3D print drugs

Five companies personalizing treatments with 3D printed drugs

There has been a noticeable shift in recent years towards the personalization of medicine, with the pharmaceutical industry showing interest in pills that are tailored to a patient’s needs. Here are five companies that are leveraging 3D printing to produce customizable drugs.

Conventional drug production relies on large-scale batch manufacturing, which is very efficient at churning out large volumes of drugs with uniform characteristics. But this becomes time-consuming and expensive when small batches are needed, such as for clinical trials where the doses need to be adjusted. The process is also associated with an environmental burden resulting from inefficient use of raw materials, expired stock and production of toxic and non-toxic waste.

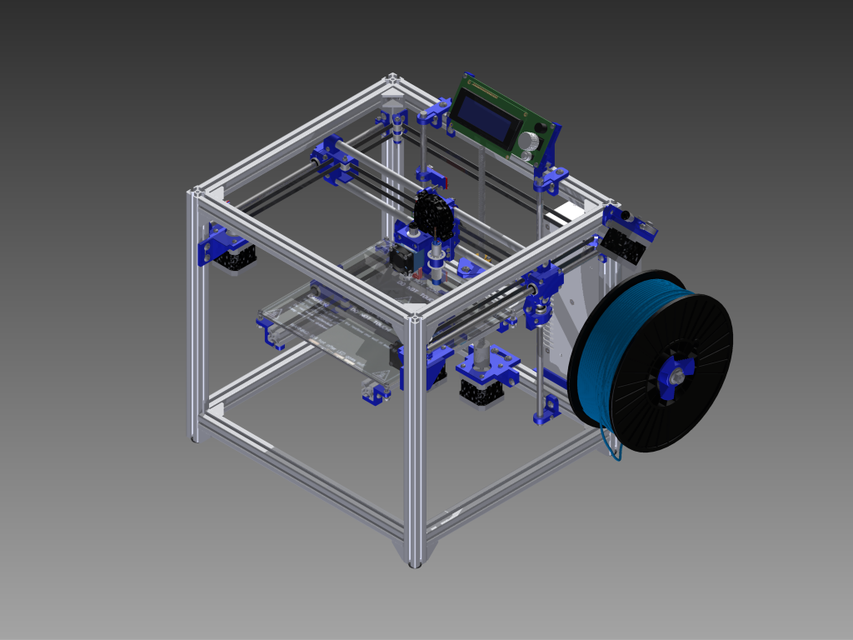

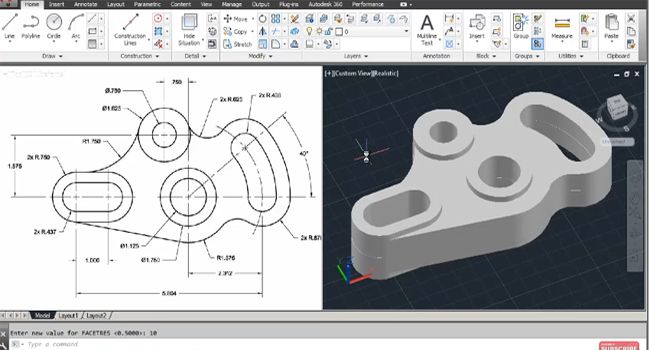

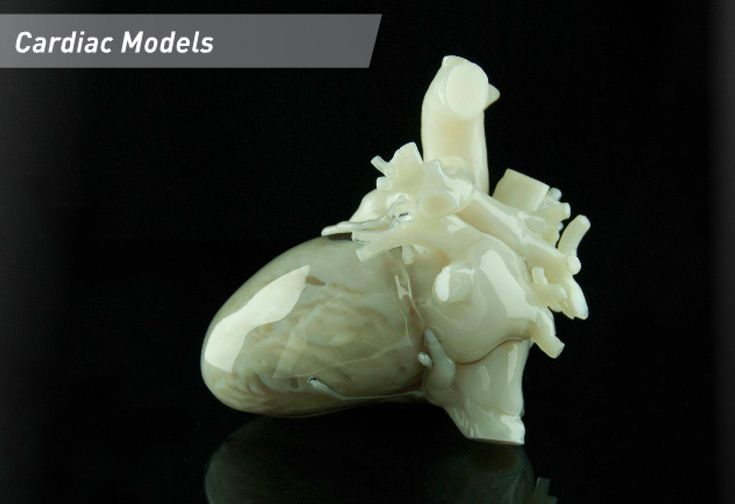

Additive manufacturing, or 3D printing, is a tool that can allow for small-scale production of medicines. This approach uses 3D modeling software to build an object layer-by-layer; for solid drugs, the 3D printer stacks ink with an excipient — inactive substances in drugs added for specific functions like improved stability and bioavailability — and the active pharmaceutical ingredient to print out a finished product. By adjusting the printing parameters, the drug dosages, drug combinations, release profiles and even flavors can be personalized.

There are many challenges that have limited widespread implementation of 3D printing technology, such as 3D printers not meeting good manufacturing practice standards and a limited range of excipients suitable for 3D printing. Nevertheless, 3D printing has the potential to revolutionize the pharmaceutical industry, and several companies are making strides in the space.

Aprecia PharmaceuticalsHeadquarters: Pennsylvania, U.S.

Aprecia Pharmaceuticals is behind the first and only U.S. Food and Drug Administration (FDA)-validated 3D printing platform for commercial-scale drug development. Their aim is to make medicines easier to take and reduce the number of pills a patient needs. Using this platform, Aprecia developed ZipDose Technology, which allows tablets to hold a high dosage load of up to 1,000 mg and still rapidly dissolve with just a sip of water.

Content continues below

Related Content

ZipDose is used in the production of Spritam (levetiracetam), a fast dissolving oral medicine for the treatment of specific types of epileptic seizures. It is targeted for patients who struggle to swallow pills or are unable to measure out the precise dosage of liquid levetiracetam. In 2015, Spritam became the first and only 3D printed drug to be approved by the FDA.

FabRxHeadquarters: London, U.K.

Founded in 2014 as a spin-out of University College London, FabRx aims to revolutionize medical treatments by facilitating the production of personalized medicines, where the size, shape, dosage and dosage combinations can be customized. In 2020, the company released M3DIMAKER, the first pharmaceutical 3D printer for personalized medicine, allowing clinicians and other professionals to “print” tailored medicines on demand.

Using their 3D printing technology, FabRx has also created a range of personalized Printlets — medicines with customized shapes, flavors, colors, dosages and release profiles, such as tablets with Braille and moon patterns for patients with visual impairments as well as Polypills, which combine several drugs in one pill.

FabRx technology is also being used to print personalized pills for children with a rare metabolic disorder called maple syrup urine disease, which requires treatments to be strictly tailored based on age, weight and blood concentrations of the amino acid isoleucine. Current manual preparation methods are time consuming and costly, so FabRx’s approach could save time and money for caregivers.

MerckHeadquarters: Darmstadt, Germany

Content continues below

Related Content

The biopharma giant Merck is also taking a stab at next-generation tablet manufacturing through 3D printing. In 2020, Merck announced a cooperation with ACMC — sister company of EOS, a worldwide provider of 3D printing solutions — to produce 3D printed tablets for clinical trials at first, before moving towards commercial-scale manufacturing. This partnership aims to advance the industrial applications of 3D printing technology and digitalization.

Triastek, Inc.

Headquarters: Nanjing, China

Triastek is a global leader in pharmaceutical 3D printing, with 41 patents that account for more than 20% of global 3D printing pharmaceuticals applications. Using their proprietary MED 3D printing technology, Triastek develops their own in-house drugs and partners with others to provide drug development solutions.

The MED 3D printing platform allows for the customizable design of tablets, with the different shapes and geometries controlling drug onset time, duration, and drug interactions with the body. This platform was accepted into the FDA’s Emerging Technology Program in 2020, and two of their 3D printed drugs have been granted investigational new drug clearances from the FDA. The first is a chronotherapeutic drug for rheumatoid arthritis, where the drug is taken at bedtime but its release is delayed until the early morning hours, when pain and joint stiffness are at their peak. The second is a one-dose pill alternative to the twice-daily marketed drug for cardiovascular and clotting disorders.

Triastek recently entered into a research collaboration with Eli Lilly and Company to improve the bioavailability of drugs in the intestine by achieving precise organ targeting and programmed drug release.

GlaxoSmithKlineHeadquarters: Brentford, U.K.

GSK was one of the first big pharma companies to show interest in 3D printing as a manufacturing tool, partnering with the University of Nottingham to study the feasibility of 3D inkjet printing and curing with ultraviolet light to produce solid drug forms; in 2017, researchers demonstrated the successful 3D printing of ropinirole tablets for Parkinson’s disease.

3D inkjet printing deposits liquid materials or solid suspensions layer-by-layer but each deposited layer must first be dried, or “cured,” between the deposition steps. GSK is exploring how to convert active pharmaceutical ingredients into curable ink to enable 3D drug printing.

Medicines 3D-printed in seven seconds

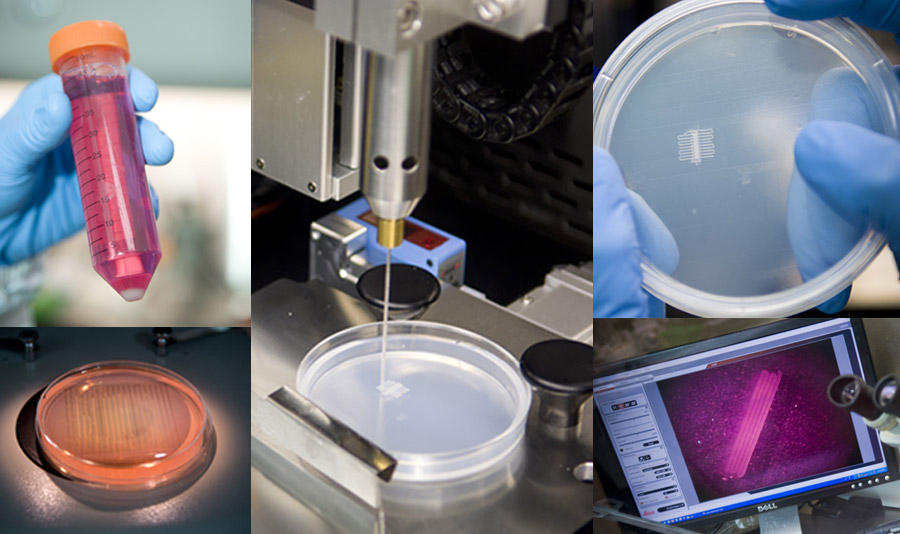

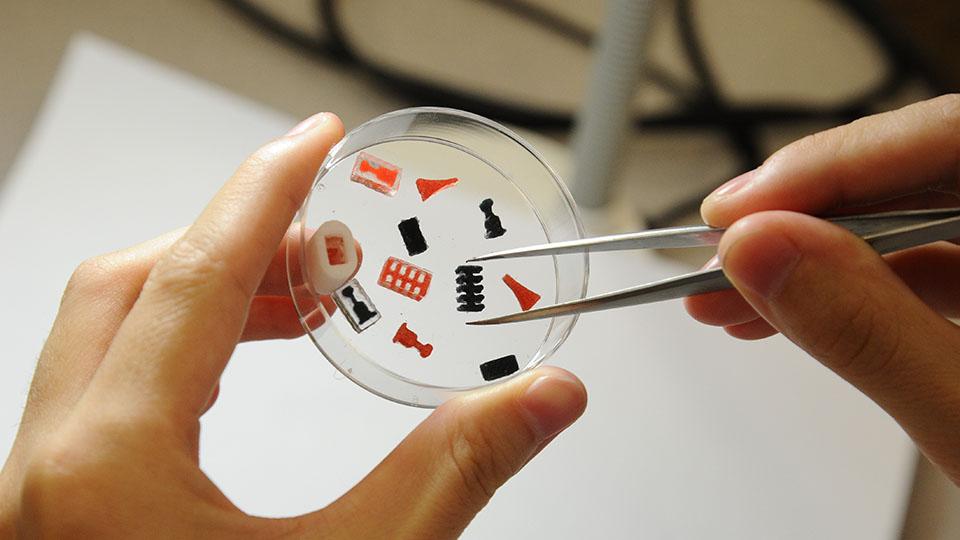

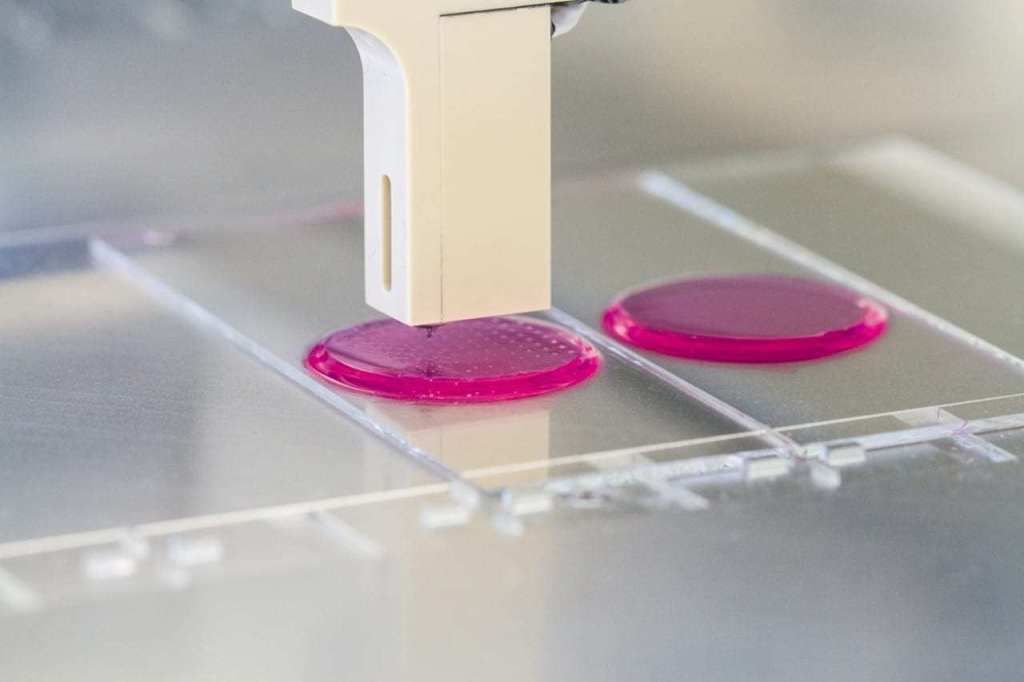

Credit: University College LondonMedicines can be printed in seven seconds in a new 3D-printing technique that could enable rapid on-site production of medicines, reports a UCL-led research team.

The findings published in the journal, Additive Manufacturing, improve the prospects of how 3D printers could be integrated into fast-paced clinical settings for on-demand production of personalized medicines.

For the current study, the researchers loaded printlets (printed tables) with paracetamol, which is one of many medicines that can be produced with a 3D printer.

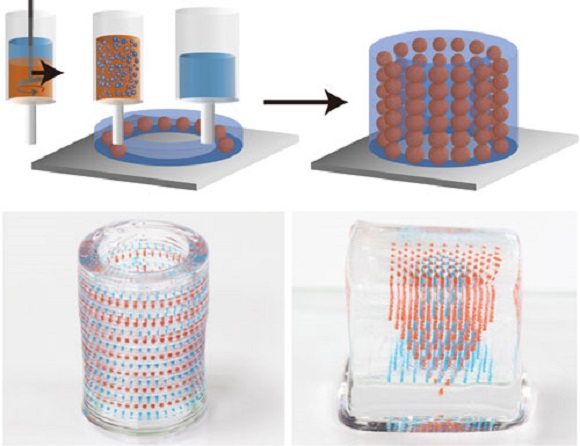

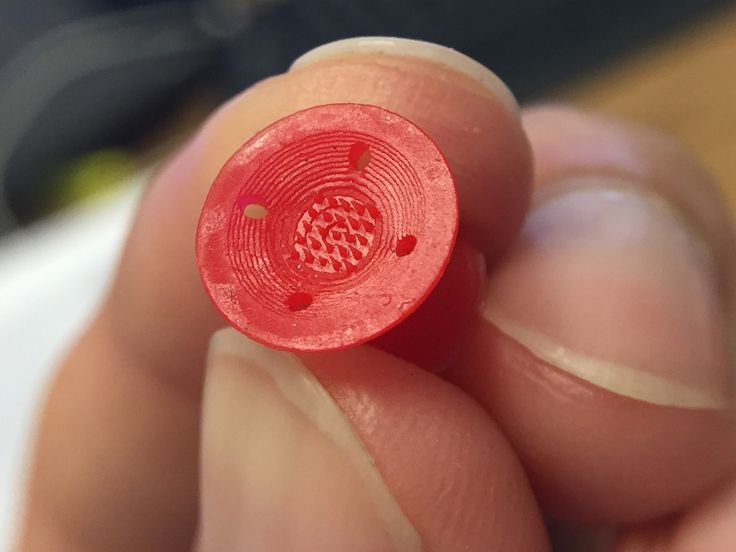

One of the leading techniques for 3D printing is vat photopolymerisation, which affords the highest resolution for complexity at microscales, and also suits many medications as it does not require high heat. For printing medicines, the technique uses a resin formulation, constituting the required drug dissolved in a solution of a photoreactive chemical, activated by light to solidify the resin into a printed tablet.

But vat polymerisation has been hampered by slow printing speeds, due to its layer-by-layer approach.

Here, scientists have developed a new vat polymerisation technique that prints the entire object all at once, reducing the printing speed from multiple minutes to just seven to 17 seconds (depending on the resin composition selected). This works by shining multiple images of the object viewed at different angles, onto the resin. The amount of light shone gradually accumulates, until it reaches a point at which polymerisation occurs. By adjusting the intensity of light at different angles and overlaps, all points of the 3D object in the resin can reach this threshold at the same time, causing the entire 3D object to solidify simultaneously.

This works by shining multiple images of the object viewed at different angles, onto the resin. The amount of light shone gradually accumulates, until it reaches a point at which polymerisation occurs. By adjusting the intensity of light at different angles and overlaps, all points of the 3D object in the resin can reach this threshold at the same time, causing the entire 3D object to solidify simultaneously.

The currently study is led by Professor Abdul Basit (UCL School of Pharmacy), and also involved researchers at Universidade de Santiago de Compostela as well as FabRx, a UCL spin-out co-founded by three members of the UCL research team.

The Basit lab has previously developed 3D-printed polypills to help people who need to take multiple medications each day, as well as pills with braille patterns to help the visually impaired.

Co-lead author Dr. Alvaro Goyanes (UCL School of Pharmacy, FabRx and Universidade de Santiago de Compostela) says that "personalized 3D-printed medicines are evolving at a rapid pace and reaching the clinic. To match the fast-paced clinical environment, we have developed a 3D printer that produces tablets within seconds. This technology could be a game changer for the pharmaceutical industry."

To match the fast-paced clinical environment, we have developed a 3D printer that produces tablets within seconds. This technology could be a game changer for the pharmaceutical industry."

More information: Lucía Rodríguez-Pombo et al, Volumetric 3D printing for rapid production of medicines, Additive Manufacturing (2022). DOI: 10.1016/j.addma.2022.102673

Provided by University College London

Citation: Medicines 3D-printed in seven seconds (2022, March 25) retrieved 5 January 2023 from https://phys.org/news/2022-03-medicines-3d-printed-seconds.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.

The content is provided for information purposes only.

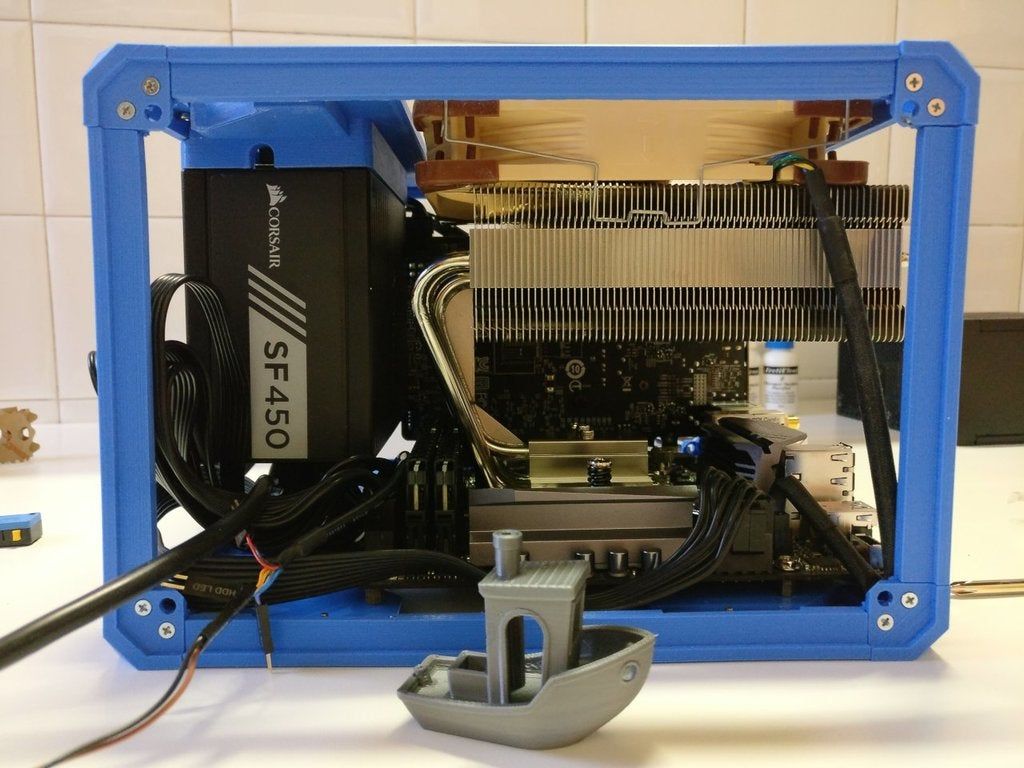

Drugs from a 3D printer - the police of Australia and Taiwan, together with the FBI, detained unusual smugglers

There are many stories of people trying to smuggle computer equipment through border control, overcoming certain restrictions. However, some devices are great for hiding other items in them. In Australia, two men have been charged with trying to smuggle 30kg of methamphetamine into the country by hiding it inside 3D printers. The suspects, aged 33 and 36, are believed to be high-ranking members of an international crime syndicate. nine0003

Helping

AFP (Australian Federal Police) and the FBI conducted a special operation called Operation Ironside, during which every message sent through the An0m encrypted communications platform was intercepted for three years, starting in 2018. One of the reports indicated that one of the detainees coordinated more than 30 attempts to import methamphetamine into Australia in 2020.

AFP, working with the Australian Criminal Intelligence Commission (ACIC), uncovered a conspiracy to import about $30 million worth of 30kg of methamphetamine into Australia using 3D printers. nine0003

Agencies intercepted drugs in the US before they reached Australia. One of the two men was arrested by the Taiwan Criminal Investigation Bureau in New Taipei City in late July, and the other in Taoyuan City in October. Both were charged with category 2 drug trafficking and could face life sentences in Taiwan if found guilty.

Course

EXCEL FOR BUSINESS

Evaluate Excel in just 1.5 months and improve the efficiency of business processes in your company. nine0003

REGISTER!

Photos from the Australian Federal Police show that the now discontinued Flashforge Creator 3 3D printer was chosen as a container by smugglers. The industrial 3D printer has a door and rather large dimensions of 627 x 485 x 615mm, which probably partly explains why it was chosen. The device weighs 52 kg, so 30 kg of methamphetamine was probably going to be distributed among several printers.

The device weighs 52 kg, so 30 kg of methamphetamine was probably going to be distributed among several printers.

Although laptops are not as spacious as 3D printers, they are often used to hide illegal items, such as a knife inside a Gigabyte laptop found by a TSA agent. nine0003

Most smuggling stories tend to involve people using unusual methods of attaching components to their bodies, including a recent story about a woman who tried to enter China with over 200 Intel processors and nine iPhones worth about $ 100 thousand, depicting pregnancy with the help of a false belly.

Also known is a man who tried to smuggle 160 processors and 16 foldable phones through customs, a smuggler who used plastic wrap to attach 256 processors to his body, and a woman who tried a similar trick with 102 iPhones. nine0003

Two Ukrainians tried to launch a drone with cigarettes from abroad to Romania - it did not work (border guards noticed them)

Source: TechSpot

3D printers, Smuggling

STL File Drug Free Zone Sign・Template for Download and 3D Printing・Cults

sonic 3d lego spinner - with mesh

0. 61 €

61 €

Pokémon fish aquarium house - or home decor 3d model

0.61 €

Funny Cartoon Joke Sports sign for indoor/outdoor use

0.85 €

Unicorn - 3d model

2.83 €

Daffy Duck - 3d foil card + night lamp cover

1.18 €

fish tank or 3d teka house

0.71 €

Family Guy - Herbert the pervert 3d model with mesh

1.56 €

jesus - do it yourself cross tile night light

0,65 €

Best 3D Printer Files in the Miscellaneous Category

nine0041 Mouse to move with your lipsFree

Crash Bandicoot

6. 25 €

25 €

Ping Pong Paddle

Free

Fortnite Mini Dark Voyager

Free

bird perch

0.71 €

2021 F1 RED BULL CAR 3D PRINT - TURKISH SPEC

6.42 €

Bear Head

2,50 €

Narrow Gauge Powered Bogie Set

Free

Bestsellers in Miscellaneous category

ITEMS-ENVIRONMENT-COMPANY-HD-PRINT

1,30 €

Addams Stuff

1.99 €

Mickey Christmas night light Litophane

3,50 €

Wednesday Addams, The Thing, The Thing

5 €

5 gnomes (without support)

2. 49 €

49 €

Articulated Raykuase Flexible Dragon Pokémon

1 €

4th planet Martial pre-Olympic god

12 €

TING Addams

8.49 €

Brackets for shock absorbers and trx4m escalators

1.89 €

Articulated Gyarados

1.99 €

MMPR Dragon Dagger

4.72 €

Gremlin 640mm FPV 9 Rail0042

0.94 €

Mate Qatar 2022 FIFA World Cup

10 € -50% 5 €

Giarados - articulated sea serpent

1,50 €

Key holder for middle finger

1 €

nine0041 CHRISTMAS TREE v21,50 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy.