3D printer horse

3d Printed Horse - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

3D printing saves the life of giant Clydesdale horse.

The veterinarian, the stable owner, the farrier, even the researcher from the local university had the best of intentions. They could barely utter the sentence. Their words stung Andrew Allshorn, as they would anyone.

“If you can’t fix her, we’re going to shoot her.” They were referring to Freda, an underweight but still huge Clydesdale with recurring canker, a debilitating foot fungus.

“No pressure,” Allshorn shot back cheekily. He already had a plan almost certain to work. It involved 3D printing, his area of expertise. Allshorn is founder of 3D-Squared, an additive manufacturing consultancy and education provider in Grange-over-Sands, a town in northwest England.

A cure for Freda’s had proven elusive. The vet scraped the fungus from both front hooves, added medication, and bandaged them. But—because she was a horse—Freda would inevitably walk over grass or straw or mulch or mud and pick up moisture from the ground, which caused the canker to grow again.

Andrew Allshorn with Freda, the Clydesdale. Allshorn saved her life by developing 3D printed plates to protect her feet.

Anne Wilson, owner of Larkrigg Riding School, where Freda lives, had already spent $5,000 on treatments and knew she’d soon have to give up. Until her recent troubles, Freda, a gentle giant who stands almost six feet tall, was a familiar site for Larkrigg students. The riding school and stable is located near Allshorn in England’s South Lakeland district of Cumbria.

Freda was in obvious pain when Allshorn met her. She hadn’t been able to move about in so long she was underweight and couldn’t be petted; even that was painful.

More on this topic: Is 3D Printing the Future of Manufacturing?

Allshorn got right to work. With his years of 3D printing experience, he knew immediately that 3D printed shields could protect her feet by sealing them from moisture and reinfection.

He tore up a nearby box, placed the cardboard under both her left and her right foot, and traced around her hooves with a pencil; like tracing your hand in kindergarten.

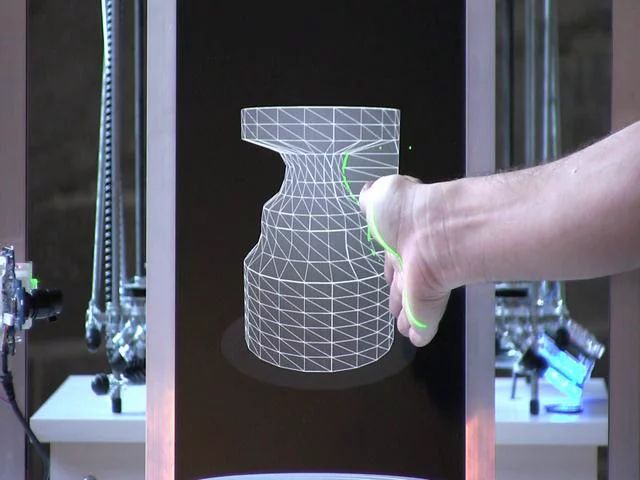

This was no kindergarten project though. Allshorn drew two, crossed lines through the image and took a photograph of it with his smartphone. That way, when he scaled up the image from his phone, he’d have the correct dimensions to import into the SolidWorks computer-aided design software.

“You don’t know if it’s the right size just from your camera, so I needed the two lines on the cardboard for reference points to work from,” he explained.

One of Freda’s foot plates emerges from the 3D printer.

He then customized the shields in his CAD software. For one thing, Allshorn needed to include a piece that could fit over the horse’s frog, which is the roughly triangular front of the hoof. He needed to make that area thicker than the surrounding shoe because the horse puts carries its weight on the front. That area of the shield would need to stand up to the weight of the horse.

He needed to make that area thicker than the surrounding shoe because the horse puts carries its weight on the front. That area of the shield would need to stand up to the weight of the horse.

“You can buy a plate very similar to what I was thinking about,” Allshorn says. “But first, they don’t make them to fit a Clydesdale and, second, they’re solid plastic. We were able to custom design this plate so it was solid in certain and more flexible in others.”

He printed the shield, made from thermoplastic urethane, a type of rubber. That first shield was about 5 millimeters thick, though thickness would vary on future designs.

He also learned an important lesson: just as humans have a left shoe and ta right shoe, so do horses. He’d need to make them differently to fit over the frog of each foot.

Humanitarian Engineering: 3D Printing for Protection

After the farrier had fit Freda with that those first plates, he noted the ways Allshorn could make some welcome changes.

“Around the outside he said needed it more solid infill because that’s where he puts the nail and the nails to hold,” Allshorn says. “I made the inside more flexible so if the horse stood on a stone the shield would give a little and wouldn’t hurt the horse.”

Another modification followed. Allshorn added what could be called little wings to either side of the shield that would help clamp to the horse’s shoe.

“Before, he’d had to align horses foot plate and horse shoe and nail it all at the same time. This gave him a hand,” Allshorn says.

Allshort began the project on November 8, 2021. The farrier told him on the day before Christmas that the solution was working. Freda’s feet were on the mend and weren’t picking up moisture.

On January 24, 2022, the farrier put on the last set of plates (they had regularly been swapped out). Soon after, Freda was home free. Her feet had fully healed and canker would not return.

Editor's Choice: Engineers 3D Print Blood Vessel to Aid Vascular Disease Treatment

Allshorn marvels that his simple solution was just waiting to be discovered by 3D printers or by farriers and veterinarians who know about 3D printing.

Many simple problems could be solved through additive manufacturing, he speculates, though the first step would be reaching out to the 3D printing community with issues like Freda’s. Or, alternately, 3D printers learning about these problems themselves.

“It’s so nice to see Freda out walking, he says. “I’ll pop around and see her. At first she could only walk 100 yards because she’d lost all her muscle mass. Now, one of the young girls is riding her properly.”

He can pet her now.

“She knows who you are know, which is really nice,” Allshorn says.

Though he’s never ridden a horse before, he’ll start taking lessons at the school, riding Freda right from the beginning.

But he’ll have to wait a few weeks to start. He’s getting married soon and his bride-to-be doesn’t want him showing up at the wedding with a twisted ankle.

“I saved a horse’s life. That’s so wild to me,” Allshorn says. “It gives me satisfaction to know I can help horses all over the world.

Jean Thilmany is a writer in Saint Paul, Minn., who writes frequently about engineering and manufacturing.

Making 3D printed horseshoes for horses

In recent years, 3D printing technology has become of great importance in medicine, both in medical equipment and in clinical applications. However, few people know that 3D printing also plays an important role in the treatment of animals.

Vaughan Ellis, founder of Australian company Pegasus Shoeing, a farrier-farmer for 40 years, has applied 3D printing technology to the design and manufacture of innovative nylon and carbon fiber horseshoes. He replaces them with traditional horseshoes.

He replaces them with traditional horseshoes.

The main function of a horseshoe is to protect the hooves and slow down their wear. At the same time, it is used as an adjuvant in horses with sore legs, with some body structure problems. Currently, the general treatment plan is to nail a special horseshoe fitted directly to the hoof.

For example, a very common foot disease in ungulates called "laminitis" is extremely painful and even disabling in horses. There are a large number of horses in the world suffering from this disease. Laminitis affects the tissues of the hoof wall and metacarpal bones, causing the metacarpal bones to drop or rotate under pressure, causing unbearable pain. Horses suffering from laminitis are treated with a heart-shaped horseshoe, but this is very harmful and painful.

To improve the situation and ease the pain of the animals, Vaughan Ellis and his team, in consultation with other farriers, veterinarians and engineers, developed horseshoe-shaped 3D printed clogs.

Designer Zach McIntyre said: “We take x-rays and circumference, take all measurements accurately to ensure a successful recovery from the disease. Then we enter this data into a CAD program, design a suitable model and print it out of carbon fiber nylon material. why nylon fiber was chosen is that it is the only durable material suitable for horses."

Zach McIntyre also noted, “farriers put dental materials under the hooves to protect the metacarpals of horses. Thanks to the 3D printed notches around the clog, fiberglass tape can be used to attach the clog to the hoof. It is painless compared to the traditional method.”

To date, the company has already developed 240 types of standard series of horseshoes, including 5 sets that can be used to treat sick horses. Compared to traditional horseshoes, 3D printed clogs are lighter, more durable, easy to replace and more efficient to manufacture. The method quickly gained popularity, and after the start of production, more than 120 kits were sold.

There is an official convenient Pegasus Shoeing website where customers can get advice and place orders. Recently, company founder Vaughan Ellis has made additional investments in printing equipment, horseshoe design and research to develop and print more innovative 3D hoof care products to help more horses.

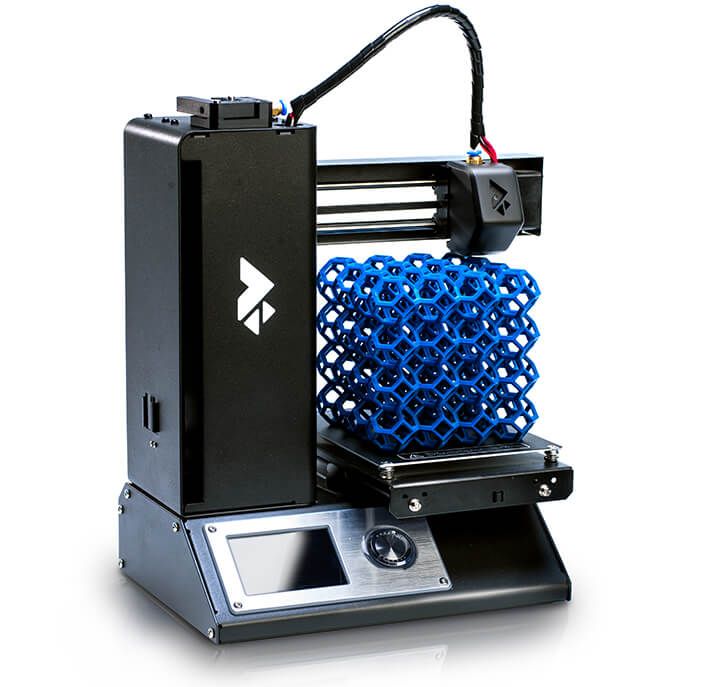

Thus, 3D printing technology contributes to the introduction of new treatment methods. Zack is very pleased with the efficiency and performance of the Flashforge Creator 3. He noted, "Creator 3 can print horseshoe clogs in 10 hours, and it has already printed almost 1,000 hours." In addition to the Creator 3, there are two more Guider 2S to support printing."

By studying the treatment and rehabilitation of horses, Pegasus Shoeing is gradually improving the digital process of making 3 D-printed horseshoes. This forces people to focus on a little-known application.

Flashforge is very pleased with the role 3D printing technology is playing in animal health and will continue to innovate in 3D printing to provide more solutions for all areas of life.

Source: https://www.flashforge.com/news-detail/119

#Application

Share

all materials

Do you have any questions?

Our specialists will help you with the choice of 3D equipment or accessories, consult on any questions.

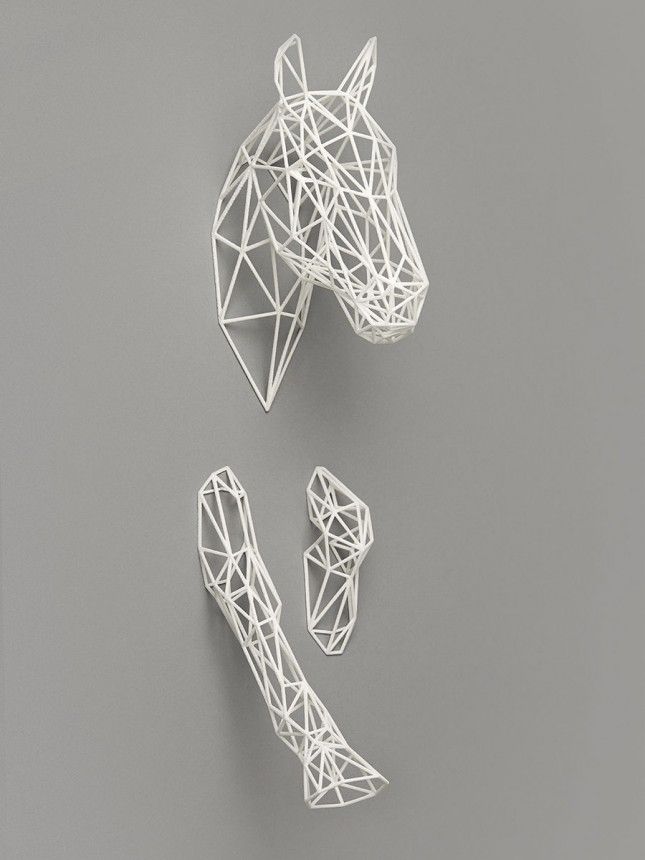

Pre-made STL files for 3D printer

Download and print ready-made STL files for 3D printer. Free and author's decor models for your home and office: figurines, miniature copies of famous art objects and much more in the UBibbl catalog!

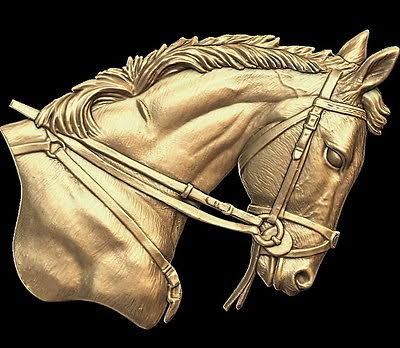

What is sculpture? These are not only smooth lines and regular shapes, but also a huge number of all kinds of small details that can make up a huge composition. Before mankind began to use innovative technologies, every, even the smallest detail, had to be poured in a special form, and then spent a long time on the final transformation of the product. Now, thanks to the STL format, the printer can print a design of absolutely any complexity and size.

How to download STL files for a 3D printer for free and use them

Many sculptors and designers consider additive technologies a real breakthrough in their professional field. One can only imagine how much time it took a designer to build a model of a building or a sculptor to carve an elephant figurine from marble or any other natural stone.

Today, thanks to 3D modeling, the creation of such products consists of several processes, including:

- radiation;

- extrusion;

- jet;

- fusion;

- lamination.

Thus, it is enough to download the STL files for the 3D printer and transfer them to the equipment. When using a printer, an incredible horizon of possibilities opens up for every creative person.

Ready-made STL-files for 3D printer in UBibbl catalog

UBibbl site offers an opportunity to find almost any model for printing in a matter of minutes. Just use the site's library to get acquainted with a wide range of different figurines and figurines that will not only decorate any room, but also become a great gift for a loved one.

Models in STL format can be downloaded for free for a 3D printer without registration. Upload the works you like and after processing with a special slicer program they can immediately go to print. Most of the models presented on the site have been checked by the site team and are ready for production. In addition, on the page of each model you will find a small description, and often tips on printing and preliminary preparation for work.

As for model makers, UBibbl allows all designers who are creative and experienced in 3D modeling to open their own store and showcase their work. You will be able to decide for yourself whether it will be possible to download free STL models for a 3D printer from your store or not. Otherwise, you can provide access to your work only after payment.

The creation of ordinary and primitive figures no longer surprises anyone, but something extraordinary and modern is always interesting and unusual. It is for such authors who feel the potential in themselves and create absolutely unique sculptures, they can quite easily sell them on the site.