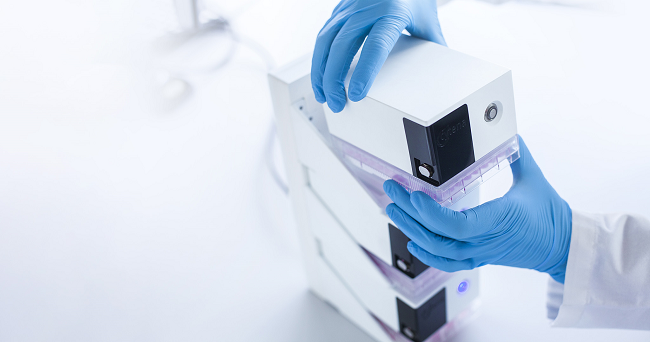

Cellink 3d printer

3D Bioprinters - Extrusion, DLP, Biodispensing

Print the future with us

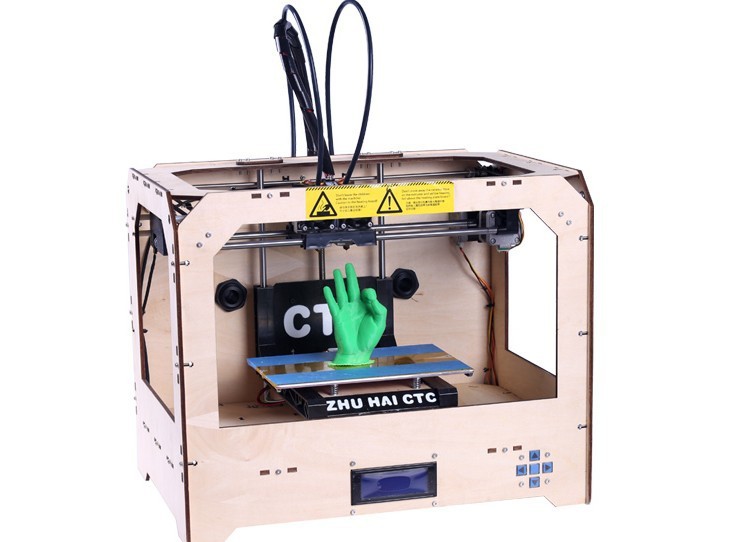

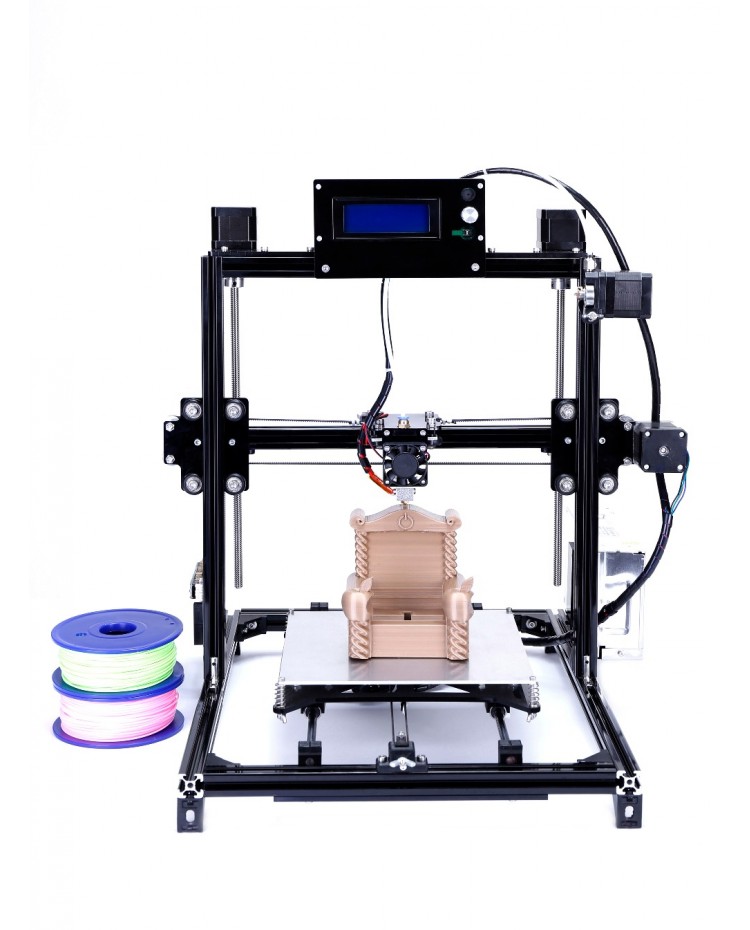

Extrusion 3D bioprinting

Based on computer numerical control (CNC) machining processes, extrusion-based bioprinting precisely dispenses bio-compatible materials layer by layer, following tool paths generated in slices from 3D models. Our extrusion-based 3D bioprinters are designed with flexibility in mind to give bioengineers the freedom to work with a wider range of biomaterials, opening the door for more relevant tissue engineering.

BIO X™

This award-winning design is a go-to bioprinter for academics, researchers and innovators.

BIO X6™

Another award-winning design delivers unparalleled bioprinting flexibility with 6 printheads.

INKREDIBLE+™

Our first bioprinter revolutionized an industry and continues working hard for training and education.

Light-based 3D bioprinting

Adapted from stereolithography (SLA) processes, light-based bioprinting produces constructs by initiating chemical reactions that solidify or cure bioinks only where they have been illuminated. With multiple types of light-based technologies, like digital light processing (DLP), they are typically much faster because they cure whole layers simultaneously. Thanks to small points of light in the millions, light-based bioprinters are also able to recreate more intricate details at much higher resolutions.

Lumen X+™

The DLP bioprinter for printing microscopic features with speed, fidelity and precision.

BIONOVA X

This DLP bioprinter lights up high resolution, high-throughput 3D bioprinting.

Quantum X bio

The bioprinter with all the features you need for printing with bioresins containing living cells.

Biodispensing

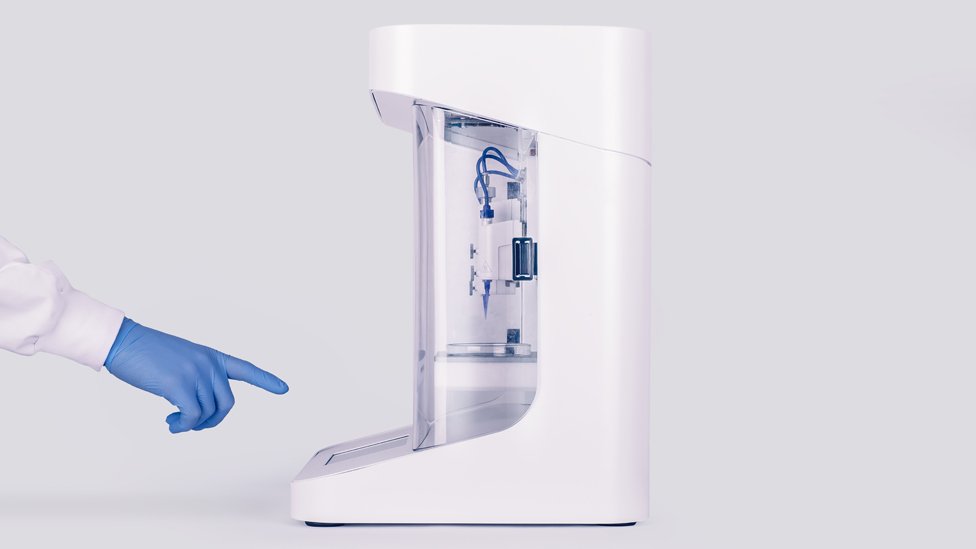

BIO CELLX

This fully automated biodispensing solution leverages bring the power of 3D cell biology to your benchtop.

The future is created in the present, and bioprinting will change the future of medicine.

Delivering high-quality products and keeping your work cutting edge

We’re equipping hundreds of labs and thousands of scientists worldwide with cutting-edge technologies that fuel groundbreaking scientific breakthroughs. With a commitment to quality and innovation, our 3D bioprinters and bioinks have contributed to revolutionary advancements in academic and clinical medicine.

With a commitment to quality and innovation, our 3D bioprinters and bioinks have contributed to revolutionary advancements in academic and clinical medicine.

CELLINK is a global leader in developing and delivering 3D bioprinting solutions for the life-science industry.

Complete in-house product development and manufacturing

A high-quality team creates high-quality, innovative bioprinters

Our tech team of mechanical, electronics, robotics and software engineers as well as our UX/UI designers, biomaterial scientist and tissue engineers make it possible for us to fully develop our bioprinters, bioinks and softwares in-house. Our development and manufacturing teams work very closely in the development process. This has enabled us to accelerate the transition from prototype to first batch and finally to series production, all under the ISO 9001 Quality Management System. Working with the ISO 9001 ensures that our customers get consistent, good quality products and services. This truly gives a complete control when delivering new and innovative products and solutions to our customers since we can utilize the full strength, expertise and passion of the team to get the job done. Having a full in-house development team that works closely with our collaborators and partners who are users of the technology has made it possible to grow our knowledge and expertise on developing products that have a direct need in the bioprinting field and life sciences.

This truly gives a complete control when delivering new and innovative products and solutions to our customers since we can utilize the full strength, expertise and passion of the team to get the job done. Having a full in-house development team that works closely with our collaborators and partners who are users of the technology has made it possible to grow our knowledge and expertise on developing products that have a direct need in the bioprinting field and life sciences.

In order to keep high standards, we do all our production in-house.

Get started now

Reach out to us with your 3D bioprinting needs, and our experts will be happy to show the capabilities of our 3D bioprinters, and how our systems can help your research.

BIO X 3D Bioprinter - CELLINK

Generation 3 of the go-to 3D bioprinter for cell biologists, tissue engineers and biomedical researchers.

Explore the most user-friendly and flexible bioprinter in the world

Open biomaterial platform

While we offer an extensive portfolio of biomaterials, we understand the necessity and importance to make the BIO X compatible with the widest range of biomaterials available.

Better Cell Safety

Thanks to built-in UV sterilization and a HEPA filter, our patented Clean Chamber™ technology, the BIO X brings the sterility of the biosafety cabinet to the benchtop.

Intelligent Printheads for flexibility

Our range of intelligent printheads brings users of the BIO X the utmost flexibility and interchangeability. The printheads are developed to suit many different biofabrication projects.

DNA Studio 4 Compatible

Generation 3 of the BIO X harnesses the power of the most advanced bioprinting software available today.

Advanced functionality and versatility.

Streamline your workflows in a wide range of application areas.

The BIO X’s compatibility with virtually any material makes it the bioprinter of choice for industry leaders at the forefront of today’s biggest scientific breakthroughs. Whether you are automating 3D cell cultures, developing complex tissue constructs or testing new drug compounds, the BIO X 3D bioprinter has the advanced functionality and versatility to streamline workflows in a wide range of application areas.

Patented Clean Chamber for better cell safety

Built-in UV sterilization and a HEPA filter bring the sterility of the biosafety cabinet to the benchtop.

Dual high-powered fans channel air through a HEPA h24 filter to remove 99.995% of unwanted particles and microorganisms as part of the Clean Chamber™ technology, which also includes UV-C germicidal lights, rounded edges and positive air pressure.

Initiate Clean Chamber before beginning your experiment to ensure full sterility around the print area for the duration of the print.

Open material platform, bioprint with the widest range of materials.

Universal biomaterial compatability

We offer an extensive portfolio of bioinks but understand the importance of material development, which is why we built the BIO X to be an open system that is compatible with the widest range of materials available. Start developing your own bioinks with our high-quality bioink development products or explore our ready-to-print bioinks.

Excellent temperature control

Bioprint with a wider range of materials and cell types thanks to precise printhead and printbed temperature control.

With a printhead temperature range of 4°C to 250°C and a printbed temperature range between 4°C and 65°C, enjoy precise control of temperatures when working with temperature-sensitive materials like collagen and gelatin. The possibilities are limitless when you are able to work with a wider range of materials and cell types.

Grow your research with multiple, interchangeable, Intelligent Printheads

BIO X is the first 3D bioprinter in the world with Intelligent Printheads (iPH), ensuring your research is always at the forefront.

With an ever-growing list of Intelligent Printheads, the possibilities are limitless, giving you more freedom to push your research further. Our family of intelligent printheads is always growing. Each printhead system is made to suit different biofabrication application, which helps ensure the best possible result for your 3D bioprint.

Designed to do even more

The BIO X’s exceptional features maximize versatility to enhance your success in the following application areas and beyond.

3D cell culture

Three-dimensional cell cultures offer multiple advantages over 2D cell cultures, including the precise geometrical arrangement of multicellular constructs that can better recapitulate the native 3D human physiology. Extrusion-based bioprinters such as the BIO X offers great flexibility when designing 3D cell culture systems, as they allow researchers to precisely control geometries and the spatial patterning of cells and other biomaterials.

Tissue models and engineering

The BIO X allows for 3D bioprinting with up to three printheads, enabling multi-material and multi-cell flixbility during small and large tissue engineering. The world’s your oyster.

Organ-on-a-chip

The merger of bioprinting and microfluidics opens the door to on-demand and personalized organ-on-a-chip models and may replace many preclinical steps in future drug trials. The BIO X, combined with microfluidic systems like the VasKit perfusion system allow for complex organ-chip models; and multi-printhead technology can be used in a one-step fabrication design with spatial heterogeneity of tissues.

The BIO X, combined with microfluidic systems like the VasKit perfusion system allow for complex organ-chip models; and multi-printhead technology can be used in a one-step fabrication design with spatial heterogeneity of tissues.

Drug delivery

Bioprinters can do more than print with cells, they can also be used for fabricating hydrogel drug encapsulation and extended-release technologies. The BIO X bioprinter offers a variety of printheads that are compatible with different hydrogels. Drugs and bioactives can be mixed within the hydrogels and printed in patterns such as large patches or micrometer-sized beads.

Soft robotics

Biohybrid soft robotics is an emerging field that combines material science, biomechanics, sensing, and cells. The advantage of utilizing 3D bioprinting is the ability to fabricate systems with precise geometries and spatial patterning of cell types. Such systems can be further integrated or bioprinted with advanced nanomaterials and biosensors to enable more diverse controls and functions.

Technical specifications

| Outer dimensions (L*W*H), mm | 477x441x365 |

| Weight, kg | 18 |

| Build Volume, mm | 130 x 90 x 70 mm |

| Build surface compatibility | Multi-well plates, petridishes, glass slides |

| Resolution XY, μm | 1 |

| Layer Resolution, μm | 1 |

| Pressure range (internal pump), kPa | 0-200 |

| Pressure range (external air supply), kPa | 0-700 |

| No. of printhead slots | 3 |

| Photocuring sources (built-in), nm | 365, 405, 485, 520 |

| Printbed temperature range, °C | 4-65 |

| Printhead temperature range, °C | 4-250 (printhead specific) |

| Filter class, chamber air-flow | HEPA 14 |

| UV-sterilization | UV-C (275nm), 20mW output |

| Calibration Options | Manual and Automatic |

| User Interface | Integrated Display, DNA Studio |

| DNA Studio OS compatibility | Windows |

| Connectivity | USB Storage, Ethernet connection |

| Supported file formats, software | . gcode, .stl gcode, .stl |

Ready to create the future of health?

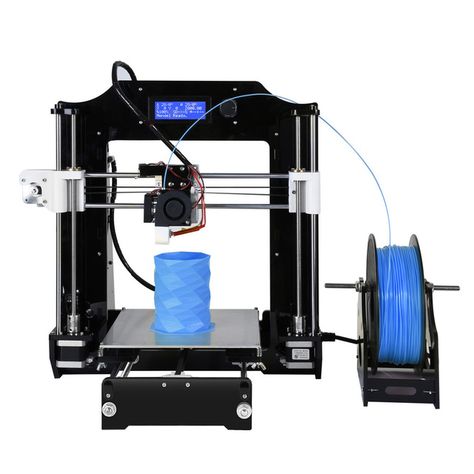

$100 mini printer powered by a cell phone.

News

Subscribe to the author

Subscribe

Don't want

12

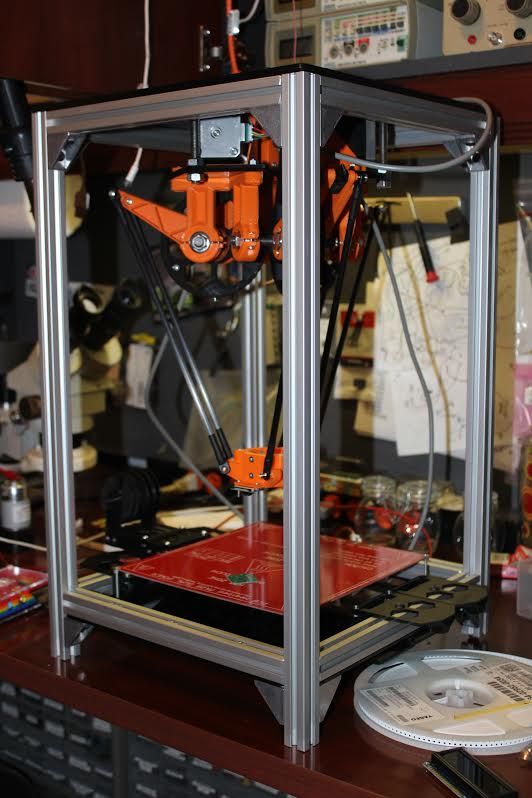

The first smartphone-based 3D printer was created by the American startup OLO. Moreover, the smartphone does not only manage printing. The screen projects an image for the light curing of the polymer. Judging by the video, there are even rubber-like polymers.

The Italian company Solido3D has demonstrated an interesting device that allows you to turn an ordinary smartphone into a DLP printer.

The idea is simple to the point of genius: most of us already have a ready-made projector with a fairly high resolution in our pockets. So why not make a box that, together with a smartphone, turns into a miniature photopolymer printer?

The device was named "OLO". In fact, this is a working chamber with a mechanized platform and a transparent bottom. The box is powered by an ordinary finger-type battery (AA), which should be enough for about 100 printing cycles. The size of the construction area reaches 76x127x50mm, although here you need to take into account the size of the smartphone screen. There is no exact information about the print quality, but the developers are pleased with the results, although they make it clear that this idea is not offered as a replacement for professional-level devices. On the other hand, the cost of such a box is estimated at only $9.9. Why not a gift to your loved one? The main thing is that friends and relatives do not steal.

The box itself is not difficult to make, but the main features of this undertaking are software and consumables. As for photopolymer resin, you will have to use options that are sensitive to white light instead of ultraviolet to work with the device, but this is not a problem, especially since Solido3D will make consumables sharpened for OLO available. The software package will consist of an application for exchanging models and, in fact, a “projector”. Of course, the developers were not too lazy to create versions that are compatible with different operating systems - Android, iOS and Windows.

https://www.kickstarter.com/projects/olo3d/olo-the-first-ever-smartphone-3d-printer

Follow author

Follow

Don't want

12

More interesting articles

12

Subscribe to the author

Subscribe

Don't want

In the village of Aisha, Zelenodolsk district of Tatarstan, work is underway to build thirty-four houses with the use of. ..

..

Read more

5

Subscribe to the author

Subscribe

Don't want

Specialists of the All-Russian Scientific Research Institute of Aviation Materials (VIAM) of the national ...

Read more

56

Subscribe to the author

Subscribe

Don't want

Dear friends!

3D printers, makers and just caring people in Russia connect...

Read more

The history of the creation of a cell phone - online presentation

Usually, the history of the creation of

mobile phone

is told something like this. On April 3, 1973, Martin Cooper, head of

Motorola's mobile communications division

, was walking

in midtown Manhattan when he decided to call

on his cell phone.

However, Martin Cooper was not the first person in

history to call

on a mobile phone. And not even

second.

Person in the picture from

of the journal "Science and

Life" was called Leonid

Ivanovich

Kupriyanovich, and

it was he who turned out to be

the person who made

calls on mobile phone

15 years

before Cooper.

Attempts to make the phone

mobile appeared soon

after its inception.

It was not until

the advent of radio communications in the VHF

(ultra-short wave) band that

the true mobility of

telephone communication became possible.

By the 1930s,

transmitters had appeared that a person could

can easily be worn on the back or held in the hands of

.

During the Great Patriotic War, the Soviet scientist and inventor

Georgy Ilyich Babat in besieged Leningrad proposed the so-called

"monophone" - an automatic radiotelephone operating in the

centimeter range of 1000-2000 MHz

"It weighs no more than the

film apparatus" watering can "- wrote G. Babat. "Wherever the subscriber is

Babat. "Wherever the subscriber is

- at home, visiting

or at work, in the foyer of the theater, on the podium

of the stadium, watching competitions - everywhere

he can include his

individual monophone in one of the

multiple endings of the

wave network ramifications. Several subscribers can connect to one

termination

, and no matter how many

there are, they will not interfere with each other.

occurred just in the midst of active attempts to create a

phone with which you can call from

vehicles. The first such service was launched in 1946

in St. Louis by AT&T Bell

Laboratories, and in 1947 a system was launched with

intermediate stations along the

highway, allowing calls from a car on the way from

New York to Boston. However, due to imperfection and high cost, these systems were not

commercially successful.

Domestic engineers G. Shapiro and I. Zakharchenko developed a telephone communication system

from a moving car with a city network,

mobile device which had a power of only 1 watt and fit under the

instrument panel. Power was from a car battery.

Power was from a car battery.

In the US, Alfred Gross was the first to attempt the impossible.

From 1939 he was fond of creating portable radios, which

decades later were called "walkie talkies". In 1949, he created the

portable radio-based device, which he called the "wireless

remote telephone". The device could be carried with you, and it

gave the owner a signal to answer the phone. It is believed that this was

the first simple pager.

Gross even implemented it in one of the

hospitals in New York, but the

telephone companies showed no interest in this

novelty, as well as in his other ideas in this

direction. So America lost the

chance to become the birthplace of the first practical

mobile phone.

In 1957, Kupriyanovich

demonstrates even more amazing thing

walkie-talkie the size of

matchbox and

weighing only 50 grams,

which can work

without changing power for 50

hours and provides

communication at a distance of two

kilometers - it is quite under

to become products of the 21st century,

which can be seen on

showcases of the current

communication stores

The 1960 edition describes a simple radio with only three ransistors,

, which can be worn on the arm.

In 1957 L.I. Kupriyanovich received

copyright certificate for "Radiofon" automatic radiotelephone with direct

set.

Through an automatic telephone

radio station from this device,

it was possible to connect with any subscriber

of the telephone network within the range of the

Radiophone transmitter. By that time,

was ready and the first operating

set of equipment, demonstrating

the principle of operation of the "Radiophone", named

by the inventor of LK-1 (Leonid Kupriyanovich,

the first sample).

Mobile phone model

from 1958, together with power supply

, weighed only 500

grams.

In 1959, engineer Khristo Bachvarov took out a patent in the field of mobile

radiotelephony, and in the 60s he created a mobile phone, conceptually

similar to Kupriyanovich's radiophone.

The first industrial

models of a mobile phone were created in Bulgaria. Among the

exhibits of the Bulgarian

exposition at the exhibition

"Interorgtekhnika-66" there were

so-called

"automatic

radiotelephones" PAT-0. 5 and

5 and

ATRT-0.5 which allow

"to carry out radio communication on

VHF band with any

telephone subscriber of

cities, regions and

enterprises without

special adaptations

for his

telephone set.

The first cell phone was produced in 1983 by Motorola.

grams, dimensions - 33 * 4.4 * 8.9 cm Battery charge was enough for an hour of

calls, and in standby mode for 8 hours Display was LED

Although the price of the first phone model was $3.995

Mobile phone - a portable

device for transmitting

predominantly voice messages

via radio.

Cell phone - a phone

operating on certain radio frequencies

in cellular networks.

1989

And now, finally, someone realized that an important parameter of the

mobile phone is its portability. Not only has the Motorola Micro TAC cell phone

received a lot of praise for its size, but it has also been praised for its

battery life (about 75 minutes) and "cheap"

price (only $2995).

1994

Although the term "smartphone" was not even invented in those years, but

the first mention of the communicator appeared in 1994. This

was an IBM Simon Personal Communicator priced at $1100

1995

The year 1995 can be called the wholesale introduction of mobile

cellular communication.

True, the size of the devices of that time

would have shocked today's

generation. Looks like a rarity slightly 9The 0083 resembles the current

cordless telephone. Even that small

functionality that

developers implemented in

cell phones of the early 90s,

could not fit into the cases of mobile phones of our

time. The reason for this is the low level of

technologies of the element base, and the absence of a dense network of

base stations of cellular operators. Therefore, there was a need for

to use the increased power of

transmitting modules and, accordingly,

increased antennas, for reliable communication.

1996

A year later, in 1996, mobile phones improved a bit and

began to look prettier. Yes, and the length of the antenna has been significantly reduced. The

picture below shows the Nokia 9000 cell phone, which was one of the most popular

phones of the time.

1997

1997 stands out with an innovation: the developers began to install

internal antennas in mobile phones, which clearly improved the appearance of

cellular devices.

1999

In 1999, mobile phones began to look more compact. The photo

below shows the Nokia 3210, which has a clean design with an internal antenna and

improved graphics. All this noticeably distinguishes this phone against the background of the previous

cell phone models.

2000

This year the world saw the first touchscreen phone. While not the cutting edge

technology available today, it was a huge springboard for the

at the time to start introducing the latest, forward-thinking technologies. The picture shows

The picture shows

is a Motorola mobile phone that is equipped with a black and white touch screen.

The use of the sensor has made it much easier for the user to access various functions of the

device.

2001

2001 was the year of birth of the world's first cell phone with

monochromatic display. As an alternative to boring, black and gray

displays, the developers have offered users displays with color

backlight. The image shows the Nokia 8250, one of the first phones to feature a

color monochromatic display. For example, blue 9The 0083 display backlight together with the compact design made this

phone a desirable model for many people of that time.

2002

In 2002, high technology made a giant, turning point in the

history of mobile phones:

large full-color display appeared in mobile phones.

integration of video cameras into mobile phones.

2003

In 2003, flip phones appeared.

This model has a small outer screen that can be used to

was to see incoming calls and text messages, and a large

internal screen for the user to dial messages and perform other

phone functions.

2004

During the development of mobile phones, manufacturers were in a race to

create the smallest phones. The smallest phones were

very expensive and not everyone could buy them.

So, 2004 brought us a surprise, in the form of one of the thinnest mobile phones of that time,

, created by Motorola. The photo below shows 9The 0083 Motorola V3 mobile phone, which was the best in its class, had

stunning appearance, slim shape, dual screen, VGA camera and

many other functional features.

2005

In 2005, Sony introduced the world's first Walkman phone. Indeed, the Sony W800i mobile phone was

an amazing device of its kind and was designed for music lovers.

The device was distinguished by excellent playback of

musical compositions and had separate buttons for controlling the player.

2007

In 2007, Apple Inc. introduced the world's first iPhone, which

was the world's first touch screen smartphone using

's advanced technology.