: a pendulum swung by gravity. The eco-friendly clock uses a masterful mechanical design to transform that swinging motion into precise clock steps, just as traditional pendulum clocks work. The difference here is that all parts are 3D printed.

There are only four non-3D printed items required for this project:

- A string or fishing line for the weight

- Silicone spray or other suitable (non-greasy) lubricant for the moving parts

- Something to fill the weight with, e.g., rice or sand

- Glue if the press fits are not tight enough

That last point is important. The first step of Andersson’s very extensive instructions ask you to 3D print a tolerance benchmark. This allows you to determine whether you’ll require glue for assembly, or if friction fit is possible. In other words, the benchmark explores the dimensional tolerance of your 3D printer to help decide on the assembly method.

In other words, the benchmark explores the dimensional tolerance of your 3D printer to help decide on the assembly method.

There’s also a rotational tolerance test that allows you to choose which size of rotational component to choose. Again, 3D printers differ in how they print parts — the dimensions, particularly of internal holes, may vary. The rotational test is a way to avoid the usual problem of “it doesn’t fit in the hole!”

The assembly itself is of many steps, as you might suspect from the number of parts required. There’s also a precise sequence these must be applied in order to build the mechanical gearing and expect it to work properly.

Lubrication spots on the 3D printed Wall Clock project [Source: Prusa Printers]Andersson explained that lubrication is mandatory on this model, otherwise the gearing will not operate smoothly. He provides a detailed diagram of where the lubrication should be applied, and how to do so.

While the assembly instructions are among the most detailed I’ve seen for a 3D printer project, Andersson also includes instructions on how to make adjustments to the clock. For example, if it’s running too fast, its speed can be slowed down.

For example, if it’s running too fast, its speed can be slowed down.

If you’re up for this incredible project and are able to print and assemble all the parts correctly, you’ll end up with a wall clock that operates like this:

But be warned: this project includes many, many parts.

Via Prusa Printers (Hat tip to SJ)

TwitterKerry Stevenson, aka "General Fabb" has written over 8,000 stories on 3D printing at Fabbaloo since he launched the venture in 2007, with an intention to promote and grow the incredible technology of 3D printing across the world. So far, it seems to be working!

View all of Kerry Stevenson's posts.

Tourbillon watch printed on a 3D printer / Habr

marks

Gadgets 3D printers DIY or DIY

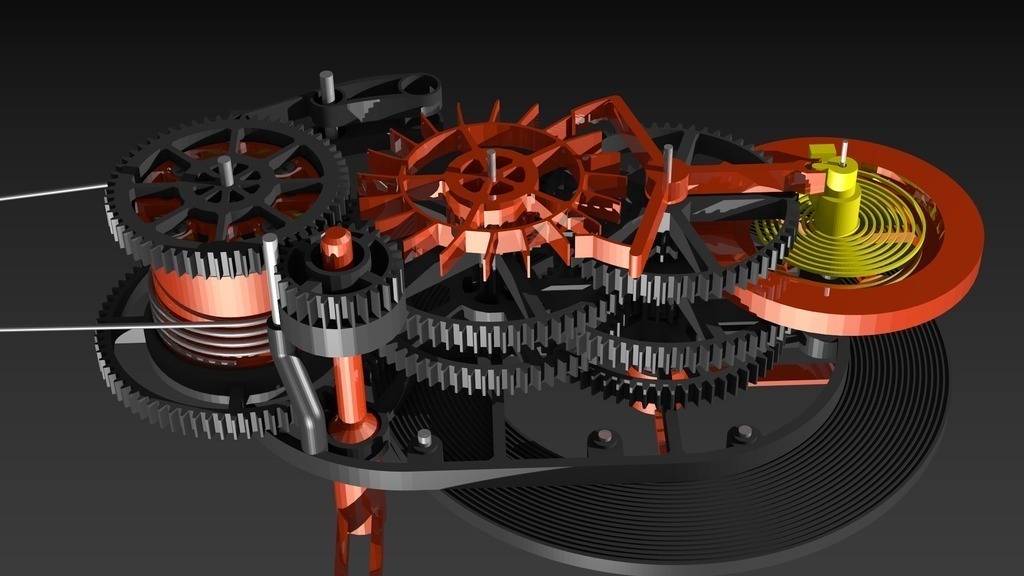

Ordinary clocks were printed on 3D printers more than once or twice. But no one has yet printed a watch with a tourbillon, until now. What is a tourbillon?

Wikipedia tells us the following: “Breguet invented in 1795, and in 1801 he patented the tourbillon (fr. tourbillon - vortex) - a device for partial compensation of the Earth's gravity. The tourbillon consists of a balance, an escape fork and an escape wheel, located on a special rotating platform (the most common rotation speed: 1 revolution per minute). This is one of the most complex and expensive additional mechanisms. The maximum accuracy of inexpensive mechanical watches reaches ±5 seconds per day; high-quality: up to ±1 sec per day, inexpensive quartz watches (this is a more modern mechanism, for comparison): ±1/2 sec. per day. Tourbillon watch accuracy is: -1/+2 sec. per day. Often the tourbillon is made visible through a window in the dial. In fact, the tourbillon rotates the entire movement around its axis within one minute, which, due to the influence of the Earth's gravity, makes the clock advance for half a minute, and lag behind for the next half minute, which eliminates the influence of the Earth's gravity on the accuracy of the movement.

Often the tourbillon is made visible through a window in the dial. In fact, the tourbillon rotates the entire movement around its axis within one minute, which, due to the influence of the Earth's gravity, makes the clock advance for half a minute, and lag behind for the next half minute, which eliminates the influence of the Earth's gravity on the accuracy of the movement.

And now this whole complex system has been printed on a 3D printer, and the result is quite interesting.

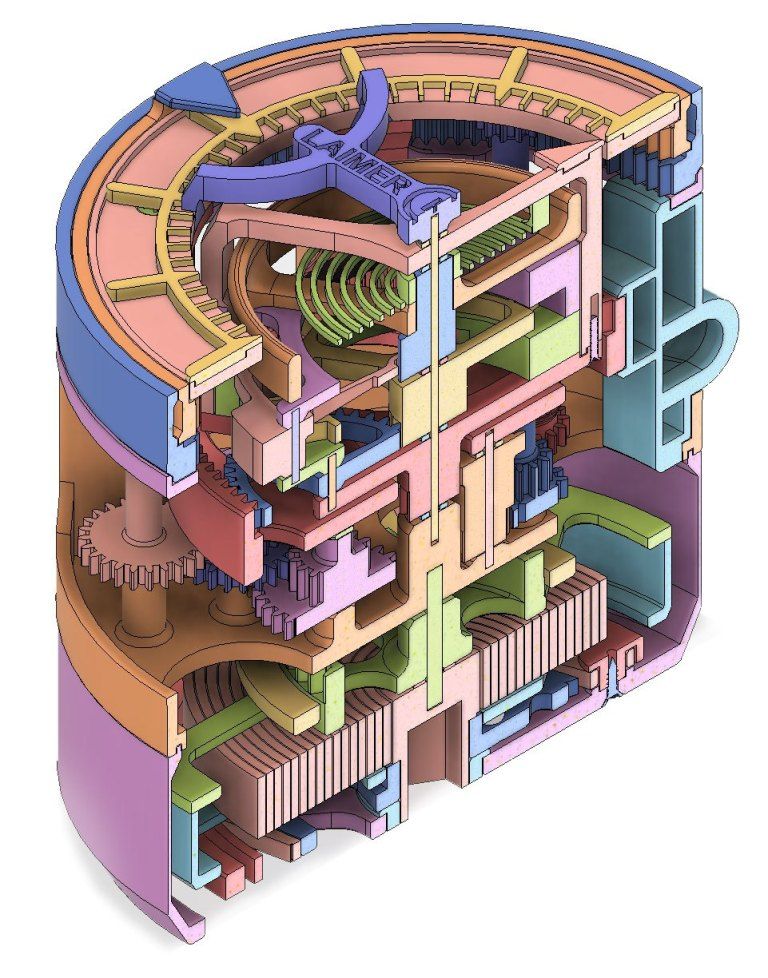

This miracle was created by Christoph Lamier, who designed everything needed in Autodesk Fusion 360. The clock consists of 50 parts, including springs, screws, and other parts. The most difficult to “print out” are the hairspring, anchor, escape wheel and some other elements.

Yes, the spring 2 meters long was also printed on the printer, and this would not have been possible without special device settings. To create such a spring, you must select the 'combing' or 'avoid crossing perimeters' setting.

If you have time, you can watch a video about half an hour long. All the features of such watches are shown here, so there is something to see.

If there is no time, then you can study the abbreviated version of the video:

Well, a little more, the assembly of the watch is shown here in an accelerated manner:

By the way, the design of this watch, according to the author, is similar to that of a pocket watch. But the result is somewhat larger than a regular pocket watch. So you either need a large pocket or a smaller watch to fit in that pocket. But the chain is already there - the author also printed it out.

Tags:

- Clock

- Tourbion

- Watch Mechanism

- 3D Printer

Habs:

- Gadgets

- 3D printers

- DIY or do

0 9 ↑ 24 0 +24

Views16K

Comments four

Maxim Agadzhanov @marks

Editor

Telegram

Comments Comments 4

“Christoph Laimer Tourbillon”, the world's first 3D printed tourbillon watch

Swiss engineer and designer Christoph Laimer has introduced the world's first fully functional 3D printed mechanical watch.

Every day 3D technologies are gaining more and more fans,

becoming more common and accessible, and their application

is becoming more diverse. Therefore, it will be interesting to see how

the art of watchmaking will be reflected in the designs created from

with this modern technology.

A few years ago, the world's first 3D printed tourbillon

was already developed and presented.

software engineer Nicholas Manousos introduced the so-called Tourbillon 1000%,

, with all parts 3D printed. In the future

Nicholas planned to create a full-fledged watch, since he was

I'm sure that sooner or later it will be possible to produce a fully functioning watch using 3D printing technology

.

This year, only two years later, Christophe Laime decided to

3D print a very complex, but really amazing project - a functioning mechanical tourbillon watch

, not just

turning into reality the idea of Nicholas, but also surpassing it. The tourbillon is one of the

The tourbillon is one of the

famous and popular watch complications, developed over 200 years ago by the famous watchmaker Louis Breguet

, and is still considered one of the most complex movements.

According to the Swiss engineer, all parts for the mechanical watch "Christoph Laimer Tourbillon", except for metal screws and pins, are printed on a 3D printer. The main task is to demonstrate that 3D printing technology is developing and its capabilities open up new horizons for creativity and serious projects.

smaller than its predecessor, it is not small enough to be worn on the arm or even in the pocket.

With a diameter of 10 cm and a height of 10 cm,

is much smaller than even the first tourbillon created by

Nicholas.

Of course, this is not the first attempt to create working hours

using this technology, but one of the most difficult

and interesting watch designs. Christoph Laime

Christoph Laime

is also not the first project, among his works there were already

working hours, but they were not so complicated and their dimensions were much larger.

The project was developed in Autodesk Fusion 360 and printed on the Ultimaker 2 3D printer. As for the reliability of the movement and the performance of the watch, the tourbillon chronometer surprisingly works quite well, of course, it is inferior in accuracy to conventional watches, its accuracy is +/- 2 seconds per minute. The power reserve of the watch is also small, they can display the time of only about 35 minutes. The clock is wound with a plastic spring.

Two already tested

materials PETG and PLA were used to create the case and movement of the watch

. For the mechanism Christophe

used a common thermoplastic

PLA (polylactide), which has a higher resistance

to strong ultraviolet

radiation, temperature and high humidity

.