Sintron 3d printer kit

[Sintron] Ultimate 3D Printer Full Complete Kit for DIY Reprap Prusa i – Sintron Technology

Sintron Prusa i3 had beed sold for over thousands quantity. we provide tech support for this when you meet any problems. buying 3D printer without tech support is just a waste of money.

Come and check below video, this is what our printer real work

Those plastic parts which we send to you are all made through this

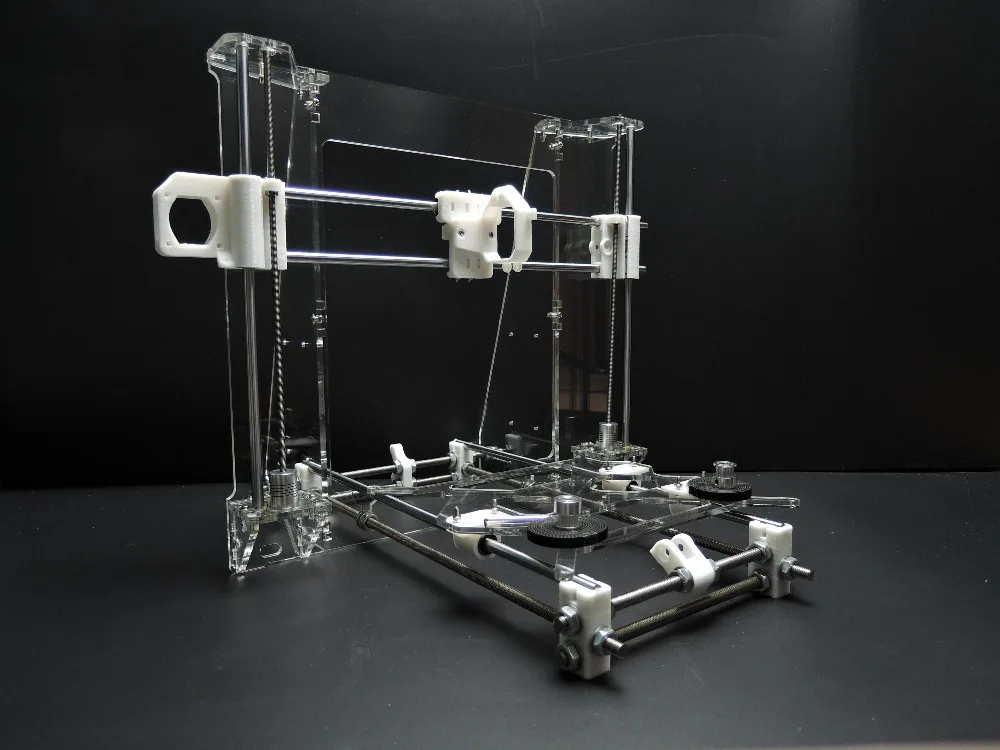

Overview

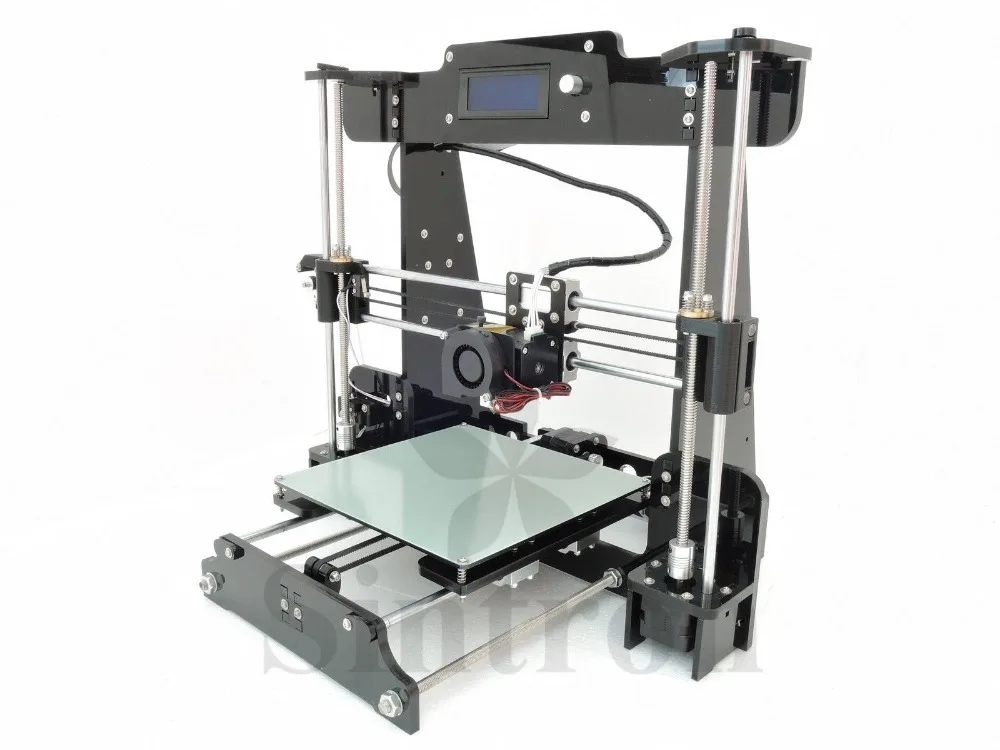

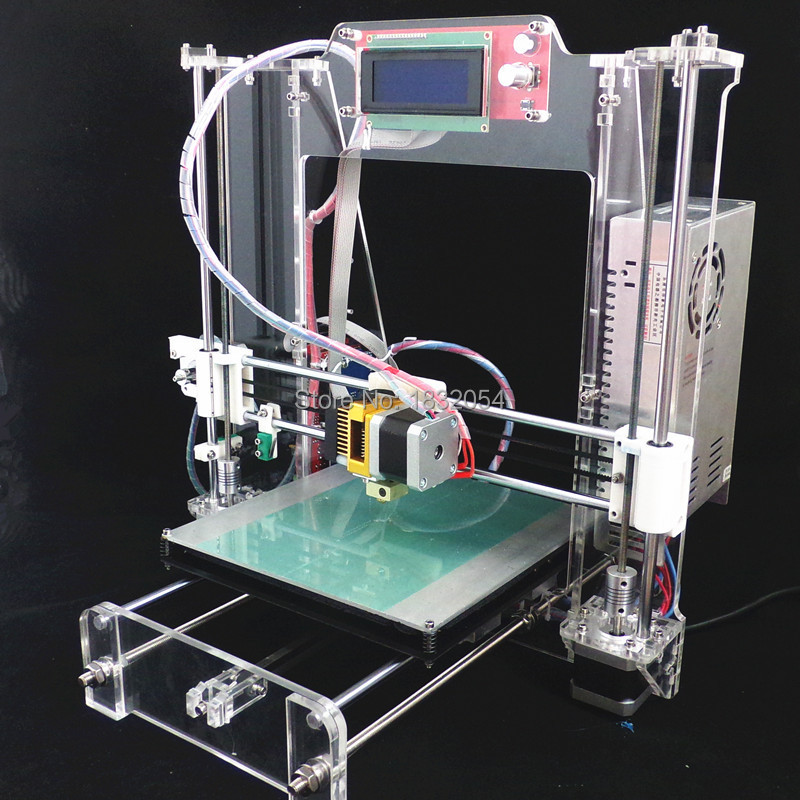

The operating principle of 3D printer is to establish a 3D model by your computer, and use slicing software system to do the slicing work for the 3D model then save to the SD card for ready to print. Made of high quality acrylic material + Steel rod (threaded & smooth), this 3D printer has a simple structure, light and portable, beautiful and trendy.

This kit include all the parts you need for building Reprap prusa i3 3D printer. you might be wondering what are the difference between ours and others.

the main difference would be :

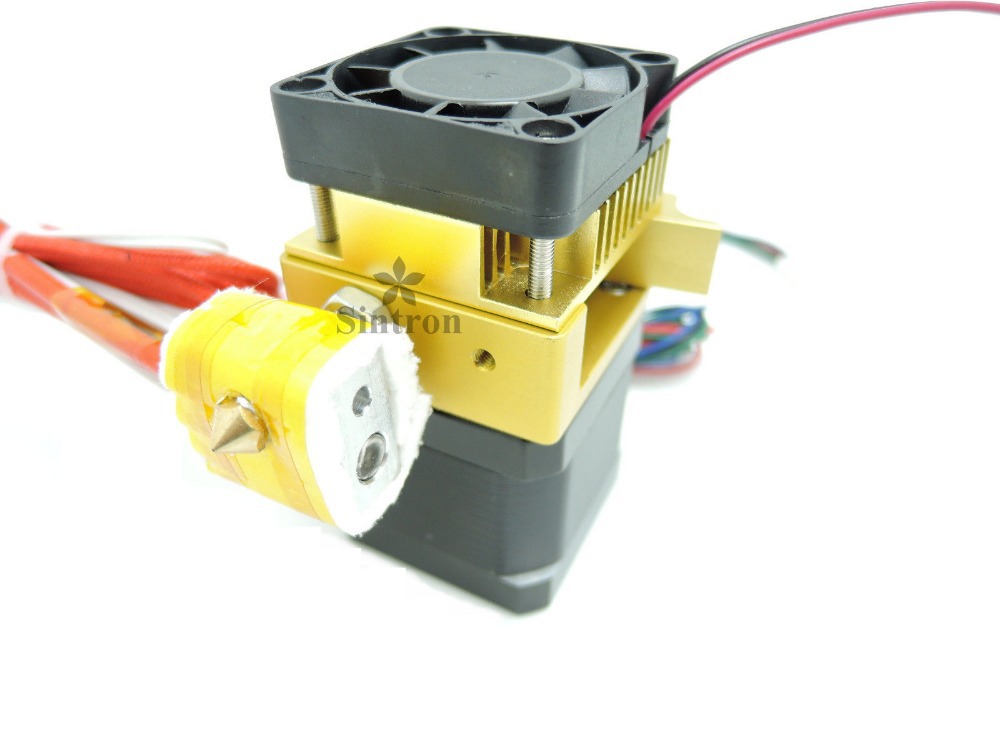

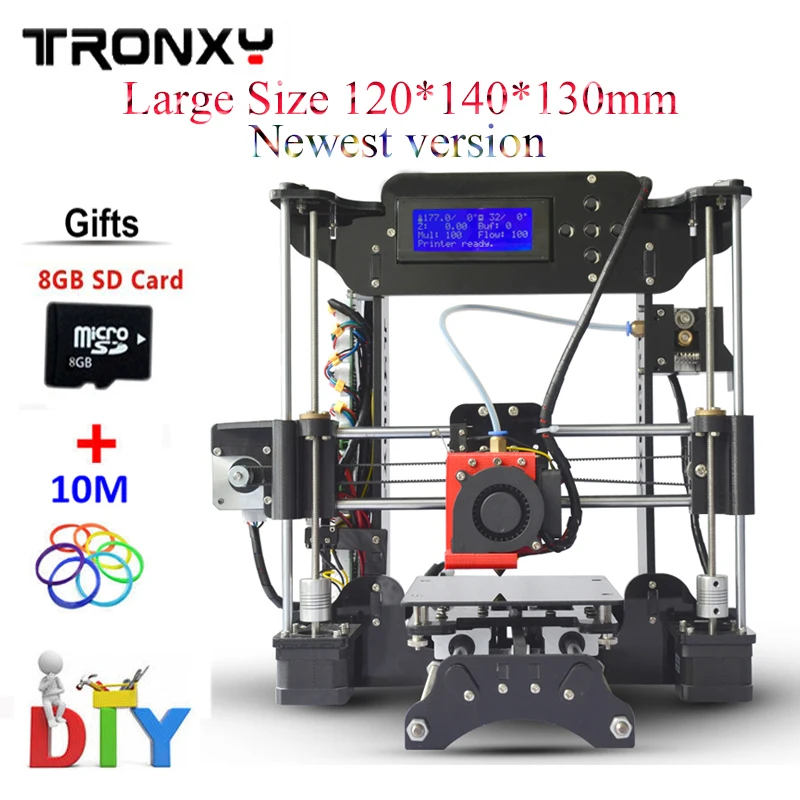

(1) we don't adapt wade extruder, we upgrade the J-head to all metal MK8 extruder.

If you use wade extruder etc, every time when you change the filament, you have to take them apart and calibrate it all again. it takes hours sometimes, so I would suggest you to use long distance extruder as below. it takes you only within 1 minute to change the filament. (how long will we change the filament? for normal use, you would change it at least 3~5 times per month. I believe you don't want to spend hours every time)

(2) We offer LCD 2004 controller with SD card design support totally off-line print, no computer needed while printing. then you don't have to spare one computer for your 3D printer use only. The default is LCD 2004 controller, if you would like to upgrade to LCD 12864, please inform us in advance. we offer this for free now.

The default is LCD 2004 controller, if you would like to upgrade to LCD 12864, please inform us in advance. we offer this for free now.

(3) We use the latest MK3 Heatbed 3mm Aluminium PCB Board, dual power supply, operate at 12V or 24V. Heated bed keeps a certain temperature to prevent warping, and cooling fan speeds up solidification of the extruded filament. this would reduct your calibration time a lot!

(4) We use well-designed standard MK8 extruder, high quality stepper motor and direct drive extrusion wheel, more accurate, quick heating and fluent injection, we have made necessary design to prevent "jammed" problem. printing speed up to 100mm/s.

Actually we have own this products for over one year, but we just started to sell it now. because we hope to went through all the details, and make sure all the components we selected are really useful, so customer can save time on worrying if it's the hardware problem and focus on project only.

Therefore, if you meet any problems (I am sure you will meet dozens of problems and questions during the building process, and it's normal), you can always contact us for technical support, because almost all the problems you will meet, we already met before, you are not just buying this product, you also get our experienced support for you. building a 3D printer is not an easy job, so if there's some one you can ask, you will save a lot of time.

We have pre-installed the 3D printer firmware for you, so even you know nothing about firmware, you can still get it working. error range would be from 0.1~0.5mm (but in order to be more precise, some knowledge about the firmware is recommended)

please feel free to send us an email, we will also help you to complete the project!

Features

(1) RepRap Prusa i3 3D printer with LCD screen, you can adjust the printing parameters via the LCD screen rotary knob, this

would reduct your calibration time a lot!

(2) High print quality, easy to install and operate, stable and reliable, without worrying the troublesome debugging.

(3) Printing speed, extruder temperature and hot bed temperature are freely adjustable during printing.

(4) XYZ axis position accurately, ensures the printing edge more neatly.

(5) Operating system compatible with Windows, Linux, Mac.

(6) We have pre-install the 3D printer firmware for you. so even you know nothing about firmware, you can still get it working.

(7) Educational institution can use 3D printer Prusa i3 to make models for teaching.

(8) Transparent frame design for you to see the printing process clearly.

(9) Simple structure for easy to install, parts and components for DIY, enjoy yourself in the assembling. can make true-to-life

and high-resolution models and objects.

(10) Especially suitable for DIY amateur, artistic design, architectural design, education, 3D photo studio, etc. can be used for

printing different items like small components model, decoration, etc.

Detail x, y, and z axis parts

Specifications

Package list

Please notice: plastic parts have some standard error, so you might need to drill it with tools.

for US customer, we will send with US plug power adapter

for UK customer, we will send with UK plug power adapter

for AU customer, we will send with AU plug power adapter

for EU customer, we will send with EU plug power adapter

if you have special request, please let us know before shipment

We could provide more!!

below are 3 must get software and firmware:

1. Marlin: firmware to communicate all the parts. ( we include the code you need )

2. Printrun: the software to communicate between 3D printer and computer.

3. Slic3r: final step to get the Gcode. ( Gcode format is what you use to run your 3D printer )

if you need them, you can contact us after you purchase.

( please write: require 3D printer firmware and software )

we have also collected some 3D model drawings, fee free to contact after your order.

below we will comment the tips and key points for each component

Please make sure to read following description, so you know what the difference between ours and other products. better spend 10 minutes here than spend additional weeks later and found out that other the one you got is with problems :)

we not just sell them, we also provide good after-sales service, so welcome to discuss with us, we will try to do technical support as much as we can.

(1) 3D Printer Controller RAMPS 1. 4

4

The RepRap Arduino-compatible MEGA Pololu Shield, or RAMPS for short. It is designed to fit the entire electronics needed for a RepRap in one small package for low cost. RAMPS interfaces an Arduino-compatible Mega with the powerful Arduino-compatible MEGA platform and has plenty room for expansion. The modular design includes plug in stepper drivers and extruder control electronics on an Arduino-compatible MEGA shield for easy service, part replacement, upgrade-ability and expansion. Additionally, a number of Arduino expansion boards can be added to the system as long as the main RAMPS board is kept to the top of the stack.

Version 1.4 uses surface mount capacitors and resistors to further cover edge issue cases.

for more informations, you can check the item listing here:

[Sintron] 3D Printer Controller RAMPS 1.4 for Reprap Prusa Mendel Arduino AVR

(1) USB type B receptacle.

(2) SD Card add on available.

(3) Fits 5 Pololu stepper driver board.

(4) LEDs indicate when heater outputs on.

(5) Expandable to control other accessories.

(6) Heated bed control with additional 11A fuse.

(7) Option to connect 2 motors to Z for Prusa Mendel.

(8) I2C and SPI pins left available for future expansion.

(9) It has provisions for the cartesian robot and extruder.

(10) All the Mosfets are hooked into PWM pins for versatility.

(11) 3 mosfets for heater / fan outputs and 3 thermistor circuits.

(12) Fused at 5A for additional safety and component protection.

(13) Pololu boards are on pin header sockets so they can be replaced easily or removed for use in future designs.

(14) Servo style connectors are used to connect to the endstops, motors, and leds. These connectors are gold plated, rated for 3A, very compact, and globally available.

(2) Arduino-Compatible Mega 2560 R3

Fully compatible with original Arduino MEGA 2560 R3, with this product, you are able to use all the Arduino open source platform to create or learn interactive objects, it will be a lot of fun while you are creating and learning it, so just get this and start it, we also provide reference pdf files that can help you to improve skills very quickly. after all, time matters, the sooner you can improve your programing skills, the sooner you can create amazing projects!

after all, time matters, the sooner you can improve your programing skills, the sooner you can create amazing projects!

Compared with UNO R3, this is with main Chip ATmega2560, with more I/O Pins, and additional 10 PWM output, of course, the EEPROM is also with larger space.

for more informations, you can check the item listing here:

[Sintron] MEGA 2560 R3 ATmega2560 + Reference PDF files for Arduino's IDE

(3) A4988 StepStick Compatible Stepper Motor Driver Module

A4988 is a complete microstepping motor driver with built-in translator for easy operation. This product is available in full, half, 1/4, 1/8 and 1/16 step modes operate bipolar stepper motors, output drive capacity of up to 35 V and ± 2 A. A4988 includes a fixed off-time current regulator, the regulator in slow or mixed decay modes. A4988 converter is the key to the easy implementation. As long as the "step" input inputting one pulse drives the motor one microstep. There are no phase sequence tables, high frequency control lines, or complex interfaces to program. A4988 interface is very suitable for complex microprocessor is unavailable or is overburdened.

As long as the "step" input inputting one pulse drives the motor one microstep. There are no phase sequence tables, high frequency control lines, or complex interfaces to program. A4988 interface is very suitable for complex microprocessor is unavailable or is overburdened.

In the micro-step operation, A4988 chopping control inside automatically selects the current decay mode (Slow or Mixed). In mixed decay mode, the device is initially set to a fixed downtime in some fast decay, then the rest of the slow decay downtime. Mixed decay current control scheme results in reduced audible motor noise, increased step accuracy, and reduced power consumption. Internal synchronous rectification control circuitry is provided to improve the pulse-width modulation (PWM) operation power consumption. Internal circuit protection includes: thermal shutdown with hysteresis, undervoltage lockout (UVLO), and crossover-current protection. Special power sequencing.

A4988 surface mount QFN package (ES), a size of 5 mm × 5 mm, nominal overall package height of 0. 90 mm, with an exposed pad for enhanced thermal dissipation. This package is Pb (suffix-T), with 100% matte tin leadframe plating.

90 mm, with an exposed pad for enhanced thermal dissipation. This package is Pb (suffix-T), with 100% matte tin leadframe plating.

for more informations, you can check the item listing here:

5 Pcs A4988 StepStick Compatible Stepper Motor Driver for 3D Printer RAMPS 1.4

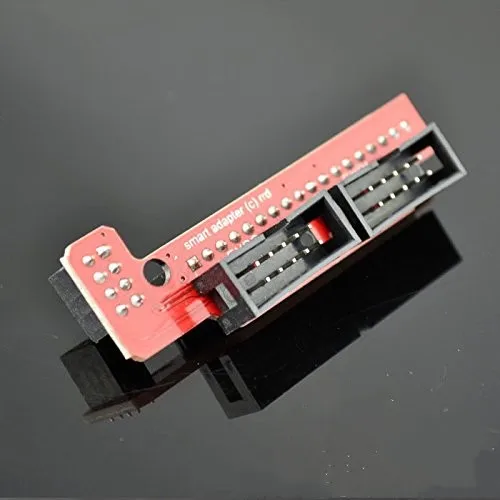

(4) LCD 2004 Smart Display Controller

This Smart Controller contains a SD-Card reader, a rotary encoder and a 20 Character x 4 Line LCD display. You can easy connect it to your Ramps board using the "smart adapter" included.

After connecting this panel to your Ramps you don't need your pc any more, the Smart Controller supplies power for your SD card. Further more all actions like calibration, axes movements can be done by just using the rotary encoder on the Smart Controller. Print your 3D designs without PC, just with a g-code design stored on the SD card.

for more informations, you can check the item listing here:

LCD 2004 Smart Display Controller Module for 3D Printer RAMPS 1. 4 Prusa Mendel

4 Prusa Mendel

(5) NEMA 17 1.8° 2.6 kg.cm flat shaft Stepper Motor

for more informations, you can check the item listing here:

NEMA 17 1.8° 2.6 kg.cm Torgue flat shaft Stepper Motor for 3D Printer RepRap

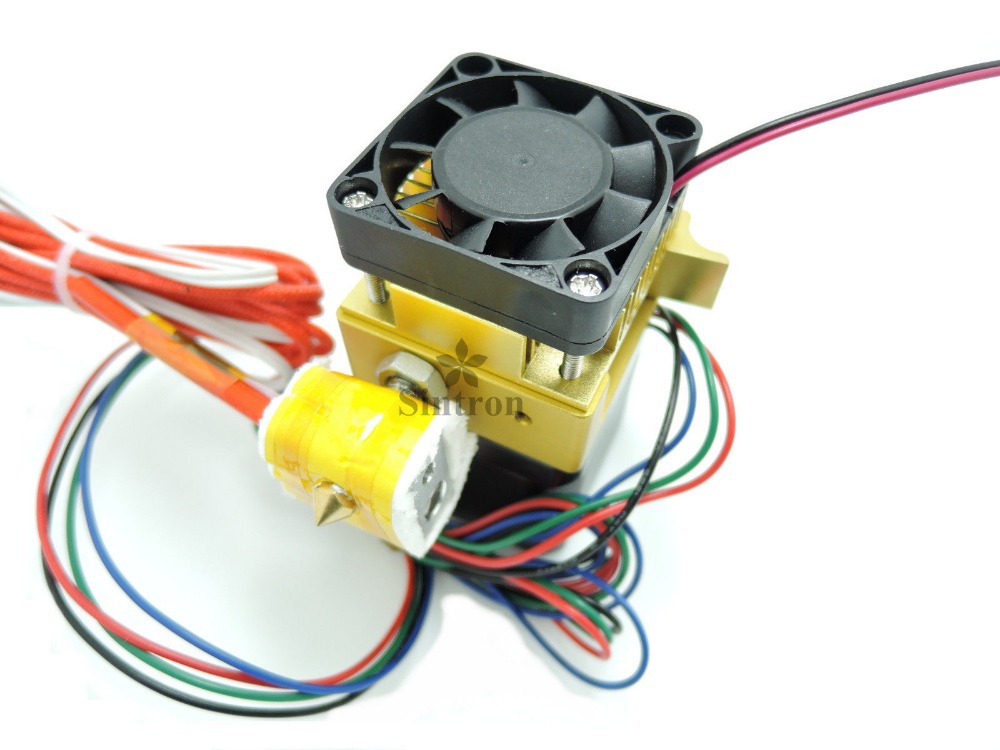

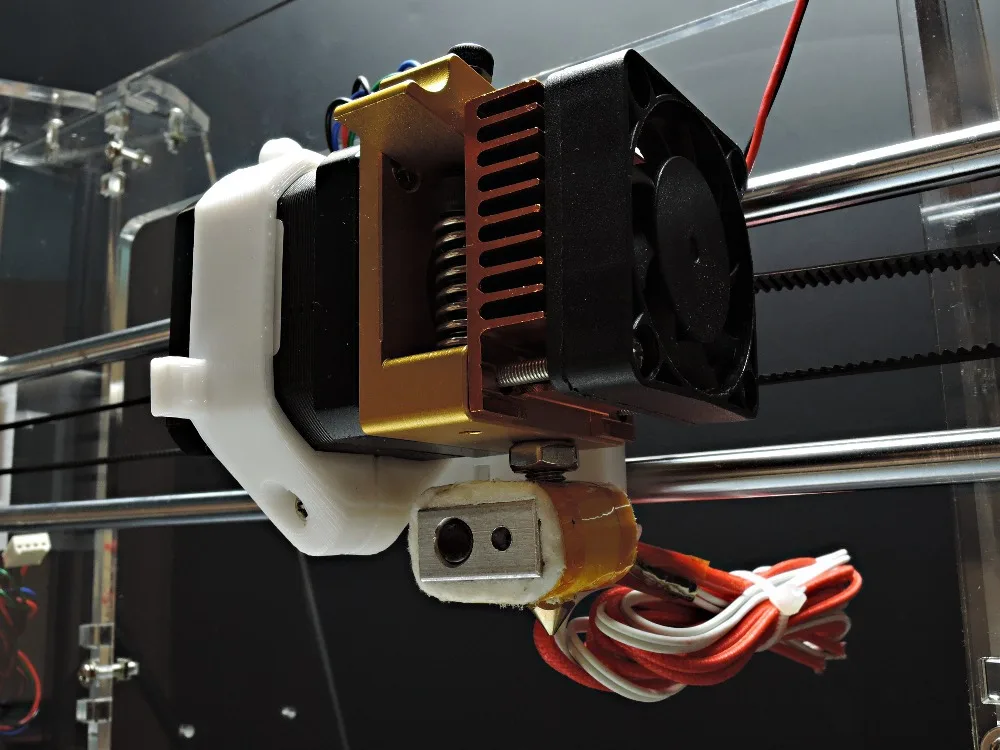

(6) MK8 Extruder Hot-end & Cold-end

The extruder is almost the most important part for 3D printer, please check the the color of the metal, it's specially processed to ensure the extruder won't have "plastic material stuck" problem. I can't emphasize any more how important this is, other sellers don't have this and would cause many problems.

for more informations, you can check the item listing here:

[Sintron] 3D Printer Extruder Nozzle MK8 Latest Upgrade Print Head Reprap Mendel

(7) MK3 Heatbed 3mm Alu PCB Board Dual Power

The Aluminum Heatbed MK3 have features similar to MK2 and you can also operate this board with 12V and 24V two voltage.

(thermistor and wires are included)

for more informations, you can check the item listing here:

MK3 Heatbed 3mm Alu PCB Board for RepRap 3D Printer Prusa i3 + Thermistor & Wire

(8) Mechanical Endstop switch module v1.2

Mechanical switches are less complicated to implement and cheaper than optical endstops. The function of endstops are to determine the original position of the extruder hot-end, so it knows where to extrude the plastic material.

while using the Endstops, please be careful! for the wrong connection, it's possible to burn the mega 2560 board!!

for more informations, you can check the item listing here:

3 pcs Mechanical Endstop Module V1.2 for 3D Printer RAMPS 1.4 RepRap Prusa i3

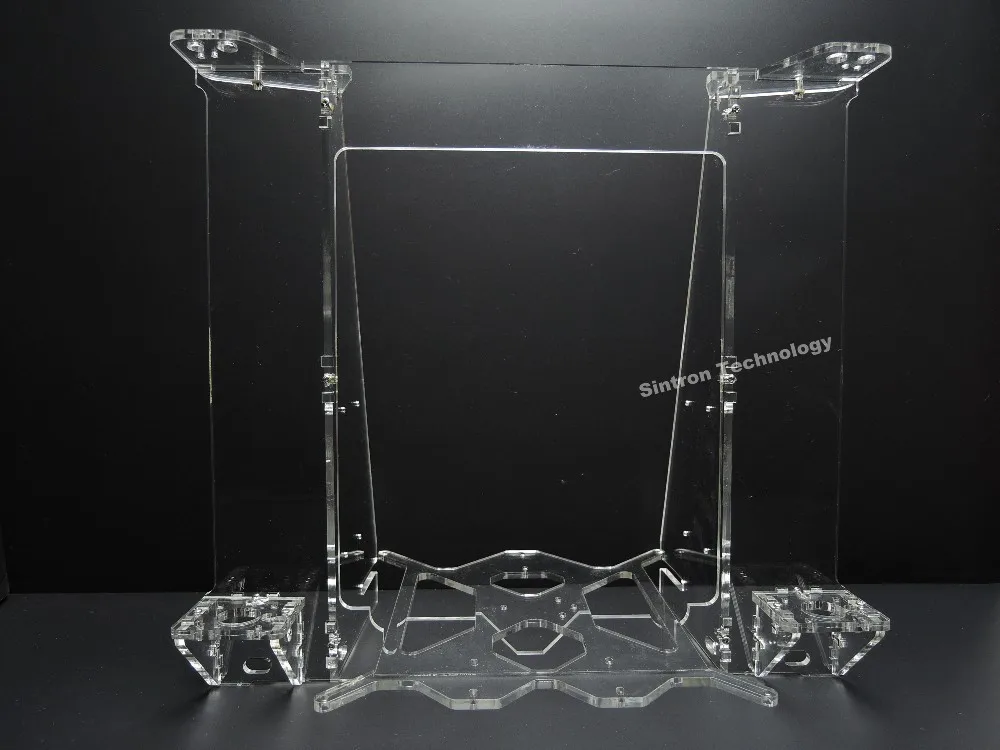

(9) Acrylic Frame kit

We use transparent acrylic sheet to building the 3D Printer, is more beautiful and sturdy.

for more informations, you can check the item listing here:

3D Printer Frame Kit for RepRap Mendel Prusa i3 , Laser Cut Acrylic Sheet Kit

(10) Smooth and Threaded rods kit

for more informations, you can check the item listing here:

3D Printer Smooth & Threaded Rods + Nuts Kit Rework Shaft for Reprap Prusa i3

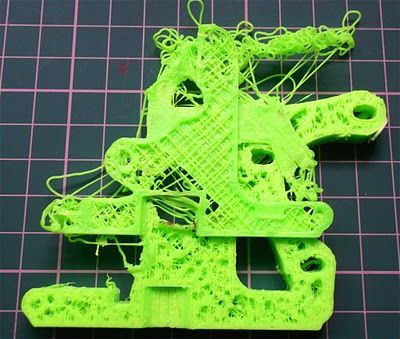

(11) Printed plastic kit, made of PLA

This is the excellent and popular plastic parts of the Prusa i3 Acrylic Frame 3D Printer, this kit comes with the following parts in PLA. these are the parts you'll need to complete your Prusa i3.

Please notice: plastic parts have some standard error, so you might need to drill it with tools.

for more informations, you can check the item listing here:

3D Printer Plastic Printed Part Frame Kit for MK8 Extuder Reprap Mendal Prusa i3

(12) 2 x GT2 Pulley + 2 x 1m belt

For 3D Printing applications, GT2 2mm belt system works better than T2. 5, T5, it gives better smoothness and accuracy of positioning, resulting in better printing quality. GT2 timing belt system especially suited for linear movement and positioning applications.

5, T5, it gives better smoothness and accuracy of positioning, resulting in better printing quality. GT2 timing belt system especially suited for linear movement and positioning applications.

for more informations, you can check the item listing here:

2M GT2 Timing Belt Set + 2X GT2 20 Tooth Pulleys for RepRap 3D Printer Prusa i3

(13) LM8UU 8mm Linear Ball Bearing

for more informations, you can check the item listing here:

12pcs LM8UU Linear Ball Bearing for 8mm Rod RepRap 3D Printer Prusa Mendel i3 UK

(14) MF105ZZ Flange Metal Double Shielded Ball Bearing

for more informations, you can check the item listing here:

4x MF105ZZ Bearing + 2x CNC Motor Shaft Coupler Coupling for 3D Printer Prusa i3

(15) Filament for test

In this kit, we also include some plastic filament for you to test.

please notice:we will only send one random color, and this is only for test, not enough to print a 3D model.

For more 3D Printer related series components, please click and check our eBay store below:

( we can combine shipping cost for multi items )

click here ==> More 3D Printer Series Store

Write a Review

Sintron Reprap Prusa I3 3D-Printer – review and first impressions

3d Printing, Making

Posted on by Jeremy Lindsay in 3d Printing, MakingI’ve wanted a 3d-printer for a while. So as part of my intention to start trying to build more things and branch out from just creating software, I decided to buy one.

I used the following criteria when I was deciding what to buy:

- It had to be a learning opportunity – it’d be pretty easy to buy a closed source device which was neatly packaged up and “consumer ready”, but I didn’t think I’d learn a lot about 3d printing from that.

- Low cost – before buying this machine, I knew next to nothing about the practicalities of 3d printing. I didn’t want to sink a lot of money into a 3d printer, and quickly discover that either it wasn’t quite what I wanted, or that maybe it wasn’t any good. I have a couple of expensive electronic white elephants and I don’t need any more.

- Large print area/volume – I wanted a minimum of 200mm x 200mm for the print bed area. I know from experience that compromising on this really limits what you can build.

- Heated bed – my research told me that if you don’t have a heated bed on your printer, you’re going to need to get one pretty quickly.

It’s possible to print without one, but it’s a lot easier if you’ve got one.

It’s possible to print without one, but it’s a lot easier if you’ve got one. - Positive reviews and community support– I wanted something that I knew at least some people had got to work.

So I didn’t care about what it looked like, and I didn’t mind having to put it together from a kit.

I decided on buying the Sintron Prusa i3 kit from Amazon as it met all my criteria.

- There’s a huge RepRap community;

- Reviews on Amazon at the time of my purchase were all good;

- It has a heated bed which is about 20cm x 20cm;

- It’s one of the the lowest cost kits that I could find – I could have sourced the parts individually and potentially got it cheaper, but I was happy enough to pay a bit more to get everything in one box;

- There are a huge bunch of Prusa i3 tutorials on YouTube, so even before buying the kit, I had a pretty good idea of how to make it and what kind of results I’d get;

Construction

I knew I was getting a kit, so I got what I expected when I opened the box!

But it was a bit disappointing to not have printed instructions in the box (or even a link to where the instructions might be). However, fortunately I was able to piece together how to do it from a couple of different sources I found. Neither are perfect matches for the kit I was supplied with, but they were close enough to let me build the machine.

However, fortunately I was able to piece together how to do it from a couple of different sources I found. Neither are perfect matches for the kit I was supplied with, but they were close enough to let me build the machine.

- Mechanical guide here.

- Electronics guide here.

I also used this video series on YouTube to guide me through construction and how to do my first print.

Initial Experiences

I tried printing in PLA first – PLA stands for Polylactic Acid, which has a melting point of about 185C. This is supposedly one of the easiest materials to print with, so I thought it was a good starting point.

- The canonical first thing to print is the 10mm x 10mm x 10mm cube, which is available on Thingiverse. I downloaded the STL file.

- Next, I downloaded Slic3r. This is a program which opens the STL file, and slices the 3d drawing into many horizontal layers. You need to:

- Enter details of the material you want to print with – in my case, 1.

75mm PLA;

75mm PLA; - Enter the temperature you want to print at – for PLA, I went with an extruder temperature of 185C, and a heated bed temperature of 60C.

- Enter the speed that you want to print at – there were many options in Slic3r, and I left them as the default for my first print.

- Enter details of the material you want to print with – in my case, 1.

- Each of these layers is converted into G-code, which is a way of instructing the printer to dribble melted plastic in a particular shape in the X and Y axis, and then lift the extruder by a very small distance in the Z-axis to print a different shape. Eventually each of these different layers will form the 3d print which replicates the object in the STL file;

- Finally, I downloaded PrintRun, which connects to the printer and sends the G-code instructions to the printer.

As a reminder – these are my initial experiences. I have a couple of hundred hours of printing experience under my belt now, and I’m not doing things exactly the same way now as I did for my first print. For example, I use ABS as my primary print material now rather than PLA, and I use Cura instead of Slic3r.

For example, I use ABS as my primary print material now rather than PLA, and I use Cura instead of Slic3r.

Initial Conclusions

The PLA cube printed well – which was enough to confirm the printer was a good purchase. I was certainly happy that I had only paid about 250GBP for a functioning printer, and had learned a lot about how these machines work.

I’ll blog next about some improvements I made to the printer which expanded the machine’s usefulness.

10 Benefits of a 3D Printer: Save Time and Money

More recently, 3D printing has been viewed as something completely new. The technology was underdeveloped, the hardware was too expensive for widespread use. But only a few years have passed, and the situation has changed radically. Not only did more and more 3D printers begin to appear in stores, but also some enthusiasts began to assemble this equipment themselves.

1. Economy

Although large-scale projects with thousands of 3D printed parts are not cheap, they are still much more profitable than other technologies. Many manufacturers use 3D printing for small runs or for prototyping. Plastic can also be used for injection molding, but casting small batches can require expensive equipment. But even in this case, manufacturers can produce cast 3D parts several times cheaper than using aluminum.

Many manufacturers use 3D printing for small runs or for prototyping. Plastic can also be used for injection molding, but casting small batches can require expensive equipment. But even in this case, manufacturers can produce cast 3D parts several times cheaper than using aluminum.

Prototype parts printed on Prusa i3 Bizon 3D printer, layer height 0.1mm, PLA material

2. Faster production cycle

Compared to traditional production methods, the entire process can take weeks or days, and most products are printed in hours. Some manufacturers have even begun to make parts to order, which has also allowed them to optimize their warehouse capacity and resource management scheme, making them more flexible. With this new approach, the manufacturer does not need to store every single part or component, they can simply be printed as needed and immediately put into action.

Miniature parts printed by Wanhao Duplicator 7 photopolymer 3D printer, layer height 0. 5mm, photopolymer resin material

5mm, photopolymer resin material

It not only affects the reputation of the company in its industry, insufficient technical control can lead to injury to employees and customers. Since 3D printing uses a completely different production method than most machine tool operations, the process has significantly fewer weaknesses and flaws overall.

Model printed on Picaso Designer X PRO 3D printer, 0.2 mm layer, ABS materials, HIPS

4. Less waste

The press is gaining more and more support in the form of supporters of the "green" movement. Because 3D printing produces significantly less waste than traditional processing, the technology is more environmentally friendly while reducing costs. 3D printing has even made its way into the textile industry, allowing clothing and prototypes to be printed.

Hercules Strong 3D printed yacht steering parts. Details printed in 15 hours with a 0. 5 mm nozzle and a layer height of 0.3 mm at a speed of 60 mm/s.

5 mm nozzle and a layer height of 0.3 mm at a speed of 60 mm/s.

5. Greater customization

3D printed products are also highly customizable. Parts can be printed not only with light plastic, some next-generation models may also have a metal coating. As a result, objects are not only aesthetic, but also functional. In addition, they can acquire thermal and chemical resistance. The existing metallization method can also be used for plastic.

Functional parts printed on Hercules. Material ABS, nozzle diameter 0.5 mm, layer height 150 µm, filling 100%. The model consists of 3 parts: the body and 2 halves of the latch, after printing and processing, the parts were glued together with acetone.

6. Customer Accessibility

If some craftsmen set up small mechanical workshops, for example, in garages, then most of us cannot afford such a luxury. 3D printing allows you to bring a significant part of the manufacturing process directly into the home, made possible by the availability of user-grade 3D technology. While it turns out to be quite expensive for one-off projects, the price of 3D printers and consumables is dropping rapidly.

While it turns out to be quite expensive for one-off projects, the price of 3D printers and consumables is dropping rapidly.

Technical wing caps in REC RUBBER or REC FLEX. The models are printed on a Prusa i3 Steel 3D printer.

7. High complexity

In most cases, when it comes to complex parts and elements, the manufacturing process imposes certain limitations. Techniques used in casting and finishing objects may not be subtle enough for sophisticated design details. 3D manufacturing processes make it possible to realize almost any design solution, regardless of its complexity, and in a reasonable time. This not only eliminates the extra assembly steps required by traditional methods, but also provides more freedom to create future-proof designs.

Zenit 3D Printing Big Details From Engine 3D Printer

8. Less risk

While there are inherent risks associated with these new technologies, in terms of day-to-day business, 3D printing risks are significantly lower than with traditional manufacturing methods. Not only is 3D printing much cheaper when it comes to testing a new design or product, the printed prototypes themselves can stir up investor and customer interest and get them to decide whether to proceed with mass production of a product, whether it is worth the time and effort required.

Not only is 3D printing much cheaper when it comes to testing a new design or product, the printed prototypes themselves can stir up investor and customer interest and get them to decide whether to proceed with mass production of a product, whether it is worth the time and effort required.

Wanhao Duplicator i3 3D Printer Miniature Printing

9. Variety of materials

The materials used in today's 3D printers are much more diverse than most raw materials in traditional production methods. 3D printing also provides the ability to mix different substances, a luxury that is not always available with conventional methods. Although many 3D printer manufacturers offer their own, very limited set of sources, 3D printers can work not only with original materials, allowing you to simulate ceramics, metal, glass and more.

Wanhao D6 3D Printer PEGT, ABS-PC, PLA, SBS

The manufacturer not only needs to clearly understand what the customer wants, the manufacturer must also be able to explain what he himself can.

Drawings, diagrams, diagrams are all good, of course, but there is nothing better than a real prototype that you can hold, look at and study. The fact that the materials are inexpensive, coupled with the short prototyping time on today's 3D printers, helps a lot during the prototyping phase, keeping all stakeholders connected.

Drawings, diagrams, diagrams are all good, of course, but there is nothing better than a real prototype that you can hold, look at and study. The fact that the materials are inexpensive, coupled with the short prototyping time on today's 3D printers, helps a lot during the prototyping phase, keeping all stakeholders connected.

THE PAST, PRESENT AND FUTURE OF 3D PRINTING

Despite a relatively slow start, the concept of 3D printing is finally gaining momentum and popularity among manufacturers and customers. We already see a lot of benefits of 3D printing, including shorter production cycles, more complex designs and improved quality, and the peak of the popularity and functionality of this technology is yet to come.

Desktop 3D home printers

Anet Anycubic Creality3D CreatBot Dremel Elegoo Felix FlashForge FLSUN Flying Bear Formlabs IBRIDGER imprinta MakerBot Peopoly Phrozen PICASO 3D QIDI Raise3D Tiertime Ultimaker Uniz Voxelab wanhao XYZPrinting ZENIT Zortrax

Availability

In stock

Manufacturer

Phrozen Raise3D Creality wanhao FlashForge

PICASO 3D Anycubic Formlabs Tiertime Flyingbear QIDI Uniz CreatBot Dremel DigiLab Felix Zortrax XYZprinting Ultimaker imprinta Elegoo MakerBot Anet FLSUN IBRIDGER Peopoly snapmaker Voltera Voxelab ZENIT

Delivery

Assembled printer Assembly kit

Application

Architecture For large objects For beginners The medicine Education

Orthopedics Production prototyping Reverse engineering Advertising, exhibitions Sculpture Dentistry Hobby jewelry

Print technology

DLP/LCD/SLA FDM/FFF LFS

Thread diameter

1. 75 mm 2.85 mm 3.00 mm

75 mm 2.85 mm 3.00 mm

Material type

ABS PLA PETG Photopolymers Flex

Nylon (Nylon) ASA Carbon HIPS PC PEEK PP TPU other Metal (Ultrafuse 316L, Ultrafuse 17-4PH)

Number of extruders (print heads)

Heating table

Yes Not

Wi-Fi or other wireless network

Yes Not

Country of origin

China Russia USA Taiwan Hong Kong

Netherlands Poland

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Custom/Transit | Goods on the way |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Custom/Transit | Goods on the way |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220 x 220 x 250 mm |

| Number of extruders (print heads) | 1 |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Custom/Transit | Goods on the way |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Voxelab |

| Construction area size | 200*200*200 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Custom/Transit | Goods on the way |

| Construction area size | 200x200x200 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Flyingbear |

| Construction area size | 255x210x210 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 102x57x165 mm |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Custom/Transit | Goods on the way |

| Construction area size | 250x250x400 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

| Manufacturer | Phrozen |

| Construction area size | 134x75x130 mm |

| Country of origin | Taiwan |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | QIDI |

| Construction area size | 260x200x200 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Custom/Transit | Goods on the way |

| Construction area size | 197 x 122 x 245 mm (5. 9 l) 9 l) |

| Chamber volume | 5.9 L |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Custom/Transit | Goods on the way |

| Construction area size | 198 x 123 x 210 mm |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 102x57x165 mm |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 200x170x∞ mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 165x72x180 mm |

| Country of origin | Taiwan |

3D printing is one of the most promising areas of technological development in the 21st century. Having gone a long way from bulky and heavy boxes to compact desktop devices, 3D printers have ceased to be something inaccessible to a wide range of users. The era of mass additive manufacturing has already arrived, and every home can now house a real desktop factory.

Having gone a long way from bulky and heavy boxes to compact desktop devices, 3D printers have ceased to be something inaccessible to a wide range of users. The era of mass additive manufacturing has already arrived, and every home can now house a real desktop factory.

You can buy a 3D printer capable of printing small models and prototyping of medium complexity today at the price of an entry-level laptop. The price of PLA or ABS plastic, which acts as a consumable, also no longer seems exorbitant. In a word, if you have long dreamed of getting to know the world of 3D printing and joining the ranks of makers, the right moment has come!

To save you time and make it easier to select equipment, we have collected in one section all desktop 3D printers optimized for home and office use. These are the real "workhorses" with the perfect balance of functionality, quality and price. Even a beginner can understand the settings, mount and calibrate a 3D printer, and as he gains experience, he will be able to print more and more complex three-dimensional models.