Wham bam 3d printer

Wham Bam Systems- 3D Printing Innovation

About Wham Bam

Wham Bam 3D Printing Innovations

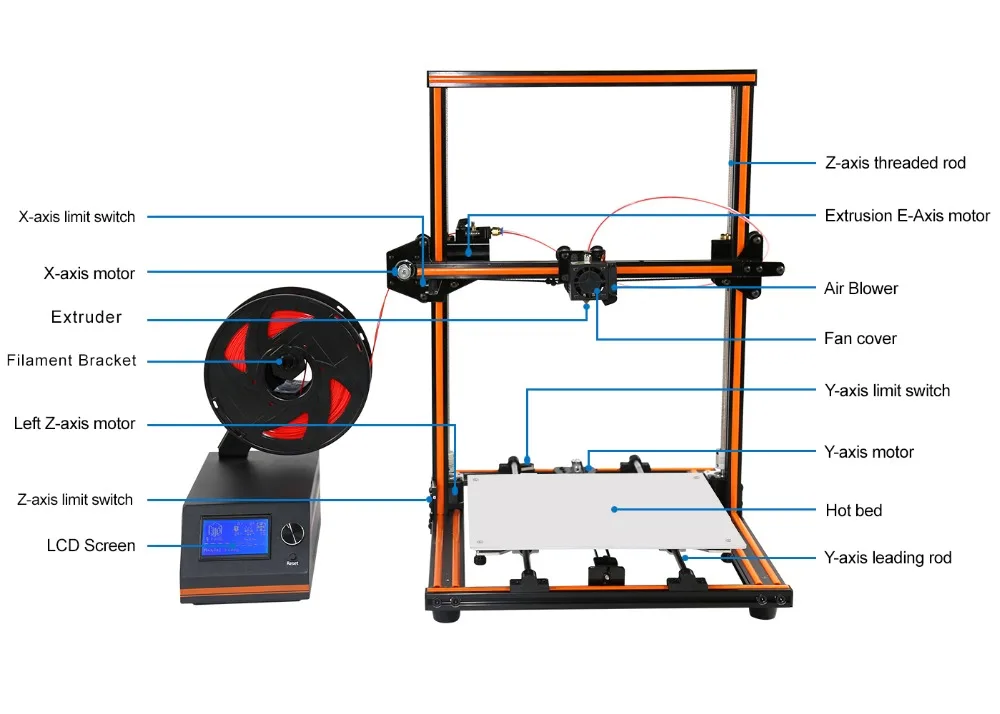

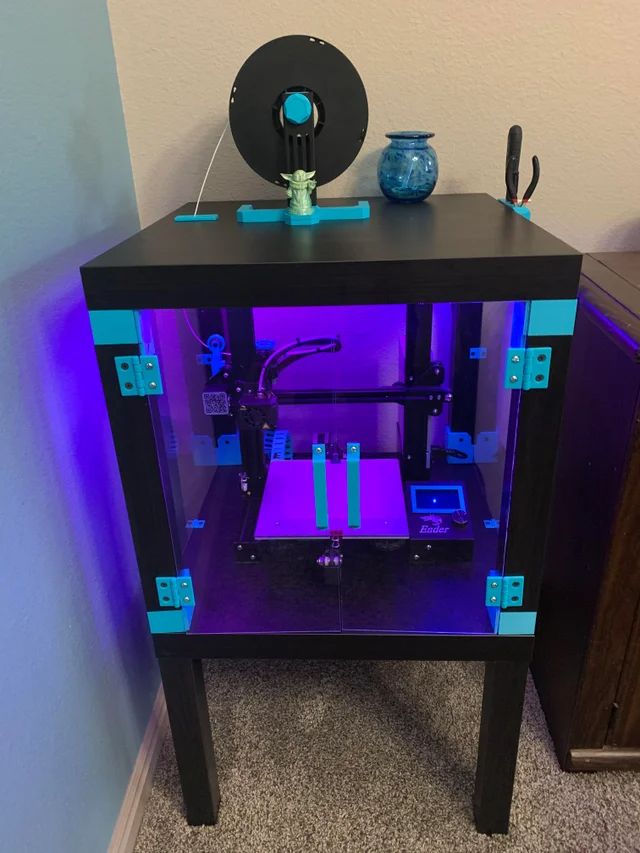

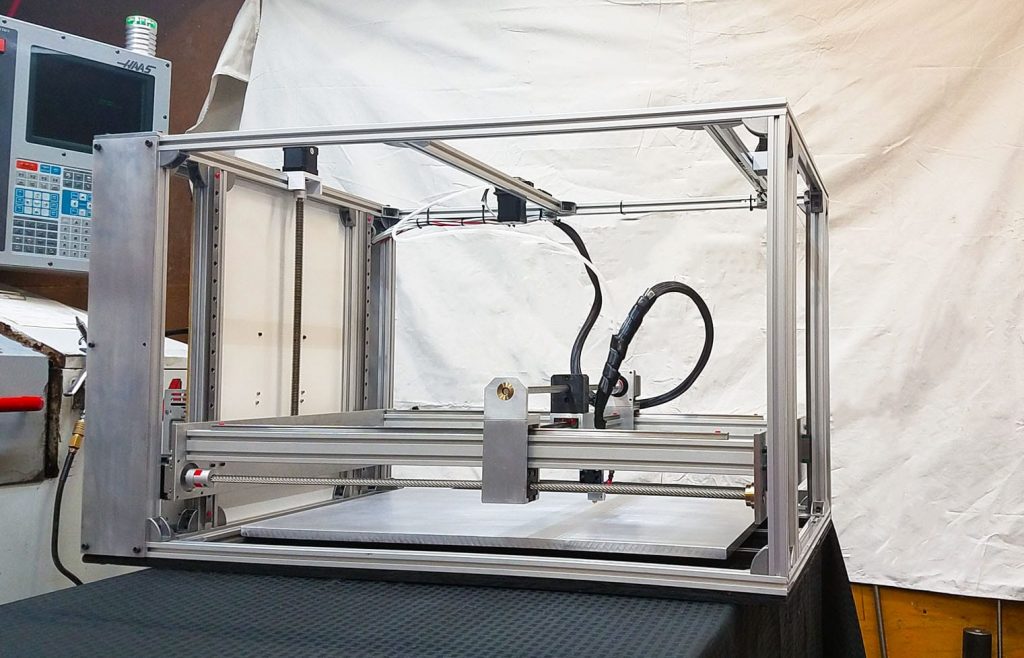

Wham Bam Systems is dedicated to improving the 3D printing experience through innovation. Our first product line, the Wham Bam Flexible Build System, addresses the need for printers to have a more reliable build surface which is easy to install and makes printing and removing a breeze. We have since released the Slap Mat for resin printing cleanup and the HotBox enclosure for 3D printers.

Wham Bam was created when Peter Solomon, a long time inventor, award-winning designer, maker and 3D printing addict realized that many of his personal modifications to his printers would be very useful to all 3D printers.

Peter has been contributing to the community for years by posting his models to thingiverse, his how-to videos on youtube, and his advice to many forums. He became obsessed with resolving first layer adhesion as this is one of the issues that affects every 3d printer, and then needed to find a way to get prints off the bed easier. When he made his first prototype and shared on social media nearly everyone wanted one, and BOOM - Wham Bam was born!

Wham Bam will continue to make high quality, economic 3D printer products following the same mission: Making 3D printing Easy, Productive and Fun!

Our First Product - Flexible Build System

Print With Confidence

Remove Prints With Ease

Remove Prints With Ease

Print sticks to our PEX build surface and build plate is secured to printer with magnets

Learn More

Remove Prints With Ease

Remove Prints With Ease

Remove Prints With Ease

A flexible, removable build plate allows easy print removal without a chisel or spatula

Learn More

Print More Efficiently

Remove Prints With Ease

Print More Efficiently

Print edge to edge with no binder clips and quickly swap build plates

Learn More

Wham Bam Newsletter

Get exclusive deals, new product insights, plus some helpful tips and tricks . .. just let us know where to send it!

.. just let us know where to send it!

Sign Up

Flexible Build System

What Is The Wham Bam Flexible Build System?

Are you having a difficult time getting your 3D print to stick to your printer bed? Does your print peel up during a long print and destroy your work? Are you tired of temporary fixes such as glue sticks, hair spray, and painter’s tape? Once you get your print to stick, do you have to pry, chisel, cut the perimeter, or put your bed in the freezer, just to get your print off the surface without gouging the surface or cutting yourself?

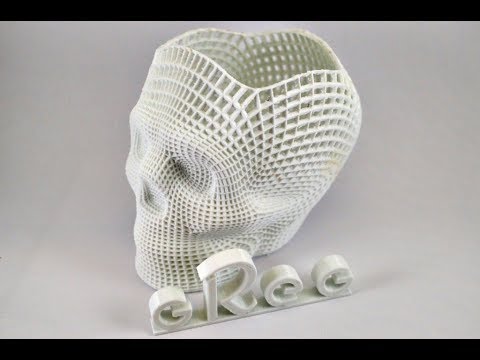

We have created the specially formulated Wham Bam PEX Polymer Build Surface which surpasses PEI in temperature resistance, performance, and material ‘stickability”. It sticks so well you would have a heck of a time getting the print off the bed without our Wham Bam Flexi Build Plate. Simply remove the Wham Bam Flexi Build Plate from the Wham Bam Flexi Magnetic Base on your 3D printer when the print is finished and flex slightly to pop your print right off! See our demo video below.

Simply remove the Wham Bam Flexi Build Plate from the Wham Bam Flexi Magnetic Base on your 3D printer when the print is finished and flex slightly to pop your print right off! See our demo video below.

Flexible Build System In Action

What the Reviewers are saying:

"Thank You Guys"

"It Just Pops Off"

"It Just Pops Off"

"I honestly stopped using my printer for a while because my prints stuck so well that I'd ruin them or break the glass trying to get them off. The Wham Bam System has got me heavily into 3D printing again. Thank you guys!" - Rob R.

The Wham Bam System has got me heavily into 3D printing again. Thank you guys!" - Rob R.

"It Just Pops Off"

"It Just Pops Off"

"It Just Pops Off"

"I’m liking how the prints look. Super smooth on the bottom. And I love that it just pops off. No more spatula. My installation experience went pretty smooth" - Carlos P

See More Reviews

"Class Of Its Own"

"It Just Pops Off"

"Class Of Its Own"

"The fact that the magnets are able to withstand higher temperatures puts this system in a class of its own. Capable of using a wide range of materials that other companies cannot claim without damaging their magnetic sheet permanently." - James P

Capable of using a wide range of materials that other companies cannot claim without damaging their magnetic sheet permanently." - James P

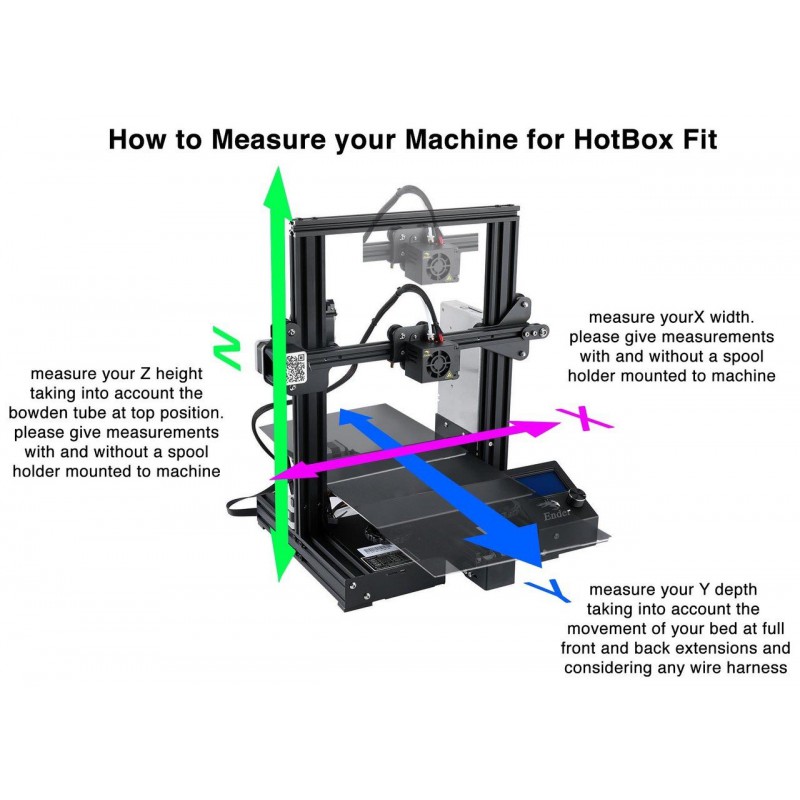

The fit to your machine is the buyer's responsibility

Please measure your bed (do not rely on build volume) before ordering noting that the spring steel Flexi Plate has two front tabs that stick out by 10mm on smaller kits and 15mm on larger kits. Wham Bam will not be responsible for mistaken sizes ordered. Click here for more sizing info

Sizes and Machine Fits

Shop Now

More sizes being developed now!

Click here to request a new size Flexible Build System.

Quality Materials

Our Wham Bam Flexi Build Plates are made from high quality spring steel that won't kink or warp when you flex them, they just return back to shape! The Spring Steel has been formulated with a Chromium Alloy creating a rust proof steel for long life.

Our magnets and films have all been formulated to resist over 150°C so you can heat your bed to high temps for specialty filaments and not worry about loss of performance.

We have developed the Wham Bam PEX Build Surface from a specially formulated polymer with a higher melt point than even PEI to attract most any filament without damaging the sheet. Prints easily pop off once cooled and flexed.

Wham Bam Newsletter

Get exclusive deals, new product insights, plus some helpful tips and tricks . .. just let us know where to send it!

.. just let us know where to send it!

Sign Up

Self-defense little helper

Application

Follow author

Subscribe

Don't want

11

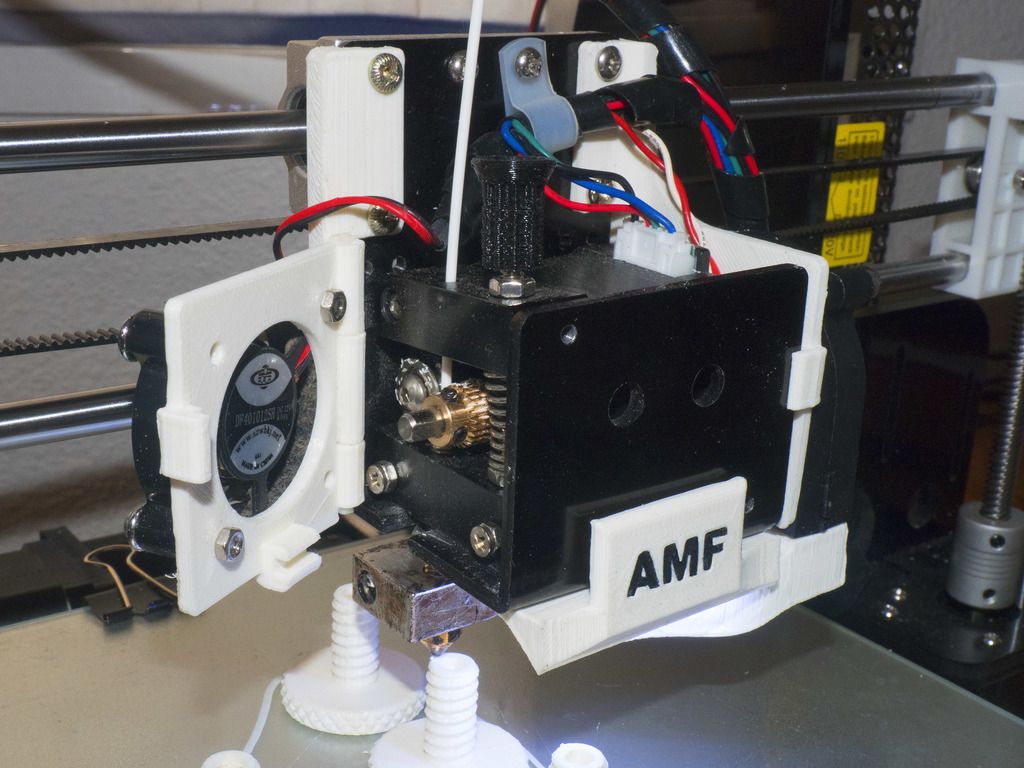

How can a printer help with self-defense?

Thoughts immediately come to mind to raise it above your head and swinging from side to side to rush at the offender. Well, seriously. Liberator stamp? Illegal. Print a costume? Somehow, too, not our methods. I like more technical methods of influence, yet a techie and love for technology is in my blood :)

Okay, let's skip the questions whether or not to carry something for self-defense and what is better. let's talk about one device and how I modified it a little. Or rather, not even his, but simply added one detail.

This detail will be the hero of this post. What's this? Double barrel detail? Nearly. very similar, but no. I think few people have heard of such a device as a 'hunter's signal'.

I think few people have heard of such a device as a 'hunter's signal'.

Now I will tell you in more detail what it is.

This is a plastic tube with a striker and a spring inside. The notch is an imitation of a shutter. As you can easily guess, the striker from the cocked state, by releasing from the hook under the action of the spring, hits the primer, and then, depending on how this signal is charged, the launch occurs.

Initially, 'Hunter's Signal' was used, you won't believe it, by hunters and served to launch signal rockets. He has 3 colors of flares. But later its functionality was expanded and an empty cartridge with a primer (blank) and pepper BAM were added. Here I got acquainted with pepper BAMs on the example of the 'Premier' pistol, now I already have the 'Dobrynya', which replaced the Udar-2M line. But it's all poetry.

'Hunter's Signal' is available in single barrel and double barrel versions, although there is no barrel, only the body. BAM itself serves as the trunk.

BAM itself serves as the trunk.

In fact, BAM is a kind of pepper spray that can shoot loudly at 5 meters. Ideal for scaring off dogs, I tell you, if there are several of them. Particularly aggressive will be flooded with pepper mixture, and the rest will be scared away with a loud shot.

And everything would be fine, but the shutter itself confuses me. In the uncocked state, it is still suspended a little bit and somehow I don’t feel like trying to see if there is enough impact force to detonate the primer. And in the cocked state there is a chance, small, but still, that it will shoot in a pocket or in a bag. It would be embarrassing to get a pepper pocket in a crowded subway car.

In general, I almost immediately decided to make a fuse for it.

I modeled a blank in Fusion 360, measuring everything with a ruler. And I cut this part out of another unnecessary part.

This is the base, nothing complicated. We make half and mirror it.

We use the same principle with the main part in which we will cut out the unnecessary.

And now the model is ready.

Print it vertically with natural ABS.

A little rough, but it will do. We try on the prototype, and understand what needs to be reduced in places. I immediately reduced it with wire cutters right on the plastic and everything almost came together. At the same time, after walking around with such a design for a day, I realized that there were not enough protruding hooks for easy removal.

Well Fusion keeps a history of actions and editing elements is not difficult. We select a rectangle in the history and reduce it in height and a little in width. Click ok and get the correct part already assembled and merged. It remains to add a couple of hooks on the sides.

Now it's perfect. Well, how perfect. It would be possible to bring some more beauty, well, let it remain so. A purely utilitarian item.

Well, how perfect. It would be possible to bring some more beauty, well, let it remain so. A purely utilitarian item.

And we put everything together.

Thank you all. I am ready to hear that a gas cartridge is more convenient and effective, that all this is a whim in self-defense, etc. :)

Follow author

Follow

Don't want

11

More interesting articles

Liris

Loading

11/24/2022

2539

22

Subscribe to the author

Subscribe

Don't want

Hello everyone, dear friends!

Foreword:

I am writing my first post on...

Read more

eight

Subscribe to the author

Subscribe

Don't want

In this article, we will share an example of restoring the dented body of a BMW M3 E30 car using numbers. ..

..

Read more

147

Subscribe to the author

Subscribe

Don't want

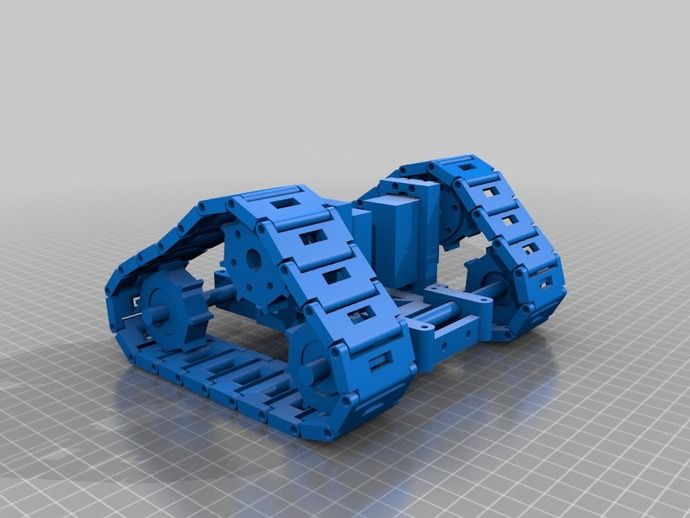

3D printing, as an activity, makes it possible to create not only decorative crafts and toys...

Read more

3D printers will print a new page in the Russian economy - ExpertRU - Russia. News. 05/13/2022. Russian news. Russia news. News Russia. Russia news today. Russia latest news. News of Russia 13.05.2022. News of Russia May 13, 2022. News May 13. (May 13, 2022)

Innovation High tech 3D printing

Ekaterina Kobits

Expert. ru correspondent

ru correspondent

May 13, 2022, 19:42

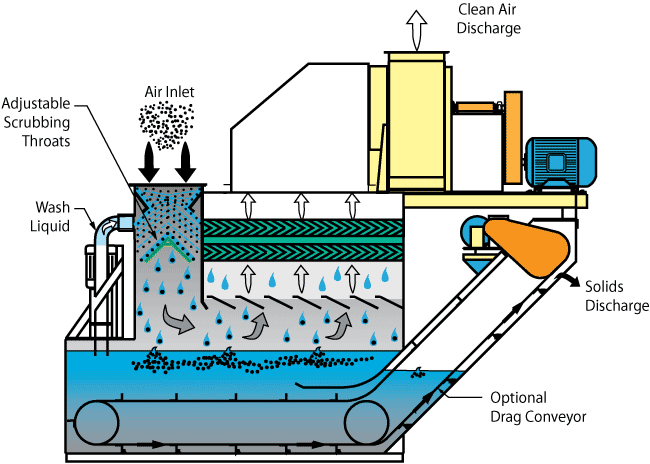

The departure of foreign companies gave Russian 3D printer manufacturers a chance to show themselves. However, the issue with the supply of some components and technologies remains open.

Gavriil Grigorov/TASS

Growing parts of a spherical shape on a 3D printer in the laboratory of the center of additive technologies of the Rostec State Corporation

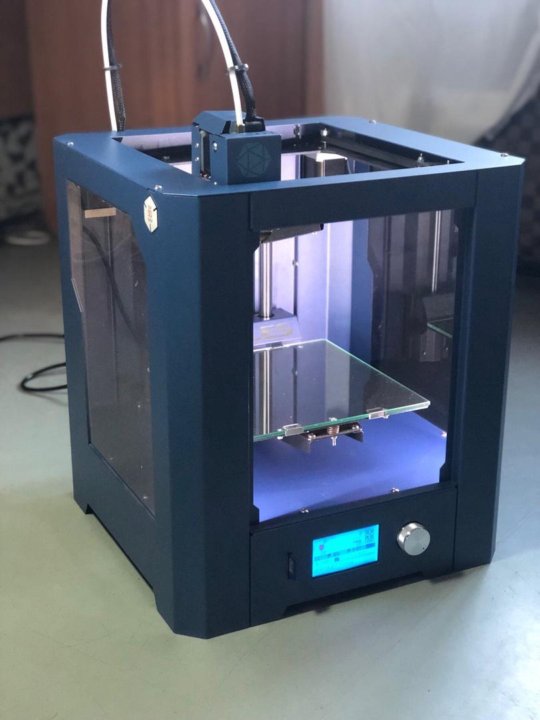

Recently, 3D printers have become especially popular in the world. In some countries, many consumer goods are produced using these machines. Additive technologies have long been very important for medicine. They are used, for example, in the manufacture of dental implants or complex bone prostheses.

In Russia, 3D printing is more common in industry. The same aircraft industry without it is already quite difficult to imagine. Our country, according to GlobalData statistics, was in 11th place in the world in the production and implementation of additive technologies in 2021.

Our country, according to GlobalData statistics, was in 11th place in the world in the production and implementation of additive technologies in 2021.

Related article:

If they don't sell, we'll print

Meanwhile, the bulk of 3D printers were supplied to Russia from Germany and the USA. Japanese technology also entered the domestic market. Currently, these deliveries have stopped due to anti-Russian sanctions.

Fortunately, in addition to the above, friendly Chinese manufacturers have played and continue to play a significant role among our suppliers, who make both the printers themselves and components for them. Most likely, products from the Middle Kingdom will remain on the market, but the departure of foreign companies should play into the hands of domestic producers.

Demand for Russian 3D printers has already begun to grow. Thus, a representative of the Tsar 3D company, which specializes in the production of large FDM printers, noted in a comment to Expert that they are recording an increased interest in their products. Taking advantage of the favorable market conditions, the company plans to expand its "possessions" and take an active part in the process of import substitution.

A representative of another manufacturer of industrial 3D printers, Total Z, told Expert that vacant niches appeared on the market in this segment due to the withdrawal of Polish and German firms. At the same time, Total Z noted that the growth in demand for their products has been permanent in recent years.

“All projects in this area are long-term. It takes an average of 9 months from the start of communication with customers to the conclusion of a contract. And there are projects designed for a period of 3 to 5 years due to the specifics of state budget financing. Something definite about the growing demand can be said next year,” said a representative of Total Z.

Something definite about the growing demand can be said next year,” said a representative of Total Z.

The company noted that they are already seeing some redistribution of budgets from research development to direct production. For example, in the same aircraft industry, where Total Z has a number of projects.

“The commissioning of the MS-21 aircraft was postponed for two years, but the production of the Tu-214 and Il-96 is being deployed, the same with the PD-35 and PD-8 engines. And in other industries there is the same dynamics, ”added a company representative.

Related article:

There is a breakthrough in the construction of 3-D houses in Russia

However, the main problem of Russian import substitution in the field of additive technologies may lie in the rather strong dependence of manufacturers from the Russian Federation on imports of software, part of the range of equipment and raw materials.