What to consider when buying a 3d printer

4 essential things to consider when buying a 3D printer

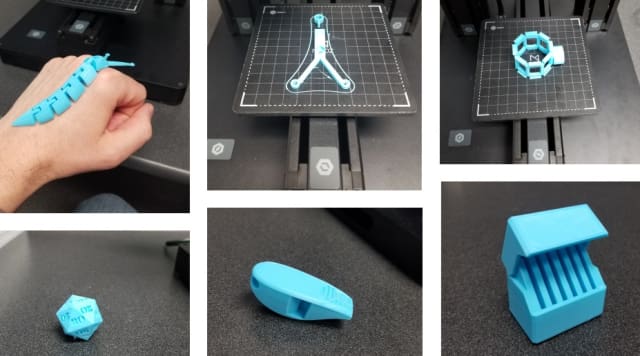

At Makers Empire we are continually testing different 3D printers in our office – we probably have the printers running 30 hours+ a week. These printers mostly fall in the $1,000-$2,000 range as we want to test the latest printers for their suitability in terms of schools.

There are four essential things you need to consider when buying a 3D printer:

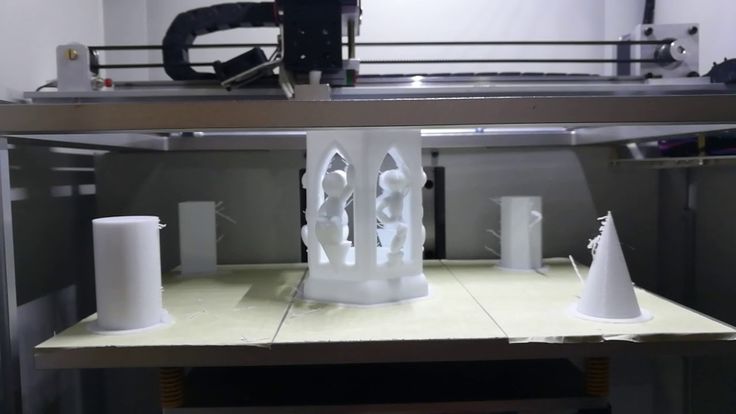

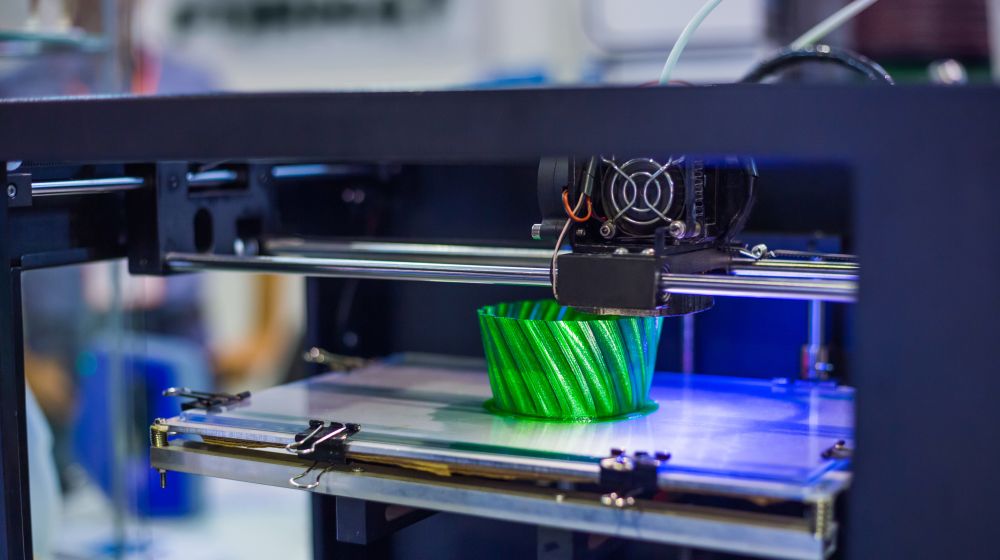

Size of the print bed

- A bigger bed means you can print bigger prints.

- A bigger bed also means you can print more students’ work at the same time. This is important because setting up to do a print run is time consuming so the more you can do at one time the better.

Auto-level/calibration

- Some machines require the user to calibrate the bed – this amounts to putting a piece of paper on the print bed and using the software to gradually move the print bed towards the nozzle until it touches. It takes about 10 minutes.

- Automatic calibration is available on many machines and we believe it is well worth the extra few hundred dollars more. With 3D printing there are already many things to learn and some things that can ‘go wrong’ so any help you can get is worth it.

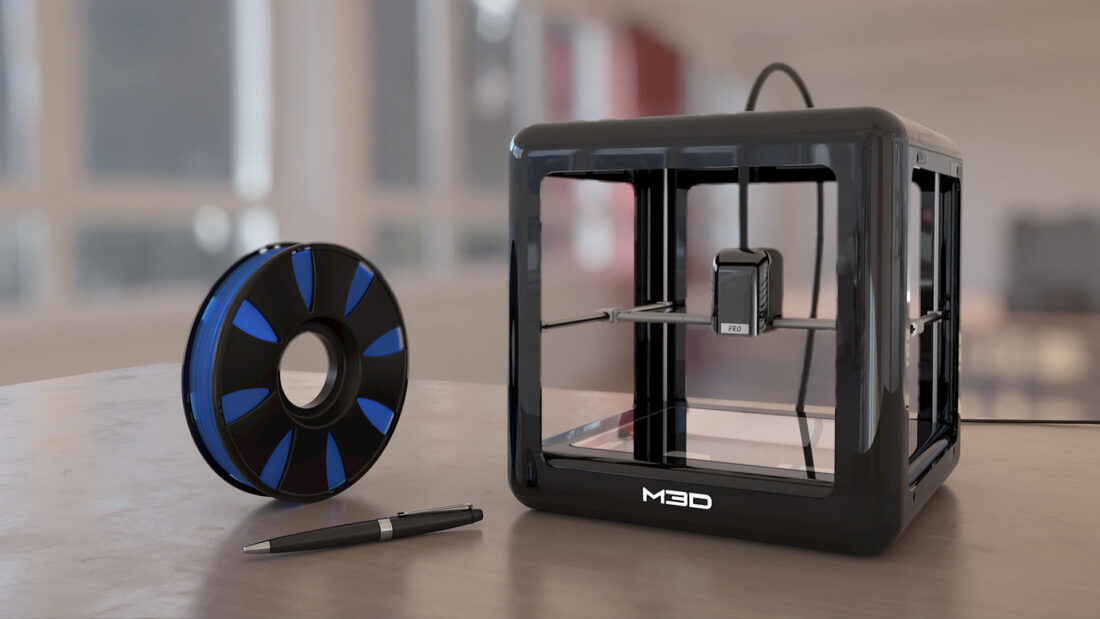

Type of filaments and cost

- Most consumer printers print ABS and PLA plastic.

- ABS is made from oil and is more toxic than PLA which is made from corn starch. Choose PLA in locations with no fan or extraction, although many places use ABS, too.

- Ensure you know how much the filament costs – $35–70/kg for ABS/PLA is normal. Some proprietary printers only work with their own filament which costs much more. Ask your supplier how much genuine or well tested non-genuine filament costs.

Software

- Is the software easy to use? Is it very configurable and powerful?

- Unless you are very technical we would suggest going for ‘easy to use’ software over power as your first foray into 3D printing — there is enough to learn already!

- Understand that many 3D printers are ‘open source’ and built for hobbyists and DIYers who want to spend a lot of time digging around software and hardware, modifying their printers and understanding from the programming code upwards how it works.

- These are easier to use: BEE THE FIRST, Up, Afinia, Makerbot

- There are more difficult to use but give you more control: 3D printers that use the open source Cura and Repetier programs.

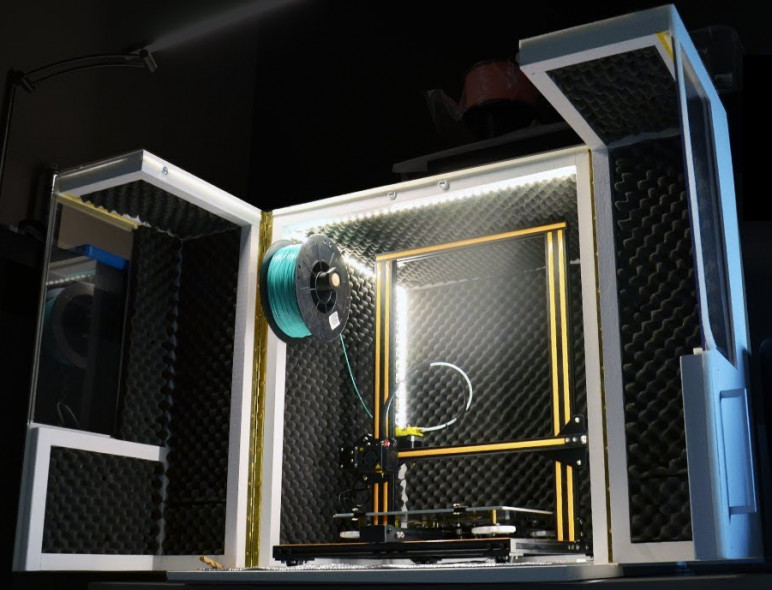

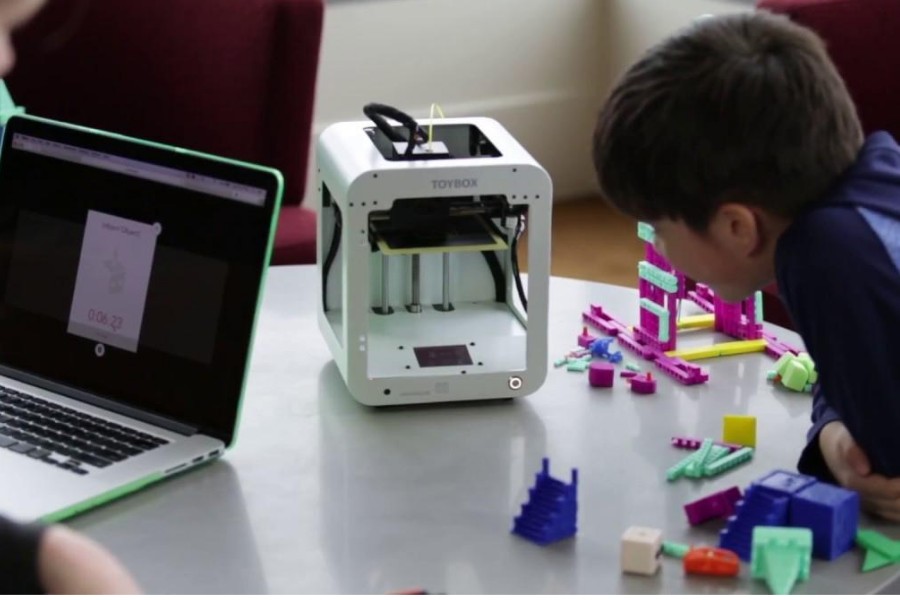

Bonus: Enclosure and air filters

- An enclosed printer is safer. Some will even stop if the door is opened. This can be very useful in a pre-K/elementary setting.

- We are beginning to see printers with built-in HEPA air filters. If your printer is not located in a well-ventilated area, this can be a great alternative and maybe an OH&S requirement.

Buying a 3D printer can be confusing so we hope the above tips and suggestions help you make an informed purchase. Hit us up on Twitter at @makersempire if you have any more questions.

10 Things You Should Know Before Buying 3D Printers

So you have decided to buy yourself a 3D printer after hearing about the amazing things it can build. You want to get started on printing models of your own a custom phone case, cosplay materials, figurines, musical instruments – the possibilities are endless.

Hold your horses, there are a few things you need to know before diving into the world of 3D printing.

There are a lot of 3D printers on the market today that have varying specifications, which in turn cater to different demands.

On top of that, there are technicalities about 3D printing that you really should look into. To help you decide on which printer to make your first, we have complied a list of 10 things you need to know before you buy a 3D printer.

10 Cheap and Affordable 3D Printers to Buy

10 Cheap and Affordable 3D Printers to Buy

There was a time when 3D printers were a novelty - but not anymore. You see hundreds of... Read more

1. Types of 3D printers

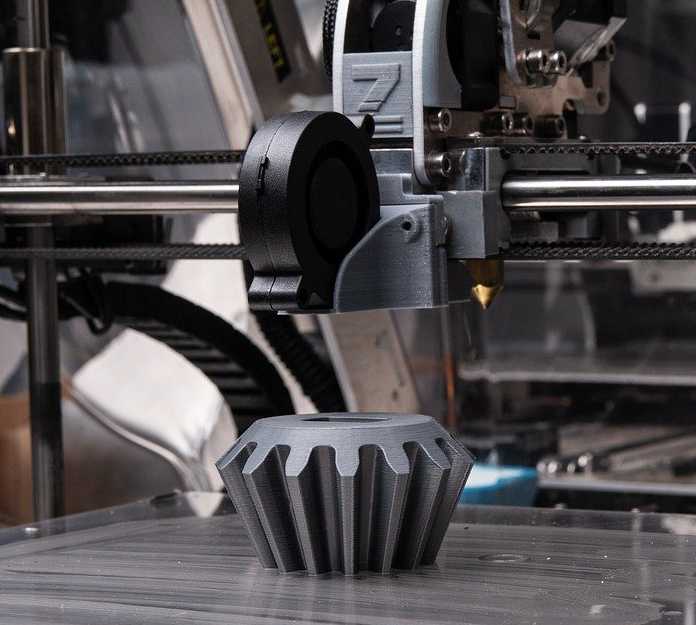

3D printing is a broad term that covers the technologies required for producing physical materials. The one you probably heard of in the media and the most popular among hobbyists is the one that uses Fused Deposition Modeling (FDM).

Fused Deposition Modeling (FDM)

FDM is an additive process, where a model is created by heating and extruding plastic, pieced together layer by layer.

Most of the 3D printers referred in this post works on FDM, as they are more widely available and easy to find.

There are 2 other types of 3D printing available: Stereolithography and Selective Laser Sintering (SLS). They are much more expensive compared to FDM.

Stereolithography

Stereolithography also uses the additive process but instead of extruding plastics, the process utilizes an ultraviolet light beam to harden a model from a pool of photosensitive liquid.

This allows for a higher quality printout.

Selective Laser Sintering (SLS)

SLS is similar to stereolithography, except that the process involves lasers and powders instead of UV light beams and liquid. A laser is used to melt the powder, creating a layer of the printed material.

This allows some models to print metal objects, which is not possible in the other two processes.

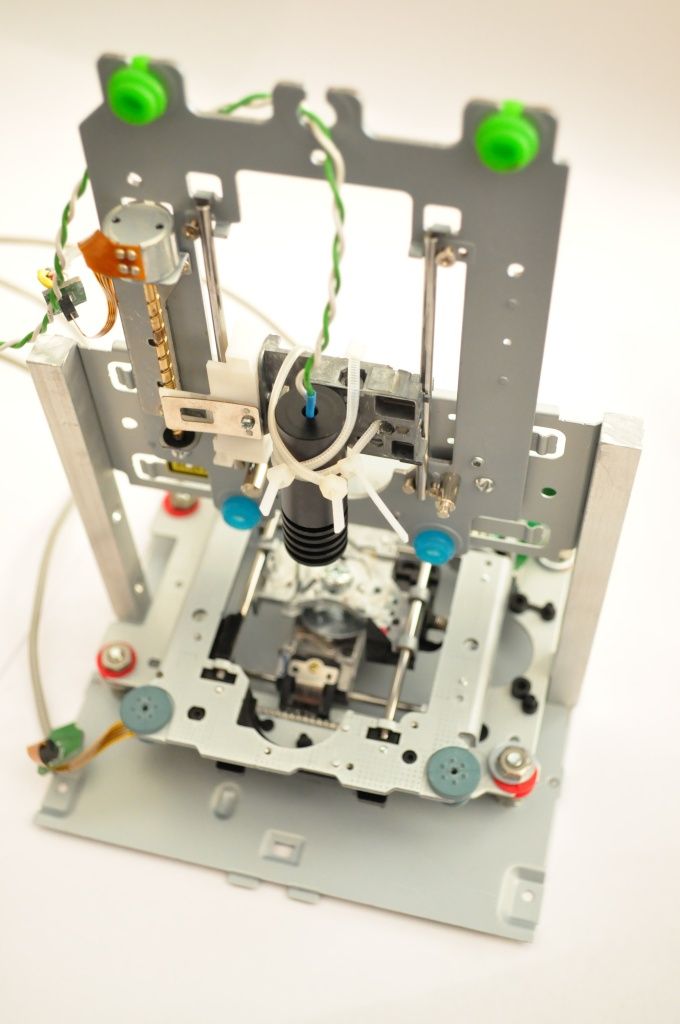

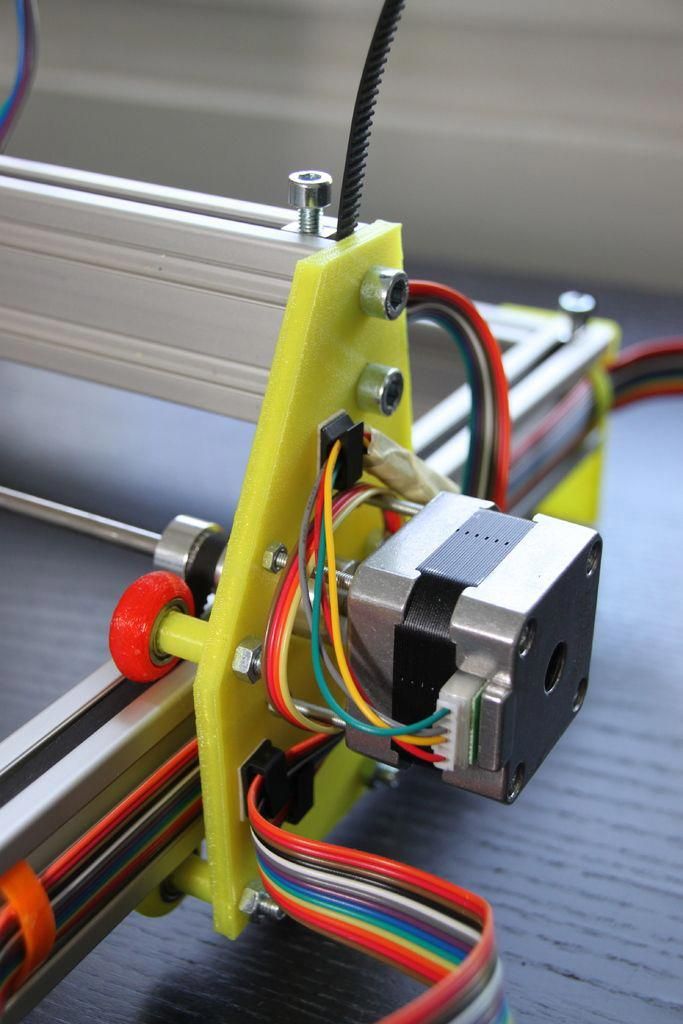

2. Build Your Own Or Buy One

The 3D printing community is one made of creators and makers, so it makes sense that many people would like to try their hand in building a 3D printer on their own.

There are building instructions and 3D printer kits available online if you decide to go with this route.

Building your own printer can be cheaper than buying one but if you don’t have the time, you could always buy a pre-assembled printer.

Your final decision will depend on whether you are interested in tinkering with the technology, or just want to start printing right away.

3. Price

One of the main factors that can help turn 3D printers mainstream is their market price. Prices depend mainly on the quality of the output.

In general, the higher-quality ones tend to go above $1000; professional printers can even go above $2000, e. g. the MakerBot series. But if you are just dipping your toes in 3D printing, you can start with simple models that go for as low as $100.

g. the MakerBot series. But if you are just dipping your toes in 3D printing, you can start with simple models that go for as low as $100.

With rising popularity and heavy competition, the prices of printers will only go down while the quality improves. Note that these printers do not come with the materials you require to print your products.

You will need to separately acquire the materials as different products may require different materials.

4. Materials used to print

The two materials required for 3D printing are Poly Lactic Acid (PLA) and Acrylonitrile Butadiene Styrene (ABS). Both are thermoplastics that will become soft and malleable when heated, frozen when cooled.

They are sold as 1kg (2.2lbs) spools of filament, priced in the $30 range.

Let’s take a look at the good and bad of both materials.

Poly Lactic Acid (PLA)

PLA is a type of plastic that is derived from corn starch, excellent for beginners to start dabbling with. Also great for creating small, simple household items. Other characteristics include:

Also great for creating small, simple household items. Other characteristics include:

- Biodegradable and environmentally sound

- Cools quickly, which prevents problems with model warping

- Available in both solid and translucent colors, gives printed objects a glossy look

- Disadvantage: Its low melting point may cause models to deform under high heat

- Disadvantage: It is difficult to work with if you require joints and interlocking parts

Acrylonitrile Butadiene Styrene (ABS)

ABS is a petroleum-based plastic that is a popular choice because of its strength and flexibility – think Lego bricks (which can be made using 3D printers, if you didn’t know).

- Its flexibility makes creating interlocking pieces easier to create and work with.

- It also has a higher melting point, so your creations will be less likely to deform under high heat.

- Disadvantage: It takes longer to cool compared to PLA; models are susceptible to warping.

- Disadvantage: It emits fumes during printing (more on this below).

How to Choose

You need to know which material is suitable for your final product. From there you can choose which type of printer you should buy. It is important to know that not all printers can accept both materials – some will work with only either one type.

When it comes to filament size – 1.75mm or 3mm in diameter – it doesn’t factor much into the end quality. More popular printer brands go with 1.75mm so it is recommended that you start with that.

5. Safety

When it comes to 3D printing, there are a few safety issues to take note.

Playing With Heat

The most important thing to remember is that you are working with heated plastics. Extruders, plastics and in some printers, the print bed itself can get very hot and can cause bad burns if you are not careful.

Some printers have no enclosure around the print area; practice extra caution with these printers.

Beware of Fumes

It is important to keep your 3D printer in an well-ventilated room. During the printing process, expect fumes to be emitted, particularly when you use ABS plastics.

These fumes are reported to be rather overwhelming although there is little to no research that states the impact they have on general health.

Still, it is best to take the necessary precautions, particularly if you will be using 3D printers a lot.

Food-Grade Plastic

3D printers can be use to create many types of household items, including kitchenware. Both ABS and PLA are generally food safe but if there are additives added in, those additives may not be.

Another major concern is that products created with FDM-type 3D printers have porous surfaces on which bacteria can collect in.

You can coat the object to make it safer to use but it is best to limit the usage of 3D printed kitchenware.

6.

Quality

QualityTo produce high quality 3D printed products, you need to take note of two things: print resolution and print speed.

Print resolution refers to the level of detail the printer can get, measured in microns – the smaller it is, the higher level of detail in the objects you can create.

Print speed measures how fast the printer can move its extruder – the higher the print speed, the faster it will print.

Note that other features may affect the print speed, such as the acceleration and deceleration of the printer, which helps prevent the printer from shaking.

In the end though, the best way to gauge the quality of a printer is to look at its output. You can look at photos, available online, of the final output of 3D printers before buying.

7. Obtaining A 3D Model

When it comes to getting a 3D model, there are two routes: you can create it yourself or download a pre-made model blueprint from the Internet.

If you intend to create your own model, there are a variety of software, both free and commercial, that will help you bring your creation into the real world. If you like, you can even learn 3D modeling.

Learning to model in a computer is a difficult task that will take time and effort to truly get used to. Fortunately, for those who are short on time, there are websites that provide 3D models of many different items, made by enthusiasts from all over.

A quick google search can probably yield you the item that you’re looking for.

8. STL Files

The STL file (STereoLithography) is the standard file format that you will use to print your 3D model into a physical object.

The file can be generated using most CAD programs so if you are building your own 3D models, chances are the software you are using can output one.

Basically inside an STL file is the information needed to produce a 3D model. The model itself is broken down to a series of triangles and a list of their XYZ coordinates is used by the printer to create the physical object, layer by layer.

9. Slicing Software

Once you have an STL file of the model you want to print, you will have to put them through a slicing software. What slicing does is that it “tells” your printer how to print your model.

It provides instructions on the number of layers needed, the starting position of the printer and the parts of the model that should be solid or hollow.

There are a number of software to help you with this although some software come with the printer. A good example would be MakerBot’s MakerWare.

10. Community

The great thing about a new tech trend is that there is almost always an online community devoted to it. It is no different with 3D printers.

Check online for a community of people who own a particular brand, to get more insight and answers to questions you may have about the ins and outs of that printer.

If the community is small or worse, nonexistent, the lack of users should raise a red flag about that particular brand.

All you need to make a sound investment is to read up more about that brand and its competitors so you know what you are getting into.

One of the main factors that can help turn 3D printers mainstream is their market price. Prices depend mainly on the quality of the output.

In general, the higher-quality ones tend to go above $1000; professional printers can even go above $2000, e.g. the MakerBot series.

But if you are just dipping your toes in 3D printing, you can start with simple models that go for as low as $100.

With rising popularity and heavy competition, the prices of printers will only go down while the quality improves.

Note that these printers do not come with the materials you require to print your products. You will need to separately acquire the materials as different products may require different materials.

4. Materials used to print

The two materials required for 3D printing are Poly Lactic Acid (PLA) and Acrylonitrile Butadiene Styrene (ABS). Both are thermoplastics that will become soft and malleable when heated, frozen when cooled.

Both are thermoplastics that will become soft and malleable when heated, frozen when cooled.

They are sold as 1kg (2.2lbs) spools of filament, priced in the $30 range.

Let’s take a look at the good and bad of both materials.

Poly Lactic Acid (PLA)

PLA is a type of plastic that is derived from corn starch, excellent for beginners to start dabbling with. Also great for creating small, simple household items. Other characteristics include:

- Biodegradable and environmentally sound

- Cools quickly, which prevents problems with model warping

- Available in both solid and translucent colors, gives printed objects a glossy look

- Disadvantage: Its low melting point may cause models to deform under high heat

- Disadvantage: It is difficult to work with if you require joints and interlocking parts

Acrylonitrile Butadiene Styrene (ABS)

ABS is a petroleum-based plastic that is a popular choice because of its strength and flexibility – think Lego bricks (which can be made using 3D printers, if you didn’t know).

- Its flexibility makes creating interlocking pieces easier to create and work with.

- It also has a higher melting point, so your creations will be less likely to deform under high heat.

- Disadvantage: It takes longer to cool compared to PLA; models are susceptible to warping.

- Disadvantage: It emits fumes during printing (more on this below).

How to Choose

You need to know which material is suitable for your final product. From there you can choose which type of printer you should buy.

It is important to know that not all printers can accept both materials – some will work with only either one type.

When it comes to filament size – 1.75mm or 3mm in diameter – it doesn’t factor much into the end quality. More popular printer brands go with 1.75mm so it is recommended that you start with that.

5. Safety

When it comes to 3D printing, there are a few safety issues to take note.

Playing With Heat

The most important thing to remember is that you are working with heated plastics. Extruders, plastics and in some printers, the print bed itself can get very hot and can cause bad burns if you are not careful. Some printers have no enclosure around the print area; practice extra caution with these printers.

Beware Of Fumes

It is important to keep your 3D printer in an well-ventilated room. During the printing process, expect fumes to be emitted, particularly when you use ABS plastics. These fumes are reported to be rather overwhelming although there is little to no research that states the impact they have on general health. Still, it is best to take the necessary precautions, particularly if you will be using 3D printers a lot.

Food-Grade Plastic

3D printers can be use to create many types of household items, including kitchenware. Both ABS and PLA are generally food safe but if there are additives added in, those additives may not be. Another major concern is that products created with FDM-type 3D printers have porous surfaces on which bacteria can collect in. You can coat the object to make it safer to use but it is best to limit the usage of 3D printed kitchenware.

Another major concern is that products created with FDM-type 3D printers have porous surfaces on which bacteria can collect in. You can coat the object to make it safer to use but it is best to limit the usage of 3D printed kitchenware.

6. Quality

To produce high quality 3D printed products, you need to take note of two things: print resolution and print speed.

Print resolution refers to the level of detail the printer can get, measured in microns – the smaller it is, the higher level of detail in the objects you can create. Print speed measures how fast the printer can move its extruder – the higher the print speed, the faster it will print. Note that other features may affect the print speed, such as the acceleration and deceleration of the printer, which helps prevent the printer from shaking.

In the end though, the best way to gauge the quality of a printer is to look at its output. You can look at photos, available online, of the final output of 3D printers before buying.

You can look at photos, available online, of the final output of 3D printers before buying.

7. Obtaining A 3D Model

When it comes to getting a 3D model, there are two routes: you can create it yourself or download a pre-made model blueprint from the Internet. If you intend to create your own model, there are a variety of software, both free and commercial, that will help you bring your creation into the real world. If you like, you can even learn 3D modeling.

Learning to model in a computer is a difficult task that will take time and effort to truly get used to. Fortunately, for those who are short on time, there are websites that provide 3D models of many different items, made by enthusiasts from all over. A quick google search can probably yield you the item that you’re looking for.

8. STL Files

The STL file (STereoLithography) is the standard file format that you will use to print your 3D model into a physical object. The file can be generated using most CAD programs so if you are building your own 3D models, chances are the software you are using can output one.

The file can be generated using most CAD programs so if you are building your own 3D models, chances are the software you are using can output one.

Basically inside an STL file is the information needed to produce a 3D model. The model itself is broken down to a series of triangles and a list of their XYZ coordinates is used by the printer to create the physical object, layer by layer.

9. Slicing Software

Once you have an STL file of the model you want to print, you will have to put them through a slicing software.

What slicing does is that it “tells” your printer how to print your model. It provides instructions on the number of layers needed, the starting position of the printer and the parts of the model that should be solid or hollow.

There are a number of software to help you with this although some software come with the printer. A good example would be MakerBot’s MakerWare.

10. Community

The great thing about a new tech trend is that there is almost always an online community devoted to it. It is no different with 3D printers. Check online for a community of people who own a particular brand, to get more insight and answers to questions you may have about the ins and outs of that printer.

It is no different with 3D printers. Check online for a community of people who own a particular brand, to get more insight and answers to questions you may have about the ins and outs of that printer.

If the community is small or worse, nonexistent, the lack of users should raise a red flag about that particular brand. All you need to make a sound investment is to read up more about that brand and its competitors so you know what you are getting into.

8 nuances worth paying attention to

Sooner or later, everyone learns about 3D printing. And only a few lucky people, imbued with the opportunities that 3D printing opens up, catch themselves thinking that they want to purchase a 3D printer. The desire gradually develops into a serious decision and the search for the right option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose among the whole variety of 3D printers. We will try to answer this question in as much detail as possible. What to look for, and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer. You need to decide for yourself for what tasks you will use this technique? What features should a 3D printer have to solve your problems?

We will try to answer this question in as much detail as possible. What to look for, and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer. You need to decide for yourself for what tasks you will use this technique? What features should a 3D printer have to solve your problems?

Tip 1 : Decide on 3D printing technology

The first step is to decide on the technology of 3D printing. There are two main paths here. If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

Nuance 2: Evaluate your needs

Of course, you always want to get all the best and with maximum opportunities. Do you need all this to solve your current problems? What can be cited as an example? For example, the size of the working area of the FDM 3D printer. There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x100mm). But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks. But options are possible ... If you plan to manufacture small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area. In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

This volume is enough to solve 95% of any tasks. But options are possible ... If you plan to manufacture small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area. In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

Nuance 3 : Decide on the complexity of the products

You should decide for yourself how complex models you will print on a 3D printer. If you plan to manufacture complex prototypes, or complex art models, then you need a 3D printer that can print with two materials. This is necessary so that your printer can print supports from soluble material. If the models are not the most complex, then you can get by with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles of more than 30 degrees.

This is necessary so that your printer can print supports from soluble material. If the models are not the most complex, then you can get by with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles of more than 30 degrees.

Point 4: Decide on the list of materials to be used.

Another important point. You must immediately determine for yourself a list of possible materials with which you are going to print. This primarily applies to materials with a high degree of shrinkage, such as ABS and Nylon. In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model. If you plan to print only with PLA plastic. You don't need a heated table. But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform the full range of tasks facing a 3D printer. One more moment. Ability to print with flexible materials Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends. Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform the full range of tasks facing a 3D printer. One more moment. Ability to print with flexible materials Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends. Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

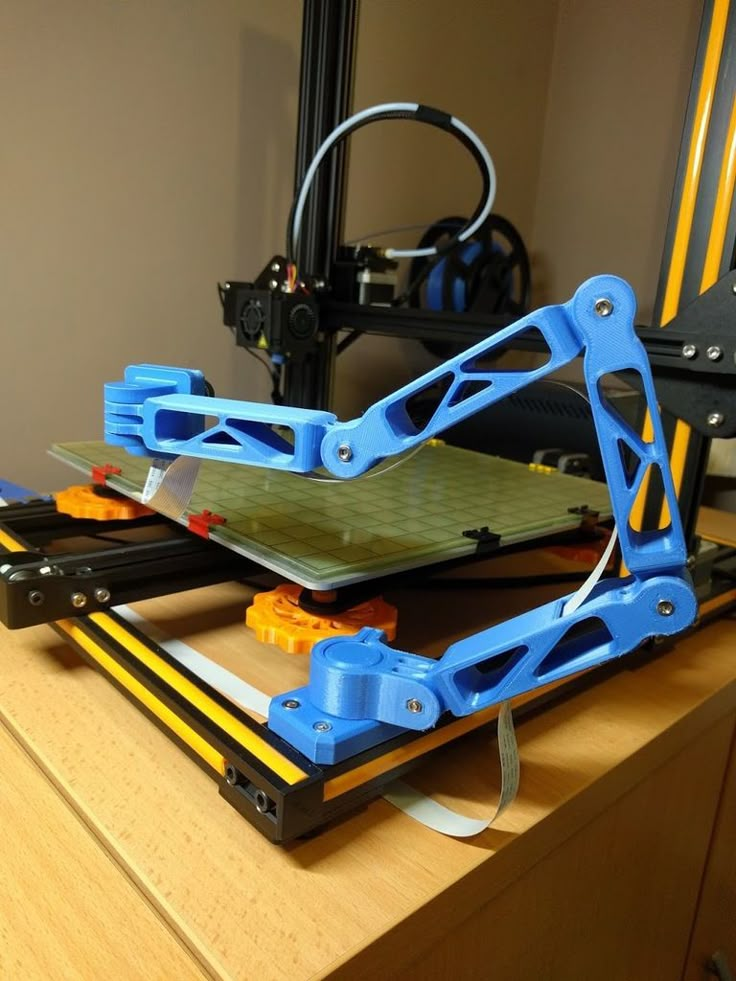

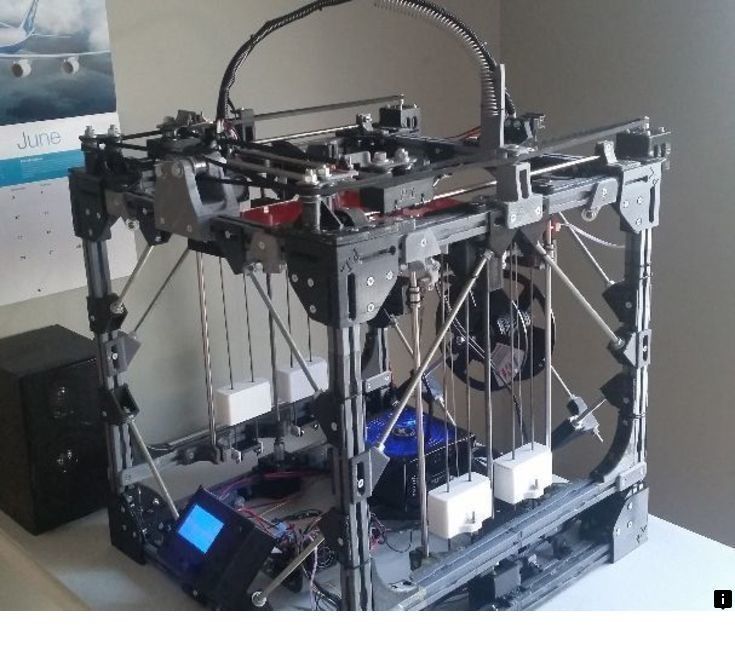

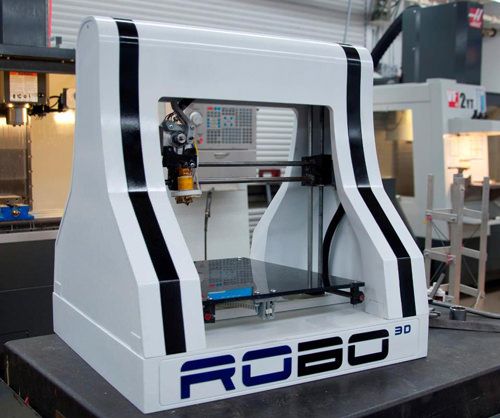

Nuance 5: Construction and kinematics

Next, you need to pay attention to the design of the 3D printer. Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And others are closed. As they like to be called in the Russian-speaking community "cubes". What does the appearance say? Printers with an open design, usually have kinematics with a horizontally moving table (based on Prusa 3D printers). This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble. Also, the lack of a closed case can cause print quality problems with high shrinkage plastics (ABS, Nylon). The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme.

Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And others are closed. As they like to be called in the Russian-speaking community "cubes". What does the appearance say? Printers with an open design, usually have kinematics with a horizontally moving table (based on Prusa 3D printers). This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble. Also, the lack of a closed case can cause print quality problems with high shrinkage plastics (ABS, Nylon). The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits.

And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits.

Nuance 6: Diameter and changeable nozzle

Most 3D printers on the market come with 0.3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer. Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary. What do we mean by specific tasks? This is especially true for printing large items, where it is very important to reduce the printing time. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

If you do not plan to do this, then this opportunity is not so necessary. What do we mean by specific tasks? This is especially true for printing large items, where it is very important to reduce the printing time. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

Nuance 7: Print thickness

It is important to understand that most models on a 3D printer are printed with a layer of 0.1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0. 05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

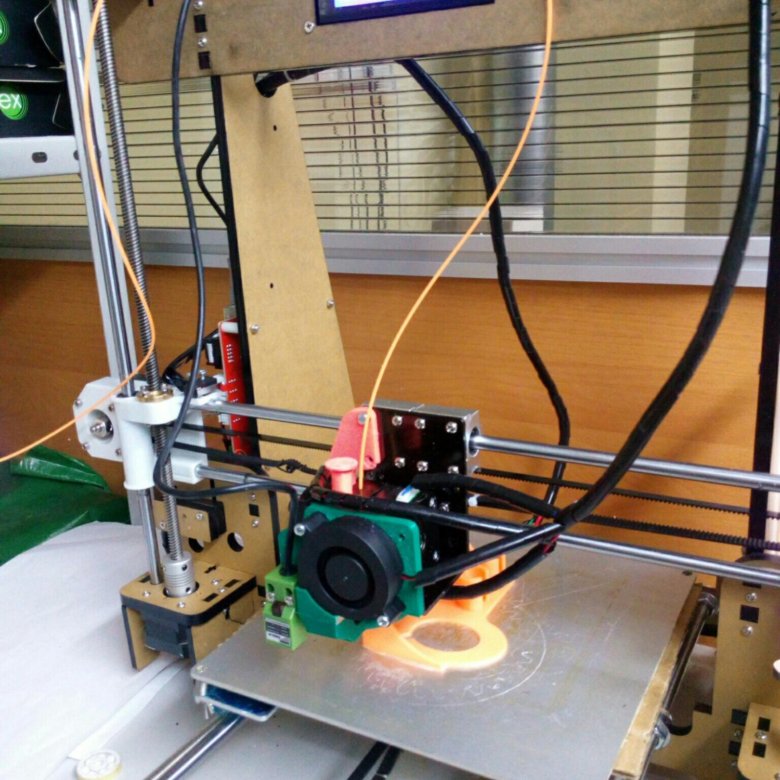

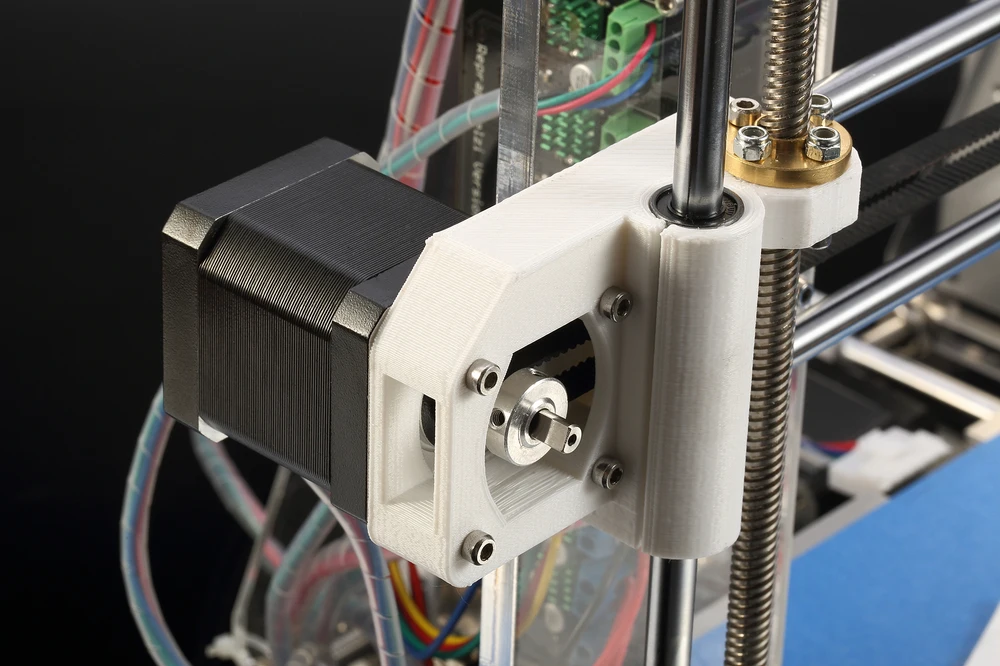

Nuance 8: Extruder type

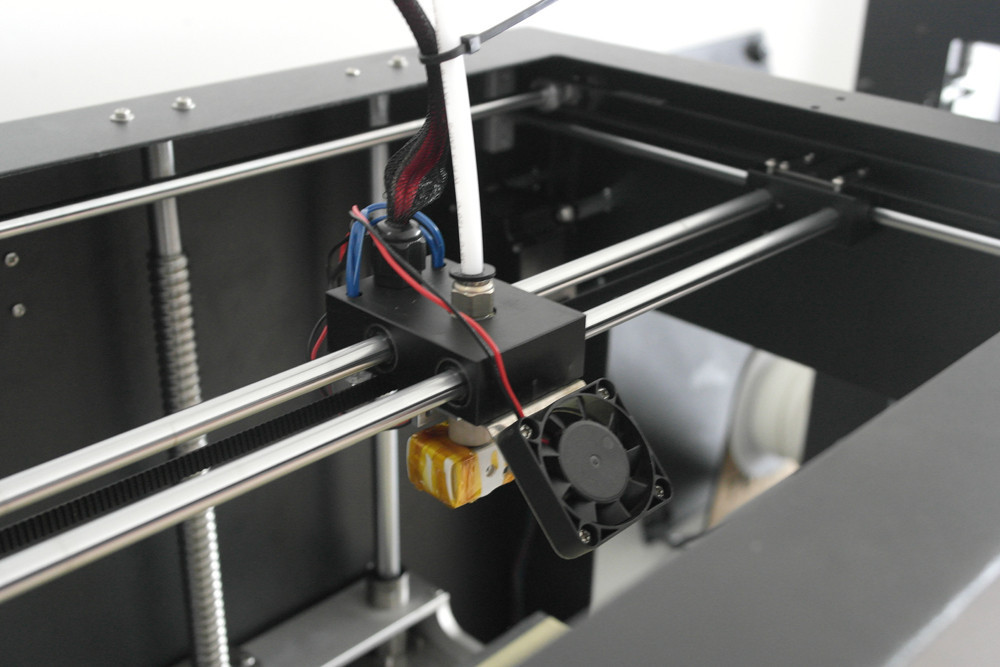

Today there are two main types of extruder. This is a direct extruder in which the bar feed motor is located in the printhead itself. And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube. What are the advantages and disadvantages of each type of extruder? Bowden extruder, due to the lack of a motor on the print head, has less weight. And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types. Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely.

But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types. Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

In our assortment you can always find 3D printers for your tasks:

1) Budget 3D printers

2) 3D printers for business

3) Large area 3D printers

4) SLA and DLP 3D printers

Do you have any questions?

Call: +7 (495) 324-07-90 (Moscow) and 8 (800) 775-86-69 (toll-free in the Russian Federation) or write to the mail: [email protected] and our employees will be happy to give you a detailed consultation on any topic of interest.

Which 3D printer to choose for home and hobby

A few years ago, 3D printers were bulky industrial machines, but now 3D printing is becoming more accessible for home use. When buying their first printer, many are disappointed. This may be due to the unsatisfactory quality of the resulting models or the complex setup and maintenance of the 3D printer.

When buying their first printer, many are disappointed. This may be due to the unsatisfactory quality of the resulting models or the complex setup and maintenance of the 3D printer.

In the reviews that are found on the Internet, printers are often shown after a lot of upgrades or a long selection of settings for printing. This is not at all the result that a beginner who first got acquainted with 3D printing will get.

In order not to be disappointed, before buying, you need to understand which model is suitable for your tasks. First of all, it is worth deciding what the printer will be used for. What is the main property that finished products should have? What is more important, the physical properties of the model or the ideal surface and detail? Not only the model depends on this, but also the technology by which the 3D printer will work.

Which technology to choose? FDM or LCD?

If you need to make a small detailed figurine with a perfectly smooth surface, you should pay attention to models that work on LCD technology (LCD works on a principle similar to DLP - Digital Light Processing or “digital light processing”).

LCD prints using a photopolymer resin that cures under UV light. This makes it possible to produce without deformation, even small and thin products that cannot be manufactured using FDM technology.

Resin model

Now on sale there are many photopolymer resins with different properties. A few years ago the choice was not great. Basically, finished products were not strong enough for use in functional models. Now engineering resins have begun to appear on sale. Products from them are not inferior in strength to models made using FDM technology from ABS or even nylon.

If it is necessary to produce large products with different properties, or the tasks will be very diverse, then the choice is with FDM technology. But it is important to understand that finished products will not have a perfectly smooth surface. Of course, you can polish the model, but this is additional time and labor costs.

FDM technology builds a model using molten plastic filament, which is fed from the print head. The print head (extruder) “grows” the model layer by layer on the printing table.

The print head (extruder) “grows” the model layer by layer on the printing table.

FDM Models

FDM technology became widespread much earlier than DLP. Thanks to this, a wide variety of 3D printers and consumables for them has appeared. You can find many decorative plastics that mimic various materials, or engineering plastics for making functional models or mock-ups.

Choosing an LCD printer

Photopolymer printers work on one of 3 technologies - DLP, LCD or SLA.

As home printers, devices based on LCD technology are usually used due to their availability and low price.

Printer design

SLA technology appeared the very first among photopolymer printers. With the help of a point-focused beam, the desired areas of the resin are gradually illuminated. This is repeated layer by layer.

How SLA 9 works0099

Since the surface of the model is perfectly smooth, SLA has become used in the jewelry and dental industries.

Pros:

Cons:

DLP technology appeared later than SLA, but it is very similar to it. The main difference is that the light source is not a focused beam, but a projector. This made it possible to illuminate the entire layer at once, which significantly accelerated the production of models. The quality of the surface was slightly inferior to SLA, but modern DLP printers, in terms of the quality of models, are almost as good as SLA technology.

How DLP works

Pros:

-

Faster production of models due to the illumination of the entire layer

-

Consumables are slightly cheaper than SLA

-

High surface quality (although may be inferior to SLA)

Cons:

LCD technology is the youngest of all. The DLP principle is taken as a basis, but an LCD display is used as a matrix or illumination pattern. LEDs are used as a source of UV light in LCD technology. Thanks to inexpensive components, we managed to get a simple, but high-quality and affordable photopolymer printer.

LEDs are used as a source of UV light in LCD technology. Thanks to inexpensive components, we managed to get a simple, but high-quality and affordable photopolymer printer.

How the LCD printer works

Pros:

-

small cost

-

Cheap parts

Cons:

-

Low accuracy compared to SLA and DLP (for jewelers and dentists, the quality of LSD prints may not be enough, although more and more accurate models appear with the development of technology)

-

Possible stray light

-

The quality of models may decrease at the edges of the printable area (this can be corrected programmatically)

Resins that are used as a consumable for photopolymer printing can smell strongly and unpleasantly during operation. Try to use the printer in a well-ventilated area, or choose a printer with a sealed cabinet and filter.

When choosing an LCD printer, pay special attention to the rigidity and positioning accuracy of the platform along the Z axis. If there are poor quality guides along the Z axis or even a slight play, then the surface quality of the finished model may turn out to be sloppy or the model will turn out to be unevenly striped.

Rating of the best LCD 3D printers for home

Anycubic Photon Mono

This is an LCD printer with a matrix that allows you to increase the speed and accuracy of printing. Anycubic Photon Mono will be a good helper for hobbyists and modellers.

Anycubic Photon Mono SE

Anycubic Photon Mono SE has an unusual parallel light source. This minimizes distortion at the edges of the printable area. You can effectively use the entire working area of the machine and produce many small models at a time.

Phrozen Sonic Mini 4K

Model with high resolution LCD display and large print area. The monochrome display transmits UV rays better and allows you to print much faster than similar devices with a conventional display. The manufacturer claims a screen life of more than 2000 hours. Phrozen Sonic mini 4k is suitable for almost any task.

The monochrome display transmits UV rays better and allows you to print much faster than similar devices with a conventional display. The manufacturer claims a screen life of more than 2000 hours. Phrozen Sonic mini 4k is suitable for almost any task.

Wanhao GR1

Wanhao GR1 has high precision and large print area (140x78x200mm). The manufacturer tried to reduce distortion at the edges of the display, this allows you to make the most of the entire work area. High precision and large print area make Wanhao GR1 not only for hobby use, but also for production.

Anycubic Photon Zero

Small and very budgetary LCD device. Its resolution and small working area (total 97x54x150 mm) is enough for printing small miniatures, figurines or small engineering models. Anycubic Photon Zero is a good choice for beginners who want to get into photopolymer printing without spending a lot of money.

Choose FDM printer

If you plan to produce large and diverse functional models or experiment, a 3D printer that prints using FDM technology is an excellent choice.

First, decide on the size of the printable area and the properties that the finished model should have. After all, some materials require a closed chamber or good airflow to work.

Some printer models can be “upgraded” in the future. For example, if necessary, purchase spare parts for a closed case, put a nozzle of a different diameter, or change the thermal barrier to an all-metal one. But not all manufacturers provide for the possibility of such upgrades.

Printer design

Despite the same principle of operation, there are several different mechanics, which have their pros and cons.

Kinematics “Prusa” (Prusa)

Perhaps the most popular kinematics among home FDM devices. Mainly due to its simplicity and low cost. The main feature is the table that moves along the Y axis, while the extruder moves along the rest of the axes. Because of this, such kinematics was nicknamed “dragstol”.

Prusa kinematics

Pros:

Cons:

-

Slow print speeds.

A massive table with a model is forced to constantly move along the Y axis, because of this, print quality will be worse at high speeds.

A massive table with a model is forced to constantly move along the Y axis, because of this, print quality will be worse at high speeds. -

Some models have design flaws (for example, insufficient frame rigidity), they can be fixed, but for this you have to be a little inventor. Or find a ready-made solution on the Internet.

This category also includes 3D printers with console kinematics. The same prusa, only halved. Because of this, the frame is less rigid, but the printer itself is more compact.

Kinematics Ultimaker

The extruder moves along the X-Y axes, and the table only along the Z axis. All motors are trying to be fixed on the body to lighten the weight of the moving mechanisms, thanks to which it is possible to achieve high print quality at high speeds.

Ultimaker kinematic diagram

Pros:

Cons:

H-BOT or Core-XY

These are 2 similar but more complex kinematics - the table moves only along the Z axis, and the extruder along the X-Y. But to move the extruder, 1 or 2 long belts and 2 stepper motors work in concert.

But to move the extruder, 1 or 2 long belts and 2 stepper motors work in concert.

Example Core-XY kinematics

Pros:

-

High print quality

-

High print speeds without loss of quality.

-

Can be easily closed completely

Cons:

MakerBot Kinematics

Similar to Ultimaker kinematics, but one of the motors is located on the Y or X axis carriage.

Pros:

Cons:

Delta

Deltas do not have the usual XYZ axes. There are 3 columns in the deltas, along which the carriages move, and the position of the extruder in space is calculated using a complex formula. The table is usually statically fixed to the body.

Delta printer example

Pros:

Cons:

Nuances of choosing an FDM 3D printer

In addition to kinematics, when choosing a printer, it is important to take into account some design features.

One or two extruders?

Two extruders can be used for dual color printing, but most commonly the second extruder is used for solvent support printing. If you need to print complex parts with internal cavities, then you should choose a dual extruder printer.

Closed or open printer?

Printing of functional models and parts uses plastic, which usually requires a closed chamber. If you plan to print functional prototypes or various models, you should look at printers with a closed chamber.

Bowden or direct?

There are 2 types of material supply to the print head of the printer - bowden and direct.

In a bowden, the feed mechanism motor is located on the printer body. This allows you to reduce the weight of the extruder and print at higher speeds without losing quality. But because of the long tube, printing with very soft plastics can be problematic.

Bowden feed pattern

In direct feeding, the motor and feed mechanism are located on the extruder. This increases the weight of the print head, but allows you to print with any kind of plastics.

This increases the weight of the print head, but allows you to print with any kind of plastics.

Direct feeding scheme

Heated table or not?

The heating of the table improves the adhesion of the first layer of the model. And engineering plastics cannot be printed without a heated table.

Many manufacturers add useful additional features. They do not affect the quality of the print, but save time and nerves. The most useful additional functions are the filament presence sensor and remembering the print location after a power outage.

Filament sensor.

It will automatically pause printing if the plastic runs out. When there is a little plastic left on the spool, this feature will allow you not to stand over the guard printer until the old spool runs out in order to have time to push in a new bar “on the go”.

Power outage protection.

Remembering where to print when the power goes out can save you a lot of nerves when printing large models. You won't have to worry that after a power outage, you will have to run the model again for many hours or cut and reprint a piece of the model. It is especially disappointing to throw away a complex underprinted model with supports due to a one-minute outage.

You won't have to worry that after a power outage, you will have to run the model again for many hours or cut and reprint a piece of the model. It is especially disappointing to throw away a complex underprinted model with supports due to a one-minute outage.

There are also many extras. features that make using the printer more comfortable. For example, automatic calibration, touch screen, Wi-Fi and others.

Rating of the best FDM 3D printers for home

Anycubic Mega Zero 2.0

Inexpensive model with Pryusha kinematics. Good for getting started with 3D printing without a big investment. Despite the low cost, Anycubic Mega Zero 2.0 has a heated table and a resume function after a power outage. Thanks to direct feed, printing with soft materials should not be difficult.

Creality3D Ender 3 Pro

A very popular device due to its low price. But despite this, the Ender 3 Pro has a heated table and a decent print area. Can be sold assembled or as a DIY kit.

Can be sold assembled or as a DIY kit.

Flash Forge Finder

Small home appliance intended for children or educational institutions. The Finder doesn't have a heated table, but it does have a calibration assistant, a Wi-Fi module, and other extras that make getting to know it a lot easier. All moving and heated elements are hidden as much as possible in the case so that the child cannot get burned.

Wanhao Duplicator 6 Plus

Wanhao Duplicator 6 Plus was based on Ultimaker kinematics, but instead of bowden feed, they made direct. Because of this, it will not be possible to print super fast, without quality loss, but there will be no problems with printing with soft types of plastics. There are 2 trim levels - with a closed case and without.

Flashforge Dreamer

The Dreamer is a closed body dual extruder printer with MakerBot kinematics. Thanks to this, he can cope with printing models of any complexity. Using a second extruder for soluble support, models with complex geometries can be produced. A good choice for engineers and those who like to experiment with different materials.

Using a second extruder for soluble support, models with complex geometries can be produced. A good choice for engineers and those who like to experiment with different materials.

FlyingBear Ghost 5

Most commonly sold as a kit (assembly kit). Assembly usually does not cause any great difficulties, even for people far from electronics or mechanics. Flying Bear is equipped with a filament sensor, a function to resume printing after a power outage and Wi-Fi connectivity.

The Flying Bear makes a great first printer for the novice user who is ready to build their own printer.

Totals

In order for the printer not to become a useless toy, you should clearly understand what it is for.

For a fan of miniatures or detailed figurines, a photopolymer printer is a good choice. A small work area is more than offset by the detail that cannot be obtained using other technologies.

For an engineer or a fan of experiments, an FDM machine with a closed chamber and two extruders is well suited.