Nikon 3d laser scanner

Nikon LC60Dx laser scanner 3D , TOP Metrology CMM

Nikon LC60Dx laser scanner 3D , TOP Metrology CMMCerere oferta

Emailul tău (obligatoriu) Numele tău (obligatoriu) Denumire firma (obligatoriu) Accept prelucrarea datelor de TopMetrology SRLhttps://topmetrology.ro/wp-content/uploads/2016/09/lc60dx-en.pdf

Descarca brosura

E-mail (obligatoriu) Accept prelucrarea datelor de TopMetrology SRL conform "Prelucrarea datelor cu caracter personal"Description

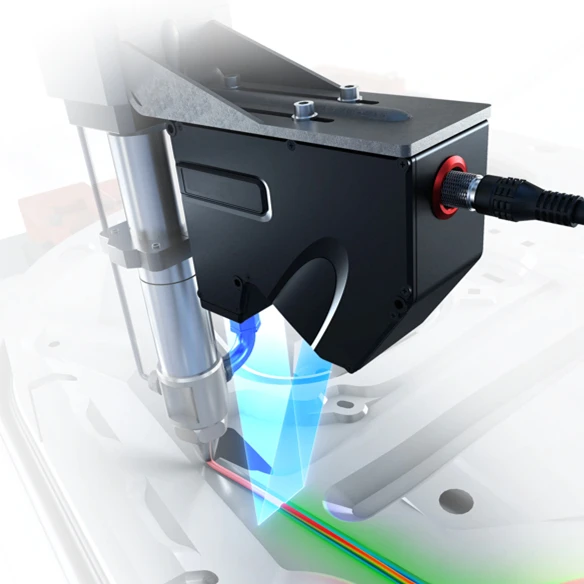

LC60Dx single line scanner brings laser scanning in the accuracy range of tactile measurement, while capturing 75,000 measurement points a second. Equipped with powerful CMOS technology, the all-digital scanner automatically digitizes the complete geometry of parts covering features and surfaces in just a few CMM strokes.

Key benefits

- Premium performance CMM scanner for every inspection job

- Gain full geometric insights from the 3D representation of the entire part

- Benefit from the unique capability to measure soft and fragile surfaces

- Increase the capacity of your CMM’s and floor space

- Run any kind of analysis on the digital copy, even building virtual prototypes instead of expensive physical prototypes

- Programming and execution of inspection job is fast and straightforward, even for novice or non-metrology users

Applications

- 3D digitizing with high detail and speed

- Complex surfaces (composites, blades, impellers, medical devices, etc)

- Features (Slot, holes, studs, etc)

- Portable / Fixed CMM scanning applications

Benefits & features

Accurate non-contact measuring technology

Powerful CMOS technology incorporated into LC60Dx translates into higher measuring accuracy, resulting in a typical MPEp value of 7 micron according to EN ISO 10360-5. This brings the all-digital scanner in the accuracy range of tactile measurement. E.g. The Multi-stylus accuracy test is comparable to EN/ISO 10360-5 MPEal and scans a sphere with 5 different scanner

orientations. Then the 3D deviation is calculated between the center of each sphere that’s fit through a single pointcloud and the center of the average sphere.

Ideal for measuring soft and fragile parts

Measuring soft, fragile or brittle parts potentially yield inaccurate measurements or surface scratches. As laser scanning technology is entirely non-contact, there is no risk for damage or inaccurate measurement. An example of such an application is the dimensional inspection of engine sand cores.

Superfast scanning

The LC60Dx laser scanner captures 75,000 measurement points per second. By acquiring a multitude of measurement points, the scanner is able to reliably digitize freeform shapes and geometric features. Both are critical for high-quality assembly and part mating.

Scanning nearly every material surface with ESP3

ESP3 incorporates dynamic point-per-point laser intensity adaptation of laser source intensity. This capability allows different surface materials, finishes and transitions to be scanned without user interaction, eliminating manual parameter tuning and part spraying altogether. ESP is a key differentiator when scanning similar parts in different manufacturing stages; initially dealing with bare sheet metal parts and finally scanning finished products painted in any color.

Seamless retrofit for most leading CMM brands

As applicable to all Nikon Metrology CMM scanners, the LC60Dx scanners can be retrofitted on a wide range of CMM brands to boost inspection productivity of existing CMM installations anywhere in the world.

Premium reliability in any working conditions

Nikon Metrology development engineers optimized scanner design for maximum operational stability and robustness. Critical in this regard is that principal scanner components are mounted in an ultra-stiff tress-free aluminum housing.

Critical in this regard is that principal scanner components are mounted in an ultra-stiff tress-free aluminum housing.

Special attention is paid to temperature stability by design and temperature compensation algorithms in order to minimize warm-up time and guarantee reliable accuracy under shop floor conditions.

Compatible with Renishaw indexing heads and change racks

The LC60Dx scanners are compatible with common Renishaw indexing heads. The scanners also fit in the ACR racks and can be used in combination with tactile probes for e.g. alignment of the part. By docking a scanner in an dedicated ARC3 rack, zero warm-up time is obtained resulting in maximum productivity.

View more See less

You can request an offer

Nikon LC60Dx laser scanner

Request offer

Funding

Financing solutions for the purchase of new equipment, through BCR Leasing or Grenke.

See Financing Methods

Guarantee

Wenzel Introduce Nikon L100 CMM Laser Scanner – Metrology and Quality News

WENZEL has introduced the NIKON L100 CMM laser scanner offering more productivity and precision. By using Nikon sensors on a WENZEL CMM, WENZEL expands its portfolio of optical sensors and states that it can offer each customer the appropriate sensor in terms of measurement time, accuracy and level of detail.

By using Nikon sensors on a WENZEL CMM, WENZEL expands its portfolio of optical sensors and states that it can offer each customer the appropriate sensor in terms of measurement time, accuracy and level of detail.

The L100 CMM laser scanner offers the best possible combination of speed, accuracy and ease-of-use. Suited for both surface and feature measurement, the L100 quickly delivers accurate data and insightful part-to-CAD comparison reports even on shiny or multi-material surfaces. The 100 mm wide Field-of-View (FOV) combined with the increased measurement speed of 420,000 points/second results in measurement productivity that was not achievable with CMM scanning before.

Ultrafast data collection

Built-in FOV projection clearly indicates to a user whether the scanner is precisely positioned, simplifying programming and allowing optimal scan path generation. The 4th generation of Nikon Metrology’s patented Enhanced Sensor Performance (ESP4) adapts the laser intensity automatically to varying colors and material surfaces for each point in the scan line making the L100 even more capable at digitizing multi-material assemblies or shiny surfaces, without the need for time-consuming treatment of the component surface.

A patent-pending, integrated mount allows the scanner to rotate around its autojoint axis in 30 degree increments up to 90 degrees. It facilitates measuring turbine blades or parts with vertically oriented features and edges. The L100 also allows the use of an extended 105-degree Ph20 A-angle, allowing better access to measure underneath or behind parts.

For more information: www.wenzel-group.com

HOME PAGE LINK

Latest Headline News

You May Also Like These 'Latest News' Stories … click image to read full articles

Digital Models Feed CMM Measurement Systems Offering Complete 3D Environment

In a Smart Manufacturing environment, the goal is to automate as many operations as possible to improve production performance. Quality control, and more specifically, measurement analysis, has to evolve at

Eight ‘Digital Reality’ Start-Ups Secure Opportunity To Advance Manufacturing

Eight of the most innovative manufacturing start-ups from across the globe have been announced by Hexagon as the second cohort of the Sixth Sense open innovation platform.

The selected start-ups

The selected start-upsEvatronix To Present eviXscan 3D Wide Range 65 Scanner

Polish manufacturer of 3D scanners, Evatronix, has announced it will present Wide Range 65 scanner at upcoming events – Fabtech in Atlanta and Formnext in Frankfurt. The portfolio of Evatronix

Software Module for Standardizing AM Machine Health Data Logs Launched

Sigma Additive Solutions, Inc., a developer of quality assurance software to the commercial 3D printing industry, has announced that it is releasing a beta version of the PrintRite3D Machine Health

Renishaw Launches Innovative CENTRUM Metal Rotary Scale

Renishaw has launched an innovative the CENTRUM CSF40 scale metal scale disc extending its ATOM DX encoder series. After an intensive research and development effort at Renishaw, rotary RCDM glass scales are

Third Dimension Strengthens Technical Expertise With Application Engineering Team

Precision measurement company, Third Dimension, has deepened its technical capabilities and strengthened its customer support resource with the creation of a new Application Engineering team.

The manufacturers of the GapGun

The manufacturers of the GapGun‘METROLOGY BREW’ News Bulletin – November 7th

Read a summary of metrology and smart manufacturing news from the past 7 days. Nikon Launches Turnkey Laser Radar Intelligent Quality Stations Nikon Industrial Metrology has announced a series of

Upcoming 3D Metrology Conference Offers Discounted Delegate Pass To Readers

“The 3D Metrology Conference is taking place this year at the Laboratory for Machine Tools and Production Engineering (WZL) of RWTH Aachen University, Germany from 15th – 17th November. A programme

Breakthrough Could Help Frequency Comb Measure Distances and Timing With Pinpoint Precision

An improvement to the Nobel Prize-winning technology called a frequency comb enables it to measure light pulse arrival times with greater sensitivity than was previously possible — potentially improving measurements

FANUC America Breaks Ground on New 800,000 Sq.

Ft. Expansion

Ft. ExpansionFANUC America has held a groundbreaking ceremony marking the start of construction of its new 800,000+ square foot West Campus facility in Auburn Hills, Michigan, USA. A major highlight of

Editors Choice … click image to read full stories

Managing Manufacturing ‘On The Edge’

Edge solutions are a nascent trend that will continue growing to enable digital transformation in every industry and integral to the implementation of Industry 4.0 in manufacturing. Digital transformation necessitates

Benefits of Interferometry During Optical Profiling

Surface characteristics can determine a range of scenarios. For instance, the finish on the body of a Formula 1 car can influence the racer’s finish time, and an engineered part’s

Developing In-Line Quality Control of Advanced Materials for Net-Zero Applications

Graphene and related 2D materials (GR2Ms) could help reduce greenhouse gas emissions from the production of advanced materials.

Using GR2M nanoplatelets in applications such as reinforcing concrete or improving battery

Using GR2M nanoplatelets in applications such as reinforcing concrete or improving batterySmart Manufacturing Powered by 5G

5G mobile phone networks make all the headlines, who wouldn’t like to download a two-hour movie in 10 seconds, but some of the first ‘killer applications’ for 5G will be

Determine Machine Tool Capability Automatically in Less Than One Minute

The Productivity+ Machine Health Check application from Renishaw provides automated machine tool performance verification in under a minute, helping to prevent scrap due to poor machine conditions. The rapid go/no-go

Add to the Favorite folder

Add to compare

more information on the website Nikon Metrology

Characteristics

-

- 3D

3D- 3D

- 3D 3D 3D 3D

- 3D measurement, inspection, for MMT

- Technology

- laser

- Other features

- high resolution, high speed

- Width

-

110 mm (4 in)

Description

The Nikon Metrology L100 is the next generation CMM laser scanner offering the best combination of speed, accuracy and ease of use. The scanner is suitable for measuring surfaces and features, even on reflective or multi-material surfaces, and extends the capabilities of CMM to quickly capture details. High quality data is provided for thorough comparison of parts to CAD and reporting. Product Overview The L100 is ideal for applications where high productivity and inspection accuracy are key. It features a high-quality Nikon glass lens designed and optimized for laser scanning, and a high-definition camera that captures 2,000 non-interpolated points per line. The device is ideal for combined measurements of surfaces and parts with a maximum speed of 420,000 points per second Automated data collection The L100 CMM Scanner connects to various brands of CMMs, turning them into versatile, multi-sensor solutions that can quickly capture complex parts of any shape and size. Using the full capabilities of CNC CMM, measurements with the L100 scanner can be fully automated, freeing up operator time and increasing productivity.

The scanner is suitable for measuring surfaces and features, even on reflective or multi-material surfaces, and extends the capabilities of CMM to quickly capture details. High quality data is provided for thorough comparison of parts to CAD and reporting. Product Overview The L100 is ideal for applications where high productivity and inspection accuracy are key. It features a high-quality Nikon glass lens designed and optimized for laser scanning, and a high-definition camera that captures 2,000 non-interpolated points per line. The device is ideal for combined measurements of surfaces and parts with a maximum speed of 420,000 points per second Automated data collection The L100 CMM Scanner connects to various brands of CMMs, turning them into versatile, multi-sensor solutions that can quickly capture complex parts of any shape and size. Using the full capabilities of CNC CMM, measurements with the L100 scanner can be fully automated, freeing up operator time and increasing productivity. Laser scanning measurements can be combined with tactile measurements for absolute inspection flexibility. Ultra-fast data collection A 100 mm FOV (Field of View) width, combined with an increased measurement speed of up to 420,000 fps, delivers measurement performance never before seen with CMM scanning. The built-in FOV projection clearly shows the user whether the scanner is accurately positioned, which simplifies programming and allows optimal scanning path formation.

Laser scanning measurements can be combined with tactile measurements for absolute inspection flexibility. Ultra-fast data collection A 100 mm FOV (Field of View) width, combined with an increased measurement speed of up to 420,000 fps, delivers measurement performance never before seen with CMM scanning. The built-in FOV projection clearly shows the user whether the scanner is accurately positioned, which simplifies programming and allows optimal scanning path formation.

---

This is an automatic translation. (View the original in English)

Catalogs

L100 Laser Scanner

8 Pages

Nikon Metrology News VOL.10

28 Pages

NIKON METROLOGY SOLUTIONS 9000 9000 9000 9000 9000 Nikon Metrology

Other products Nikon Metrology

3D Metrology

See all Nikon Metrology 9 products0004

*Prices are pre-tax, exclude delivery charges and customs duties, and do not include additional charges for installation or activation options. Prices are indicative and may vary depending on country, commodity prices and exchange rates.

Prices are indicative and may vary depending on country, commodity prices and exchange rates.

Model Maker MMCx Laser Scanner

- Downloads

- Accessories

- Features

- Description

- Description

- Specifications

- Accessories

- Downloads

Model Maker MMCx Laser Scanner: Description

ModelMaker MMCx handheld laser scanners deliver great results at an affordable price. These versatile scanners are ideal for portable 3D inspection and reverse engineering applications where ModelMaker's unparalleled ability to scan any surface meets tough economic requirements.

Its camera technology ensures adequate frame rates and bandwidths up to 160mm. The MMCx has the ability to automatically adjust the laser power in real time depending on the reflective properties and color of the measured object ESP3 to scan samples from any material and any machined surface in a single pass.

Key benefits

- Digital scanner for every budget

- Scanning accuracy of a level sufficient to perform inspection of complex surfaces and geometric elements

- Rugged design for use in all industrial environments

- Ergonomic, lightweight and compact scanner

- Scans virtually any industrial material

- Standard portable system

- Easy and fast plug-and-play installation

- Optimized for hard-to-scan surfaces

Model Maker MMCx Laser Scanner Specifications

| MMCx80 | MMSX160 | Line width (Y), mm | 80 | 160 |

| The minimum distance to the scanned surface, mm | 100 | 150 | |

| Acquisition frequency at full field of view, Hz | 30 | 30 | Maximum acquisition frequency, Hz | 30 | 30 | 131 | 800 | 800 | Thermal compensation | is not | no |

| Laser power | Completely automatic, depending on the reflective properties and color of the measured object (ESP3) 901 901 depending on the reflective properties and color of the measured object (ESP3) | Laser scanner weight, g | 400 (±20) | 400 (±20) |

| Laser power | Class 2 | Class 2 | Compatibility with | NikonMetrologyMCAx / MCAII 7-axis / MCA 2. 5 and 2.5 axis systems Nikon Metrology K-Series: K600 / K610 Romer/CimCoreInfnite 1.0SC 7-axis / Infnite 2.0SC 7-axis 5 and 2.5 axis systems Nikon Metrology K-Series: K600 / K610 Romer/CimCoreInfnite 1.0SC 7-axis / Infnite 2.0SC 7-axis | NikonMetrologyMCAx / MCAII 7-axis / MCA 7-axis (v2.2 and 2.5) Nikon Metrology K-Series: K600 / K610 Romer/CimCoreInfnite 1.0SC 7-axis / Infnite 2.0SC 7-axis |

Model Maker MMCx Laser Scanner: MCAx Measuring Arms

Nikon Metrology's MCAx and MCAx+ series portable coordinate measuring machines (also called "arms" or "arms") are mobile 7-axis metrology measuring systems. They are ideal for fast and accurate measurements of objects in any place convenient for you due to the mobility and ease of installation of the system.

The MCAx manipulator has a number of key features that significantly distinguish this line from other similar systems:

- Ergonomic design and comfortable handling with smooth running of all axes of the manipulator

- Size from 2.0 to 4.5 meters and 2 different ranges of systems differing in accuracy

- CFRP manipulator tubes reduce system weight, reduce temperature errors due to full thermal stability and increase reliability and strength

- Patented angle sensors (encoders) inside the joints of the manipulator allow measurements with unsurpassed accuracy and reliability of results

- Improved counterbalance system simplifies the operator's work and allows better control of the system in all positions

- System for locking the manipulator in an intermediate position

- Various mounting systems and mounts for tripods, magnetic and vacuum bases, marking plates and more

- Infinite rotation of all main axes for continuous operation (no end position for the axes)

- Instant initialization and start-up

- Automatic stylus recognition system with simultaneous use of laser and touch probes

- Basic set of different types of stylus, base, calibration tools

- The low weight of the system, as well as the presence of a powerful built-in Li-Ion battery and a wireless data transmitter via Wi-Fi, allow the manipulator to be used almost anywhere in the workshop, laboratory, subject to the operating conditions

- aviation industry

- automotive industry

- energy industry

- modeling and design

- etc.

:quality(80)/images.vogel.de/vogelonline/bdb/841500/841567/original.jpg)

The arms from Nikon Metrology can be supplied with both laser scanners and touch probes for point measurements and contact scanning.

Nikon Metrology manipulators are available in two types: MCAx (standard precision arm) and MCAx+ (high precision arm).

Scanner not included as standard with MCAx and MCAx+.

MCAx and MCAx+ standard configuration

| Model | MCAx+ | MCAx | Compatible scanners | Manipulator scanners: MMDx / MMCx; Dual use scanner (for manipulators and CMM): LC60Dx; Model Maker h220 scanner | Manipulator scanners: MMDx / MMCx; Dual use scanner (for manipulators and CMM): LC60Dx; Scanner Model Maker h220 |

| Feature Pack | Scan Pack | Scan Pack | Styli | Steel, 15 mm diameter, 50 mm length; Ruby, diameter 6 mm, length 100 mm; Ruby, 3 mm dia., 100 mm long | Steel, 15 mm dia. , 50 mm long; Ruby, diameter 6 mm, length 100 mm; Ruby, diameter 3 mm, length 100 mm , 50 mm long; Ruby, diameter 6 mm, length 100 mm; Ruby, diameter 3 mm, length 100 mm |

| TESA TKJ connectors | Standard | Standard | Locking device | Foundation | Magnetic | with bolt compounds |

General operating conditions

| Storage temperature | from -30 ° C to 50 ° C to 50 ° C (from –20 installed battery) | Measurement ambient temperature | 0 to 50° C |

Temperature conditions under which specified length measurement uncertainties (deviations) are guaranteed

| Environmental temperature | 20 ± 3.3 ° C | Air temperature fluctuations | per hour: ± 1.1 ° C |

| Max. 80% relative humidity up to 31°C with a linear decrease to 50% relative humidity at 40°C | Pollution | Degree 2 |

| Altitude | 0-2000 m | Vibration | (from 55 to 2000 Hz): <= 100 ms/ |

| Shock loads | at t = 6 ms <1000 ms² | Vibration | ISO 9022-3:1998-0710, up to 150 Hz ±0. 15 mm, 2g; 20 swing cycles per axis at 1 octave/min 15 mm, 2g; 20 swing cycles per axis at 1 octave/min |

| Maximum room vibration measured | 55-2000 Hz (IEC 68-2-27) | Power requirements | 220 ± 20 V AC, 50-60 Hz |

| Permissible angular acceleration | 100 Rad/s² |

Credite characteristics of manipaners without a scanner (work in contact mode)

99999999999999 ) .The test procedure is based on the multiple measurement of a single point, which is placed in front of the manipulator. Technically, the measurement of a single point is performed using an internal cone, the size of which corresponds to the diameter of the spherical tip, which makes it possible to exclude accidental exit of the probe from the measured point. Measurements are made at different orientations of the manipulator axes. Based on the measurement results, the value of the midpoint (coordinates of the midpoint) and the deviation of each point from it are calculated. The calculated value of the test result complies with the standards: ASME B89.4.22 SPAT and VDI/VDE 2617-9 Sphereform (MPE PF ) &Sphereposition (MPE PL ).

The calculated value of the test result complies with the standards: ASME B89.4.22 SPAT and VDI/VDE 2617-9 Sphereform (MPE PF ) &Sphereposition (MPE PL ).

The Volumetric Accuracy Test most accurately represents the expected (probable) accuracy of a manipulator, as it uses the method of repeatedly measuring a certified length standard in various positions and orientations and comparing the measurement results with its true length. This test is the most suitable for determining the accuracy and repeatability of a manipulator. The result is the maximum deviation of the measured length from the reference length. The calculated value of the test result complies with the standards: ASME B89.4.22 VolumetricPerformance and VDI/VDE 2617-9 Spheresize (MPE PS ) &Indicationforsize (MPE E ).

Contact probes for testing are installed in both the central and offset port of the manipulator. Tests are carried out under stable environmental conditions, the MCAx manipulator is fixed on a base or magnetic base, the measured objects (inner cone and length standard) are fixed on the surface, a steel probe is used 50 mm with a tip diameter of 15 mm.

Tests are carried out under stable environmental conditions, the MCAx manipulator is fixed on a base or magnetic base, the measured objects (inner cone and length standard) are fixed on the surface, a steel probe is used 50 mm with a tip diameter of 15 mm.

049

049 Credite characteristics of manipulators with scanners

The accuracy of the system with laser scanner . The test is performed by scanning a high-precision plane standard in 5 (five) different system orientations. The 5 (five) point clouds obtained as a result of scanning are combined into 1 (one) and on their basis the average plane is built by the best-fit best-fit method using the least squares method.