Best abs filament for 3d printing

The 9 Best ABS Filaments in 2022 (Including From Top Brands Like Flashforge and Inland)

Welcome to the Thomas guide to the best ABS filament 2022. Thomas has been connecting North American industrial buyers and suppliers for more than 120 years. When you purchase products through our independent recommendations, we may earn an affiliate commission.

Acrylonitrile butadiene styrene filaments, more easily known as ABS filaments, are built for 3D printers. They’re one of several filaments that can be used with these machines and, for several reasons, are one of the more popular options for building creations on a print bed. Experts and amateurs exploring the world of 3D printing will no doubt come across ABS filaments, but when should they be chosen over others, what makes them different, and which are the best?

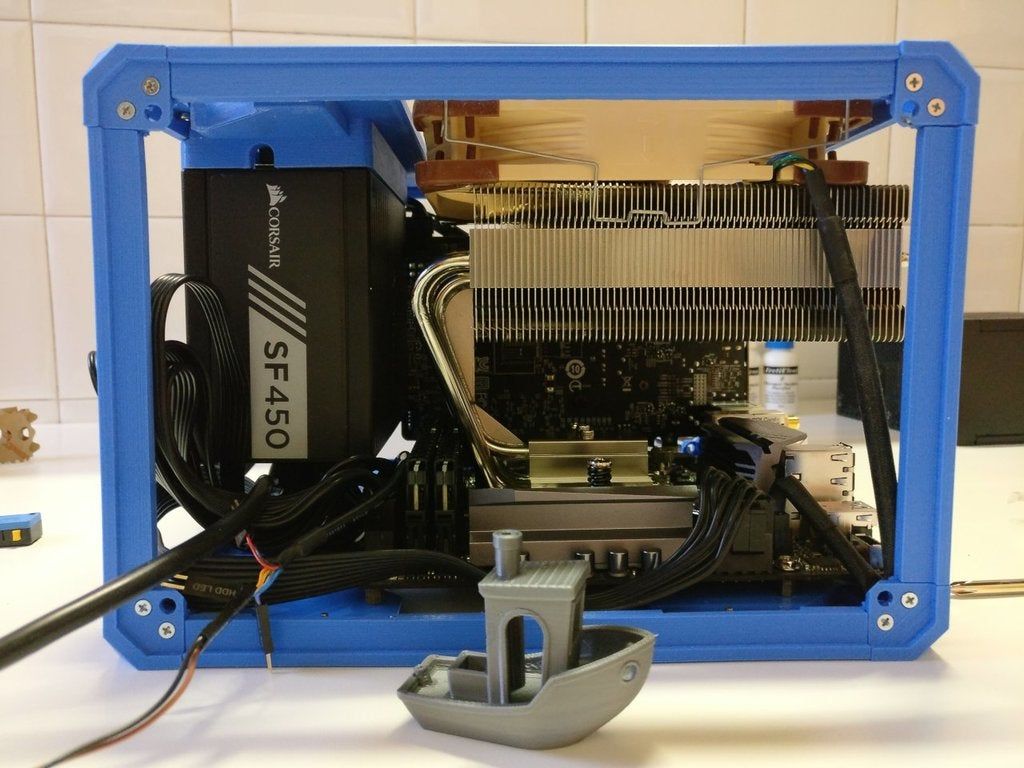

For consistent quality during the printing process, good ABS filaments are neededImage credit: Shutterstock/asharkyu

Two top reasons why ABS filaments are popular among professionals and hobbyists is that they’re flexible and simple for most users to figure out. ABS prints out designs that are of decent quality, too. Though there are many options on the market, including carbon fiber, PETG, PLA, nylon, and wood filament choices, ABS filaments are best for products that require resistance to stress, heat, and wear and tear.

Best ABS Filament—Buying Guide

Below, you’ll find a breakdown of what to look for in ABS filaments, including fine details like spool width, temperature range, and adhesion. When browsing sites for ABS material, shoppers will want to consider ABS filament diameter, temperature range, and how well it bonds. All of these will be indicators of a quality filament that will work well with the machine being used.

- Diameter and spool hub hole diameter depends on what the specific 3D printer requires, so be sure to check the recommended spool diameter listed in a printer’s manual. Keep an eye on the mechanical winding done to the spool, too, to prevent annoying tangles.

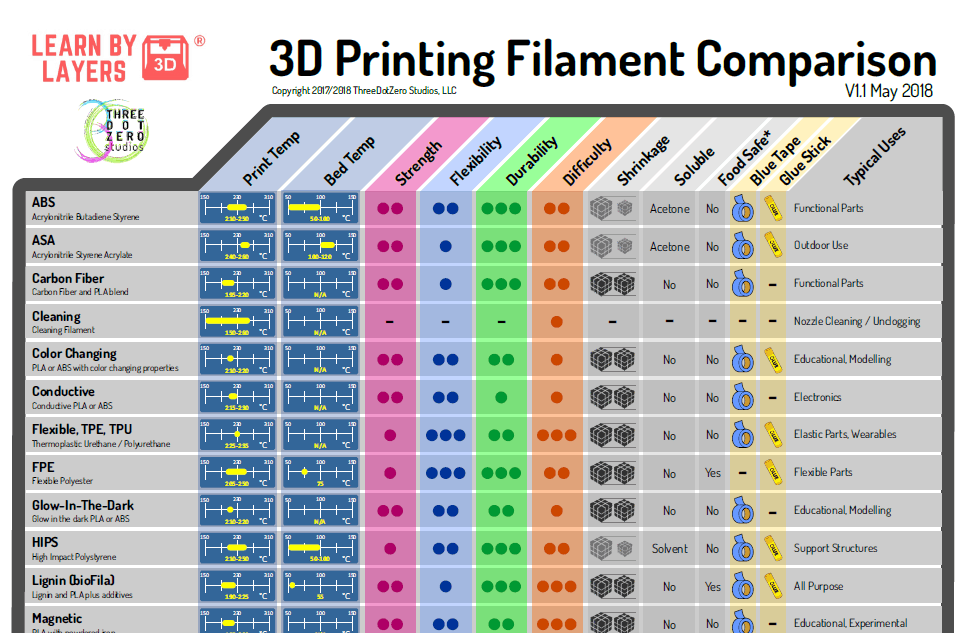

- The temperature range is the point at which the filament will melt and begin adhering to other layers—too cold, and the first few layers won’t bond; too hot, and the material won’t maintain its properties and could become stringy. 3D printing with ABS requires looking at both extruder temperature and bed temperature in most cases.

- Fantastic layer bonding means that once the design has been printed, it’ll stay together, and its layers won’t separate.

- Good ABS filaments should also stand up well to a manual finishing process, like an acetone vapor treatment. Acetone vapor should smooth the texture of the print and help clean up anything that looks uneven or rough. At the same time, the filament should be strong enough to withstand it while creating a smooth surface finish and not completely melt during an acetone vapor bath.

ABS Filament Brands

Popular 3D printer brands often make filaments on top of 3D printers that are favored among users, including Markforged, MakerBot, Flashforge, and Ultimaker. Which is better comes down to personal preference in most cases as differences are often minute.

Thomas’ Top Picks for the Best ABS Filaments 2022

Shop the best ABS filament brands and options for good dimensional accuracy, and quality 3D printed creations.

Best ABS Filament for Multiple 3D Printer Brands: Inland 1.75mm ABS 3D Printer Filament | Buy Now Best Reliable ABS for 3D Printing: HATCHBOX ABS 3D Printer Filament | Buy Now Best Good Quality ABS Filament for Consistency: SUNLU ABS 3D Printer Filament | Buy Now Best ABS Filament for Beginners: Polymaker ABS Filament | Buy Now Best Filament for Lower Heat Build Platform: Flashforge ABS Pro Filament | Buy Now Best Filaments for Pen 3D Printing: MIKA3D ABS 3D Pen Printer Filament Refill | Buy Now Best Low-Warp ABS Filament for 3D Printing: Reprapper Low Warping ABS 3D Printer Filament | Buy Now Best Thicker Filaments for 3D Printing: Ultimaker 3D Printer Filament, 2. 85mm | Buy Now Best Budget ABS Filament: Amazon Basics ABS 3D Printer Filament | Buy Now

85mm | Buy Now Best Budget ABS Filament: Amazon Basics ABS 3D Printer Filament | Buy Now Scroll down to read more about these top picks for the best ABS filament, according to many happy buyers.

*Prices listed in this article were as shown in US$ on amazon.com (USA) and newark.com as of April 2022

1. Best ABS Filament for Multiple 3D Printer Brands—Inland 1.75mm ABS 3D Printer Filament

Traditional ABS resins can be difficult to work with, and though it’s a popular material, ABS often gets a bad rap for being finicky. Though it’s not expensive, many buyers cast Inland’s vacuum-sealed, silica gel-padded ABS rolls as a high-quality filament.

It’s smooth, sticks well, and isn’t as odorous as other ABS filaments. This option has 13 different color options to meet a variety of project needs, from light blue and purple to yellow and white.

“I have printed several kilometers using many brands of ABS filament, and this is my go-to,” wrote one reviewer. “Inland is remarkably uniform, consistent, and makes very high-quality prints. I have not used any brand that was easier. If you are set up to print ABS, then this is the brand to go with.”

Specifications

Best for: Hardware parts, small models

Filament diameter: 1.75 mm

Print temperature: 464° F to 500° F

BUY NOW:

US$20.99, Amazon2. Best Reliable ABS for 3D Printing—HATCHBOX ABS 3D Printer Filament

Like most ABS filament brands, it takes a bit of time to get any printer set up and functioning properly with the specific needs of this filament from HATCHBOX, but once things are good to go, it prints out models smoothly and efficiently.

This filament is also durable, sticking together from the first layer that’s laid down and staying strong throughout its usage. It’s built for both hobbies and for more functional ABS parts, like creating handles for tools or mounts.

“It is currently my favorite filament and creates amazing prints and is very easy to vapor smooth, and creates a detailed model with a marble-like shine and a smooth texture,” noted a customer. “I have had this filament for nearly a year now, and there have been no issues with the filament cracking or breaking, like several of my other filaments did within the first couple of months.”

Specifications

Best for: Functional parts and models

Filament diameter: 1.75 mm

Print temperature: 410° F to 464° F

BUY NOW:

US$21.47, Amazon3. Best Filament for Consistency—SUNLU ABS 3D Printer Filament

ABS is great for 3D printer operators looking for a heat-resistant material that can withstand stress, and SUNLU’s is no exception.

It works with multiple models of printers to create smooth models, and as a small perk, the vacuum-sealed bag comes with an easy-to-find filament end to prevent tangles. Other shoppers have noted this adheres well enough on a heated bed to avoid needing a glue stick or masking tape, too.

“I have an order for 200 printed units, [and] I switched to this brand due to a recommendation on YouTube,” explained a buyer. “I had to raise my nozzle temperature to 250° C, and the bed at 100° C, and I am just churning out the units six at a time with no clogs or issues of any kind… The quality is there, and everything is very consistent. This is the best I have ever run with ABS.”

Specifications

Best for: Adaptors, busts, models, and hardware parts

Filament diameter: 1.75 mm

Print temperature: 446° F to 464° F

BUY NOW:

US$21. 99, Amazon

99, Amazon 4. Best ABS Filament for Beginners—Polymaker Polylite ABS Filament

ABS 3D printing often leaves users with a bad impression when they first try it out—even with a popular filament brand.

This Polymaker option is worth a shot, especially for newbies, according to numerous reviewers. It’s low on odor due to its significantly lower volatile content, which is normally a frequent complaint of experts and enthusiasts who rely on ABS.

“If you’re a first-time ABS printer, I strongly suggest you try this filament,” remarked a customer. “It is super easy to use and work with. I don't even use an enclosure when I'm just printing a few items. I use a Prusa MK3S and a Creality Cr10s Pro v2, and both work well with just the generic ABS settings.”

Specifications

Best for: Beginners, users sensitive to smells, and for making holders, hardware, and mounts

Filament diameter: 1. 75mm

75mm

Print bed temperature: 473° F to 509° F

BUY NOW:

US$21.99, Amazon5. Best Filament for Lower Heated Build Platform—Flashforge ABS Pro Filament

More popular for its PLA filament options, printing ABS models is also doable with Flashforge’s ABS filaments. Hailing from the Pro line, the filaments in this spool set are equipped to create better dimensional accuracy and prevent shrinkage.

It won’t produce the same smell as traditional options, either. However, this one isn’t as resistant to high temperatures and requires a lower heated bed and extruder temperature.

That being said, a higher melt temperature isn’t needed for this filament to have good layer bonding. “I have used several different types of ABS filament, and this one is right up there with all the good ones,” explained one customer. “Printed nicely, and odor was no more than usual. ”

”

Specifications

Best for: Household items and LEGOs

Filament diameter: 1.75 mm

Print temperature: 176° F to 212° F platform temperature

BUY NOW:

US$21.99, Amazon6. Best Filaments for Pen 3D Printing—MIKA3D ABS 3D Pen Printer Filament Refill

ABS print models can come from 3D printing pens, too, and don’t require an enclosed print chamber. These machines are better used for hobby projects, and for such, this set of multi-colored filaments from MIKA3D is great and made specifically for MYNT3D and SCRIB3D pens.

Though they’re built for pens and create well-made models, they’re even usable for extra-small 3D printer projects.

“I just purchased a 3D pen; we have a 3D printer, but I wanted to build manually,” described a customer. “This came vacuum sealed and packed in a way that they were not directly stacked on top of each other. It works well in my pen, and it doesn't jam.”

“This came vacuum sealed and packed in a way that they were not directly stacked on top of each other. It works well in my pen, and it doesn't jam.”

Specifications

Best for: 3D pens and figurines

Diameter: 1.75 mm

Print temperature: 410° F to 464° F

BUY NOW:

US$12.99, Amazon7. Best Low-Warp ABS Filament for 3D Printing—RepRapper Low Warping ABS 3D Printer Filament

The surface finish of a printed product can be tough to nail down. Excess moisture or the incorrect temperature can be a cause for concern during a strict manual examination—causing warping, roughness, or stringy texture.

RepRapper’s filaments are great for printers who are concerned with warping in particular and made for less manual finishing process time and effort. The brand recommends low cooling fan levels for proper first-layer adhesion and an overall strong structure.

“I'm printing on a thick, smooth PEI sheet,” wrote one reviewer who was initially skeptical about buying this filament as it seemed a little too economical to be any good. “Bed at 100, nozzle at 260, 20% fan, and it's printing like an absolute dream. The bed and layer adhesion are both rock solid. The surfaces and bridges are gorgeous. Still tinkering with the support settings, but it's going well.”

Specifications

Best for: Printer mechanical parts, hardware, models

Filament diameter: 1.75 mm

Print temperature: 446° F to 500° F

BUY NOW:

US$23.99, Amazon8. Best Thicker Filaments for 3D Printing—Ultimaker 3D Printer Filament, 2.85mm

The Ultimaker ABS filament spools are on the top end of the ABS options from the printer and filament manufacturer.

This black tone is perfect for having in any collection of filaments, though it can be found in multiple other hues. It’s a thicker filament at 2.85mm in diameter and is made for sticking to the bed well without pulling apart when it's time to remove the final product.

The Ultimaker ABS filaments also aren’t exclusive to Ultimaker printers as long as the machine uses fused deposition modeling (FDM) tech.

Specifications

Best for: Models, prototypes, end hardware

Diameter: 2.85 mm

Print temperature: 437° F to 473° F

BUY NOW:

US$49.99, Newark9. Best Budget ABS Filament—Amazon Basics ABS 3D Printer Filament

The best ABS filament brands are fairly well-known, but for a no-nonsense spool, Amazon Basics’ version does the trick nicely.

Even at such a low price, this is a decent filament for making products where ABS reigns supreme over other materials. The product description states that it’s built to avoid jamming, though it’s notably thinner than some other ABS options on the market.

“New to 3D printing and wanted to test out ABS after PETG and PLA,” explained a customer. “I have a Prusa MK3S, and this filament was one of the best I’ve printed with… Stuck to bed almost too well, and the quality of print was absolutely perfect. I was shocked. Didn’t do anything but slice in the Prusa slicer and sent to printer. Came back four hours later, and BAM, it was epic.”

Specifications

Best for: Models, cell phone cases, small hardware pieces

Diameter: 1.75 mm

Print temperature: 455° F max

BUY NOW:

US$20.47, AmazonThe Best ABS Filaments—Summary

3D printing ABS models and parts with good dimensional accuracy and little need for glue or ABS slurry requires great ABS 3D printing filaments. Ones protected from excess moisture are doubly as important (though this can be prevented through using a filament dryer). The best ABS filament brands listed above will help make ABS 3D printing easier.

Ones protected from excess moisture are doubly as important (though this can be prevented through using a filament dryer). The best ABS filament brands listed above will help make ABS 3D printing easier.

Printers running on lower temp settings will function well with FlashForge’s spools (US$21.99, Amazon). For reliable 3D printing, HATCHBOX ABS filament rolls (US$21.47, Amazon) make the cut. A great runner-up from one of the best ABS filament brands is the Push Plastic ABS filament ($39, Amazon). Push Plastic ABS is high quality and prints out clean designs.

We hope our review of the best ABS filaments from the best ABS filament brands like Flashforge, Polymaker, SUNLU, Push Plastic, and HATCHBOX ABS has been helpful. For more suppliers of related products, including 3D printer filaments, bioplastic 3D printer filaments, and metal 3D printing additive manufacturing, consult our additional guides, or visit the Thomas Supplier Discovery Platform.

Sources

- https://www.machinedesign.com/buyers-journey/consideration/article/21835444/whats-the-difference-between-pla-abs-and-nylon

- https://www.imaginethat-3d.com/how-to-succeed-when-printing-with-abs

Other 3D Printing Articles

- Top 3D Printing Services Companies in the USA

- Origins of 3D Printing and Additive Manufacturing

- Overview of 3D Printing Technologies

- Top 3D Printing Manufacturers and Suppliers (Publicly Traded and Privately-Owned)

- The Best 3D Printers under $300

- The Best 3D Printers under $200

- The Best 3D Printing Software

- The Best 3D Printer Under $1000

- The Best 3D Printer Under $500

- All About Multi Jet Modeling (MJM) 3D Printing

- All About Stereolithography 3D Printing

- All About Direct Energy Deposition 3D Printing

Other Best Product Articles

- The Best Commercial Backpack Vacuum

- Best Mouse for Solidworks Users

- Best Monitor for AutoCAD

- The Best Garden Hose Reel

- The Best Commercial Cotton Candy Machine

- The Best Commercial Drones

- The Best Commercial Hedge Trimmer

- The Best Commercial Meat Slicer

- The Best Commercial Chainsaw

- The Best Wheelbarrow

- The Best Commercial Ice Cream Machine

- The Best Commercial Pizza Oven

- The Best Commercial Deep Fryer

- The Best Commercial Mop

- The Best Arduino Starter Kit for Beginners and IoT Projects

- The Best Mig Welders

- The Best Pipe Wrench

- The Best Single Stage Automotive Paint

- The Best Drywall Knife

- The Best Heat Gun For Removing Paint

- The Best Polycarbonate Filament in 2022

- The Best Reel Mowers

- The Best Mulching Lawn Mowers

- The Best Expandable Garden Hose

- The Best Automatic Center Punch

- The Best Rotary Laser

- The Best Two Wheel Wheelbarrow

More from Electrical & Power Generation

5 Best ABS Filaments In 2022

- Last Updated: October 19, 2022

- Jackson O'Connell

Tired of weak and brittle 3D prints? Maybe it’s time to switch to a different filament material… one like ABS!

ABS filament is known for its superior strength over PLA, making it perfect for real-use 3D prints that require some durability. Plus, the material also offers other benefits, like slight flexibility, vapor smoothing compatibility, and more!

Plus, the material also offers other benefits, like slight flexibility, vapor smoothing compatibility, and more!

There are tons of ABS filaments you can choose from, but not all are worth your money. In this article, we’ll review the best ABS filaments for 3D printing, so read on!

Sunlu ABS

Check Latest Price

Hatchbox ABS

Check Latest Price

IC3D ABS

Check Latest Price

Table of Contents

- Best ABS Filaments At A Glance

- 1. Hatchbox ABS (Best Overall)

- 2. Sunlu ABS (Best Value)

- 3. IC3D ABS (Premium Choice)

- 4. Overture ABS (Easy to Use)

- 5. Polymaker PolyLite ABS (Quality Prints)

- What is ABS Filament?

- When Should You Print with ABS?

- Advantages and Disadvantages

- Advantages

- Disadvantages

- How to Print Using ABS Filament?

- ABS vs.

PLA

PLA - ABS vs. PETG

- Is ABS Toxic to Print?

- Conclusion

Best ABS Filaments At A Glance

1. Hatchbox ABS (Best Choice)

2. Sunlu ABS (Best Value)

3. IC3D ABS (Premium Choice)

4. Overture ABS (Easy to Use)

5. Polymaker Polylite ABS (Quality Prints)

Our first ABS filament comes from Hatchbox, which is my personal favorite manufacturer of filament. Hatchbox ABS filament sits at about the market price, but it’s a lot easier to print than your regular ABS filament.

While it requires slightly higher-than-normal printing temperatures, Hatchbox ABS is super reliable. Of course, you still need an enclosure, but once you’ve tuned your slicer profile, you can expect consistently high-quality models throughout the entire spool.

I actually have fewer problems printing Hatchbox ABS than I do for most of my PLA filaments. But don’t take my word for it! Take the 8,000+ positive reviews that mention how overall amazing Hatchbox ABS is!

But don’t take my word for it! Take the 8,000+ positive reviews that mention how overall amazing Hatchbox ABS is!

Additionally, the filament comes in a handful of different colors, like white, black, red, orange, hot pink, purple, and more!

So if you’re just starting out with ABS or want an easy-to-use and reliable option, definitely try out a spool of Hatchbox ABS!

- Good bang for your buck

- Prints are usually pretty strong

- Comes in a fair amount of different colors

- Very reliable

- Not too sensitive to print settings and the environment

- Some brittle prints here and there

- A bit hygroscopic

Check Latest Price

2.Now, if you’re looking for the best bang for your buck, look no further than Sunlu ABS. This filament costs over $5 less than your typical ABS material filament but performs better than $50+ spools. And while this price difference doesn’t sound so significant, if you print as much as I do, you’re burning through one or two spools per month, so it adds up quickly!

But the price isn’t the only reason I like Sunlu’s ABS filament. It’s known to have a dimensional tolerance of just +/- 0.02 mm, almost half the average for filaments (+/- 0.05 mm). With such high diameter accuracy, you’re not likely to run into extrusion issues from Sunlu’s ABS filament due to their precise manufacturing methods.

Additionally, I recommend Sunlu ABS for anyone trying to use ABS on a printer that has a subpar bed heater. That’s because the recommended bed temperature is just 85 °C, which is lower than most ABS filaments, meaning it’s compatible with more printers.

Sadly, this filament only comes in a few colors, including black, red, white, blue, and grey. But I feel Sunlu makes up for it with their lower-than-low prices, wide printer compatibility, and overall reliability, as indicated by the diameter accuracy and the many reviews for this filament.

- Super inexpensive and a great bang for your buck

- Good (low) diameter accuracy

- Reliable

- Low printing temperatures

- Limited color options

- Prints can be rather brittle

Check Latest Price

3. IC3D ABS (Premium Choice)

IC3D ABS (Premium Choice) If you’ve got a pretty big 3D printing budget, then a) good for you for embracing your hobby and b) try some IC3D ABS filament.

IC3D produces some of the highest quality filament I’ve ever used, and their ABS options provide the holy trinity of filament: strength, printability, and good looks. Though it’s a bit more expensive than other options, its hundreds of good ratings (including mine) vouch for its excellence.

What surprised me most about this filament was how easy it was to post-process, and I can’t say that about all ABS filaments. Not only do prints made out of IC3D ABS dissolve well to acetone, but they also work really well with acrylic paints. Even the ones I bought at the dollar store!

So if you want an ABS filament that works well across all categories, then IC3D is my recommendation!

- Responds well to post-processing

- Pretty strong

- Decently easy to print

- Reliable

- Relatively expensive

- Limited color options

Check Latest Price

4. Overture ABS (Easy to Use)

Overture ABS (Easy to Use) Overture is another filament brand you’ve probably seen while scrolling through the Amazon results of “ABS filament”.

I first started to dabble with Overture filament after I saw the low price on their PLA filament (which also is really good), but then got to love the brand more through their ABS option. At first glance, Overture ABS looks like just another “budget” filament option. But it’s also super easy to print, which is why I continue to use Overture on some of my printers.

And when I say “easy to print”, I don’t just mean only a few issues every now and then; I mean basically zero issues since using the filament. It doesn’t warp, isn’t brittle, doesn’t clog, and the four available colors somehow manage to make my ugliest designs look decent.

The only issue I’ve really had with Overture ABS is that it’s definitely a little more hygroscopic than other options. So, if your printer or filament stash is in a place near a sink or bathroom, consider also getting a filament storage container to keep your Overture filament dry.

But, other than that, Overture ABS is a filament I strongly suggest, especially for those who want a stress-free printing experience.

- Very easy to print

- Prints aren’t brittle

- Low price (good value)

- Hygroscopic

Check Latest Price

5. Polymaker PolyLite ABS (Quality Prints)Lastly, Polymaker is another manufacturer of 3D printing filaments, from PLA to dissolvables (e.g. PVA) and nylon. PolyLite ABS is a great option for those interested in this material. Plus, it has a lot more to offer than just its attractive low price.

First off, PolyLite ABS is known for being easy to use.

This is especially true when it comes to print speed. While Polymaker officially recommends using a print speed between 30-50 mm/s (the standard for ABS), many reviews mention that you can use speeds around 80+ mm/s with still near-perfect results. I myself used 70 mm/s, 20 mm/s than my typical ABS print speed, and was absolutely fascinated by the detail preserved in the prints.

PolyLite ABS also is decently strong. Though it’s probably not the strongest of ABS filaments out there, it carries its weight, still massively outperforming PLA prints in tensile strength.

Of course, this higher-than-usual strength comes at the cost of a higher-than-normal recommended printing temperature of 245-265 °C. This limits which printers can handle PolyLite ABS, but if yours can, yay for you!

Finally, I can’t say goodbye to my review for PolyLite ABS without mentioning the vast color options. I’ve always been a fan of the filament colors offered by Polymaker, and they really nailed it with PolyLite ABS too. You can get the filament in 15 different colors, including every main color of the rainbow, black, white, teal, “Polymaker Teal”, and more!

You can get the filament in 15 different colors, including every main color of the rainbow, black, white, teal, “Polymaker Teal”, and more!

So, if you want a low-price ABS material filament that’s high-quality overall, don’t forget about PolyLite ABS. It’s strong, fast, colorful, and so much more!

- Many color options

- Decently strong

- Can be printed very fast

- Low price

- Requires printing temperatures higher than the average for ABS

- Known to warp a fair amount

Check Latest Price

What is ABS Filament?

Source: Youtube Maker’s MuseFirst off, ABS stands for Acrylonitrile Butadiene Styrene and is a thermoplastic sourced from processed oil. While it’s not the most environmentally-friendly material, its low-cost, strength, and other mechanical properties make it the perfect choice for manufacturers. That’s why it’s used for everything from LEGOs to car interior panels.

While it’s not the most environmentally-friendly material, its low-cost, strength, and other mechanical properties make it the perfect choice for manufacturers. That’s why it’s used for everything from LEGOs to car interior panels.

As for how ABS relates to 3D printing, it’s considered the 2nd most popular material for filaments, with PLA taking the 1st place spot. Your typical 1-kilogram spool of ABS filament costs under $25, and can be bought from basically any online retailer.

Unfortunately, ABS gets a bad rep in the community because it’s relatively difficult to print. Moreover, plastic is a lot more sensitive to environmental factors (e.g. ambient temperature) than PLA, so achieving high-quality models is more difficult.

When Should You Print with ABS?

Source: Youtube HubsAlthough printing with ABS can make you hate your printer because it’s challenging to print, there are many times when the material is useful. Mainly, though, you should consider printing with ABS whenever strength is a factor for a print. For example, ABS is perfect for printing things like door hinges, gears, a phone case, or a monitor stand.

For example, ABS is perfect for printing things like door hinges, gears, a phone case, or a monitor stand.

But ABS filament’s usefulness goes beyond just raw strength!

The material is also a lot more durable and resistant to the elements. While a PLA model will deform under the sun (UV light), prints in ABS filament will keep their shape in outdoors for years. I’ve literally had the same outdoor cup holder on my porch for two and a half years, and there aren’t any noticeable defects yet.

You also want to use ABS filament if you plan on layer smoothing your print, such as for cosplay items or display pieces. That’s because ABS plastic is soluble in acetone (nail polish remover), so you can use this chemical to dissolve the top layer of your print, achieving a shiny surface finish.

Check out our article on acetone vapor smoothing for ABS here to learn more.

Advantages and Disadvantages

Obviously, ABS filament has its ups and downs. We’ve compiled a list of the advantages and disadvantages of this filament material below to help you decide if ABS is for you!

Advantages

- Soluble in acetone so that you can layer smooth prints

- Slightly flexible, which makes it very durable

- Terrific mechanical properties, such as high strength, good resistance to UV light, waterproof, and resistance to high temperatures

- Inexpensive and widely available

Disadvantages

- Very difficult to print because the plastic is so sensitive to environmental factors, print settings, and more

- An enclosure and high-temperature heated bed are (basically) required

- Not environmentally friendly

- Considered toxic (not food safe)

How to Print Using ABS Filament?

Source: Youtube Thomas SanladererAs we mentioned, printing ABS filament is pretty challenging, especially compared to PLA or PETG. But don’t let that scare you because, in this section, we’ve gone over exactly how you can print this type of filament.

But don’t let that scare you because, in this section, we’ve gone over exactly how you can print this type of filament.

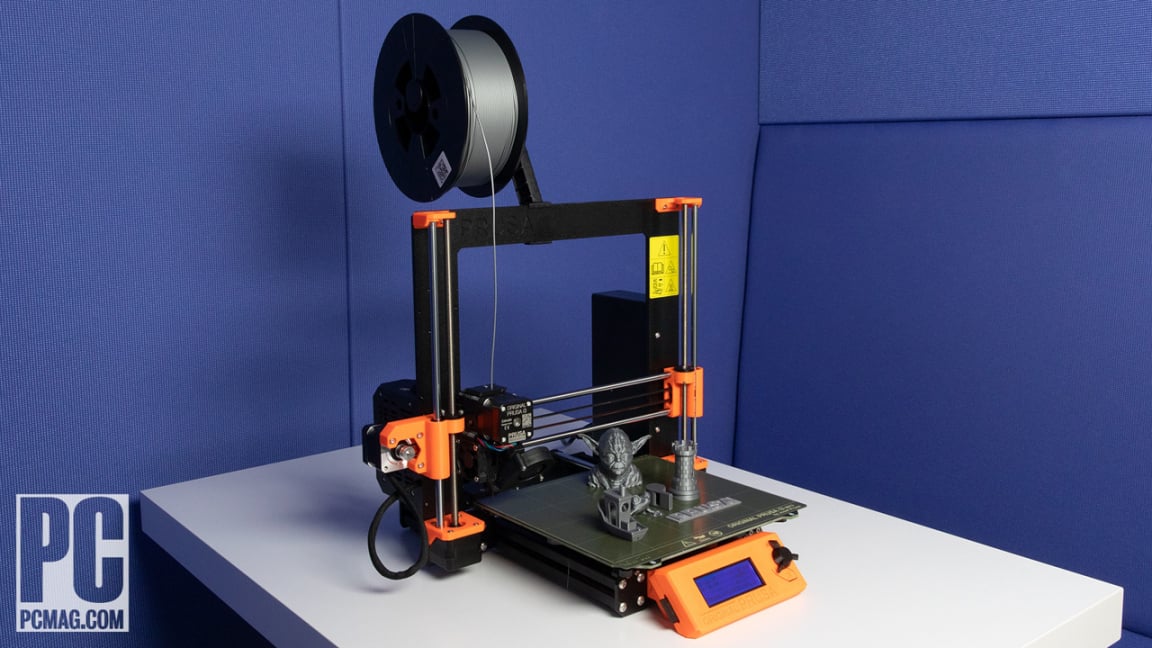

First off, you’ll need an enclosure for your printer. An enclosure traps heat around your printer, ensuring that the ABS plastic has good layer-to-layer adhesion, resulting in stronger prints. An enclosure also keeps out air drafts (winds) to ensure high-quality prints.

Secondly, you’ll need to make sure that your nozzle and heated bed can reach the necessary printing temperatures. That would be around 240 °C and 100 °C, respectively.

If your printer can’t reach these temperatures, you’ll either need to use a different printer or upgrade the heating components on your current one. If you choose the former option, make sure to check out my guide to the best machines for printing ABS filament!

Third, you’ll need a well-tuned slicer profile. The exact slicer settings for printing ABS vary for everyone because every 3D printer is different. A raft or brim is recommended, though, as ABS is known for having issues with bed adhesion.

I recommend starting by using Cura’s default ABS profile for your printer (Dynamic or Regular quality), printing a test model, and adjusting individual settings based on the results. Do this until you achieve a level of quality that you’re okay with.

And that’s it! If you follow these steps, you should be printing high-quality ABS models in no time!

ABS vs. PLA

Source: Youtube HubsSo how does ABS compare to its nemesis, PLA, the most popular 3D printing material? Well, there’s no clear winner, but there are a good bit of differences between the two.

ABS is a good bit stronger and less brittle than PLA, but PLA is a lot easier to print. That’s the main difference, but there are a few other small ones, like how PLA is more environmentally-friendly and slightly less expensive (by like $1) in most places.

But, overall, I’d say PLA is the better option for beginners and those who want a very stress-free printing experience. On the other hand, ABS is better for printing any part that needs to be strong, durable, or outside. It’s also the better filament material for multi-part assemblies because of its responsiveness to solvents like ABS.

It’s also the better filament material for multi-part assemblies because of its responsiveness to solvents like ABS.

Learn more about ABS vs. PLA here.

ABS vs. PETG

Source: Youtube Ultimate Hydraulic Press ChannelPETG is another popular filament material and is very similar (chemically) to the plastics used in water bottles and a lot of Tupperware. PETG is actually about just as strong as ABS and even more resistant to UV light.

However, ABS is less abrasive, meaning it won’t degrade your nozzle as fast. Additionally, it has a higher temperature resistance, so ABS parts can survive (without deforming) in hotter climates than PETG parts.

But it’s worth noting that PETG is a good bit easier to print than ABS and no enclosure is required. Sadly, if you’re printing PETG, your models are likely to have some stringing (makes prints look bad), which won’t happen with ABS.

So, if you want strong 3D prints but still want a pretty easy printing experience, PETG is definitely a material you should consider. However, ABS is the better choice for instances where you need that extra temperature resistance or don’t want to deal with stringing on models.

However, ABS is the better choice for instances where you need that extra temperature resistance or don’t want to deal with stringing on models.

You can learn more about ABS vs. PETG here.

Is ABS Toxic to Print?

Our last bit of background information about ABS relates to its toxicity. Generally, people like to call ABS a toxic filament to print because it can release harmful carcinogens in the air when melted. However, don’t be too scared because, while you can usually smell the melted ABS nearby your printer, most of the fumes stay in your enclosure.

Conclusion

Whether you want to print stronger models or are looking to experiment with post-processing techniques, like layer smoothing, ABS is an excellent 3D printing material. While it’s a bit difficult to print compared to PLA, its strength and versatility prove useful in many scenarios.

But if you’re going to buy an ABS filament, don’t just click the first one you see. Instead, I’d recommend taking a look at Hatchbox or Sunlu’s ABS filaments. Both brands offer an amazing value for your dollar, are decently strong, and are considered reliable by many users.

Both brands offer an amazing value for your dollar, are decently strong, and are considered reliable by many users.

However, if you want to take your ABS prints to the next level, then perhaps IC3D ABS is the one for you. If you’re willing to drop the extra $10-20 for this brand, you’ll get a whole lot better performance, like improved strength, ease of printing, and more!

Best 3D Printer Filaments (Review 2021)

Once you've chosen your 3D printer, you need to choose the type of filament intended for your project. Filament is a raw material used in 3D printers that will be heated to a high temperature to turn it into a semi-solid state. At this point, the printer can easily create the appropriate design layers and print the entire 3D CAD model onto the plate.

However, as you research the various 3D printer filaments, you will hear of numerous materials that can only make it harder to choose the right one for you. This is especially true for people who are just starting to explore the world of the 3D printing process. nine0003

nine0003

While most of us are not new to PLA and ABS, there are other fiber materials you should be aware of such as HIPS, PET, PETG, TPE, TPU, TPC and a few others. And to get a better idea of them, here are some of the more typical types of 3D printer filaments available on the market.

3D Printer Filament Types

PLA Filament

Polylactic acid (PLA) reigns supreme in the industrial 3D printing world. 3D printing with PLA is so easy. It has a lower plate temperature, so it doesn't need a heating bed and therefore has fewer warping issues. nine0003

It is widely used in prototyping, such as printing low-wear toys, prototype parts and containers. Please note that it cannot be used for anything that has a temperature rating of 60°C or higher as it warps at 60°C. For all other purposes, PLA is suitable for a general 3D printer.

ABS Filament

ABS (also known as Acrylonitrile Butadiene Styrene) is the second most popular 3D printing filament. In general, ABS withstands high loads and high temperatures. Thus, it is suitable for most applications. It is great for items that are frequently handled, dropped or heated. For example, mobile phone cases, high-wear items, automotive trim parts, and electronic houses. nine0003

In general, ABS withstands high loads and high temperatures. Thus, it is suitable for most applications. It is great for items that are frequently handled, dropped or heated. For example, mobile phone cases, high-wear items, automotive trim parts, and electronic houses. nine0003

Nylon filament

Nylon is the preferred family of synthetic polymers for many industries, professional 3D printing being one of them. As for other forms of filament, they have better performance, efficiency, versatility and durability. Given the strength and versatility of nylon, this type of 3D printer filament can be used to make loops, buckles or gears, as well as working prototypes.

PET (G) thread

The most widely used plastic in the world is polyethylene terephthalate (PET). It is best known as water bottle thread, but it is also used in clothing fibers as well as food containers. Although PET is commonly used in 3D printing, its modified version PETG is becoming more common.

The G in PET stands for glycol, resulting in a more transparent filament that is less prone to cracking and easier to use. PETG is versatile but surpasses many forms of 3D printer filament in its strength and inability to reach high temperatures or withstand strong impacts. The fulfillment of the following conditions makes it an excellent choice for 3D printing filament for practical parts such as mechanical parts, printer parts, and protective materials. nine0003

TPE, TPU, TPC filament

Thermoplastic polyurethane (TPE) is a flexible and durable plastic similar to rubber. In addition, TPE is mainly used for the production of auto parts and household appliances.

TPU (Thermoplastic Polyester E) is a special form of TPE that is very common among high end 3D printers. Compared to conventional TPE, TPU is significantly more flexible, hence allowing more control during printing.

What's more, TPC (Thermoplastic Copolyester) is also another form of TPE that is not as widely used as TPU. The key advantage of TPC over TPE is its greater resistance to chemical and UV attack, as well as heat (up to 150°C). nine0003

The key advantage of TPC over TPE is its greater resistance to chemical and UV attack, as well as heat (up to 150°C). nine0003

If you need to create items that require a lot of wear, use TPE or TPU because these filaments use 3D printed filaments that are vulnerable to deformation. Products such as toys, mobile phone cases, or wearable items such as wristbands can be some examples of its application. On the other hand, TPC performs well for comparable applications, but outperforms it in harsher environments, including outdoors. nine0003

Wood filament

Technically not wood because it contains wood fiber in enhanced PLA. Generally speaking, wood products are valued for their natural beauty rather than their practical utility. When printing items for tables, tables or shelves, it is recommended to use wood 3D printing media. Any of the application examples include chalices, figurines, and trophies. What's more, it's a truly innovative application for 3D printers, which are often used to model real buildings, structures, or trees. nine0003

nine0003

Metal thread

Like wood thread, it is not 100% metal. Specifically, it is composed of metal powder, and one of the following materials is PLA or ABS. However, the effects also have a metal-like aesthetic appeal. Metal Infused can be printed for both decorative and practical purposes. Figures, prototypes, toys, including tokens, can be 3D printed from metal and give them a great look. You can also use metallic 3D printer filament to make parts such as tools or finishing components in light applications. nine0003

Biodegradable (biophila) filament

This biodegradable 3D printer filament aims to reduce the impact of all plastic waste into the atmosphere. Although biodegradable 3D filament was originally environmentally friendly, it can still produce quality printed products. Choose this biophile if you don't have special requirements for strength, versatility or endurance. For projects that require prototyping, you can also benefit from these flawless fiber prints that can be biodegraded responsibly. nine0003

nine0003

Conductive thread

This is a kind of three-dimensional material with conductive carbon particles in it. It is ideal for Arduino-based open source businesses. You'll want to look into this filament if you want to make circuits, LEDs, sensors, and other low voltage projects.

Magnetic filament

PLA magnetic iron filament is as magnetic as the name suggests. This one-of-a-kind filament is made from PLA material impregnated with powdered iron. It is ideal for making fridge magnets and other custom-made decorative items. Also, it can be used to create multiple DIY structures, sensors, educational resources, etc.0003

Top Five 3D Printer Filaments

Access to a 3D printer creates a whole new world of creative printing. There are several purposes and hobbies that 3D printing serves, but they all rely on the same raw material - 3D printer filament.

While unique materials are recommended for durable and impressive models, you need to select the right material for your 3D image. need printer. You also need to consider the quality and attributes of the thread. That being said, finding the right 3D filament is no picnic. nine0003

need printer. You also need to consider the quality and attributes of the thread. That being said, finding the right 3D filament is no picnic. nine0003

As such, we sought the advice of tech experts and 3D printer enthusiasts to find the most popular 3D printing filaments on the market. And to give you a clearer idea of their main features and specifications, we have done a detailed analysis to better understand which filament you should pair with your 3D printer. Also, don't forget to click on the buttons below to get the best deals on Amazon!

Plastics for 3D printer

The choice of plastic for a 3D printer is very important, especially when the goal is to print a functional model with certain properties. It will be a shame if the printed gear breaks almost immediately, or the decorative model quickly loses its beauty.

It is important to understand whether the printer will be able to work with the selected plastic. Some materials (most often engineering) require certain conditions for successful printing.

First, decide which model you want to print. What properties should it have? Does the model need to be durable? Or is it a master model for further replication, in which the quality of the surface is important? nine0003

90% of 3D printers use 1.75 diameter filament. 3mm diameter is rare, but it is better to check in advance which size is used in your printer.

PLA

PLA (Polylactide) is the most popular and affordable 3D printer plastic. PLA is made from sugar cane, corn or other natural raw materials. Therefore, it is considered a non-toxic, biodegradable material.

Extruder temperature - 190-220 degrees. Table heating is not needed, but if the printer's table has a "heater" for better adhesion, you can heat it up to 50-60 degrees. PLA is very easy to work with. The only requirement is to blow the model. There is practically no shrinkage in this material. When printed, it is practically odorless, and if it smells, it smells like burnt caramel.

Pros:

-

Does not shrink. This makes it easy to build prefabricated or huge models without changing dimensions. nine0003

-

There are no specific requirements for a 3D printer. Any working 3D printer will do. PLA doesn't need a heated table or a closed case.

-

Non-toxic. Due to this, during printing it does not smell or has a barely perceptible aroma of burnt caramel.

-

Diverse color palette.

nine0123 Cons:

-

PLA is poorly sanded and machined.

-

It begins to deform already with a slight heating (about 50 degrees).

-

Fragility. Compared to other materials, PLA is very brittle and breaks easily.

-

Decomposes under the influence of ultraviolet radiation. Of course, it will not fall apart into dust, but it can become more brittle and fade. nine0003

PLA is perfect for making dimensional or composite models. For example, decorative interior items, prototyping, electronics cases, etc.

For example, decorative interior items, prototyping, electronics cases, etc.

Recently, PLA+ has appeared on the market. It may differ from conventional PLA in improved performance. For example, more durable, with improved layer adhesion.

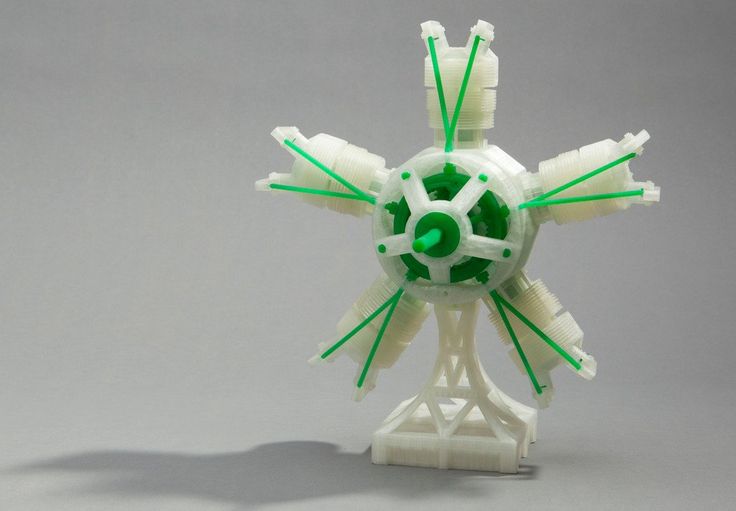

Dummy turbine

Decorative coasters

ABS

ABS (acrylonitrile butadiene styrene) is the second most popular plastic for 3D printing due to its properties, availability and low price.

Extruder temperature - 220-240 degrees. The temperature of the table is 80-100 degrees. For printing, a heated table is required at the printer. It is desirable to have a closed chamber, because ABS "does not like" drafts. Due to a sharp temperature drop, it can “unstick” from the table or crack in layers. ABS can smell bad when printing, so it is recommended to use the printer with a closed chamber and filters, or print in a well-ventilated area. nine0003

nine0003

Pros:

-

Good strength characteristics allow the production of functional prototypes from ABS.

-

Simple mechanical and chemical processing. ABS is easy to sand and drill, and with an acetone bath you can achieve a perfectly smooth surface.

-

It is currently the most inexpensive type of plastic for 3D printing. nine0003

-

Large selection of colors and shades.

Cons:

-

High shrinkage. Because of this, it can be problematic to manufacture overall products.

-

Printing requires a heated bed and a closed chamber. Without this, the ABS may peel off the table or crack in layers.

nine0080 -

During the printing process, ABS can smell bad. Therefore, it is recommended that you print in a ventilated area or use the printer with a sealed chamber and filter.

ABS is an engineering plastic. It is suitable for the manufacture of simple functional products.

It is suitable for the manufacture of simple functional products.

ABS after chemical treatment in an acetone bath

nine0003

RU model made of ABS

ABS+ differs from conventional ABS in improved strength characteristics (elasticity, rigidity, hardness), less shrinkage and sometimes resistance to certain oils and solvents (eg gasoline).

HIPS

HIPS (high impact polystyrene) - originally conceived as a soluble support plastic for materials with high printing temperatures. For example for ABS or Nylon. nine0003

The extruder temperature is 230-260 degrees. The temperature of the table is 80-100 degrees. It is desirable to have a closed camera for a 3D printer.

Pros:

-

Less shrinkage than ABS.

-

Ease of machining.

-

The matte surface looks very advantageous on decorative products.

nine0003

nine0003 -

Food contact allowed (but be sure to check with a specific manufacturer for certificates)

Cons:

-

For printing, you need a printer with a heated table and a closed chamber.

-

More flexible and less durable than ABS. Because of this, it will not be possible to produce functional products. nine0003

-

Small palette of colors.

Most often, HIPS is used for its intended purpose for printing on 2x extruder printers as a support for ABS. It dissolves perfectly (though not very quickly) in limonel.

Sometimes HIPS is used as an independent material. Products from it are not very durable, but this plastic is loved for easy post-processing. HIPS can be used for models that will subsequently come into contact with food (not hot). nine0003

Using HIPS as a Soluble Support

Decorative vase made of HIPS

PVA

PVA (polyvinyl alcohol) is a material that was developed as a water-soluble support for PLA.

Extruder temperature - 190-210. Table heating is not required. PVA is a slightly "capricious" material, it is not recommended to overheat it and print at high speeds. nine0003

PVA is very hygroscopic and dissolves in plain water. Therefore, it is only used as a support for PLA or other plastics with print temperatures close to PVA.

Soluble PVA Support

Add to compare

Item added to compare Go

| Manufacturer | Tiger3D | nine0337

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go nine0003

| Manufacturer | Esun |

PETG

PETG (polyethylene terephthalate) combines the best properties of PLA and ABS. It is easy to work with, it has a low percentage of shrinkage and excellent sintering of the layers.

It is easy to work with, it has a low percentage of shrinkage and excellent sintering of the layers.

Extruder temperature - 220-240 degrees. Table temperature - 80-100 degrees. During the printing process, the model must be well blown.

Pros: nine0003

-

Excellent sinterability of layers.

-

PETG is very strong and wear resistant. Good impact resistance.

-

Virtually no smell when printing.

-

Non-toxic.

-

Little shrinkage.

nine0101 -

slight shrinkage

-

Transparency. After treatment with solvent, limonel or dichloromethane, beautiful transparent products with an almost smooth surface can be obtained.

nine0077 -

Allowed contact with food.

-

High strength and wear resistance.

nine0080 -

High slip factor.

-

Heat resistance compared to other 3D printing plastics.

-

High resistance to many solvents.

-

Good for mechanical processing.

Perfectly polished and drilled.

Perfectly polished and drilled. -

Some fillers (eg clay) are abrasive. For such plastics, the standard brass nozzle cannot be used. Will have to buy a harder steel nozzle.

-

Some decorative plastics can clog the small nozzle (0.4 or less). For them, you need to use a “thicker” nozzle. nine0003

-

Hardness and strength.

-

Low flammability or non-combustibility.

-

High precision due to low shrinkage.

nine0101

Cons:

PETG is perfect for printing functional models. Due to its low shrinkage, it is often used to make large or composite models. Due to its low toxicity, PETG is often used for products that will come into contact with food.

Cookie cutters and patterned rolling pin

SBS

It is a highly transparent material. At the same time, it is durable and resilient. SBS is a low toxicity plastic. It can be used to print food contact models. nine0003

SBS is a low toxicity plastic. It can be used to print food contact models. nine0003

Extruder temperature - 230 -260 degrees. Table temperature - 60-100 degrees. You can print without the closed case on the printer.

Pros:

Easily processed mechanically or chemically.

Cons:

SBS is excellent for translucent vases, children's toys and food containers. Or functional things that require transparency, such as custom turn signals for a motorcycle or car, lamps or bottle prototypes. nine0003

Vases are perfectly printed with a thick nozzle (0.7-0.8) in one pass (printing in 1 wall or spiral printing in a slicer).

Models of bottles after chemical treatment

Nylon

Nylon (polyamide) is considered the most durable material available for home 3D printing. In addition to good abrasion resistance and strength, it has a high slip coefficient. nine0003

Extruder temperature - 240-260 degrees. The temperature of the table is 80-100 degrees. Nylon is a very capricious and hygroscopic material - it is recommended to dry the coil with plastic before use. For printing, you need a printer with a heated table and a closed chamber, without this it will be difficult to print something larger than a small gear.

Pros:

nine0123 Cons:

Nylon is perfect for making wear-resistant parts - gears, functional models, etc. Sometimes nylon is used to print bushings.

Nylon gear

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go nine0003

| Manufacturer | Bestfilament |

Soft plastics

FLEX (TPU, TPE, TPC) is a material similar to silicone or rubber. It is flexible and elastic, but at the same time tear-resistant. For example, TPE is a rubbery plastic, while TPU is more rigid.

FLEX are printed at a temperature of 200-240 (depending on the material). A heated table is not required. On printers with direct material feed (feed mechanism on the print head), there are usually no problems with printing. On a bowden feeder (the feed mechanism is located on the body), printing with very soft plastics can be difficult. Usually it is necessary to additionally adjust the clamping of the bar. The main nuance is the very low print speeds - 20-40mm. nine0003

Pros:

Cons:

Depending on the type of FLEXa, the models can be flexible or rubber-like. This material, depending on its softness, can be used to print gaskets, insoles, belts, tracks or other models that require flexibility or softness.

FLEX belt

nine0174 Trainers with flexible soles

Wheel for RC model

Decorative plastics

Decorative plastics are PLA plastics with various fillers (wood or metal shavings). Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Extruder temperature - 200-220 degrees (depending on the manufacturer). A heated table is not required. nine0003

Pros:

Cons:

Depending on the filler, different material properties are obtained. Plastics that use only dye do not require additional processing. Materials with "fillers" may sometimes require additional post-processing.

Plastics with metal fillers after printing must be processed with a metal brush. Then the Metal content will show through and the model will resemble a metal casting.nine0115

Plastics with metallic powder

These plastics are often used for printing key chains, decorative models and interior details.

If the plastic has a high content of wood dust, then it is recommended to use a larger nozzle diameter (0.5 or more), a smaller nozzle can quickly become clogged during printing.

Wood-filled plastic ground

Plastic key rings with copper dust

Engineering plastics

These are nylon-based plastics with fillers that improve strength, heat-resistant and other characteristics, help to achieve less shrinkage of the material. For example - carbon fiber, carbon fiber or fiberglass.

Extruder temperature - 240-300 degrees (depending on the manufacturer). Table temperature - 90-110 degrees. Since plastics are based on nylon, the requirements for printing are similar. This is a heated table and a closed printer case.

Pros:

Cons:

3D printers use brass nozzles, some plastics can quickly “waste” it during printing. For such materials it is recommended to use steel nozzles.

These are highly specialized plastics used for a specific task, depending on the filler. For example, functional parts that do not lose their shape when heated, are resistant to many solvents, etc. nine0003

Functional Carbon Fiber Composite Prototype

Composite frame

Polycarbonate ashtray

Totals

This is of course not the whole list of materials for 3D printing. There are many highly specialized engineering and decorative plastics for specific tasks.

nine0003

Manufacturers are constantly trying to replenish the range of materials for 3D printing. Already familiar materials are improved for more comfortable printing. There are many interesting decorative plastics imitating different materials - ceramics, clay, wood, metals.

And of course, the assortment of engineering plastics is constantly updated. Now there are many interesting materials for highly specialized tasks - for example, burnable plastic with a low ash content for subsequent casting in metal. nine0003

Burnout plastic

Before buying a coil, read the information on the website of the manufacturer or seller. There you can find some nuances of printing for a particular plastic. The manufacturer indicates the recommended temperature range on the box. Sometimes, for quality printing, it is recommended to print several tests to adjust the temperature settings, retract, etc.

Try to store the started coil in silica gel bags.

Learn more