Fedex 3d printing

FedEx Introduces New 3D Printing Services with FedEx Forward Depots - 3DPrint.com

In 2016, logistics company UPS began offering on-demand 3D printing services. It wasn’t the first dip into 3D printing for the company, which began offering 3D printing services at 100 of its stores in 2014, but it was 2016 that really marked UPS’ large-scale adoption of 3D printing, and signified a willingness to work with a technology that could be seen as a threat to the logistics industry as a whole. Many wondered if rival FedEx would soon follow suit, but FedEx hasn’t shown much of an interest in 3D printing – until now.

Yesterday, FedEx announced that it would be realigning its specialty logistics and e-commerce solutions under FedEx Trade Networks, Inc. (FTN). It will be split into five divisions: FedEx Custom Critical, FedEx Cross Border, FedEx Supply Chain, FedEx Trade Networks Transport & Brokerage, and a new company called FedEx Forward Depots, which will be responsible for Critical Inventory and Service Parts Logistics, 3D Printing, Repair Center and the FedEx Packaging Lab.

“In order to improve our ability to leverage the unique capabilities of our specialty companies, we are realigning several companies in a new organizational structure under FedEx Trade Networks, led by FTN CEO Richard W. Smith,” said David J. Bronczek, President and Chief Operating Officer, FedEx Corporation. “Richard brings a strong background in working with the unique capabilities that have existed in many parts of the FedEx portfolio for several years and is well suited to lead this new organization that will bring these solutions to customers more seamlessly than ever.”

FedEx has not provided much detail on what exactly its 3D printing services will entail, but it’s not a surprise that the company is initiating some sort of a 3D printing service. If 3D printing means that companies are manufacturing their own parts in-house, and storing less inventory, that means reduced business for logistics companies. Those companies then need to make up that revenue elsewhere, and it makes sense for them to turn the technology threatening their business to their advantage.

It will be interesting to see exactly what kinds of 3D printing services FedEx plans to offer. Will it follow the UPS model, giving customers the opportunity to 3D print their designs in-store as well as to order on-demand 3D printed parts? Or will it be something different? Either way, it appears that FedEx has embraced 3D printing in a big enough way to dedicate a new division to it, at least in part.

“This realignment under FedEx Trade Networks will allow us to offer customers the full power of our wide array of unique and competitively advantaged customized services in a way that is even more convenient and intuitive,” said Richard W. Smith, CEO, FedEx Trade Networks. “I am delighted to lead this organization of talented FedEx team members in delivering to customers the power of the broad FedEx global portfolio.”

The new FedEx realignment will go into effect on March 1st of this year.

Discuss this and other 3D printing topics at 3DPrintBoard. com or share your thoughts below.

com or share your thoughts below.

[Images: FedEx]

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: fedex • FedEx Forward Depots • logistics • shipping • ups

Please enable JavaScript to view the comments powered by Disqus.

FedEx launches 3D printing inventory and repair company Forward Depots

0Shares

A FedEx and 3D printing venture has been expected for some time.

From 3D printed drone-delivery, to on-demand bureau services, postage and shipping companies are investing in the future of additive manufacturing.

In the latest news from the logistics sector, FedEx has announced that it will be launching a new, 3D printing oriented, company under the name FedEx Forward Depots.

The company is the product of a company-wide structural realignment, dedicated to “customized,” “convenient,” and “intuitive” services.

FedEx and 3D printing

When UPS started offering on demand 3D printing services in 2013, many predicted that FedEx would be quick to follow. A case study from 2014, featuring 3D printed medical implant manufacturer Stryker, in fact shows that FedEx has been paying keen attention to 3D printing, and the idea of “Going local” with manufacturing.

“Currently, some medical device companies are delivering 3D printed implants manufactured around the world to hospitals within 24 hours,” reads the company case study.

“But what about when hospitals have an immediate need for devices that are not stocked in their inventory?”

One answer is installing 3D printers in the hospital themselves. With the more expensive metal 3D printers though, this may never be economical. The answer for FedEx, is responsive delivery services that meet customer demand.

Van, truck, plane, or 3D printing? Fedex is committed to customer deliveries. Image via FedExLeveraging speciality

Richard W. Smith, CEO of FedEx Trade Networks (FTN) freight forwarding services, is leading the company’s custom-service driven realignment. In total, five elements will soon be organised under FTN, from same day courier services through to international logistics:

Smith, CEO of FedEx Trade Networks (FTN) freight forwarding services, is leading the company’s custom-service driven realignment. In total, five elements will soon be organised under FTN, from same day courier services through to international logistics:

- FedEx Custom Critical

- FedEx Cross Border

- FedEx Supply Chain

- FedEx Trade Networks Transport & Brokerage, and

- The new, FedEx Forward Depots

According to David J. Bronczek, president and COO of FedEx Corporation, the realignment has been made “In order to improve our ability to leverage the unique capabilities of our speciality companies.”

A FedEx Custom Critical truck, for on-demand, same-day delivery. Photo via FedExFedEx Forward Depots

The “3D printing segment” of the realignment, FedEx Forward Depots, will encompass 5 interlinked custom services.

Two parts, Critical Inventory and Service Parts Logistics, allow customer to outsource their logistics, supporting a “time-sensitive, high-value service parts inventory. ” Service Part Logistics in particular is also designed to meet “demanding Just-In-Time requirements” set by high-value industry lead times, i.e. in automotive.

” Service Part Logistics in particular is also designed to meet “demanding Just-In-Time requirements” set by high-value industry lead times, i.e. in automotive.

A third, the FedEx Repair Center, is charged with fixing electronics devices for internal services and external companies. The facility, based at the Memphis HQ, is also currently “working on innovation in the areas of Additive Manufacturing (3D printing) and Robotics,” and looking for interns in the area.

The fourth part, FedEx Packaging Lab, is a research center designed to assess, test and design packaging, helping customers make the most of shipping.

The fifth and final segment, 3D printing, easily feeds into each of the four other areas. Providing quick response production, and a custom devized service.

Drop test of a parcel at FedEx Packaging Lab. Photo by Wayne Risher/The Commercial AppealFull power portfolio

FedEx Forward Depots will officially start business on 1st March 2018. In closing comments, FTN CEO Richard W. Smith says, “This realignment under FedEx Trade Networks will allow us to offer customers the full power of our wide array of unique and competitively advantaged customized services in a way that is even more convenient and intuitive,”

In closing comments, FTN CEO Richard W. Smith says, “This realignment under FedEx Trade Networks will allow us to offer customers the full power of our wide array of unique and competitively advantaged customized services in a way that is even more convenient and intuitive,”

“I am delighted to lead this organization of talented FedEx team members in delivering to customers the power of the broad FedEx global portfolio.”

Click here for a free subscription to the 3D Printing Industry newsletter. You can also follow us on Twitter, and like us on Facebook.

Nominate the best additive manufacturing applications in the 2018 3D Printing Industry Awards.

Featured image shows a scale model of FedEx’s T-Rex trailer used to transport “The Nation’s T-Rex” to the Smithsonian in 2014. Photo via 1-87vehicles

Tags Critical Inventory David J. Bronczek FedEx FedEx Forward Depots FedEx Trade Networks Forward Depots inventory logistics on demand repair Richard W. Smith robotics Spare parts Stryker supply chain UPS

Smith robotics Spare parts Stryker supply chain UPS

Beau Jackson

FedEx and UPS refuse shipments for fear of weapons production

The topic of 3D printed weapons requires a special approach due to its volatility. As a rule, the division occurs into two camps: in one, those who defend the right to own weapons, and in the other, those who consider 3D printing of firearms as a threat to law and order. Actually, it is easier to buy weapons in a store, and the reliability and quality in this case will be much higher than that of 3D printed samples made on an FDM printer. It's more a matter of turnover control.

Fueling the fire is once again Defense Distributed, an unrestricted-bearer organization that has already created quite a stir by distributing print files for the Liberator pistol and the bottom of the receiver for AR-15 rifles. This time, the group came up with a compact CNC milling machine suitable for making metal components of firearms. The use of such a machine theoretically makes it possible to manufacture weapons at home, bypassing registration. Pre-orders for the Ghost Gunner device were accepted as early as October, and the first batch was sold out in just two days. But now there are problems: the largest postal and courier companies in the US, Federal Express and United Parcel Service, refuse to deliver the machine to customers.

The use of such a machine theoretically makes it possible to manufacture weapons at home, bypassing registration. Pre-orders for the Ghost Gunner device were accepted as early as October, and the first batch was sold out in just two days. But now there are problems: the largest postal and courier companies in the US, Federal Express and United Parcel Service, refuse to deliver the machine to customers.

This is not the first attempt to thwart gun enthusiasts. When Defense Distributed released the liberator's 3D printable files, the US State Department ordered the files removed. But it was too late, because by that time the digital model had been downloaded more than 100,000 times and was immediately distributed on torrents. Even before officials intervened, Stratasys had seized a rented industrial 3D printer from Liberal author Cody Wilson after learning the device was being used to print weapons components. When Defense Distributed tried to launch an investment campaign on Kickstarter in 2012, the site administrators removed the page.

All this interference did nothing to stop the 3D printing of weapons. The most striking example was the arrest of Yoshimoto Imura, who was sentenced to two years in prison for manufacturing five plastic handguns. Such harsh punishment is explained by the strict laws of Japan, where private ownership of firearms is practically prohibited. As a result of all these punctuations, some countries, including the US and Australia, are actively creating amendments to legislation aimed at restricting the circulation of printed weapons. The problem is that some of the initiatives may limit the use of 3D printing in general. Although most such proposals do not find the necessary support, Philadelphia became the first city to officially ban the 3D printing of firearms.

But while officials are looking for the right approach, big companies are exerting their own influence. For example, the UPS postal service said that its growing network of 3D printing services will not be available for printing weapons components, but they have no complaints about sex toys. And thanks for that. Laser sintering machine manufacturer Solid Concepts, however, demonstrated the capabilities of its equipment by printing a series of metal guns. True, this was done carefully, in accordance with applicable laws, and accusations of supporting weapons activists were immediately rejected.

And thanks for that. Laser sintering machine manufacturer Solid Concepts, however, demonstrated the capabilities of its equipment by printing a series of metal guns. True, this was done carefully, in accordance with applicable laws, and accusations of supporting weapons activists were immediately rejected.

Now FedEx has stepped in and refused to ship the Ghost Gunner milling machines. Ghost Gunner is a very compact device, a kind of cube with a side length of thirty centimeters. The cost of the machine is $1,500, and it can be used for other purposes not related to the production of firearms. The most piquant thing in this story is that there are already enough such machines on the market. And yes, they are used for the illegal production of weapons. But the Ghost Gunner was the first machine to suffer from its own marketing, as it was touted as a home production solution for those same receivers. Why these details? Simply because they are stamped with registration numbers, and all other parts of the AR-15 can be bought without any verification or accounting.

Not without irony: Cody Wilson, de facto head of Defense Distributed, chose FedEx because of the carrier's close ties to the US National Rifle Association. Not only that, FedEx is also a major military contractor that transports cargo for the US Armed Forces. Obviously, this company is not run by pacifists. Hence Wilson's surprised remark, caused by a denial of service: “What's the problem? It's just a milling machine. Are you transporting weapons? And transport 3D printers, and other milling machines. Drilling machine maybe? What is the difference?"

The crux of the matter lies in the confusion born of misinterpretation of the law. As Adam Winkler, a professor of law at the University of California, Los Angeles, explains, there is no real ban on home-made guns in the US. “They act like there is some kind of federal law against artisanal production. There is nothing like it in nature. In fact, it is simply an expression of political preferences. In addition, we are talking about a milling machine that has no direct connection with weapons, except for marketing.

In addition, we are talking about a milling machine that has no direct connection with weapons, except for marketing.

FedEx spokesman Scott Fiedler admitted that the company itself is unsure whether the machine is on the restricted list. Thus, the denial of service became a safety measure, taken before the circumstances were clarified. UPS, for its part, said it has the right to issue a denial of shipment if the item is an item that could be used for illegal activities. The company will not be transporting the Ghost Gunner at this time, but will continue to review the situation.

If this sort of battle is taking place in a reasonably gun-friendly America, one can only imagine how Russia's legislature will react when confronted with the problem of 3D printed firearms. So far, there have been no such cases, but sooner or later it must happen. It remains to be hoped that the result will not be a ban on 3D printing by individuals in general, which would be quite in the style of our authorities.

WHAT ROLE DOES 3D PRINTING PLAY IN PACKAGING?

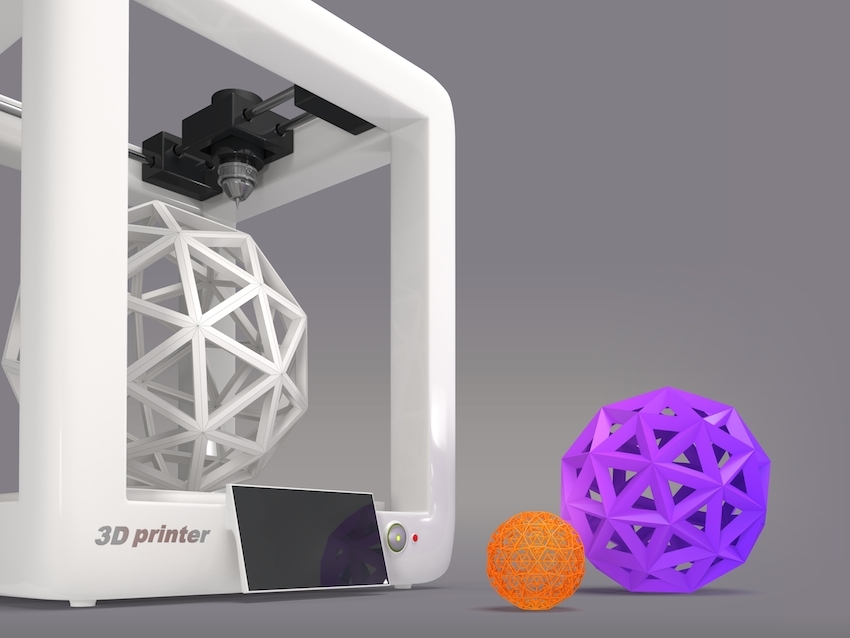

Although 3D printing has been around for quite some time, it is only in the last few years that it has begun to make its way into our daily lives more and more. This happens because this technology is becoming less expensive, more mature and more accessible from year to year and can become a real solution to problems for many creators and manufacturers, including packaging manufacturers.

3D printing is still underestimated by many manufacturers. While various media tell us about the benefits, many ordinary people and professionals are rather skeptical and do not notice the huge potential of this technology and its multifaceted possibilities, which seriously question the traditional methods of production and consumption.

A wide variety of materials and production methods allows the production of a very wide range of products. To dispel myths and fill gaps in knowledge on this subject, let's see in which areas this technology can be used.

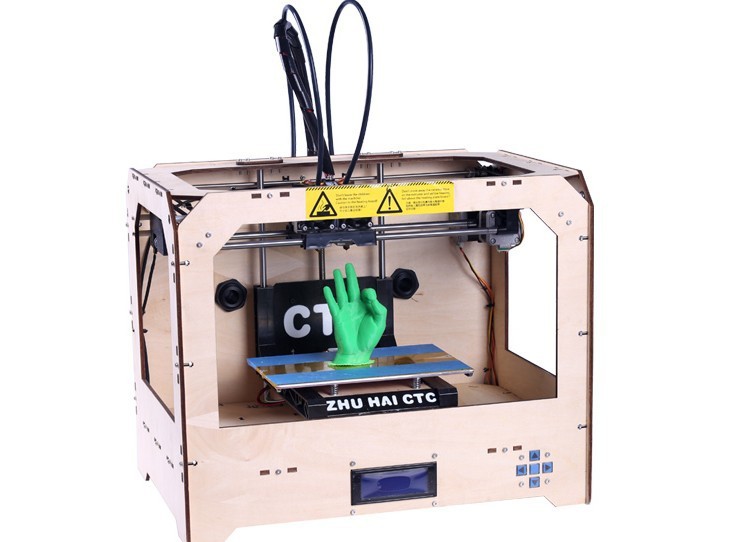

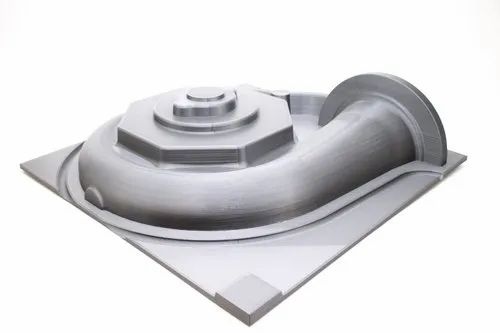

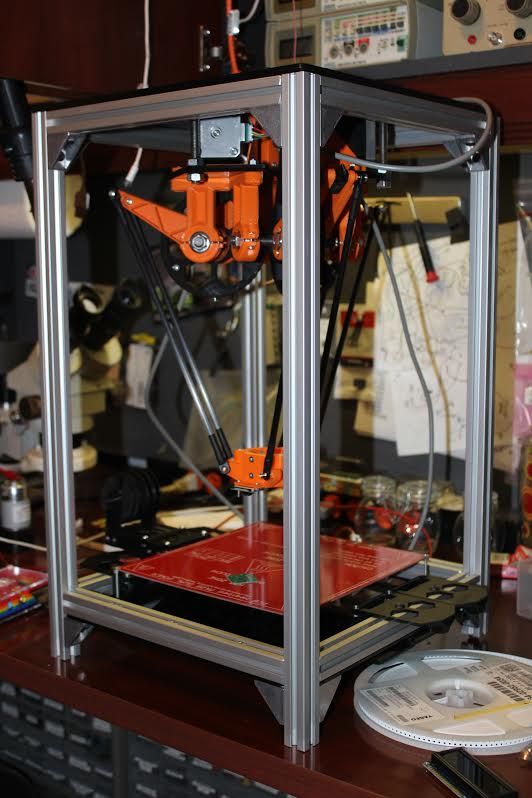

3D printing was only talked about a few years ago, although this technology has been known for quite some time... The first patent application for this technology was filed in 1984 by three French scientists. At the time, this was referred to in the industry as "additive manufacturing" or "rapid prototype" manufacturing. The latter term was given to this type of manufacturing due to the fact that this technology was the only one at that time that allowed creating prototypes, that is, the first copies of a particular product, in a short time. This is a very important stage in production, as the prototype allows you to test, check the viability of the concept and its manufacturability. 3D printing is very economical compared to traditional manufacturing processes. It omits many of the steps of traditional production methods, such as assembly and many others, which greatly reduces the use of labor and production time. Manufacturers of goods can immediately move from the idea stage to the implementation of a real object, that is, from a 3D model to the first copy and in just a few hours, not weeks! This opportunity to reduce production time and costs is increasingly attractive to industrialists and entrepreneurs in various fields. Well-known companies such as Renault or Adidas are using this technology to create a rapid prototype.

Well-known companies such as Renault or Adidas are using this technology to create a rapid prototype.

As for the topic of immediate interest to us, that is packaging, 3D printing can be used to create packaging on demand, according to specific needs. This could significantly reduce both waste and the amount of packaging produced.

In addition, this technology is very good for packaging intended for events limited in time space, such as any special sporting or cultural event, such as the World Cup or the Olympic Games, which require special packaging for souvenirs.

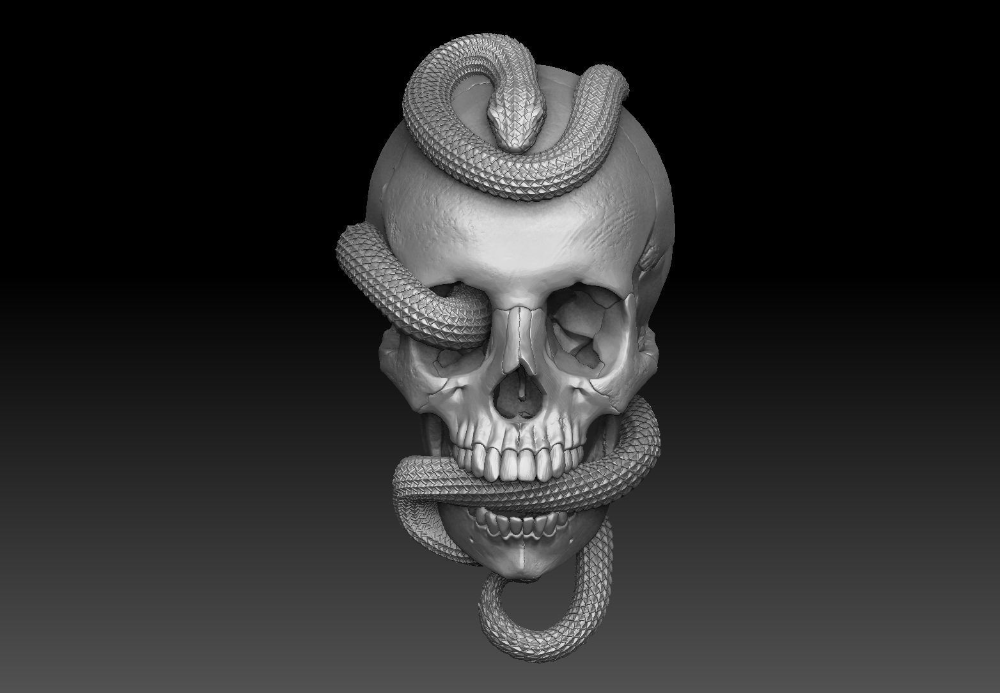

Also, this technology could allow companies to produce personalized packaging for their customers, choosing from a series of pre-existing concepts or making a completely new personalized design. This includes the entire process, from the label to improve or tweak a concept, to a complete redesign of an existing concept for a particular client. This technology is also very important, for example, for gift manufacturers who could add a name, photo or any other element to the package for their client.

At this stage, 2.5D technology can already give excellent results. For example, Casio's Mofrel printer can make textured prints using special paper that is coated with a powder that dissolves under near-infra-red light to create texture. As a result, paper can take on the texture of leather, wood, fabric, and other materials, which can allow manufacturers to create interesting designs for their packaging.

Of course, 3D printers won't be the mainstream for packaging production, but they could change the way layouts are designed, allowing packaging makers to make prototypes in a very short time. This would allow the creators to quickly concretize their ideas and resolve emerging technological problems in the shortest possible time. Also, the use of 3D printers would give packaging creators the opportunity to be more creative and interactive, and would allow for faster viability testing.

But not only manufacturers and brand creators are interested in 3D printing, but also logistics companies, big players in the logistics market such as UPS or FedEx.