3D print burger

McDonald's will offer completely 3D printed burgers by 2020

3D printing news News McDonald’s will offer completely 3D printed burgers by 2020

Published on April 1, 2019 by Carlota V.

Fast food giant McDonald’s has just announced the creation of a brand new 3D printed burger, its 3D Mic Mac. Restaurants should be equipped with 3D printers by the end of 2020 in order to offer this customisable hamburger. According to the company, 3D Mic Mac can be preserved for longer than traditional burgers, significantly reducing kitchen waste while maintaining the original Big Mac flavour. The 3D Mic Mac will be offered with meat or a tofu alternative to address the growing demand from vegetarians today.

A few years ago, McDonald’s announced that it would print its Happy Meal toys in 3D, giving children the opportunity to choose directly what they really like. The American chain wants to go further and use 3D technologies directly in the kitchen: by offering a customisable burger that is easy to prepare and above all more durable. In fact, the 3D printed burger should have a longer shelf life to avoid being thrown away too quickly, as is unfortunately the case in many restaurants. The chain is very aware of this problem and often criticised on this subject. 3D printing could allow it to rethink the supply chain.

3D Mic Mac, a long thought-out project

In an official press release, John Catfish, Global Technology Senior Auditor, said: “We have been studying 3D food printing in our restaurants for the last 3 years. We aim to equip our kitchens in the United States by the end of 2020 and offer a customisable burger. We had some difficulties with the printing of the meat, especially in the preservation of amino acids and myoglobins, but our teams are confident – we have succeeded in printing the rest of the ingredients, including tofu, in 3D.”

McDonald’s says that the ingredients of 3D Mic Mac will all be printed in 3D, from meat, onions, to tomatoes and bread. The sauce will be the only component to be added by hand – its viscosity did not allow it to be extruded optimally. The company remains quite discreet about the technology and 3D printer used, but explains that it has worked with one of the leading manufacturers of food-based 3D printers on the market. Leslie Trout, Product Manager at McDonald’s, says: “We are working with a European manufacturer of food 3D printers who has developed various machine prototypes for us, adapted to our current needs. The challenge was the consistency of our ingredients, which was different every time – our partner designed a nozzle capable of extruding these mixtures and above all a tray that adhered to the materials.”

The company remains quite discreet about the technology and 3D printer used, but explains that it has worked with one of the leading manufacturers of food-based 3D printers on the market. Leslie Trout, Product Manager at McDonald’s, says: “We are working with a European manufacturer of food 3D printers who has developed various machine prototypes for us, adapted to our current needs. The challenge was the consistency of our ingredients, which was different every time – our partner designed a nozzle capable of extruding these mixtures and above all a tray that adhered to the materials.”

3D printing to reduce food waste

But why choose 3D printing when we know that some processes take a longer time to produce the final part? Actually, the technology should allow McDonald’s to redesign its supply chain by creating the necessary amount, thereby significantly reducing the amount of waste in the kitchen. The company explains that it has developed a formulation that allows it to better preserve these 3D printed burgers while retaining their flavour. No need to throw burgers away if they are not eaten within minutes of preparation! They can even be prepared in advance. Mike Turbot, Quality Engineer at McDonald’s, concludes: “3D printing will enable us to meet the challenges of our consumer society. We will be able to produce the right amount while preserving the flavour of the food. It is a fascinating technology with significant advantages in the food industry and we are proud to be the first fast food chain to offer it!”

No need to throw burgers away if they are not eaten within minutes of preparation! They can even be prepared in advance. Mike Turbot, Quality Engineer at McDonald’s, concludes: “3D printing will enable us to meet the challenges of our consumer society. We will be able to produce the right amount while preserving the flavour of the food. It is a fascinating technology with significant advantages in the food industry and we are proud to be the first fast food chain to offer it!”

McDonald’s is expected to launch its first 3D Mic Mac with meat or tofu in 2020 in the US. Find more information on the official website of the company HERE.

Would you try McDonald’s 3D printed burgers? Let us know what you think in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Robot 3D Prints Vegan Burger in Just 6 Mins—Here’s How it Works

Teejay Boris, Tech Times

A robot 3D prints a customizable vegan burger in merely six minutes, which allows its users to custom-make the composition of their vegan meat via an app on their smartphone.

(Photo : by JACK GUEZ/AFP via Getty Images)

Racheli Vizman, CEO of SavorEat, the start-up specializing in the production of alternatives to meat, holds a cut half of a plant-based patty with a meaty taste, made and cooked by a robot according to customer requirements, offered by Israeli fast food brand BBB in the Israeli coastal town of Herzliya on December 28, 2021. - The Israeli fast food restaurant BBB is serving up a veggie steak made and cooked by a robot that tailors ingredients and cooking time to customer tastes.

Robot 3D Print Vegan Burger

As per the report by VegNews, an Israel-based firm that goes by the name SavorEat developed the 3D printer robot, which seeks to change how vegan consumers order their burgers.

The CEO and co-founder of SavorEat Racheli Vizman said in a press release that the firm "believed that the food industry is in need of significant changes in order to remain relevant."

As such, the Israeli firm went on to go the extra mile to serve a customizable burger to its vegan consumers.

Vizman further noted that the firm "boldly looks at the changes of our future to challenge the status quo" at least in the food industry."

The SavorEat boss touted that the 3D printer robot allows its users to express their "changing needs" due to its highly customizable feature.

3D Print Vegan Burger Customization

The mobile phone app that pairs with the 3D printing robot allow its users to tweak multiple specifications of the burger that they want.

The phone app options include changing the fat and protein content, the size of the patty, as well as the temperature of cooking.

Not to mention that the 3D printed burger removes the cow slaughtering from the process of creating their meal.

On top of that, as the patty is created from scratch, it is not stored frozen and cooked in the grill.

Read Also: Humanoid Robot Ameca Could Perfectly Mimick Human-like Facial Expressions But Can it Walk or Run?

3D Printing Robot Chef

According to the news story by Gadgets360 of NDTV, the Israeli food-tech company has now begun selling its robot chef to a number of businesses.

Initially, the 3D printing robot chef will be rolling out to nearly a hundred food joints in Israel. SavorEat is also looking to set its foot in the United States market later on.

For now, the food-tech has forged a partnership with Sodexo to test the robot chefs in universities in the US to target 47 percent of the flexitarian market.

The robot chef primarily uses the expansive power of 3D printing tech, along with its plant-based nano-cellulose fiber, which is made from ingredients like potato protein, pea, and more. Thus, achieving a meat-like texture similar to a non-vegan burger patty.

Aside from that, the 3D printed patty also includes coloring, flavoring, and fat to make it taste great and look like its meat as well.

Related Article: Robots with Soft Grip? NUS Researchers Debut Machine with Delicate Fingers for Soft Materials

This article is owned by Tech Times

Written by Teejay Boris

ⓒ 2022 TECHTIMES. com All rights reserved. Do not reproduce without permission.

com All rights reserved. Do not reproduce without permission.

Tags: Robot 3d Print Vegan Burger Vegan burger Robot 3D printer

How soon will we 3D print burgers

Growing consumer retail demand for plant-based proteins has been a clear post-Covid trend and has certainly sparked investor interest. For startups rushing to meet this demand, the strategy seems pretty straight forward: expand data processing capabilities as quickly and affordably as possible. So far this has mostly meant larger and more automated hubs - building them from scratch; buying and reselling them from no longer existing meat processing plants; or finding co-production partners, usually from existing protein producers.

But is there a need for distributed, hyperlocal processing models? SavorEat CEO Rachel Wiesman thinks we need to network 3D printers that print and cook plant-based food at the same time. This idea has provided a significant share of the investment over the past few weeks. Two Israeli investment houses, Mor and Meitav Dash, will invest $3 million in her company and have the opportunity to invest another $1 million.

This idea has provided a significant share of the investment over the past few weeks. Two Israeli investment houses, Mor and Meitav Dash, will invest $3 million in her company and have the opportunity to invest another $1 million.

According to the Israeli business news agency Globes, "The first $1 million will be invested immediately to raise $13 million, and another $2 million will be invested up to $35 million." And that comes weeks after SavorEat received a similar $1.75 million commitment from the Food Technology Millennium Partnership (which had its own TASE IPO earlier in July).

Next microwave revolution

“The is another microwave revolution,” Wisman emphasized as she talked about her company's technology and approach. Founded in 2018 with co-founders Oded Shoseev and Ido Braslavsky, the SavorEat team is developing a custom 3D printer that uses infrared light to cook a hamburger when it's printed. The team has been working on using new ingredients such as nanocellulose as an emulsifier. Most of these technologies are distributed to the Hebrew University's Faculty of Agriculture, with SavorEat receiving an exclusive commercialization license from the university's technology transfer company, Yissum.

Most of these technologies are distributed to the Hebrew University's Faculty of Agriculture, with SavorEat receiving an exclusive commercialization license from the university's technology transfer company, Yissum.

The current state of affairs seems to suggest that the network of 3D printers will be equipped with a bio-cartridge containing vegetable proteins, fats, flavors and nanocellulose, a fiber that can be used for various purposes. Textures, including those that mimic beef muscle and fat.

A distributed processing strategy will have numerous benefits for another 2020 food technology trend, says Wiesman: dietary personalization. Simultaneous preparation and cooking will eliminate the need for refrigeration or excess preservatives, allowing each consumer to choose the level of salt, fat, protein, texture, flavor or vitamin that will suit their particular diet, lifestyle or health condition. And thanks to automated food preparation, she added, restaurants will be less labor intensive and the kitchen will be easier to biocontrol in an era when consumers are more wary of contact transmission of disease. For the manufacturer, this creates a convenience in collecting data on individual consumer dietary and culinary preferences.

For the manufacturer, this creates a convenience in collecting data on individual consumer dietary and culinary preferences.

This technology is also relevant in a post-Covid world where online food delivery is taking on new importance as consumers increasingly eat at home. Supply chain disruptions also make local production important.

Military Protein

Offering the look and feel of these companies, FTW Ventures' Brian Frank underlined the importance and challenges of sound market research for the kind of product that has never existed before. “Such equipment can be difficult to manufacture and difficult to sell,” he warned. While he doubted whether even the most luxurious home kitchens would see them in the near future, he added that he would be much less surprised to see such personalized food printers find their way into automated fast food restaurants, hospitals, or even the military.

“ Optimal, personalized experience ,” he said. " There are institutional needs for this . "

"

In other areas related to foodtech and agtech, there were quite a few companies in the early stages that made progress with a focus on distributed locality. InFarm has pantry-sized vertical farms. Better Origins is designing insect mini-farm networks. So, why not distribute plant-based food to restaurants, hospitals, or even homes? How far-fetched or implausible is the vision of a Star Trek replicator?

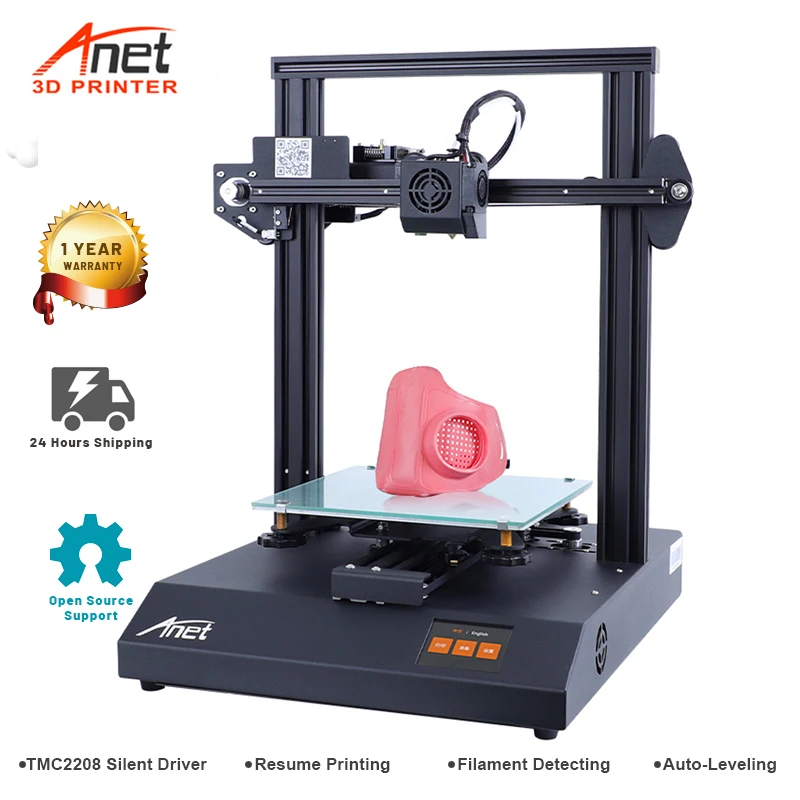

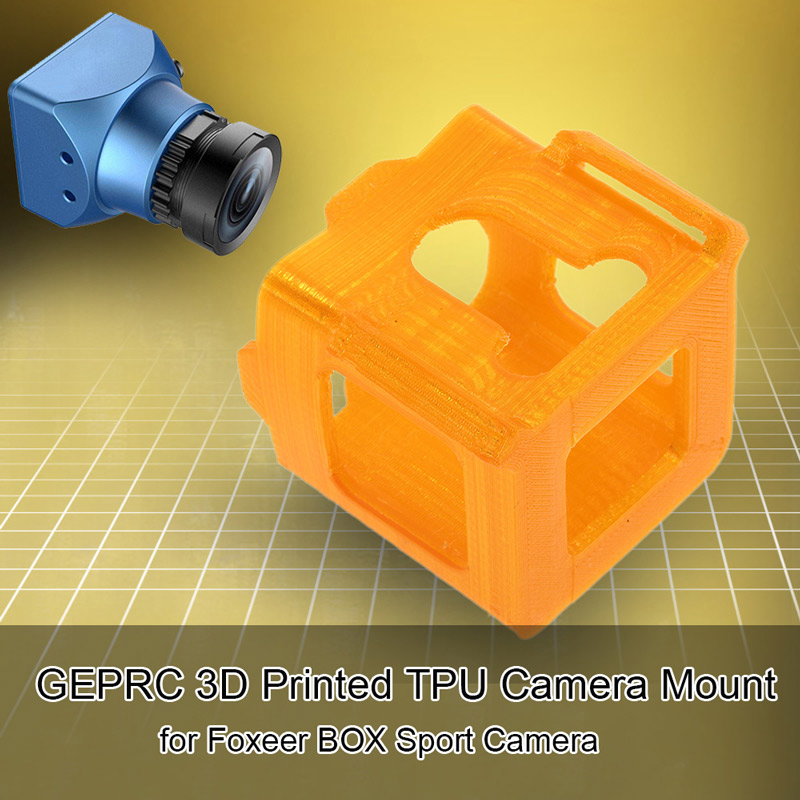

But before going that far, you need to consider basic things like Print Accuracy, Portability, and Cost think so far, you need to consider basic things like Print Accuracy, Portability, and Price of a 3D printer.

However, there are already some companies that are in the early stages of plant protein production. Inspired by the promise of 3D printing for everything from airplane parts to kidney transplants, startups like Redefine Meat and NovaMeat are developing ways to model the taste and texture of muscle tissue through 3D printing – a more complex texture to model than hamburger patties or chicken nuggets.

Space Steaks

And by growing animal cells as a source of protein, 3D printing is already helping companies like BlueNalu or AlephFarms create forests and texture their steak or fish fillet products. Russian 3D Bioprinting Solutions even offer innovative solutions for creating microscopic pieces of fish pie under weightless conditions on the International Space Station.

Although the temptation to use 3D printers is quite high today, there are 2 questions:

- How practical, easy and cost effective will it be to refill cartridges?

- How environmentally friendly are these cartridges?

What do you think?

Want to know more about AgTech? Read all the agriculture news at AgroTimes

Related news

McDonald's to offer fully 3D printed burgers by 2020

McDonald's to offer fully 3D printed burgers by 2020

help 3D print , his 3D Mic Mac. Restaurants must be equipped with 3D printers by the end of 2020 in order for diners in this restaurant to enjoy this customizable hamburger. According to the company, 3D Mic Macs can be stored longer than traditional burgers, significantly reducing kitchen waste while maintaining the original Big Mac flavor. 3D Mic Mac will be offered with a meat or tofu alternative to meet the growing demand from vegetarians today.

According to the company, 3D Mic Macs can be stored longer than traditional burgers, significantly reducing kitchen waste while maintaining the original Big Mac flavor. 3D Mic Mac will be offered with a meat or tofu alternative to meet the growing demand from vegetarians today.

A few years ago, McDonald's announced that it would print its Happy Meal toys in 3D, giving kids the freedom to choose what they really like. The American fast food chain wants to go one step further and use 's 3D technology directly in the kitchen: offering a customizable burger that is easy to prepare and, above all, has a longer shelf life. In fact, a 3D printed burger should have a longer shelf life to avoid being sold out too quickly, which is common in most 3D-printed restaurants. The American fast food chain is very aware of this issue and is often criticized on this issue. 3D printing of could greatly minimize the disposal of expired products.

3D Mic Mac

In an official press release, John Catfish, Senior Auditor at Global Technology, said: “We have been studying 3 D-printing products in our restaurants for the past 3 years. We aim to equip our kitchens in the United States by the end of 2020 and offer a customizable burger. We had some difficulties with printing meat, especially in preserving amino acids and myoglobins, but our team of professionals coped with this difficult task - we managed to print the rest of the ingredients in 3D, including tofu.”

We aim to equip our kitchens in the United States by the end of 2020 and offer a customizable burger. We had some difficulties with printing meat, especially in preserving amino acids and myoglobins, but our team of professionals coped with this difficult task - we managed to print the rest of the ingredients in 3D, including tofu.”

McDonald's claims that all components of the 3D Mic Mac will be 3D printed, from meat, onions, to tomatoes and bread. The sauce will be the only component added by hand - its viscosity did not allow it to be optimally extruded. The company remains quite cautious about the technology and the 3D printer used, but explains that it has worked with one of the leading manufacturers of food-based 3D printers on the market. Leslie Trout, product manager at McDonald’s, says: “We are working with a European food manufacturer 3D Printer , who has developed various machine prototypes for us, adapted to our current needs. The challenge was the consistency of our ingredients, which was different every time – our partner developed a nozzle that was able to extrude these mixtures, and most of all, a tray that stuck to the materials.”

The challenge was the consistency of our ingredients, which was different every time – our partner developed a nozzle that was able to extrude these mixtures, and most of all, a tray that stuck to the materials.”

3D printing will reduce food waste

But why choose 3D printing when we know that some processes take longer to produce the final piece? In fact, the technology should allow McDonald's to modernize its supply chain by creating the quantity it needs, thereby significantly reducing waste in the kitchen. The company explains that it has developed a recipe that allows these burgers to be better preserved thanks to 3D print while maintaining their taste. Don't throw away hamburgers unless they're eaten within minutes of cooking! They can even be prepared ahead of time. Mike Turbo, Quality Engineer at McDonald's, concludes: “ 3D printing of will enable us to meet the challenges of our consumer society.