3D print hair spray

Best Hairspray for 3D Printing (& Adhesion Guide)

Hairspray isn’t just for bathroom vanity anymore, it can also be a powerful tool in a maker’s arsenal. More than just a cosmetic product, hairspray is a potent adhesive that will maximize your 3D printing success and prevent damage to your machine.

Just one little can of hairspray can streamline your 3D printing process- and might even save your machine.

TOP PICKS

Best Hairspray for 3D Printing

- Aqua Net Extra Super Hold Unscented: Best overall

- Suave Max Hold (pack of 3): Best for 3D printing adhesion

- FRAGFRE Hair Finishing Spray: Best unscented hairspray

- Rave 5X Freeze Hairspray: Best budget hairspray

Table Of Contents

- Best Hairspray for 3D Printing

- Why would I need to use hairspray for 3D printing?

- Hairspray provides a sticky surface for better adhesion

- Hairspray prevents damage to the 3D printer bed surface

- Is hairspray the best choice for 3D printing?

- How do I use hairspray for 3D printing?

- Can I use any hairspray on a 3D printer?

- What kind of hairspray should I use for 3D printing?

- Our guide to the best hairspray for 3D printing

- Best Overall – Aqua Net Extra Super Hold Unscented

- Best Hairspray for 3D Printing Adhesion – Suave Max Hold (pack of 3)

- Best Unscented – FRAGFRE Hair Finishing Spray

- Best Budget- Rave 5X Freeze Hairspray

- Using Hairspray to Solve Adhesion Problems in 3D Printing

Why would I need to use hairspray for 3D printing?

Hairspray can solve the trickiest dilemma of 3D printing – it helps the model you are printing both stick tightly to the bed, and also easily release when it is finished, without damaging the part or the printing bed surface.

Hairspray provides a sticky surface for better adhesion

A thin layer of hairspray on the printing bed surface provides a tacky structure to increase your chances of getting perfect adhesion the first time.

One problem that many people have while 3D printing is poor adhesion. It is crucial that your first layer attaches to the bed so that the rest of your print can stay in place and come out the way you planned.

Hairspray prevents damage to the 3D printer bed surface

Using hairspray on your 3D printer bed prevents damage by creating a barrier between the bed surface and the finished model.

Even if your print initially adheres correctly, you may face another common adhesion problem that can happen just as you’ve finished printing, and the consequences are worse than just one bungled print job.Sections of Ender 3 glass bed adhered to the filament. Source: Reddit

Sometimes a piece of your glass bed can seem to glue itself to your filament, so when your print is done and you go to remove the part you have just printed, a chunk of your glass bed can break off with it.

If this happens, you’ll need to replace your entire printing bed plate before you can use the machine again. The replacement can be time-consuming, and purchasing a whole new printing bed is expensive.

Even a thin layer of hairspray on the printing bed will create a barrier between the bed surface and the part you are printing. That way when you remove the part, it will separate easily from the bed, leaving you with a functional surface to print on again in the future.

Is hairspray the best choice for 3D printing?

3D printing enthusiasts, faced with these adhesion issues, have come up with a variety of solutions.

Some people use specific adhesive sprays, but those can be costly.

Glue sticks are often recommended for 3D printers, but they take longer to apply than hairspray, and even with the extra time, it’s hard to get an even layer. Glue sticks can also be messy and difficult to clean up after.

Hairspray is inexpensive, easy to use, and extremely effective at both making sure your parts stick to the bed, and also serving as a separator so that the part will lift from the bed easily and without damage.

How do I use hairspray for 3D printing?

Spraying Aqua Net Extra Super Hold on Prusa heatbed steel sheet. Credit: Grimm3DTo use hairspray on your 3D printer, first remove the printing bed surface from the printer. If you are using a printer that does not have a removable bed, be careful to spray only on the printing surface and avoid the rest of your machine.

Spray the hairspray directly onto the bed in a thin, even layer. Wait about one minute for the hairspray to dry, then carefully put the bed back into place.

The surface of your bed should now be slightly sticky to the touch and ready for printing.

You can do this process once, and then you only need to reapply another layer of hairspray every 5-10 prints.

Using this technique with a printer that has a heated bed will give you very reliable returns. If your printer does not have a heated bed, an effective adhesion strategy is even more important to ensure proper results, so a carefully selected can of hairspray can save you a lot of time and effort.

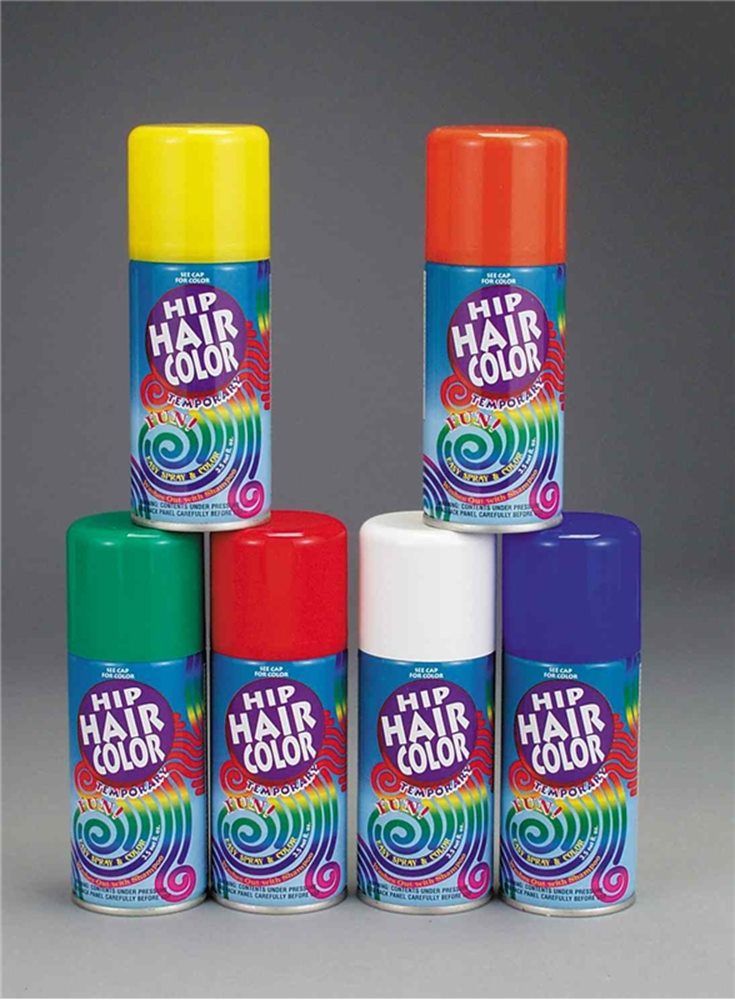

Can I use any hairspray on a 3D printer?

Suave Max Hold with Ender 3D printer in the background. Source: RedditYou can use any hairspray on a 3D printer. All kinds of hairspray will help provide better adhesion and prevent damage to the printer bed surface. You’ll want to consider cost and strength when choosing which hairspray to purchase for use on your 3D printer to make sure you find the one that meets your needs the best.

What kind of hairspray should I use for 3D printing?

You should always use strong, unscented hairspray for 3D printing. Look for hairspray with labels like “extra strength” to ensure that the hairspray will be substantial enough to create a durable printing surface. Make sure that the hairspray is also unscented so that it will do the job without any ingredients that might interfere with the printing.

Our guide to the best hairspray for 3D printing

Best Overall – Aqua Net Extra Super Hold Unscented

Aqua Net hairspray is the best-known standard spray adhesive in the 3D printing world. The Amazon reviews are filled with people saying that they can’t speak to the product’s use in hair because they purchased it specifically for 3D printing! Reviewers comment on using this hairspray for a huge variety of printers and filaments including PLA, PETG, and ABS.

The Amazon reviews are filled with people saying that they can’t speak to the product’s use in hair because they purchased it specifically for 3D printing! Reviewers comment on using this hairspray for a huge variety of printers and filaments including PLA, PETG, and ABS.

It’s a classic for good reason. This hairspray is strong enough to create a reliable layer on your 3D printer bed surface. It’s thick and clingy so you’ll never have to worry about your parts not sticking to the bed properly.

This hairspray is also our top choice because its simple ingredients don’t include any additives that could potentially interfere with your bed or filaments. Aqua Net’s pure adhesion power is perfect for a wide variety of filaments and will always ensure your parts stick to the bed and print appropriately.

Aqua Net has a very even spray, which makes it easy to thoroughly coat the entire bed surface in one uniform layer. This consistency is key for removing your finished part from the printing bed surface and preventing sticking or chipping.

It’s also super durable. You can spray your printer’s bed surface just once, and then print onto that layer of hairspray up to 10 times before it’s time to reapply again.

Overall, Aqua Net is the best hairspray choice for most 3D printing needs. It’s inexpensive, strong, and generally a very reliable choice, which is why it’s the brand most people turn to when facing printing bed adhesion issues.

Best Hairspray for 3D Printing Adhesion – Suave Max Hold (pack of 3)

If you’re having trouble getting your filament to initially stick to the printing bed surface, your priority will be finding the stickiest adhesive for your model to cling to. This prevents any movement and makes sure that you don’t have issues with globing or stringing on the print.

Suave Max Hold Hairspray has one of the strongest hairspray formulations that will guarantee effective sticking.

This is another hairspray that is famous for its non-cosmetic purposes, coming recommended by artists to seal in finished acrylic paint projects. It has a robust hold without being too thick, and is firm and dependable.

It has a robust hold without being too thick, and is firm and dependable.

The unique formula in Suave Max Hold that gives this hairspray its notable hold strength and makes it appealing for sealing in paint also makes it a perfect base layer for your 3D printing because it is certain to provide adequate adhesion.

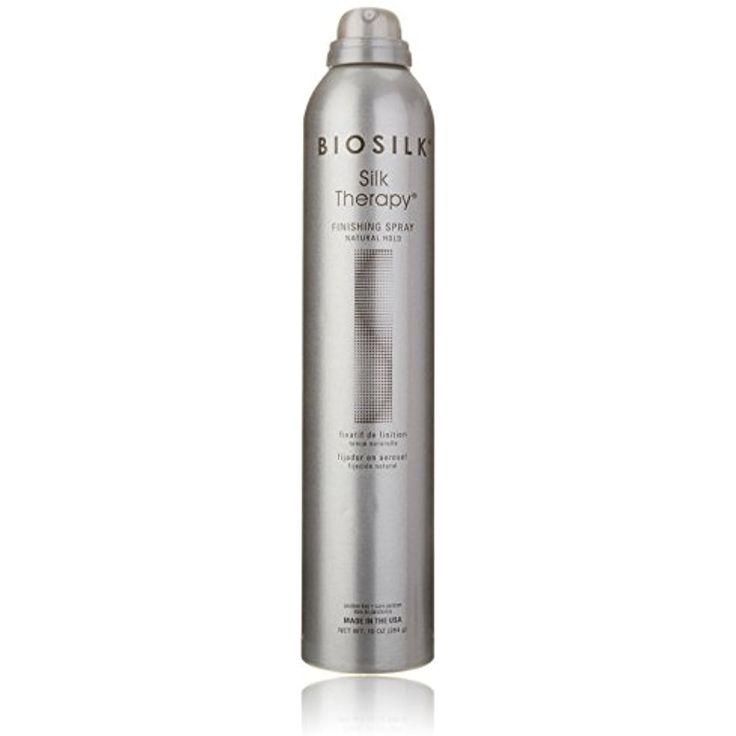

Best Unscented – FRAGFRE Hair Finishing Spray

Sometimes even a product marketed as “unscented” or “fragrance free” can be overpowering. If you are particularly sensitive to fragrances, or if your 3D printer is in a very tight studio space, the last thing you need is a strong-smelling hairspray that bothers your skin and has you wheezing throughout your print.

FRAGFRE hair finishing spray is specially formulated to be odorless and gentle on sensitive skin. In a 3D printing space, you can rely on this hairspray to help solve adhesion issues while maintaining fresh air.

You will want to watch out for issues with the spray nozzle. Some people report problems with clogging after a few uses. To avoid this, you can simply rinse the nozzle with clean water after each use, and you should be able to achieve an even spray each time you need to reapply.

To avoid this, you can simply rinse the nozzle with clean water after each use, and you should be able to achieve an even spray each time you need to reapply.

For people with allergies, skin sensitivities, or respiratory concerns, or if you simply want to keep the air in your small workspace clear, FRAGFRE’s truly odorless hair finishing spray ensures that a sticky printing bed surface is attainable safely.

Best Budget- Rave 5X Freeze Hairspray

If you want to give hairspray adhesion a chance for your 3D printing, but want to keep your costs low, Rave 5X Freeze Hairspray is one of the most affordable options on the market.

This spray is strong and will definitely help with bed adhesion issues. It is widely available in grocery stores and pharmacies, so you may be able to find it in your local area without too much trouble.

While this hairspray is unscented, you may find that the odor of the spray is stronger than some of the others on this list. If your 3D printer is in a well-ventilated area you may not notice the strong smell, but in a smaller space you may find it overpowering.

Using Hairspray to Solve Adhesion Problems in 3D Printing

Great first layer adhesion using Aqua Net Extra Super Hold Hairspray. Source: ImgurMakers of all experience levels sometimes face issues with adhesion. It is important to make sure that your print sticks to the printing bed surface without getting so stuck that you risk chipping off a piece of your print bed when removing your new model.

Using an adhesive barrier helps deliver the best results. While spray adhesives are available, they are expensive.

Glue sticks are often recommended, but are a messy option. The best way to create a tacky texture on your 3D printing bed surface is to spray it with a thin layer of hairspray. Aqua Net hairspray is easy, inexpensive, and incredibly effective for all of your 3D printing adhesion needs.

Related Posts:

- How Important Are 3D Printer Heated Beds?

- Guide: Ender 3 Glass Beds (Pro/V2) And The Best Options

- Full Buyer’s Guide: Best Prusa 3D Printers

- What Type of Build Plate Surface Should You Use?

Best Hairspray For 3d Printing in 2022 (TOP 10)

It may sound weird if someone is looking for the best hairspray for 3D printing. However, when the material breaks from the bed, it is one of the quickest ways for a print to fail. You can buy expensive sticky sprays, but you can also use cheap hairspray to improve adhesion.

However, when the material breaks from the bed, it is one of the quickest ways for a print to fail. You can buy expensive sticky sprays, but you can also use cheap hairspray to improve adhesion.

In this article, we introduced to you the top products that you can pick based on personal needs.

Moreover, you can also find tips to deal with bed adhesion and get the perfect print ever!

Let’s take a look!

The Top-Rated Hairspray For 3d Printing (Recommendations)

1 – L’OREAL PARIS ADVANCED HAIRSTYLE – TOP PICK

2 – PAUL MITCHELL FINISHING SPRAY – STRONGHOLD

3 – AQUA NET EXTRA SUPER HOLD HAIR SPRAY UNSCENTED

4 – R+CO OUTERSPACE FLEXIBLE

5 – SUAVE EXTREME HOLD UNSCENTED

6 – GARNIER FRUCTIS TYLE EXTREME CONTROL

7 – AUSSIE INSTANT FREEZE

On This Page

- The Top-Rated Hairspray For 3d Printing (Recommendations)

- Why We Can Use Hair Products In Technical Work?

- Why Does My Object Not Stick To The Bed?

- 1.

Make the first layer to stick:

Make the first layer to stick: - 2. Avoid warping:

- 3. Strong bonding and best hold:

- 1.

- How To Use Hairspray For 3D Printing?

- Step 1:

- Step 2:

- Step 3:

- Step 4:

- Step 5:

- Glue stick And Hairspray, Which One Is Better?

- Best Hairspray For 3D Printing Shortlist

- Best Hairspray For 3D Printing: Which One To Choose?

- 1 – L’OREAL PARIS ADVANCED HAIRSTYLE – TOP PICK

- Pros:

- Cons:

- 2 – PAUL MITCHELL FINISHING SPRAY – STRONGHOLD

- Pros:

- Cons:

- 3 – AQUA NET EXTRA SUPER HOLD HAIR SPRAY UNSCENTED

- Pros:

- Cons:

- 4 – R+CO OUTERSPACE FLEXIBLE

- Pros:

- Cons:

- 5 – SUAVE EXTREME HOLD UNSCENTED

- Pros:

- Cons:

- 6 – GARNIER FRUCTIS TYLE EXTREME CONTROL

- Pros:

- Cons:

- 7 – AUSSIE INSTANT FREEZE

- Pros:

- Cons:

- 1 – L’OREAL PARIS ADVANCED HAIRSTYLE – TOP PICK

- How To Prevent Bad Adhesion?

- How To Fix The Sticking Issue?

- 1 – Level the bed

- 2 – Check the distance between the bed and print head

- 3 – Check the nozzle speed

- 4 – Check the bed temperature

- 5 – Use adhesion support

- 6 – Use brims and rafts

- Best Hairspray For 3D Printing: Frequently Asked Questions

- 1 – What Can I Do If My PLA Does Not Stick To The Heated Bed?

- 2 – How To Get My Object To Stick To The Bed?

- 3 – What Are The Differences Between Hairspray And Glue Stick?

- 4 – What Do You Spray On Your Objects?

- 5 – When Can I Remove My Print From Bed?

- Conclusion

Why We Can Use Hair Products In Technical Work?

The idea of getting the first layer right is one of the most typical challenges with 3D printing. Only when this is done correctly can the 3D printed model attach properly to the print surface. Hairspray has great bonding and holding qualities, which may explain why it is said to be ideal for holding things in place. Moreover, it is cheap and you can easily buy it from malls or also online.

Only when this is done correctly can the 3D printed model attach properly to the print surface. Hairspray has great bonding and holding qualities, which may explain why it is said to be ideal for holding things in place. Moreover, it is cheap and you can easily buy it from malls or also online.

It does, however, need some preparation, without which it may ruin the whole bed. Choose a product carefully that will keep the printing and the bed together. Before using it, try to spray it many times to check its excellent binding.

Why Does My Object Not Stick To The Bed?

The first layer of your print must tightly adhere to the printer’s build platform in order for the rest of your item to be created on top of it.

If the first layer does not stick to the build platform, problems will arise later. Below are some common reasons:

- Not using adhesion support

- Using an incorrect print bed surface

- Bad first layers or a poorly leveled bed

- Temperature differences are not being taken advantage of.

- Using neither a raft nor a brim

A failed first layer (Source: Reddit)

But do not worry, get yourself the best hairspray for 3D printing and everything will be fixed easily. It helps:

1. Make the first layer to stick:

One of the issues is getting the first layer and then keeping your impressed model on the printed plate.

This is extremely hard for ABS and a big issue for Nylon filaments because Nylon fleece is easy to warping. This is why we need to use hairspray.

The issue is that the model shrinks when the material refreshes and the soft corners curl up.

The degree to which it distinguishes has an impact on the use of 3D printers. Furthermore, because the model does not attach to the model sheet when the nozzle head moves, a big nest will result.

2. Avoid warping:

The plastic often shrinks as it begins to cool. It will curl at the corners as a result, and the model will eventually warp.

The material is not sticking to the surface as well as it should be. This problem is usually avoided by using a good hairspray for quality printing.

This problem is usually avoided by using a good hairspray for quality printing.

3. Strong bonding and best hold:

Thanks to the excellent holding ability, we can use it as a replacement for glue sticks with a lower cost and easy application.

Many tests have proved that hairspray helps things to stick evenly and strongly to their plate.

How To Use Hairspray For 3D Printing?

Not every type of hairspray can be used as adhesion support. To know which one you should choose, take a look at its ingredients.

If you can find copolymer constituents such as PVA, vinyl, or acetate, that is the product you need.

It is very simple to use. First, we need to prepare some things:

- Hairspray

- Issue or soft cloth

- Working table

Then, follow the steps below:

Step 1:

Find your best hairspray for 3D printing.

Step 2:

Make the bed hot. Hairspray adheres best to a hotbed. It will work on a cool bed, but for best results, set the temperature to around 50 degrees Celsius.

It will work on a cool bed, but for best results, set the temperature to around 50 degrees Celsius.

However, hairspray is a flammable material. Although most printer operating temperatures are much below the ignition point, do not move the printer when spraying because sparks could start a fire.

Keep in mind that some products are made of acetone, which is flammable as well. It is still a good idea to be careful.

Temperature setting example (Source: Instructables)

Step 3:

Spray on the bed. It is better with a thick layer.

(Source: Instructables)

Step 4:

Let it rest for about 30 seconds to 1 minute. After that, wipe it off with a tissue or soft cloth. Try to lay the towel flat and absorb the spray instead of wiping it away actually.

( Source: Instructables )

Step 5:

Check the bed. It should have a sticky feel to it. If not, go through the process again.

Try putting up different small parts of the bed.

Prints will stay in the bed lot better now, and they will have a much lower possibility of peeling off, so you will not need to use a raft. Every 2 to 8 prints, you will most likely need to reapply.

Glue stick And Hairspray, Which One Is Better?

Both glue sticks and hairspray can effectively attach 3D prints to the print bed, but some people are unsure which is best. Hairspray, according to many people who have tried both, has a better overall success rate, especially with surfaces like glass and ABS filament.

Glue sticks can stick to glass surfaces a little too well for PLA, especially if it is a larger work.

Others say that using glue to minimize warping issues gave them the best results, allowing them to move from using rafts and brims to just skirts.

When compared to glue, hairspray is quite easy to clean. A simple wash with hot water should remove its layer and will not cling together like glue.

Some people also say that this type is messy, too liquid, and hard to remove. However, this depends on the type of hairspray you buy, as not all brands are the same.

However, this depends on the type of hairspray you buy, as not all brands are the same.

One user who uses hair gel says to put it on before a 3D print and only wash it off after about 10 prints, implying that using the right product and following the necessary steps can make life much easier.

When comparing the experiences of others with glue sticks and hairspray, the overall opinion seems to be that hairspray is cleaner, easier to clean and re-apply, and lasts longer between coats.

Glue can be a harder thing to deal with. And it does not look well on the glass as well.

Best Hairspray For 3D Printing Shortlist

| Product images | Product names | Editor's rating | Price |

|---|---|---|---|

| L’OREAL PARIS ADVANCED HAIRSTYLE | 4.5 | Check Price | |

| PAUL MITCHELL FINISHING SPRAY | 4.6 | Check Price | |

| AQUA NET EXTRA SUPER HOLD HAIR SPRAY UNSCENTED | 4. 8 8 | Check Price | |

| R+CO OUTERSPACE FLEXIBLE | 4.7 | Check Price | |

| SUAVE EXTREME HOLD UNSCENTED | 4.7 | Check Price | |

| GARNIER FRUCTIS TYLE EXTREME CONTROL | 4.6 | Check Price | |

| AUSSIE INSTANT FREEZE | 4.7 | Check Price |

*Ratings are from Amazon at the time of publication and can change

Best Hairspray For 3D Printing: Which One To Choose?

1 –

L’OREAL PARIS ADVANCED HAIRSTYLE – TOP PICKSee Latest Price

Pros:

- The anti-frizz ensures a super-strong bonding

- Water-free and humidity resistant

Cons:

- Defective spray nozzle design makes it clogged and dripping in all directions

- Have a bad smell

2 – PAUL MITCHELL FINISHING SPRAY – STRONGHOLD

See Latest Price

Pros:

- Famous brand

- Cover all the print area

- Easy to remove from the bed

- Apple scent

Cons:

- The bottle size is too small for the price

- The spray head gets clogged after a few use

3 – AQUA NET EXTRA SUPER HOLD HAIR SPRAY UNSCENTED

See Latest Price

Pros:

- Firmly bonding on glass and many difficult surfaces

- Withstand high temperatures

- Great for PLA materials

Cons:

- Kind of expensive

Using Aqua Net Tutorial: (105) How to use hairspray on 3d printer

4 – R+CO OUTERSPACE FLEXIBLE

See Latest Price

Pros:

- Beautiful appearance

- Affordable

Cons:

- Do not have a very strong bonding

- The spray head gets clogged after a few use

5 – SUAVE EXTREME HOLD UNSCENTED

See Latest Price

Pros:

- Unscented

Cons:

- Hard to remove the object from the bed

- The spray head gets clogged after a few use

Using Suave Tutorial: (105) How to use Hairspray for 3d Printing

6 – GARNIER FRUCTIS TYLE EXTREME CONTROL

See Latest Price

Pros:

- Very cheap

- Hold greatly

Cons:

- Spray head clogs and breaks easily

7 – AUSSIE INSTANT FREEZE

See Latest Price

Pros:

- Firm hold

- Platinum shine

Cons:

- Bad spray head design

- Quality degrades after a short time.

How To Prevent Bad Adhesion?

During the 3D printing job, you will face problems such as shrinking, warping, and adhesion. When working with nylon, ABS, resins, and other materials, these issues become even more visible. As the plastic cools, it is likely to shrink. This causes the print to curl up in the corners, and the sculpture may eventually warp as a result.

There are also cases where the print material does not stick to the surface. Although we have other easy to harder ways and settings that can improve bed adhesion, the following are the most useful. If you do the following, you can improve it:

- Clean dirt and residues from the build plate

- Level the build plate properly

- Change and adjust the cooling fan speed

- Nozzle and printing temperature calibration

- Make use of 3D Printer rafts and brims

- Bed adhesives are used to configure and calibrate the first layer settings.

For quality printing, it is normal to see the use of the best hairspray for 3D printing to avoid this problem. It helps in the proper adhesion of 3D printers. With so many options available, finding the perfect hairspray for this purpose is hard.

Hairsprays can also help in the finishing and coating of your final result. They can support the bonding of printed materials to hotbeds, while they may also work on cold beds. At a temperature of around 50 ℃, they are known to work best.

How To Fix The Sticking Issue?

We have 6 easy solutions for you:

1 – Level the bed

First of all, if your printer has an adjustable bed and you are having sticking problems, check sure its base is leveled.

An uneven bed could mean that one side is closer to the nozzle than the other, making printing tricky. Additionally, uneven bed surfaces can cause your thing to warp or break.

The method for leveling your bed varies depending on the printer. Some modern ones, for example, are designed with automated bed leveling, but you can also manually adjust your bed. If your machine does not have an automatic feature, you will have to do it by yourself.

Some modern ones, for example, are designed with automated bed leveling, but you can also manually adjust your bed. If your machine does not have an automatic feature, you will have to do it by yourself.

2 – Check the distance between the bed and print head

Between the bed and the nozzle, there is a sweet spot. It is the perfect distance between close and far.

Check the gap between the bedplate and the nozzle if your 3D print is not sticking to the bed.

The filament will not be able to come out if the nozzle is too close to the bed, and the extruder may damage or drag the previously produced layer. However, if the nozzle is too far away from the bed, the filament will not correctly place on the bed and will not attach.

To find out what works best for the filament you are printing, you will have to experiment.

The nozzle should be close enough to the bed so the filament is slightly pressed onto the surface. This gives the filament a bit of traction on the surface.

3 – Check the nozzle speed

Nozzle speed can also affect whether or not your 3D print sticks to the bed. Similar to nozzle distance, nozzle speed must be found in a sweet spot, especially when printing the first few layers.

Slowing down the nozzle’s speed allows the plastic to bond to the bed more fully and get a firmer hold. The filament may not stay on the bed if you print too quickly because the plastic cools down too soon. After you have laid down your first few layers and are happy with the adhesion of your print to the bed, you can set the nozzle to its normal speed.

4 – Check the bed temperature

The temperature of your plate is the last thing to consider. If you are printing with a heated one, double-check that you are using the right temperature for your filament. Different materials for 3D printing need different plate temperatures.

It may also be helpful to raise the temperature by a few degrees to help in the adhesion of the first layer. You can lower the temperature to maintain a normal heat once the print has built a tight hold.

You can lower the temperature to maintain a normal heat once the print has built a tight hold.

5 – Use adhesion support

If you have checked all of your bed and nozzle settings and still have issues with bed adhesion, it is time to bring in some backup plans. If your 3D print still does not attach to the bed, apply an adhesive straight to the bed where the filament will land.

You have a few different options to choose from, including:

- Glue sticks

- Painter’s tape

- Best hairspray for 3D printing

- 3D printing-specific adhesives such as Magigoo

Moreover, using bonding support can also help you to correctly remove the glue from your object after it is finished. This typical method is cheap and quick, and it can save you a lot of time and effort. Only a small layer needs to apply to the bed. Different filaments stick to different adhesives, so try out a few different combinations to see what works best for you.

6 – Use brims and rafts

If you do not want to use adhesives but your item still does not attach to the bottom, a brim or raft may be the best solution.

A brim is a layer of filament that surrounds the print and connects to the object’s first layer. It is like the brim of a hat. It does not sit beneath the part, but rather adds a layer of protection around it.

A raft, on the other hand, is a thin layer of filament that is placed on top of the rest of your print before it begins. This produces a flat filament base on which the rest of your print will be made. Once the printing is completed, the rafts and brims are removed from the final product.

These are super useful when making very small prints or prints that need more support in the first few layers. Both, for example, will help in the anchoring and adhesion of the print.

Best Hairspray For 3D Printing: Frequently Asked Questions

1 – What Can I Do If My PLA Does Not Stick To The Heated Bed?

You must follow a few tested steps that may assist you in fixing the issue.

To begin, clean the printing bed as well as the nozzle of the printing ingredients.

Make sure your 3D printer bed is level and free of any rough edges. Reduce the print speed for the first layer if possible. Only raise the bed temperature for the first layer this time.

2 – How To Get My Object To Stick To The Bed?

If your thing is not sticking to the bed properly, there could be a number of causes.

Many 3D printer filaments need a heated print bed for good adhesion.

Without one, proper bonding may be hard. As a result, this must be effectively addressed. You should also make sure that the 3D printed material does not cool too quickly or unevenly.

This could also cause the part to retract.

3 – What Are The Differences Between Hairspray And Glue Stick?

Both two types have their own advantages and disadvantages, and they may or may not work in a similar way.

They help to keep the 3D printing firmly in place by strengthening the bed.

In general, we recommend starting with a glue stick.

If that doesn’t work, we recommend using a stronger product, such as hairspray. In comparison to glue sticks, hairspray is very simple to use.

4 – What Do You Spray On Your Objects?

Because it quickly covers a surface with an even coating, spray primer is the best way to paint your printed parts.

Although brush ones are available, they are more difficult to work with and are best used for fine touch-ups.

Choose a plastic-compatible type and paint from the same brand for the best results.

5 – When Can I Remove My Print From Bed?

If you can cool the print to below room temperature, it will contract more and lift itself off the print bed.

Placing your entire work, including the bed, inside a fridge is the easiest way to do this. It should be much easier to remove after an hour or two if you leave it there.

Conclusion

Previously, we believed that “extra hold,” “firm hold,” and larger numbers were the keys to a good hairspray for 3D printing adhesion, but after testing some low-cost, own-brand hairspray, we have changed our minds. This one outperformed the others. We still have not got the same results as with the glue stick, but it is a lot easier to use. It also appears that cheap ones are still good.

This one outperformed the others. We still have not got the same results as with the glue stick, but it is a lot easier to use. It also appears that cheap ones are still good.

In summary, we suggest you pick L’OREAL PARIS ADVANCED HAIRSTYLE if this is the first time you use hairspray to fix bed sticking. This product is safe and easy to work with, even when you do not have many professional experiences. Besides, GARNIER FRUCTIS TYLE EXTREME CONTROL is also a good choice. Garnier ones are cheap, too.

In fact, there is no certain best hairspray for 3D printing. The best should be the one that meets all your needs and requirements. We hope after reading our article, you now know which one to choose.

Further Reading:

- Best Creality 3d Printer– How To Choose The Best One?

- Best Filament For Ender 3

- Top 6 Best 3D Printer For Cosplay Armor

- Best 3d Printer For Board Games

- Best Filament For Lithophanes: What To Use

- Top 7 Best Dual Extruder 3d Printer Under $500

Casting varnishes for 3D printing

Good day to you earthlings.

Many of you have encountered the problem of poor adhesion of the 3D printer bed when printing with ABS plastic (and not only). Someone used already proven methods read on the Internet, someone tried and tried to find their own methods to keep the plastic on the table.

I went both ways) But about the second way in the end.

(who doesn't like water turn down, turn down)

- First way - hairspray

At the factory where I work, they bought us two 3D printers - Picaso 3D and Prism mini. Both of them came with varnish, and it so happened that for these two printers we began to use varnish for adhesion. And soon, as it usually happens, the varnish ended unexpectedly. And a reasonable question arose - 'aaaaa!!! what to do, how to live next?!', go to the store of course) for candidates for the role of a suitable varnish for printing on a 3D printer.

Primary selection of candidates passed according to strict criteria, namely the obligatory presence of the inscription 'peace' on the fence 'strong hold', 'very strong hold', 'super hold', 'extreme hold', 'extra hold', 'super mega duper hold', 'ultra 3000 customer turbo hold' and numbers '5', '6', '10' and '2851' on the bottle.

Yee... welcome! 10 shortlisted winners:

In order from left to right:

- Taft three weather invisible hold (extra strong hold number 5)

- Hairspray great price 365 days all year round (super strong hold) (hairspray called hairspray - SHTA?!)

- Syoss many beeches ceramide complex (maximum strong fixation, number 5)

- Taft Three Weather Volume Millions of CALogen Molecules (Mega Hold Number 5)

- Taft Three Weather Power Caffeine Firming Formula (Mega Hold Number 5)

- Professional Perfection in Scosmetic Form (Mega Strong Hold Number 5)

- Charm Professional Memory effect (extra strong hold, number 5)

- Charm Professional Ultra Power (extreme hold, number 6)

- Jet Personal Styling (extra strong hold, number 5)

the name of the varnish, the manufacturer, or just the text 'ala I'm the coolest of all'. I just rewrote what I considered a distinctive feature, so that it could not be confused with the rest of the variety of similar products.

I won't pull the rubber, let's move on to the main thing:

- Final selection

'Stick' tests were carried out on an open printer (Prism mini), freshly printed REC ABS plastic. It's not advertising, it's just plastic.

Table temperature 100 parrots, extruder temperature 245 degrees, print speed 40 mms. We print Facebook 'thumbs up' or down, whoever shows himself. The varnish was applied in one thin layer on a hot table. After each candidate, the glass table was removed, washed with running water, wiped dry, and, before the test of the next subject, warmed up in its native place for 2-3 minutes.

Let's go!

1 - Taft three weather invisible hold (super strong hold, number 5)

Spray on, the smell is quite pleasant, but perhaps only

Failed at the very beginning. Farewell, Mr. Taft, we are not on our way.

Our next one is

2 - Hairspray great price 365 days all year round (super strong hold) year

Next

3 - Syoss many beeches ceramide complex (maximum strong hold, number 5)

Pshhhhhhh towards the table.. the smell is below average in my opinion.

Yes, I forgot to film him posing in front of a prism, who doesn't happen to. And yes, to celebrate, I forgot to take a picture of what was printed on it. You'll have to take my word for it. Syoss gets a 'thumbs up' achievement!) The first candidate to make it to the finals!

After finishing printing, tore off part with little effort.

Next in line

4 - Pure line extra fixation nettle (very strong hold, number 5)

The smell is average, not annoying at all.

and as I said earlier, he did not pass the test, he does not hold at all.

Let's go further

5 - Taft three weather Volume millions of CALogen molecules (mega fixation, number 5)

We apply, the smell is average.

He tried to keep something somehow, I gave him a chance again and again, but alas, this candidate is also leaving us.

Next

6 - Taft three bears Power with caffeine firming formula (megafix, number 5)

The smell is average, or I have already inhaled these smells and I can't distinguish them.

Not his path, it doesn't work for him, apparently it was created for hair.

Next! do not hesitate to pass

7 - Professional perfection in the form of Scosmetic (mega-strong fixation, number 5)

The smell is like a smell.

Generally not surprised, does not hold at all.

This is mine.

8 - Charm Professional Memory effect (super strong hold, number 5)

Smells like hairspray.. probably.

Worried and screwed up the test.

Who's next? oh yes

9 - Charm Professional Ultra Power (extreme fixation, number 6)

It should smell somehow.

And he did the job! After printing, the part came off quite easily, I would give it a 4 out of 5. Requires additional tests.

And last

10 - Jet Personal Styling (extra strong hold, number 5)

The room smells. It's not me. These are varnishes varnishes..

And he copes with our task perfectly! After the end of printing and the cooling of the table, the part did not come off by itself, I had to tear it off with a little effort.

A group photo with earned achievements

and a photo of the winners separately

Phew.. have passed fierce tests and now you can breathe deeply, preferably going out into the street.. otherwise your head already hurts.

3 candidates out of 10, I think an excellent result)

Further dry calculations based on the results

Varnishes suitable for printing

Syoss many beeches ceramide complex (maximum strong fixation, number 5)

Jet Personal Styling number 5)

Varnishes questionable

Beauty Professional Ultra Power (extreme hold, number 6)

0003

No one has a sharp, unpleasant smell, the cost is in the range of about 500 to 1000 tenge (yes, I'm from Kazakhstan, who needs to translate into rubles, dollars, euros, bitcoins)

Oh, yes, I almost forgot

- The second way - Glue Master klein

Discovered by me in the course of experiments on different substances (not narcotic!) method of printing ABS plastic. This glue - Master klein, took it as glue for fillets in the construction industry,

This glue - Master klein, took it as glue for fillets in the construction industry,

(photo honestly stolen from the open spaces of the tyrnet)

is diluted with medical alcohol (alcohol-soluble glue, 90% alcohol) approximately 1 to 10 (1 part glue and 10 alcohol, you can experiment). Next, we apply the composition on a cold table. It is problematic to apply on a hot one due to the fact that the alcohol evaporates quickly and it becomes problematic to evenly distribute the liquid over the table. This is the first drawback, the second drawback is a thin film that will definitely remain on the bottom surface of the part. Not to say that this is a problem, but if there are a lot of holes on the bottom of the printed part, then peeling off the film from each hole becomes a little tedious.

But there are also pluses - almost complete absence of smell, it doesn’t smell strongly of alcohol, and maybe it will be more familiar to someone)) Another plus is good adhesion, tearing off a part from a hot table is simply not realistic. I tried once and tore the part, some of the layers remained on the glass. After the table cools down, the part itself comes off at about 30 degrees with a characteristic click. I use this method at home on a pruche, because I don’t like smells.

I tried once and tore the part, some of the layers remained on the glass. After the table cools down, the part itself comes off at about 30 degrees with a characteristic click. I use this method at home on a pruche, because I don’t like smells.

In the comments, I suggest adding to the list of proven, easily accessible hairsprays suitable for 3D printing.

Thank you for your attention.

(There is a solution) Why does hairspray work like an adhesive for ABS plastic?

adhesion fdm

Since I have a 3D printer, I have worked mainly with ABS printing. I have tried several adhesion methods (various soluble adhesives, ABS juice) but have always had the most success with pure borosilicate glass hairspray if I printed above 75°C on the table and inside the case.

So I wonder if it is known why and on what basis of chemicals the hairspray method works so well?

@TheEquah, 👍14

Talk

1 answer

Best answer:

▲ 13

First of all, not all hairsprays work. The chemicals in hairspray that cause bonding are "VA/Crotonate Copolymer", also referred to as "vinyl acetate/crotonic acid copolymer". Most commonly known as PVA, which is also a filament used as a water soluble support material. It is a synthetic polymer created from monomers.

The chemicals in hairspray that cause bonding are "VA/Crotonate Copolymer", also referred to as "vinyl acetate/crotonic acid copolymer". Most commonly known as PVA, which is also a filament used as a water soluble support material. It is a synthetic polymer created from monomers.

When heated to a certain temperature, this ingredient becomes sticky, which causes the thread to stick to the plate. It's the double bonded oxygen molecule that makes this happen. This is present not only in the chemicals you put on the table, but also in the chemistry of some table materials. Quoting our own Ryan Carlyle from this thread, Aquanet hairspray replacement?? Wolfbite by Airwolf:

Most popular build surfaces have very similar chemistry. This is because they all rely on diffusion bonding for adhesion. The molecular chains at the interface slightly dissolve into each other.

Adhesive active ingredient - http://en.wikipedia.org/wiki/Polyvinylpyrrolidone

Aquanet and liquid PVA glue active ingredient - http://en.

wikipedia.org/wiki/Polyvinyl_acetate

If you're familiar with organic chemistry, here you see an identical polyvinyl backbone and functional groups that both have a ketone/etheric oxygen double bond adjacent to the space-filling component. (The space-filling component probably reduces adhesion, so the print can be released.) And you know what? Permanent building slab surfaces rely on the same basic chemistry:

Lexan also exhibited polymer-based double oxygen: http://en.wikipedia.org/wiki/Polycarbonate

Kapton also exposed polymer-based double bound oxygen: http://en.wikipedia.org/wiki/Kapton

Acrylic also has an open oxygen polymer based double bond: http://en.wikipedia.org/wiki/Poly(methyl methacrylate)

PET also has an open oxygen double bond on the polymer backbone: http://en.wikipedia.org/wiki/Polyethylene_terephthalate

Now, if you look at some of the common thread thinners, what do you often see? Oxygen with a double bond on small molecules.

Learn more