New york times 3d printing

3D printing grows beyond its novelty roots

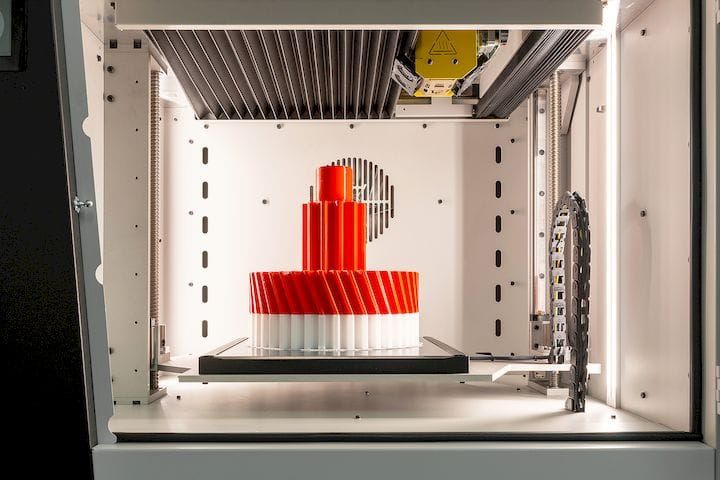

DEVENS, Mass. – The machines stand 20 feet high, weigh 60,000 pounds and represent the technological frontier of 3D printing.

Each machine deploys 150 laser beams, projected from a gantry and moving quickly back and forth, making high-tech parts for corporate customers in fields including aerospace, semiconductors, defense and medical implants.

The parts of titanium and other materials are created layer by layer, each about as thin as a human hair, up to 20,000 layers, depending on a part’s design. The machines are hermetically sealed. Inside, the atmosphere is mainly argon, the least reactive of gases, reducing the chance of impurities that cause defects in a part.

The 3D-printing foundry in Devens, Massachusetts, about 40 miles northwest of Boston, is owned by VulcanForms, a startup that came out of the Massachusetts Institute of Technology. It has raised $355 million in venture funding. And its workforce has jumped sixfold in the past year to 360, with recruits from major manufacturers like General Electric and Pratt & Whitney and tech companies including Google and Autodesk.

“We have proven the technology works,” said John Hart, a co-founder of VulcanForms and a professor of mechanical engineering at MIT. “What we have to show now is strong financials as a company and that we can manage growth.”

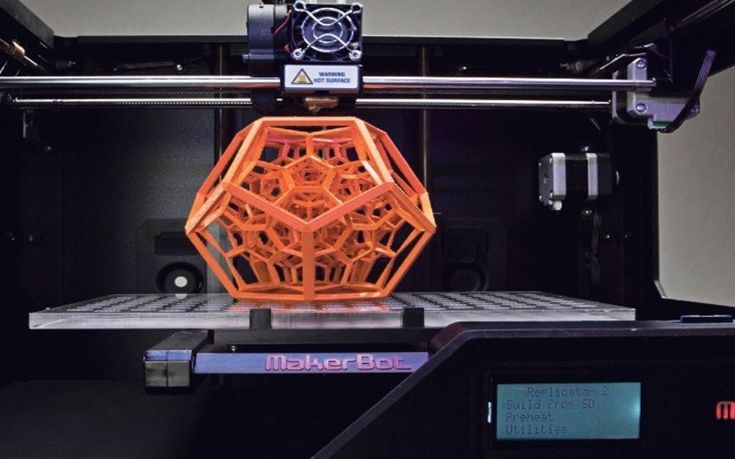

For 3D printing, whose origins stretch back to the 1980s, the technology, economic and investment trends may finally be falling into place for the industry’s commercial breakout, according to manufacturing experts, business executives and investors.

They say 3D printing, also called additive manufacturing, is no longer a novelty technology for a few consumer and industrial products, or for making prototype design concepts.

“It is now a technology that is beginning to deliver industrial-grade product quality and printing in volume,” said Jörg Bromberger, a manufacturing expert at McKinsey & Co. He is the lead author of a recent report by the consulting firm titled, “The Mainstreaming of Additive Manufacturing.”

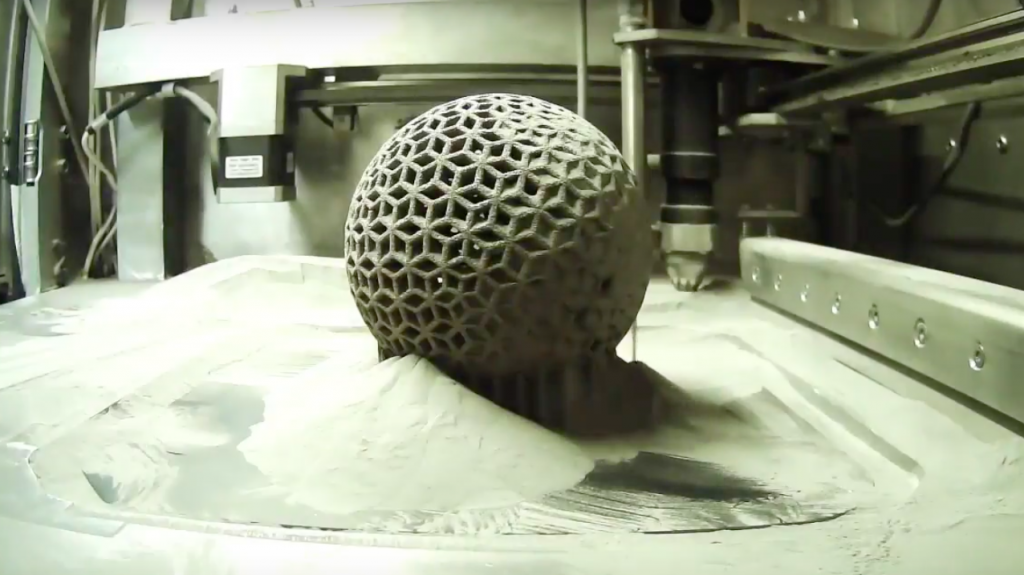

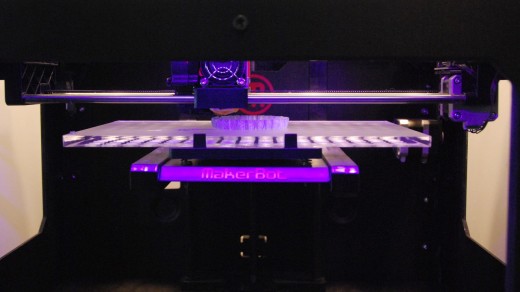

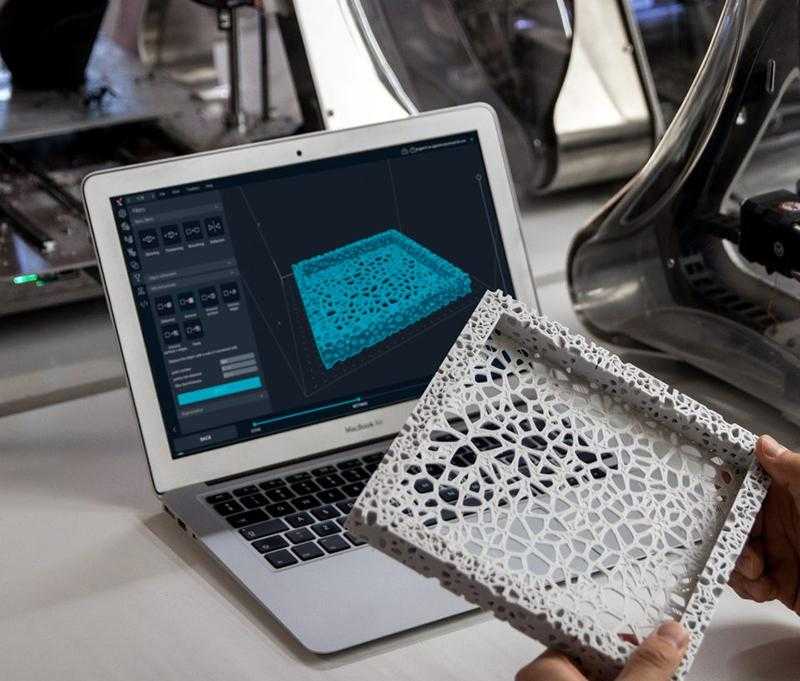

3D printing refers to making something from the ground up, one layer at a time. Computer-guided laser beams melt powders of metal, plastic or composite material to create the layers. In traditional “subtractive” manufacturing, a block of metal, for example, is cast and then a part is carved down into shape with machine tools.

Computer-guided laser beams melt powders of metal, plastic or composite material to create the layers. In traditional “subtractive” manufacturing, a block of metal, for example, is cast and then a part is carved down into shape with machine tools.

In recent years, some companies have used additive technology to make specialized parts. General Electric relies on 3D printing to make fuel nozzles for jet engines, Stryker makes spinal implants and Adidas prints latticed soles for high-end running shoes. Dental implants and teeth-straightening devices are 3D printed. During the Covid-19 pandemic, 3D printers produced emergency supplies of face shields and ventilator parts.

Today, experts say, the potential is far broader than a relative handful of niche products. The 3D printing market is expected to triple to nearly $45 billion worldwide by 2026, according to a report by Hubs, a marketplace for manufacturing services.

The Biden administration is looking to 3D printing to help lead a resurgence of US manufacturing. Additive technology will be one of “the foundations of modern manufacturing in the 21st century,” along with robotics and artificial intelligence, said Elisabeth Reynolds, special assistant to the president for manufacturing and economic development.

Additive technology will be one of “the foundations of modern manufacturing in the 21st century,” along with robotics and artificial intelligence, said Elisabeth Reynolds, special assistant to the president for manufacturing and economic development.

In May, President Joe Biden traveled to Cincinnati to announce Additive Manufacturing Forward, an initiative coordinated by the White House in collaboration with major manufacturers. The five initial corporate members – GE Aviation, Honeywell, Siemens Energy, Raytheon and Lockheed Martin – are increasing their use of additive manufacturing and pledged to help their small- and medium-size US suppliers adopt the technology.

The voluntary commitments are intended to accelerate investment and build a broader domestic base of additive manufacturing skills. Because 3D printing is a high-tech digital manufacturing process, administration officials say, it plays to America’s strength in software. Additive manufacturing, they add, will make American manufacturing less dependent on casting and metalworking done overseas, especially in China.

Additive manufacturing also promises an environmental bonus. It is far less wasteful than the casting, forging and cutting of traditional manufacturing. For some metal parts, 3D printing can cut materials costs by 90% and reduce energy use by 50%.

Industrial 3D printing, experts say, has the potential to substantially cut the total expense of making specialized parts, if the technology can be made fast and efficient enough for higher-volume production.

VulcanForms was founded in 2015 by Hart and one of his graduate students, Martin Feldmann. They pursued a fresh approach for 3D printing that uses an array of many more laser beams than existing systems. It would require innovations in laser optics, sensors and software to choreograph the intricate dance of laser beams.

By 2017, they had made enough progress to think they could build a machine, but would need money to do it. The pair, joined by Anupam Ghildyal, a serial startup veteran who had become part of the VulcanForms team, went to Silicon Valley. They secured a seed round of $2 million from Eclipse Ventures.

They secured a seed round of $2 million from Eclipse Ventures.

The VulcanForms technology, recalled Greg Reichow, a partner at Eclipse, was trying to address the three shortcomings of 3D printing: too slow, too expensive and too ridden with defects.

The startup struggled to build a first machine that proved its concept workable. But it eventually succeeded. And later versions grew larger, more powerful and more precise.

Its printers, VulcanForms said, now generate 100 times the laser energy of most 3D printers, and can produce parts many times faster. That print technology is the company’s core intellectual asset, protected by dozens of patents.

But VulcanForms has decided not to sell its machines. Its strategy is to be a supplier to customers in need of custom-made parts.

That approach allows VulcanForms to control the entire manufacturing process. But it is also a concession to the reality that the ecosystem of additive manufacturing is lacking. The company is building each stage of the manufacturing process itself, making its own printers, designing parts, doing final machining and testing.

“We absolutely have to do it ourselves – build the full stack of digital manufacturing – if we are to succeed,” said Feldmann, who is the CEO. “The factory is the product.”

The Devens facility has six of the giant printers. By next year, there should be 20, the company said. VulcanForms has scouted four locations for a second factory. In five years, the company hopes to have several 3D printing factories up and running.

The do-it-yourself strategy also magnifies the risk and the cost for the startup. But the company has convinced a roster of high-profile recruits that the risk is worth it.

Brent Brunell joined VulcanForms last year from General Electric, where he was an additive manufacturing expert. The concept of using large arrays of lasers in 3D printing is not new, Brunell said, but no one had really pulled it off before. After he joined VulcanForms and examined its technology, he said, “it was obvious these guys were onto the next architecture, and they had a process that was working. ”

”

Beside each machine in VulcanForms’ facility, an operator monitors its performance with a stream of sensor data and a camera image of the laser beams at work, piped to a computer screen. The sound of the factory is a low, electronic hum, much like a data center.

The factory itself can be a potent recruiting tool. “I bring them here and show them the machinery,” said Kip Wyman, a former senior manufacturing manager at Pratt & Whitney, who is head of operations at VulcanForms. “The usual reaction is, ‘Heck, I want to be part of that.’ ”

For some industrial parts, 3D printing alone is not enough. Final heat treatment and metal machining are needed. Recognizing that, VulcanForms acquired Arwood Machine this year.

Arwood is a modern machine shop that mostly does work for the Pentagon, making parts for fighter jets, underwater drones and missiles. Under VulcanForms, the plan over the next few years is for Arwood to triple its investment and workforce, currently 90 people.

VulcanForms, a private company, does not disclose its revenue. But it said sales were climbing rapidly, while orders were rising tenfold quarter by quarter.

Sustained growth for VulcanForms is going to depend on increasing sales to customers like Cerebras, which makes specialized semiconductor systems for AI applications. Cerebras sought out VulcanForms last year for help making a complex part for water-cooling its powerful computer processors.

The semiconductor company sent VulcanForms a computer-design drawing of the concept, an intricate web of tiny titanium tubes. Within 48 hours VulcanForms had come back with a part, recalled Andrew Feldman, CEO of Cerebras. Engineers for both companies worked on further refinements, and the cooling system is now in use.

Accelerating the pace of experimentation and innovation is one promise of additive manufacturing. But modern 3D printing, Feldman said, also allows engineers to make new, complex designs that improve performance. “We couldn’t have made that water-cooling part any other way,” Feldman said.

“We couldn’t have made that water-cooling part any other way,” Feldman said.

“Additive manufacturing lets us rethink how we build things,” he said. “That’s where we are now, and that’s a big change.”

This article originally appeared in The New York Times.

Technology Industry

Subscribe to our Newsletters

Enter your information below to receive our weekly newsletters with the latest insights, opinion pieces and current events straight to your inbox.

Kathimerini may send occasional special offers and promotions.

By signing up you are agreeing to our Terms of Service and Privacy Policy.

The world's first community of 3D printed homes

What were the circumstances for the community and families this project impacted?

These families were some of the lowest income, highest-need families we have ever served. At the outset of the project, we partnered with local government officials to survey more than 500 families in the area, to identify those with the greatest need. The 10 families in this community have an average median income of $76.50 per month, which is well below the lowest threshold we typically require of families we serve in Mexico. Families in this community work in a variety of occupations, and work often changes based on what is available in each season. Additionally, most of the homes the families previously lived in were prone to flooding because of their proximity to the nearby river, which overflows during the rainy season.

At the outset of the project, we partnered with local government officials to survey more than 500 families in the area, to identify those with the greatest need. The 10 families in this community have an average median income of $76.50 per month, which is well below the lowest threshold we typically require of families we serve in Mexico. Families in this community work in a variety of occupations, and work often changes based on what is available in each season. Additionally, most of the homes the families previously lived in were prone to flooding because of their proximity to the nearby river, which overflows during the rainy season.

How did you select the families?

Families were selected using a three-part process:

1. We worked closely with nonprofit partners to identify an area with the greatest need.

2. Once an area was identified, we worked with partners to survey each family individually to understand their specific circumstances.

3. After surveying, we selected the families who have the greatest physical and financial need for a home.

When do families move-in?

The families moved in November 2021.

Did the families receive the homes for free?

Families received the homes at a zero interest, zero profit mortgage. The total mortgage amount is around 400 pesos a month, a manageable amount even for very low-income families, and lasts for seven years. The rest of the cost of the home is considered a subsidy from New Story. The mortgage funds don’t return to New Story or ECHALE, but rather are pooled into a community investment fund where families over time vote on how the funds are used.

By investing into their homes, families are more likely to stay in the homes long-term, take better care of the community, and provide more meaningful feedback through the planning process.

Did this project take jobs from locals?

Build out on the homes still required for land clearing, foundations, doors, windows, and roofs. We hired locals for all of the build out and didn’t decrease the numbers of individuals hired as compared to traditional construction.

What type of maintenance will the houses require? What is the estimated cost of maintenance and is this covered by the families or New Story?

Homes will require the same maintenance as traditional CMY block homes. New Story monitors home and community aging through our Impact Data Program. Families are surveyed before home intervention and again at various milestones following move-in. This allows us to identify any community issues that need to be addressed by New Story. Traditional wear and tear on homes is covered by the families.

STL File NEW YORK - TIMES SQUARE・3D Printing Idea for Download・Cults

New York - Manhattan - 3D print model

1.45 €

Eiffel Tower - City of Paris

0.99 €

CITY OF LONDON - 3D miniature map

5.02 €

NEW YORK - EMPIRE STATE BUILDING - MANHATTAN

1. 94 €

94 €

London City - skyscrapers

0.99 €

King Kong at the Empire State Building - New York

3.69 €

Godzilla in New York - Manhattan

3.60 €

Cable Holder

1.53 €

Best 3D Printer Files in Architecture Category

Passerelle pieton HO

Free

Christmas tree key hanger or Christmas boot

0.75 €

HO Scale 145 ft Steel Arched Truss Bridge

Free

Parametric Wall Shelf Stand

3,20 €

Loading or unloading crane or port crane

15. 25 €

25 €

LAS VEGAS FRAME WALL ART CITY LANDSCAPE ARCHITECTURE BUILDINGS SOUVENIR CITY MAP ART

15 €

Staircases

Free

Millau Viaduct Bridge - France

Free

Bestsellers in the category Architecture

Northrop YF-23 Black Widow II 1:72

2 €

Eiffel Tower - City of Paris

0.99 €

House Toretto v2

4.98 €

Birdhouse -3 pieces

3,80 €

UNITY STATUE - MINIATURE OF THE WORLD'S LARGEST STATUE

1.86 €

Cinderella's Parisian castle at Disneyland

3. 50 €

50 €

The Myers House

11.45 €

New York - Manhattan - 3D print model

1.45 €

BOCA JR. Stadiums

6.17 €

Cessna 172 Skyhawk 1:72

2 €

1-100th scale furniture Architecture

0,78 €

OBELISK

2.65 €

NEW YORK - CITY OF MANHATTAN

4.99 €

London City - skyscrapers

0.99 €

Pumpkin Cottage

€4.80

Model Machu Picchu

5.13 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable the AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

The future of 3D printing

- 5761

Christine Macher

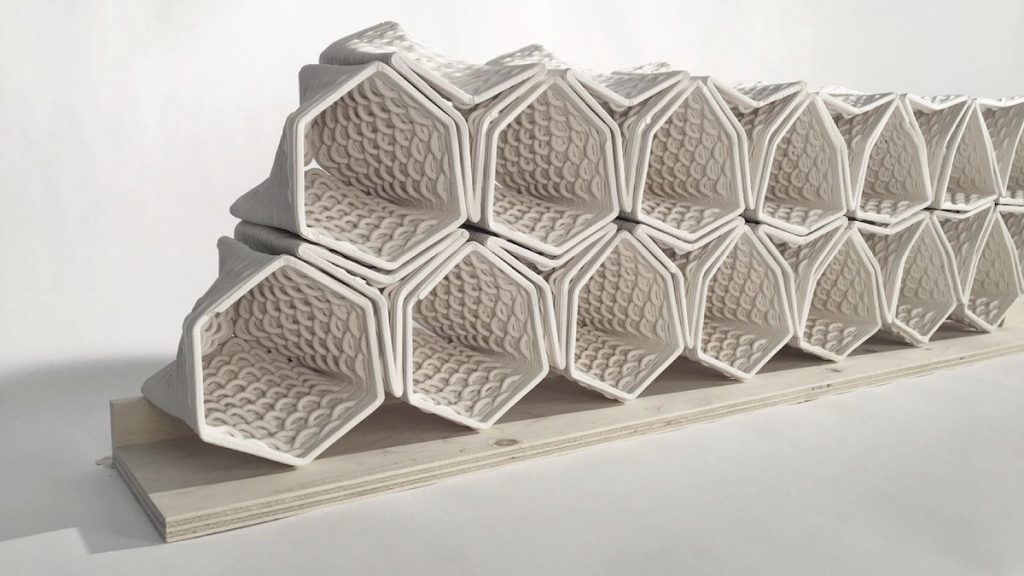

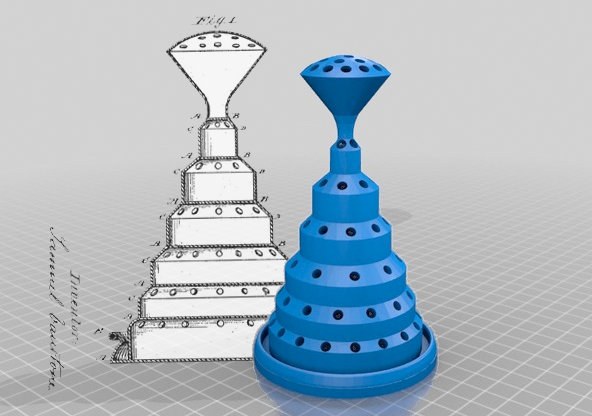

3D printing, or "layer printing technology" as it is sometimes called, allows you to create physical objects layer by layer from metal, thermoplastic and even ceramic based on a given design.

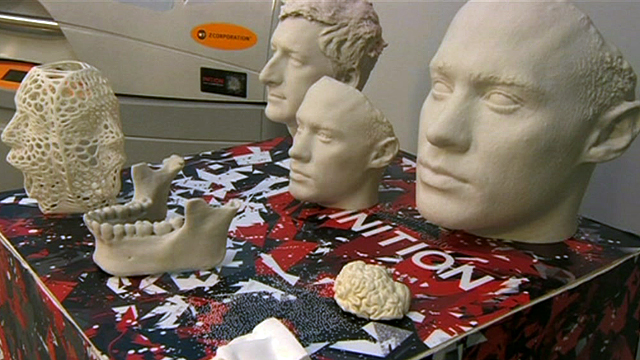

This technology has already been used in the creation of certain specific products - difficult to manufacture in the traditional way - such as hearing aids and aircraft engine parts.

3D printing technology is already widely adopted by several companies. For example, one of the world leaders in the development of innovative medical technologies, Align Technology, uses it to produce Invisalign dental braces, designed for the individual characteristics of patients. And in the aerospace industry, layer-by-layer printing technology is used to create high-tech devices. The world's largest manufacturer General Electric has developed a 3D printed fuel injector using an alloy of cobalt, chromium and molybdenum. The part is on our Best of Technology 2013 list. And according to the company, it has fewer parts and is 25% lighter and five times more durable than previous nozzles.

Yes, there are pioneers. Nevertheless, the attractiveness of this technology is limited by high cost and low speed. For 3D printing technology to become more widespread, the entire process must become cheaper, and printers must be redesigned to be faster and support a wider range of materials.

For 3D printing technology to become more widespread, the entire process must become cheaper, and printers must be redesigned to be faster and support a wider range of materials.

“This market is still too costly,” explains Dominik Rietzel, specialist for layer-by-layer printing technology at the BMW Group's Research and Innovation Center in Munich. While 3D printing saves on the use of material needed to produce a part, the preparation and development of materials for printing presses can be costly. And the results are not always satisfactory. Ultimately, the traditional mold casting process remains more economical for mass production, Ritzel concludes.

BMW, which has invested heavily in metal and plastic 3D printing since purchasing its first layer-by-layer printer in 1989, uses the technology for rapid prototyping and evaluating the potential of new car designs, but not for mass-producing parts. The automaker, which produced 2 million vehicles last year, said the cost of printing devices and materials would need to be cut significantly before the company could consider a mass launch.

Some researchers are working to reduce the cost of reshaping metal and plastic for 3D printers. Others are hoping to find a way to eliminate the need to reshape.

Rotherham, UK-based Metalysis says it has developed a way to significantly reduce the cost of 3D printing by using titanium, which is valued for its light weight and high strength.

Unlike traditional manufacturing, where titanium can be used in its natural state, layer-by-layer printing requires turning the metal into powder. This process is quite costly. Using a method based on research from the University of Cambridge, Metalysis was able to create titanium powder at a cost 25% lower than the conventional process.

The Oak Ridge National Laboratory at the US Department of Energy (Tennessee) is working on developing a device that can print using high quality plastics that are widely used in traditional production. The portable printer, which may be commercially available as early as 2015, uses thermoplastic plates reinforced with glass and carbon fibres. The cost of these plates, widely used in the foundry industry, varies between $1 and $10 per half kilogram. Also, the printer developed by Oak Ridge can use them to produce a wide range of objects, from affordable equipment to drones. What's more, as lab researcher Lonnie Love clarifies, there's an added benefit: Tests have shown that joining materials in a layer-by-layer process increases their strength and density by bonding carbon fibers.

The cost of these plates, widely used in the foundry industry, varies between $1 and $10 per half kilogram. Also, the printer developed by Oak Ridge can use them to produce a wide range of objects, from affordable equipment to drones. What's more, as lab researcher Lonnie Love clarifies, there's an added benefit: Tests have shown that joining materials in a layer-by-layer process increases their strength and density by bonding carbon fibers.

In addition to cost, another problem is the possibility of using 3D printing in mass production. Existing systems can produce 15 cubic centimeters per hour. This means that it will take several days or even weeks to produce an item the size of a shoebox. But a new device developed by Oak Ridge can print 200 or even 500 times faster. The reverse side - the quality of the surface finish suffers. And to give the final appearance, the manufactured parts still have to go through a standard processing process.

Google's "Ara" project, which plans to print prefabricated parts for cell phones by 2015, is also gaining momentum. Supplier 3D Systems, the first manufacturer of a commercial 3D printer, has revised its original approach. The new printing process includes an assembly line on which the parts move on a special belt and are molded by means of printheads fixed on top. 3D Systems claims that their technology has already broken the molding speed record.

Supplier 3D Systems, the first manufacturer of a commercial 3D printer, has revised its original approach. The new printing process includes an assembly line on which the parts move on a special belt and are molded by means of printheads fixed on top. 3D Systems claims that their technology has already broken the molding speed record.

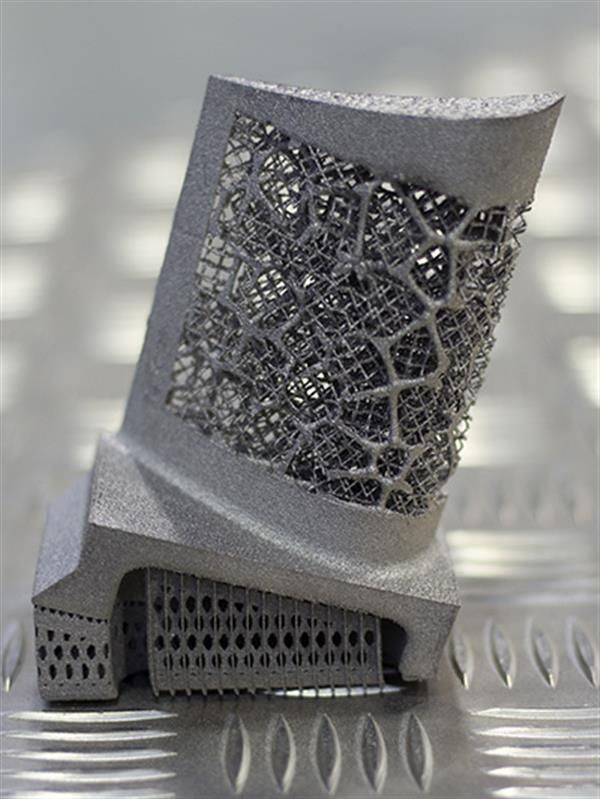

In addition to speed and cost, manufacturers are faced with another challenge - improving the composition of materials to give them the strength and versatility needed for industrial applications. NASA's Jet Propulsion Laboratory in Pasadena, California, in collaboration with the California Institute of Technology and Pennsylvania State University, uses lasers to melt metal powder and create alloys that are then layered around a rotating rod. The process can give manufacturers the ability to use two different alloys during production and make parts from more than one type of metal.

“We're learning more about how devices and materials interact together, how they create properties as well as form,” says Christine Furstoss, Technical Director of General Electric's Manufacturing and Materials Department.