3D printing comparison

FDM vs. SLA vs. SLS

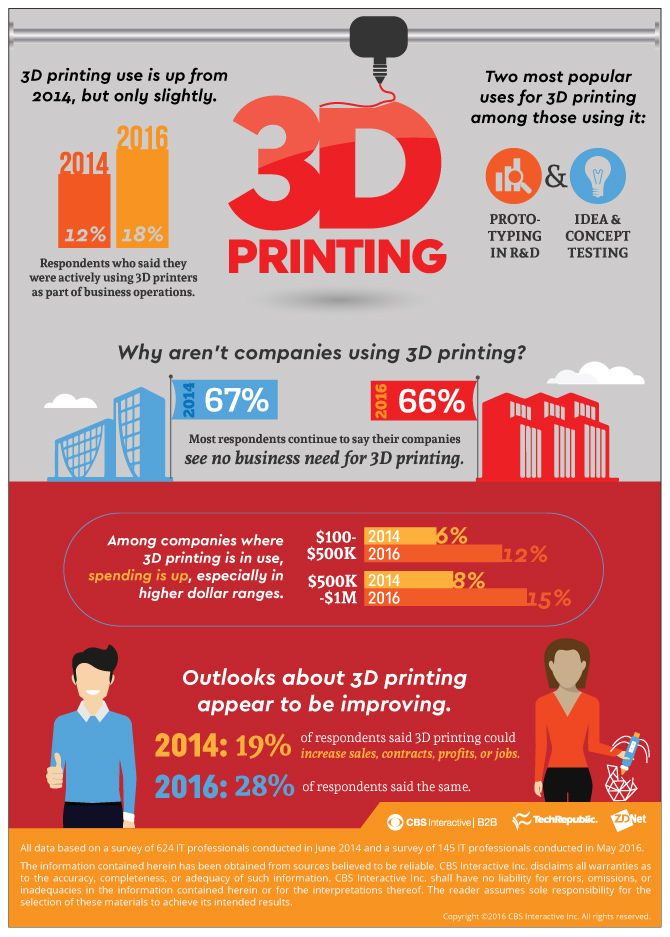

Additive manufacturing, or 3D printing, lowers costs, saves time, and transcends the limits of fabrication processes for product development. From concept models and functional prototypes in rapid prototyping to jigs, fixtures, or even end-use parts in manufacturing, 3D printing technologies offer versatile solutions in a wide variety of applications.

Over the last few years, high-resolution 3D printers have become more affordable, easier to use, and more reliable. As a result, 3D printing technology is now accessible to more businesses, but choosing between the various competing 3D printing solutions can be difficult.

Which technology is suitable for your particular application? What materials are available? What equipment and training do you need to get started? How about costs and return on investment?

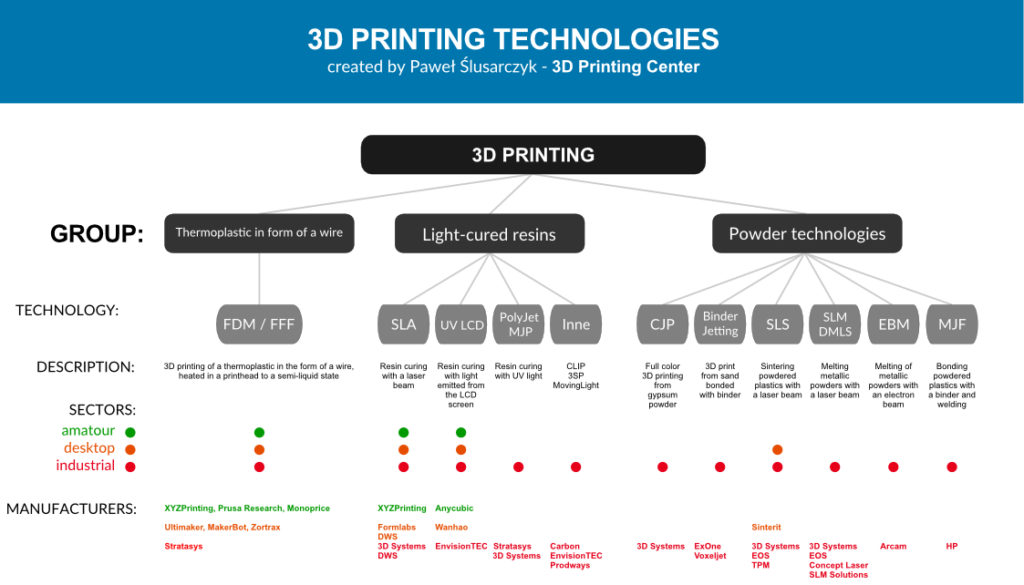

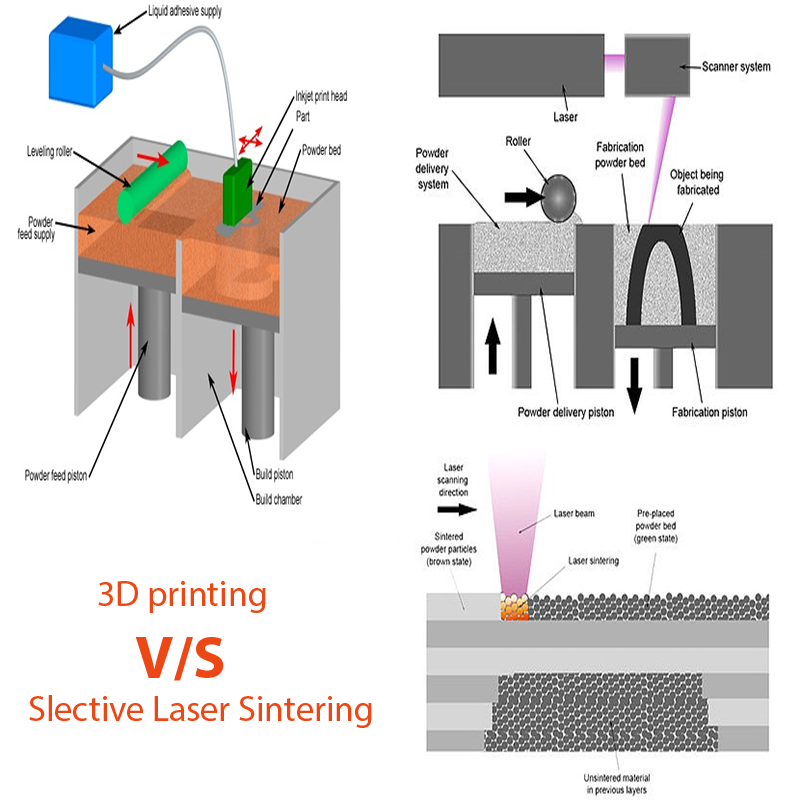

In this article, we’ll take a closer look at the three most established plastic 3D printing processes today: fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS).

Trying to decide between FDM and SLA 3D printers? Check out our in-depth FDM vs. SLA comparison.

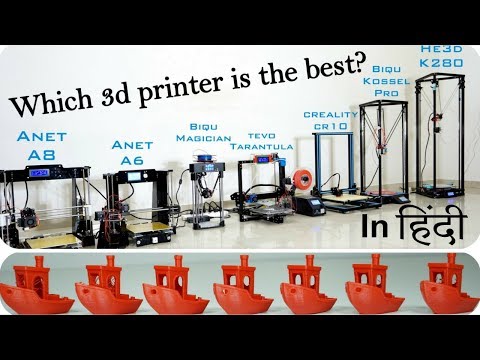

Video Guide

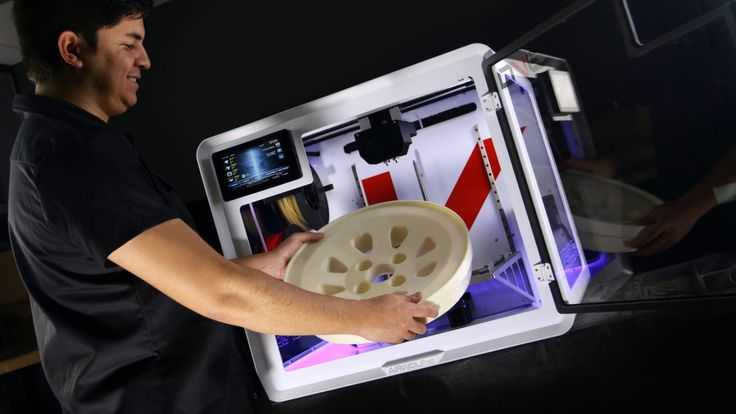

Having trouble finding the best 3D printing technology for your needs? In this video guide, we compare FDM, SLA, and SLS technologies across popular buying considerations.

Watch the Videos

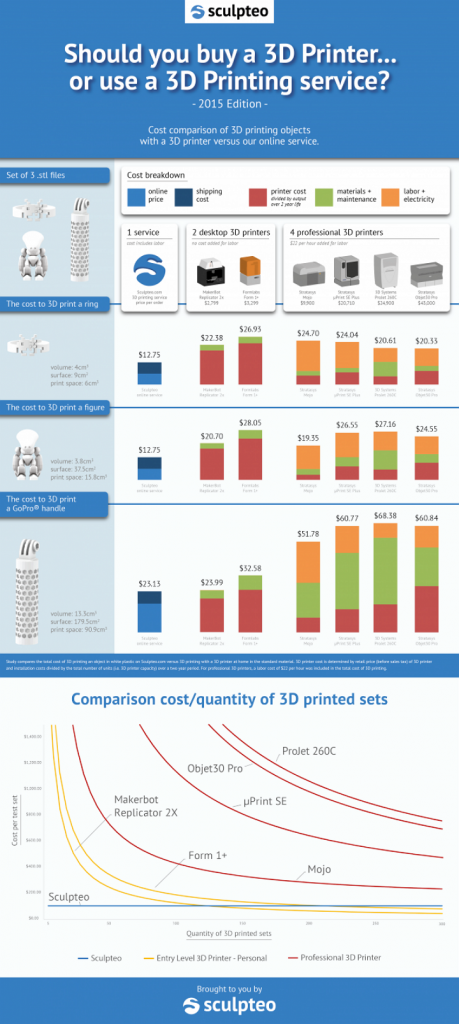

Download the high-resolution version of this infographic here.

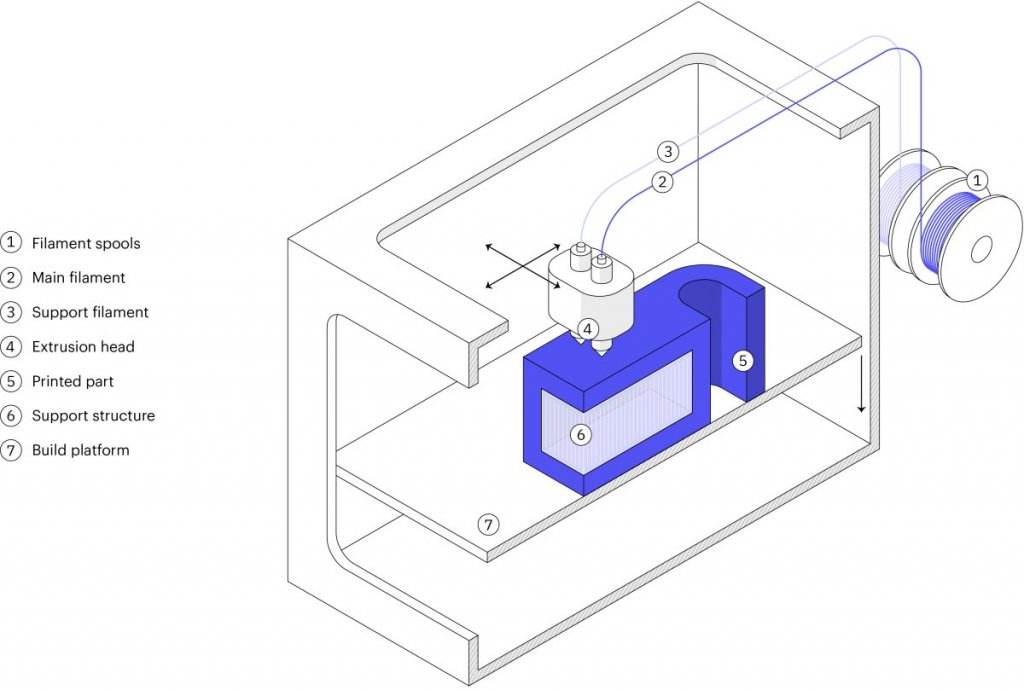

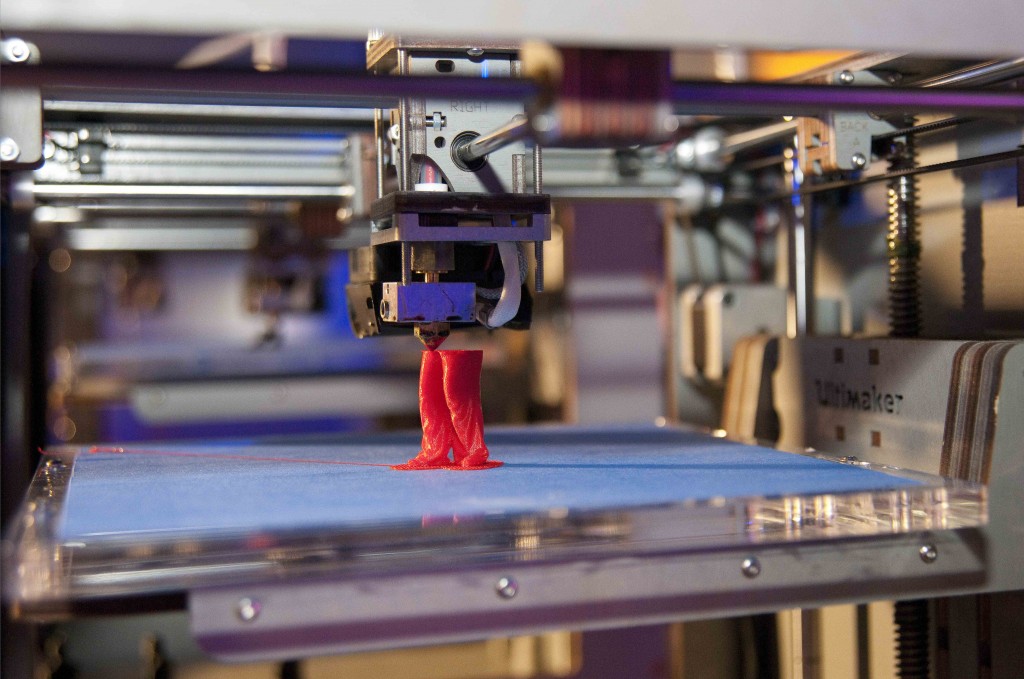

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers. FDM 3D printers build parts by melting and extruding thermoplastic filament, which a printer nozzle deposits layer by layer in the build area.

FDM works with a range of standard thermoplastics, such as ABS, PLA, and their various blends. The technique is well-suited for basic proof-of-concept models, as well as quick and low-cost prototyping of simple parts, such as parts that might typically be machined.

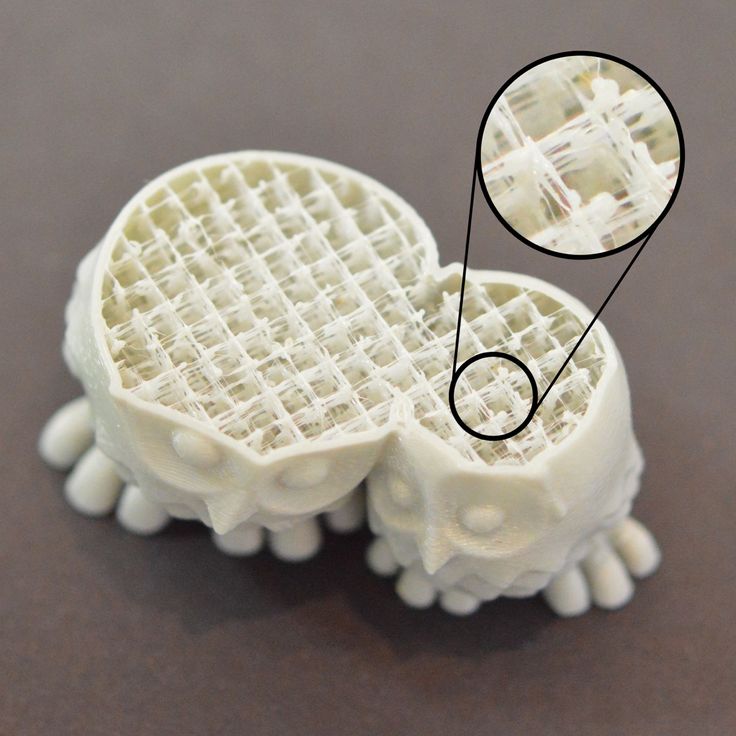

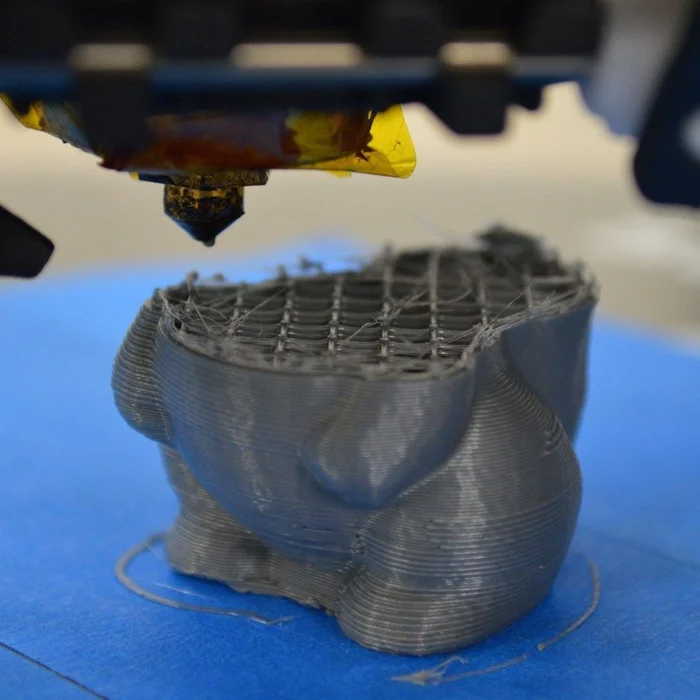

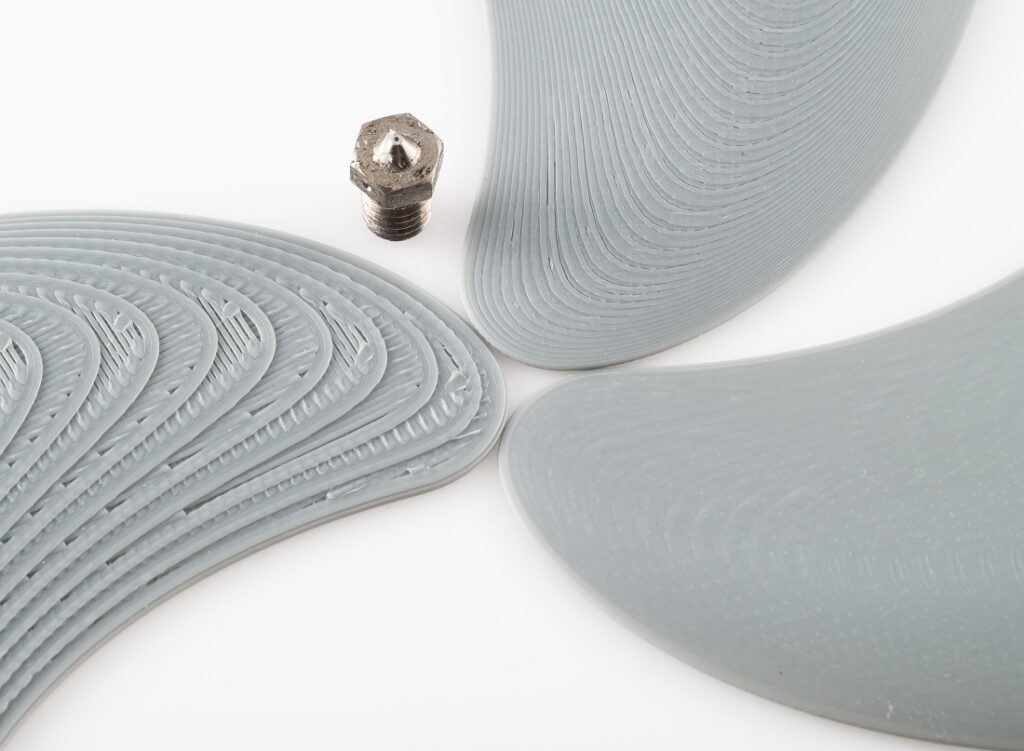

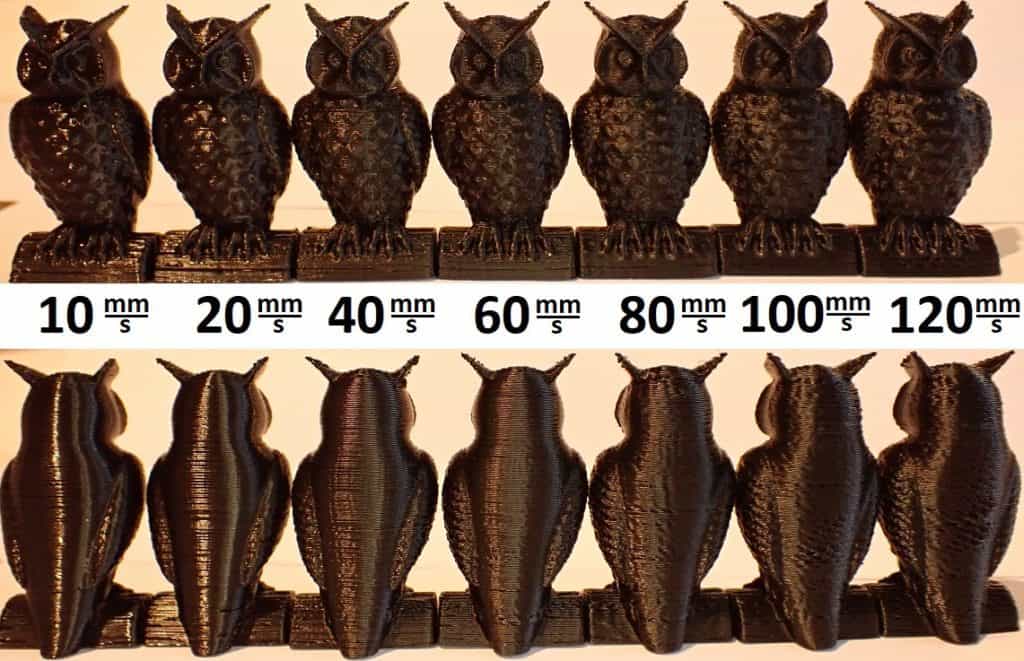

FDM parts tend to have visible layer lines and might show inaccuracies around complex features. This example was printed on a Stratasys uPrint industrial FDM 3D printer with soluble supports (machine starting at $15,900).

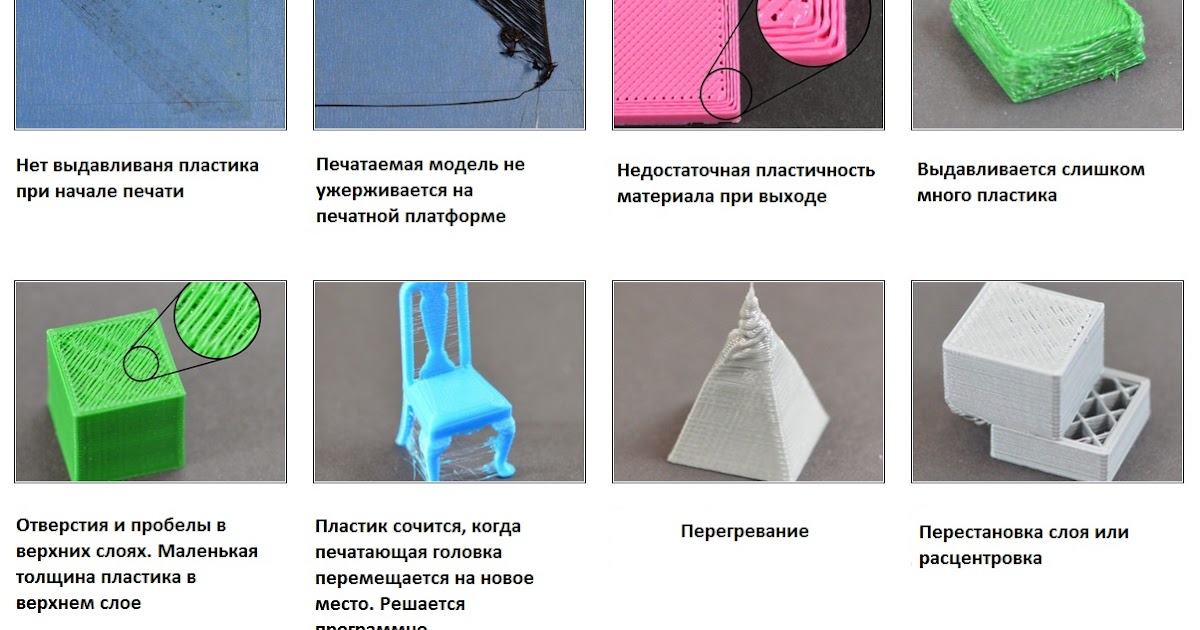

FDM has the lowest resolution and accuracy when compared to SLA or SLS and is not the best option for printing complex designs or parts with intricate features. Higher-quality finishes may be obtained through chemical and mechanical polishing processes. Industrial FDM 3D printers use soluble supports to mitigate some of these issues and offer a wider range of engineering thermoplastics, but they also come at a steep price.

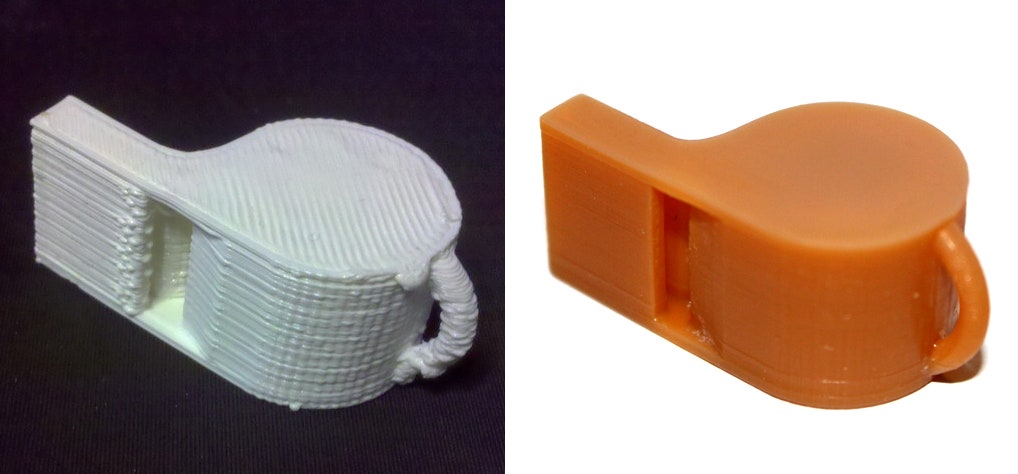

FDM printers struggle with complex designs or parts with intricate features (left), compared to SLA printers (right).

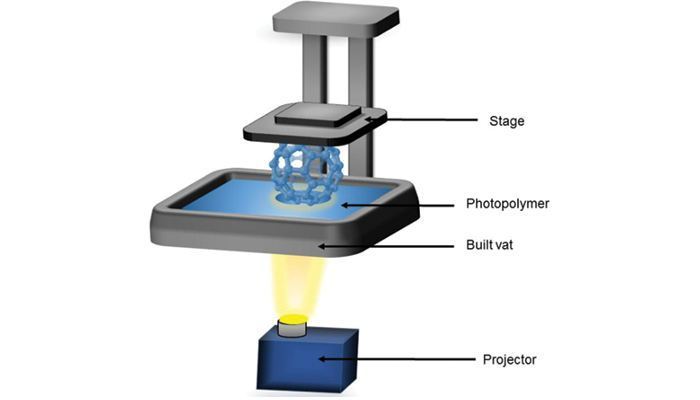

Stereolithography was the world’s first 3D printing technology, invented in the 1980s, and is still one of the most popular technologies for professionals. SLA resin 3D printers use a laser to cure liquid resin into hardened plastic in a process called photopolymerization.

See how stereolithography works.

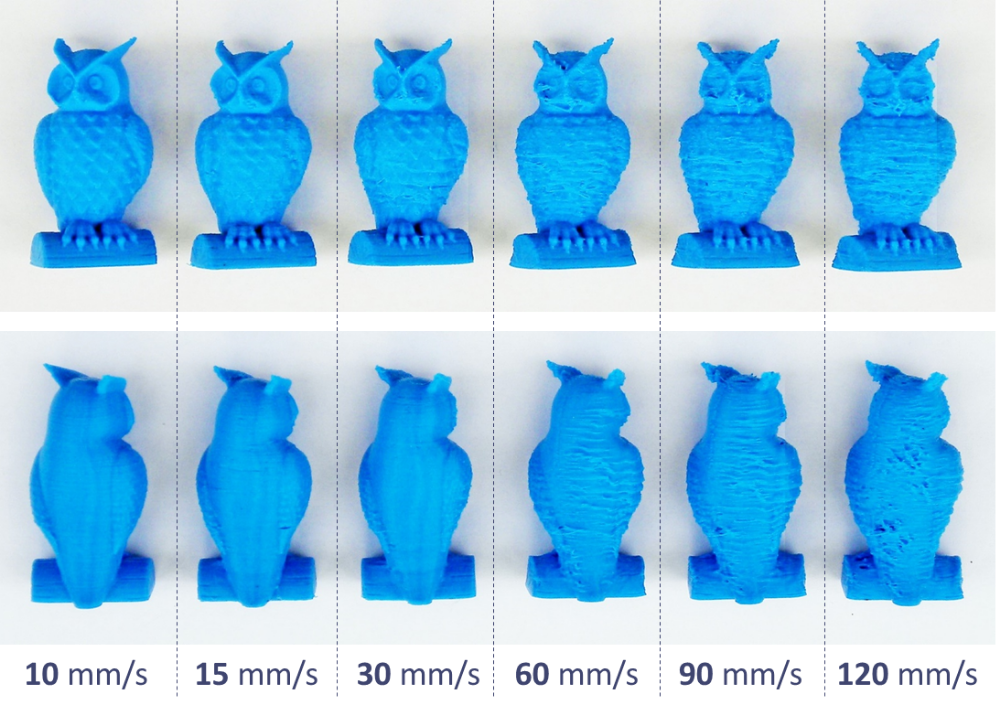

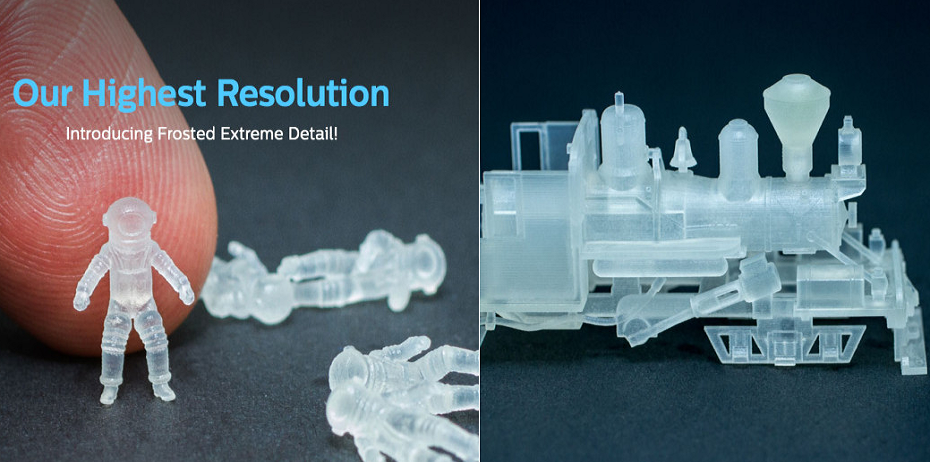

SLA parts have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies, but the main benefit of SLA lies in its versatility. Material manufacturers have created innovative SLA photopolymer resin formulations with a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

SLA parts have sharp edges, a smooth surface finish, and minimal visible layer lines. This example part was printed on a Formlabs Form 3 desktop SLA 3D printer (machine starting at $3,750).

SLA is a great option for highly detailed prototypes requiring tight tolerances and smooth surfaces, such as molds, patterns, and functional parts. SLA is widely used in a range of industries from engineering and product design to manufacturing, dentistry, jewelry, model making, and education.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

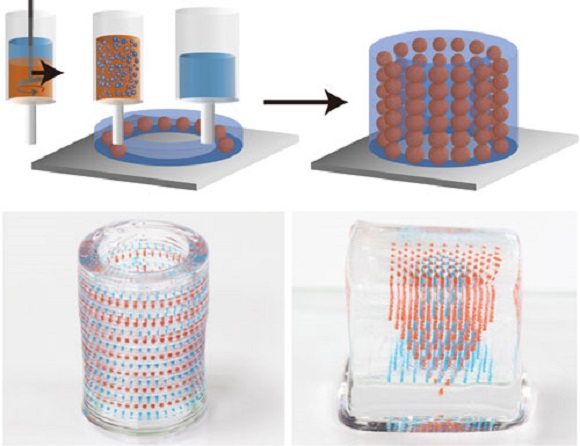

Selective laser sintering is the most common additive manufacturing technology for industrial applications, trusted by engineers and manufacturers across different industries for its ability to produce strong, functional parts.

See how selective laser sintering works.

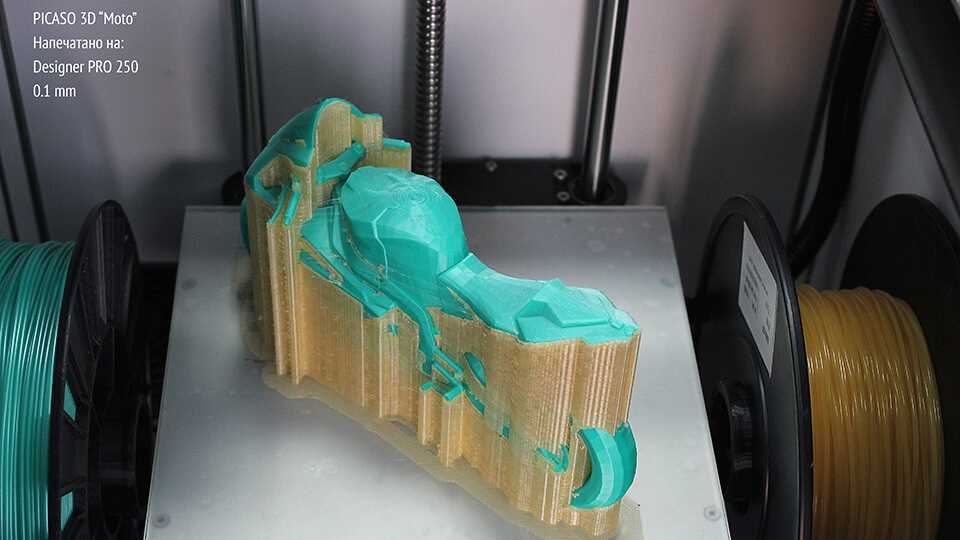

SLS 3D printers use a high-powered laser to fuse small particles of polymer powder. The unfused powder supports the part during printing and eliminates the need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features. Parts produced with SLS printing have excellent mechanical characteristics, with strength resembling that of injection-molded parts.

SLS parts have a slightly rough surface finish, but almost no visible layer lines. This example part was printed on a Formlabs Fuse 1 benchtop SLS 3D printer (machine starting at $18,500).

The most common material for selective laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is lightweight, strong, and flexible, as well as stable against impact, chemicals, heat, UV light, water, and dirt.

The combination of low cost per part, high productivity, and established materials make SLS a popular choice among engineers for functional prototyping, and a cost-effective alternative to injection molding for limited-run or bridge manufacturing.

White Paper

Looking for a 3D printer to create strong, functional parts? Download our white paper to learn how SLS printing works and why it's a popular 3D printing process for functional prototyping and end-use production.

Download the White Paper

Sample part

See and feel Formlabs SLS quality firsthand. We’ll ship a free sample part to your office.

We’ll ship a free sample part to your office.

Request a Free Sample Part

Each 3D printing technology has its own strengths, weaknesses, and requirements, and is suitable for different applications and businesses. The following table summarizes some key characteristics and considerations.

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | |

|---|---|---|---|

| Resolution | ★★☆☆☆ | ★★★★★ | ★★★★☆ |

| Accuracy | ★★★★☆ | ★★★★★ | ★★★★★ |

| Surface Finish | ★★☆☆☆ | ★★★★★ | ★★★★☆ |

| Throughput | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| Complex Designs | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| Ease of Use | ★★★★★ | ★★★★★ | ★★★★☆ |

| Pros | Low-cost consumer machines and materials Fast and easy for simple, small parts | Great value High accuracy Smooth surface finish Fast printing speeds Range of functional applications | Strong functional parts Design freedom No need for support structures |

| Cons | Low accuracy Low details Limited design compatibility | Sensitive to long exposure to UV light | Rough surface finish Limited material options |

| Applications | Low-cost rapid prototyping Basic proof-of-concept models | Functional prototyping Patterns, molds, and tooling Dental applications Jewelry prototyping and casting Modelmaking | Functional prototyping Short-run, bridge, or custom manufacturing |

| Print Volume | Up to 300 x 300 x 600 mm (desktop and benchtop 3D printers) | Up to 300 x 335 x 200 mm (desktop and benchtop 3D printers) | Up to 165 x 165 x 300 mm (benchtop industrial 3D printers) |

| Materials | Standard thermoplastics, such as ABS, PLA, and their various blends. | Varieties of resin (thermosetting plastics). Standard, engineering (ABS-like, PP-like, flexible, heat-resistant), castable, dental, and medical (biocompatible). | Engineering thermoplastics. Nylon 11, Nylon 12, and their composites. |

| Training | Minor training on build setup, machine operation, and finishing; moderate training on maintenance. | Plug and play. Minor training on build setup, maintenance, machine operation, and finishing. | Moderate training on build setup, maintenance, machine operation, and finishing. |

| Facility Requirements | Air-conditioned environment or preferably custom ventilation for desktop machines. | Desktop machines are suitable for an office environment. | Workshop environment with moderate space requirements for benchtop systems. |

| Ancillary Equipment | Support removal system for machines with soluble supports (optionally automated), finishing tools. | Washing station and post-curing station (both can be automated), finishing tools. | Post-processing station for part cleaning and material recovery. |

Ultimately, you should choose the technology that makes the most sense for your business. Prices have dropped significantly in recent years, and today, all three technologies are available in compact, affordable systems.

Calculating 3D printing costs does not end with upfront equipment costs. 3D printing material and labor costs have a significant influence on cost per part, depending on the application and your production needs.

Here’s a detailed breakdown by technology:

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | |

|---|---|---|---|

| Equipment Costs | Budget printers and 3D printer kits start at a few hundred dollars. Higher quality mid-range desktop printers start around $2,000, and industrial systems are available from $15,000. | Professional desktop printers start at $3,750, large-format benchtop printers at $11,000, and large-scale industrial machines are available from $80,000. | Benchtop industrial systems start at $18,500, and traditional industrial printers are available from $100,000. |

| Material Costs | $50-$150/kg for most standard and engineering filaments, and $100-200/kg for support materials. | $149-$200/L for most standard and engineering resins. | $100/kg for nylon. SLS requires no support structures, and unfused powder can be reused, which lowers material costs. |

| Labor Needs | Manual support removal (can be mostly automated for industrial systems with soluble supports). Lengthy post-processing is required for a high-quality finish. | Washing and post-curing (both can be mostly automated). Simple post-processing to remove support marks. | Simple cleaning to remove excess powder. |

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

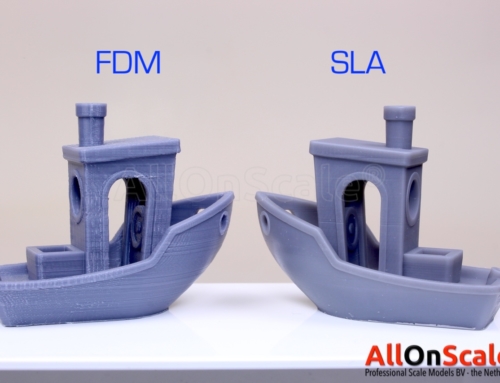

Prototypes of a ski goggles' frame printed with FDM, SLA and SLS technology (from left to right).

We hope this article has helped you focus your search for the best 3D printing technology for your application.

Explore our additional resources to master the intricacies of 3D printing, and dive deeper into each technology to learn more about specific 3D printing systems.

Learn More About 3D Printing

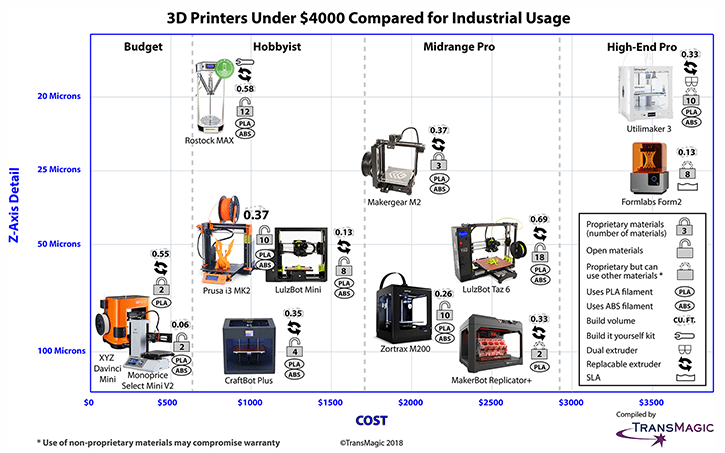

3D Printer Comparison Chart

Select the specs of your dream 3d printer and then scroll down to see matching 3d printers.

Creality Ender 3

Price: $199.00 as of Jan 5, 2023, 00:02 PST - Details

Width: 8.66 inch

Height: 9.84 inch

Depth: 8.66 inch

Anycubic Kobra Max

Price: $549.99 as of Jan 5, 2023, 05:17 PST - Details

Width: 17.72 inch

Height: 15.75 inch

Depth: 15. 75 inch

75 inch

Anycubic Kobra

Price: $255.99 as of Jan 5, 2023, 05:42 PST - Details

Width: 8.7 inch

Height: 9.8 inch

Depth: 8.7 inch

Elegoo Mars 2 Pro

Price: $170.99 as of Jan 5, 2023, 02:43 PST - Details

Width: 5.08 inch

Height: 6.3 inch

Depth: 3.15 inch

Elegoo Mars 3 Pro

Price: $284.99 as of Jan 5, 2023, 09:27 PST - Details

Width: 5.65 inch

Height: 6.8 inch

Depth: 3.52 inch

Creality Ender 3X

Price: $399.00 as of Jan 5, 2023, 01:41 PST - Details

Width: 8.7 inch

Height: 9.8 inch

Depth: 8.7 inch

Elegoo Saturn

Price: $379.99 as of Jan 5, 2023, 09:53 PST - Details

Width: 7.55 inch

Height: 7.87 inch

Depth: 4.72 inch

Elegoo Saturn S

Price: $463.99 as of Jan 5, 2023, 00:49 PST - Details

Width: 7. 72 inch

72 inch

Height: 8.27 inch

Depth: 4.8 inch

Elegoo Saturn 2

Price: $670.99 as of Jan 5, 2023, 12:42 PST - Details

Width: 8.62 inch

Height: 9.84 inch

Depth: 4.85 inch

Flashforge Adventurer 3

Price: $369.00 as of Jan 5, 2023, 06:51 PST - Details

Width: 5.9 inch

Height: 5.9 inch

Depth: 5.9 inch

Anycubic Vyper

Price: $339.99 as of Jan 5, 2023, 08:07 PST - Details

Width: 9.64 inch

Height: 10.23 inch

Depth: 9.64 inch

Anycubic Photon M3 Max

Price: $1299.99 as of Jan 5, 2023, 12:42 PST - Details

Width: 11.8 inch

Height: 11.7 inch

Depth: 6.46 inch

Anycubic Photon Mono 4K

Price: $279.99 as of Jan 4, 2023, 16:22 PST - Details

Width: 5.2 inch

Height: 6.5 inch

Depth: 3.14 inch

Anycubic Photon M3

Price: $319. 99 as of Jan 5, 2023, 08:03 PST - Details

99 as of Jan 5, 2023, 08:03 PST - Details

Width: 7.1 inch

Height: 6.4 inch

Depth: 4 inch

Voxelab Aquila S2

Price: $199.00 as of Jan 5, 2023, 04:07 PST - Details

Width: 8.66 inch

Height: 9.45 inch

Depth: 8.66 inch

Creality Ender 3 V2 Neo

Price: $319.00 as of Jan 5, 2023, 01:40 PST - Details

Width: 8.66 inch

Height: 9.84 inch

Depth: 8.66 inch

Creality Ender 3 S1 Pro

Price: $499.00 as of Jan 5, 2023, 02:47 PST - Details

Width: 8.66 inch

Height: 10.63 inch

Depth: 8.66 inch

Phrozen Sonic Mini

Price: $129.99 as of Jan 5, 2023, 05:00 PST - Details

Width: 4.7 inch

Height: 5.1 inch

Depth: 2.6 inch

Phrozen Sonic Mini 4K

Price: $499.99 as of Jan 5, 2023, 05:00 PST - Details

Width: 5.2 inch

Height: 5. 1 inch

1 inch

Depth: 2.9 inch

Anycubic Photon Mono X 6K

Price: $619.99 as of Jan 5, 2023, 04:07 PST - Details

Width: 7.76 inch

Height: 9.65 inch

Depth: 4.8 inch

Sovol SV06

Price: $299.00 as of Jan 5, 2023, 06:38 PST - Details

Width: 8.66 inch

Height: 9.84 inch

Depth: 8.66 inch

Sovol SV01

Price: $179.00 as of Jan 5, 2023, 05:41 PST - Details

Width: 9.44 inch

Height: 11.81 inch

Depth: 11.02 inch

Creality CR-10

Price: $459.00 as of Jan 5, 2023, 05:19 PST - Details

Width: 11.81 inch

Height: 15.74 inch

Depth: 11.81 inch

Creality Ender 3 V2

Price: $279.00 as of Jan 5, 2023, 02:43 PST - Details

Width: 8.66 inch

Height: 9.84 inch

Depth: 8.66 inch

Sovol SV04

Price: $579. 00 as of Jan 5, 2023, 09:40 PST - Details

00 as of Jan 5, 2023, 09:40 PST - Details

Width: 11.81 inch

Height: 15.75 inch

Depth: 11.81 inch

Flsun Super Racer SR

Price: $499.00 as of Jan 5, 2023, 05:01 PST - Details

Width: 10.24 inch

Height: 12.99 inch

Depth: 10.24 inch

Prusa i3 MK3S+

Price: $949.00 as of Jan 4, 2023, 13:26 PST - Details

Width: 9.84 inch

Height: 8.3 inch

Depth: 8.3 inch

Creality Ender 5 Plus

Price: $599.00 as of Jan 5, 2023, 06:08 PST - Details

Width: 13.77 inch

Height: 15.74 inch

Depth: 13.77 inch

Voxelab Aquila X2

Price: $179.00 as of Jan 5, 2023, 04:07 PST - Details

Width: 8.66 inch

Height: 9.84 inch

Depth: 8.66 inch

Phrozen Sonic Mighty 8K

Price: $599.99 as of Jan 5, 2023, 12:42 PST - Details

Width: 8.58 inch

Height: 9. 25 inch

25 inch

Depth: 4.84 inch

Creality Ender 3 Pro

Price: $236.00 as of Jan 5, 2023, 05:41 PST - Details

Width: 8.6 inch

Height: 9.8 inch

Depth: 8.6 inch

Qidi Tech X-Plus

Price: $699.00 as of Jan 5, 2023, 09:27 PST - Details

Width: 10.6 inch

Height: 7.9 inch

Depth: 7.9 inch

Creality Ender 5 Pro

Price: $399.00 as of Jan 5, 2023, 05:40 PST - Details

Width: 8.66 inch

Height: 11.81 inch

Depth: 8.66 inch

Voxelab Aquila C2

Price: $165.00 as of Jan 4, 2023, 23:28 PST - Details

Width: 8.66 inch

Height: 9.84 inch

Depth: 8.66 inch

Flashforge Adventurer 3 Pro

Price: $399.00 as of Jan 5, 2023, 07:19 PST - Details

Width: 5.9 inch

Height: 5.9 inch

Depth: 5.9 inch

Original Prusa i3 MK3S

Price: $1299. 00 as of Jan 4, 2023, 14:21 PST - Details

00 as of Jan 4, 2023, 14:21 PST - Details

Width: 9.84 inch

Height: 8.3 inch

Depth: 8.3 inch

Creality Ender 3 S1 Plus

Price: $549.00 as of Jan 5, 2023, 05:21 PST - Details

Width: 11.81 inch

Height: 11.81 inch

Depth: 11.81 inch

Voxelab Aries

Price: $279.00 as of Jan 5, 2023, 09:58 PST - Details

Width: 7.87 inch

Height: 7.87 inch

Depth: 7.87 inch

Flashforge Finder 3

Price: $499.00 as of Jan 5, 2023, 07:58 PST - Details

Width: 7.48 inch

Height: 7.87 inch

Depth: 7.68 inch

Flashforge Creator Pro 2

Price: $649.00 as of Jan 4, 2023, 16:19 PST - Details

Width: 7.87 inch

Height: 5.9 inch

Depth: 5.82 inch

Creality Ender-5 S1

Price: $579.99 as of Jan 5, 2023, 06:29 PST - Details

Width: 8.66 inch

Height: 11. 02 inch

02 inch

Depth: 8.66 inch

Creality CR-10S

Price: $299.00 as of Jan 5, 2023, 04:07 PST - Details

Width: 11.81 inch

Height: 15.74 inch

Depth: 11.81 inch

Qidi Tech X-Max

Price: $999.00 as of Jan 4, 2023, 23:37 PST - Details

Width: 11.8 inch

Height: 11.8 inch

Depth: 9.8 inch

Voxelab Proxima 8.9 Pro

Price: $195.00 as of Jan 4, 2023, 20:06 PST - Details

Width: 7.56 inch

Height: 7.87 inch

Depth: 4.72 inch

Qidi Tech i-Mate S

Price: $399.00 as of Jan 5, 2023, 06:51 PST - Details

Width: 10.23 inch

Height: 7.87 inch

Depth: 7.87 inch

Creality Ender 3 Max Neo

Price: $369.00 as of Jan 5, 2023, 05:40 PST - Details

Width: 11.81 inch

Height: 12.6 inch

Depth: 11.81 inch

Sovol SV02

Price: $279. 00 as of Jan 5, 2023, 05:42 PST - Details

00 as of Jan 5, 2023, 05:42 PST - Details

Width: 9.44 inch

Height: 11.81 inch

Depth: 11.02 inch

Sovol SV03

Price: $399.00 as of Jan 4, 2023, 23:49 PST - Details

Width: 13.78 inch

Height: 15.75 inch

Depth: 13.78 inch

Elegoo Mars 3

Price: $245.99 as of Jan 5, 2023, 09:53 PST - Details

Width: 5.63 inch

Height: 6.89 inch

Depth: 3.5 inch

Creality CR-10 Mini

Price: $729.00 as of Jan 5, 2023, 06:54 PST - Details

Width: 11.8 inch

Height: 11.8 inch

Depth: 8.6 inch

Monoprice Voxel

Price: $444.88 as of Jan 4, 2023, 15:58 PST - Details

Width: 5.9 inch

Height: 5.9 inch

Depth: 5.9 inch

Flashforge Adventurer 4

Price: $749.00 as of Jan 5, 2023, 04:11 PST - Details

Width: 8.67 inch

Height: 9.84 inch

Depth: 7. 87 inch

87 inch

Phrozen Sonic Mighty 4K

Price: $499.99 as of Jan 4, 2023, 18:39 PST - Details

Width: 7.87 inch

Height: 8.66 inch

Depth: 4.92 inch

Creality Ender 5 Plus

Price: $599.00 as of Jan 5, 2023, 01:41 PST - Details

Width: 13.78 inch

Height: 15.74 inch

Depth: 13.78 inch

Longer LK5 Pro

Price: $369.99 as of Jan 5, 2023, 02:43 PST - Details

Width: 11.81 inch

Height: 15.75 inch

Depth: 11.81 inch

Creality Halot One Plus

Price: $398.00 as of Jan 4, 2023, 15:35 PST - Details

Width: 6.77 inch

Height: 6.29 inch

Depth: 4.01 inch

Creality Ender 3 S1

Price: $399.00 as of Jan 5, 2023, 02:46 PST - Details

Width: 8.66 inch

Height: 10.63 inch

Depth: 8.66 inch

Sovol SV05

Price: $349. 00 as of Jan 5, 2023, 04:07 PST - Details

00 as of Jan 5, 2023, 04:07 PST - Details

Width: 8.66 inch

Height: 11.81 inch

Depth: 8.66 inch

Artillery Sidewinder SW-X2

Price: $399.99 as of Jan 5, 2023, 08:14 PST - Details

Width: 11.81 inch

Height: 15.75 inch

Depth: 11.81 inch

Creality Ender 6

Price: $569.00 as of Jan 4, 2023, 15:19 PST - Details

Width: 9.84 inch

Height: 15.75 inch

Depth: 9.84 inch

Lotmaxx Shark V3

Price: $499.99 as of Jan 5, 2023, 00:28 PST - Details

Width: 9.25 inch

Height: 10.43 inch

Depth: 9.25 inch

Creality CR-6 SE

Price: $364.99 as of Jan 5, 2023, 02:17 PST - Details

Width: 9.25 inch

Height: 9.84 inch

Depth: 9.25 inch

Mingda Magician X

Price: $349.99 as of Jan 5, 2023, 05:17 PST - Details

Width: 9.06 inch

Height: 10. 24 inch

24 inch

Depth: 9.06 inch

BIBO2 Touch Laser X

Price: $528.00 as of Jan 5, 2023, 10:46 PST - Details

Width: 8.4 inch

Height: 6.3 inch

Depth: 7.3 inch

XYZprinting da Vinci Mini

Price: $199.95 as of Jan 4, 2023, 10:43 PST - Details

Width: 5.9 inch

Height: 5.9 inch

Depth: 5.9 inch

Qidi Tech i-Fast

Price: $2499.00 as of Jan 5, 2023, 09:14 PST - Details

Width: 14.17 inch

Height: 12.6 inch

Depth: 9.84 inch

FlashForge Creator Pro

Price: $399.00 as of Jan 4, 2023, 20:55 PST - Details

Width: 8.9 inch

Height: 5.7 inch

Depth: 5.9 inch

Snapmaker 2.0 A250T

Price: $1499.00 as of Jan 5, 2023, 10:52 PST - Details

Width: 9.06 inch

Height: 9.25 inch

Depth: 9.84 inch

Qidi Tech X-CF Pro

Price: $1849. 00 as of Jan 4, 2023, 20:04 PST - Details

00 as of Jan 4, 2023, 20:04 PST - Details

Width: 11.8 inch

Height: 11.8 inch

Depth: 9.8 inch

Snapmaker 2.0 A350T

Price: $1799.00 as of Jan 5, 2023, 08:15 PST - Details

Width: 12.6 inch

Height: 13 inch

Depth: 13.78 inch

Flashforge Foto 8.9

Price: $219.00 as of Jan 5, 2023, 06:51 PST - Details

Width: 7.6 inch

Height: 7.9 inch

Depth: 4.7 inch

Monoprice MP Select Mini

Price: $211.43 as of Jan 4, 2023, 12:17 PST - Details

Width: 4.7 inch

Height: 4.7 inch

Depth: 4.7 inch

Creality Ender 3 Max

Price: $279.00 as of Jan 5, 2023, 00:49 PST - Details

Width: 11.81 inch

Height: 13.38 inch

Depth: 11.81 inch

Flashforge Adventurer 3C

Price: $269.00 as of Jan 5, 2023, 05:42 PST - Details

Width: 5.9 inch

Height: 5. 9 inch

9 inch

Depth: 5.9 inch

JGAURORA A5S

Price: $329.00 as of Jan 4, 2023, 18:46 PST - Details

Width: 12 inch

Height: 12.6 inch

Depth: 12 inch

Monoprice MP Mini

Price: $199.97 as of Jan 5, 2023, 09:53 PST - Details

Width: 4.6 inch

Height: 4.3 inch

Depth: 2.6 inch

MakerBot Replicator+

Price: $2099.00 as of Jan 4, 2023, 14:20 PST - Details

Width: 7.6 inch

Height: 6.5 inch

Depth: 11.6 inch

JGMAKER Magic

Price: $169.99 as of Jan 5, 2023, 00:07 PST - Details

Width: 8.66 inch

Height: 9.84 inch

Depth: 8.66 inch

Monoprice Delta Pro

Price: $1724.83 as of Jan 4, 2023, 15:47 PST - Details

Width: 10.63 inch

Height: 11.81 inch

Depth: 10.63 inch

Tronxy CRUX 1

Price: $189. 00 as of Jan 5, 2023, 03:25 PST - Details

00 as of Jan 5, 2023, 03:25 PST - Details

Width: 7.08 inch

Height: 7.08 inch

Depth: 7.08 inch

Dremel Digilab 3D40 Flex

Price: $1499.00 as of Jan 5, 2023, 02:43 PST - Details

Width: 10.03 inch

Height: 6.69 inch

Depth: 6.1 inch

Geeetech Mizar S

Price: $429.99 as of Jan 5, 2023, 03:24 PST - Details

Width: 10.04 inch

Height: 10.24 inch

Depth: 10.04 inch

Creality Ender 2 Pro

Price: $173.99 as of Jan 5, 2023, 02:41 PST - Details

Width: 6.5 inch

Height: 7.09 inch

Depth: 6.5 inch

Longer Orange 30

Price: $275.38 as of Jan 4, 2023, 18:46 PST - Details

Width: 4.72 inch

Height: 6.69 inch

Depth: 2.68 inch

TwoTrees SP-5 CoreXY

Price: $459.99 as of Jan 5, 2023, 08:06 PST - Details

Width: 11.81 inch

Height: 13. 78 inch

78 inch

Depth: 11.81 inch

Flashforge Foto 6.0

Price: $129.00 as of Jan 5, 2023, 05:41 PST - Details

Width: 5.12 inch

Height: 6.1 inch

Depth: 3.07 inch

Flashforge Adventurer 4 Lite

Price: $499.00 as of Jan 5, 2023, 06:37 PST - Details

Width: 8.67 inch

Height: 9.84 inch

Depth: 7.87 inch

Anet Storm G1

Price: $179.99 as of Jan 5, 2023, 02:43 PST - Details

Width: 8.66 inch

Height: 9.84 inch

Depth: 8.66 inch

Voxelab Proxima

Price: $169.99 as of Jan 5, 2023, 05:41 PST - Details

Width: 5.11 inch

Height: 6.1 inch

Depth: 3.22 inch

Flashforge Creator Pro 3

Price: $3499.00 as of Jan 5, 2023, 09:46 PST - Details

Width: 11.81 inch

Height: 7.87 inch

Depth: 9.84 inch

XYZprinting da Vinci Jr. 1.0 A Pro

1.0 A Pro

Price: $199.95 as of Jan 5, 2023, 04:15 PST - Details

Width: 6.9 inch

Height: 6.9 inch

Depth: 6.9 inch

Anycubic Chiron

Price: $599.99 as of Jan 5, 2023, 01:41 PST - Details

Width: 15.74 inch

Height: 17.71 inch

Depth: 15.74 inch

Creality 3DPrintMill CR-30

Price: $982.00 as of Jan 5, 2023, 07:30 PST - Details

Width: 7.87 inch

Height: 6.69 inch

Depth: Infinite inch

SainSmart INFI-20 Belt

Price: $489.99 as of Jan 4, 2023, 19:15 PST - Details

Width: 7.87 inch

Height: 7.09 inch

Depth: Infinite inch

Lotmaxx Shark V2

Price: $399.00 as of Jan 5, 2023, 05:40 PST - Details

Width: 9.25 inch

Height: 10.43 inch

Depth: 9.25 inch

Flashforge Guider II

Price: $999.00 as of Jan 4, 2023, 15:58 PST - Details

Width: 11 inch

Height: 11. 8 inch

8 inch

Depth: 9.8 inch

Dremel DigiLab 3D45

Price: $2001.69 as of Jan 5, 2023, 01:35 PST - Details

Width: 10 inch

Height: 6.7 inch

Depth: 6 inch

Longer Orange 10

Price: $195.00 as of Jan 5, 2023, 05:18 PST - Details

Width: 3.86 inch

Height: 5.5 inch

Depth: 2.17 inch

Monoprice MP10 Mini

Price: $239.99 as of Jan 5, 2023, 00:27 PST - Details

Width: 7.87 inch

Height: 7.08 inch

Depth: 7.87 inch

Anycubic Photon M3 Plus

Price: $668.99 as of Jan 5, 2023, 08:01 PST - Details

Width: 9.6 inch

Height: 7.8 inch

Depth: 4.8 inch

Monoprice Joule

Price: $256.28 as of Jan 5, 2023, 02:16 PST - Details

Width: 8.66 inch

Height: 9.84 inch

Depth: 8.66 inch

Longer LK4

Price: $351. 41 as of Jan 5, 2023, 09:39 PST - Details

41 as of Jan 5, 2023, 09:39 PST - Details

Width: 8.66 inch

Height: 9.84 inch

Depth: 8.66 inch

Monoprice MP10

Price: $329.99 as of Jan 5, 2023, 05:40 PST - Details

Width: 11.81 inch

Height: 15.74 inch

Depth: 11.81 inch

Elegoo Jupiter

Price: $1300.00 as of Jan 5, 2023, 10:34 PST - Details

Width: 10.94 inch

Height: 11.81 inch

Depth: 6.14 inch

Weedo X40

Price: $569.00 as of Jan 5, 2023, 09:03 PST - Details

Width: 11.8 inch

Height: 15.8 inch

Depth: 11.8 inch

ADIMLab Gantry I3 Plus

Price: $449.00 as of Jan 5, 2023, 01:26 PST - Details

Width: 12.2 inch

Height: 16.14 inch

Depth: 12.2 inch

Ultimaker S5

Price: $6950.00 as of Jan 5, 2023, 00:28 PST - Details

Width: 13 inch

Height: 11.8 inch

Depth: 9. 4 inch

4 inch

Silhouette Alta Plus

Price: $299.99 as of Jan 5, 2023, 10:52 PST - Details

Width: 4.88 inch

Height: 5.11 inch

Depth: 4.88 inch

Anet A8 Plus

Price: $259.99 as of Jan 5, 2023, 02:43 PST - Details

Width: 11.8 inch

Height: 13.8 inch

Depth: 11.8 inch

MakerBot Method

Price: $6006.79 as of Jan 4, 2023, 16:22 PST - Details

Width: 7.5 inch

Height: 7.75 inch

Depth: 7.5 inch

BIQU B1

Price: $399.95 as of Jan 5, 2023, 05:40 PST - Details

Width: 9.25 inch

Height: 10.63 inch

Depth: 9.25 inch

FlashForge Dreamer

Price: $849.08 as of Jan 5, 2023, 12:17 PST - Details

Width: 9 inch

Height: 5.9 inch

Depth: 5.9 inch

Monoprice Maker Ultimate 2

Price: $334.99 as of Jan 5, 2023, 06:51 PST - Details

Width: 7. 9 inch

9 inch

Height: 5.9 inch

Depth: 5.9 inch

He3D K280

Price: $329.00 as of Jan 4, 2023, 23:28 PST - Details

Width: 11.02 inch

Height: 23.62 inch

Depth: 11.02 inch

Kywoo Tycoon

Price: $416.99 as of Jan 5, 2023, 05:20 PST - Details

Width: 9.45 inch

Height: 9.06 inch

Depth: 9.45 inch

Kywoo Tycoon Max

Price: $452.99 as of Jan 5, 2023, 09:13 PST - Details

Width: 11.81 inch

Height: 9.05 inch

Depth: 11.81 inch

LulzBot TAZ Pro

Price: $6299.99 as of Jan 5, 2023, 00:58 PST - Details

Width: 11.02 inch

Height: 11.22 inch

Depth: 11.02 inch

Artillery Genius Pro

Price: $373.32 as of Jan 4, 2023, 11:57 PST - Details

Width: 8.66 inch

Height: 9.84 inch

Depth: 8.66 inch

Sindoh 3DWOX 1

Price: $1473. 59 as of Jan 5, 2023, 09:27 PST - Details

59 as of Jan 5, 2023, 09:27 PST - Details

Width: 8.26 inch

Height: 7.67 inch

Depth: 7.87 inch

Creality CR-200B

Price: $473.32 as of Jan 5, 2023, 02:16 PST - Details

Width: 7.87 inch

Height: 7.87 inch

Depth: 7.87 inch

Geeetech A10M

Price: $729.99 as of Jan 4, 2023, 22:08 PST - Details

Width: 8.66 inch

Height: 10.23 inch

Depth: 8.66 inch

JGMAKER Artist-D Pro

Price: $499.99 as of Jan 5, 2023, 01:41 PST - Details

Width: 11.81 inch

Height: 13.38 inch

Depth: 11.81 inch

LulzBot Mini 2

Price: $1943.10 as of Jan 4, 2023, 12:38 PST - Details

Width: 6.3 inch

Height: 7.09 inch

Depth: 6.3 inch

Flashforge Guider IIS

Price: $1525.00 as of Jan 5, 2023, 04:07 PST - Details

Width: 11.02 inch

Height: 11.81 inch

Depth: 9. 84 inch

84 inch

Anet ET4

Price: $356.20 as of Jan 5, 2023, 09:58 PST - Details

Width: 8.66 inch

Height: 9.84 inch

Depth: 8.66 inch

Longer LK4 Pro

Price: $449.00 as of Jan 4, 2023, 11:57 PST - Details

Width: 8.66 inch

Height: 9.84 inch

Depth: 8.66 inch

Creality Halot-Sky

Price: $775.20 as of Jan 5, 2023, 12:42 PST - Details

Width: 7.56 inch

Height: 7.87 inch

Depth: 4.72 inch

Dremel 3D40 Idea Builder 2.0

Price: $1519.00 as of Jan 5, 2023, 05:22 PST - Details

Width: 10 inch

Height: 6.7 inch

Depth: 6 inch

Raise3D E2

Price: $3499.00 as of Jan 5, 2023, 12:22 PST - Details

Width: 13 inch

Height: 9.4 inch

Depth: 9.4 inch

Geeetech A20T

Price: $799.99 as of Jan 4, 2023, 13:49 PST - Details

Width: 9. 84 inch

84 inch

Height: 9.84 inch

Depth: 9.84 inch

Cubicon Prime

Price: $399.00 as of Jan 4, 2023, 13:57 PST - Details

Width: 8.66 inch

Height: 9.25 inch

Depth: 8.66 inch

Raise3D Pro2

Price: $3999.00 as of Jan 5, 2023, 08:16 PST - Details

Width: 12 inch

Height: 11.8 inch

Depth: 12 inch

Creality Halot-One

Price: $369.99 as of Jan 5, 2023, 03:28 PST - Details

Width: 5 inch

Height: 6.3 inch

Depth: 3.15 inch

Raise3D Pro3 Plus

Price: $7599.00 as of Jan 5, 2023, 06:51 PST - Details

Width: 11.81 inch

Height: 23.82 inch

Depth: 11.81 inch

Robo E3

Price: $999.99 as of Jan 4, 2023, 17:05 PST - Details

Width: 5.9 inch

Height: 5.9 inch

Depth: 5.9 inch

Tenlog TL-D3 Pro

Price: $599. 99 as of Jan 4, 2023, 11:58 PST - Details

99 as of Jan 4, 2023, 11:58 PST - Details

Width: 11.81 inch

Height: 13.78 inch

Depth: 11.81 inch

XYZprinting Da Vinci 1.0 Pro

Price: $1499.95 as of Jan 5, 2023, 04:07 PST - Details

Width: 7.8 inch

Height: 7.8 inch

Depth: 7.8 inch

Raise3D Pro2 Plus

Price: $4999.00 as of Jan 5, 2023, 06:51 PST - Details

Width: 12 inch

Height: 23.8 inch

Depth: 12 inch

Dobot Mooz

Price: $799.00 as of Jan 4, 2023, 23:28 PST - Details

Width: 5.11 inch

Height: 5.11 inch

Depth: 5.11 inch

LulzBot TAZ Workhorse

Price: $3989.00 as of Jan 4, 2023, 16:09 PST - Details

Width: 11.02 inch

Height: 11.22 inch

Depth: 11.02 inch

Ultimaker 2+ Connect

Price: $2750.00 as of Jan 5, 2023, 09:38 PST - Details

Width: 8.7 inch

Height: 8 inch

Depth: 8. 6 inch

6 inch

CEL Robox RBX01

Price: $918.95 as of Jan 5, 2023, 11:31 PST - Details

Width: 8.27 inch

Height: 3.94 inch

Depth: 5.91 inch

Raise3D Pro3

Price: $5599.00 as of Jan 4, 2023, 23:37 PST - Details

Width: 11.81 inch

Height: 11.81 inch

Depth: 11.81 inch

Sindoh 3DWOX 2X

Price: $2699.00 as of Jan 4, 2023, 12:08 PST - Details

Width: 8.9 inch

Height: 11.8 inch

Depth: 7.9 inch

JGAURORA A-8

Price: $6465.45 as of Jan 5, 2023, 04:52 PST - Details

Width: 13.78 inch

Height: 11.8 inch

Depth: 9.8 inch

Monoprice MP Mini

Price: $351.99 as of Jan 4, 2023, 19:15 PST - Details

Width: 4.7 inch

Height: 7.8 inch

Depth: 2.7 inch

Kywoo Tycoon Slim

Price: $319.99 as of Jan 5, 2023, 05:42 PST - Details

Width: 9. 45 inch

45 inch

Height: 11.81 inch

Depth: 9.45 inch

Artillery Sidewinder X1

Price: $600.00 as of Jan 5, 2023, 06:50 PST - Details

Width: 11.81 inch

Height: 15.75 inch

Depth: 11.81 inch

MakerBot Replicator Z18

Price: $12049.50 as of Jan 5, 2023, 03:25 PST - Details

Width: 11.8 inch

Height: 18 inch

Depth: 12 inch

Monoprice 300

Price: $782.02 as of Jan 5, 2023, 04:09 PST - Details

Width: 11 inch

Height: 11.8 inch

Depth: 9.8 inch

UP Plus 2

Price: $799.00 as of Jan 4, 2023, 18:56 PST - Details

Width: 5.3 inch

Height: 5.5 inch

Depth: 5.5 inch

FlashForge Creator Max

Price: $879.00 as of Jan 4, 2023, 15:54 PST - Details

Width: 8.93 inch

Height: 5.9 inch

Depth: 5.82 inch

Robo E3 Pro

Price: $1999. 00 as of Jan 5, 2023, 00:46 PST - Details

00 as of Jan 5, 2023, 00:46 PST - Details

Width: 9.8 inch

Height: 11.8 inch

Depth: 11 inch

Anet N4

Price: $250.00 as of Jan 4, 2023, 15:22 PST - Details

Width: 4.72 inch

Height: 5.43 inch

Depth: 2.55 inch

LeapFrog Creatr

Price: $593.53 as of Jan 5, 2023, 11:52 PST - Details

Width: 10.62 inch

Height: 7.87 inch

Depth: 9.05 inch

Makerbot Method X

Price: $5999.99 as of Jan 4, 2023, 12:37 PST - Details

Width: 7.5 inch

Height: 7.75 inch

Depth: 7.5 inch

Raise3D E2CF

Price: $4499.00 as of Jan 5, 2023, 10:34 PST - Details

Width: 13.4 inch

Height: 9.4 inch

Depth: 9.4 inch

Gowe Singl

Price: $999.00 as of Jan 4, 2023, 12:18 PST - Details

Width: 4.7 inch

Height: 4.7 inch

Depth: 4.7 inch

Gowe Reprappro Huxley

Price: $999. 00 as of Jan 4, 2023, 19:35 PST - Details

00 as of Jan 4, 2023, 19:35 PST - Details

Width: 5.51 inch

Height: 5.51 inch

Depth: 4.33 inch

Cube Printer 2nd Generation

Price: $349.00 as of Jan 5, 2023, 09:26 PST - Details

Width: 5.5 inch

Height: 5.5 inch

Depth: 5.5 inch

Geeetech Prusa I3 A Pro

Price: $642.00 as of Jan 5, 2023, 00:45 PST - Details

Width: 7.87 inch

Height: 7.48 inch

Depth: 7.87 inch

Kloner3D Kids XL

Price: $1389.00 as of Jan 4, 2023, 11:57 PST - Details

Width: 5.91 inch

Height: 13.39 inch

Depth: 5.51 inch

Kloner3D 500

Price: $10518.00 as of Jan 5, 2023, 07:21 PST - Details

Width: 19.69 inch

Height: 5.51 inch

Depth: 9.45 inch

Kloner3D Kids

Price: $926.00 as of Jan 5, 2023, 07:08 PST - Details

Width: 4.72 inch

Height: 4.72 inch

Depth: 4. 72 inch

72 inch

Kloner3D 240

Price: $6390.00 as of Jan 5, 2023, 04:07 PST - Details

Width: 8.66 inch

Height: 5.51 inch

Depth: 9.45 inch

Kloner3D 240Twin

Price: $11973.00 as of Jan 4, 2023, 18:19 PST - Details

Width: 14.17 inch

Height: 5.51 inch

Depth: 9.45 inch

Kloner3D 300H

Price: $2579.00 as of Jan 5, 2023, 06:51 PST - Details

Width: 12.6 inch

Height: 12.99 inch

Depth: 10.24 inch

Kloner3D 320

Price: $9009.00 as of Jan 4, 2023, 17:06 PST - Details

Width: 12.6 inch

Height: 5.51 inch

Depth: 9.45 inch

Tiertime UP BOX+

Price: $1449.00 as of Jan 5, 2023, 09:45 PST - Details

Width: 10 inch

Height: 8 inch

Depth: 8 inch

Zortrax M300

Price: $4199.00 as of Jan 4, 2023, 17:24 PST - Details

Width: 11. 81 inch

81 inch

Height: 11.81 inch

Depth: 11.81 inch

Geeetech Aluminum Prusa I3

Price: $577.50 as of Jan 5, 2023, 11:30 PST - Details

Width: 7.87 inch

Height: 7.08 inch

Depth: 7.87 inch

Velleman K8800

Price: $500.00 as of Jan 5, 2023, 09:28 PST - Details

Width: 7.87 inch

Height: 8.85 inch

Depth: 7.87 inch

Monoprice MP Cadet

Price: $199.99 as of Jan 4, 2023, 11:47 PST - Details

Width: 3.9 inch

Height: 3.9 inch

Depth: 4.1 inch

ToAuto Pyramid A1

Price: $854.30 as of Jan 5, 2023, 09:27 PST - Details

Width: 11.81 inch

Height: 15.74 inch

Depth: 11.81 inch

Geeetech Prusa I3 Pro B

Price: $372.81 as of Jan 5, 2023, 11:30 PST - Details

Width: 7.87 inch

Height: 7.08 inch

Depth: 7.87 inch

JGAURORA Z603S

Price: $1850. 00 as of Jan 4, 2023, 16:28 PST - Details

00 as of Jan 4, 2023, 16:28 PST - Details

Width: 11.02 inch

Height: 7.08 inch

Depth: 7.08 inch

BQ Hephestos 2

Price: $999.99 as of Jan 4, 2023, 16:09 PST - Details

Width: 8.26 inch

Height: 8.66 inch

Depth: 11.69 inch

Anet ET5X

Price: $550.00 as of Jan 4, 2023, 19:33 PST - Details

Width: 11.81 inch

Height: 15.74 inch

Depth: 11.81 inch

Creality CR-10 Smart

Price: $490.00 as of Jan 5, 2023, 06:55 PST - Details

Width: 11.81 inch

Height: 15.74 inch

Depth: 11.81 inch

Comparison of 3D printing technologies: FDM, SLA and SLS

Additive manufacturing or 3D printing reduces costs, saves time and expands the technological possibilities in product development. 3D printing technologies offer versatile solutions for applications ranging from rapid concept and functional prototypes in the field of prototyping to fixtures and clamps or even final parts in manufacturing.

Over the past few years, high resolution 3D printers have become more affordable, more reliable and easier to use. As a result, more companies have been able to use 3D printing technology, but choosing between different competing 3D printing solutions can be difficult. nine0003

Which technology is right for your needs? What materials are available for her? What equipment and training is needed to get started? What are the costs and payback?

In this article, we take a closer look at three of today's most well-known plastic 3D printing technologies: Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Choosing between FDM and SLA 3D printer? Check out our detailed comparison of FDM and SLA technologies. nine0012

Download this high resolution infographic here.

VIDEO MANUAL

Can't find the 3D printing technology that best suits your needs? In this video tutorial, we compare Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) technologies in terms of the top factors to consider when purchasing.

Watch Video

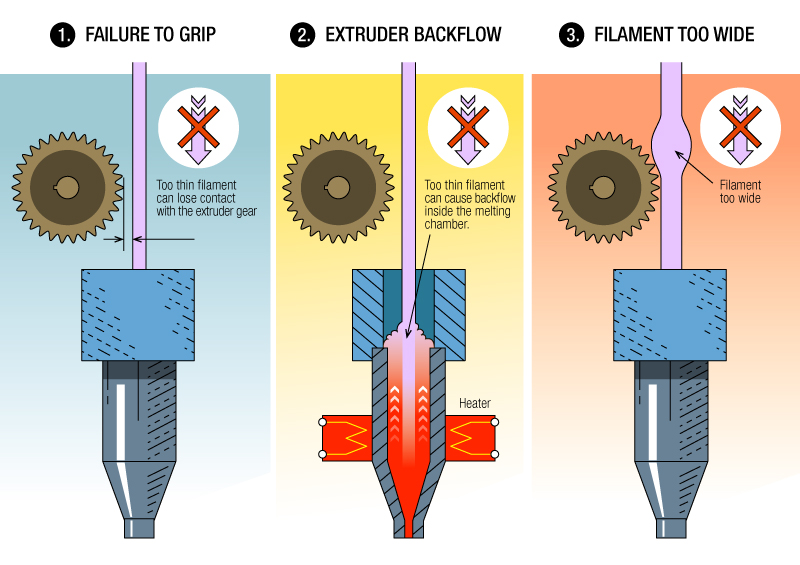

Fused Deposition Modeling (FDM), also known as Fused Filament Manufacturing (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the rise of consumer 3D printers. On FDM printers, models are made by melting and extruding a thermoplastic filament, which the printer's nozzle applies layer by layer to the model being built. nine0003

The FDM method uses a range of standard plastics such as ABS, PLA and their various blends. It is well suited for making basic experimental models, as well as for quickly and inexpensively prototyping simple parts, such as parts that are usually machined.

FDM models often show layer lines and may have inaccuracies around complex features. This sample was printed on a Stratasys uPrint FDM industrial 3D printer with soluble support structures (printer price starting at $15,900).

FDM printers have the lowest resolution and accuracy of SLA or SLS and are not the best option for printing complex designs or parts with complex features. Surface quality can be improved by chemical and mechanical polishing processes. To address these issues, industrial FDM 3D printers use soluble support structures and offer a wider range of engineering thermoplastics, but they are also expensive. nine0003

Surface quality can be improved by chemical and mechanical polishing processes. To address these issues, industrial FDM 3D printers use soluble support structures and offer a wider range of engineering thermoplastics, but they are also expensive. nine0003

FDM printers do not handle complex designs or parts with complex features well (left) compared to SLA printers (right).

Invented in the 1980s, stereolithography is the world's first 3D printing technology and is still one of the most popular technologies among professionals today. SLA printers use a process called photopolymerization, which is the conversion of liquid polymers into hardened plastic using a laser.

See stereolithography in action.

Models printed on SLA printers have the highest resolution and accuracy, the sharpest detail and the smoothest surface of all plastic 3D printing technologies, but the main advantage of the SLA method is its versatility. Materials manufacturers have developed innovative formulas for SLA polymers with a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics. nine0003

nine0003

Models created using SLA technology have sharp edges, a smooth surface and almost invisible layer lines. This sample was printed on a Formlabs Form 3 Desktop Stereolithographic 3D Printer (price starting at $3499).

SLA is an excellent option for making highly detailed prototypes that require tight tolerances and smooth surfaces such as molds, templates and functional parts. SLA technology is widely used in industries ranging from engineering and design to manufacturing, dentistry, jewelry, modeling, and education. nine0003

White Paper

Download our in-depth white paper to learn how SLA printing works, why thousands of professionals use it today, and how this 3D printing technology can be useful in your work.

Download white paper

free sample

Experience Formlabs print quality firsthand. We will send a free 3D printing sample directly to your office.

Request a free sample

Selective laser sintering is the most common additive manufacturing technology used in industry.

Selective Laser Sintering (SLS) 3D printers use a high power laser to sinter fine polymer powder particles. The unsprayed powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper. Models produced using SLS printing have excellent mechanical characteristics: their strength can be compared with the strength of injection molded parts. nine0003

Models created with SLS technology have a slightly rough surface, but almost no visible layer lines. This sample was printed on the Formlabs Fuse 1 SLS workshop 3D printer (price starting at $18,500).

The most common selective laser sintering material is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is light, strong and flexible, resistant to impact, heat, chemicals, UV radiation, water and dirt. nine0003

Nylon is light, strong and flexible, resistant to impact, heat, chemicals, UV radiation, water and dirt. nine0003

The combination of low part cost, high productivity, and widely used materials makes SLS a popular method for engineering functional prototyping and a cost-effective alternative to injection molding in cases where production runs are limited.

White Paper

Looking for a 3D printer to create durable, functional models? Download our white paper to learn how selective laser sintering (SLS) technology works and why it is popular in 3D printing for functional prototypes and end-use products. nine0003

Download white paper

Each 3D printing technology has its strengths, weaknesses, limitations and applications. The following table summarizes the key characteristics and factors.

| Modeling method (FDM) | Stereolithography (SLA) | Selective laser sintering (SLS) | |

|---|---|---|---|

| ★★★★☆ | |||

| accuracy | ★cle ★cle \ ★★★★★ | ||

| Easy to use | ★★★★★ | ★★★★★ | ★★★★★★★★★★★★★0104 |

| Benefits | Speed Inexpensive custom machines and materials | High cost efficiency High accuracy Smooth surface Wide range of functional applications | Robust functional parts Design flexibility No need for supporting structures |

| Disadvantages | Poor accuracy low detail Limited Compliance with Design Design | Susceptibility to prolonged UV exposure | Uneven surface Material Limitations |

| Applications | Inexpensive Rapid Prototyping Basic experimental models | Functional prototyping Templates, forms and tools Dental products Prototyping jewelry and molds Model building | Functional prototyping Small-scale and custom manufacturing |

| Print volume | Up to ~300 x 300 x 600 mm (desktop 3D printers) | Up to ~300 x 335 x 200 mm (Desktop and Workshop 3D printers) | Up to 165 x 165 x 300 mm (Workshop 3D printers) |

| Materials | ABS plastic, PLA and their various mixtures. | Various polymers (thermosets). Standard, engineering (with properties of ABS plastic, polypropylene, flexible, heat-resistant), molding, dental and medical (biocompatible). | Engineering thermoplastics. Nylon 11, Nylon 12 and their composites. nine0104 |

| Training | Minimum training in equipment setup, machine operation and surface treatment; short maintenance training. | Plug and play concept. Minimal training in equipment setup, maintenance, machine operation and surface treatment. | Short training in equipment setup, maintenance, machine operation and surface treatment. |

| Room requirements | Air-conditioned environment or preferably individual ventilation for desktop machines. | Desktop machines suitable for office use. | Workshop systems have moderate space requirements and can be installed in a production environment. |

| Accessories | Support removal system for machines with soluble support structures (optionally automated), finishing tools. nine0104 nine0104 | Finishing station, washing station (optionally automated), finishing tools. | Post-processing station for cleaning models and restoring materials. |

Either way, you should choose the technology that best suits your business. Prices have dropped significantly in recent years, and today all three technologies are offered in compact and affordable systems.

3D printing costing doesn't end with initial equipment costs. Material and labor costs have a significant impact on the cost of each part, depending on the application and production needs. nine0003

Below is a detailed breakdown by technology.

| Modeling method (FDM) | Stereolithography (SLA) | Selective laser sintering (SLS) | Equipment costs and sets for 3D-dimensions for 3Ds and sets several hundred dollars. Offering higher quality, mid-range desktop printers start at $2,000, while industrial systems start at $15,000. | Professional desktop printers start at $3,500, large-format workshop printers start at $10,000, industrial systems for large-scale production start at $80,000. |

|---|---|---|---|

| Material cost | $50-$150/kg for most standard and engineering yarns and $100-$200/kg for auxiliary materials. | $50-$150/L for most standard and engineering polymers. | $100/kg for nylon. SLS does not require supporting structures and unused powder can be reused, reducing material costs. |

| Labor | Manual removal of support structures (may be automated for industrial systems with dissolvable supports). Long post-processing is required to obtain a high quality surface. | Washing and final polymerization (both can be automated). Simple post-processing to remove supporting structures. nine0104 | Easy cleaning to remove excess powder. |

INTERACTIVE MATERIAL

Try our interactive ROI tool to see how much time and money you can save by printing with Formlabs 3D printers.

Calculate savings

FDM, SLA and SLS printed prototype ski goggle frames (left to right).

We hope this article has helped you narrow down your search for the 3D printing technology best suited to your needs. nine0003

Take advantage of our additional resources to learn the ins and outs of 3D printing, learn more about each technology and learn more about specific 3D printing systems.

Learn more about 3D printing technologies

compare 3D printers in 2020

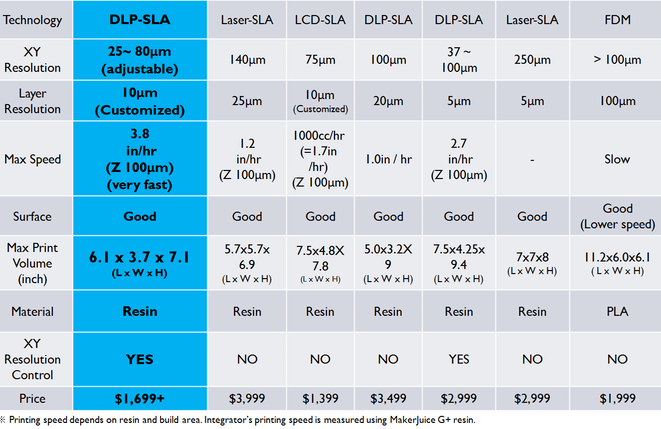

A variety of 3D printing technologies are available on the market today. Getting to know the nuances of each helps you understand what you can expect from the final models and decide which technology is right for you.

Stereolithography (SLA) and digital light processing (DLP) are the two most common 3D printing technologies using resins. 3D printers that use resin as consumables have become very popular due to their ability to produce highly accurate, isotropic and waterproof prototypes and models with high detail and smooth surfaces.

Where these technologies used to be complex and prohibitively expensive, today's compact desktop SLA and DLP printers produce industrial quality parts at an affordable price and offer tremendous application flexibility through a wide range of materials. nine0003

Both of these processes selectively expose the liquid polymer to a light source: an SLA laser, a DLP projector, forming very thin, hard layers of plastic that fold into a solid object. Although the principle of operation of these technologies is very similar, they can give significantly different results.

In this detailed guide, we will explain the features of these two 3D printing processes and see how they differ in terms of resolution, accuracy, print volume, speed, workflows, etc.

sample print

Experience the quality of stereolithography prints for yourself. We will send a free sample of the Formlabs stereolithographic 3D printed model directly to your office.

Request a free print sample

Desktop stereolithography 3D printers contain a resin tank with a transparent bottom and a non-adhesive surface that serves as a base for the liquid resin to cure, allowing newly formed layers to be carefully separated. nine0003

The printing process begins with the platform lowered into the resin tank, leaving a free space corresponding to the height of the layer between the platform or the last finished layer and the bottom of the tank. The laser beam is fed to two mirror galvanometers, with the help of which it enters the desired coordinates on a series of mirrors. This allows a focused beam of light to be fed upwards through the bottom of the tank, under the influence of which the polymer layer hardens.

Then the hardened layer is separated from the bottom of the tank, and the platform rises higher, and liquid polymer enters the vacant space. This process is repeated until printing is complete. nine0003

The Form 3 and Form 3L Low Force Lithography (LFS) stereolithography technology is a new step in the development of stereolithographic 3D printing.

In LFS-based 3D printers, the optical components are located in the Light Processing Unit (LPU). Inside the LPU, a galvanometer positions the high-density laser beam in the y-direction, passes it through a spatial filter, and directs it into a deflecting and parabolic mirror to ensure that the beam always remains perpendicular to the plane of the platform, ensuring print accuracy and reproducibility. nine0003

As the LPU moves in the X direction, the printed model is gently separated from the flexible bottom of the tank, which greatly reduces the forces on the models during the printing process.

LFS-based 3D printing greatly reduces the stress placed on parts during the printing process by using a flexible reservoir and linear illumination for incredible surface quality and print accuracy.

This advanced stereo lithography technology features higher surface quality and print accuracy. The lower print tear force also allows the creation of lightweight support structures that can be detached without force, and the method itself opens up great opportunities for the further development of advanced production-ready materials. Learn more about stereolithographic 3D printing

Learn more about stereolithographic 3D printing

White Paper

Download our in-depth white paper to learn how SLA printing works, why thousands of professionals use it today, and how this 3D printing technology can help your work.

Download white paper

Desktop DLP printers use a transparent bottom resin tank and a platform that descends into the tank to layer upside down models. In this they are no different from stereolithographic 3D printers. nine0003

The difference between them is the light source. DLP-based 3D printers use a digital screen to project the image of the layer onto the entire platform, causing all the desired dots to solidify at the same time.

Light is reflected on a digital micromirror screen (DMD), a dynamic mask consisting of microscopic mirrors that are located in a matrix on a semiconductor chip. The rapid switching of these tiny mirrors between lenses that direct light to the bottom of a tank or radiator determines the coordinates at which the liquid polymer must solidify in order to form the current layer. nine0003

nine0003

Because the projector is a digital screen, each layer's image is made up of square pixels, resulting in a three-dimensional layer of rectangular cubes called voxels.

When it comes to 3D printer specifications, resolution is the focus, but it often leads to confusion. The basic units of the SLA and DLP processes are different forms, making it difficult to compare printers by numbers alone.

In 3D printing, there are three dimensions to consider: two planar 2D dimensions (X and Y) and a third vertical Z dimension, which is used for 3D printing. nine0003

The resolution of the Z measurement is determined by the thickness of the layer that the 3D printer can print. Printers based on SLA and DLP technology have one of the best Z resolutions of any other process, allowing you to print layers with minimal thickness. Typically, users can set the layer height to between 25-300µm, allowing developers to trade-off between level of detail and speed.

In DLP printers, XY resolution is determined by the pixel size, the smallest detail that the projector can reproduce in a single layer. It depends on the resolution of the projector (the most common is Full HD (1080p)) and its distance from the optical glass. Therefore, most desktop DLP printers have a constant XY resolution of 35 to 100 microns. nine0003

It depends on the resolution of the projector (the most common is Full HD (1080p)) and its distance from the optical glass. Therefore, most desktop DLP printers have a constant XY resolution of 35 to 100 microns. nine0003

In stereolithographic 3D printers, the XY resolution is determined based on the size of the laser spot and the number of steps that can be used to control the beam. For example, a Form 3 3D printer based on LFS technology has a laser with a spot size of 85 μm, but due to the constant line scanning process, the laser can move at a smaller step, and the printer can consistently print models with an XY resolution of 25 μm.

Resolution itself is often only an indicator of vanity. It gives some idea of the performance, but does not necessarily directly correspond to the accuracy and quality of the print. nine0003

Learn more about resolution in 3D printing in our detailed guide.

Since 3D printing is an additive process, violations can potentially occur in every layer. The process of forming layers affects the level of accuracy and correctness of each layer. Accuracy and accuracy depend on many factors: 3D printing process, materials, software settings, post-processing, etc.

The process of forming layers affects the level of accuracy and correctness of each layer. Accuracy and accuracy depend on many factors: 3D printing process, materials, software settings, post-processing, etc.

In general, SLA and DLP printers are among the most accurate. Differences in print accuracy are often more noticeable between printers from different manufacturers than between the technologies themselves. nine0003

For example, entry-level SLA or DLP printers may use off-the-shelf projectors, lasers, or galvanometers, and their manufacturers strive to achieve optimum performance from these parts. Professional SLA and DLP printers (such as Formlabs Form 3) have a special optical system that is adjusted according to the needs of users.

Precision is critical for parts such as mouthguards (left) and surgical guides (right). nine0012

Precision is critical for parts such as mouthguards (left) and surgical guides (right).

Equally important is calibration. When using DLP projectors, manufacturers face uneven distribution of light on the platform and optical lens distortion, which means that the size and shape of the pixels in the middle and at the edges are different. Stereolithographic 3D printers use the same light source for all parts of the model, ensuring uniformity, but they still need to be carefully calibrated to avoid distortion. nine0003

When using DLP projectors, manufacturers face uneven distribution of light on the platform and optical lens distortion, which means that the size and shape of the pixels in the middle and at the edges are different. Stereolithographic 3D printers use the same light source for all parts of the model, ensuring uniformity, but they still need to be carefully calibrated to avoid distortion. nine0003

Even a 3D printer with the best components and the best degree of calibration can produce different results depending on the consumables used. Resin parameters have to be changed to ensure the best quality, but they may not be available for new materials that have not been properly tested with the appropriate 3D printer model.

What conclusion can be drawn from this? Knowing only the technical characteristics, it is impossible to get a complete picture of the quality. The best way to evaluate a 3D printer is to study the models printed on it or ask the manufacturer to make a test model for your project. nine0003

nine0003

DLP printers have an inverse relationship between resolution and working volume. The resolution depends on the projector, which determines the number of pixels/voxels available. If you move the projector closer to the optical glass, the pixels will become smaller and the resolution will increase, but the working area will be limited.

Some manufacturers install multiple projectors side by side or use a 4K high-definition projector to increase the working area, but this increases the cost significantly. The price of such models is much higher than other desktop 3D printers. nine0003

Therefore, DLP printers are usually optimized for specific purposes. Some of them have a smaller workspace and allow you to produce in high resolution such small and detailed models as jewelry, while others can print larger parts, but with a lower resolution.

The stereolithography process is inherently more scalable because the print volume of an SLA printer is independent of model resolution. A single model can be of any size and resolution, and can be placed anywhere on the workspace. This allows you to print large high-resolution 3D models or large batches of finely detailed models to increase printer performance. nine0003

A single model can be of any size and resolution, and can be placed anywhere on the workspace. This allows you to print large high-resolution 3D models or large batches of finely detailed models to increase printer performance. nine0003

Another hurdle to increasing print volume in both SL and DLP printers is the release force. When printing large models, the forces applied to them increase exponentially as the cured layer separates from the reservoir.

With LFS printing, the flexible film at the base of the resin reservoir gently peels off when the platform pulls the model up, greatly reducing stress on the model. This unique feature has dramatically increased print volume in the first affordable large-format stereolithography printer, the Form 3L. nine0003

Form 3L is the first affordable 30 x 33.5 x 20cm large format 3D lithography 3D printer. compared to solutions based on other technologies. When we talk about differences, in most cases they are only visible on very small parts and models with a high degree of detail.

Because 3D printers print in layers, finished models often have noticeable horizontal lines. And due to the fact that digital light processing technology uses rectangular voxels, the effect of vertical lines can also be observed. nine0003

DLP printers use rectangular voxels to render images, which can result in vertical lines. In this image, the vertical voxel lines are shown as they appear when printed (left), highlighted for better visibility (right).

Since voxels are rectangular, they affect the shape of the curved edges. Let's draw an analogy with creating a round shape from a LEGO constructor - the edges will have a stepped shape both along the Z axis and on the X-Y plane. nine0003

The rectangular shape of the voxels makes the curved edges appear jagged. Removing visible voxels and layer lines requires post-processing such as sanding.

Layer lines are virtually invisible when printed on LFS-based 3D printers. As a result, surface roughness is reduced, resulting in a smooth surface, and when using transparent materials, models with greater transparency.

When talking about the speed of 3D printing, it is important to consider not only the printing speed itself, but also the productivity. nine0003

The overall print speed of 3D printers based on SLA and DLP technologies is approximately the same. Since the projector exposes each layer as a whole, the speed of DLP 3D printing is uniform and depends only on the height of the model, while SLA 3D printers laser shape each part. As practice shows, as a result, stereolithographic 3D printers become comparable in speed or even faster when printing one small or medium model, while DLP printers are faster at printing large solid models or several models that almost completely fill the space of the platform. nine0003

But do not forget that in printers based on DLP technology, there is an inverse relationship between resolution and working volume. A small DLP printer can quickly print small models or high-resolution (small) batches of small models, but print volume limits model size and device performance. Another high volume device can produce larger models, or batches of smaller models, faster but at lower resolution than a stereolithographic printer. nine0003

Another high volume device can produce larger models, or batches of smaller models, faster but at lower resolution than a stereolithographic printer. nine0003

With a stereolithographic 3D printer, all this can be done on one machine. At the same time, users can decide what they want to optimize in each case: resolution, speed or performance.

DLP printers use rectangular voxels to render images, which can result in vertical lines. In this image, the vertical voxel lines are shown as they appear when printed (left), highlighted for better visibility (right). nine0012

Stereolithographic 3D printers have a higher print volume, allow you to make models in batches and print models at night, increasing productivity.

| 100 microns | 200 microns |

|---|---|

| | |

| nine0455 Grey Resin 100 microns | 200 microns |

|---|---|

| | |

| 100 Microns | 200 Microns |

|---|---|

| | |

Stereolithographic 3D printers have a higher print volume, allow you to make models in batches and print models at night, increasing productivity.

INTERACTIVE

Try our interactive ROI tool to see how much time and money you can save by printing with Formlabs 3D printers.

Calculate savings

As with accuracy, differences in workflows and available materials are more printer dependent than technology. nine0003

Most SLA and DLP printers are plug and play and allow easy replacement of platforms and resin tanks. Some more sophisticated models come with a cartridge system to automatically refill the reservoir with liquid resin, requiring less attention and making it easier to print at night.

Some printers come with their own software for preparing 3D models for printing (for example, PreForm for Formlabs stereolithographic 3D printers), while other manufacturers offer ready-made standard solutions. Different software tools have different features, such as PreForm allows you to customize the printing process with one click, powerful tools for optimizing the density and size of supporting structures, adjustable layer thickness, and features to save materials and time. Fortunately, the software can be downloaded and tested before purchasing a 3D printer. nine0003

Fortunately, the software can be downloaded and tested before purchasing a 3D printer. nine0003

As with precision, differences in workflows and available media are more printer dependent than technology.

3D printers can work with a wide range of polymer materials for different applications.

One of the main advantages of polymer-based 3D printing is the large number of materials from which models can be made for various purposes. Polymers with different compositions have a variety of characteristics: they can be soft or hard, contain additives such as glass and ceramics, or have special mechanical properties such as high bending temperature under load or impact resistance. nine0003

But at the same time, the range of supported materials depends on the specific model of the 3D printer, so we recommend that you check this information with the manufacturer before making a purchase.

SLA and DLP prints require post-processing after printing. First, the models must be washed in solvent to remove excess resin. In some cases, such as models made from engineering and biocompatible materials, final polymerization is also required. For stereolithographic 3D printers, Formlabs offers solutions to automate these steps, saving you time and effort. nine0003

In some cases, such as models made from engineering and biocompatible materials, final polymerization is also required. For stereolithographic 3D printers, Formlabs offers solutions to automate these steps, saving you time and effort. nine0003

Finally, 3D models printed on supporting structures require the removal of such structures. This must be done manually - the process is similar for both SLA and DLP printers. LFS-based 3D printers use lightweight support structures with very small contact points, allowing for easy release with minimal marks.

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins. nine0003

Recommend Me a Material

We hope that after understanding the differences in technologies and print results, it will be much easier for you to choose the 3D printer that best suits your needs and workflow.