Which 3d printer should i buy

The Best Cheap 3D Printers for 2022

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

Original Prusa Mini

Best Overall Budget 3D Printer

4.5 Outstanding

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

PROS

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

CONS

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

| Sold By | List Price | Price | |

|---|---|---|---|

| Prusa Research | $399.00 | $399.00 | See It (Opens in a new window) |

Read Our Original Prusa Mini Review

XYZprinting da Vinci Mini

Best Budget 3D Printer for Schools, Community Centers

4.0 Excellent

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

PROS

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

CONS

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

| Sold By | List Price | Price | |

|---|---|---|---|

| Walmart | $199.95 | $199.95 | See It (Opens in a new window) |

| Amazon | $199.95 | $199.95 | See It (Opens in a new window) |

Read Our XYZprinting da Vinci Mini Review

Toybox 3D Printer

Best Budget 3D Printer for Children

4.0 Excellent

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

Just bear in mind the tiny build area.

PROS

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

CONS

- Tiny build area

- Not ideal for importing 3D files created elsewhere

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.00 | $299.00 | See It (Opens in a new window) |

Read Our Toybox 3D Printer Review

Monoprice Mini Delta V2 3D Printer

Best Budget 3D Printer for Beginners, Non-Techies

4.0 Excellent

Bottom Line:

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

PROS

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

CONS

- Tiny build area

- So-so print quality

- Mere one-year warranty

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $179.99 | $179.99 | See It (Opens in a new window) |

Read Our Monoprice Mini Delta V2 3D Printer Review

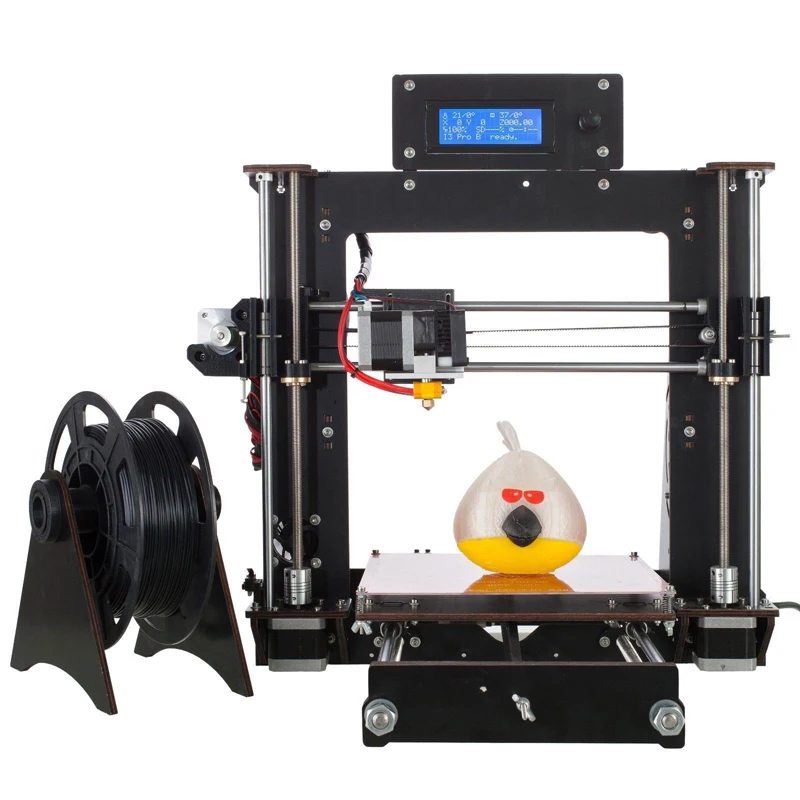

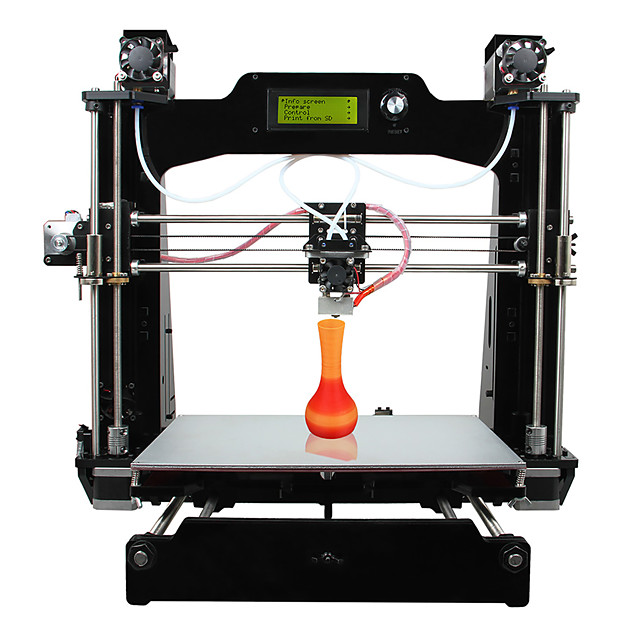

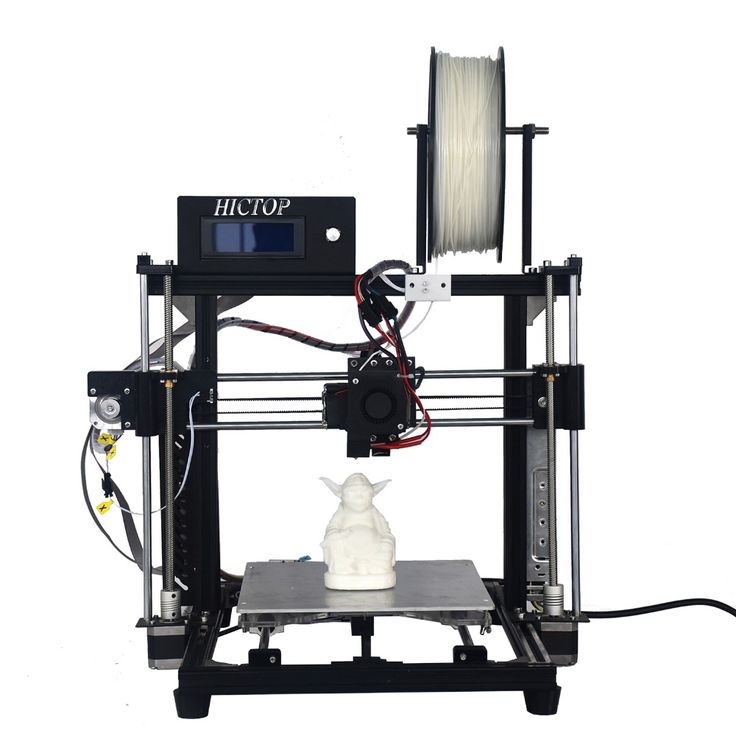

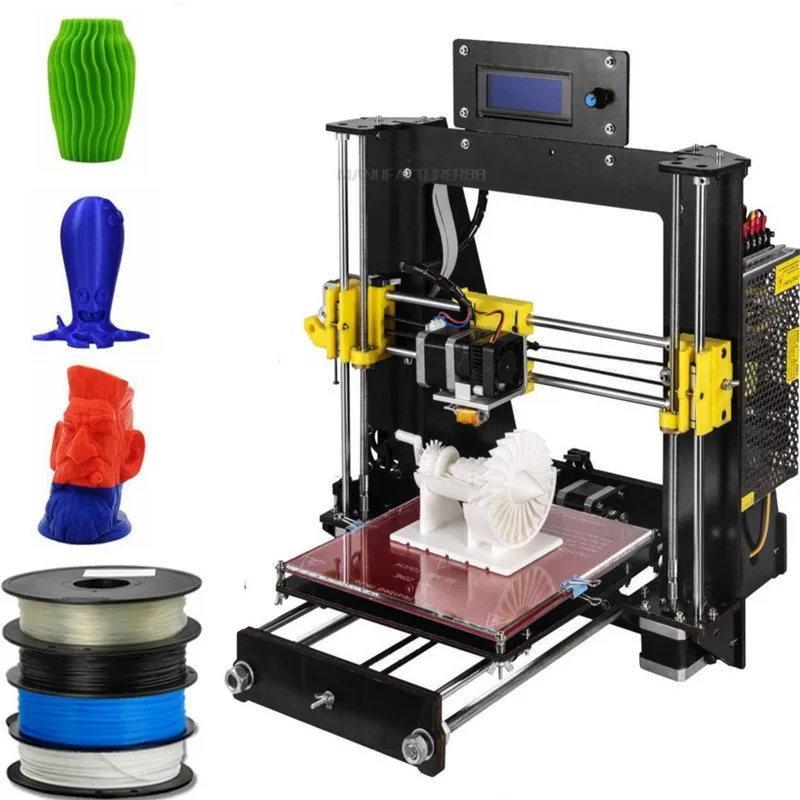

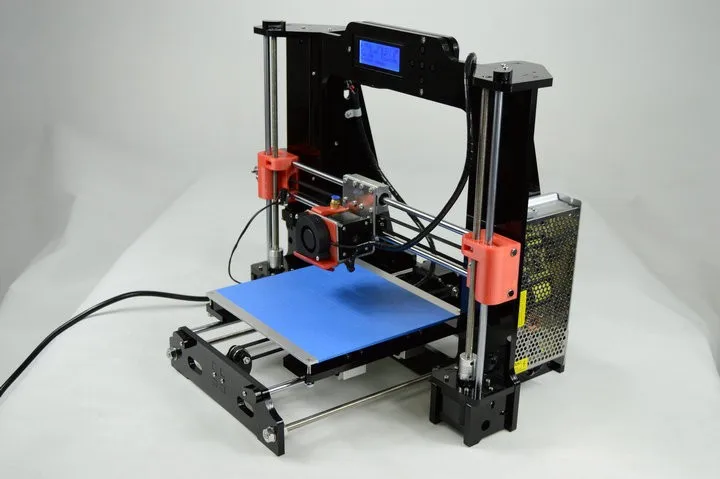

Anycubic i3 Mega S

Best Budget 3D Printer With an Open Design, Big Build Area

3.5 Good

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

PROS

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

CONS

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $229. 98 98 | $229.98 | Check Stock (Opens in a new window) |

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

Best Budget 3D Printer for the Biggest Build Area Possible

3.5 Good

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

PROS

- Relatively large build area

- Automatic bed leveling

- Simple assembly

CONS

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $429. 99 99 | $429.99 | See It (Opens in a new window) |

| AnyCubic | $369.00 | $319.00 | See It (Opens in a new window) |

Read Our Anycubic Vyper Review

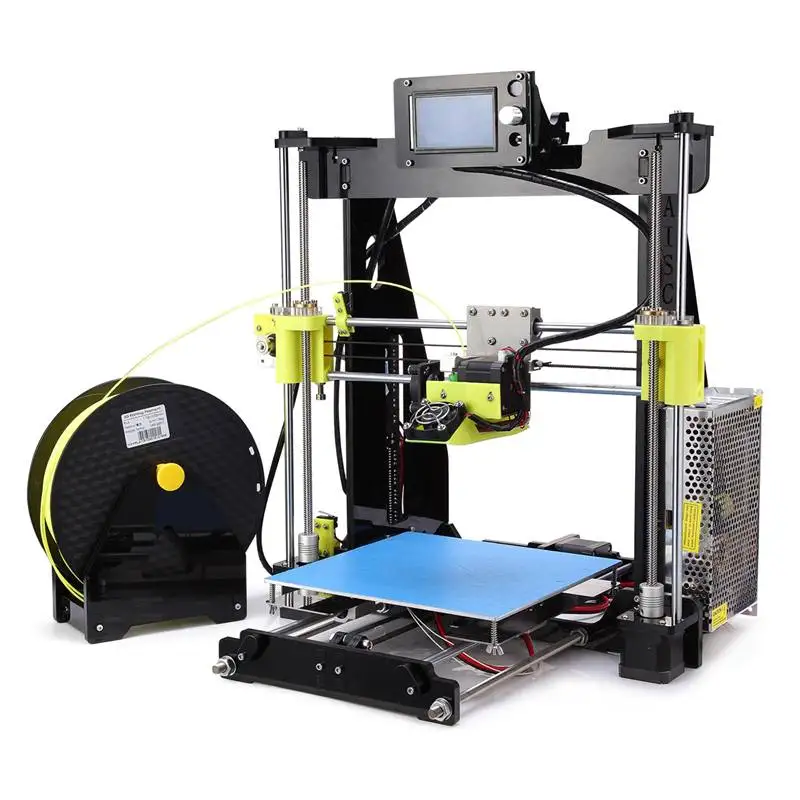

Creality Ender-3 V2

Best Budget 3D Printer for Tinkerers and DIY Types

3.5 Good

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

PROS

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

CONS

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299. 00 00 | $246.00 | See It (Opens in a new window) |

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

Best 3D Printer for the Very Tightest Budgets

3.5 Good

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

PROS

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

CONS

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $729.00 | $729.00 | Check Stock (Opens in a new window) |

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

Best Budget 3D Printer for Dabbling in Small Objects

3. 5 Good

5 Good

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

PROS

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

CONS

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $699.00 | $699.00 | See It (Opens in a new window) |

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

Best Budget 3D Printer With Closed Design, Roomy Build Area

3. 5 Good

5 Good

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

PROS

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

CONS

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.95 | $199.95 | See It (Opens in a new window) |

| Best Buy | $449.95 | $449.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

Best Budget 3D Printer for Cheap Filament

3. 0 Average

0 Average

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

PROS

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

CONS

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $449.99 | $329.46 | See It (Opens in a new window) |

| Walmart | $429.99 | $369.26 | See It (Opens in a new window) |

Read Our Monoprice Voxel 3D Printer Review

Buying Guide: The Best Cheap 3D Printers for 2022

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

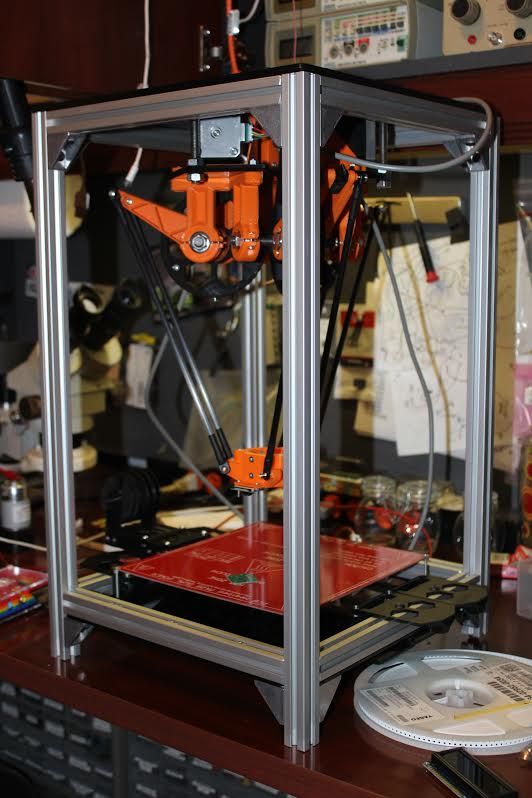

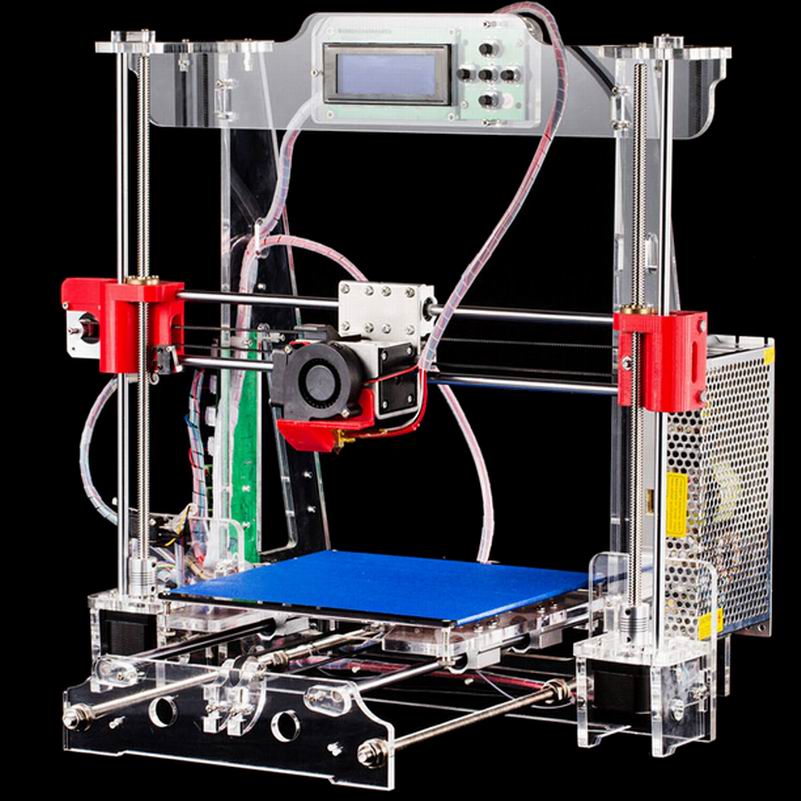

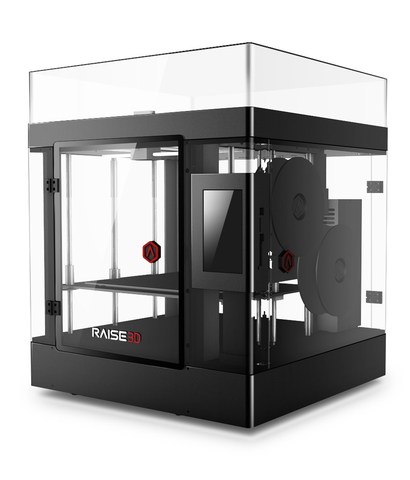

Should I Get an Open-Frame or Closed-Frame 3D Printer?

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

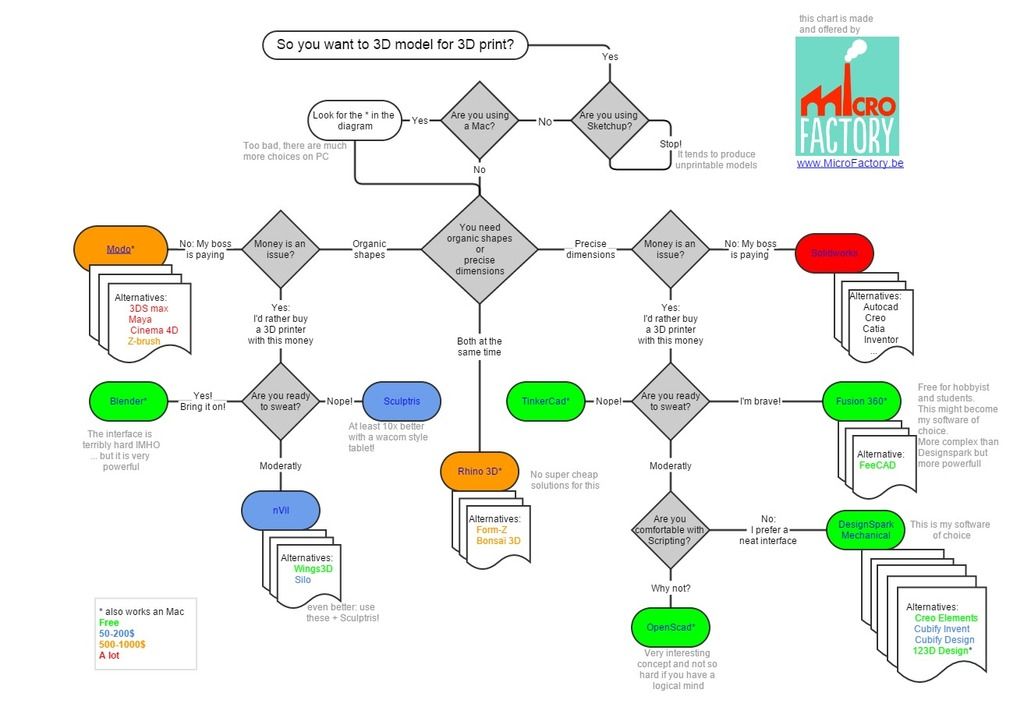

What 3D Printer Should You Buy? A Simple Buying Guide – 3D Printerly

Buying a 3D printer is an important step to getting optimal results and making sure you don’t experience many issues that might stop you from getting into 3D printing with enthusiasm. There are some important factors you’ll want to know before buying a 3D printer, so I decided to write an article about it.

There are some important factors you’ll want to know before buying a 3D printer, so I decided to write an article about it.

What to Look For in 3D Printers – Key Features

- Printing Technology

- Resolution or Quality

- Printing Speed

- Build Plate Size

Printing Technology

There are two main 3D printing technologies that people use:

- FDM (Fused Deposition Modeling)

- SLA (Stereolithography)

FDM (Fused Deposition Modeling)

The most popular 3D printing technology today is FDM 3D printing. It’s very suitable for beginners, up to experts for creating 3D prints. When you are choosing a 3D printer most people will start with an FDM 3D printer, then decide to branch out with more experience.

This is personally how I got into the 3D printing field, with the Ender 3 (Amazon), priced at around $200.

The best thing about FDM 3D printers is the cheaper cost, ease of use, larger build size for models, wide range of materials to use, and overall durability.

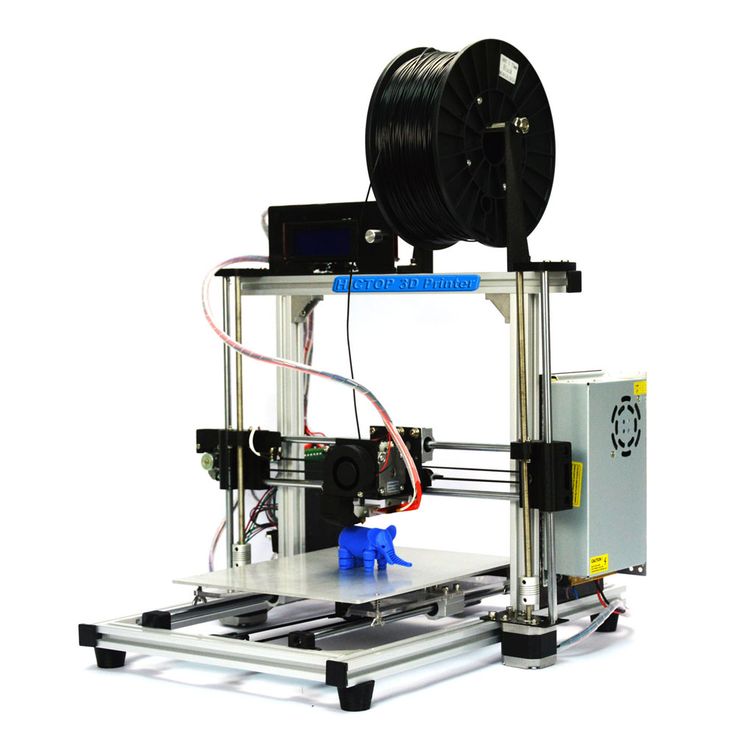

It works mainly with a spool or roll of plastic which gets pushed through an extrusion system, down into a hotend that melts the plastic through a nozzle (0.4mm standard), and gets placed down onto a build surface, layer by layer to form your 3D printed model.

It does require some basic knowledge to get things right, but as things have developed, it’s very easy to set an FDM 3D printer up and get some models 3D printed within the hour.

SLA (Stereolithography)

The second most popular 3D printing technology is SLA 3D printing. Beginners can still start with this, but it will be a little more challenging than FDM 3D printers.

This 3D printing technology works with a photosensitive liquid called resin. In other words, it’s a liquid that reacts and hardens to a certain wavelength of light. A popular SLA 3D printer would be something like the Elegoo Mars 2 Pro (Amazon), or the Anycubic Photon Mono, both around $300.

The best thing about SLA 3D printers is the high quality/resolution, speed of printing multiple models, and ability to make unique models that manufacturing methods can’t produce.

It works with a vat of resin placed on the main machine, which sits on top of an LCD screen. The screen shines a UV light beam (405nm wavelength) in specific patterns to produce a layer of hardened resin.

This hardened resin sticks to a plastic film at the bottom of the resin vat, and peels off onto a build plate above due to the suction force from the build plate lowering down into the resin vat.

It does this layer-by-layer until your 3D model has completed, similar to FDM 3D printers, but it creates models upside down.

You can create really high quality models with this technology. This type of 3D printing is growing quickly, with many 3D printer manufacturers starting to build resin 3D printers for cheaper, with higher quality and more durable features.

Working with this technology is known to be more difficult as compared to FDM because it requires more post-processing to finish off 3D models.

It’s also known to be quite messy since it works with liquids and plastic sheets which can sometimes pierce and leak if a mistake is made with not cleaning out the resin vat properly. It used to be more expensive to work with resin 3D printers, but the prices are starting to match up.

It used to be more expensive to work with resin 3D printers, but the prices are starting to match up.

Resolution or Quality

The resolution or quality that your 3D printer can reach is usually limited to a level, detailed in the 3D printer’s specifications. It’s common to see 3D printers that can reach a 0.1mm, 0.05mm, down to 0.01mm.

The lower the number, the higher the resolution since it refers to the height of each layer the 3D printers will produce. Think of it like a staircase for your models. Each model is a series of steps, so the smaller the steps, the more details you’ll see in the model and vice versa.

When it comes to resolution/quality, SLA 3D printing that uses the photopolymer resin can get much higher resolutions. These resin 3D printers usually start off with a resolution of 0.05mm or 50 microns, and reach up to either 0.025mm (25 microns) or 0.01mm (10 microns.

For FDM 3D printers that use filament, you’ll usually see resolutions of 0.1mm or 100 microns, down to 0. 05mm or 50 microns. Although the resolution is the same, I find that resin 3D printers that use 0.05mm layer heights produce better quality than filament 3D printers that use the same layer height.

05mm or 50 microns. Although the resolution is the same, I find that resin 3D printers that use 0.05mm layer heights produce better quality than filament 3D printers that use the same layer height.

This is because of the method of extrusion for filament 3D printers have a lot more movements and weight that reflect imperfections on the models. Another factor is with the small nozzle where the filament comes out from.

It can get slightly clogged or not melt fast enough, leading to small blemishes.

But don’t get me wrong, filament 3D printers can produce really high quality models when calibrated and optimized properly, quite comparable to SLA 3D prints. 3D printers from Prusa & Ultimaker are known to be very high quality for FDM, but costly.

Printing Speed

There are differences in printing speed between 3D printers and 3D printing technologies. When you look at the specifications of a 3D printer, they will usually detail a specific printing speed maximum and an average speed that they recommend.

We can see a key difference of printing speeds between FDM and SLA 3D printers due to the way they create 3D models. FDM 3D printers are great for creating models with a lot of height and lower quality models quickly.

The way SLA 3D printers work, their speed is actually determined by the height of the model, even if you use the whole build plate.

This means that if you have one small model that you want to replicate many times, you can create as many as you can fit on the build plate, at the same time that you can create one.

FDM 3D printers don’t have this same luxury, so the speed would be slower in that case. For models like a vase, and other tall models, FDM works very well.

You can even change your nozzle diameter for a larger one (1mm+ vs 0.4mm standard) and create 3D prints a lot quicker, but at the sacrifice of quality.

An FDM 3D printer like the Ender 3 has a maximum printing speed of around 200mm/s of extruded material, which would create a much lower quality 3D print. . An SLA 3D printer like the Elegoo Mars 2 Pro has a printing speed of 30-50mm/h, in terms of height.

. An SLA 3D printer like the Elegoo Mars 2 Pro has a printing speed of 30-50mm/h, in terms of height.

Build Plate Size

The size of the build plate for your 3D printer is important, depending on what your project goals are. If you are looking to do some basic models as a hobbyist and don’t have specific projects, then a standard build plate should work well.

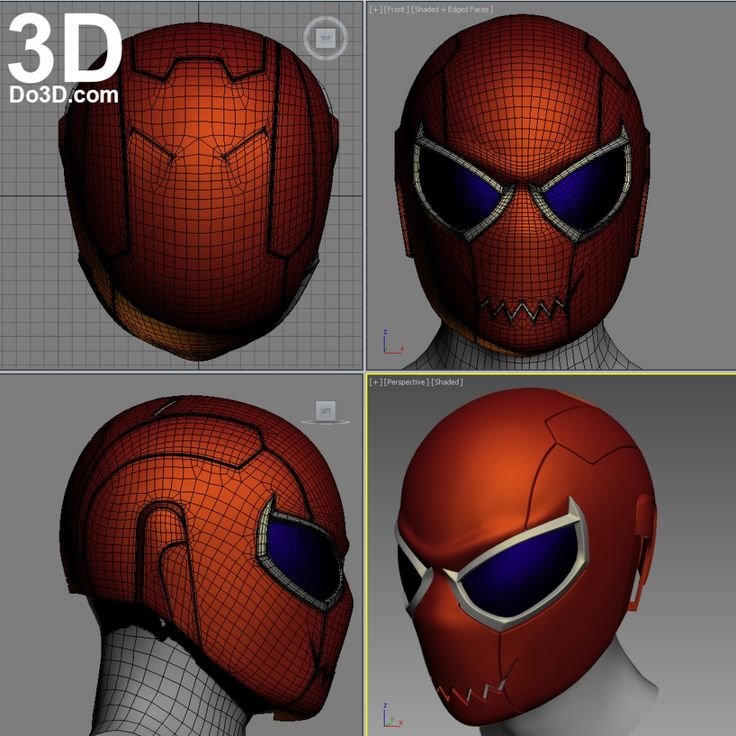

If you plan to do something like cosplay, where you’re creating outfits, helmets, weapons like swords and axes, you’ll want a larger build plate.

FDM 3D printers are known to have a significantly larger build volume compared to SLA 3D printers. An example of a common build plate size for FDM 3D printers would be the Ender 3 with a 235 x 235 x 250mm build volume.

A common build plate size for an SLA 3D printer would be the Elegoo Mars 2 Pro with a build volume of 192 x 80 x 160mm, at a similar price. Larger build volumes are possible with SLA 3D printers, but these can get pricey, and harder to operate.

A larger build plate in 3D printing can save you a lot of time and money in the long run if you are looking to 3D print large objects. It’s possible to 3D print objects on a smaller build plate and stick them together, but that can be tedious.

Below is the list of some essential things to consider whether you are buying an FDM or SLA 3D printer.

How to Choose a 3D Printer to Buy

As mentioned in the previous section, there are a couple of different 3D printing technologies and you need to first decide on whether you are going to buy an FDM or an SLA 3D printer.

Once this has been sorted, it’s time to look for the features that should be in your desired 3D printer to perform your task efficiently and get 3D models of your desires.

Below are the major features according to the 3D printing technologies you are going with. Let’s start from FDM and then move on to SLA.

Key Features to Look For in FDM 3D Printers

- Bowden or Direct Drive Extruder

- Build Plate Material

- Control Screen

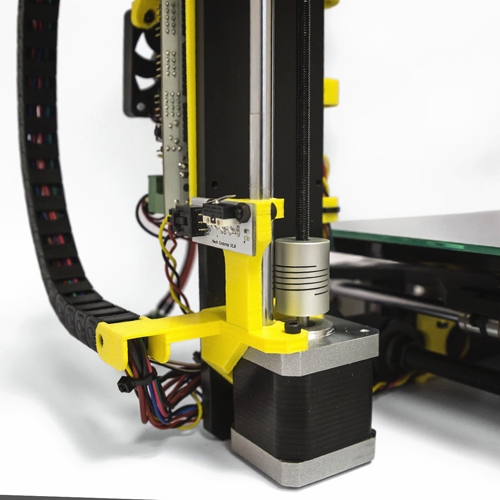

Bowden or Direct Drive Extruder

There are two main types of extruders with 3D printers, Bowden or Direct Drive. They can both produce 3D models to a great standard but there are a few differences between the two.

They can both produce 3D models to a great standard but there are a few differences between the two.

A Bowden extruder will be more than enough if you are going to print 3D models using standard FDM printing materials while requiring a high level of speed and accuracy in details.

- Faster

- Lighter

- High Precision

You should go for a direct drive extruder setup if you have plans to print abrasive and tough filaments on your 3D printers.

- Better retraction and extrusion

- Suitable for a wide range of filaments

- Small size motors

- Easier to change filament

Build Plate Material

There are a range of build plate materials that 3D printers use in order for filament to adhere to the surface nicely. Some of the most common build plate materials are tempered or borosilicate glass, a magnetic flex surface, and PEI.

It’s a good idea to choose a 3D printer with a build surface that works well with the filament you’ll be using.

They all are usually good in their own ways, but I think PEI build surfaces work the best with a range of materials. You can always choose to upgrade your existing 3D printer bed by purchasing the new bed surface and attaching it to your 3D printer.

Most 3D printers won’t have this advanced surface, but I’d recommend getting the HICTOP Flexible Steel Platform with PEI Surface from Amazon.

Another option you have is to simply apply an external printing surface like Blue Painter’s Tape or Kapton Tape across your build surface. This is a great way to improve adhesion of the filament so your first layer sticks well.

Control Screen

The control screen is fairly important for having a good control over your 3D prints. You can either get a touch screen or a screen with a separate dial to scroll through options. They both work pretty well, but having a touch screen makes things a little easier.

Another thing about the control screen is the firmware of the 3D printer. Some 3D printers will improve the amount of control and options you can access, so ensuring you have a fairly modern firmware can make things easier.

Key Features to Look For in SLA 3D Printers

- Type of Printing Screen

- Build Plate Size

Type of Printing Screen

For resin or SLA 3D printers, there are a few types of printing screens that you can get. They make a significant different on the level of quality you can get in your 3D prints, as well as how long your 3D prints will take, based on the UV light strength.

There are two factors you want to look into.

Monochrome Vs RGB Screen

Monochrome screens are the better option because they provide a stronger UV light, so the exposure times that are required for each layer are significantly shorter (2 seconds vs 6 seconds+).

They also have a longer durability and can last around 2,000 hours, versus RGB screens which last for around 500 hours of 3D printing.

Check out the video below for a full explanation on the differences.

2K Vs 4K

There are two main screen resolutions with resin 3D printers, a 2K screen and a 4K screen. There is a pretty significant different between the two when it comes to the final quality of your 3D printed part. They are both in the monochrome screen category, but provide a further option to choose from.

I’d highly recommend going with a 4K monochrome screen if you want the best quality, but if you are balancing out the price of your model and don’t need anything too high quality, a 2K screen can work just fine.

Do keep in mind, the main measure to look at is the XY and Z resolution. A larger build plate size will require more pixels, so a 2K and a 4K 3D printer could still produce similar quality.

A larger build plate size will require more pixels, so a 2K and a 4K 3D printer could still produce similar quality.

When you have a higher XY & Z resolution (lower number is higher resolution), then you can produce higher quality 3D models.

Check out the video below by Uncle Jessy detailing the difference between a 2K and a 4K monochrome screen.

Build Plate Size

The build plate size in resin 3D printers were always known to be smaller than filament 3D printers, but they are definitely getting bigger as time goes on. You want to identify what kind of projects and goals you might have for your resin 3D printer and select a build plate size based on that.

If you are only 3D printing miniatures for tabletop gaming like D&D, a smaller build plate size can still work well. A larger build plate would be the optimal option since you could fit more miniatures on the build plate at a time though.

A larger build plate would be the optimal option since you could fit more miniatures on the build plate at a time though.

A standard build plate size for something like the Elegoo Mars 2 Pro is 129 x 80 x 160mm, while a larger 3D printer like the Anycubic Photon Mono X has a build plate size of 192 x 120 x 245mm, comparable to a small FDM 3D printer.

What 3D Printer Should You Buy?

- For a solid FDM 3D printer, I’d recommend getting something like the modern Ender 3 S1.

- For a solid SLA 3D printer, I’d recommend getting something like the Elegoo Mars 2 Pro.

- If you want a more premium FDM 3D printer, I’d go with the Prusa i3 MK3S+.

- If you want a more premium SLA 3D printer, I’d go with the Elegoo Saturn.

Let’s go through the two standard options for an FDM & SLA 3D printer.

Creality Ender 3 S1

The Ender 3 series is very well known for its popularity and high quality output. They’ve created the Ender 3 S1 which is a version that incorporates many desired upgrades from users. I have one of these myself and it performs very well right out the box.

I have one of these myself and it performs very well right out the box.

The assembly is simple, the operation is easy, and the print quality is excellent.

Features of the Ender 3 S1

- Dual Gear Direct Drive Extruder

- CR-Touch Automatic Bed Leveling

- High Precision Dual Z-Axis

- 32-Bit Silent Mainboard

- Quick 6-Step Assembling – 96% Pre-Installed

- PC Spring Steel Print Sheet

- 4.3-Inch LCD Screen

- Filament Runout Sensor

- Power Loss Print Recovery

- XY Knob Belt Tensioners

- International Certification & Quality Assurance

Specifications of the Ender 3 S1

- Build Size: 220 x 220 x 270mm

- Supported Filament: PLA/ABS/PETG/TPU

- Max. Printing Speed: 150mm/s

- Extruder Type: “Sprite” Direct Extruder

- Display Screen: 4.3-Inch Color Screen

- Layer Resolution: 0.05 – 0.35mm

- Max. Nozzle Temperature: 260°C

- Max.

Heatbed Temperature: 100°C

Heatbed Temperature: 100°C - Printing Platform: PC Spring Steel Sheet

Pros of the Ender 3 S1

- Print quality is fantastic for FDM printing from the first print without tuning, with a 0.05mm maximum resolution.

- Assembly is very quick compared to most 3D printers, only requiring 6 steps

- Leveling is automatic which makes operation a lot easier to handle

- Has compatibility with many filaments including flexibles due to the direct drive extruder

- Belt tensioning is made easier with the tensioner knobs for the X & Y axis

- The integrated toolbox clears up space by allowing you to keep your tools within the 3D printer

- Dual Z-axis with the connected belt increases stability for better print quality

Cons of the Ender 3 S1

- Doesn’t have a touchscreen display, but it’s still really easy to operate

- The fan duct blocks the front view of the printing process, so you’ll have to look at the nozzle from the sides.

- The cable at the back of the bed has a long rubber guard which gives it less space for bed clearance

- Doesn’t let you mute the beeping sound for the display screen

Get yourself the Creality Ender 3 S1 from Amazon for your 3D printing projects.

Elegoo Mars 2 Pro

The Elegoo Mars 2 Pro is a respected SLA 3D printer in the community, known for its reliability and great printing quality. Although it’s a 2K 3D printer, the XY resolution is at a respectable 0.05mm or 50 microns.

I also have an Elegoo Mars 2 Pro and it has been working very well since I started using it. Models always stick securely to the build plate and you don’t need to re-level the machine. The quality output is really good, though it’s not the largest build plate size.

Features of the Elegoo Mars 2 Pro

- 6.08″ 2K Monochrome LCD

- CNC-Machined Aluminum Body

- Sanded Aluminum Build Plate

- Light & Compact Resin Vat

- Built-In Active Carbon

- COB UV LED Light Source

- ChiTuBox Slicer

- Multi-Language Interface

Specifications of the Elegoo Mars 2 Pro

- Layer Thickness: 0.

01-0.2mm

01-0.2mm - Printing Speed: 30-50mm/h

- Z Axis Positioning Accuracy: 0.00125mm

- XY Resolution: 0.05mm (1620 x 2560)

- Build Volume: 129 x 80 x 160mm

- Operation: 3.5-Inch Touch Screen

- Printer Dimensions: 200 x 200 x 410mm

Pros of the Elegoo Mars 2 Pro

- Offers high-resolution prints

- Cures a single layer at an average speed of just 2.5 seconds

- Satisfactory build area

- High level of precision, quality, and accuracy

- Easy to operate

- Integrated filtration system

- Minimum maintenance required

- Durability and Longevity

Cons of the Elegoo Mars 2 Pro

- Side-mounted resin vat

- Noisy fans

- No protective sheet or glass on the LCD screen

- Less pixel density as compared to its simple Mars and Pro versions

You can get yourself the Elegoo Mars 2 Pro from Amazon today.

Which 3D printer to choose for home and hobby use

A few years ago, 3D printers were bulky industrial machines, but now 3D printing is becoming more accessible for home use. When buying their first printer, many are disappointed. This may be due to the unsatisfactory quality of the resulting models or the complex setup and maintenance of the 3D printer.

When buying their first printer, many are disappointed. This may be due to the unsatisfactory quality of the resulting models or the complex setup and maintenance of the 3D printer.

In the reviews that are found on the Internet, printers are often shown after a lot of upgrades or a long selection of settings for printing. This is not at all the result that a beginner who first got acquainted with 3D printing will get.

In order not to be disappointed, before buying, you need to understand which model is suitable for your tasks. First of all, it is worth deciding what the printer will be used for. What is the main property that finished products should have? What is more important, the physical properties of the model or the ideal surface and detail? Not only the model depends on this, but also the technology by which the 3D printer will work.

Which technology to choose? FDM or LCD?

If you need to make a small detailed figurine with a perfectly smooth surface, you should pay attention to models that work on LCD technology (LCD works on a principle similar to DLP - Digital Light Processing or “digital light processing”).

LCD prints using a photopolymer resin that cures under UV light. This makes it possible to produce without deformation, even small and thin products that cannot be manufactured using FDM technology.

Resin model

Now on sale there are many photopolymer resins with different properties. A few years ago the choice was not great. Basically, finished products were not strong enough for use in functional models. Now engineering resins have begun to appear on sale. Products from them are not inferior in strength to models made using FDM technology from ABS or even nylon.

If it is necessary to manufacture large products with different properties, or the tasks will be very diverse, then the choice is with FDM technology. But it is important to understand that finished products will not have a perfectly smooth surface. Of course, you can polish the model, but this is additional time and labor costs.

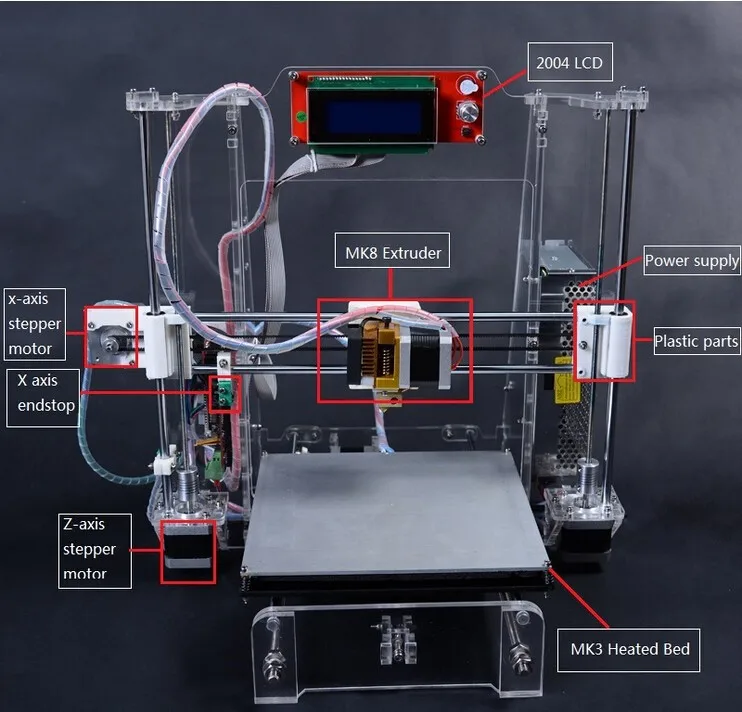

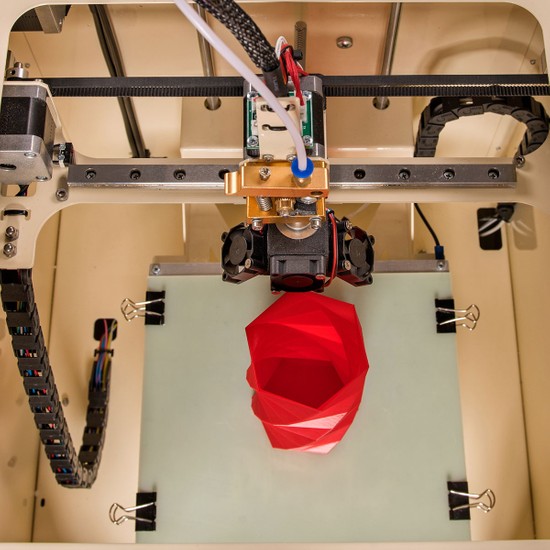

FDM technology builds a model using molten plastic filament, which is fed from the print head. The print head (extruder) “grows” the model layer by layer on the printing table.

The print head (extruder) “grows” the model layer by layer on the printing table.

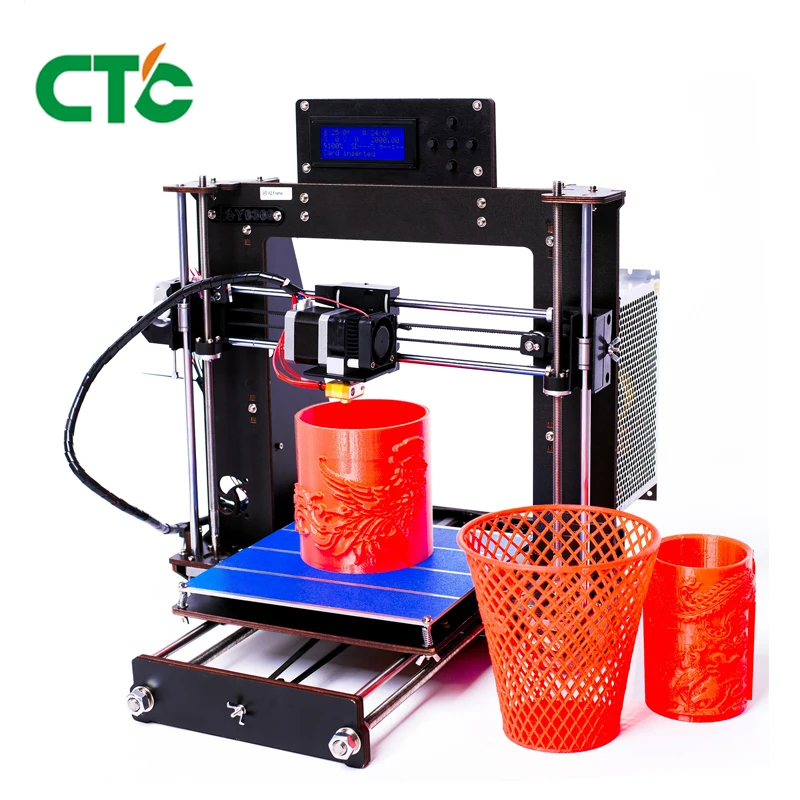

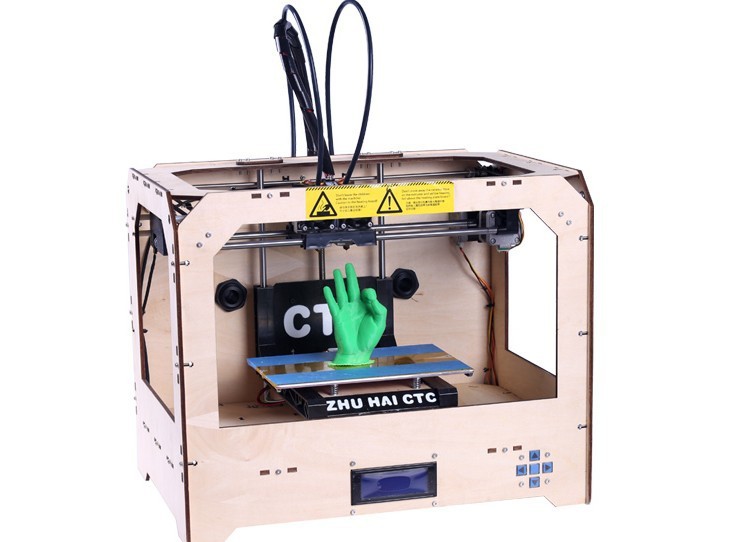

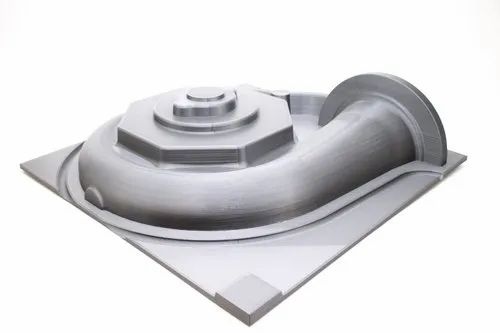

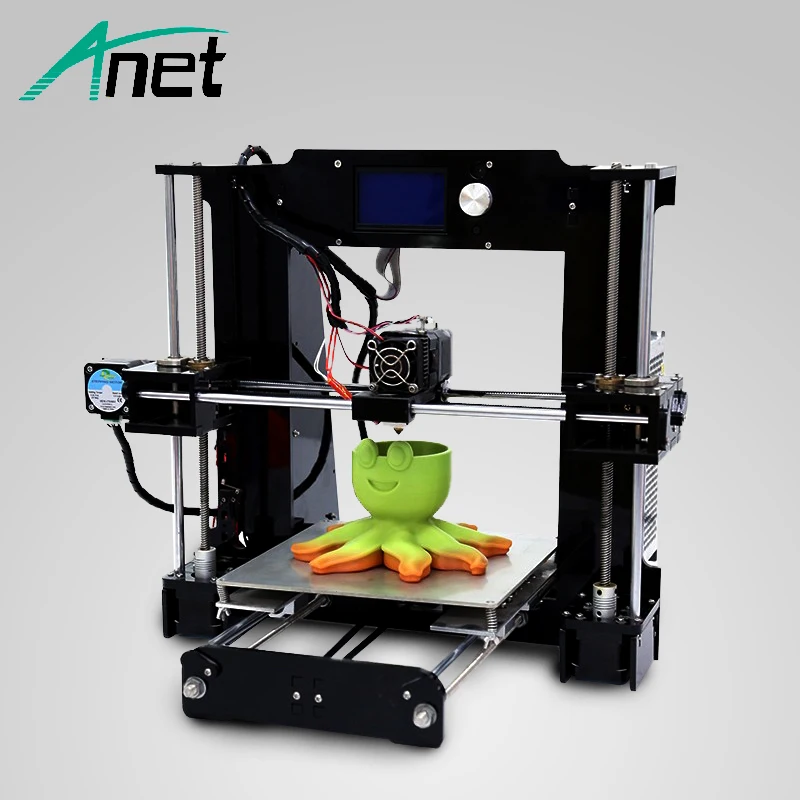

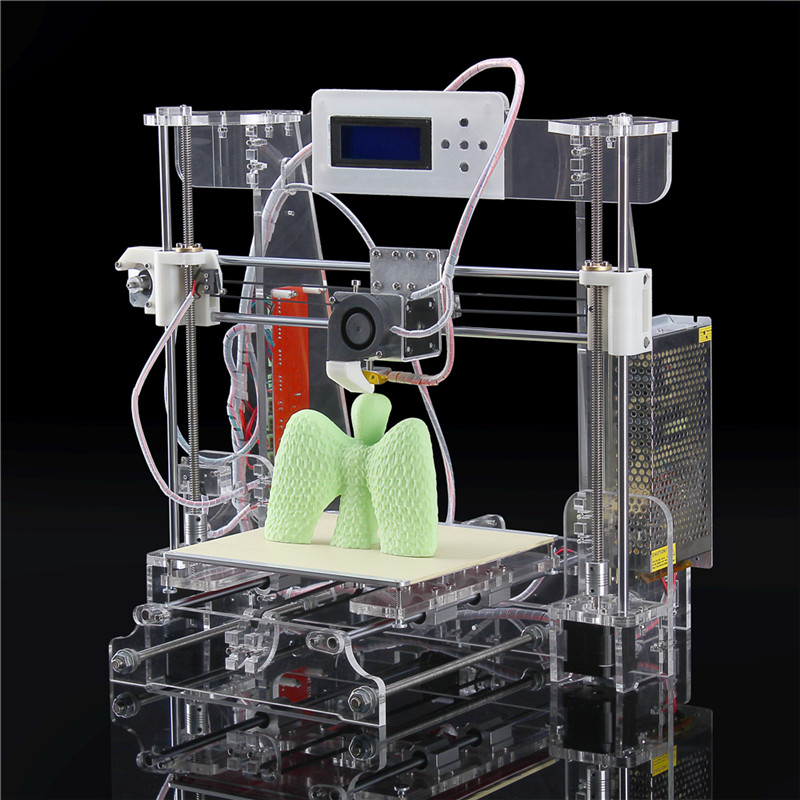

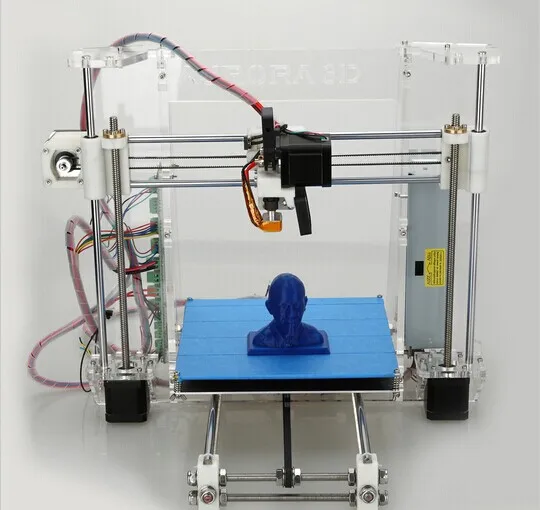

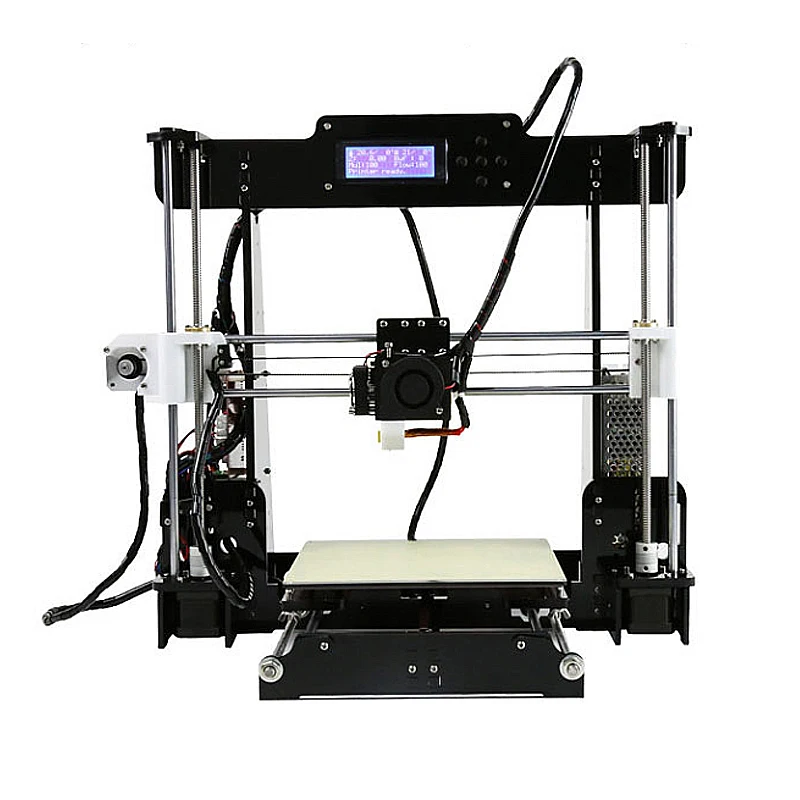

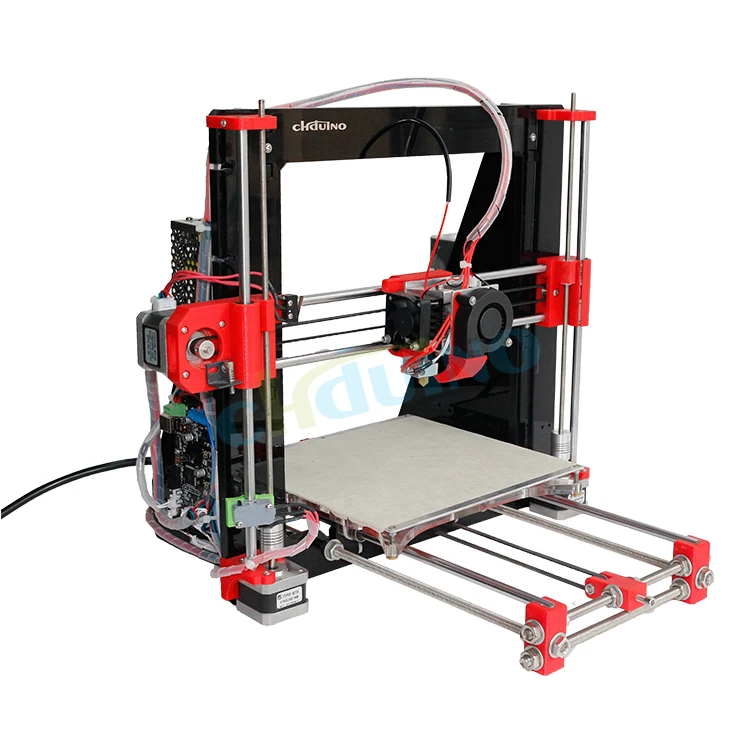

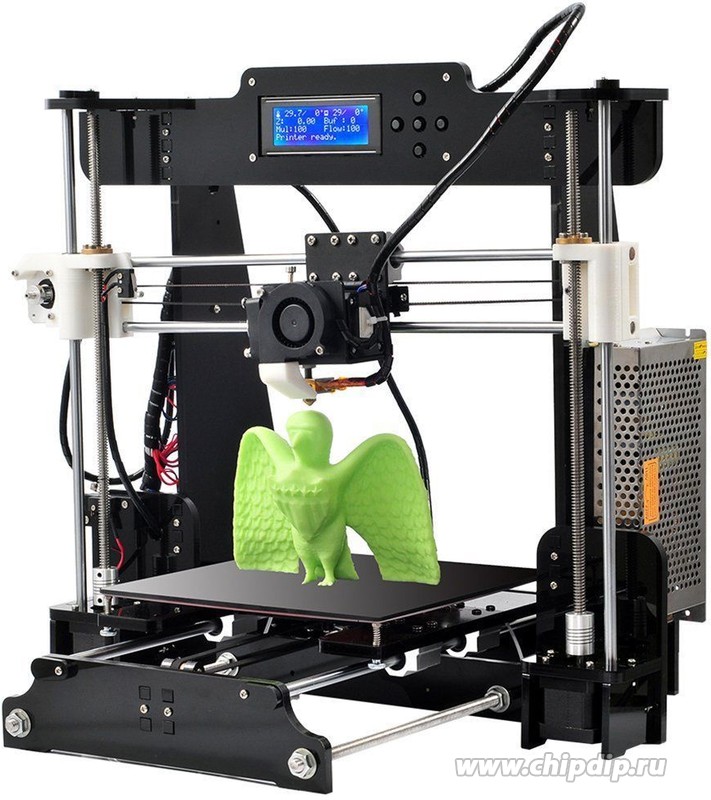

FDM Models

FDM technology became widespread much earlier than DLP. Thanks to this, a wide variety of 3D printers and consumables for them has appeared. You can find many decorative plastics that mimic various materials, or engineering plastics for making functional models or mock-ups.

Choosing an LCD printer

Photopolymer printers work on one of 3 technologies - DLP, LCD or SLA.

As home printers, devices based on LCD technology are usually used due to their availability and low price.

Printer design

SLA technology appeared the very first among photopolymer printers. With the help of a point-focused beam, the desired areas of the resin are gradually illuminated. This is repeated layer by layer.

How SLA 9 works0018

Since the surface of the model is perfectly smooth, SLA has become used in the jewelry and dental industries.

Pros:

Cons:

DLP technology appeared later than SLA, but it is very similar to it. The main difference is that the light source is not a focused beam, but a projector. This made it possible to illuminate the entire layer at once, which significantly accelerated the production of models. The quality of the surface was slightly inferior to SLA, but modern DLP printers, in terms of the quality of models, are almost as good as SLA technology.

How DLP works

Pros:

-

Faster production of models due to the illumination of the entire layer

-

Consumables are slightly cheaper than SLA

-

High surface quality (although may be inferior to SLA)

Cons:

LCD technology is the youngest of all. The DLP principle is taken as a basis, but an LCD display is used as a matrix or illumination pattern. LEDs are used as a source of UV light in LCD technology. Thanks to inexpensive components, we managed to get a simple, but high-quality and affordable photopolymer printer.

LEDs are used as a source of UV light in LCD technology. Thanks to inexpensive components, we managed to get a simple, but high-quality and affordable photopolymer printer.

How the LCD printer works

Pros:

-

small cost

-

Cheap parts

Cons:

-

Low accuracy compared to SLA and DLP (for jewelers and dentists, the quality of LSD prints may not be enough, although more and more accurate models appear with the development of technology)

-

Possible stray light

-

The quality of models may decrease at the edges of the printable area (this can be corrected programmatically)

Resins that are used as a consumable for photopolymer printing can smell strongly and unpleasantly during operation. Try to use the printer in a well-ventilated area, or choose a printer with a sealed cabinet and filter.

When choosing an LCD printer, pay special attention to the rigidity and positioning accuracy of the platform along the Z axis. If there are poor quality guides along the Z axis or even a slight play, then the surface quality of the finished model may turn out to be sloppy or the model will turn out to be unevenly striped.

Rating of the best LCD 3D printers for home

Anycubic Photon Mono

This is an LCD printer with a matrix that allows you to increase the speed and accuracy of printing. Anycubic Photon Mono will be a good helper for hobbyists and modellers.

Anycubic Photon Mono SE

Anycubic Photon Mono SE has an unusual parallel light source. This minimizes distortion at the edges of the printable area. You can effectively use the entire working area of the machine and produce many small models at a time.

Phrozen Sonic Mini 4K

Model with high resolution LCD display and large print area. The monochrome display transmits UV rays better and allows you to print much faster than similar devices with a conventional display. The manufacturer claims a screen life of more than 2000 hours. Phrozen Sonic mini 4k is suitable for almost any task.

The monochrome display transmits UV rays better and allows you to print much faster than similar devices with a conventional display. The manufacturer claims a screen life of more than 2000 hours. Phrozen Sonic mini 4k is suitable for almost any task.

Wanhao GR1

Wanhao GR1 has high precision and large print area (140x78x200mm). The manufacturer tried to reduce distortion at the edges of the display, this allows you to make the most of the entire work area. High precision and large print area make Wanhao GR1 not only for hobby use, but also for production.

Anycubic Photon Zero

Small and very budgetary LCD device. Its resolution and small working area (total 97x54x150 mm) is enough for printing small miniatures, figurines or small engineering models. Anycubic Photon Zero is a good choice for beginners who want to get into photopolymer printing without spending a lot of money.

Choosing an FDM printer

If you plan to produce large and diverse functional models or experiment, a 3D printer that prints using FDM technology is an excellent choice.

First, decide on the size of the printable area and the properties that the finished model should have. After all, some materials require a closed chamber or good airflow to work.

Some printer models can be “upgraded” in the future. For example, if necessary, purchase spare parts for a closed case, put a nozzle of a different diameter, or change the thermal barrier to an all-metal one. But not all manufacturers provide for the possibility of such upgrades.

Printer design

Despite the same principle of operation, there are several different mechanics, which have their pros and cons.

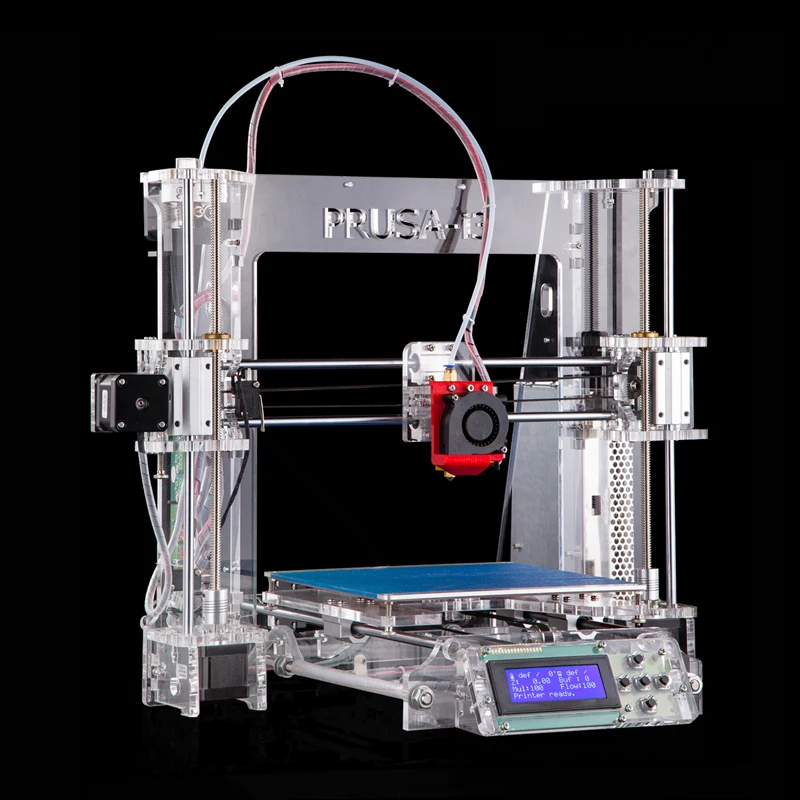

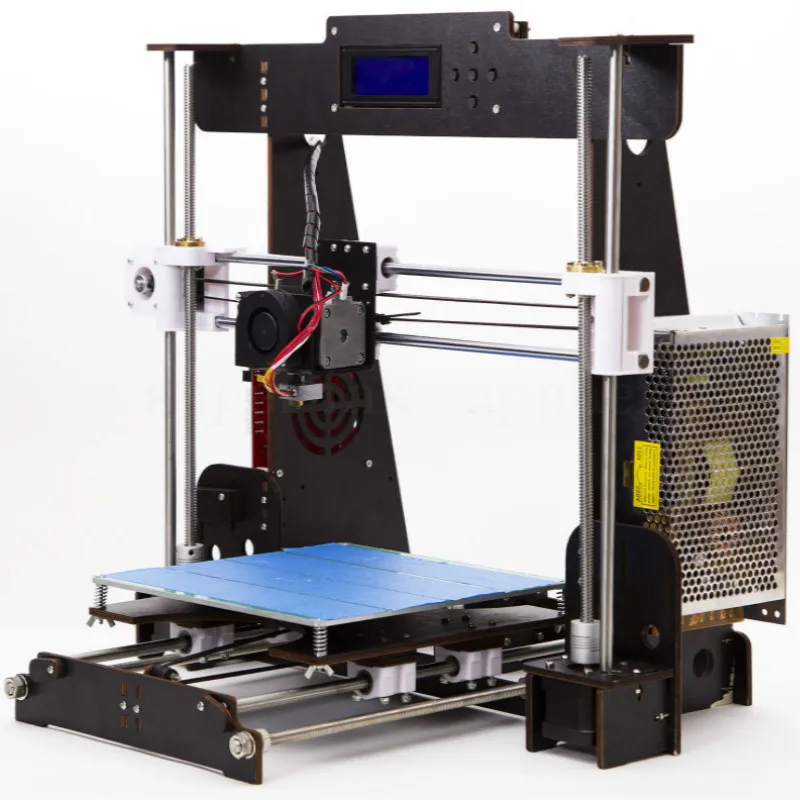

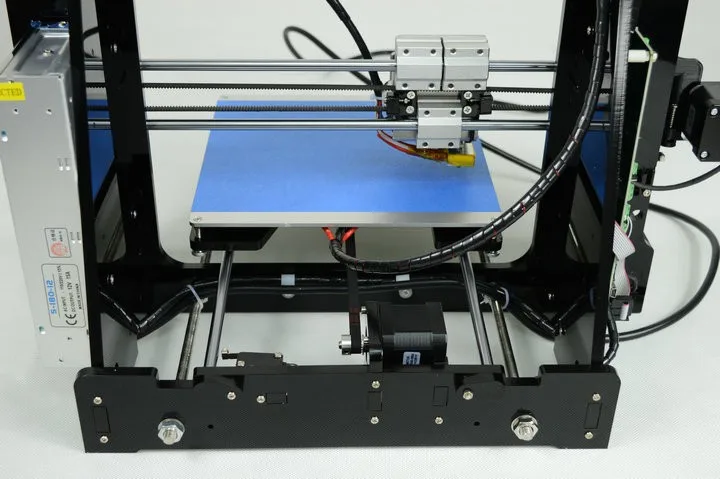

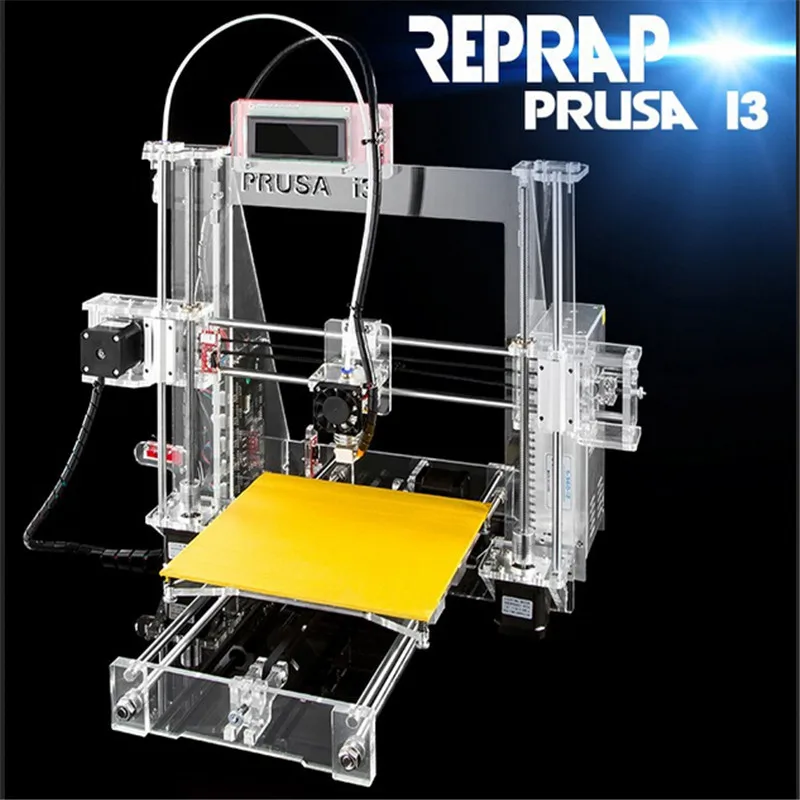

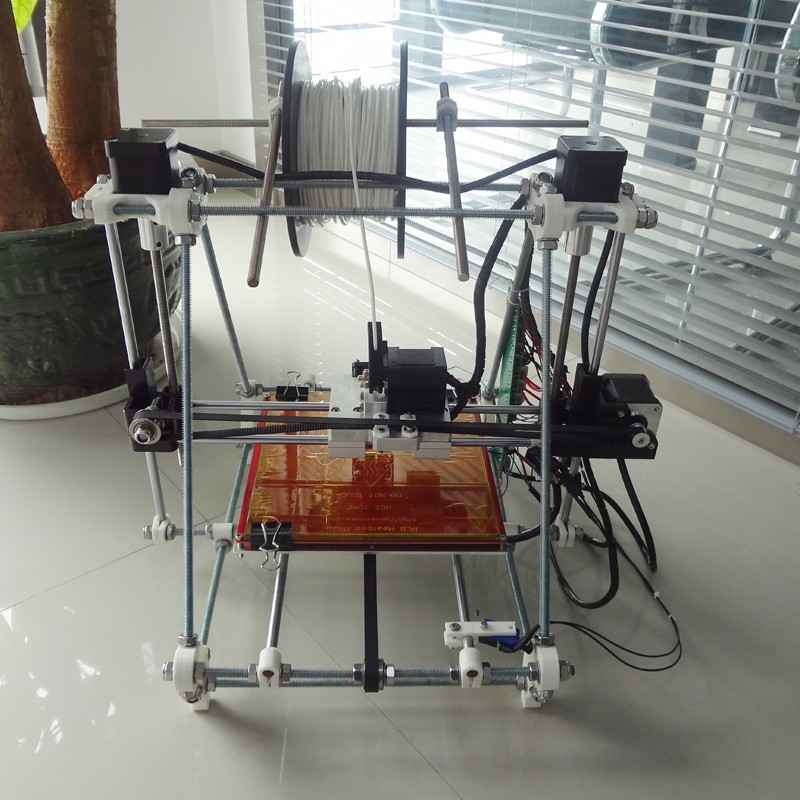

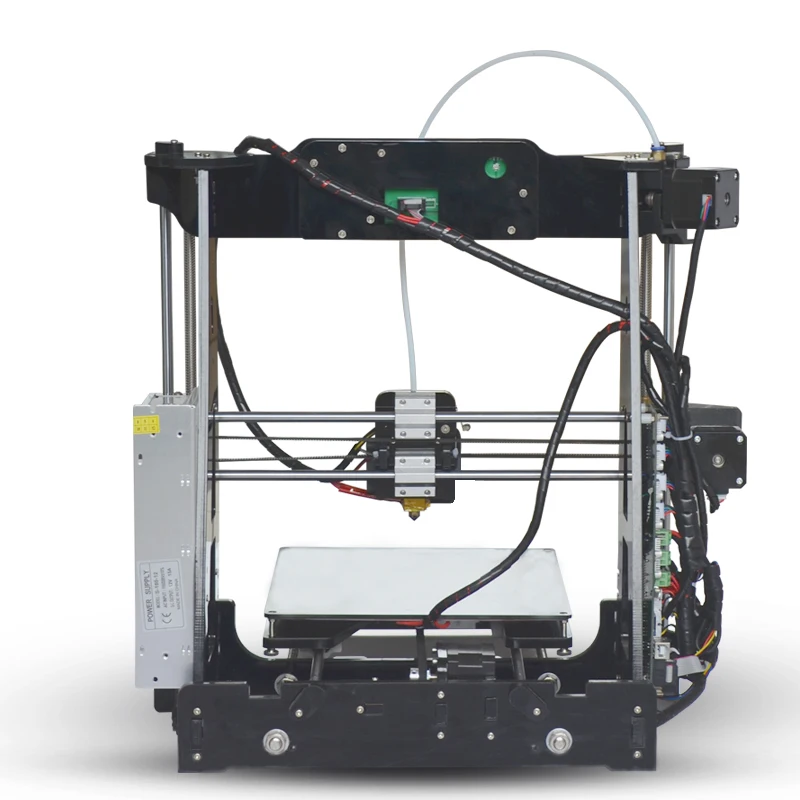

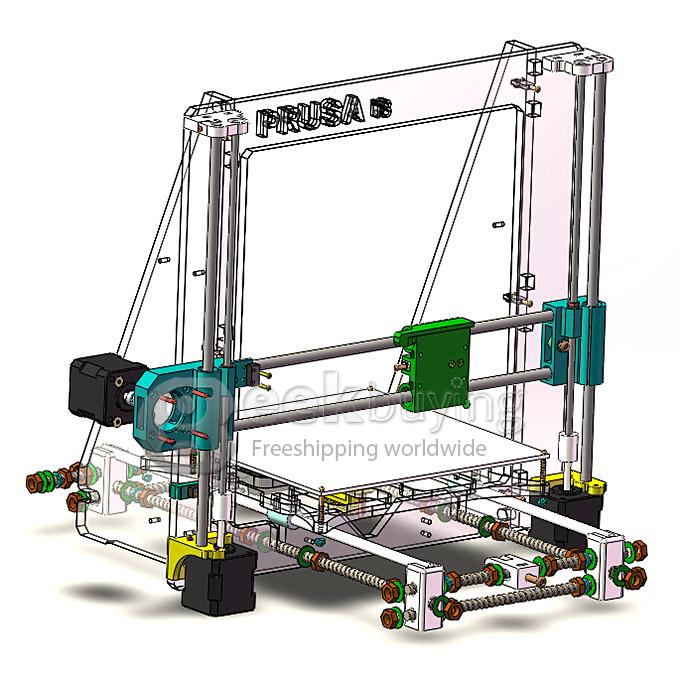

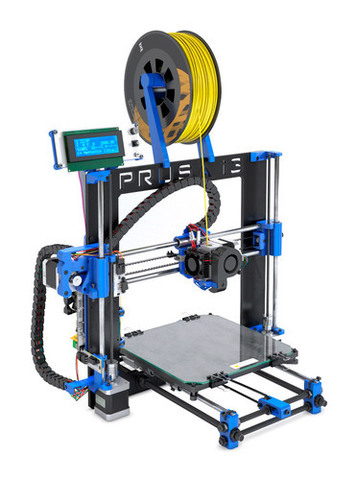

Kinematics “Prusa” (Prusa)

Perhaps the most popular kinematics among home FDM devices. Mainly due to its simplicity and low cost. The main feature is the table that moves along the Y axis, while the extruder moves along the rest of the axes. Because of this, such kinematics was nicknamed “dragstol”.

Prusa kinematics

Pros:

Cons:

-

Slow print speeds.

A massive table with a model is forced to constantly move along the Y axis, because of this, print quality will be worse at high speeds.

A massive table with a model is forced to constantly move along the Y axis, because of this, print quality will be worse at high speeds. -

Some models have design flaws (for example, insufficient frame rigidity), they can be fixed, but for this you will have to be a little inventor. Or find a ready-made solution on the Internet.

This category also includes 3D printers with console kinematics. The same prusa, only halved. Because of this, the frame is less rigid, but the printer itself is more compact.

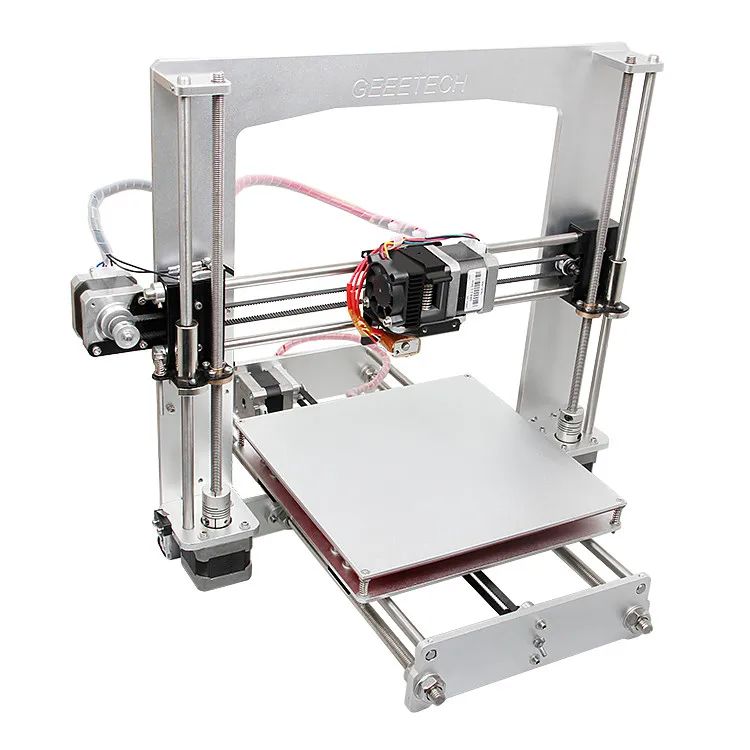

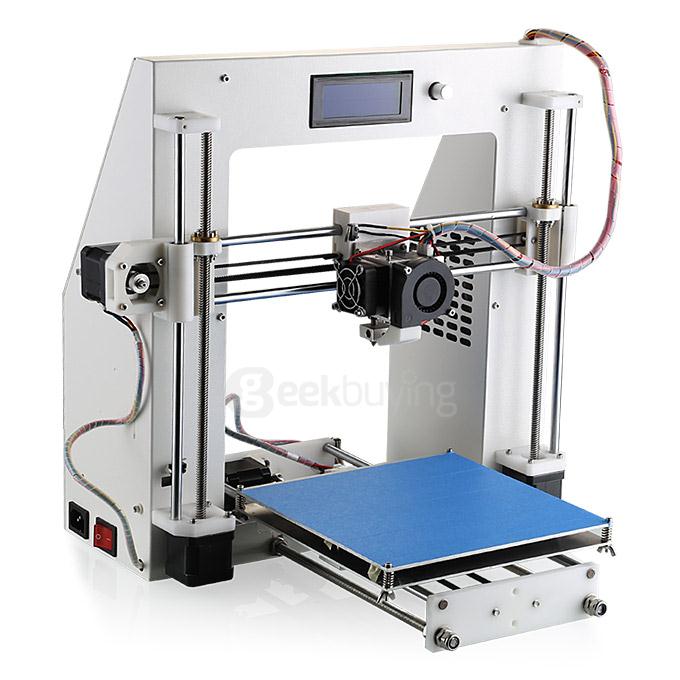

Kinematics Ultimaker

The extruder moves along the X-Y axes, and the table only along the Z axis. All motors are trying to be fixed on the body to lighten the weight of moving mechanisms, thanks to which it is possible to achieve high print quality at high speeds.

Ultimaker kinematic diagram

Pros:

Cons:

H-BOT or Core-XY

These are 2 similar but more complex kinematics - the table moves only along the Z axis, and the extruder along the X-Y. But to move the extruder, 1 or 2 long belts and 2 stepper motors work in concert.

But to move the extruder, 1 or 2 long belts and 2 stepper motors work in concert.

Example Core-XY kinematics

Pros:

-

High print quality

-

High print speeds without loss of quality.

-

Can be easily closed completely

Cons:

MakerBot Kinematics

Similar to Ultimaker kinematics, but one of the motors is located on the Y or X axis carriage.

Pros:

Cons:

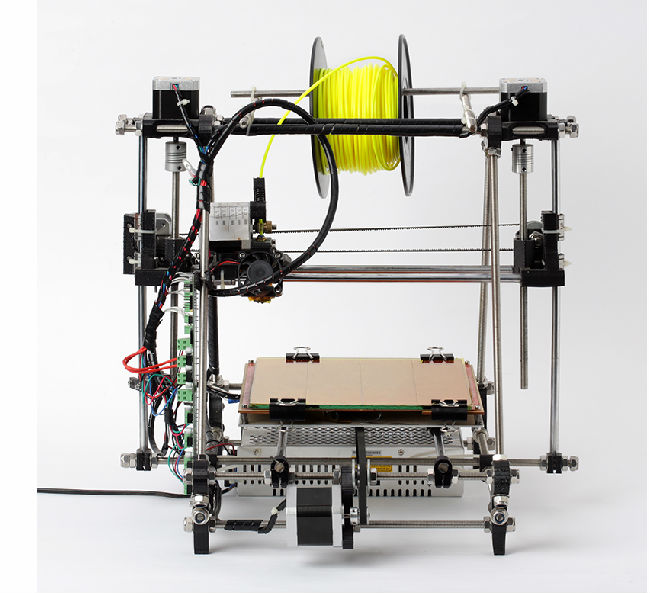

Delta

Deltas do not have the usual XYZ axes. There are 3 columns in the deltas, along which the carriages move, and the position of the extruder in space is calculated using a complex formula. The table is usually statically fixed to the body.

Delta printer example

Pros:

Cons:

Nuances of choosing an FDM 3D printer

In addition to kinematics, when choosing a printer, it is important to take into account some design features.

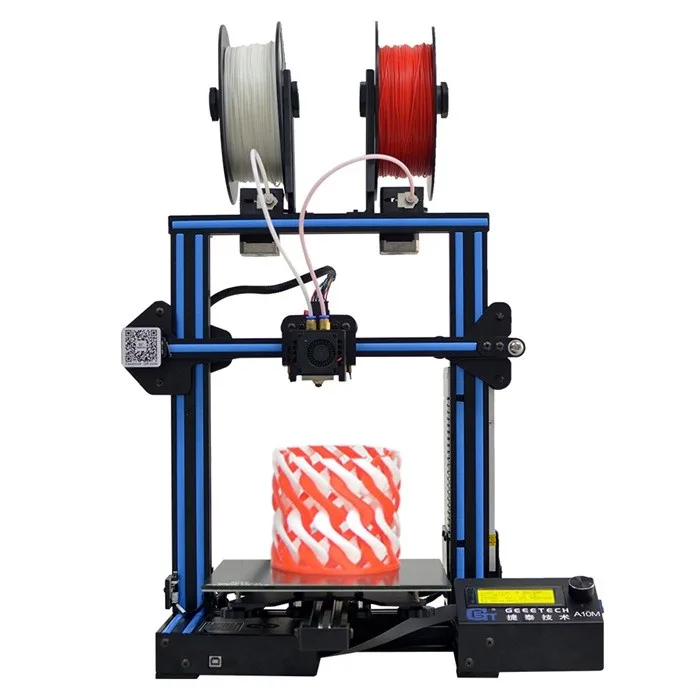

One or two extruders?

Two extruders can be used for dual color printing, but most commonly the second extruder is used for solvent support printing. If you need to print complex parts with internal cavities, then you should choose a dual extruder printer.

Closed or open printer?

Printing of functional models and parts uses plastic, which usually requires a closed chamber. If you plan to print functional prototypes or various models, you should look at printers with a closed chamber.

Bowden or direct?

There are 2 types of material supply to the print head of the printer - bowden and direct.

In a bowden, the feed mechanism motor is located on the printer body. This allows you to reduce the weight of the extruder and print at higher speeds without losing quality. But because of the long tube, printing with very soft plastics can be problematic.

Bowden feed pattern

In direct feeding, the motor and feed mechanism are located on the extruder. This increases the weight of the print head, but allows you to print with any kind of plastics.

This increases the weight of the print head, but allows you to print with any kind of plastics.

Direct feeding scheme

Heated table or not?

The heating of the table improves the adhesion of the first layer of the model. And engineering plastics cannot be printed without a heated table.

Many manufacturers add useful additional features. They do not affect the quality of the print, but save time and nerves. The most useful additional functions are the filament presence sensor and remembering the print location after a power outage.

Filament sensor.

It will automatically pause printing if the plastic runs out. When there is a little plastic left on the spool, this feature will allow you not to stand over the guard printer until the old spool runs out in order to have time to push in a new bar “on the go”.

Power outage protection.

Remembering where to print when the power goes out can save you a lot of nerves when printing large models. You won't have to worry that after a power outage, you will have to run the model again for many hours or cut and reprint a piece of the model. It is especially disappointing to throw away a complex underprinted model with supports due to a one-minute outage.

You won't have to worry that after a power outage, you will have to run the model again for many hours or cut and reprint a piece of the model. It is especially disappointing to throw away a complex underprinted model with supports due to a one-minute outage.

There are also many extras. features that make using the printer more comfortable. For example, automatic calibration, touch screen, Wi-Fi and others.

Rating of the best FDM 3D printers for home

Anycubic Mega Zero 2.0

Inexpensive model with Pryusha kinematics. Good for getting started with 3D printing without a big investment. Despite the low cost, Anycubic Mega Zero 2.0 has a heated table and a function to resume work after a power outage. Thanks to direct feed, printing with soft materials should not be difficult.

Creality3D Ender 3 Pro

A very popular device due to its low price. But despite this, the Ender 3 Pro has a heated table and a decent print area. Can be sold assembled or as a DIY kit.

Can be sold assembled or as a DIY kit.

Flash Forge Finder

Small home appliance intended for children or educational institutions. The Finder doesn't have a heated table, but it does have a calibration assistant, a Wi-Fi module, and other extras that make getting to know it a lot easier. All moving and heated elements are hidden as much as possible in the case so that the child cannot get burned.

Wanhao Duplicator 6 Plus

Wanhao Duplicator 6 Plus was based on Ultimaker kinematics, but instead of bowden feed, they made direct. Because of this, it will not be possible to print super fast, without quality loss, but there will be no problems with printing with soft types of plastics. There are 2 trim levels - with a closed case and without.

Flashforge Dreamer

The Dreamer is a closed body dual extruder printer with MakerBot kinematics. Thanks to this, he can cope with printing models of any complexity. Using a second extruder for soluble support, models with complex geometries can be produced. A good choice for engineers and those who like to experiment with different materials.

Using a second extruder for soluble support, models with complex geometries can be produced. A good choice for engineers and those who like to experiment with different materials.

FlyingBear Ghost 5

Most commonly sold as a kit (assembly kit). Assembly usually does not cause any great difficulties, even for people far from electronics or mechanics. Flying Bear is equipped with a filament sensor, a function to resume printing after a power outage and Wi-Fi connectivity.

The Flying Bear makes a great first printer for the novice user who is ready to build their own printer.

Totals

In order for the printer not to become a useless toy, you should clearly understand what it is for.

For a fan of miniatures or detailed figurines, a photopolymer printer is a good choice. A small work area is more than offset by the detail that cannot be obtained using other technologies.

For an engineer or a fan of experiments, an FDM machine with a closed chamber and two extruders is well suited. This will allow you not to limit yourself in the choice of plastics and comfortably experiment with any materials.

This will allow you not to limit yourself in the choice of plastics and comfortably experiment with any materials.

For a beginner who has not yet decided whether he needs 3D printing, you can opt for inexpensive machines with slick kinematics. Due to their great popularity, you can find a lot of upgrades and reviews on them. In the future, it will be possible to modify the printer for specific tasks or change it to a more suitable model.

For a child, safety is paramount. As the first children's printer, models without a heated bed are suitable, in which the main emphasis is on printing with safe PLA plastic. Or models in which all moving and heating mechanisms are hidden in the case.

A 3D printer is a handy tool, and whether it brings joy or frustration depends on the user.

8 nuances worth paying attention to

Sooner or later, everyone will learn about 3D printing. And only a few lucky people, imbued with the opportunities that 3D printing opens up, catch themselves thinking that they want to purchase a 3D printer. The desire gradually develops into a serious decision and the search for the right option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose among the whole variety of 3D printers. We will try to answer this question in as much detail as possible. What to look for, and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer. You need to decide for yourself for what tasks you will use this technique? What features should a 3D printer have to solve your problems?

The desire gradually develops into a serious decision and the search for the right option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose among the whole variety of 3D printers. We will try to answer this question in as much detail as possible. What to look for, and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer. You need to decide for yourself for what tasks you will use this technique? What features should a 3D printer have to solve your problems?

Tip 1 : Decide on 3D printing technology

The first step is to decide on the technology of 3D printing. There are two main paths here. If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

Nuance 2: Evaluate your needs

Of course, you always want to get all the best and with maximum opportunities. Do you need all this to solve your current problems? What can be cited as an example? For example, the size of the working area of the FDM 3D printer. There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x100mm). But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks. But options are possible ... If you plan to manufacture small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area. In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x100mm). But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks. But options are possible ... If you plan to manufacture small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area. In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

Nuance 3 : Decide on the complexity of the products

You should decide for yourself how complex models you will print on a 3D printer. If you plan to manufacture complex prototypes, or complex art models, then you need a 3D printer that can print with two materials. This is necessary so that your printer can print supports from soluble material. If the models are not the most complex, then you can get by with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles of more than 30 degrees.

Point 4: Decide on the list of materials to be used.

Another important point. You must immediately determine for yourself a list of possible materials with which you are going to print. This primarily applies to materials with a high degree of shrinkage, such as ABS and Nylon. In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model. If you plan to print only with PLA plastic. You don't need a heated table. But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform the full range of tasks facing a 3D printer. One more moment. Ability to print with flexible materials Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends.

In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model. If you plan to print only with PLA plastic. You don't need a heated table. But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform the full range of tasks facing a 3D printer. One more moment. Ability to print with flexible materials Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends. Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

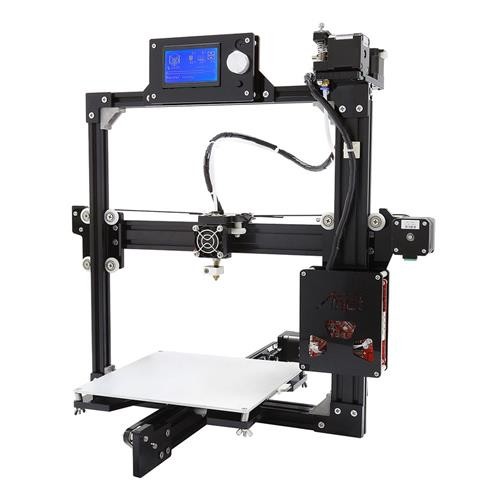

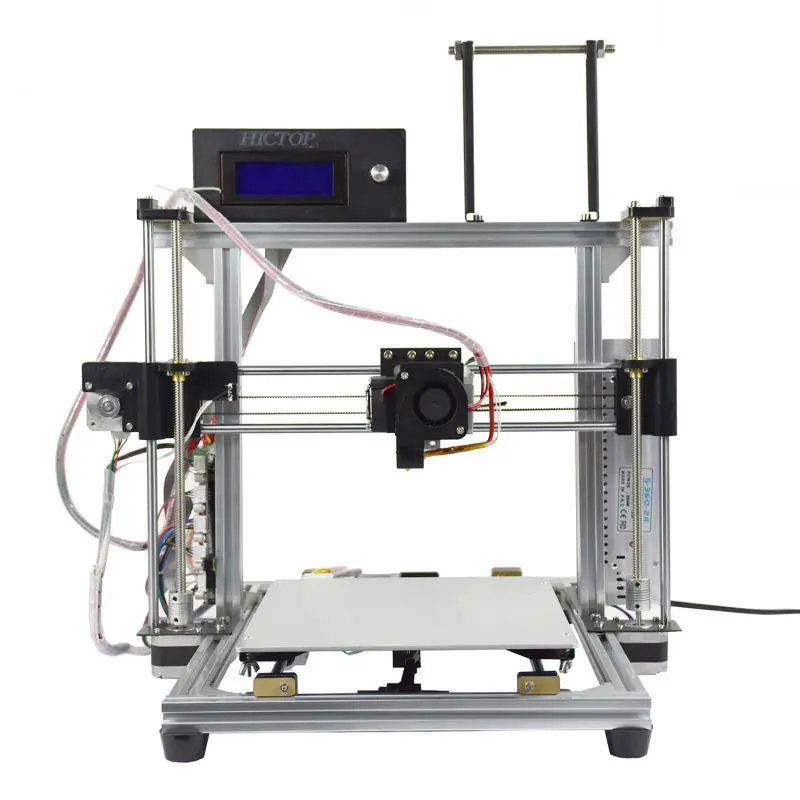

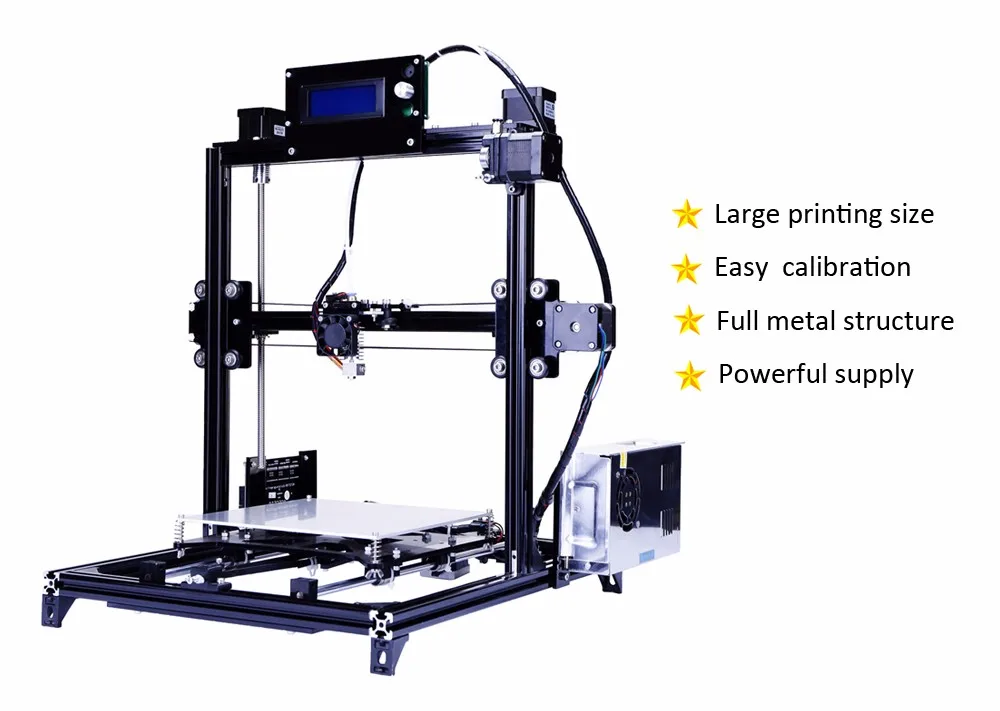

Nuance 5: Construction and kinematics

Next, you need to pay attention to the design of the 3D printer. Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And others are closed. As they like to be called in the Russian-speaking community "cubes". What does the appearance say? Printers with an open design, usually have kinematics with a horizontally moving table (based on Prusa 3D printers). This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble. Also, the lack of a closed case can cause print quality problems with high shrinkage plastics (ABS, Nylon). The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits.

The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits.

Nuance 6: Diameter and changeable nozzle

Most 3D printers on the market come with 0. 3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer. Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary. What do we mean by specific tasks? This is especially true for printing large items, where it is very important to reduce the printing time. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer. Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary. What do we mean by specific tasks? This is especially true for printing large items, where it is very important to reduce the printing time. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

Nuance 7: Print thickness

It is important to understand that most models on a 3D printer are printed with a layer of 0. 1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0.05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0.05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

Nuance 8: Extruder type

Today there are two main types of extruder. This is a direct extruder in which the bar feed motor is located in the printhead itself. And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube. What are the advantages and disadvantages of each type of extruder? Bowden extruder, due to the lack of a motor on the print head, has less weight. And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types.

And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types. Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

In our assortment you can always find 3D printers for your tasks:

1) Budget 3D printers

2) 3D printers for business

3) Large area 3D printers

4) SLA and DLP 3D printers

Do you have any questions?

Call: +7 (495) 324-07-90 (Moscow) and 8 (800) 775-86-69 (toll-free in the Russian Federation) or write to the mail: sales@3dtool.