Zmorph 3d printer review

Zmorph 2.0 SX Review 2022

Want to learn more about the Zmorph 2.0 SX 3D printer and if it's worth the money? Read our review of it and find out TODAY!

By Justin Evans

3.8

See Price

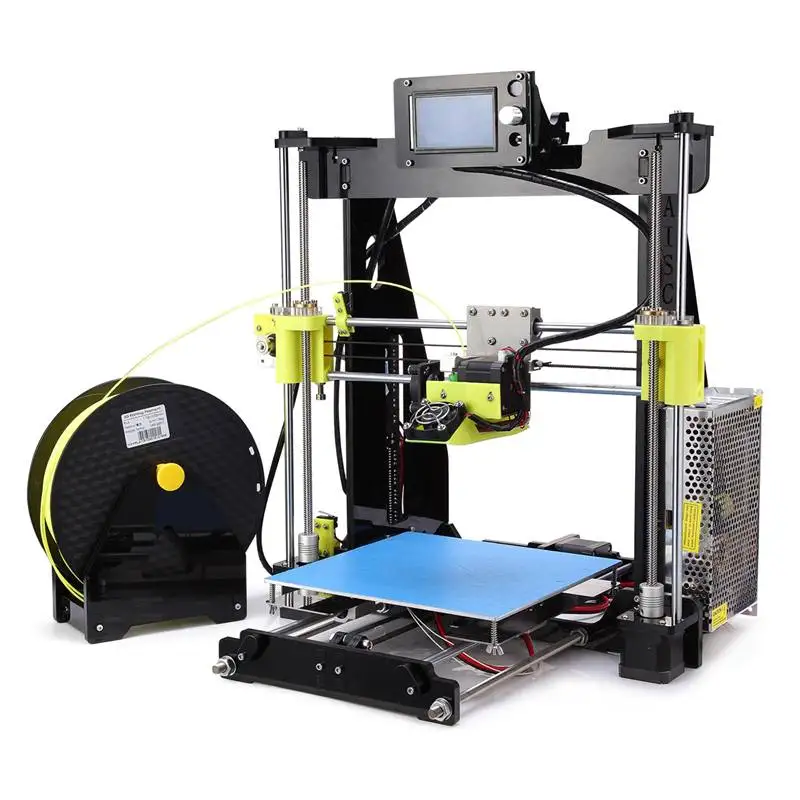

3D printers can be pretty complicated. They’re relatively new tech, and it’s easy to get overwhelmed by the sheer amount of jargon manufacturers like to throw your way. There’s one thing we think every customer can agree on, though: When you buy a 3D printer, you want it to be able to handle just about anything.

Zmorph seems to have taken this to heart when creating the 2.0 SX, though: it’s an ultra-versatile product with all kinds of different attachments. How well does it hold up as a printer, though? That’s what we’re here to find out.

| Filament Diameter | 1.75mm |

| Extruders | 1, optional second |

| Supported Materials | PLA, ABS, HIPS, PVA, PETG, Exotics |

| Connectivity | USB, SD Card, Ethernet, WiFi |

| Printing Speed | 40mm/s |

| Build Volume | 9. |

Table of ContentsShow

Design

Although this printer looks complicated, it’s actually nice and simple. It has a modular design, so parts can be swapped in and out easily to suit the task at hand. For instance, while it uses 1.75mm filament by default, you can swap the standard extruder for the included 3mm one if you’d like.

We’re big fans of the built-in touchscreen. It uses a simple interface with minimal clutter, so it’s easy to use even if you’re not particularly tech-literate. Zmorph claims that its interface is based upon a smartphone’s, so it makes sense that it’d be easily accessible to new users.

Let’s not forget about the fantastic connectivity options. Usually, you’d expect to see USB and SD slots, but it’s a rare printer which includes WiFi functionality and an Ethernet port. These features allow you to start and stop prints when out of the office, so you have a better range of control over how and when you print.

Printing

We’re pretty impressed by how well this model prints. Admittedly, the objects aren’t ultra-detailed, but when you use the secondary extruder, you can create some stunning, eye-catching models. There’s very little material wasted, and edges come across sharp and crisp. It is a little slower than many of its rivals, though, with a top speed of just 40mm/s.

The build volume is about average for a printer in this price range. It can be slightly expanded by opening up the case, but to be honest, this will prove unnecessary in most situations. Still, having the option is always a positive thing.

The 2.0 SX can print with an incredible range of materials, from the simple to the exotic. You can use a selection of thermoplastics, and even some water-soluble supports. You’ll still need a metal nozzle to print with wood-based filaments, but to be honest, this is a very tiny investment for a huge return.

Features

What’s most interesting about this printer is that it can do other things as well. For instance, there are attachments that turn it into a bona fide laser cutter, engraver, and food printer. Of course, you can expect to pay a little more for this functionality, but if you’re interested in generating some more unusual prints, this is definitely the model you need.

For instance, there are attachments that turn it into a bona fide laser cutter, engraver, and food printer. Of course, you can expect to pay a little more for this functionality, but if you’re interested in generating some more unusual prints, this is definitely the model you need.

There’s also a built-in error adjustment feature called the closed loop system. This automatically takes the steps needed to correct any printing issues before continuing on normally. As such, you won’t spend eight hours printing something just to have it fail – the 2.0 SX will always complete the print.

We were particularly impressed by the snap-on, snap-off magnetic design. This allows you to customize your printer for a particular job by adding, say, an extra fan, or a secondary extruder. Best of all, there’s very little fuss given that the whole process takes a couple of seconds.

Cost

As you might expect, this kind of all-in-one 3D printer doesn’t come cheap. It retails for around $2600 and is no longer available directly from Zmorph. This is because it’s been superseded by the 2.0 VX, an upgraded version that costs about the same.

This is because it’s been superseded by the 2.0 VX, an upgraded version that costs about the same.

However, this is just for the printer itself. Toolheads can be bought individually, but they tend to cost around $250 each. You could also buy a full set for around $1600 if you’d rather, but it’s far more cost-effective to only buy the ones you need. Really, the value of these tool heads depends on the work you’d like to do.

Ultimately, this printer is likely to be too expensive for the casual hobbyist. Instead, it seems aimed at craftsmen, people who want to create fewer objects, each with a higher overall quality. If you can use it to make a profit, there’s very little reason to choose anything else, but if it’s your first printer, you might want to look elsewhere.

Support

The Zmorph 2.0 SX is fairly well supported, with in-depth maintenance and troubleshooting guides available on the official website. There’s also a forum where you can find more specific help for any given problem, and Zmorph Academy – a short series of lectures designed to introduce people to 3D printing.

Zmorph can be contacted via email, phone, snail mail, or their online support form. Better yet, their site is available in both English and Polish, so you can use whichever language you’re more comfortable with.

The warranty on this printer is pretty standard, lasting one year from the date of purchase. Be sure to take good care of it, though, since it doesn’t cover damage caused by any attempted repairs. This is one situation where you’d be wise to consult the tutorials we mentioned earlier.

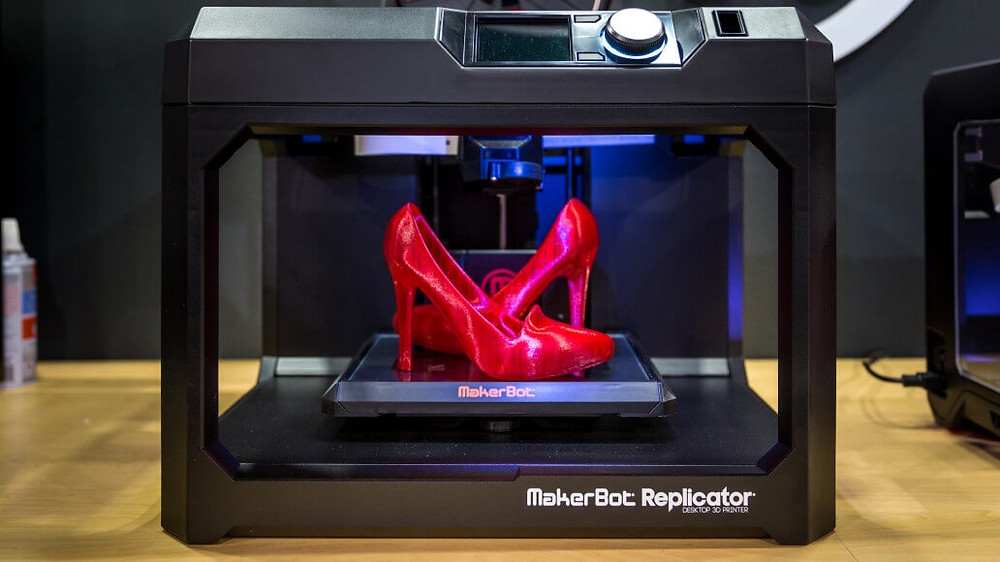

MakerBot Replicator 2 Review

REVIEW: ZMorph VX, a strong 3D printer with multi tool capabilities

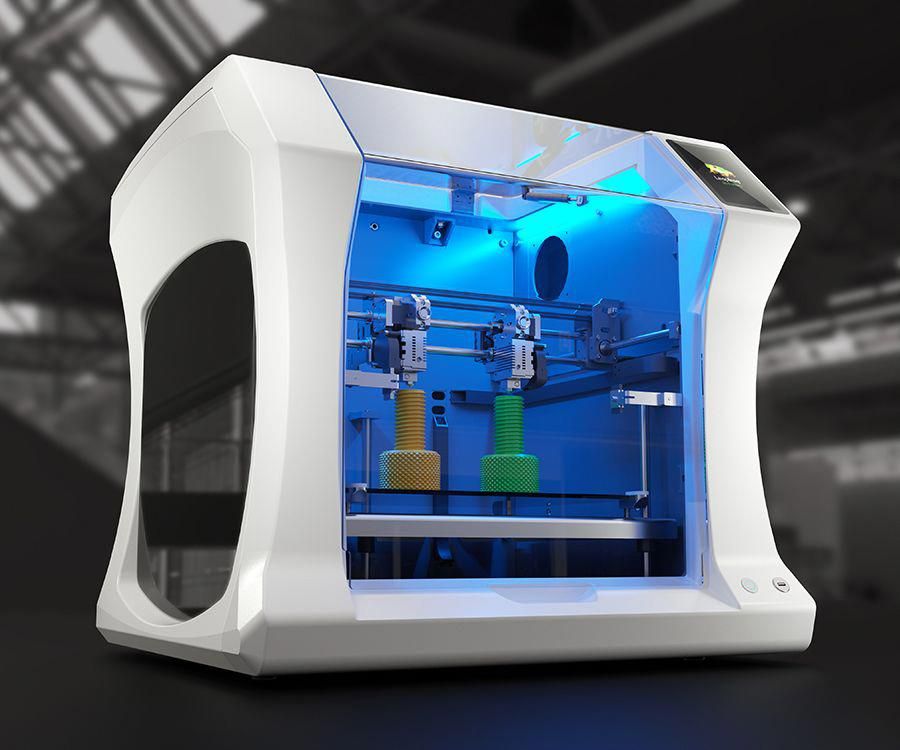

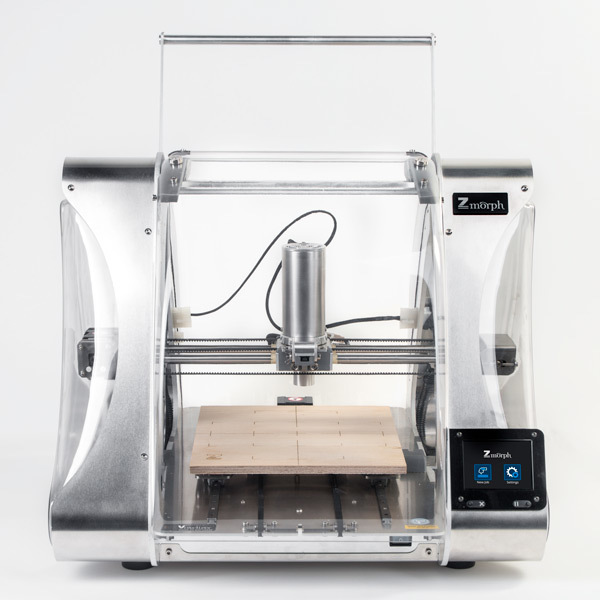

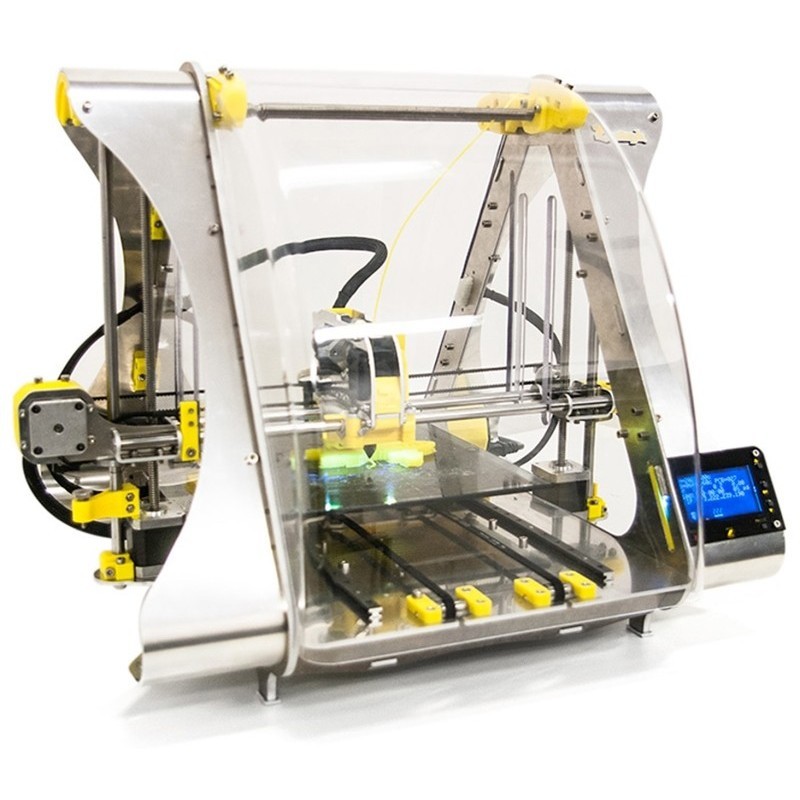

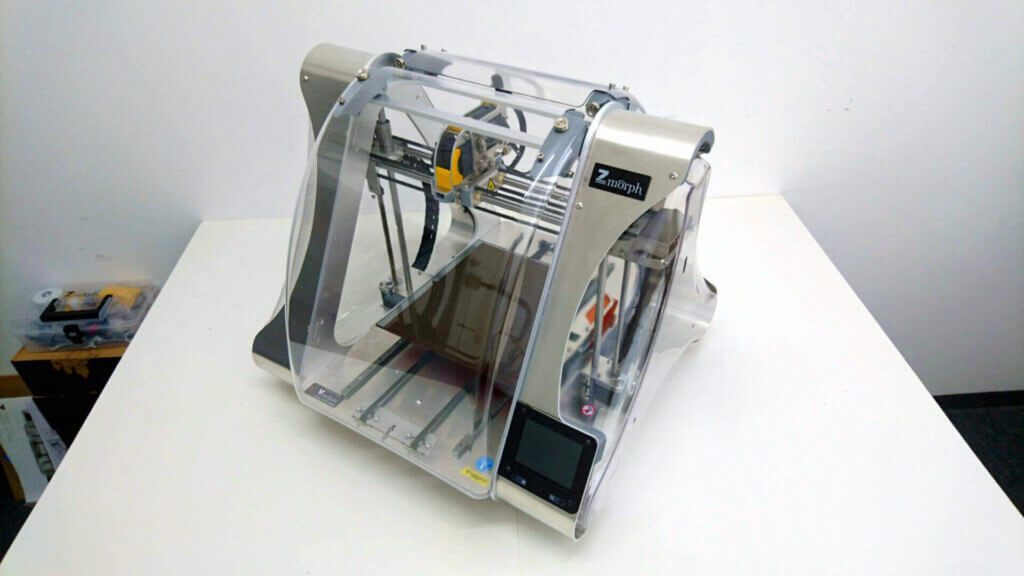

3D printing, CNC carving and laser engraving – the ZMorph VX makes some bold claims about its capabilities. This multiple function desktop system was launched by its Polish namesake manufacturer, ZMorph, at TCT 2017. Now 3D Printing Industry engineers have been given the chance to put it to the test.

According to its core claims, the ZMorph VX is of robust construction and designed for prolonged use. Its multiple toolheads, including a paste extruder and dual extruder, should be easily transferable, and the free ZMorph Academy course should enable users to learn how to operate each one effectively. Though a multitool machine, with CNC PRO and Laser PRO toolheads, the VX promises uncompromising FFF 3D printing quality. Each of these claims have been taken into account throughout testing the machine, and serve as the basis for our review.

Its multiple toolheads, including a paste extruder and dual extruder, should be easily transferable, and the free ZMorph Academy course should enable users to learn how to operate each one effectively. Though a multitool machine, with CNC PRO and Laser PRO toolheads, the VX promises uncompromising FFF 3D printing quality. Each of these claims have been taken into account throughout testing the machine, and serve as the basis for our review.

The ZMorph VX out of the box

After the five minutes taken to unpack the ZMorph VX, and a further three to attach the spool holder, the machine can be considered as “ready to go.” A concise, quick setup guide is provided in the box detailing each of its five modes of operation, and the customer is also referred to the ZMorph Knowledge Base and ZMorph Academy for extra help and how-tos.

The spool holder has an efficient design and is capable of holding up to four rolls of filament at the same time, only two of these spools, it should be noted, can be extruded simultaneously when the appropriate toolhead is attached.

Each of the toolheads is mounted by a single screw. When exchanging toolheads, this simple construction enables each head to be changed within one minute, as stated by the company in its advertising. It is also easy to switch between functions via the in-built touchscreen panel, which is powered by ZMorph Voxelizer software.

Calibration can be completed both automatically and manually on the VX. In tests we found that auto calibration was more than suitable for every task.

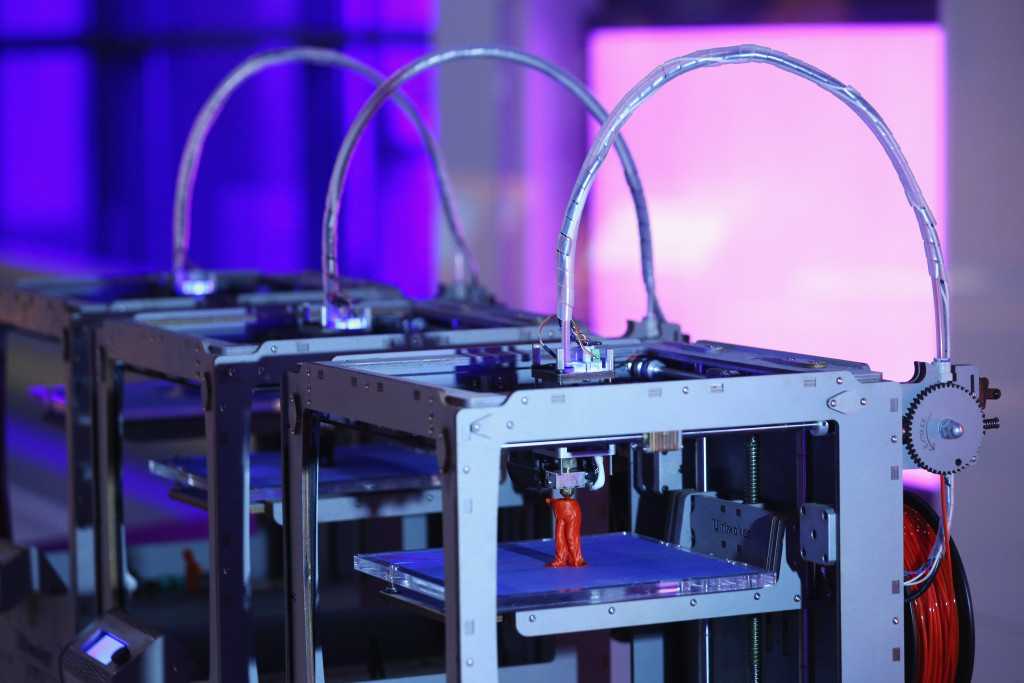

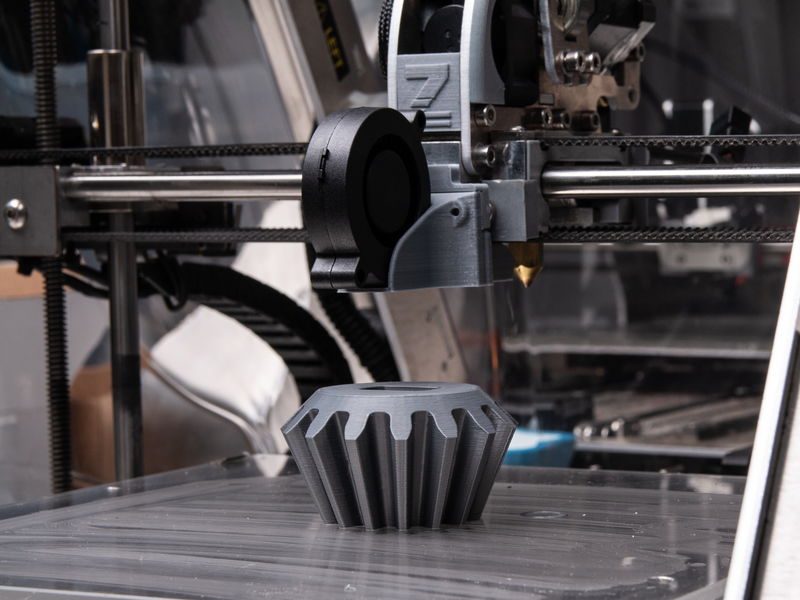

Straight into 3D printing

The first test our engineers performed was, of course, an assessment of the ZMorph VX’s 3D print quality. For this purpose, first with a single extruder, we tried five different models:

– A ZMorph pyramid sample print (PLA silver)

– A 3D Benchy in two different sizes (PLA silver and white)Complex flower vase (PLA silver)

– Large detailed house model (PLA silver)

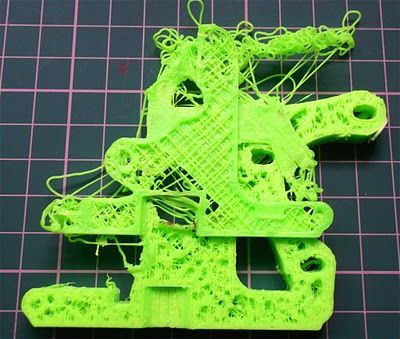

– 3D Torture test (PLA white)

Put briefly, across all test prints, the ZMorph VX worked very well. The sample triangle was 3D printed with fine features, despite the fact that it is a challenging printout for some 3D printers due to its extensive details.

The sample triangle was 3D printed with fine features, despite the fact that it is a challenging printout for some 3D printers due to its extensive details.

Similarly, both 3D Benchy’s were 3D printed without fault. Though of varying sizes, and using a different filament to the ZMorph triangle, the test Benchys were produced at a high quality without any stringing across difficult areas like the windows.

In the vase, a slightly more complex model, the walls were of a good quality, but some stringing could be noticed on the inside. It should be noted however, that the stringing was nothing unusual, and was most likely due to the small size of the object. A test of stamina, the large house model, which took 20 hours to complete, also printed well.

And, in the final torture test, the ZMorph VX proved that it can handle overhangs, bridges, hinges and floating strings with ease.

Pyramid sample print Larger PLA 3D Benchy 3D Torture test 3D printed architectural model printed on the ZMorph VX. Photo via ZMorph

Photo via ZMorphDual extrusion on the ZMorph VX

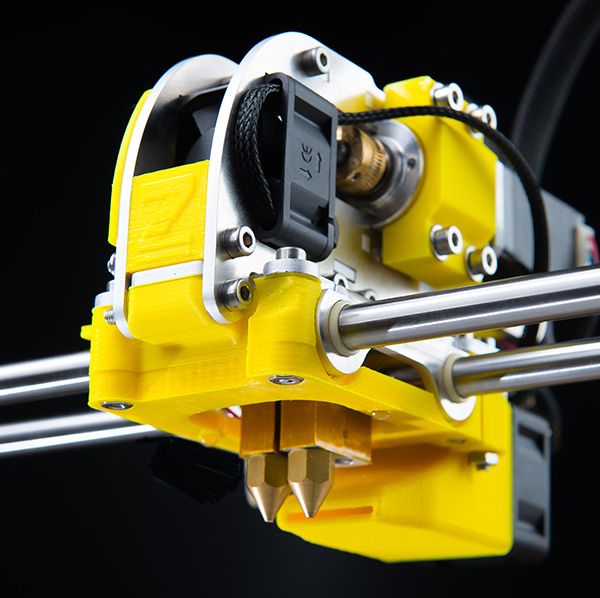

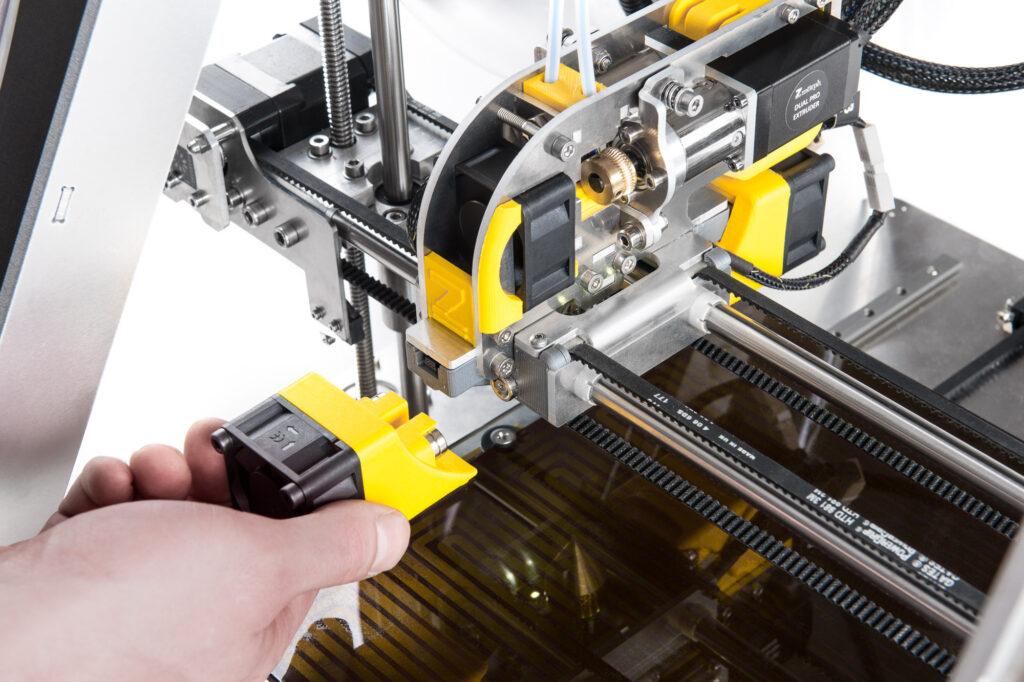

A similar design to the single extruder, the dual extruder on the ZMorph X has two feeders and two inlets, which lead to a single nozzle. The feeders on this nozzle are open, a welcome feature of the head as it is handy for spotting any clogging. The heating element with the nozzle assembly is modular too, which also helps to just heat up the needed area during a clog.

In a test of dual extrusion capabilities, the team used ZMorph’s Voxelizer to add a basic text 3D Printing Industry (3DPI) logo to the side of a miniature rocket part.

The combination process in Voxelizer was quick and straightforward. Preprogrammed blending options for the two filaments where also clear and easy to understand, i.e. separate, 5050, gradient and texture.

ZMorph VX dual extrusion test.Both sample parts 3D printed using the dual extruder were of a decent quality though the surface finish was not of the same quality when compared to single extrusion 3D prints. Adding text/images to the face of dual 3D printed objects is in fact better served by larger objects, allowing the pictures and characters to become more defined.

Adding text/images to the face of dual 3D printed objects is in fact better served by larger objects, allowing the pictures and characters to become more defined.

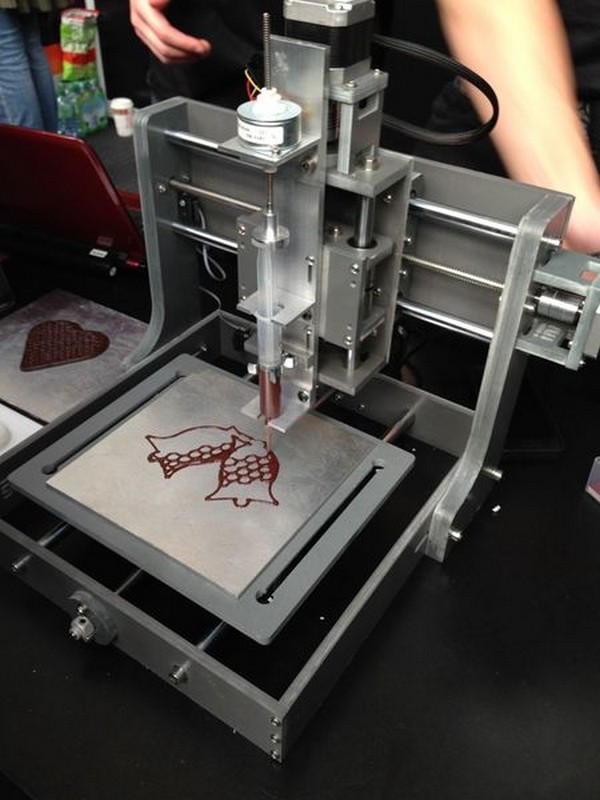

Laser engraving, CNC carving, paste extrusion

Now, onto the extra features of the Zmorph VX multiool 3D printer. For laser engraving CNC carving and paste extrusion, first the print bed had to be replaced with the CNC worktable.

Due to the simple, magnetic design of both platforms, the exchange was easy to do. With this construction, planar aligning was also very easy, and calibration process was acceptable.

For the engraving test, we effectively reproduced the ZMorph logo from the sample files provided by the company. In a further test, the team also succeeded in converting a .jpeg image into our own engraving .gcode using a tutorial from ZMorph Academy.

Overall we were impressed by the quality of the engraving, especially considering features were very close together in the tests.

For CNC carving, five types of cutter tip were provided, each easily mountable within the toolhead.

For carving, we used a 6mm thick piece of plywood provided by the company, and tested the sample “Rocket Holder” file downloaded from ZMorph Academy. At 75% and 125% speed, were were decently impressed by the results.

CNC carving test. of rocket holder parts.Sample nylon cog carved on the VX. Photo via ZMorphAnd finally, attaching the partially 3D printed paste extruder, we achieved the successful guided extrusion of a thick chocolate icing. A handy addition for consistently decorating cakes, or experimentation with gels.

A multilayered “M” initial was achieved at layer height 3 mm, path width 3 mm, travel speed 120 mm/s and print speed 5 mm/s.

M initial paste extrusion on the VX.The all in one tool for workshops, schools and FabLabs

Based on our internal testing, the ZMorph VX is indeed a brilliant multitool 3D printer, which performed very well across all functions, especially for 3D printing. All prints demonstrated good layer adhesion, and the ability to pick out fine detail in chosen objects. Generally, the process also made it easy to remove supports, and the ZMorph VX produced a near perfect Torture Test proving its ability to overcome the breadth of 3D printer challenges, i.e. overhangs bridges, hinges and floating strings.

All prints demonstrated good layer adhesion, and the ability to pick out fine detail in chosen objects. Generally, the process also made it easy to remove supports, and the ZMorph VX produced a near perfect Torture Test proving its ability to overcome the breadth of 3D printer challenges, i.e. overhangs bridges, hinges and floating strings.

With the ability to reference ZMorph Academy for free, we were able to conduct our tests with ease, and found instructions incredibly clear and to the point. Simple tool mounting, the integrated touch screen, and Zmorph’s Voxelizer all contributed to an enjoyable, and intuitive user experience. It has a very sturdy frame, and could conceivably be used time and again over a long period of time. In addition, the machine’s multitool features, CNC carving, laser engraving and paste extrusion, all performed well, indicating the ZMorph VX’s capability as an all in one workshop tool.

The ZMorph VX would be a welcome addition to a classroom, FabLab, or the workbench of an in house engineering/design department. Buy the ZMorph VX here.

Buy the ZMorph VX here.

For all the latest 3D printing news and reviews subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows the ZMorph VX multitool 3D printer. Photo via ZMorph.

Zmorph is the most multi-head 3D printer. Investigation from REC.

Hello everyone! Not so long ago, we got to see the unique multifunctional Zmorph platform. This article will tell you about our experience, observations and technical aspects revealed during 3D printing. However, since the Zmorph is not just a simple single extruder 3D printer, there will be additional articles about each interchangeable head describing the work, nuances and results.

General information about the device.

1. External dimensions - 530 mm x 555 mm x 480 mm.

2. Printable area - 250mm x 235mm x 165mm.

3. Number of printheads - 1

4. Weight is ~ 25 kg.

5. The printer is equipped with a thermal table, card reader, ethernet port and touch monitor.

6. Maximum nozzle temperature: ~260

7. Nozzle diameter: 0.4 mm, resolution: 200 to 70 microns

8. Build speed 60-150 mm/s

9. Printing materials declared by the manufacturer: PLA, ABS, PETG, Laywood, nylon, rubber, etc.

10) Features - the main bonus of this printer is interchangeable heads. In our kit there are 1.75 single extruder head, 1.75 double extruder head, milling cutter, laser and extruder-syringe,

11) The printer has its own software, called Voxelizer. The program provides all the options for the heads of this device and has many settings.

Review

The printer itself looks quite serious, thanks to the metal and transparent plastic, it evokes the feeling of some kind of device from sci-fi films, although in principle we see a Prusa i2, but with a very rigid body.

The extruder looks serious, the carriage itself is assembled from metal and a small number of printed parts. The airflow of the model is attached with magnets, which is very convenient.

Thermotable moves on two belts and rails, adjustable with 3 screws. Fastening is realized through magnets.

The axle guides are also made of sheet metal. No backlash, everything is very rigid.

The printer has a nice touch screen display with its own menu.

Cable management is perfectly arranged in the printer body itself. All wires are perfectly protected from breaking and bending. All connectors that the user will have to work with are signed and marked.

The printer has an interesting implementation of the spool attachment mechanism and the filament channel.

This is how 0 is implemented on the Z axis.

Very pleased with the highlighting and marking of important elements on a 3D printer. There is a feeling of working with an expensive industrial device.

Diode illumination of the printed model is a very nice element.

Like many other units, the outer protective case is also attached with a magnet.

Software

Voxilaser looks like this

this is the first menu of transformations and settings, here we place objects, set their sizes, and also select the work area. In this case, workflow costs as 3D printer.

press voxilase and go to voxel editor. It has the usual print settings for all of us.

after we click generate g-code

here we see the generated task, it remains to press play

save it to a USB flash drive and print it.

Print.

First print on a ZMorph 3D printer. A single extruder print head is used. Material natural REC PLA. Before printing, I had to calibrate the table.

Model can be found here: https://www.thingiverse.com/thing:1803617

Material red REC PLA plastic, print speed 90 mms

Material red REC PLA plastic, print speed 70 mms. (outer wall)

Relax

Material natural REC RELAX plastic, print speed 60 mm with 0.4 mm nozzle and 0.2 mm layer.

Bicycle pedals made of natural and white REC RELAX plastic. Layer height 0.15 mm, speed 30. In total, it took 48 hours to print, the result is stable.

Bonus

And now an unexpected bonus - ABS + HIPS printing test on the Dual PRO head.

It differs from the previous one by the ability to print two materials through one nozzle.

The slicing is not much different, all you need to do is set extruder 2 in some places. Thanks to the software, the head is able not only to create supports from another material or to imprint parts from different materials into each other, but also to mix them.

Now let's look at "two-color" printing.

The algorithm of actions is described here, but in general, it's very simple.

The result is just wonderful.

Now let's try blending. Let's fiddle a little with the settings again.

This tutorial describes how to do it.

Looking at the result

Unfortunately we overlooked the amount of pink ABS and ran out of it during the printing process, leaving most of the vase under extruded, but the resulting part shows that the mixing occurs without any problems according to the given program.

Anyway, we did it again.

And now the result:

Conclusions.

Pros:

- Rigid frame, good design and very high quality assembly and components.

- Very precise kinematics.

- The ability to quickly remove and put on additional elements such as protective screens, a model air cooler, a working head and even a heating table.

- Easy-to-learn software with lots of settings and features.

- Convenient printable area.

- The printer has all the necessary warnings and markings, heated table, extruder and powered Z and X axes are illuminated by diodes. The printed object itself is also illuminated, which helps to keep track of the printing process.

- User-friendly interface with a set of useful features. Fine-tuning printing is easy enough, all the icons are unambiguous and large enough not to miss them.

- The printer produces excellent results at low to medium speeds from PLA and RELAX

Cons:

- It is very easy to calibrate the table because of the magnetic mount, you will not only have to level the table plane but also very likely to set zero on the Z axis, after removing the part or detaching the table.

- This printer is conceived and designed as an MFP, not as a 3D printer, so it has a high margin of safety and rigidity, while at the expense of print speed there may be traces of underextrusion or, conversely, excessive drops on the surfaces of models, especially when it comes to a large number of retracts.

- The spool mounting on the printer is interesting, but practice has shown that the filament supply channels can get stuck in the case, stretch and thereby interfere with the plastic supply.

- The software calculates the print time very accurately, but not the amount of plastic required.

- Printing with flexible materials is difficult, again due to thermal distribution, difficulty in feeding the plastic through the tube, and too much pressure that compresses the bar.

Pro Dual PRO

This head has been tested for the main tasks conceived in the design. This system is capable of printing solvent-based supports in PLA+PVA and ABS+Hips combinations, and also allows two-color printing. and The ability to mix colors with a gradient comes as a special feature.

and The ability to mix colors with a gradient comes as a special feature.

Plug&play head, we installed it, filamented it, and started the job. Slicing in Voxeliser, even for this mode, is very simple and intuitive. If you don’t figure it out yourself, there are good tutorials on working in text and video format on the manufacturer’s website.

Conclusion.

Zmorph is a unique platform with many possibilities. Our practice of using it as a 3D printer has shown that this device requires very thoughtful use. This is also due to the software, in which the interface is very clear, but overloaded with elements, which makes it easy to miss something in the settings. It is worth noting a very tough and thoughtful case filled with useful features, markers and indicators. Despite its robust and simple design, the Zmorph printer is not one of the best offerings on the market, as it is built solidly and reliably to handle a range of versatile tasks, not just printing. Therefore, the printer is quite reliable, but not very fast in the additive manufacturing of objects.

Therefore, the printer is quite reliable, but not very fast in the additive manufacturing of objects.

At the same time, working with Zmorph is very simple, in order for the device to behave like a plug and play you just need to remove the printed models very carefully, trying not to pull the table off its mounts and thereby violate its calibration.

In general, the printer produced the best results at speeds from 30 to 70 mm s (infill and outer contour, travel from 120 to 180 mm s) with REC PLA and REC RELAX plastics. When printing ABS and ETERNAL, it is necessary to install protective screens, as they are enough to avoid delamination of the object.

Summing up, we note that Zmorph is a unique machine that will give the user great opportunities, and in return they will only ask you to follow the instructions. This device will find its well-deserved place in various workshops, design bureaus, and especially in educational institutions.

If you have any questions, write comments, call, contact us in the social. networks or by mail, we are always ready to answer. And don't forget that we welcome guests in our office.

networks or by mail, we are always ready to answer. And don't forget that we welcome guests in our office.

Website: https://rec3d.ru/Phone: +7 (800) 775-7331 (free of charge from anywhere in Russia)

http://www.viber.com/rec3d https://telegram.me/Rec3d_bot https://vk.com/rec3dcompanyhttps://www.instagram.com/rec3dcompany/Office: Moscow, st. Godovikova d. 9, building 1, entrance 1.19, office 2.3. Technopark "Caliber".

Thank you for your attention and happy printing!

ZMORPH 2.0 SX - more than a 3D printer / Sudo Null IT News . Now her products are not just a printer for volumetric printing, but a multifunctional machine, which differs from the best industrial samples only in size - it still fits on an ordinary desk.

What can he do?

The ZMORPH 2.0 SX is a transparently encased unit that allows precise positioning of working heads in three dimensions. The wide functionality of these heads, as well as their easy interchangeability, is the uniqueness of this device.

The concept of interchangeable working units allows for a wide range of operations - traditional 3D printing, CNC milling, laser engraving and cutting, as well as 3D printing with thick substances - from clay and silicone to food materials.

The device is equipped with a convenient touch control panel, and preparation and operation are carried out using special Voxelizer Software. The area of operation of the 3D printer is 250 by 235 millimeters, and precision stepper motors provide accuracy.

Attachments:

Laser Head

The Zmorph laser head is equipped with a dual-watt blue diode laser that can easily cut and engrave materials such as plastic, paper, cardboard, foil, textiles, plywood, wood and leather. The recommended working speed is 5 mm/sec.

https://www.youtube.com/watch?v=1H7oQrSBEbc

Thick Paste Extruder

This extruder allows 2D and 3D printing of dense materials such as silicone, clay, dough or chocolate. Printed materials are easily changed in seconds in standard disposable syringe containers for convenience and hygiene. The speed of operation depends on the density of the material and the width of the nozzle of the syringe, and is in the range from 10 to 100 millimeters per second.

Printed materials are easily changed in seconds in standard disposable syringe containers for convenience and hygiene. The speed of operation depends on the density of the material and the width of the nozzle of the syringe, and is in the range from 10 to 100 millimeters per second.

DUAL PRO plastic extruder

The ZMorph DUAL PRO plastic extruder is one of the most advanced devices in this field today, it allows you to print two different materials with the same melting point and fluidity, for example - different colors, and makes it possible their controlled blending for different visual effects.

The ZMorph DUAL PRO allows printing on a variety of plastics in standard spools, with a feed thickness of 1.75 mm. Despite a single nozzle and a single temperature sensor, mixing takes advantage of the use of different materials - if one of them is water-soluble and used as support in printing, complex shapes can be created that are not possible with conventional 3D printers.

Regular single extruders are also available: standard 1.75 mm and wide 3 mm.

https://www.youtube.com/watch?v=z1rVgDZBHKI

ZMorph DualHead extruder

ZMorph DualHead extruder is another interesting attachment for this machine. This extruder has two independent heating elements and temperature sensors, respectively, and two separate nozzles, which makes it possible to work simultaneously with two materials with different melting temperatures.

The use of easily soluble materials, in combination with conventional ones, will help create complex 3D objects that are incredible and unattainable for a conventional 3D printer. For example - consisting of separate, unrelated parts, or objects made of materials of different colors, transparency, different mechanical properties.

CNC PRO head

ZMorph CNC PRO is a milling head for engraving, milling and cutting various materials. The head is equipped with one cutter, but you can buy several additional ones - of various diameters and shapes. Easily cuts, carves bas-relief images and does everything else that a CNC router is capable of.

Easily cuts, carves bas-relief images and does everything else that a CNC router is capable of.

Works with all kinds of plastics, wood and plywood, various composite materials such as textolite, fiberglass and G10, and even with rigid plexiglass and polycarbonate. The device comes with a special table for milling, which is attached to the base of the printer with magnets.

All attachments can be changed in seconds and are ready to use right away, and these are not empty words - watch the video on the manufacturer's website - it's as easy and fast as putting on an electric kettle.

https://www.youtube.com/watch?v=j3Gd-3C2B1A

Who needs this?

While it is difficult to imagine such a thing in every home, after all, even a basic kit - with one simple single extruder 1.76 mm and a milling nozzle - will cost the buyer $4000.

Which, however, for true enthusiasts and craftsmen is quite a feasible amount, albeit not immediately. In the near future, a similar unit may appear anywhere, from the kitchen to the office.