Lmi 3d scanner

3D Laser Line Profile Sensors | Gocator 3D Smart Sensors

LINE PROFILERS

AUTOMATE. INSPECT. OPTIMIZE.

EMPOWER YOUR FACTORY WITH SMART 3D

3D LASER LINE PROFILE SENSORS

For All Your Inline Inspection and Optimization NeedsGocator line profile sensors use a projected laser line to perform high-resolution scanning, measurement and control for automated quality inspection and material optimization at inline production speed.

GET GOCATOR BROCHURE

FIND THE RIGHT 3D LINE PROFILER FOR YOUR APPLICATION

Gocator 2100 Series

Entry-Level 3D Line Profilers

- Handles all of your basic quality inspection needs

- VGA imager, 640 points per profile resolution

- Field-of-view up to 1260 mm

- Measurement range up to 800 mm

MORE DETAILS

Gocator 2300 Series

Workhorse 3D Line Profilers

- Handles a wide range of high-speed, high-volume applications

- Megapixel imager, 1280 points per profile resolution

- Field-of-view up to 1260 mm

- Measurement range up to 800 mm

MORE DETAILS

Gocator 2400 Series

High-Resolution 3D Line Profilers

- Handles targets from small electronics parts to large boxes and automotive body frames

- 2-Megapixel imager.

Up to 1940 points per profile resolution

- Field-of-view (FOV) up to 2 m

- Measurement range up to 1525 mm

- Includes RED LASER and BLUE LASER models for optimal performance and maximum flexibility in your scanning applications

MORE DETAILS

Gocator 2500 Series

High-Speed 3D Line Profilers

- Handles small parts inspection on a wide range of surface types (e.g., shiny, dark)

- 2-Megapixel imager. Up to 1920 points per profile resolution

- Scan, measurement, and control at up to 10 kHz

- Field-of-view (FOV) up to 100 mm

- Measurement range up to 80 mm

MORE DETAILS

Gocator 2600 Series

4K+ Resolution and Wide Field of View 3D Line Profilers

- Handles microscopic features and large conveyor applications

- 9-Megapixel imager. Up to 4200 points per profile resolution

- Scan, measurement, and control at up to 5 kHz

- Field-of-view (FOV) up to 2 m

- Measurement range up to 1550 mm

Gocator 2800 Series

Dual Triangulation 3D Line Profilers

- Two cameras maximize scan coverage and minimize occlusions for

applications such as primary log scanning - Megapixel imager, 1280 points per profile resolution

- Field-of-view up to 1260 mm

- Measurement range up to 800 mm

MORE DETAILS

Find Your Sensor

Need some help finding the right Gocator® for your application? No problem.

Simply visit our dedicated Product Selector, enter a few details about your application, and the Selector will automatically generate a list of suitable sensor models for you to choose from.

TRY PRODUCT SELECTOR

FactorySmart® SensorsCONTACT US

All LMI products are backed by documentation and a team of experts to help you.

PRODUCT SUPPORT

Our Knowledge Base has a wealth of information about 3D technology and its applications.

KNOWLEDGE BASE

Please contact us if you have any questions about your LMI implementation or product.

CONTACT US

Gocator 2500 Series

High-Speed 3D Line Profilers

- Handles small parts inspection on a wide range of surface types (e.g., shiny, dark)

- 2-Megapixel imager.

Up to 1920 points per profile resolution

Up to 1920 points per profile resolution - Scan, measurement, and control at up to 10 kHz

- Field-of-view (FOV) up to 100 mm

- Measurement range up to 80 mm

MORE DETAILS

Company | LMI Technologies

ADVANCING 3D MEASUREMENTWITH SMART SENSOR TECHNOLOGY Networking Basics, Sensor Networking Hubs,

Power, Laser Safety, and Cabling

We are LMI Technologies

Since 1998, LMI Technologies has worked to advance 3D smart sensor technology for fast and accurate measurement. Our flagship Gocator and FocalSpec product lines help factories achieve 100% inspection, reduce waste by optimization, and improve efficiency by simplifying automation. Trusted in the most challenging applications, our 3D solutions help customers improve control of their processes and stay ahead of the competition.

Watch the video for the story of Gocator—from design and manufacturing to implementation and application.

Download Corporate Brochure

We Are Part of the TKH Group

LMI Technologies is a proud member of the TKH group—an internationally operating, innovative technology company with its registered office in the Netherlands. The TKH technology base covers four core technologies: vision & security, mission-critical communication, connectivity and smart manufacturing.

As part of the TKH group, LMI Technologies is focused on the design, development, and delivery of smart 3D technologies, while our sister machine vision companies are dedicated to providing high-performance camera-based solutions.

LEARN MORE

From our chip-level engineering expertise,

to your next big idea, we help you make it real.

One of our first Selcom Displacement Sensors deployed in the late 1970s.

LMI’s award-winning, FactorySmart™ sensors improve the quality and efficiency of factory production by providing fast, accurate, reliable inspection solutions that leverage smart 3D technologies. Unlike contact based measurement or 2D vision, our products remove complexity and dramatically reduce implementation cost.

Unlike contact based measurement or 2D vision, our products remove complexity and dramatically reduce implementation cost.

LMI Technologies is part of the TKH Group NV, a publicly listed Dutch company specializing in the creation and delivery of innovative Telecom, Building and Industrial Solutions. The TKH core technologies – vision & security, communications, connectivity and production systems – are interlinked to form complete systems and solutions in vertical markets TKH has defined.

All Gocator sensors are manufactured in our Headquarters in Burnaby, British Columbia, Canada. This facility has been officially ISO certified by a third-party under the (1) ISO 9001:2015 Quality Management Systems and (2) ISO 14001:2015 Environmental Management Systems standards for the Design, Development, Assembly, and Servicing of 3D Imaging Products and Software.

These certifications are an investment in the continued quality of our manufactured products and the future health of the planet. We encourage all companies to take this step to increase their production standards, and reduce waste, costs, and risks while supporting the environment in the process.

We encourage all companies to take this step to increase their production standards, and reduce waste, costs, and risks while supporting the environment in the process.

Our customers are welcome to return any unwanted product to LMI Headquarters for proper recycling and disposal.

“3D scanning and inspection is all we do, and it is this specialized knowledge and experience that helps drive profitability, reduce time-to-market, and open up new possibilities for our customers.”

MARK RADFORD, CHIEF EXECUTIVE OFFICER

<

Our Four Pillar Business-to-Business Approach

Chip Level Engineering

We design and deliver proven 3D technologies

at the lowest cost.

Smart Technology

Smart sensors run standalone to produce

inspection solutions out-of-the-box.

Simple User Experience

You don’t need to be a rocket scientist to use our

products—just point and click.

Progressive Partnerships

We build OEM solutions

in support of our long term partnerships.

Your Career at LMI

Looking for a career in the rapidly evolving field of 3D vision? We would love to hear from you.

SEE JOB OPENINGS

3D scanners LMI Technologies Inc.

Filter

Designation

Designation

tabletop

manual

stationary

3D scanner type

3D scanner type

Dental

Industrial

Architectural

Manufacturer

Manufacturer

Creaform Inc.

24

MakerBot Industries, LLC

1

Open Technologies Srl

5

Fuel 3D Technologies Limited

1

DAVID 3D Solutions GbR

3

SHINING 3D TECH

44

AICON and Breuckmann

3

3D Systems

3

4DDynamics Bvba

8

Artec 3D

6

Volumetric technologies

1

Range Vision

9

Roland DGA Corporation

3

Rubicon Technologies

1

Solutionix Corp.

7

Dental Wings inc.

3

FARO Technologies UK Ltd

8

nextengine, inc.

1

Basis Software Inc.

10

LLC RIFTEK

1

Trimble Navigation Limited

5

LMI Technologies Inc.

3

smart optics Sensortechnik GmbH

7

DotProduct LLC

1

GOM mbH

9

Leica Geosystems

6

Texel

1

AGE Solutions

1

SMARTTECH 3D

7

XYZprinting

1

Thunk 3D Technology Co. , Ltd.

, Ltd.

Thor3D

1

ScanTech

6

Peel 3D

5

Reset filters

Filter

Sort: By price Rated

HDI Advance R1x

LMI Technologies HDI Advance R1x is a professional fixed optical scanner...

No offers

HDI Advance R3x

LMI Technologies HDI Advance R3x is a fixed professional optical scanner that...

No offers

HDI 120

LMI Technologies HDI 120 - portable fixed scanning system professional. ..

..

No offers

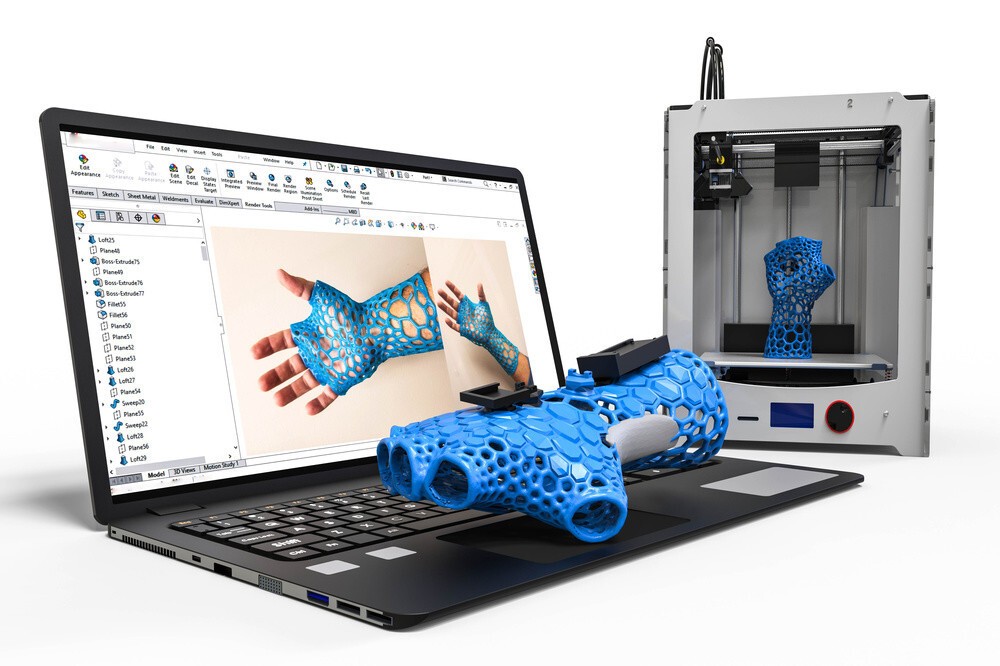

What is a 3D printer?

90,000 technologies, methods and principles of 3D scanners04/16/2021

Content

-

- What is 3D scan and for which it is used

- How 3D scanner

3D scanning - methods work 3D scanners

- Contact 3D scanners

- Non-contact 3D scanners

- Types of 3D scanners by usage

- Advantages and disadvantages of 3D scanners

- What to consider when choosing a 3D scanner

- Applications

Currently, few people are not familiar with such a concept as 3D printing. Many companies are using modern 3D printers with might and main, recreating layouts of various shapes and sizes with their help. There are also those that recreate whole objects - not only small ones (for example, phone cases, souvenirs, sneakers), but also large ones (houses, engine parts, etc.). But all this would not be possible without 3D scanners. It is they who allow you to accurately copy almost anything - from huge buildings and structures to humans, animals, small objects and much more.

It is they who allow you to accurately copy almost anything - from huge buildings and structures to humans, animals, small objects and much more.

What is 3D scanning and what is it used for

Three-dimensional scanning is a technology that appeared in the 60s of the 20th century. It was created in order to transfer the physical parameters of the object into a digital format in the form of a three-dimensional model. The need for this naturally arose when people around the world increasingly began to use computers both in everyday life and in production.

The first samples of 3D scanners were quite simple and did not have wide functionality. Gradually, they became more complex and improved, making it possible to achieve an ever clearer image of the object. This has become especially relevant with the advent of lasers.

3D scanners allow you to transfer object data into digital format

3D scanning has opened up new opportunities in various areas of human activity - from the automotive industry and the military industry to design, medicine and cinema.![]()

How a 3D scanner works

A 3D scanner is a device that examines an object by digitizing it using sensors and using the information received to create a three-dimensional model. In fact, a 3D scanner creates a digital copy of a physical object of any configuration and complexity. In this, it fundamentally differs from its predecessors - conventional scanners that can only read information from documents and photos.

The scanning process itself can take place in different ways - depending on the type of 3D device and the technology used, as well as on what object you want to process with it - moving or static.

3D Scanning Technologies

There are 2 main types of 3D scanners - laser and optical. Their fundamental difference lies in how and with the help of what the “removal” of data takes place. Let's take a closer look at both.

3D laser scanning, as the name implies, uses a laser and can be carried out both at near and far distances from the object.![]()

Laser Scanner

For the most part, 3D laser scanners work on the principle of triangulation, when the camera finds a beam on the surface of an object and measures the distance to it, after which a cloud of points is created, each of which has its own coordinates in space, and a 3D model is built. Their "advantages" are affordable price and ease of use combined with high scanning accuracy. Of the "minuses" - there are restrictions on the remoteness and size of the object.

Another type of laser scanner works by measuring the response time of a beam from the surface of an object - the so-called laser range finder. They are widely used where it is necessary to create 3D models of various buildings and structures. It is not advisable to use them at short distances, since in such cases the response time is very short and the accuracy of the data is reduced. Otherwise, this type of scanner is characterized by high scanning speed and the ability to read all the details.

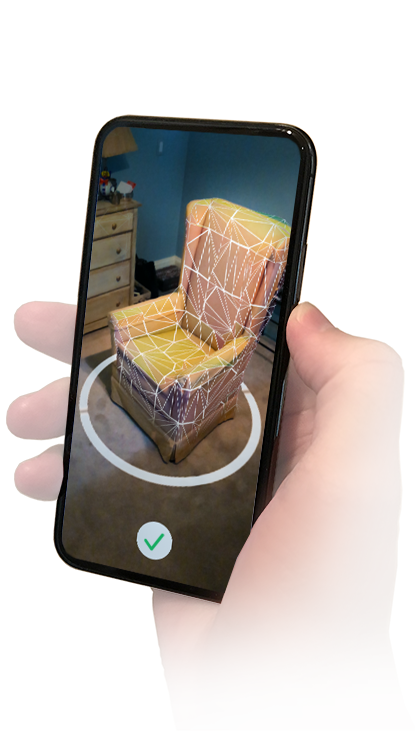

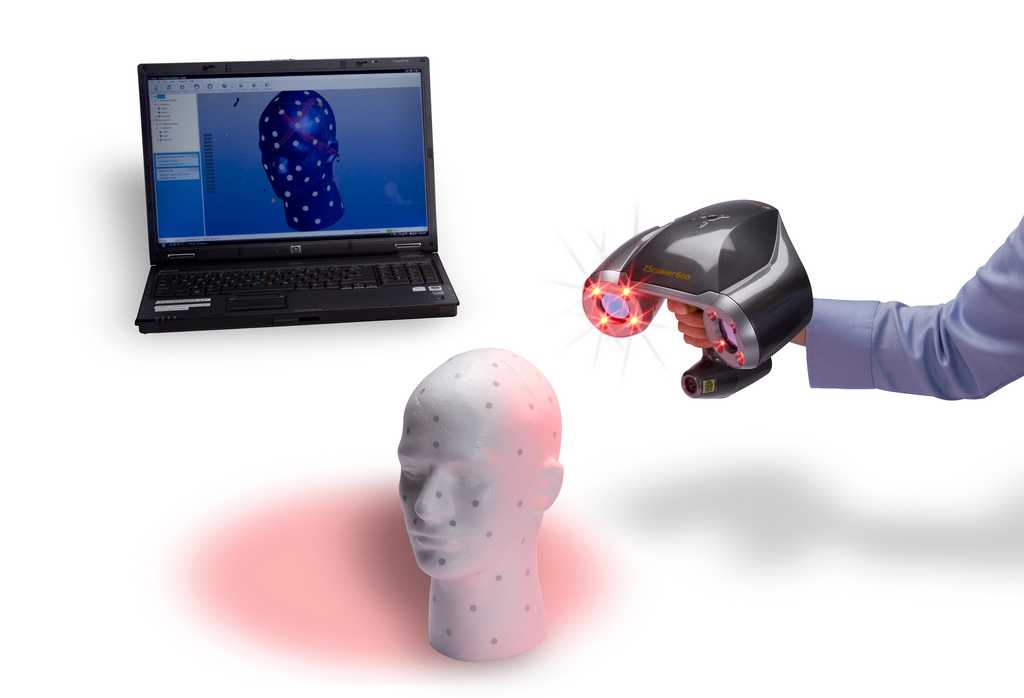

The disadvantage of laser scanners is the impossibility of their use on moving objects. Then optical 3D scanners come to the rescue, which shoot with one or more cameras from different angles an object illuminated by a special projector. Based on the received image, a three-dimensional image is built.

Optical scanner

A "contraindication" for the use of this technology are reflective and translucent surfaces - shiny, mirror or transparent. But when scanning a person, they are simply irreplaceable.

3D scanning methods

Any object can be digitized both by contact and non-contact methods. In the first case, active interaction with the subject is necessary, in the second, accordingly, no. Both of these methods have their advantages and disadvantages.

Contact 3D scanners

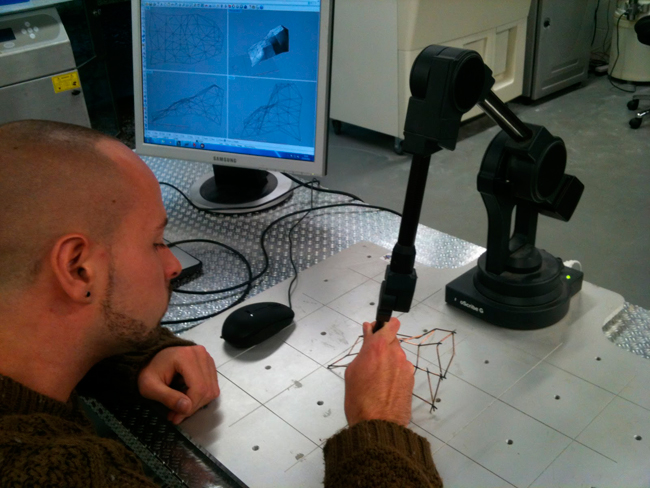

They have a mechanical probe with a special sensor that measures parameters and transmits the collected information to the device. To do this, the object under study is placed on a special surface and fixed (if necessary). Such tight physical contact makes it possible to determine and then build a 3D image as accurately as possible, however, there is a small risk of damage to the prototype.

To do this, the object under study is placed on a special surface and fixed (if necessary). Such tight physical contact makes it possible to determine and then build a 3D image as accurately as possible, however, there is a small risk of damage to the prototype.

Non-contact 3D scanners

This category includes all devices capable of scanning at a distance. This is especially true for objects located in hard-to-reach places.

Non-contact 3D scanner

A stream of radiation (it can be ultrasound, light, X-rays or a laser) is directed to the object and reflected from it, it is recognized by the 3D scanner. They are similar in principle to a video camera and may require the use of additional devices for better lighting.

Non-contact 3D scanners come in 2 types:

-

Active - work with the help of a laser beam or structured light directed at an object, which, when reflected, give information about the location of the object in the form of coordinates.

-

Passive - use time-of-flight rangefinders that read the time and distance that the laser beam travels to the object, and so - for each point in space, which ultimately allows you to accurately recreate its three-dimensional image.

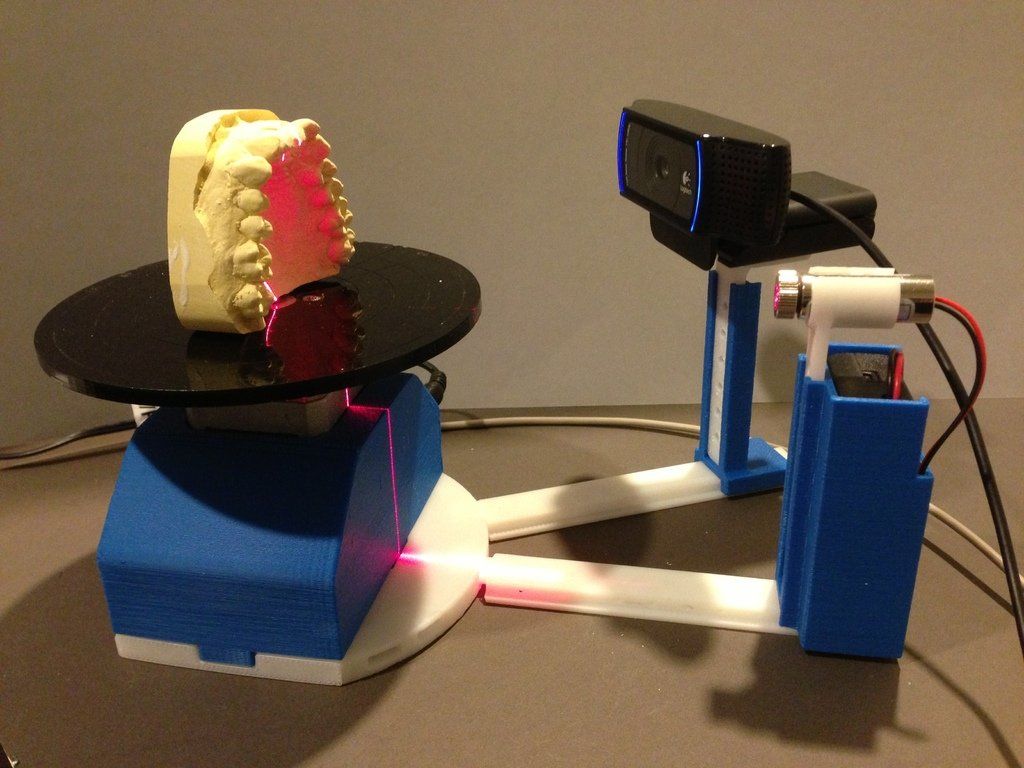

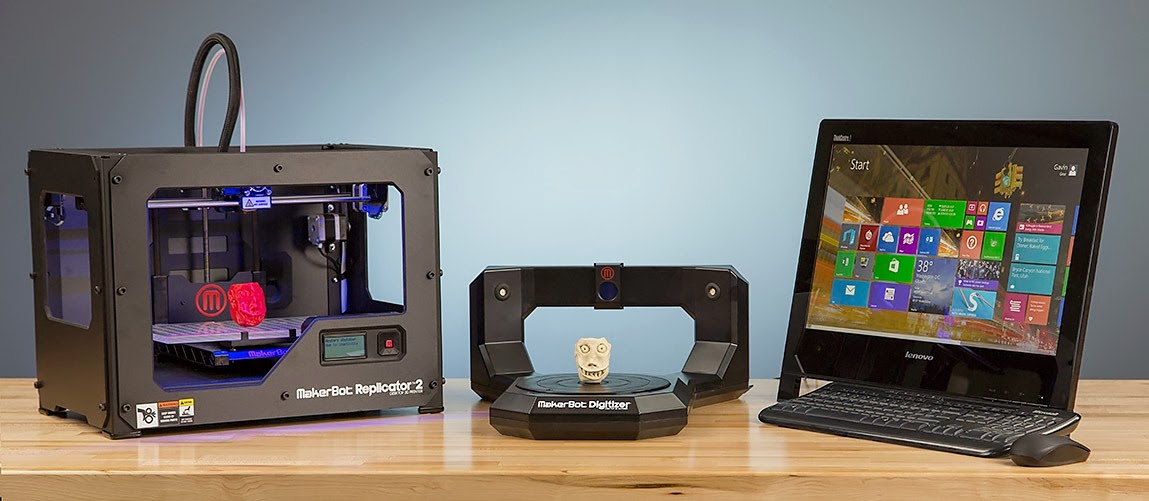

Desktop 3D scanners are very popular and widespread, since they are mostly simple and safe to use, do not require any special technical skills and are quite cheap. The EinScan-SE 3D scanner is one such example. It can be used both at home and in the office. It has access to the API of many popular 3D printers, which makes it possible to immediately print the created three-dimensional model.

Add to compare

Product added to compare Go

| Manufacturer | Thor3D |

Add to compare

Product added to compare Go

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go

| Manufacturer | Range Vision |

Types of 3D scanners according to the principle of use

There is also a variety of species here. Let's highlight the main ones:

Let's highlight the main ones:

-

Manual: The are handy and simple models that are easy to use as they are quite compact and do not require special skills. True, their technical capabilities may be somewhat limited.

-

Portable: are mainly used for field work, they are convenient to take with you.

-

Desktop: have extended functionality and are used to create high-quality 3D models. Most often used in offices.

-

Stationary: are used, as a rule, in production, various enterprises, as they can scan a large number of objects of the same type at once. Mounted on special turntables.

Handheld 3D scanner Calibry

Such a choice of products allows you to select the right model for a specific task. In some cases, scanners independently measure objects, in others - with the help of a person who sequentially moves the device until all the necessary information is collected.

Such options for hand-held 3D scanners as Calibry are in high demand among buyers. Despite the apparent simplicity of execution, it has a high resolution and scanning accuracy, due to which it is able to digitize objects with a length of 0.2 to 10 meters. Objects that have a non-standard surface - dark or shiny, with a large number of corners and small details will not become a problem either. Among other things, its undoubted advantage is its low weight, only 900 grams.

Advantages and disadvantages of 3D scanners

Surely, many of the potential buyers are wondering: do you really need a 3D scanner to invest a lot of money in it? What can this acquisition give and will such an investment be justified?

3D scanning has become an integral part of any modern manufacturing process

In order to understand how much you need this equipment, we will list its advantages and disadvantages.

Benefits:

-

They make it possible to scan objects located at a remote distance and in places inaccessible to the presence.

-

They have the ability to "read" not only colors and images, but also to convey the texture of the surface.

-

Significantly speed up the process of "taking" data from any object, even a very complex one with a large number of planes.

-

A variety of models allows you to choose the most convenient version of the scanner, including manual or portable, which can be easily taken with you.

Weaknesses:

-

Some scanners are unable to recognize transparent or black and white objects. In this case, their preliminary preparation (treatment with a special composition) is required.

-

I do not always display complex objects correctly, with a large number of inserts and partitions.

-

To obtain a high-quality result, they require skills and abilities to work with certain computer programs for creating 3D models.

-

If the rules of operation are constantly violated, it may become necessary for expensive repairs to the equipment.

If you need high-precision and high-quality three-dimensional copies of objects, then you cannot do without a 3D scanner. It makes it possible to work in almost any conditions - indoors and outdoors, and with any objects by type and size. It is not surprising that now these devices are in great demand, which gives rise to the annual release of a large number of models, from which you can always choose the one that suits you in terms of quality and price.

Things to consider when choosing a 3D scanner

The computer equipment market offers a huge amount of all kinds of equipment, including devices for three-dimensional scanning. Navigating that variety is sometimes not at all easy: some buyers are only concerned about the cost, others are interested in the number of options (sometimes completely useless), but the most far-sighted look at the ratio of the first and second.

Choosing the right 3D scanner is a big deal

It is not always easy to take into account all the technical points that can significantly affect what result will be ultimately achieved. We will tell you what you should pay attention to if you are thinking about buying a 3D scanner.

We will tell you what you should pay attention to if you are thinking about buying a 3D scanner.

Focus on the following parameters:

-

How high is the accuracy of the 3D scanner. This is one of the most important features. It needs to be targeted first.

-

Resolution also plays an important role. It follows from the first, since the accuracy of measurements and the quality of copying depend on the resolution.

-

In what range the device operates, how close / far it can be from the scanned object.

-

The scanning field is the parameters of that object, thing that it is able to process in 1 session.

-

Does the scanner capture various atypical types of surfaces with complex terrain - channels, partitions, holes, etc.).

-

Portability, mobility of the device - how easy it can be moved if desired, taken with you, its size.

-

The time it takes to prepare for work, as well as the duration of the digitization process itself.

-

The range of possibilities in terms of copying: are there any restrictions on shapes, textures, material, as well as operating conditions - temperature, light, etc.

Of course, the better the quality of the 3D scanner, the more expensive it is. However, you should focus primarily on the tasks that you face, and only then take into account everything else.

Applications

Three-dimensional scanners are in demand in many areas of human life. They are irreplaceable both in the industry, and for household needs. The range of their application is so wide that it is possible to list for a very long time. It's easier to say where they are not needed.

The most common areas of use are, of course, medicine, industry, architecture, construction, film industry and design.

For example, in dentistry, these devices allow you to create ultra-precise three-dimensional models of dentures. One type of such a scanner is Shining 3D's AutoScan DS-EX PRO, which does a great job with a variety of tasks while being quite affordable and reliable.

Medical 3D Scanner

In engineering, such technologies are also indispensable. Digital building prototypes are now much easier and faster to obtain than in the past, when it required multiple manual measurements and then entered into a database. Any physical object can now be recreated in three-dimensional form, moreover, in the shortest possible time and with a minimum error.

In cinemas, we can see with our own eyes "revived" fantastic characters, which were created using motion capture technology, which made it possible to make them as realistic and impressive as possible. This would not have been possible without 3D scanners.

A few decades ago, it was even difficult to imagine all the things that we use all the time today. And in many ways this has become achievable thanks to three-dimensional digitization. This approach provides huge advantages in work (especially for technical specialists - engineers, designers, designers), however, in order to use them to the maximum, it is also necessary to understand computer programs for 3D scanning.