Supreme 3d print

Supreme best 3D printing files・Cults

Kaws Companion x Flayed Open

€9.43

BART SUPREME

€1.32

Suport para Creme de Pele (cream holder)

€0.61

Bearbrick Solid

€4.62

Super Leon Professional Xmas Bullet

€7.54

Super Leon Professional Christmas Deer

€7.54

Kaws Final Days

€4.72

Kaws Santa Claus

€6.60

Kaws BFF x Dior

€7.07

Kaws BFF x Dior

€7.07

Sport Model Girl Supreme

€1

Kaws The Promise

€8. 49

Kaws Holiday Changbai Mountain

€9.90

Kaws The Promise

€9.90

Kaws Chicago Bulls Along The Way

€7.54

Kaws CupHead x MugMan

€8.49

Kaws MugMan

€5.66

Kaws CupHead

€5.66

G1 transformers Omega Supreme Large shield

€2.02

Kaws Space

€6.60

Kaws Companion Funko Pop

€5.66

Supreme Key Chain

€2.09

Cutter SUPREME

€0.94

Titan Class Ark Conversion Kit Pack

Free

Horus

€9. 43

43

Obey Face Logo Keychain

€1.89

Supreme Logo

Free

Kaws 8 bits

€6.60

Kaws x The Cat in the Hat x Thing 1 Thing 2

€10.37

Kaws Thing 1 Thing 2

€5.66

Kaws x The Cat in the Hat

€7.54

Kaws x Supreme 2

€5.66

Kaws x Supreme

€5.66

Kaws Companion x Off White

€6.60

Mr. Bone x Pupu Aliens

€7.07

Mr. Bone Skate Kid

€5.66

nike logo

€0. 50

50

Kaws Ronald McDonald

€7.54

Dr. Strange Cape (Lego Compatible)

€20

Peeing Balloon Dog

€4.48

Stretching Balloon Dog

€4.48

Downward Balloon Dog

€4.48

Humpek Balloon Dog Flayed Open

€5.66

LIBERTYDEAD ART TOY - GREEN

€6.13

THE KING OF SAUNA ART TOY

€6.13

BEARBRICK (HYPE) -COMMERCIAL LICENSE-.

€50

CASINODEAD ART TOY

€5.66

SWAGLIM ART TOY

€5.66

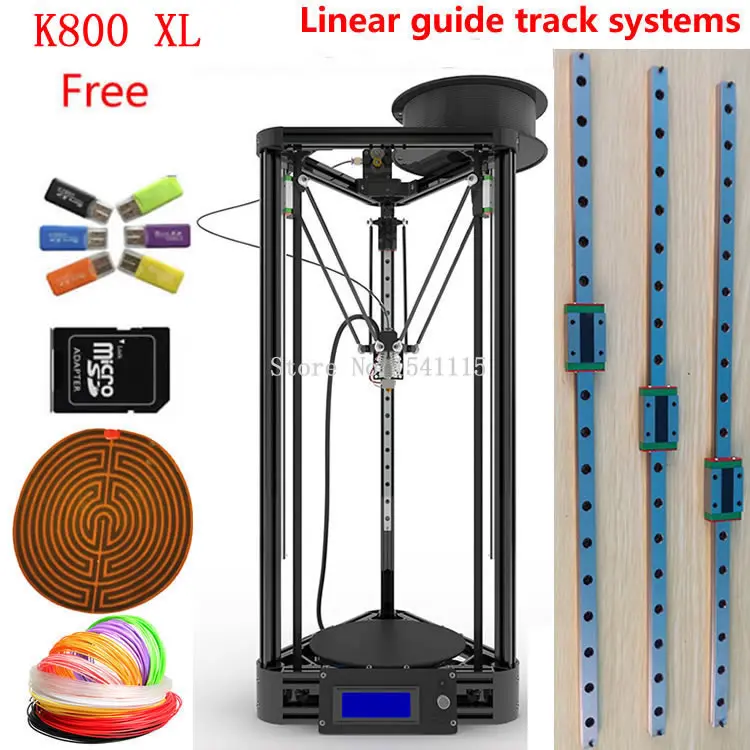

▷ supreme print 3d models 【 STLFinder 】

Dr Strange Supreme - What If? - low poly 3d print

cults3d

3d model dr strange supreme low polygons to print Simil Marvel Movie Collection

Supreme Master Ching Hai 3D Printable 3D print model

cgtrader

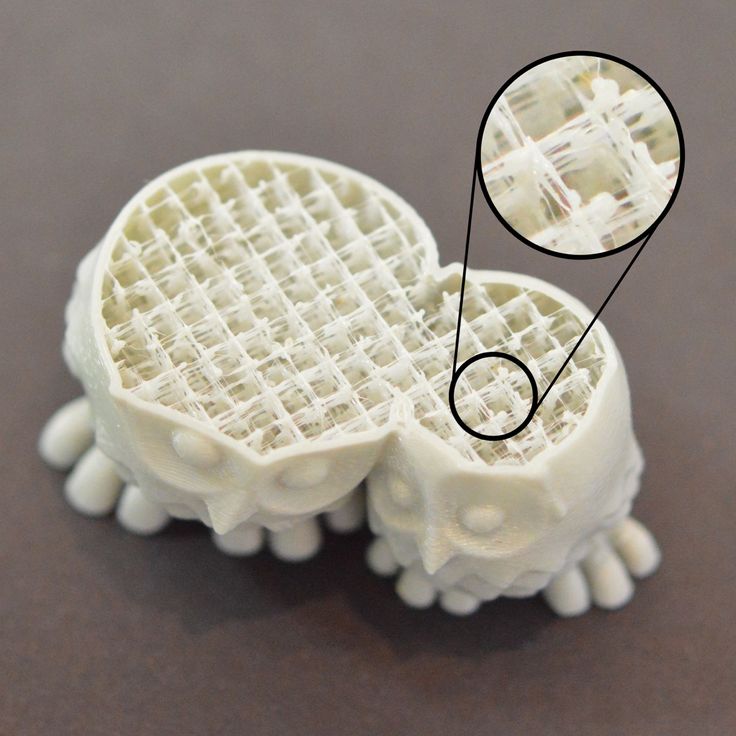

Personally, I prefer to print it without supports since it worked even on a 101 Hero without them but if you have a fancy printer that allows you to remove supports cleanly then supports will make the print look flawless. It comes with a high poly...

It comes with a high poly...

Captain America Hail Hydra Supreme Shield - Marvel Cosplay 3D print model

cults3d

Amazon's Choice Face Mask 50Pcs: https://amzn.to/3fhAWj2 Best Choise 3D Print Paint: https://amzn.to/2AwBSkl Best Precision Knife: https://amzn.to/2yW6DPu BEST 3D PRINTER UNDER $200: https://amzn.to/2XFVt9M BEST 3D PRINTER UNDER $300:...

Supreme Cameo Free 3D print model

cgtrader

Youll be the Supreme Leader of the pack with this charmant cameo. ...

3d Printed Supreme Block

pinshape

look in your printing software its a little block that says supreme and has stars around the edges of the box. ...this was made with https://www.tinkercad.com/#/da...

...this was made with https://www.tinkercad.com/#/da...

Andy Serkis - Supreme Leader Snoke - Star Wars 3D print model

cgtrader

A bust based on Star Wars force awakens and the last jedi character Supreme Leader Snoke, interpreted by Andy Serkis. Contains several file formats and modes. Includes: Source .Ztl for zbrush with all subtools (hair, eyes, beard, clothes) head...

supreme louis vuitton case prints

thingiverse

al are 5mm thick and printed in pla look good at you setting first! ...not an easy print you have 3 case prints with backplate with incut case print needed them for a project enjoy

supreme tag

thingiverse

Supreme tag for 3D printing

supreme tag

thingiverse

In work

recommended printing - 0. 15mm, Prusament PLA

15mm, Prusament PLA

Supreme Picatinny

thingiverse

print in 2 tone I think you have to print it scaled to 98% since it is a bit loose but I have only tried it 100%

Supreme logo

thingiverse

Believe it or not, this Supreme logo is free. ...Print Settings Printer Brand: RepRap Printer: Discovery 200 Rafts: No Supports: No Notes: Print it in red for best results

Supreme keychain

thingiverse

hi if you use this programme ( https://www. prusaprinters.org/color-print/ ) put color change 3.00 or higher becaus bottom piece (extrusion1) end then

prusaprinters.org/color-print/ ) put color change 3.00 or higher becaus bottom piece (extrusion1) end then

Supreme Keychain

thingiverse

This is a very easy and simple design to print. It is accurate and fits on zippers and keyrings. The printing time is fast and it is very easy to make. It works on any 3D printer, and is very durable. ... The only work that would need to be done is...

Supreme Brick

thingiverse

Why pay $50 for a brick that says supreme when you can print one? Also, the brick is the same size as the real one. ...Print Settings Printer: Prusa i3 mk2 Rafts: Doesn't Matter Supports: Doesn't Matter Resolution: Images shown are 0. 35 mm layer...

35 mm layer...

Supreme Hat

thingiverse

I made this on Autodesk Inventor. ...This is one of my first creations. I will make more at some point. Have fun printing this and comment if you have any questions!

MORPHEUS SUPREME

thingiverse

This is MORPHEUS supreme its the one of my first that has the name printed in the blade from the supreme range would be awesome for cosplay or for a show peice if you do like this as much as me and you 3d print it id love to see a pic inbox is always...

Oreo Supreme Cookies - 3D Printed Master Silicone Molding

pinshape

3D Printed Master Silicone Molding for make Supreme Oreo cookies

1980 Oldsmobile Cutlass Supreme

cults3d

Cutlass Supreme that can be printed in multiple scales.

supreme gold bar

thingiverse

looks great, have fun printing it, I printed it at 150% and .15mm layer height, 15% infill worked great!

A proud Supreme Court

cults3d

I sliced up the original and colored the columns for full color 3D printing. ...3D print some equality!

supreme box logo

myminifactory

for all you hypebeasts out there. ...suggested that you print vertically and not flat due to printers rounding the corners on the letters. ...support needed on vertical prints.

...support needed on vertical prints.

Supreme Box Logo Keychain

thingiverse

Print at .2 mm layer heights, 20% infill Feel Free To tip

Send Nudes / Supreme style

thingiverse

You can print in 2 different color, the background in red and the text in white

Supreme box logo

prusaprinters

Fun print, letters and background printed separately so you can try other colorsThis example is printed at 0. 15mm layer height, 15% infillNo support or brim neededIf necessary use a drop of super glue to secure lettersDon't forget to print two letter...

15mm layer height, 15% infillNo support or brim neededIf necessary use a drop of super glue to secure lettersDon't forget to print two letter...

Supreme iPhone 6 case

thingiverse

5/15/17 - added SupremeIphone6CaseV2SUPPORT, a tilted version of V2 with support to fit smaller print beds 5/15/17 - added SupremeIphone6CaseV2, flipped text so it looks normal from outside view 5/14/17 - added SupremeIphone6CaseSUPPORT, a tilted...

CherryCraft Supreme SharkFin

thingiverse

A SharkFin for CherryCraft Supreme. ...I printed this with support on a highly cutsomized AnycubicI3 Mega with TitanAero. ...I used the Sainsmart TPU for it.

...I used the Sainsmart TPU for it.

Supreme Commander Cybran ACU

thingiverse

Supreme Commander Cybran ACU model easy to assemble no articulation designed to be 15-20 cm tall and printed with 0.3 nozzle

Supreme Logo Connected

thingiverse

I made this design for one of my friends who wanted the Supreme logo, but I couldn't print the original file because the letters weren't connected.

Supreme Pop Socket

thingiverse

Supreme Pop Socket Cover. ... Print the pop socket base with supports touching the build plate. ... Use super glue or model glue to glue all the pieces together.

... Print the pop socket base with supports touching the build plate. ... Use super glue or model glue to glue all the pieces together.

OK supreme logo/keyring

thingiverse

Centre detail from OK motorcycle logo, left off smaller text to to enable printing . ... may do another with all detail as a plaque?

KNF pumps in 3D sandblast printing

Examination

Smart Slab developed in an innovative architectural project by ETH Zurich researchers

ETH Zurich researchers create an intelligent lung design as part of the Smart Slab architectural project concrete ceiling. A Swiss university applies an innovative formwork method for floor production using a 3D sandblast printer manufactured by Voxeljet AG, Friedberg (Germany) and equipped with pumps manufactured by KNF. nine0003

nine0003

Benefits of Digital Manufacturing

Smart Slab combines the structural strength of concrete with the design flexibility of 3D printing. This digital fabrication method is much more cost-effective and environmentally friendly than conventional methods used in construction to create rigid ceilings. The thickness of the Smart Slab at its thinnest point is only 20 millimeters without loss of strength. This means that its weight is less than 50% of a normal ceiling slab, i.e. less material is required to manufacture, which not only reduces production costs, but also reduces the carbon footprint. nine0003

Origins of the project

The Smart Slab ceiling slab was developed at ETH Zurich under the direction of Benjamin Dillenburger, Associate Professor at the Department of Digital Building Technologies. Representing one of the main elements of the DFAB House residential block, this ceiling was installed in the summer of 2018 in Empa and Eawag's research and innovation building NEST in Dübendorf. The area of this eleven-segment concrete ceiling, which connects the foundation to the two-story wooden structure above it, is 80m2 and weighs 15 tons. nineless concrete is better matrices. They used a large format sandblast 3D printer made by Voxeljet. This printer is equipped with two KNF diaphragm fluid pumps, one of which supplies cold binder (NF60KTDC) and the other removes excess raw material (NF60KTDC). Formwork manufacturing is the most time-consuming step in the creation of concrete structures, especially non-standard components. nine0003

The area of this eleven-segment concrete ceiling, which connects the foundation to the two-story wooden structure above it, is 80m2 and weighs 15 tons. nineless concrete is better matrices. They used a large format sandblast 3D printer made by Voxeljet. This printer is equipped with two KNF diaphragm fluid pumps, one of which supplies cold binder (NF60KTDC) and the other removes excess raw material (NF60KTDC). Formwork manufacturing is the most time-consuming step in the creation of concrete structures, especially non-standard components. nine0003

One of the eleven structural segments of the Smart Slab is gently lowered and placed in place

One-touch fabrication

With the completion of the computer planning, the industrial partners of the Smart Slab researchers got to work. One of them made the formwork using high-resolution sandblast pressure 3D printing, and the other used a CNC laser to create the wooden formwork. The prefabricated formwork gives the desired shape to the top side of the Smart Slab and provides cavities to reduce material consumption and weight, as well as space for electrical cables. These two types of formwork were then delivered to the company's third partner for concrete pouring. The company first poured fiber-reinforced concrete into a 3D sandblasted injection mold to form the bottom surface of the finely ribbed concrete slab, and then poured concrete into the rest of the Smart Slab slab using wood molds. nine0003

These two types of formwork were then delivered to the company's third partner for concrete pouring. The company first poured fiber-reinforced concrete into a 3D sandblasted injection mold to form the bottom surface of the finely ribbed concrete slab, and then poured concrete into the rest of the Smart Slab slab using wood molds. nine0003

Pre-planning yielded impressive results

After two weeks of concrete curing, eleven individual concrete segments were ready for transport to DFAB House. Detailed planning and advance preparation of the manufacturing process, as well as the selection of experienced partners and reliable technologies, ensured the successful completion of the project without delay. “It was amazing to see on site how our flawlessly crafted elements matched each other and the existing DFAB House components,” says Mr. Dillenburger. “This would not have been possible without the unique interdisciplinary collaboration with our partners.” nine0003

We support life in space

KNF pumps are used for air recirculation on the ISS

Read more

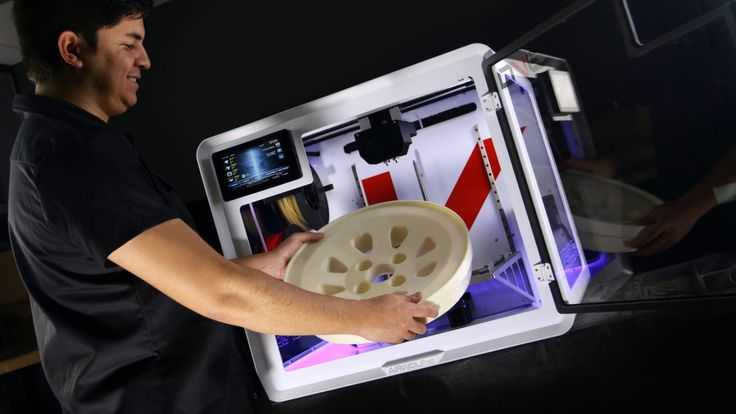

School 3D printed the classroom into a real-life workplace simulator

Staten Island Tech High School has 900 budding engineering students.

The task of school is to create all conditions for study, which will be as close as possible to the conditions of the professional engineering world, as well as to enable all students to translate their projects into physical prototypes. nine0003

Solution is the use of low cost 3D printing to engage students, teach them how to design and help them improve their skills in this area.

Outcomes:

- Students begin to delve more deeply into the meaning of their design decisions

- Having achieved high results in school, students become interested in deepening knowledge and strive to achieve more after graduation

- Students can better prepare for higher education education, because during their time at school they acquire a powerful portfolio that can be submitted to the university admissions committee. nine0003

- Students are exposed early to advanced engineering technology that they will use later in their real work.

- Staten Island Tech maximizes resources by using the fastest, most affordable way to create physical 3D objects from computer-aided design (CAD) models.

Staten Island Tech School (STS) is a New York City public school for aspiring engineers offering 900 students a challenging college prep curriculum and an impressive body of knowledge that they can use in their future careers. After passing a challenging entrance exam, students complete a required curriculum that includes technical drawing, electronics, computer-aided design, computer science, networking, and the humanities. Graduation scores approach 100 percent, so students after graduation go to Ivy League universities (Harvard, Yale, Princeton, etc.), military academies and elite technical universities. From the moment students enter the corridors of the HTSSA, they begin to "speak the language of engineering." nine0003

Tasks. Recreating the conditions of professional engineering.

As engineering constantly competes for the best products, computer-aided design coordinator Frank Mazza brings that spirit to his classroom, bringing the learning process closer to the tasks of actual design departments in existing companies.

"It's a simulated workplace, and my students are designers!" he says. "I give students design problems and they come up with solutions. It could be a simple jewelry box, a complicated toy, a building or a piece of machinery made of gears, pistons and threads. We never do the same thing twice." nine0003

The mission of WTSSA is to fill a dynamic learning environment with technologies that are at the forefront of engineering. Like professional engineers, Staten Island Tech students start with a concept, work their way up to a 2D sketch and then to a 3D model.

Just as design doesn't end with a 3D CAD model in professional design departments, it doesn't end with a 3D model in the ETH classroom either. Engineers turn their ideas into prototypes, which allows them to get an idea of how the design will look in the real world, as well as to functionally test them. To prepare students for these processes, WTSSA needed a way to quickly and inexpensively build prototypes. nine0003

Solution. 3D printing

3D printing

WTShSA, like many other companies, has discovered a cost-effective way to quickly turn designs into physical objects using 3D printing.

A 3D printer is a device for outputting (printing) a three-dimensional model, which works similarly to a 2D printer (a device for outputting words and pictures on a computer screen). The difference is that a 3D printer creates 3D models and prototypes from a composite material, layer by layer building a physical object from a digital 3D model. 3D printing is gaining popularity as progress follows the pattern of 2D printers: hardware capabilities are rising and 3D printer prices are dropping. nine0003

The introduction of 3D printing to the WTSCA happened in 2005 when Frank Mazza, a professional engineer, saw a 3D printer in professional magazines. "I thought I could use 3D printing technology in the classroom." Low operating costs, material savings and minimal post-processing were key decision criteria. After researching all standard 3D printing technologies, the school chose the ZPrinter 310 from 3D Systems, the manufacturer of the fastest 3D printers with the lowest operating costs. nine0003

nine0003

Results. Portfolio, pride and in-depth understanding of the issue.

Today, the 3D printer is the center of creativity. Mr. Mazza presses the print button at the end of the school day, and the next morning he retrieves the completed objects from the printer. The best of them are on display, as well as drawings made with AutoCAD can fall into the category of the best. Mazza also uses the printer to create prototypes that help explain design problems and nuances to students. This gives students the opportunity to improve their projects according to the tasks set. nine0003

According to Mr. Mazz, 3D printing enriches engineering education in a number of ways. First, 3D printing gives students an impressive portfolio to present to college and university admissions. Secondly, it introduces them to advanced equipment, and this is the most important thing in engineering, as it is quickly becoming the standard for competitive companies. “Perhaps most importantly, 3D printing gives students the opportunity to better understand their models, designs, designs,” he says. “What looks good on a computer screen may not always be exactly the same in the real world. Therefore, 3D printing enhances and strengthens their conceptual design skills, including in computer-aided design systems. 3D printing is a very valuable achievement in terms of learning. Holding the object in your hands at the end of the design process - especially for engineering oriented students, is a kind of anchor in the physical world. The pride of HTSSA students is the demonstration of their achievements in the field of design, this inspires them to constantly improve their work.” nine0003

“What looks good on a computer screen may not always be exactly the same in the real world. Therefore, 3D printing enhances and strengthens their conceptual design skills, including in computer-aided design systems. 3D printing is a very valuable achievement in terms of learning. Holding the object in your hands at the end of the design process - especially for engineering oriented students, is a kind of anchor in the physical world. The pride of HTSSA students is the demonstration of their achievements in the field of design, this inspires them to constantly improve their work.” nine0003

WTShSA students expect that the scope of 3D printing in education will expand in the future. For example, science classes will use it to print microscopic objects such as DNA molecules. In electronics, students will use it to better understand the design of electrical objects. The two sectors, public and private, will also interact, such as printing building models for nearby architectural firms.

"It's a distinct advantage for our students to be able to use 3D printing technology, which is important and in demand in the industry," says Mr.