3D printer spain

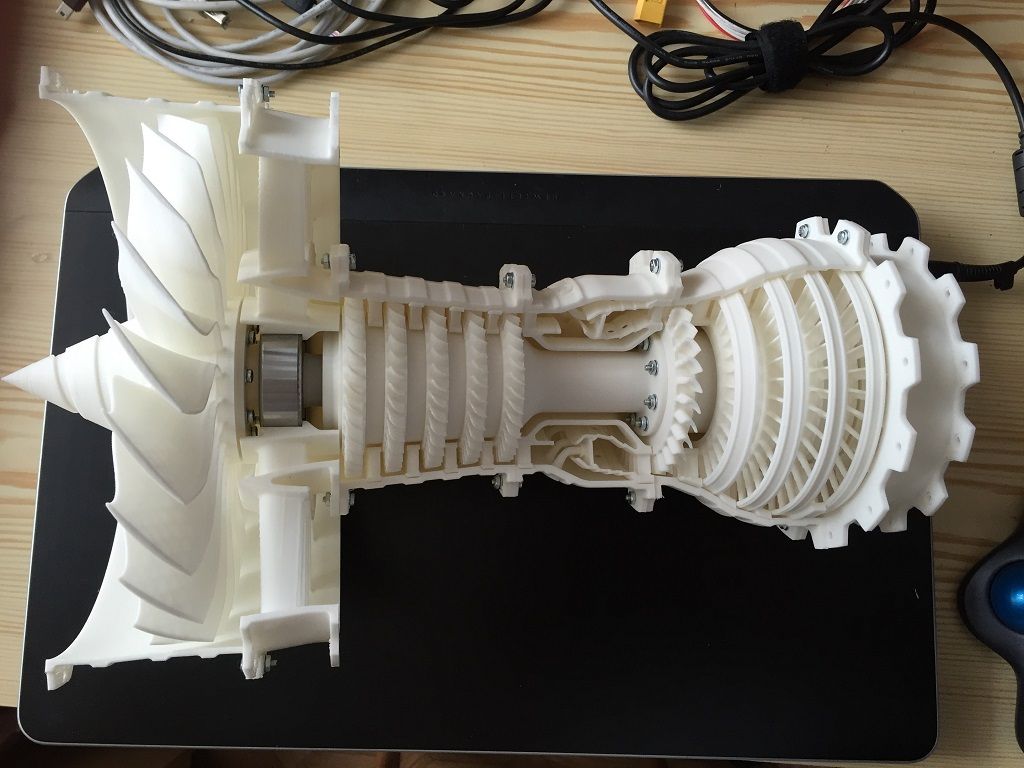

3D printing in Engineering Industry. Case studies

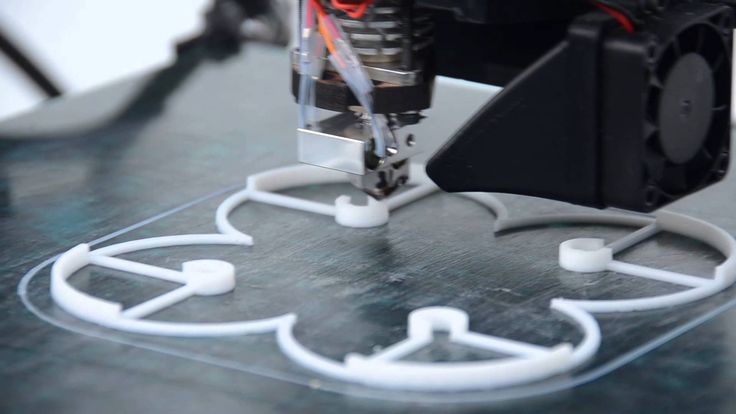

When engineering new products, 3D printing lets you test functional prototypes and finding solutions as you go, saving time and costs at every stage of product development.

Create low-volume batches of end-use parts with industrial-grade materials that closely match common injection-molded plastics.

Reduce costs by verifying a design before investing in molds and tooling that can become useless.

Turn conceptual ideas into functional prototypes in a matter of days and rapidly iterate designs in-house with no cost penalties.

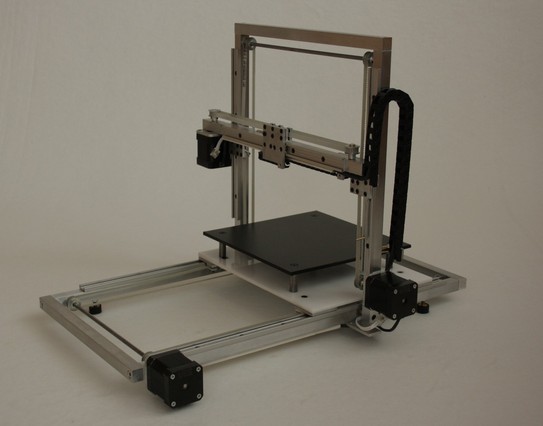

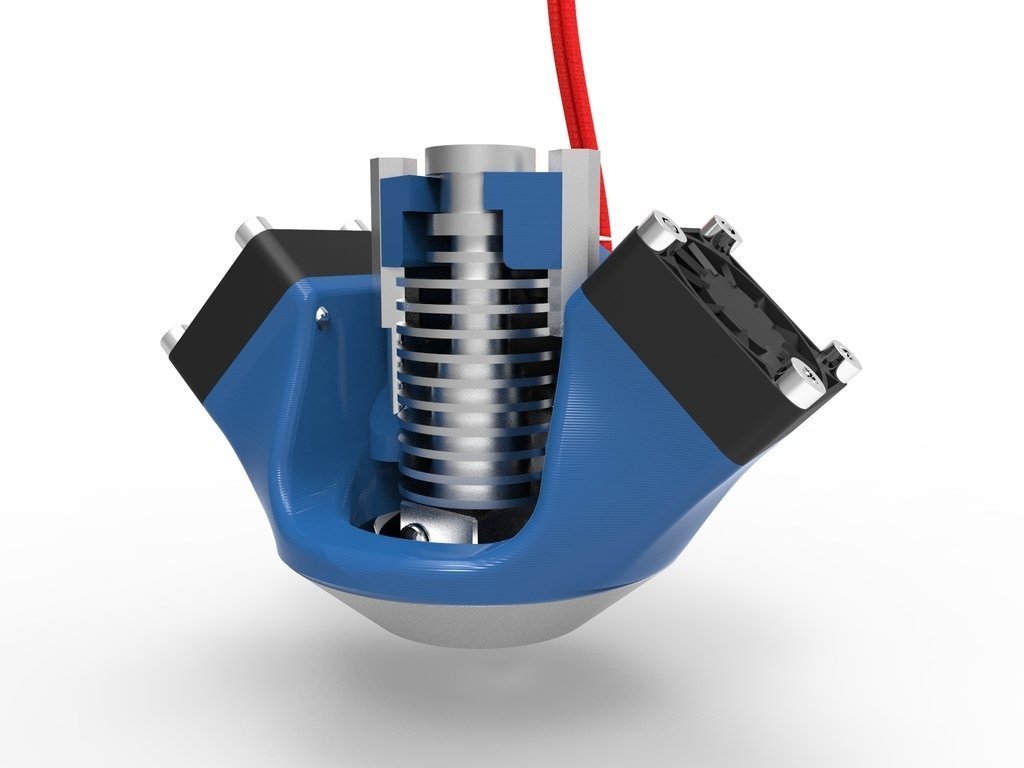

IDEX technology: Same investment, double productivity

IDEX technology is the only extrusion system capable of printing with two heads independently. This system allows enabling Duplication and Mirror printing modes capable of printing two pieces at a time. Double printing capacity means double productivity, all with the same investment. Unlike any other dual extrusion machines on the market, when you acquire a Sigma or Sigmax machine, you get one printer but you double your productivity. All thanks to the IDEX technology.

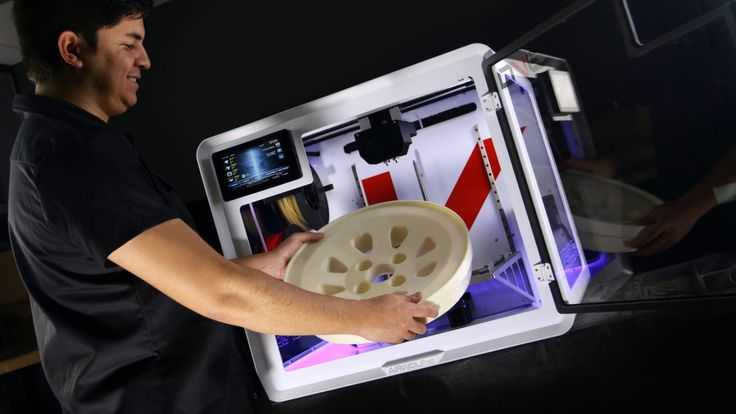

Big volume with the biggest printing surface

The BCN3D Epsilon offers a large print volume of 420x300x400mm. The main advantage of this feature is its proportions, offering the largest printing surface on the market with an incredible height of 400mm. This allows to print the vast majority of parts that are manufactured.

High-performance materials for professional prototyping

BCN3D Filaments are manufactured by BASF and Mitsubishi Chemical, two of the most renowned chemical corporations in the world. Their reputation in the manipulation and production of plastic materials, along with the advanced plastic processing techniques, allows BCN3D to provide the filaments with more repeatability of the market. Each spool will consistently show the same quality and will always offer the same results.

Use cases in Engineering Industry

Iterative design with 3D printing gives TwoNav’s GPS devices steadfast reliability

Outdoor equipment manufacturer TwoNav is experiencing a more flexible, iterative design process, a quicker time to market, and a reduction in expenses since incorporating 3D printing. The company is not only using BCN3D’s technology for designing, prototyping, and end-use parts, but also for tooling in and around their production line.

The company is not only using BCN3D’s technology for designing, prototyping, and end-use parts, but also for tooling in and around their production line.

Learn more

Replique and BASF Forward AM’s food safe 3D printing process for Miele

German 3D printing platform Replique and BASF Forward AM’s material experts are working together to create parts for home appliances manufacturer Miele, using a food safe 3D printing process for parts in contact with consumable goods. IDEX technology ensured a fast-tracked, profitable process for this low volume batch production.

Learn more

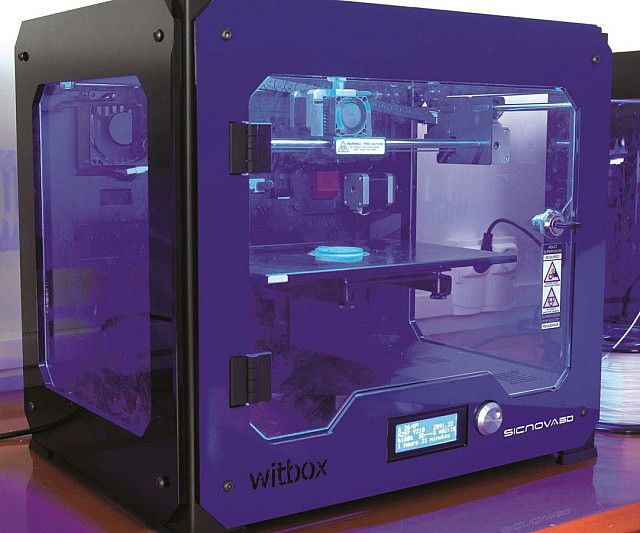

The CIM UPC step up their game with an army of BCN3D printers and Smart Cabinets

With the implementation of a small print farm of BCN3D printers and Smart Cabinets, the CIM UPC has accomplished a radical transformation of the way they produce end-use applications. Experts in the field of additive manufacturing technologies, the CIM UPC team have found the Epsilon series printers with Smart Cabinet to be the most valuable solution for both low-volume batch production and big parts.

Learn more

Dlimit: achieving maximum efficiency thanks to 3D printed tooling

Dlimit has revolutionized its workflow since incorporating 3D printing to fabricate 100% functional customized tooling, which enables them to maximize efficiency, reducing a significant amount of time and costs in their production process of queue management systems.

Learn more

NGNY Devices: Thousands in savings on end-use parts thanks to 3D printing

Incorporating in-house 3D printing at the engineering and fabrication workflows of end-use parts for their automated machines is saving NGNY over 40,000€ a year.

Learn more

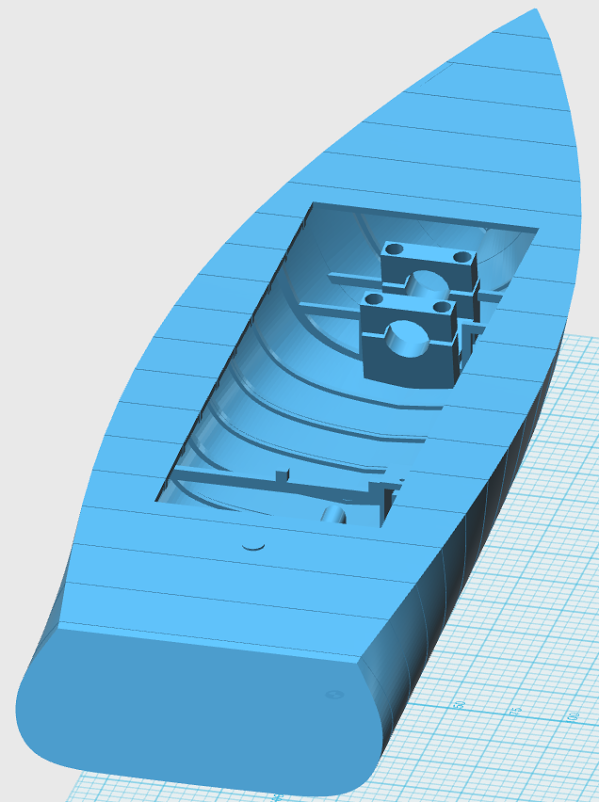

3D printing revolutionizes ETSEIB Motorsport workflow with the BCN3D Sigmax

ETSEIB Motorsport, one of the most experienced teams in the Formula Student competition, uses 3D printing to revolutionize their day-to-day operations.

Learn more

IDEX Technology for low volume batch production: Doubling productivity at the BCN3D Print Farm

BCN3D has proven that additive manufacturing is the most cost-effective solution for producing low volume batches, including 47 3D printed plastic pieces in each manufactured 3D printer.

Learn more

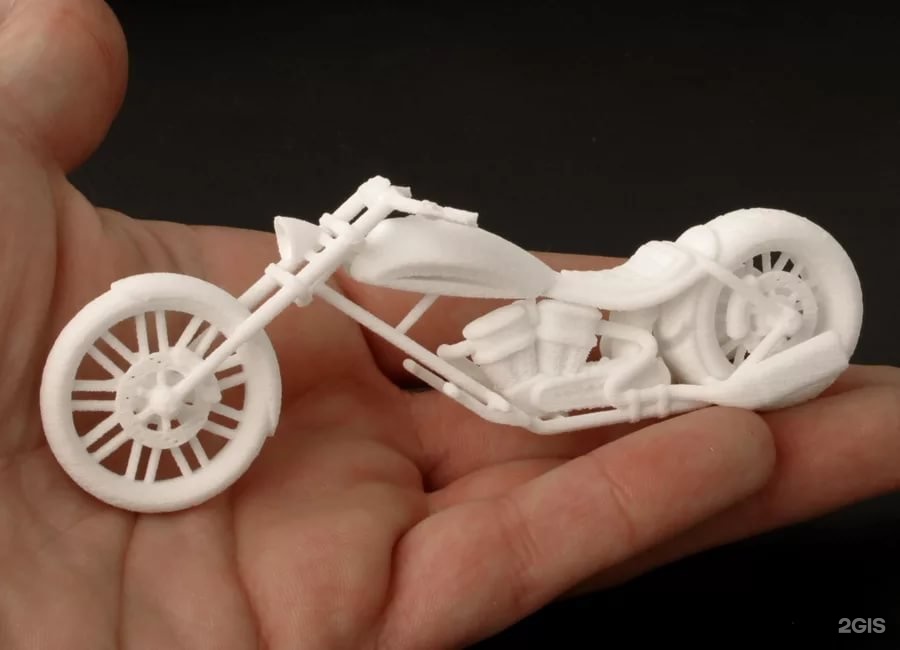

BORN Motor: 3D printed motorcycle parts for time and cost savings

BORN Motor customizes high-quality deconstructed motorcycles and is using 3D printing for manufacturing final parts instead of traditional processes, saving €2,000 for each motorcycle modified.

Learn more

3D Printing in Universities. Success case studies

In-house desktop 3D printing is used at universities for prototyping and functional testing, speeding up students creative process and turning conceptual designs into reality.

Provide students the capacity to learn in a more hands-on way.

Elevate student's critical thinking during a project development stage with physical realistic prototypes.

Encourages creativity and exposes students to professional tools used by a wide range of industries, preparing them for the coming future.

Reliable dual extrusion 3D printing with IDEX technology

IDEX architecture is the most reliable and neat solution on the market when it comes to dual extrusion technology. This is because the two extruders work independently when printing water-soluble supports or multi-material parts. While one extruder is printing the second one is parked, preventing the drip of molten plastic into the part. Conventional dual extrusion printers have both extruders together, which may result in filament threads left on the piece.

This is because the two extruders work independently when printing water-soluble supports or multi-material parts. While one extruder is printing the second one is parked, preventing the drip of molten plastic into the part. Conventional dual extrusion printers have both extruders together, which may result in filament threads left on the piece.

Big volume with the biggest printing surface

The BCN3D Epsilon offers a large print volume of 420x300x400mm. The main advantage of this feature is its proportions, offering the largest printing surface on the market with an incredible height of 400mm. This allows to print the vast majority of parts that are manufactured.

High-performance materials for professional prototyping

BCN3D Filaments are manufactured by BASF and Mitsubishi Chemical, two of the most renowned chemical corporations in the world. Their reputation in the manipulation and production of plastic materials, along with the advanced plastic processing techniques, allows BCN3D to provide the filaments with more repeatability of the market. Each spool will consistently show the same quality and will always offer the same results.

Each spool will consistently show the same quality and will always offer the same results.

Use cases in Universities Industry

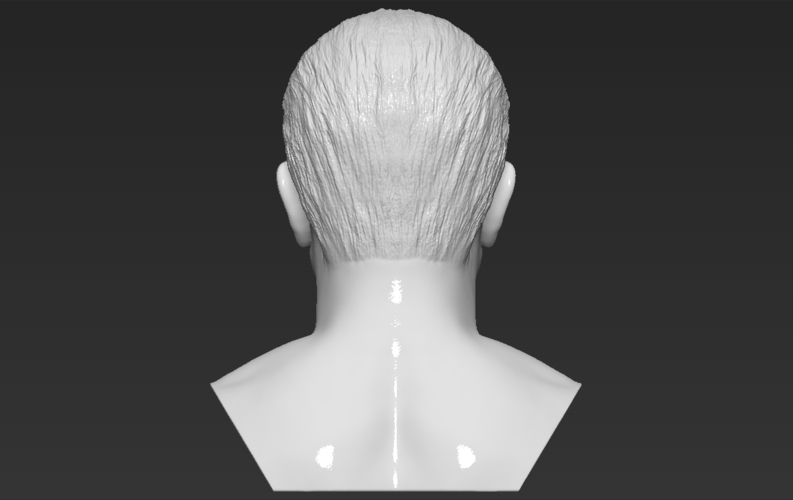

Hyperloop CHF’s train prototype with 3D printed parts goes for gold at the Hyperloop pod competition

We followed Hyperloop CHF’s journey of the creation of a high-speed subsonic train prototype to the 2021 Hyperloop Competition in Valencia. Using a BCN3D Epsilon W50, the team could quickly and efficiently 3D print molds and end-use parts in a variety of different materials.

Learn more

Elisava students design outside the box with 3D printing

At Elisava, Barcelona School of Design and Engineering, Undergraduate Degree students have been utilizing 3D printing as a way of exploring different design possibilities and tremendously speeding up their processes.

Learn more

ELISAVA Racing Team’s Mountain Rescue Motorcycle Taken to New Heights by 3D Printing

Elisava Racing Team are creating a fully electric, intelligent motorcycle equipped for mountain rescue in hostile terrains. Collaborating with us at BCN3D, 19 end-use parts were printed using 3D FFF technology in a variety of different technical materials and sizes.

Collaborating with us at BCN3D, 19 end-use parts were printed using 3D FFF technology in a variety of different technical materials and sizes.

Learn more

3D printing revolutionizes ETSEIB Motorsport workflow with the BCN3D Sigmax

ETSEIB Motorsport, one of the most experienced teams in the Formula Student competition, uses 3D printing to revolutionize their day-to-day operations.

Learn more

3D printing at Istituto Europeo di Design: Accelerating students’ creative thinking

IED, the Istituto Europeo di Design, is an international network of universities specialized in training, development and research in the disciplines of Management, Fashion, Design and Visual Communication.

Learn more

Accelerating stroke rehabilitation thanks to a customized 3D printed orthotic swimming fin

Two industrial designers from Barcelona have created a swimming fin to accelerate the rehabilitation of Pedro, a 16-year-old boy who suffered a stroke, which paralyzed half part of his body.

Learn more

The first 3D printed building in Spain is located in Catalonia. Spain in Russian

Subscribe to our newsletter and be the first to know about all offers

News

- nine0007

The Institute for Advanced Architecture of Catalonia (IAAC) unveiled the first 3D printed building in Spain. The project is located on the premises of Valldaura Labs (Horta Cerdagnola) and was created using a 3D printing system for construction. nine0003

The project is located on the premises of Valldaura Labs (Horta Cerdagnola) and was created using a 3D printing system for construction. nine0003

The idea came from a team of IAAC PhD students and researchers who were looking for solutions to develop sustainable building. The TOVA building was built using one of the most sustainable and environmentally friendly building methods to date. The carbon footprint emitted during its creation turned out to be close to zero. This experience will become the basis for the construction of sustainable housing in the future, which can become a more affordable alternative to conventional housing. nine0003

Read Spanish news on our Telegram channel @ espanarusaNew. Subscribe and be the first to know about key events!

We are on Patreon. By becoming our patron, you will be the first to receive useful collections about life in Spain, expert advice in various fields and interesting facts that few people know about. We are waiting for you at the link . nine0043

We are waiting for you at the link . nine0043

AG

Need help in Spain? The center of services for life and business "Spain in Russian" is more than 100 types of services in the native language in any region of Spain.

+7 495 236 98 99 or +34 93 272 64 90, [email protected]

Tags: modern architecture spain, 3d printer spain, 3d printer catalonia, sustainable buildings spain

Was this article helpful? nine0003

Yes

(1)

Your criticism helps us improve the content. Please write what is wrong.

Send

No

(0)

More in Technology

10/28/2022

In Alcobendas, robots deliver home deliveries

09/08/2022

When will Starlink satellites fly over Madrid?

09/06/2022

Barcelona digital coin for buying tickets for cultural events

02. 09.2022

09.2022

Video game creators from Seville conquer the world

/ispaniya-1728807037.html

In Spain they found a workshop where they made weapons on a 3D printer

In Spain they found a workshop where they made weapons on a 3D printer0002 In Spain they found a workshop where weapons were made on a 3D printer

The Spanish National Police discovered on the island of Tenerife (Canary Islands) a workshop where weapons were printed on 3D printers. RIA Novosti, 18.04.2021

2021-04-18T13: 28

2021-04-18T13: 28

2021-04-18T13: 28

in the world

Spain

Canary Islands

Tenerife

/ html/head/meta[@name='og:title']/@content

/html/head/meta[@name='og:description']/@content

https://cdnn21.img.ria.ru/images/07e5/03/04/1599861403_0:239:2163:1456_1920x0_80_0_0_a5c974af136f1390551aa9dc5a15ed6f.jpg

15ed6f.jpg The National Police of Spain discovered on the island of Tenerife (Canary Islands) a workshop where weapons were printed on 3D printers. This is the first such workshop that was found in the country, the National Police said. -Tenerife, one person was detained, he was charged with possession of weapons and explosives. During the search, two 3D printers were seized, as well as cartridge cases, silencers, magazines, a carbine, various parts for weapons and blanks. In addition, two stun guns, five knives, a machete, a sword, and a holster with a swastika were seized. Three dozen books were found on the production of weapons and explosives, printing weapons on a 3D printer, a textbook on warfare in the city, and more. Also found substances for the manufacture of explosives. nine0003

This is the first such workshop that was found in the country, the National Police said. -Tenerife, one person was detained, he was charged with possession of weapons and explosives. During the search, two 3D printers were seized, as well as cartridge cases, silencers, magazines, a carbine, various parts for weapons and blanks. In addition, two stun guns, five knives, a machete, a sword, and a holster with a swastika were seized. Three dozen books were found on the production of weapons and explosives, printing weapons on a 3D printer, a textbook on warfare in the city, and more. Also found substances for the manufacture of explosives. nine0003 https://ria.ru/20200610/1572720262.html

https://ria.ru/20170121/1486208510.html

Spain

Tenerife

9000 9000 5000 5000 5000 5000

4.7

96

7 495 645-6601

Federal State Unitary Enterprise MIA "Russia Today"

https: //xn--C1ACBL2ABDLKAB1OG.xn-p1ai/AWARDS/

9000 9000 9000 2021RIA Novosti

1

5

4. 7

7

9000

7 495 645-6601

FSUE MIA Today

https: //xn--c1acbl2abdlkab1og.xn--p1ai/AWAWARDS /

News

ru-RU

https://ria.ru/docs/about/copyright.html

https://xn--c1acbl2abdlkab1og.xn--p1ai/

RIA Novosti

1

5

4.7

96

96

7 495 645-6601

Rossiya Segodnya

https://xn--c1acbl2abdlkab1og.xn--p1ai/awards/

1

5

4.7

9000

7 495 645-6601

FSUE MIA Today "

https: //xn--c1acbl2abdlkab1og.xn-p1ai /awards/

worldwide, spain, canary islands, tenerife

In the world, Spain, Canary Islands, Tenerife

MADRID, April 18 - RIA Novosti. The Spanish National Police discovered on the island of Tenerife (Canary Islands) a workshop where weapons were printed on 3D printers.