Mattel 3d toy printer

From Creepy Crawlers to 3D Printers: Mattel Resurrects the ThingMaker - 3DPrint.com

One sign that I’m getting old is that I’ve started to do the “back in my day!” thing more often than I’m entirely comfortable with. One example of this is when it comes to kids’ toys. I’ve written a bit about 3D printers for kids, which are becoming more common; I’ve also seen virtual reality headsets, tablets, and even robots designed specifically for children. “Back in my day, we played with rocks!” This is actually true: rocks made great currency, “food” for the outdoor “kitchen,” buried treasure and projectiles.

I did play with a few high-tech toys, though, which in the ’90s meant a Skip-it, a Lite Brite, a Teenage Mutant Ninja Turtles pizza shooter, Shrinky Dinks (I still have a magnet on my fridge made from a California Raisins Shrinky Dink I was very proud of) and Creepy Crawlers, the official name for which, I’m just now learning, was “ThingMaker.” The toy consisted of metal molds into which you poured a dubious, colorful chemical substance. The molds were then heated until the chemical substance solidified into wibbly-wobbly, Jello-like insects, which were NOT to be eaten. I’m not sure what their purpose was, actually, other than throwing them at your cousins, but they were fun.

ThingMaker back in my day.

Like I said, high tech! Most of my childhood toys are obsolete now, though I did just discover, to my surprise, that Shrinky Dinks are still a thing. But now comes the news that Mattel has resurrected the ThingMaker. Yes! It’s not the goopy mess it was back in my day, though – it’s now been upgraded to…a 3D printer for kids!

Yes, even Creepy Crawlers are cooler than I am now. The new and improved ThingMaker was just unveiled at Toy Fair in New York, and the noxious chemicals and metal molds have been replaced by PLA filament and, naturally, an app for iOs and Android. While the printer itself won’t be on the market until the fall, the ThingMaker Design app is live now and can be used to design items for other 3D printers. (As of Monday, you can start pre-ordering the printer on Amazon.)

(As of Monday, you can start pre-ordering the printer on Amazon.)

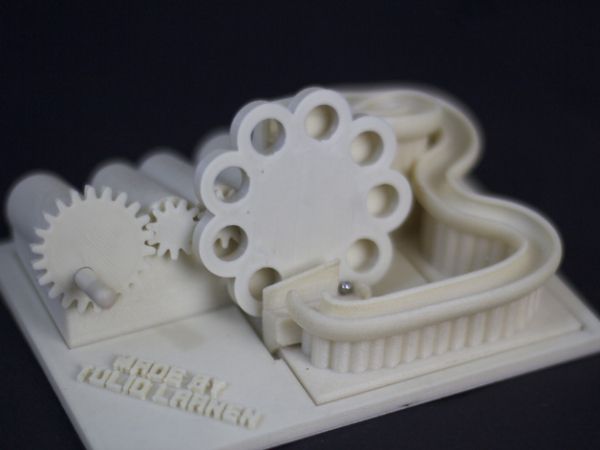

ThingMaker now.

“We’re going to use these seven months to really learn and gain analytics of how people are using it,” said Aslan Appleman, a senior director at Mattel. “Our thought is we want to make this open to makers. What we want to highlight is the ThingMaker ecosystem.”

Image: USA Today

The easy-to-use app lets kids design toys by dragging and dropping parts from a palette into a template, where they can arrange and assemble them as they wish. Several parts are printed together in batches; kids choose the colors in the app and they are then printed one color at a time. The door automatically locks once printing starts – a safety feature common to most kid-friendly printers.

The printer and app were designed in conjunction with Autodesk, who announced an official partnership with Mattel last year for the purpose of marketing 3D printing and technology apps to kids, and they look like they’ll be a good way for children to start grasping how 3D design works. While the drag-and-drop format isn’t exactly CAD, it still helps kids to understand how a digital design can be turned into a physical object.

While the drag-and-drop format isn’t exactly CAD, it still helps kids to understand how a digital design can be turned into a physical object.

“All the physical behaviors are as it would be when it was actually printed out, so you can get an idea for how it is going to mechanically move and what the limits of all the joints and sockets that you create are,” said Dan Pressman, creative director at Autodesk.

Still a bit creepy, actually.

The ThingMaker printer, which will retail for $299.99, is listed as being for kids ages 13 and older, but the toys you can print out are safe for children as young as 3. For kids too young to use a 3D printer themselves, I imagine it could still be a great parent-child project.

Although this ThingMaker bears little or no resemblance to the ThingMaker of my childhood, keeping the name is a nice shout-out to ’90s kids, many of whom have children of their own now. (“Back in my day, all my ThingMaker could make was fake Jello bugs!”) How do you think apps like this will affect the world of toy manufacturing in the future? Discuss in the ThingMaker 3D Printed Toys forum over at 3DPB. com.

com.

[Images: Mattel / ThingMaker / USA Today]

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d design app for kids • 3d printed games and toys • 3d printed toys • 3d printed toys and games • 3d printer for children • 3d printer for kids • autodesk • Creepy Crawlers • mattel • ThingMaker • ThingMaker 3d printer • ThingMaker Design

Please enable JavaScript to view the comments powered by Disqus.

Mattel brings back ThingMaker as a 3D printer for kids

Children

View 6 Images

View gallery - 6 imagesMattel has announced that it's bringing back ThingMaker, its toy making kits which launched in the 1960s. But this time around ThingMaker will get a modern make-over and consist of a fully functioning US$300 3D printer designed specifically for kids. Used with a companion app, this will allow young creators to design and print their own toys at home.

But this time around ThingMaker will get a modern make-over and consist of a fully functioning US$300 3D printer designed specifically for kids. Used with a companion app, this will allow young creators to design and print their own toys at home.

The original ThingMaker let children produce their own toys from Creepy Crawlers to Hot Wheels cars, using die-cast metal molds, Plastigoop and an oven. However, those kits haven't been sold for a number of years (though we can still remember the combination of hot plastic and burnt fingers). Recently it's been 3D printers which once again promise to give children the ability to make their own endless supply of toys, including the Bonsai Lab BS Toy, Printeer 3D, and the hand-held 3Doodler Start 3D pen.

Now toy brand Mattel is also getting in on the action. In collaboration with Autodesk it's producing the ThingMaker 3D printer and the ThingMaker Design App. This combo will allow users to create their own toys using hundreds of predesigned parts and print them using a variety of filament material and color options.

Mattel

After wirelessly linking the 3D printer to a mobile device running the ThingMaker Design App for iOS or Android, users decide whether they want to create a toy figure or jewelry, with the option to print ready-designed toys, or mix and match from hundreds of parts which can be popped together after printing thanks to ball and socket joints. After designing their creation, users simply push a button to start printing.

Features of the ThingMaker 3D printer which make it more suitable for children than your typical 3D printer include it being simple to use, and having an auto-locking door. This will stay shut until your toy is at a safe temperature and the hot print head has retracted into a recess, so that it can't burn eager little fingers.

One limitation, as with other 3D printers, is the time it will take to print a toy. A typical plastic figure can take 12 hours to print, so you'll want patient children, or to print overnight when they're asleep. Also, while available models currently include an array of figures including dinosaurs, dolls, skeletons and jewelry, you can't yet print your own Barbie, Hot Wheels or Mega Bloks. However, Mattel says additional design content including branded options will roll out at a later date.

Also, while available models currently include an array of figures including dinosaurs, dolls, skeletons and jewelry, you can't yet print your own Barbie, Hot Wheels or Mega Bloks. However, Mattel says additional design content including branded options will roll out at a later date.

Mattel

The ThingMaker 3D printer is due to be available later this year priced at $300. The ThingMaker Design App is available now and also works with other 3D printers.

Source: ThingMaker

View gallery - 6 imagesSimon Crisp

Simon is a journalist and photographer who has spent the last ten years working for national UK newspapers - but has never hacked a mobile phone - and specializes in writing about weird products and photography technology. When not writing for New Atlas, Simon is often found playing with LEGO and drinking far too much coffee.

When not writing for New Atlas, Simon is often found playing with LEGO and drinking far too much coffee.

From doll to aircraft engine: 3D printers are becoming a popular means of production

David Paul Morris / Bloomberg

Companies from industries ranging from industrial conglomerate General Electric to automaker Ford Motor to toy maker Mattel are beginning to actively use 3D printers in their activities.

3D printing, also known as additive printing (which builds up material layer by layer as an object is produced), allows companies to produce goods cheaper and faster. Unlike traditional technologies, where parts are machined from blanks, as a result of which part of the material ends up in waste, 3D printing allows you to model an object on a computer and “print” it from plastic, metal or composite materials. “With it, we can dramatically improve productivity, efficiency and be more innovative in design,” said Scott Goodman, senior vice president of global product development at Mattel.

Materials used in 3D printing are more expensive than traditional materials, although prices are steadily declining. As the demand for 3D printing grows, the cost will decrease even more, predicts Pete Basilier, an analyst at Gartner.

Analyst Wohlers Associates estimates that the 3D printing market grew 29.4% in 2011 and is expected to reach $3.7 billion in global revenue in 2015, up from $2.2 billion in 2012 d.

Here's how the three companies above are using the new technology.

Ford Motor

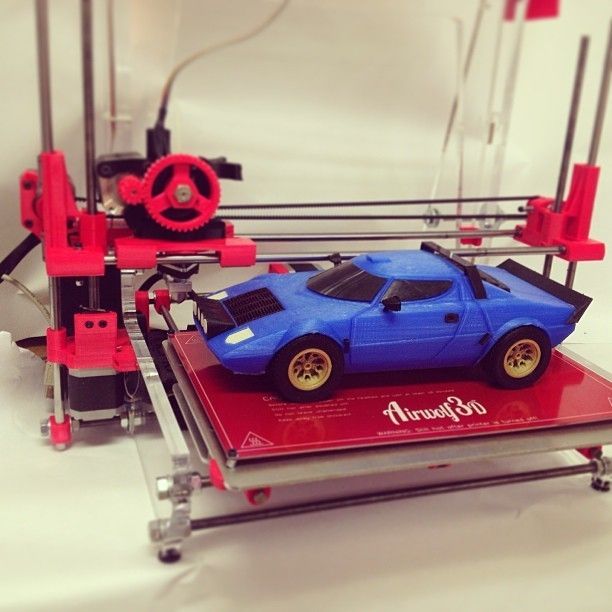

Ford believes that in the future, car owners will be able to produce, that is, print their own parts. Theoretically, a person can go to the site, scan a barcode or print an order, go to a local 3D printing store (as people now go to a photo store for pictures) - and in a few hours, or even minutes, they will have the necessary part.

In the meantime, Ford engineers are using 3D printers to produce prototype parts for test vehicles. At the Beech Daly Technical Center, they use industrial 3D printers costing up to $1 million to produce prototypes of cylinder heads, brake discs, axles in significantly less time than with the traditional production method, says Paul Susalla, rapid prototyping supervisor at Ford.

At the Beech Daly Technical Center, they use industrial 3D printers costing up to $1 million to produce prototypes of cylinder heads, brake discs, axles in significantly less time than with the traditional production method, says Paul Susalla, rapid prototyping supervisor at Ford.

By using 3D printing, Ford saves an average of about a month in producing a prototype cylinder head for its EcoBoost fuel-efficient engine family. This complex part includes numerous ports, channels, passages and valves for transferring fuel and air. According to Susalli, the traditional casting process, which requires the development of a mold and a tool for turning a workpiece, takes four to five months.

Engineers can also produce multiple cylinder heads at the same time and test different prototypes of the same part to select the best model for subsequent production.

General Electric

GE's aviation division prints injectors and other components for the combustion system in a jet engine made by CFM International, a joint venture between GE and France's Snecma. By 2016, the LEAP engine is expected to be ready for use on aircraft such as the Boeing 737 MAX and Airbus A320neo, which are still under development.

By 2016, the LEAP engine is expected to be ready for use on aircraft such as the Boeing 737 MAX and Airbus A320neo, which are still under development.

By building up metal powder layer by layer, details in an airflow system can be made more precise than if they were cut from a ceramic blank, says Mark Little, senior vice president and director of GE's global research group. This process is technically more efficient and will save the company money in the future. So far, GE has declined to talk about the scale of savings. “Now we can make these parts in ways we simply couldn't before, and still improve cooling efficiency,” says Little.

GE is also experimenting with 3D printing for a medical device, an ultrasound scanner. According to the company's researchers, as a result, the cost of manufacturing individual parts can be reduced by 30%.

Mattel

Toy makers used to make samples out of wax and clay before they started making plastic models. Today, Mattel engineers have 30 3D printers that can create almost any part of all the toys produced by the company, including Barbie dolls and Hot Wheels cars.

Today, Mattel engineers have 30 3D printers that can create almost any part of all the toys produced by the company, including Barbie dolls and Hot Wheels cars.

However, the company does not intend to sell software to consumers so that they can make their own toys on cheap 3D printers. In this case, Mattel can't guarantee the toys will be safe for children, a company spokesperson says, acknowledging that as 3D printing becomes more widespread, "the entire industry will have to face this issue and address it."

Translated by Mikhail Overchenko

Media news2

Do you want to hide ads? Subscribe and read without distraction$299 family 3D printer from Autodesk and Mattel

Last April (2015), Autodesk first announced its partnership with legendary toy maker Mattel, in which promises were made to improve the toy companies' applications. And now we can see the result of such cooperation - Mattel "relaunches" its classic product ThingMaker (Creator of Things). While the ThingMaker was the desktop version of the plastic injection machine from the 60s to the 90s, in the 21st century it will become the desktop 3D printer.

While the ThingMaker was the desktop version of the plastic injection machine from the 60s to the 90s, in the 21st century it will become the desktop 3D printer.

Read more..

First introduced in the 1960s and then resurrected from the ashes in the 1990s, the ThingMaker was a device that allowed children to make "soft" toys such as various bugs or flowers. To do this, it was necessary to fill the cavity in a metal mold with liquid rubber, and place the mold in the oven for polymerization. I got burned a few times in the process of making my own Creepy Crawler toys. The modern version (2016) is much more secure and has many advantages due to

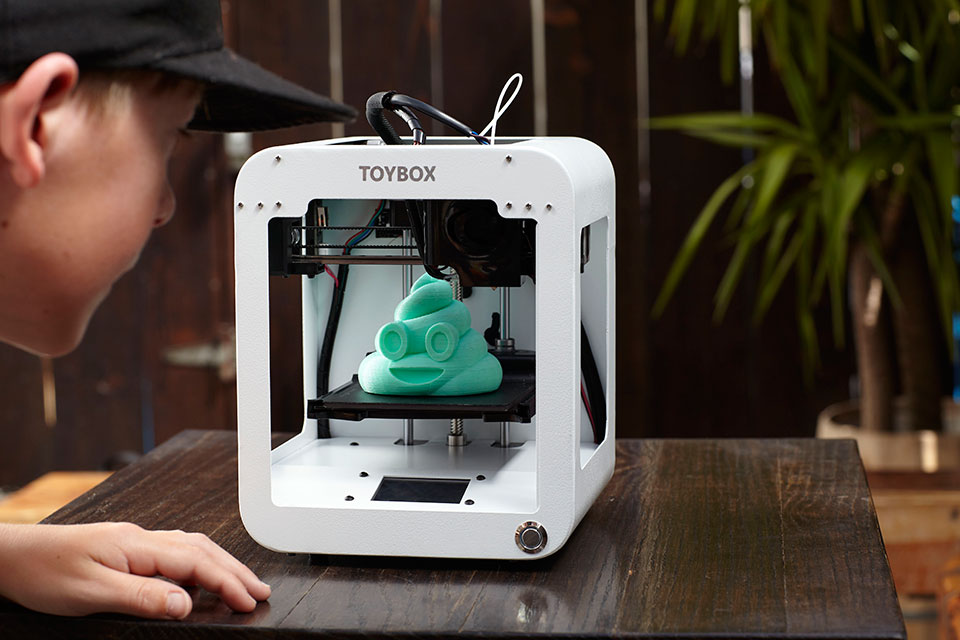

ThingMaker, shown for the first time this weekend at the New York Toy Fair, is a $299.99 family-friendly 3D printer controlled by specialized apps from Android and iOS devices. In addition to managing the printing process, applications allow users to select models prepared in advance for 3D printing. The door that gives access to the printing area will not allow printing to start until it is closed, and as soon as the printing process of toy parts begins, it will be blocked. This feature eliminates the danger of getting burned, as was the case with the Creepy Crawler in the past. Using only PLA as a print material and a non-heated base reduces additional safety concerns. At the same time, there is no information that this device can only work with plastic from Mattel.

The door that gives access to the printing area will not allow printing to start until it is closed, and as soon as the printing process of toy parts begins, it will be blocked. This feature eliminates the danger of getting burned, as was the case with the Creepy Crawler in the past. Using only PLA as a print material and a non-heated base reduces additional safety concerns. At the same time, there is no information that this device can only work with plastic from Mattel.

ThingMaker has a "striking" resemblance to Tinkerplay. Tinkerplay is a mobile app created by Autodesk after purchasing the Modio app, and aimed at children. In this application, users can assemble characters from separate blocks, which, after printing, will allow them to assemble the same character in reality. Given the simple printing without additional settings and the ability to quickly change filler cartridges, such characters can be multi-colored and satisfy your idea.

Leveraging Mattel's brand and capabilities and new approaches using 3D printing technology opens up the world of Tinkerplay directly to its target audience - children and teens. According to Dan Pressman, Creative Director of Autodesk: “In the application, the created objects behave as close as possible to the real world, i.e. they work the same in the application and after printing, and this allows you to check your thoughts on how the details will be in advance. move, taking into account all the created hinges and their restrictions.

According to Dan Pressman, Creative Director of Autodesk: “In the application, the created objects behave as close as possible to the real world, i.e. they work the same in the application and after printing, and this allows you to check your thoughts on how the details will be in advance. move, taking into account all the created hinges and their restrictions.

This device is part of a larger trend that Mattel is trying to keep up with the times both technologically and socially. For example, Apple recently started selling a Google Cardboard analogue - a virtual reality device for the iPhone. This unit is an updated version of Mattel's classic View-Master product. Mattel also launched a new series of Barbie dolls designed to accommodate the diverse tastes of today's consumers. Even though the dolls still suffer from not entirely correct reflection of racial features (with a bias towards the classic "Caucasian"), especially in terms of the morphological elements of the faces, and there are distortions in the figures (what Mattel calls a curvaceous figure can be soon medium or slim), and even more so despite the perpetuation of the division of toys by gender and strict female stereotypes .