3D print laser

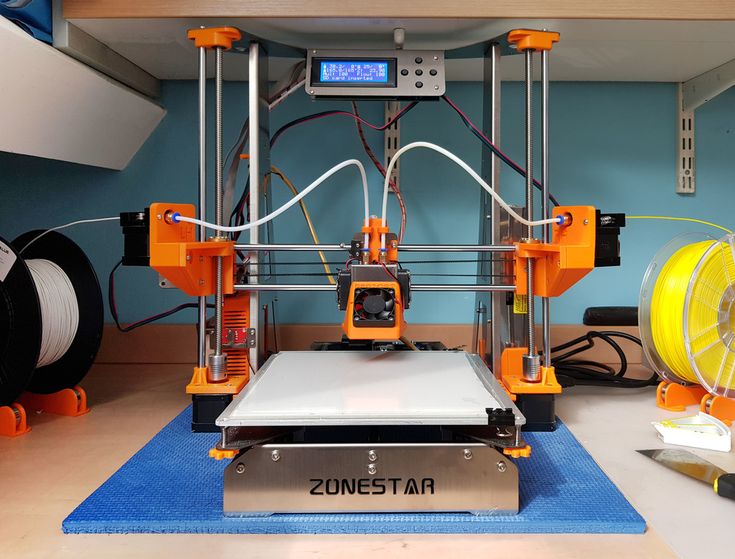

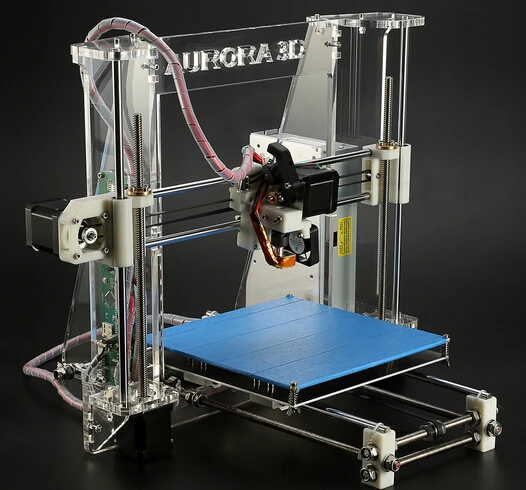

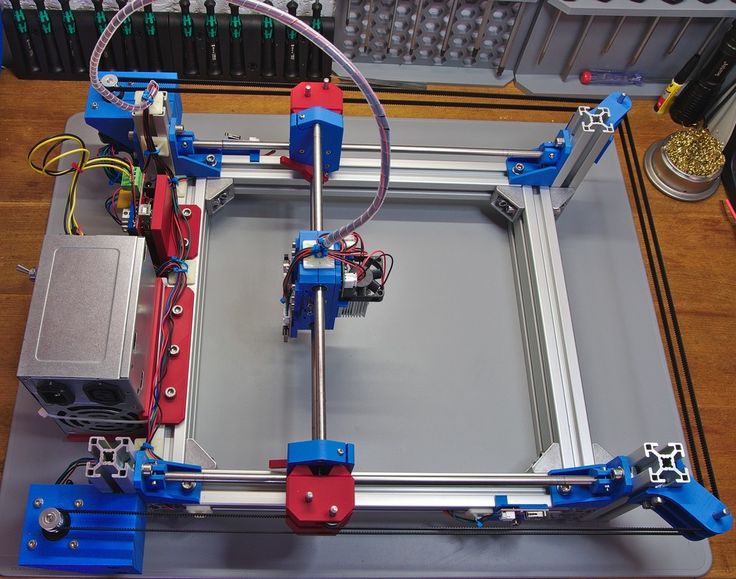

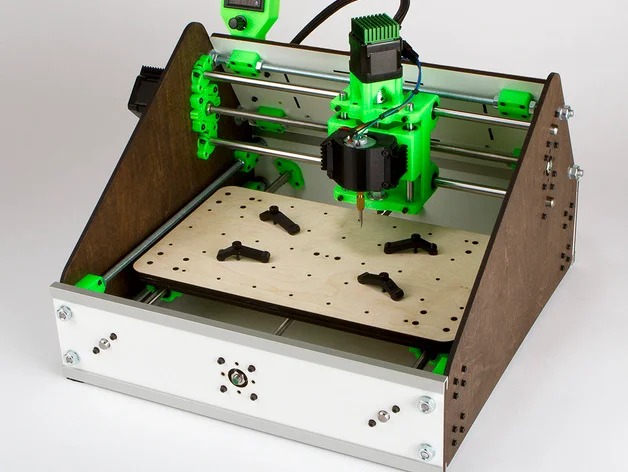

Best 3D Printer, Laser Engraver, CNC Carver for Sale

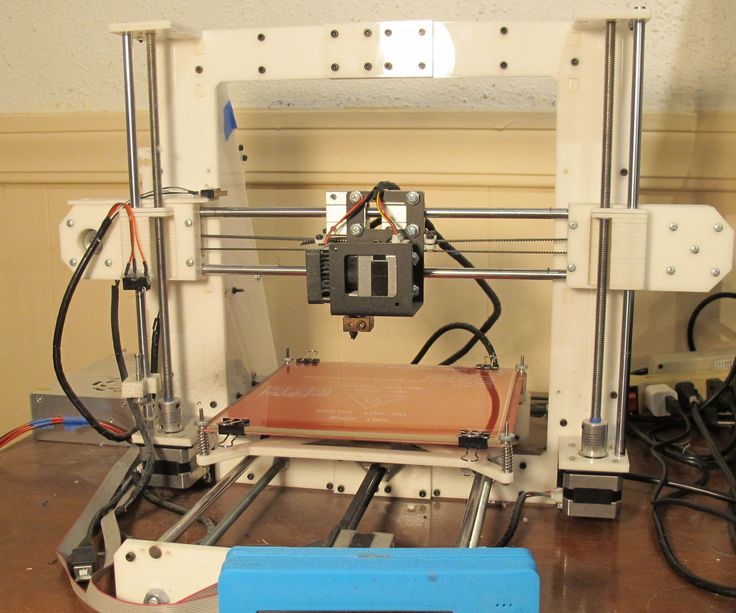

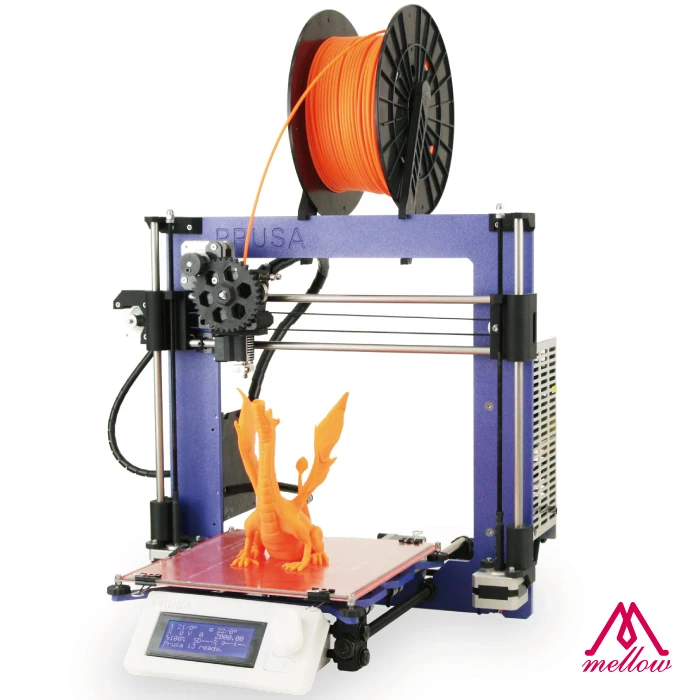

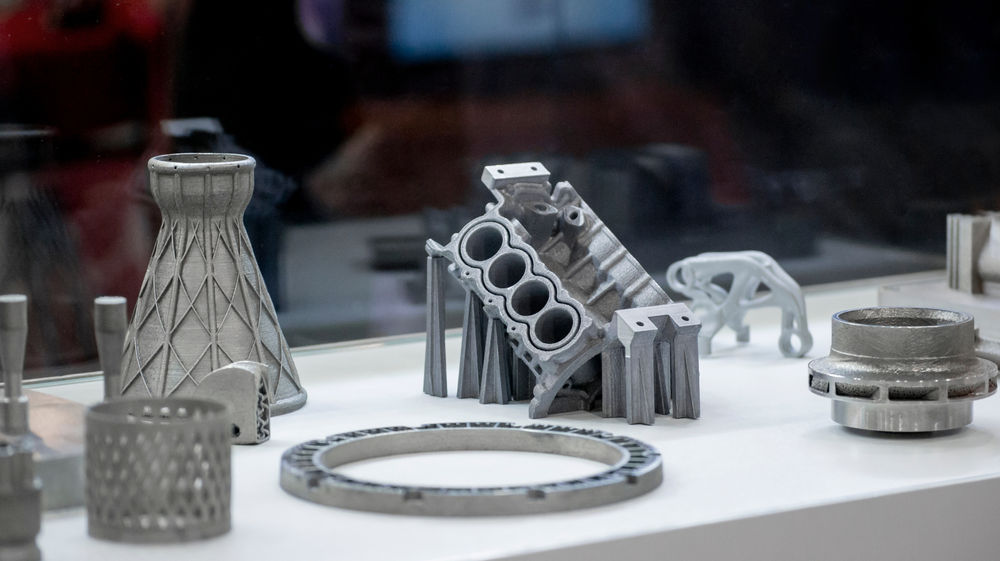

3D printing can create virtually anything from just about any material at a fraction of the cost and time traditionally associated with such processes, from mission-critical parts for airplanes to building blocks for custom homes and everyday items — ranging far beyond what we can imagine today.But what exactly is 3D printing? How does it work? And why should you use it?Well, we're glad you asked! Here's everything to know about using a 3D printer.

We have probably heard of 3D printing and maybe even done some experimenting with it. Still, most people don't know what 3D printing is.3D printing is one of the hottest new technologies in the world right now—and it's not going away any time soon. It's a process that allows us to create physical objects by putting together thin layers of material, layer by layer, until we get to the final product. We can do this on almost any material: metal, plastic, ceramic, glass—even food!So, what does this mean for our everyday life? It means that if we have an idea for something we want to make but don't have the time or resources to make it ourselves (or if we are just too busy), then 3D printing can help.

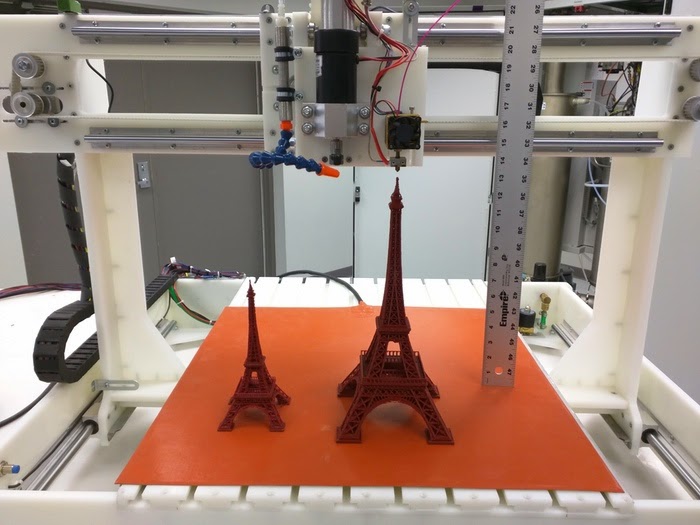

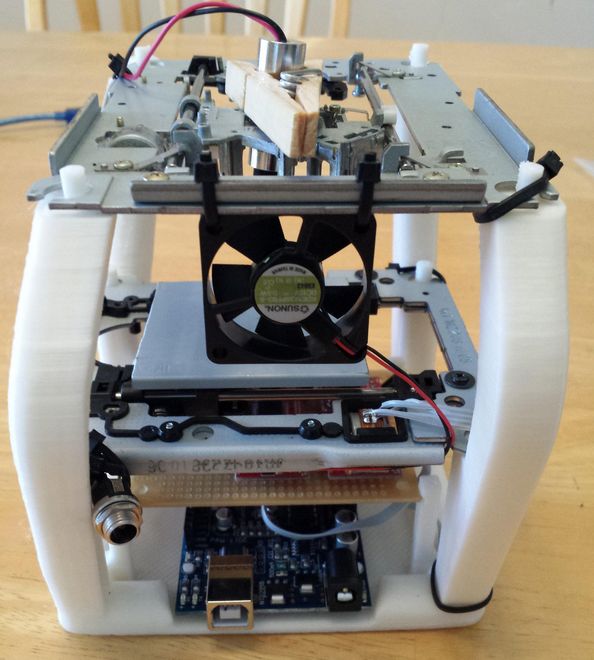

3D printing works like this: First, you download a model online or design one yourself. Then, you import the model into the slicing software for processing. Finally, you print the model by using a 3D printer. The printer does this by laying down successive layers of material, one after another until the object is completed. The printer needs to know the size of each layer and where it should be placed for the object to come together correctly.

Additionally, the printer needs a supply of raw materials (typically plastic) that can be melted down and formed into shapes. Once these raw materials have been melted down into their final shape, they are extruded through tiny holes in what's called a "printhead." This printhead feeds the material through small holes into whatever space it needs filling with plastic filament.

The printer doesn't actually create anything out of nothing; it creates an object from a previously existing model or blueprint. Since every part of this process is done by computerized machinery, there are no limitations on how complex or detailed our creation can be—the only limit is our imagination!

The possibilities for what can be created with this technology are endless. 3D technology allows us to design and create our own products without having to worry about how they will fit together or whether they will function properly.Some benefits 3D technology offers include: It Offers Many Design Possibilities. We can choose from hundreds of different materials, colors, and designs. The flexibility offered by this technology means no two items will be the same.

3D technology allows us to design and create our own products without having to worry about how they will fit together or whether they will function properly.Some benefits 3D technology offers include: It Offers Many Design Possibilities. We can choose from hundreds of different materials, colors, and designs. The flexibility offered by this technology means no two items will be the same.

1.It's Inexpensive To Use

It doesn't cost a lot to get started with a 3D printer. All you need is a computer and internet access. We can choose from many different types of printers with varying price ranges. The cheaper models will still print quality models, but they may not be able to handle large projects like furniture or large items that need to be printed out in multiple pieces.

2.Sustainable and reduces waste

3D printers have a huge environmental impact because they are extremely energy efficient. Instead of creating parts from waste plastic or scrap metals, we can create them from recycled materials like aluminum and plastic, reducing the amount of waste material in landfills by up to 90%.

3.Make Custom Products at a Minimal Cost

3D printing can be used to make clothes, costume jewelry, toys, figurines, and more. We also use 3D printers to make items for ourselves or sell them as gifts. Additionally, we can customize our own shoes, use 3D printers for rapid prototyping (which means we can quickly create working prototypes), manufacture, and even in greenhouses where tropical plants are grown.

3D technology has come a long way since the first 3D printer was built in 1984, and today there are many different types of printers on the market. 3D printers come in all shapes and sizes, and their capabilities vary greatly depending on our chosen brand and model. For instance, beginners who want a feel of 3D technology before splashing money on a superior model can buy entry-level printers for as low as $1000. When choosing a suitable printer, some key features to keep in mind include:

· Good resolution (or print quality): A high-resolution 3D printer will produce better results than one with a lower resolution. Remember, we need to see the details clearly when designing our project.

Remember, we need to see the details clearly when designing our project.

· Print size: The print size is the size of the finished object. It's usually measured in millimeters or inches, but some models have larger (and smaller) print sizes than others. When looking to make full-size products, we must know what size is right for our needs before investing in a machine!

· Speed: The printer's speed determines how quickly it can do its job—if it's slow, it can't support large projects like furniture or art pieces.

from 2980 reviews

Ryan Daw

Laser Engraving and Cutting Platform for Snapmaker 2.0

Amazing!

Was able to make highly detailed images on tile with absolutely no problems Very impressive results on tile

07/18/2022

Nicolas Belin

Snapmaker 2.0 Modular 3D Printer F350/F250

Great Snapterrarium ehh Snapmaker.

Great Snapterrarium ehh Snapmaker.

Works great. Had a faulty touchscreen but SM send me a new one and now all works like a charm.

06/30/2022

Jaime Ramirez

Snapmaker 10W High Power Laser Module

Very good laser

My first job was a vernier on my 1600mw module it took 55 min to cut, now with the 10W module only 9 min.

05/09/2022

Eric Worrall

Snapmaker 2.0 Modular 3-in-1 3D Printers

Does exactly what it says

I’ve loved my Snapmaker since I unboxed it.

It’s not perfect, it’s complex, you need to dedicate time to learning 3D technology. The software sometimes needs to be restarted to work, and sometimes has annoying bugs.

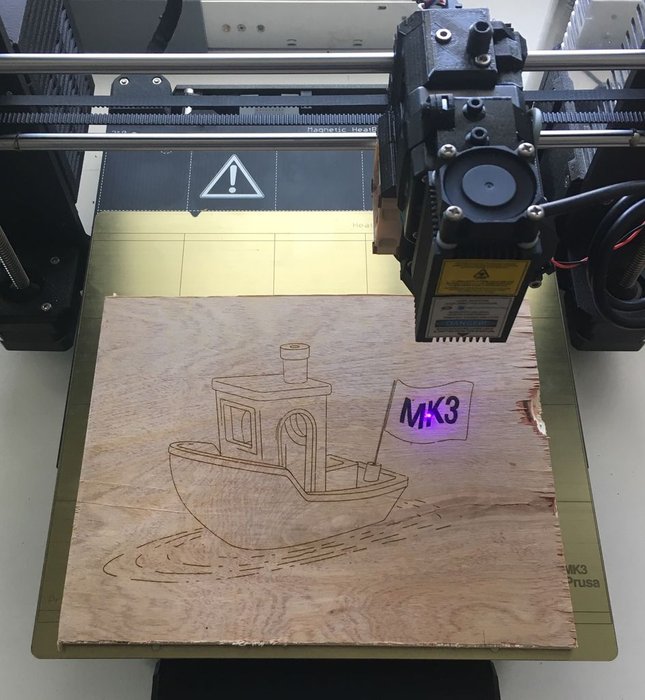

But the engineering precision is breathtaking, I’ve created beautiful 3D PLA prints which don’t need finishing, high quality mechanical parts, like a bicycle pump holder, and ornate wooden gift boxes with laser engraved messages for loved ones.

If you have the commitment and time to learn a new skill, Snapmaker will help you realise your creative vision.

04/14/2022

Robert Allard

Enclosure for Snapmaker 2. 0

0

A good addition to my a350

Very satisfied with my purchase, and service for helping me with problems I had assembly.

03/24/2022

Mike L

Snapmaker Original 3-in-1 3D Printer

Printing in an hour!

Was really impressed with how easy it went together, I was up and printing in about an hour, easy calibration and no fussing. Awesome choice for a first-timer! Simple software, takes up little space and the smaller bed is still big enough for most jobs any first-timer would want. Laser engraving works well too! No regrets choosing Snapmaker as my first printer, great value for $$. Highly recommend it! Pictured: Enigma Rotor replica

03/12/2022

Maker Leigh

Snapmaker 2.0 Modular 3D Printer F350/F250

It's my second one :-)

This was my second SM2 350 purchase, Chrismas sale provided a cheap way to upgrade my set up. Super fast delivery over new year in the UK. Well done Snapmaker.

02/10/2022

wentsung Peng

Straight Groove V-bits (3 Bits)

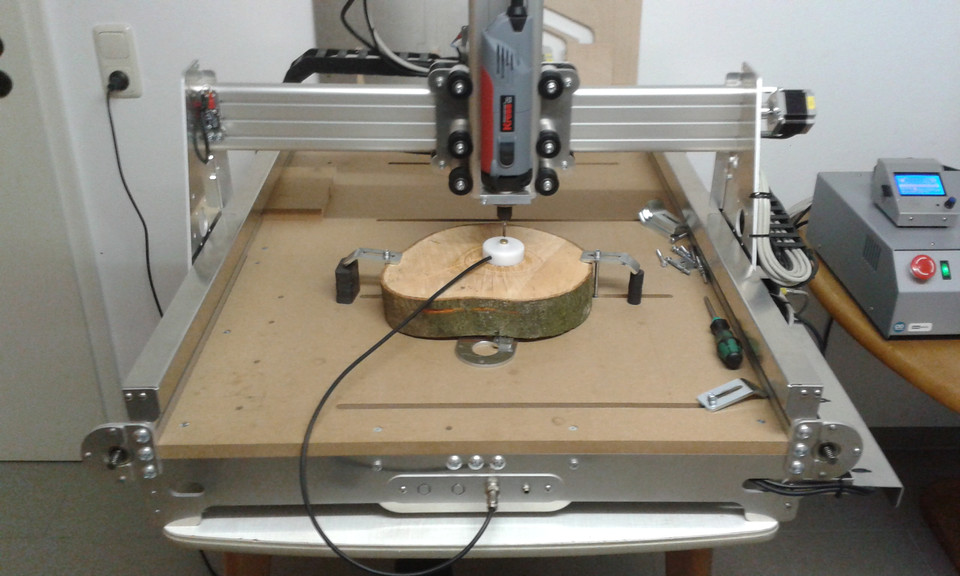

Small problems with using Straight Groove V-bit

I used the Straight Groove V-bit to complete the Rotary Module CNC Carving a few days ago, and everything was almost perfect. My material is wood with a diameter of 50cm. When the Straight Groove V-bit goes deep into the center of the wood, because the radius of the wood exceeds the length of the flute, the wood touches the shaft and generates a lot of friction and noise, causing the 3-jaw Chuck to loosen. The diameter of 3-jaw Chuck Inward-clamping of Rotary Module can reach 60CM. The above problem may be more obvious. Is there a solution?

My material is wood with a diameter of 50cm. When the Straight Groove V-bit goes deep into the center of the wood, because the radius of the wood exceeds the length of the flute, the wood touches the shaft and generates a lot of friction and noise, causing the 3-jaw Chuck to loosen. The diameter of 3-jaw Chuck Inward-clamping of Rotary Module can reach 60CM. The above problem may be more obvious. Is there a solution?

09/22/2021

Yousif Alsabbagh

Snapmaker 2.0 Modular 3-in-1 3D Printers

A350

The only negative point is that the machine makes loud noise, other than that it’s fantastic!

09/20/2021

Best High Resolution Industrial 3D Printer – Snapmaker

Skip to contentFilter Filter3-in-1 3D PrinterAddonsFeatureLaserMachinesMaterialsParts & AccessoriesSnapmaker 2.0Snapmaker ArtisanSnapmaker J1Snapmaker Original

Sort SortFeaturedBest sellingAlphabetically, A-ZAlphabetically, Z-APrice, low to highPrice, high to lowDate, old to newDate, new to old

- Snapmaker Artisan

- Snapmaker J1

- Snapmaker 2.

0

0 - Snapmaker Original

- 3D Printers Comparison

Quick view

Snapmaker Artisan 3-in-1 3D Printer with Enclosure

Regular price USD $2,999.00 Sale price USD $2,899.00

Quick view

Snapmaker 2.0 Modular 3-in-1 3D Printer A350T/A250T

Regular price USD $1,649.00 Sale price from USD $1,199.00

Quick view

Snapmaker 2.0 Modular 3D Printer F350/F250

from USD $899.00

Quick view

Snapmaker Dual Extrusion 3D Printing Module

Regular price USD $599.00 Sale price USD $429.00

Quick view

Snapmaker Rotary Modules

from USD $569.00

Quick view

Snapmaker Air Purifier

USD $499.00

Quick view

Snapmaker 10W High Power Laser Module

from USD $459. 00

00

Quick view

Enclosure for Snapmaker 2.0

Regular price USD $399.00 Sale price from USD $199.00

Quick view

Linear Module for Snapmaker 2.0

Regular price USD $349.00 Sale price from USD $179.00

Quick view

Snapmaker 3D Printing Module

USD $149.00

Quick view

Power Module for Snapmaker 2.0

Regular price USD $129.00 Sale price USD $64.50

Quick view

Filter Cartridge for Air Purifier (2 Pcs)

USD $199.00

Quick view

TPU Filament (1kg)

USD $34.99

Quick view

Snapmaker 2.0 Emergency Stop Button

USD $59.00

Quick view

Carbon Fiber Sheet (3 Pcs)

Regular price USD $18.99 Sale price USD $9. 99

99

Quick view

Snapmaker CAN Hub

USD $59.00

Quick view

Laser Safety Goggles

Regular price USD $49.00 Sale price USD $36.75

Quick view

Laser Engraving and Cutting Platform for Snapmaker 2.0

from USD $29.00

Quick view

ABS Filament (1 kg)

USD $24.99

woocommerce social proof plugin

Top

English

- Chinese (Traditional)

- Japanese

- French

- German

- English

English

- Chinese (Traditional)

- Japanese

- French

- German

- English

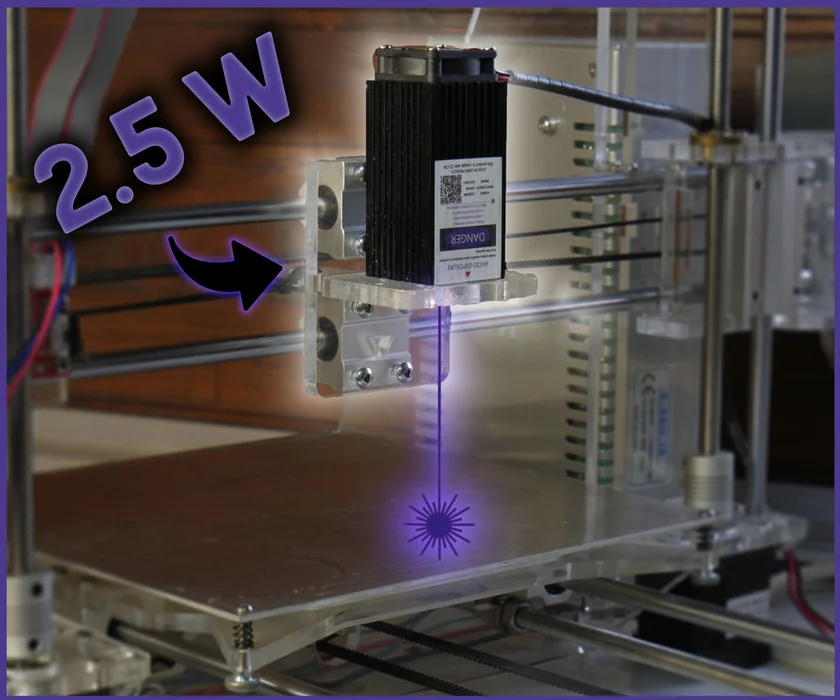

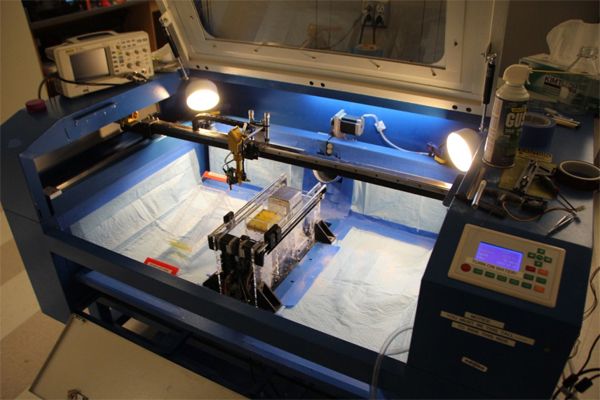

How do 3D printing lasers differ from cutting lasers?

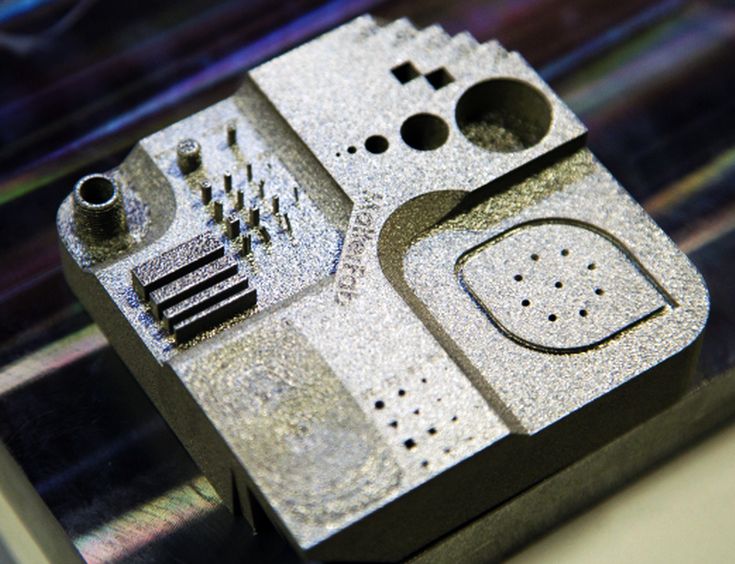

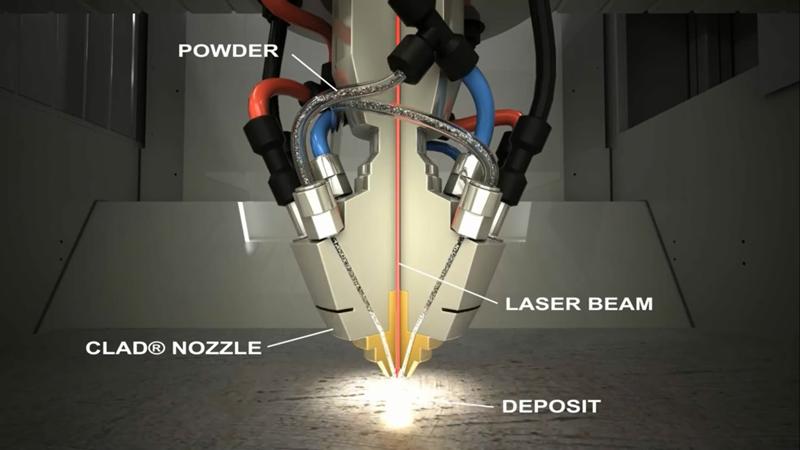

EOS uses lasers to fuse polymer powders (SLS) and metals (DMLS).

Over the past four decades, laser cutting machines have become a must-have tool for the vast majority of sheet metal fabricators.

From CO2 lasers to their newer and more capable solid-state counterparts, what began as a laboratory experiment in the 1960s is today the method of choice for quickly and accurately cutting virtually any metal less than 2.54 cm thick.

However, soon after lasers began to appear in workshops everywhere, another use was found for collimated light, which seems destined to play an equally important role in production.

In 1987, 3D Systems co-founder Chuck Hull sold the first SLA-1 machine using an ultraviolet laser to cure thin layers of photoreactive resin. Additive manufacturing (AM), better known as 3D printing, was born.

Since then, 3D printing has evolved from a photopolymer-only prototyping process to a viable method for producing final parts. With a variety of materials available, including engineering plastics, superalloys such as titanium and INCONEL, maraging steels, tool steels, and stainless steels, there is nothing that 3D printers cannot produce. And while laser light is not the only technology used to solidify, sinter, melt, or otherwise combine these various materials, it is definitely the leader in additive manufacturing. nine0006

And while laser light is not the only technology used to solidify, sinter, melt, or otherwise combine these various materials, it is definitely the leader in additive manufacturing. nine0006

Note: This article is a translation.

Long live the difference?

How is a laser capable of cutting through 18 mm thick steel different from a laser used to print tooling for press brakes, assembly fixtures and robotic end effectors?

"Metal 3D printing in industry mainly uses fiber lasers with a wavelength of 1070 nanometers, i.e. in the infrared range, while for cutting, a continuous solid-state fiber or disk laser with a wavelength in the range from 1030 to 1080 nm is usually used" , explains Dave Locke, Additive Manufacturing Sales Specialist at TRUMPF Inc. nine0006

Obviously the wavelengths are similar, but this is not the case for power. The power of lasers installed in TRUMPF printers for metal processing by powder coating (PBF) does not exceed 500 W. Lasers used for cutting, on the contrary, produce up to 6 kilowatts - 12 times more. If you put that much laser power into a 3D printer, it will burn a hole in the bottom of the machine.

Lasers used for cutting, on the contrary, produce up to 6 kilowatts - 12 times more. If you put that much laser power into a 3D printer, it will burn a hole in the bottom of the machine.

However, it is important to understand that laser power is only one operating parameter of many, whether the metal is being fused or cut into pieces. In addition to power, manufacturers are also looking to provide versatility. For example, they go to great lengths to make their products "customizable" (adjustable to work with different materials) depending on the grade and thickness of the material being cut. nine0006

Fiber lasers are now able to effectively cut thicker materials that were previously reserved for CO2 lasers.

"bell-shaped Gaussian waveform, similar to that generated by fiber lasers provide very high spot densities, which is what gives them the ability to cut through thin materials,” explains Dustin Deal, product manager for Amada America's laser division. “However, this small spot size becomes less effective when you move up to 1.3 mm cm and above, and this is the reason why CO2 lasers have long offered better speeds and better edge quality on thicker materials."

“However, this small spot size becomes less effective when you move up to 1.3 mm cm and above, and this is the reason why CO2 lasers have long offered better speeds and better edge quality on thicker materials."

"But as technology evolved, Amada (and other companies) found ways to adjust the laser beam diameter and waveform to create a larger spot - shaped like a hat. That's why, and for other reasons, Amada switched completely to fiber in its standard line of laser cutting machines,” says Deal.

Does this mean that CO2 lasers are going down in history? Unlikely. "Polymers are basically transparent to shorter fiber laser wavelengths, so using them in 3D printing is like shining a flashlight through the snow," says Damien Gray, Principal Laser Optics Engineer at EOS North America Inc, Pflugerville, Texas. It goes right through. "The light from a CO2 laser, on the other hand, is strongly absorbed by most polymers." nine0006

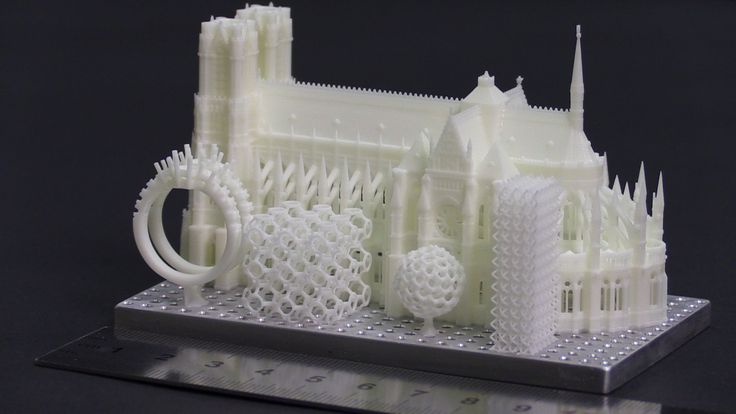

This is good news for selective laser sintering (SLS), the plastic alter ego of PBF metal printing. But there is a caveat: CO2 lasers provide lower print resolution and cannot do the fine details that fiber lasers can.

But there is a caveat: CO2 lasers provide lower print resolution and cannot do the fine details that fiber lasers can.

David Cullen, Director of Application Engineering, 3D Systems Inc. in Rock Hill, South Carolina, explained that the CO2 laser used in his company's SLS printers has a wavelength of about 10,600 nm, which is 10 times longer than a conventional fiber laser. As the wavelength increases, so does the spot size. nine0006

"You get a print resolution of 475 microns, or about half a millimeter, which is much better than a powder coated machine," he says. "On a positive note, the SLS print speed is one of the fastest in the industry."

Two spots beat one

Like laser cutting equipment manufacturers, 3D printer manufacturers use advanced optics and electronics to change laser parameters on the fly - at least in some cases. nine0006

The detail layer is printed on an SLA 3D printer from 3D Systems, the inventor of the stereolithography system.

The SLS setup just reviewed has a fixed beam size, but Cullen said stereolithography (SLA), the technology his company was founded on, now offers two spot sizes.

"By adjusting the crystal orientation in the YAG laser, we can generate a large spot to quickly scan large areas on the inside of a part, and then dynamically switch to a small spot for fine detail and contour tracking," he said. "The result is better part quality and faster assembly." nine0006

Ankit Saharan, application development and R&D manager at EOS, agreed on the importance of spot size control, but added that in the case of additive laser manufacturing, there are many more characteristics than spot size and the wavelength or type of laser used for it. creation.

"A small spot size is better than a large one because the smaller the spot size, the smaller the melt pool, which means less stress in the workpiece," Saharan said. "We start at around 45 µm on small platforms and go up to 100 µm on large platforms. " nine0006

" nine0006

However, smaller spot sizes also mean slower settling rates, so a balance must be struck between process stability and cost. In addition, there are many other factors such as layer thickness, powder grain size, powder delivery and application mechanisms, feed material reflectance, and various equipment parameters.

Saharan says, "This is a very complex scenario, and a high-quality laser, although important, is only part of what is needed to create a stable additive process." nine0006

We advise you to read articles published in our blog earlier: “Need non-standard plate bending equipment? Print it on a 3D printer! [Part 1]" and "3D Printed Press Brake Stamping Tools".

If you liked the article, please like, share it with your friends and leave comments!

Selective Laser Sintering (SLS) 3D Printing Guide

Selective Laser Sintering (SLS) 3D printing is a technology trusted by engineers and manufacturers across industries to create durable and functional models. nine0006

nine0006

In this detailed guide, we'll explain selective laser sintering technology, the different systems and materials on the market, the workflow and different applications of SLS printers, and when to choose 3D printing with this technology over others. additive and traditional manufacturing methods.

White Paper

Looking for a 3D printer to create durable, functional models? Download our white paper to learn how selective laser sintering (SLS) technology works and why it is popular in 3D printing for functional prototypes and end-use products. nine0006

Download white paper

Selective laser sintering (SLS) is an additive manufacturing technology that uses a powerful laser to sinter fine polymer powder particles into a solid structure based on a 3D model.

SLS 3D printing has been popular with engineers and manufacturers for decades. With its low model cost, high productivity, and common materials, this technology is well suited for a wide range of applications, from rapid prototyping to low-volume production, limited trial runs, or custom-made products. nine0006

nine0006

Recent advances in technology, materials and software have opened up the possibility of SLS printing to a wider range of companies. Previously, such tools were used only in a few high-tech industries.

Introducing the Fuse 1 high performance SLS 3D printer, finally available.

Webinar

Watch our product demo to learn about Fuse 1 and SLS 3D printing from Formlabs. nine0006

Watch webinar

Schematic representation of the selective laser sintering process. The SLS method uses a powerful laser to sinter small particles of polymer powder into a solid structure based on a 3D model.

-

Seal: A thin layer of powder is applied to the top of the platform inside the working chamber. The printer preheats the powder to just below the melting point of the feedstock. This allows the laser to more easily raise the temperature of certain areas of the powder bed and monitor the solidification of the model.

The laser scans the cross section of the 3D model, heating the powder to the material's melting temperature or just below. Particles are mechanically joined together to form a single solid object. The unsprayed powder supports the model during printing and eliminates the need for special support structures. The platform is then lowered into the working chamber one layer, typically 50-200 µm thick, and the process is repeated for each layer until the models are complete. nine0006

The laser scans the cross section of the 3D model, heating the powder to the material's melting temperature or just below. Particles are mechanically joined together to form a single solid object. The unsprayed powder supports the model during printing and eliminates the need for special support structures. The platform is then lowered into the working chamber one layer, typically 50-200 µm thick, and the process is repeated for each layer until the models are complete. nine0006 -

Cooling down: after printing and before post-processing, the build chamber should cool down a little in the printer body and then outside the body to ensure optimal mechanical properties of the models and avoid their deformation.

-

Postprocessing: finished models must be removed from the working chamber, separated from each other and cleaned of excess powder. The powder can be recycled and printed models can be blasted or tumbled. nine0006

To learn more about the workflow, see the SLS 3D Printing Workflow section below.

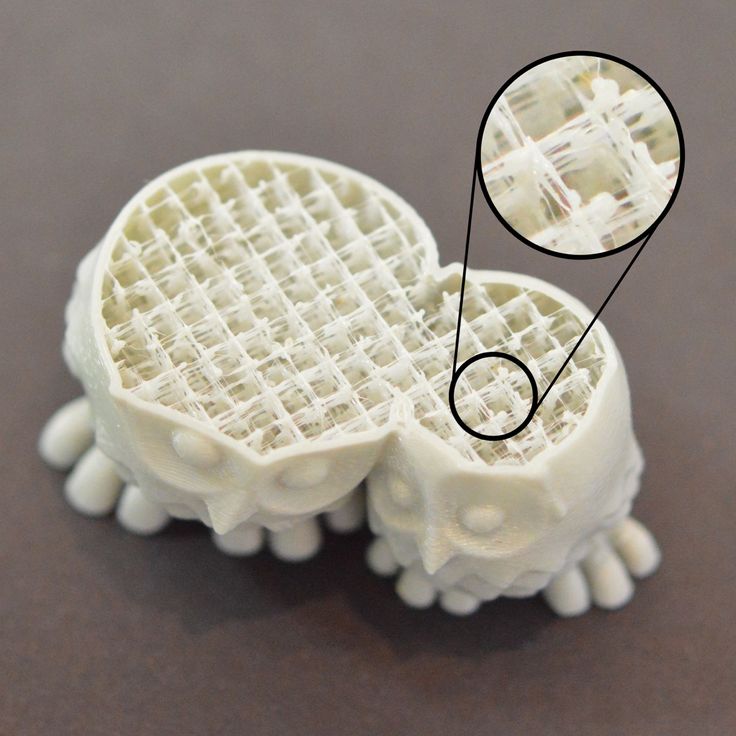

Models created using SLS technology have a slightly grainy surface, but the layer lines are almost invisible. To achieve a smooth surface, SLS models are recommended to be blasted or tumbled. This sample was printed on a Fuse 1 industrial 3D printer with SLS technology for workshops from Formlabs. nine0006

The green powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, undercuts, thin walls, and negative draft features.

Models created using SLS 3D printing have excellent mechanical properties: their strength is comparable to that of injection molded models. nine0006

Compare Selective Laser Sintering (SLS) 3D printing with other common plastic modeling technologies: Fused Deposition Modeling (FDM) and Stereolithography (SLA).

Selective Laser Sintering (SLS) is one of the first additive manufacturing technologies developed in the mid-1980s by Dr. Carl Deckard and Dr. Joe Beeman at the University of Texas at Austin. Since then, the method has been adapted to work with a variety of materials, including plastics, metals, glass, ceramics, and various powdered composite materials. Today, all of these technologies are classified as wafer synthesis, additive manufacturing processes that selectively sinter regions of a powder layer under the influence of thermal energy. nine0006

Carl Deckard and Dr. Joe Beeman at the University of Texas at Austin. Since then, the method has been adapted to work with a variety of materials, including plastics, metals, glass, ceramics, and various powdered composite materials. Today, all of these technologies are classified as wafer synthesis, additive manufacturing processes that selectively sinter regions of a powder layer under the influence of thermal energy. nine0006

The two most common substrate synthesis systems currently available are a plastic based method commonly referred to as Selective Laser Sintering (SLS) and a metal based method known as Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM). ). Until recently, both systems were very expensive and complex, which limited their use to the production of small batches of expensive models or custom-made products, such as aerospace components or medical devices. nine0006

Innovation in this area will make plastic-based SLS as affordable as other 3D printing technologies such as stereolithography (SLA) and Fused Deposition Modeling (FDM) and widely available in affordable, compact systems.

All selective laser sintering 3D printers use the process described in the previous section. Basically, such printers differ in the type of laser, the volume of printing and the complexity of the system. Different solutions are used for temperature control, powder dosing and layering in different devices. nine0006

Selective laser sintering technology requires high precision and strict control during the printing process. The temperature of the powder and (incomplete) models must be controlled within 2°C during the three stages of production: preheating, sintering and storage before extraction, in order to minimize warping, stress and thermal deformation.

For decades, selective laser sintering has been one of the most popular professional 3D printing technologies, but due to its complexity, strict requirements and high price, only service bureaus and large enterprises could use it. nine0006

Conventional industrial SLS 3D printing systems have one or more powerful lasers. An inert atmosphere (nitrogen or other gases) is needed to prevent the powder from oxidizing and breaking down during the printing process, which requires specialized air handling equipment.

An inert atmosphere (nitrogen or other gases) is needed to prevent the powder from oxidizing and breaking down during the printing process, which requires specialized air handling equipment.

These installations also require special heating, ventilation and air conditioning (HVAC) systems and industrial power supplies. In addition, even the smallest industrial installations occupy an area of at least 10 square meters. m.

Due to the high initial cost of approximately $100,000 (and much more for complete solutions), traditional industrial systems with SLS technology were out of reach for many enterprises.

As with other 3D printing technologies such as Fused Deposition Modeling (FDM) and Stereolithography (SLA), more affordable, compact systems with SLS technology have recently begun to appear on the market. However, these solutions had significant drawbacks. These include low quality models and complex manual workflows due to a lack of post-processing solutions. This severely limited their use in industrial production. nine0006

This severely limited their use in industrial production. nine0006

The Formlabs Fuse 1 printer is in a new category with these deficiencies fixed . It is the first industrial SLS 3D printer for the workshop, delivering high quality, compact size, streamlined workflow, and cost far less than traditional industrial systems of the same type.

The Fuse 1 printer does not require any special infrastructure and will easily fit into your workplace.

The Fuse 1 uses a single laser and has a smaller working chamber that requires less heat. The powder is exposed to elevated temperatures for a shorter period of time, so there is no need for inert gases and specialized ventilation equipment. Thanks to its lower power consumption, it can run on a standard AC power supply without requiring special infrastructure. nine0006

The Fuse 1 features patent pending Surface Armor technology. This creates a semi-baked shell that heats evenly around the models as they are printed. This results in excellent surface quality, stable mechanical properties, high reliability and a high material renewal rate.

In addition, to provide a compact, self-sustaining ecosystem and complete powder processing capability, Fuse 1 is complemented by the Fuse Sift Station, a separate stand-alone device for model retrieval, recovery, storage and powder mixing. nine0006

Overall, the Fuse 1 industrial 3D printer with SLS for workshops has slightly less print volume than traditional entry-level SLS systems, but is smaller, easier to work with and less expensive.

| Fuse 1 Industrial SLS Workshop Printer | Conventional SLS Industrial 3D Printers | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| from 18,500 US dollars | 100 000 - 500,000 US dollars and more than | ||||||||

| Press volume | to 165 x 165 x 300 mm | 9 Benefits | Availability High quality models High performance Simplified workflow Compact dimensions Low maintenance | High print volume High quality models High performance Many material options | |||||

| Disadvantages | Less print volume Limited material options | Expensive equipment Big sizes Infrastructure Requirements Large amount of maintenance Special Operator Required |

The most common selective laser sintering (SLS) material is nylon. It is a high performance engineering thermoplastic for both functional prototyping and end-use fabrication. Nylon is ideal for the production of complex knots and strong models with high environmental resistance. nine0006

It is a high performance engineering thermoplastic for both functional prototyping and end-use fabrication. Nylon is ideal for the production of complex knots and strong models with high environmental resistance. nine0006

3D printed SLS nylon for strength, rigidity and durability. The final models are impact-resistant and highly wear-resistant. Nylon is resistant to UV, light, heat, moisture, solvents, temperature and water. Nylon models printed on a 3D printer are also biocompatible and do not cause allergic reactions. This means that they can be worn and used safely in many situations.

Nylon is ideal for a range of functional applications, from consumer product design to healthcare applications. nine0006

Nylon is a synthetic thermoplastic polymer from the polyamide family. It is available in several versions, each designed to print different products. Nylon 12 Powder has a wide range of applications and is a general purpose, general purpose SLS 3D printing powder. Nylon 12 GF Powder is a composite material with a high fiber content, increased stiffness and heat resistance for difficult industrial conditions. Nylon 11 Powder helps fill a gap in prototyping and end-use applications where increased ductility, impact resistance and the ability to withstand wear without brittle fracture are required. nine0006

Nylon 11 Powder helps fill a gap in prototyping and end-use applications where increased ductility, impact resistance and the ability to withstand wear without brittle fracture are required. nine0006

- Impact proof prototypes, fixtures and fittings

- Thin-walled pipes and bodies

- Rivets, fasteners and latches

- Orthopedic products and prostheses*

- High Performance Prototyping

- Small batch production

- One-piece clamping and holding fixtures and tooling

- Conventional SLS Models

- Heavy-duty clamping and fastening fixtures and spare parts

- Continuous models

- Threads and sockets

- High temperature models

* Material properties may vary depending on model design and manufacturing method. It is the manufacturer's responsibility to confirm the suitability of printed models for their intended use.

| 40% | ||||||

| Extension when rupture, Z (%) | 6% | 3% | ||||

|---|---|---|---|---|---|---|

| DISCOUSE | 932 J/m | J/m32 J/m | 32 J/m | 32 J/m | 71 J/m | |

Bending temperature under load at 1. 8 MPa (°C) 8 MPa (°C) | 87 °C | 113 °C | 46 °C | 170°C | 171°C | 182 °C |

Nylon 12 Powder and Nylon 11 Powder are one-component powders, but some SLS 3D printers can also use two-component powders, such as coated powders or powder blends.

Nylon 12 GF Powder is a composite material with a high fiberglass content, while other nylon composites with aluminide, carbon or glass are designed to increase the strength, stiffness or flexibility of models. In such two-component powders, only the component with the lower glass transition point is sintered, which binds both components. nine0006

SLS 3D printing accelerates innovation and helps businesses in a wide range of industries such as engineering, manufacturing and healthcare.

Manage the entire product development process, from iteration of first concept design to production of ready-to-use products:

- Rapid Prototyping

- Product mockups for user feedback

- Functional Prototyping

- Functional testing of products under severe conditions (e.

g. piping, brackets)

g. piping, brackets)

Manage your supply chain and respond quickly to changing needs:

- End-Use Manufacturing

- Small batch production

- Mass production of new customized consumer products

- Spare parts manufacturing, supply chain sustainability

- Durable, durable clamping and fastening devices (such as clamps and clamps) and accessories

- Custom manufacture of automotive, motorcycle and marine equipment parts, and restock military items on demand

Self-manufacturing of ready-to-use medical devices, taking into account the individual characteristics of patients:

- Medical device prototyping

- Prostheses and orthotics (e.g. prosthetic limbs and orthoses)

- Surgical models and instruments

- End use products (nylon 12 biocompatible and sterilizable*)

* Material properties may vary depending on model design and production method. It is the manufacturer's responsibility to confirm the suitability of printed models for their intended use.

Use any CAD software or 3D scan data to design the model and export it to a 3D printable format (STL or OBJ) file. All printers with SLS technology use software that allows you to adjust settings, position models, estimate print times, and layer your digital model. Once set up, the model preparation software sends commands to the printer via a wireless or cable connection. nine0006

The Fuse 1 uses PreForm print preparation software (free download). It allows you to easily duplicate and place multiple models on a 3D grid to maximize your print volume. PreForm automatically suggests the optimal orientation and position of models with the ability to make manual changes.

The workflow for preparing the printer varies from system to system. Most traditional SLS systems require extensive training, tools, and physical actions to prepare and maintain them. nine0006

Fuse 1 redefines the SLS workflow, making it simple and efficient, as well as providing trouble-free printing and complete powder handling thanks to modular components.

The Fuse 1 can be easily loaded with powder using a special cartridge.

The Fuse 1 uses a detachable build chamber so you can start a new print while the previous build chamber is still cooling.

Once all pre-checks have been completed, the machine is ready to print. Depending on the size and complexity of the 3D models, as well as their density, printing using SLS technology can take from several hours to several days. nine0006

When printing is completed, the build chamber in the housing should cool down a bit before proceeding with the next step. To start the next print, you can remove the build chamber and insert a new one. Before post-processing, the working chamber must cool down to ensure optimal mechanical properties of the models and avoid their deformation. This can take up to half of the total print time.

Fuse 1 is equipped with a touch screen that allows you to see in real time how each new layer is formed during the printing process. This camera image can also be transferred to a computer using PreForm to monitor the print without leaving the workplace. nine0006

nine0006

Compared to other 3D printing processes, post-processing of SLS-printed models requires minimal time and effort. With no supporting structures, it is easy to scale and provides consistent results across batches of models.

After printing is complete, remove the finished models from the build chamber, separate them and clean them of excess powder. As a rule, this is done manually at the cleaning station using compressed air or a jet apparatus. nine0006

The excess powder left after the creation of the model is filtered to remove large particles from it. After that, it can be recycled. Under the influence of high temperature, the properties of green powder deteriorate slightly, so for subsequent printing it must be mixed with new material. Due to the possibility of reusing materials, SLS technology produces a minimum amount of waste.

SLS technology typically uses separate devices for powder recovery, storage and mixing. The Fuse 1 workflow uses a single Fuse Sift to retrieve patterns and greens, store, dispense, and mix material streams. nine0006

nine0006

Fuse Sift completes the Fuse 1 SLS printing workflow. This system is used for safe and efficient model retrieval and powder recycling.

Fuse Sift automatically doses and mixes used and new powder, reducing waste and controlling powder delivery.

After the powder has been sieved, the 3D models printed using selective laser sintering technology are ready for use. However, there are a few more post-processing steps you can perform on these models. nine0006

By default, the surface of 3D models created using SLS technology remains grainy. To achieve a smooth surface, Formlabs recommends blasting or tumbling models made using this method. Models can be spray painted, lacquered, electroplated or otherwise to achieve the desired color, surface quality and properties such as water resistance (special coating) and electrical conductivity (electrolytic coating). Models created with SLS Formlabs are dark in color and therefore not well suited for staining. nine0006

Immersion printed SLS model from Partial Hand Solutions.

SLS models can be electroplated for a metal-like surface.

Selective laser sintering is preferred by engineers and fabricators for its wide design options, high productivity, low model cost, and proven end-use materials. nine0006

Most additive manufacturing processes such as stereolithography (SLA) and deposition modeling (FDM) require specialized support structures to fabricate overhang structures.

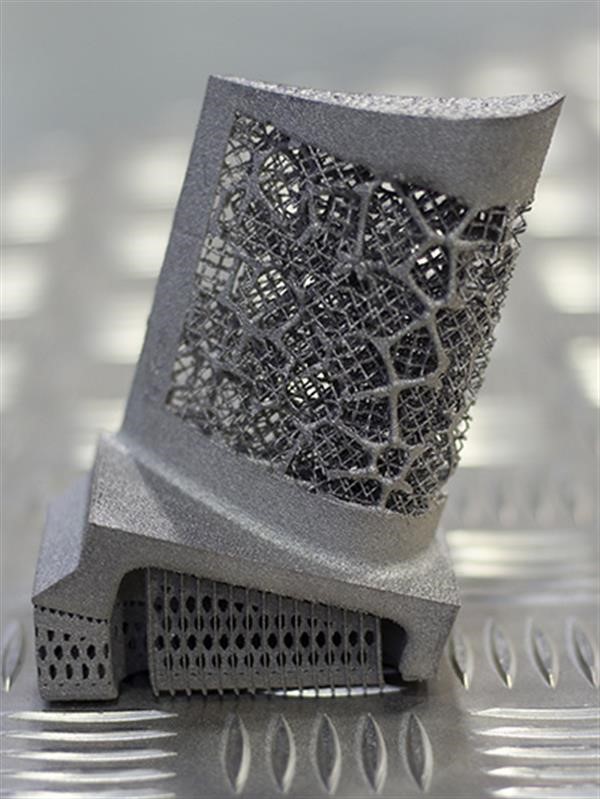

Selective laser sintering does not require support structures because the unsintered powder surrounds the model during printing. SLS printing makes it easy to create overhangs, intricate geometries, interconnecting parts, internal channels and other intricate details. nine0006

Intricately patterned arm splint for weight reduction.

Engineers typically design models to meet the capabilities of the final manufacturing process, also known as design-to-technology (DFM). When additive manufacturing is only used for prototyping, it comes down to creating models and designs that can be replicated in the manufacturing process using traditional tools.

Selective laser sintering is emerging as a viable rapid manufacturing method and its application area continues to expand, so it can open up new possibilities in design and construction. 3D printers with SLS technology can create complex geometries that are impossible or incredibly expensive to manufacture using traditional processes. SLS technology also allows design professionals to combine complex assemblies into a single model that would normally require multiple models to be created. This helps avoid the problem of loose connections and saves assembly time. nine0006

Selective laser sintering can unleash the potential of generative design, as it allows the creation of lightweight models that use complex lattice structures that cannot be fabricated by traditional methods.

Selective laser sintering is the fastest additive manufacturing technology for making functional, durable prototypes and end-use products. Lasers used for powder sintering have much faster scanning speeds and are more accurate than the layering methods used in other processes such as Industrial Fused Deposition Modeling (FDM). nine0006

nine0006

To maximize the available print volume in each printer, multiple models can be placed side by side. Operators can use the software to optimize print volume and maximize productivity by leaving only minimal clearance between models.

SLS technology allows operators to fill the build chamber with as many models as possible, as it allows them to be printed without supporting structures, saving time in post-processing. nine0006

SLS 3D printing requires the right materials for functionality and versatility. Nylon and its composites are proven, high quality thermoplastic materials. Laser-sintered nylon models have close to 100% density and mechanical properties that are comparable to products made using traditional manufacturing methods such as injection molding.

Screwdriver printed in Nylon 12 Powder. After a simple post-processing, nylon models have a smooth, professional quality surface. nine0006

SLS Printable Nylon is an excellent replacement for conventional injection molded plastics. The latches and other mechanical connections produced from it are superior to products created using any other additive manufacturing technology. It is ideal for making functional plastic parts that will work and not break down over time like products created through other additive manufacturing methods.

The latches and other mechanical connections produced from it are superior to products created using any other additive manufacturing technology. It is ideal for making functional plastic parts that will work and not break down over time like products created through other additive manufacturing methods.

When calculating the cost of one model, it is usually necessary to take into account the cost of ownership of equipment, material costs and labor costs:

-

Equipment cost of ownership: The more models a printer can produce over its lifetime, the lower the cost per model. Therefore, higher performance results in a lower cost of ownership per model. With high laser scanning speeds, the ability to produce multiple models at once to maximize the working volume, and a simple post-processing process, SLS 3D printing guarantees the highest productivity of any additive manufacturing method. nine0006

-

Material: Most 3D printing technologies use proprietary materials, while nylon is a common thermoplastic that is produced in large quantities for industrial applications.

This makes it one of the most inexpensive raw materials for additive manufacturing. SLS 3D printing requires no support structures and allows you to print with recycled powder with minimal waste. nine0006

This makes it one of the most inexpensive raw materials for additive manufacturing. SLS 3D printing requires no support structures and allows you to print with recycled powder with minimal waste. nine0006 -

Labor: Labor is a disadvantage of many 3D printing solutions. Work processes in most technologies are quite laborious and difficult to automate, which can significantly affect the cost of one model. Easy post-processing with SLS printing reduces manual labor and allows for easy scalability.

A 3D printer with SLS technology is a significant investment initially, but this investment often pays off even faster than buying smaller devices. SLS for workshop technology significantly reduces initial acquisition costs and also reduces model costs in most applications. nine0006

If 3D printing is rarely used in your business, it is recommended to use the services of third-party service bureaus. But in this case, the cash costs will be higher and you will have to wait longer for the order to be completed. One of the main advantages of 3D printing is its speed compared to traditional production methods. But this advantage loses its value when it takes up to several weeks for a third-party company to deliver a model.

One of the main advantages of 3D printing is its speed compared to traditional production methods. But this advantage loses its value when it takes up to several weeks for a third-party company to deliver a model.

REEKON Tools