Bmg 3d printer

Bondtech BMG Extruder - 1.75mm

- Home

- Store

- 3D Printer Accessories

- 3D Printer Extruders

- Bowden Extruders

The Bondtech BMG extruder is a top-of-the-line option for anyone looking to get the most out of their 3D printer. With Dual-Drive hobbed gears for maximum contact and power, and hardened steel drive gears for processing abrasive materials, the BMG is built for reliability and performance.

- Dual-Drive hobbed gears for maximum contact and power

- Hardened extruder gears for increased durability

- CNC-machined teeth for maximum grip

Remove from wishlist Add to wishlist loading...

Product No. loading...

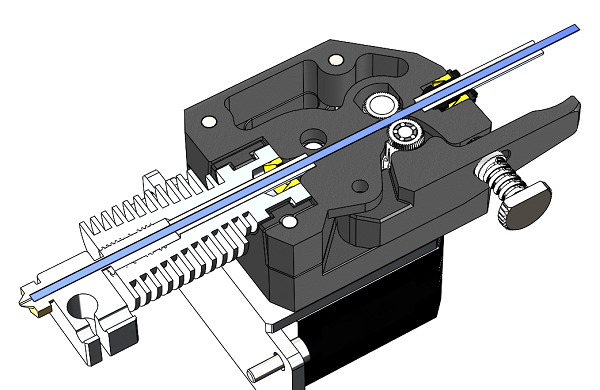

Notify me when this item becomes available Success You will be notified when ... becomes available. The Bondtech BMG leverages Dual-Drive hobbed gears for maximum contact and powerNo matter what your use case is with 3D printing, absolutely everyone can benefit from enhanced extruder performance. The Dual-Drive gears of the Bondtech BMG create constant contact with both sides of the loaded filament, allowing for greater grip during both extrusion and retraction operations. Not only are there hobbed gears on both sides of the filament, but they are geared together to apply pressure evenly on both sides of the filament at all times. Idled extruders leave room for slippage as the filament can simply slide along the bearing if pressure is too high, but Dual-Drive ensures constant grip over a much larger pressure range.

The most significant growth in the 3D printing world today is the constant stream of new and exciting materials being manufactured for desktop 3D printers. Entry-level materials like PLA, ABS, and PETG remain available in a wide variety of colors from many manufacturers, but stronger, reinforced composites are becoming more prominent every day. Carbon-fiber reinforced materials like NylonX or PRO Series Carbon Fiber PLA provide superior stiffness over their regular counterparts, but at the cost of having to process an abrasive material. This abrasion is a concern for 3D printer nozzles, but also for the extruder gears that have to control this material going into the machine. All Bondtech extruders are built with hardened steel drive gears with CNC-machined teeth for maximum grip. Using a Bondtech extruder means peace of mind no matter what materials you are processing, from high volumes of PLA for prototyping to kilograms upon kilograms of carbon or glass-fiber reinforced materials.

Carbon-fiber reinforced materials like NylonX or PRO Series Carbon Fiber PLA provide superior stiffness over their regular counterparts, but at the cost of having to process an abrasive material. This abrasion is a concern for 3D printer nozzles, but also for the extruder gears that have to control this material going into the machine. All Bondtech extruders are built with hardened steel drive gears with CNC-machined teeth for maximum grip. Using a Bondtech extruder means peace of mind no matter what materials you are processing, from high volumes of PLA for prototyping to kilograms upon kilograms of carbon or glass-fiber reinforced materials.

One of the Hardened Gears is visibly attached to the tension lever

A 3:1 gear ration makes the Bondtech BMG a beast of torque and speedEvery 3D printer hotend shares one thing in common, the filament must transition from a large diameter into a smaller diameter to pass through the nozzle and be added to a 3D print. This transition is made possible by heating the filament, but even at extrusion temperatures, there is pressure to overcome when extruding material. While most Nema 17 stepper motors are capable of producing enough torque to overcome this pressure, there is still a speed limitation. To overcome this, Bondtech has designed the BMG with a 3:1 gear ratio for triple the torque output, even in this compact package. This gear ratio is a great choice because not only does it provide additional torque but does so without sacrificing speed. Another benefit of this gearing is the ability to create smaller extruder movements with increased precision over direct extruders.

This transition is made possible by heating the filament, but even at extrusion temperatures, there is pressure to overcome when extruding material. While most Nema 17 stepper motors are capable of producing enough torque to overcome this pressure, there is still a speed limitation. To overcome this, Bondtech has designed the BMG with a 3:1 gear ratio for triple the torque output, even in this compact package. This gear ratio is a great choice because not only does it provide additional torque but does so without sacrificing speed. Another benefit of this gearing is the ability to create smaller extruder movements with increased precision over direct extruders.

3:1 gear reduction applied more torque than direct connection

Nothing escapes the constrained filament path of the Bondtech BMGNot all 3D printing filament is created equal, and while most are rigid plastic that easily flows through the extruder and to the hotend, thermoplastic elastomers like NinjaFlex and MatterHackers PRO Series Flex have the consistency of cooked spaghetti and have a tendency to travel along unwanted paths, leading to failed prints and other hardware issues. The BMG extruder body is designed by and SLS printed for Bondtech. This design constrains the filament path from the entrance, through the dual hobbed gears, and out the exit of the extruder, leaving no room for flexible materials to turn sideways and cause a misfeed.

The BMG extruder body is designed by and SLS printed for Bondtech. This design constrains the filament path from the entrance, through the dual hobbed gears, and out the exit of the extruder, leaving no room for flexible materials to turn sideways and cause a misfeed.

In the same way that every maker is unique in their use case, from the hobbyist experimenting with new materials to mass-manufacturing operations who rely on 3D printing to run their business, every 3D printer and filament are unique in their own ways. Having the ability to adjust the grip strength or tension of the extruder is a key element to adjust when setting up and fine-tuning any operation. The Bondtech BMG features a thumbscrew and spring mechanism for adjustable tension without needing special tools while maintaining the ability to handle slightly out-of-diameter materials. Filament tension is something that may need to be adjusted due to changes in material or hotend configuration, and not all extruders make it easy to adjust on-the-fly. With a Bondtech BMG, you can constantly keep your extruder tension just right with the easy-access thumbscrew.

With a Bondtech BMG, you can constantly keep your extruder tension just right with the easy-access thumbscrew.

Easy access thumbscrew tension adjustment

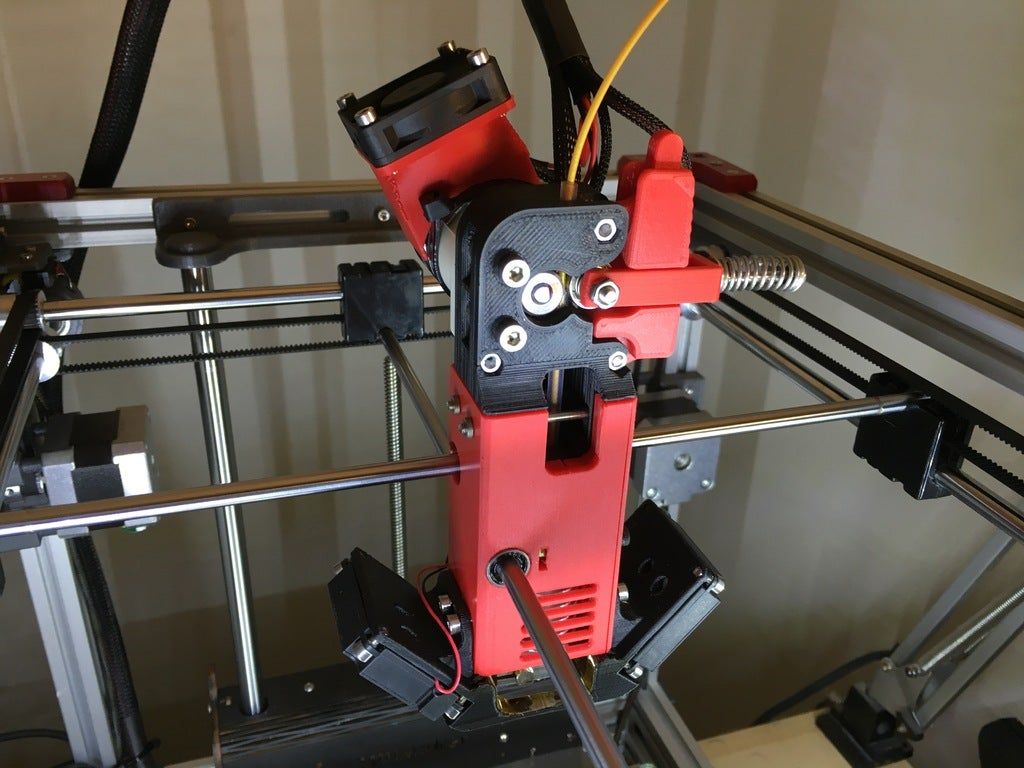

A master of bowden or direct drive configurations, the Bondtech BMG is a valuable upgrade for any FFF 3D printerThe extruder is a necessary component of any and all FFF 3D printers, so choosing a powerful and reliable extruder is a worth-while endeavor. Beyond that, making the extruder easy to integrate into a printer design only makes life easier, and also opens up more options for mounting positions and configuration styles. The Bondtech BMG is designed to mount directly onto the extruder stepper motor, sharing its dimensions and mounting hole pattern. The BMG itself is held together by three screws, which also affix it to the stepper motor. For bowden-drive 3D printers, it's easy to integrate the BMG and it's attached stepper motor via a sandwiched mount between them, while direct-drive configurations take advantage of the small extruder profile and integrated Groove Mount slot for easy and secure assembly. No matter what kind of filament feed system your 3D printer is based on, the Bondtech BMG makes it easy to upgrade the performance or migrate to a different configuration if desired.

No matter what kind of filament feed system your 3D printer is based on, the Bondtech BMG makes it easy to upgrade the performance or migrate to a different configuration if desired.

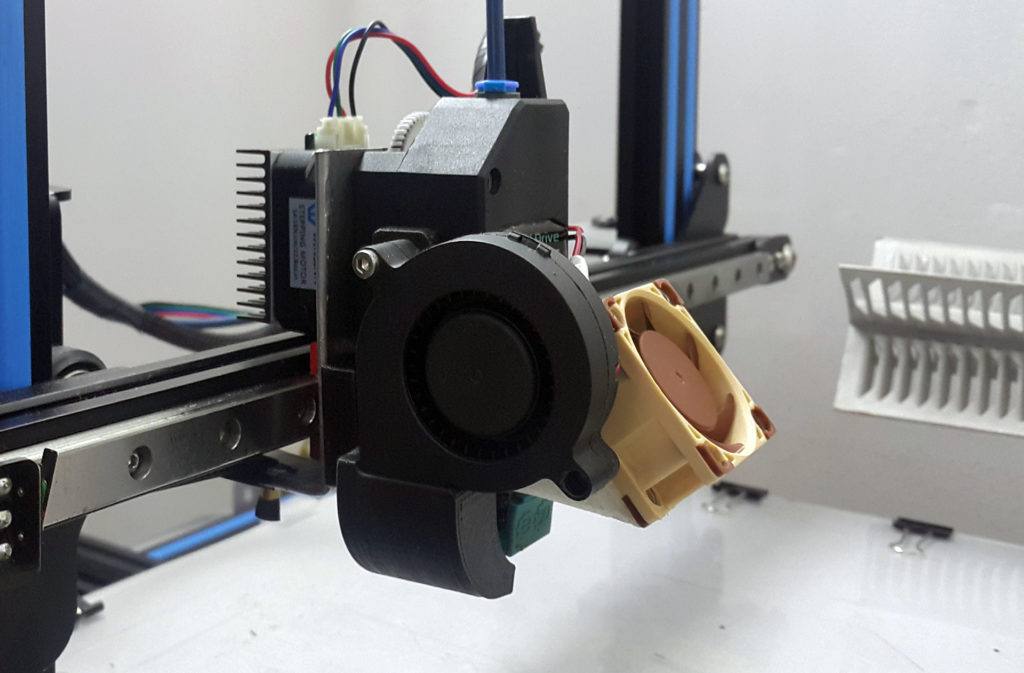

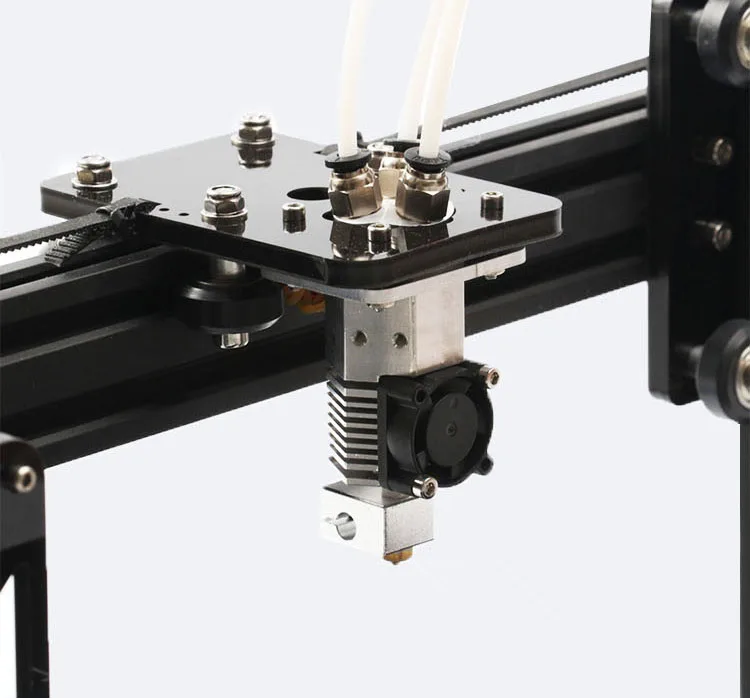

BMG and E3D v6 in a direct-drive configuration

Technical Specifications- Filament Diameter: 1.75mm

- Compatible Motor: Nema 17

- Compatible Motor Shaft Diameter: 5mm

- Gear Ratio: 3:1

- Weight: 75g

- E-Steps: 415 (Start with this value but also follow our guide on fine-tuning for best results)

- Motor Gear Material: Brass

- Output compatibility: Groove Mount

- Bondtech BMG Extruder Body

- Bondtech Motor Gear

- BMG POM Gear

- Tension Thumbscrew with spring and washer

This item cannot be shipped to a PO Box or APO/FPO/DPO address. This item takes longer to ship due to its size and/or weight.

BondTech Extruder & Upgrades - 3DJake International

Shop by category.

3D Printer Upgrades

Accessories

Direct Drive eXtruder

Extruder

LGX

Nozzles

Stepper

BondTech: 164 products

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

-

BondTech CHT MK8 Coated Nozzle 4 diameters- Nickel plated

- Higher melting capacity

- High hotend compatibility

-

BondTech Extruder BMG right- Dual-Drive

- Adjustable tension

- Versatile use

-

BondTech LGX DD for Sidewinder X1- Easy installation

- Dual drive technology

- Better filament grip

-

BondTech NEMA17 Pancake Stepper 25mm- Removable cable

- High torque

- Original Bond Tech

-

BondTech CHT Coated Nozzle M6 x 1.75 mm 7 diameters- Nickel plated

- Higher melting capacity

- High hotend compatibility

-

BondTech LGX PA12 Fan Shroud- For LGX extruders

- Compatible with the Artillery Sidewinder X1

- Compact design

-

BondTech LGX Lite Large Gear Extruder- For 1.

75 mm filament

75 mm filament

- Raised filament handle

- Easy maintenance

- For 1.

-

Slice engineering Copperhead Heat Break 6 Model types- Made of stainless steel

- With copper alloy

- Up to 450 ° C

-

BondTech Drivegear Kit 1.75 mm 2 Model types- CNC machined

- Made of hardened steel

-

BondTech Heatsink- Better heat dissipation

- Self-adhesive backing

-

BondTech IFS Extruder for the Prusa Mini- Compatible with the filament sensor

- Hardened drive gears

- Adjustable tension

-

BondTech EZABL Holder for DDX 2 Model types- For EZABL upgrades

- FDM printed

-

BondTech DDX V3 extruder for Creality- High precision

- Dual drive extruder

- More choice of print materials

-

BondTech Mini After LGX Lite Hotend Adapter 5 Model types- Different finishes

-

BondTech LGX B for Anycubic Mega X 1 set- Easy installation

- Strong filament grip

- Compact and light

-

BondTech Mini After LGX Lite Cowling- Replacement cowling

- Plastic part made of grey polyamide (PA12)

-

BondTech Prusa i3 MK2.5S / MK3S extruder upgrade- Better quality

- Lower weight

- Optimized geometry

-

BondTech Extruder BMG - Left- Dual-Drive

- Adjustable tension

- Versatile use

-

BondTech LGX for the MK3S & Mosquito- Easy installation

- Strong filament handle

- Maintenance window

-

BondTech Coated Nozzle for the CR-10S Pro 4 diameters- Low friction

- Wear resistant

- Nickel coated

-

BondTech Extruder Upgrade Kit Tevo Tornado- Reliable upgrade

- Easy construction

- Dual drive system

-

BondTech DDX Mounting Plate for the CR-10 V2- Original spare part

- Compact design

- Easy installation

-

BondTech DDX Z-Sensor Plate for CR-10 V2- Original spare part

- Compact design

- Easy installation

-

BondTech BMG-M & Mosquito Magnum Set 2 Model types- Perfect upgrade

- Complete set

- Safe 3D printing process

All prices incl. VAT.

VAT.

3D Printer Extruder (Feeder) Test, BMG Extruder Review from Mellow Store from China

Hello friends.

I decided to please you with a comparative review of extruders.

Today we will compare standard plastic, metal and BMG extruder from Mellow Store.

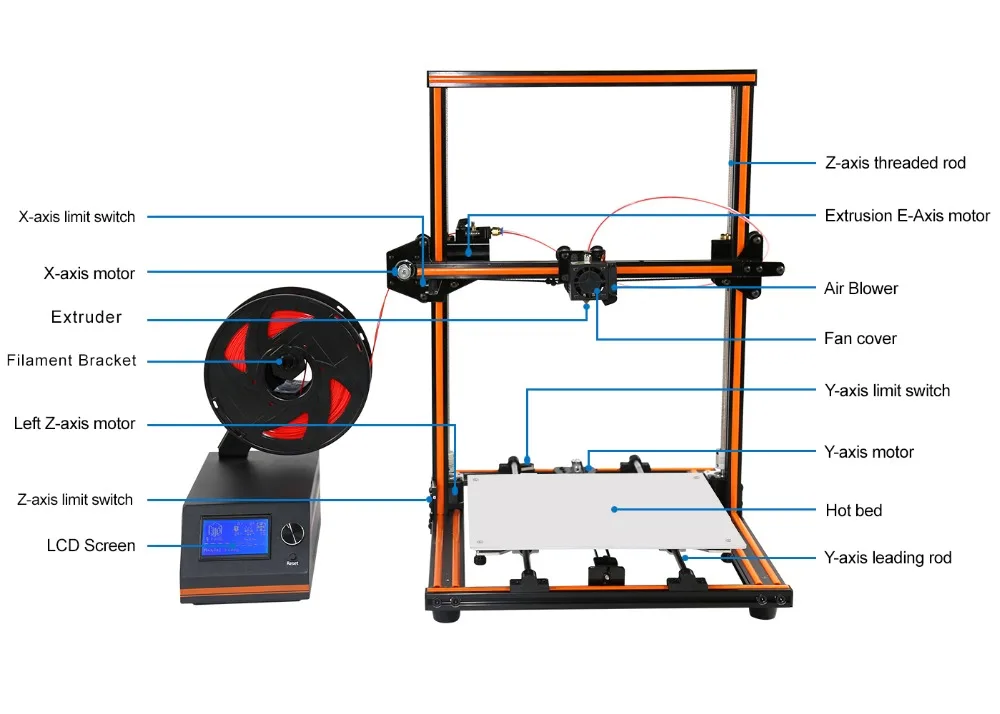

But first, let's weigh the stock motor from Creality Ender 3 and the short motor from Mellow Store:

Now let's weigh the motors + extruders: It should be noted that the installation of light short motors is not possible on a standard extruder and a metal extruder due to design features, namely the absence of a gearbox, unlike the BMG extruder, which has a gearbox.

Let's start the review with a regular extruder from Creality:

It has only one plus - it's low cost at the factory, but at the same time, when buying a new one, you will overpay a significant amount for the brand, and he not worth it.

After all, it has a huge number of minuses:

- Acrylic body, which bursts very often, namely the clamping lever itself.

- Acrylic body has no rigidity, which sometimes leads to print defects. Underextrusion when using harder plastics.

- No plastic preload adjustment mechanism, like the BMG extruder

- Spur gear, which is not designed to work with soft and very hard plastics.

- Poor body geometry, due to which, when printing with soft plastics, the filament is squeezed out, and not forced through the Teflon tube.

- There is no gearbox, which means that it is not possible to use short motors, since they simply do not pull such loads

Moving on to the metal extruder review:

Here, the situation is better.

Pluses:

- high reliability due to metal

- high structural rigidity

- correct body geometry, which allows printing with soft plastics

like a BMG extruder

- A spur gear that is not designed to work on soft and very hard plastics.

- No gearbox, which means there is no way to use short motors, since they simply do not pull such loads

Let's look at the Mellow Store BMG extruder:

Pros:

1) high-quality NYLON body. Unlike cheaper clones, which have thin walls, the construction here is very reliable and rigid.

Unlike cheaper clones, which have thin walls, the construction here is very reliable and rigid.

2) A gearbox is used, which allows you to install less powerful but lighter motors.

3) High versatility, for example, there is a bolt for adjusting the pressure of the plastic, which allows you to print with both hard and soft plastics.

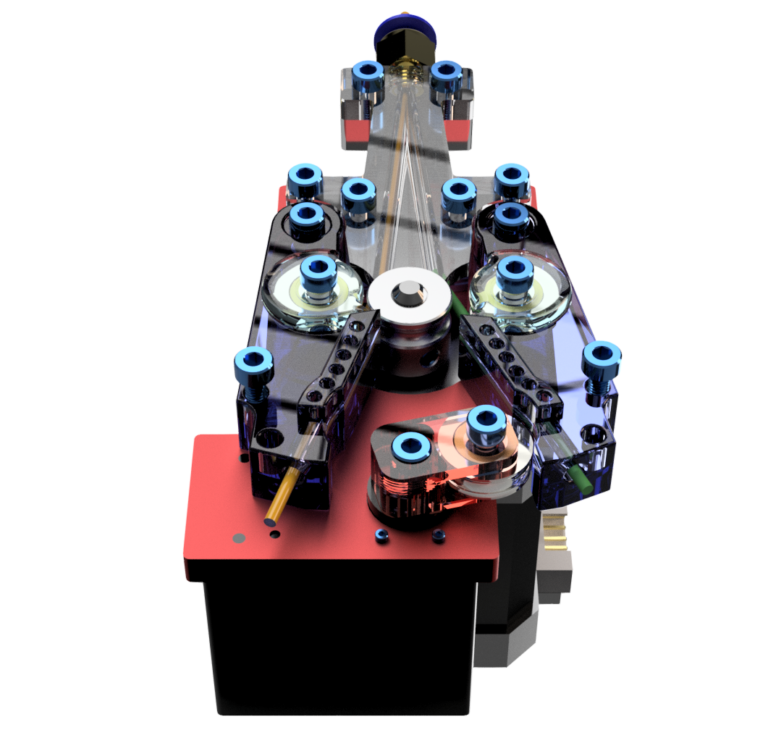

4) Two plastic feed gears are used, which are synchronized with each other by a gear train. This reduces the pressure on the plastic itself and prevents its deformation, even with slight pressure, the plastic is pressed through better than on any other extruder, including the well-known Titanium.

5) The gears have the correct geometry, the plastic feed notches are made in a video circle, due to which the plastic is wrapped around from all sides and fed smoothly.

6) This BMG extruder has a universal adapter, that is, it can be used as a BOWDEN, or you can put it on an E3D V6 hotend or even as a direct extruder.

7) High-quality roller bearings are used on the gears, while there are no backlashes and all shafts are seated on ball bearings.

Of the minuses, only the price, but given such a high quality, this is the best extruder to date.

But I understand that there will be SKEPTS, there is a video for you on the English channel, which confirms my words about the uniqueness of the BMG extruder:

, white is ABS and black is FLEX (imitation rubber, very soft) from plexiwire.

I tied the loop and we will check the maximum tension load at which the plastic will begin to break off the gear, while I want to note that I fixed the gear so that it does not spin.

We put it on the stand, put it on the scales (I checked the accuracy of the scales), and thread it through the extruder.

We start to stretch until the plastic breaks.

Creality stock extruder:

- ABS white did not exceed 0. 9 kg and began to break off the gear

9 kg and began to break off the gear

- FLEX (rubber) gave a maximum of 0.6 kg

These are very low values.

Red metal extruder, slightly better results:

- ABS white - max 2.7kg

- FLEX (rubber) gave out a maximum of 0.67 kg

As you can see, it delivers standard plastic like ABS well, but as for FLEX, everything is sad here (

BMG extruder from Mellow Store, it's SONG)))

- ABS white - max. 6.6kg

- FLEX (rubber) gave out 1.3 kg

IMPORTANT! I did the pressing of the plastic in the test with little effort, and if I press harder, the figures will be twice as high.

And now some Printing))

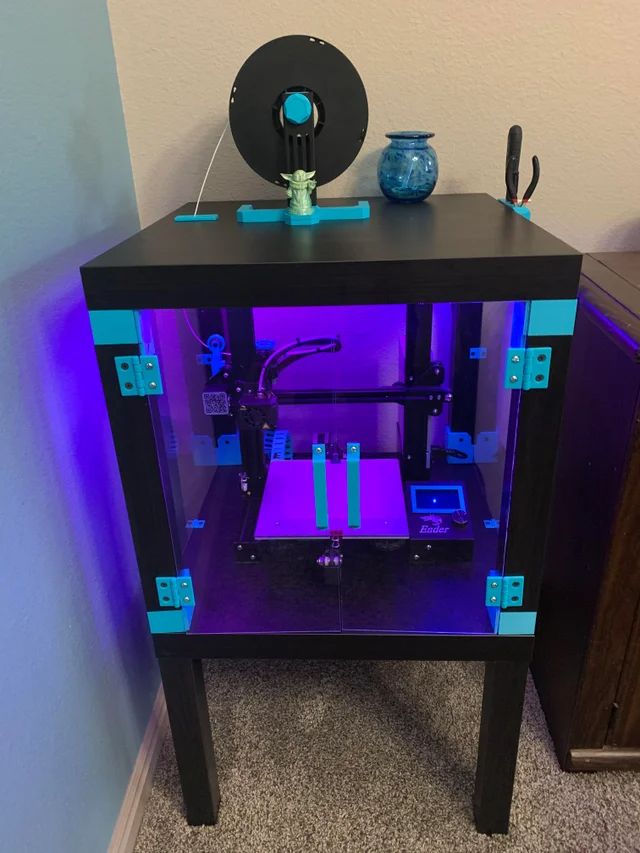

Don't laugh, I don't prepare the printer for sleigh rides. This is a temporary place, because the other day I designed the THERMAL CHAMBER and already sent the materials for cutting.

There will be a separate review on my YouTube channel ChuchaTV)

Installed an extruder as Bowden. Got up like a cast.

Got up like a cast.

Printed on PLA and FLEX plastic

PLA plastic (blue), printed with great pleasure, the quality is simply gorgeous.

But most of all I was pleased with the FLEX plastic. The part was printed without problems, the part turned out soft.

At the same time, the quality of the fusion of the layers is simply AWESOME, a monolithic structure.

In the next video, I will do a detailed review of this plastic.

I recommend Mellow Store in China, where I bought this wonderful device:

Mellow Store aliexpress.com/store/1531088

Kit Mellow Drivegear Kit 9$ https://www.aliexpress.com/item/32958065801.html

Metal MK8 extruder 10 $ https://www.aliexpress.com/item/32958337720.html

BMG extruder Btech 22 $ https://en.aliexpress.com/item/32958337720.html .aliexpress.com/item/32966821963.html

BMG extruder with reducer 29$ https://ru.aliexpress.com/item/4000072198732. html

html

Motor short TITAN https://ru.aliexpress.com/item/32806789343.html

Motor from Mellow Store https://ru.aliexpress.com/item/32675848057.html

A set of high-quality motors 5pcs https://ru.aliexpress.com/item/32252636591.html

You can also see a more detailed review of extruders on my YouTube channel ChuchaTV

BMG plastic feed mechanism - plastic / metal

580 UAH – 980 UAH

A copy of the famous BMG feeder – Dual Drive with a gear with a reducer

Provides smooth, uniform filament feeding, suitable for Direct and Bowden.

Choice of plastic or metal BMG feed mechanism.

*Feeder is sold as an assembly kit, ie. disassembled - plastic version. Metal version supplied assembled.

Assembly kit supplied in factory box.

Nema 17 motor not included as standard.

Heading: Spare parts for extruder (hotend) 3D printer Article: bmg-11 Tags: BMG BMG extruder plastic feeder feeder presser feeder

- Description

- Details

- Reviews (0)

Description

The BMG Dual Drive plastic feeder is a copy of Trianglelab's well-known BMG feeder..jpg) Buying an original mechanism is an expensive pleasure. Therefore, we offer you an analogue that is 3 times cheaper than the original!

Buying an original mechanism is an expensive pleasure. Therefore, we offer you an analogue that is 3 times cheaper than the original!

The peculiarity of this mechanism is that it is simple and reliable, it provides a smooth supply of plastic. The main advantage of such a feeder is the guiding channel from the pulling mechanism to the hot end. It prevents the thread from bending or tangling. Thus, it is one of the best feed mechanisms for 3D printing with flexible and elastic materials. Also, in this mechanism there are 2 gears that evenly press the thread during the feeding process. One of the gears is with a gearbox. With its help, the supply of plastic to the clamping mechanism was greatly simplified. This is especially true for remote feed printers (Bowden type).

BMG plastic feed mechanism features convenient pressure adjustment, as well as a large vertical “trigger”.

There are mounting holes for standard Nema 17 stepper motors. This mechanism is compatible with standard extruders such as E3D V6

Plastic version kit (see 2 photos)

- extruder body 2pcs

- trigger 1 pc

- gears 2 pcs

- spring, washer, adjusting bolt 1 pc

- fitting in housing 1 pc

- Teflon tube 1 pc

- hexagons 2 pcs

- screws for fastening to the engine 3 pcs

Feeder is sold as an assembly kit, ie.