What is the biggest 3d printer

Largest 3D printers in 2022 for XXL prints

Large-scale 3D printers are able to print massive objects thanks to their gigantic build volumes. This guide covers some of the largest 3D printers in the world that are commercially available.

Last update June 23, 2022

We removed discontinued products and updated the BLB Industries The BOX lineup, which has been replaced by The Industry MAGNUM. We also added MASSIVit's latest solution, the Massivit 10000.

Table of contents

Handpicked related content

Large scale 3D printers (XXL): 2022 selection

BIG-Meter

F1000

BigRep ONE v4

400 Series WORKBENCH XTREME

T3500

MAGNUM

Massivit 10000

MAMA

3D printing furniture

3D printing large prototypes

3D printing production series

Customized large scale 3D printers

What are the best large scale 3D printers?

Large-scale 3D printers have been in the spotlight for quite some time. When we say large scale, we mean it– these machines can 3D print objects of over 1 square meter. They can be used to 3D print pieces of furniture, large prototypes, or several series of smaller objects in one go.

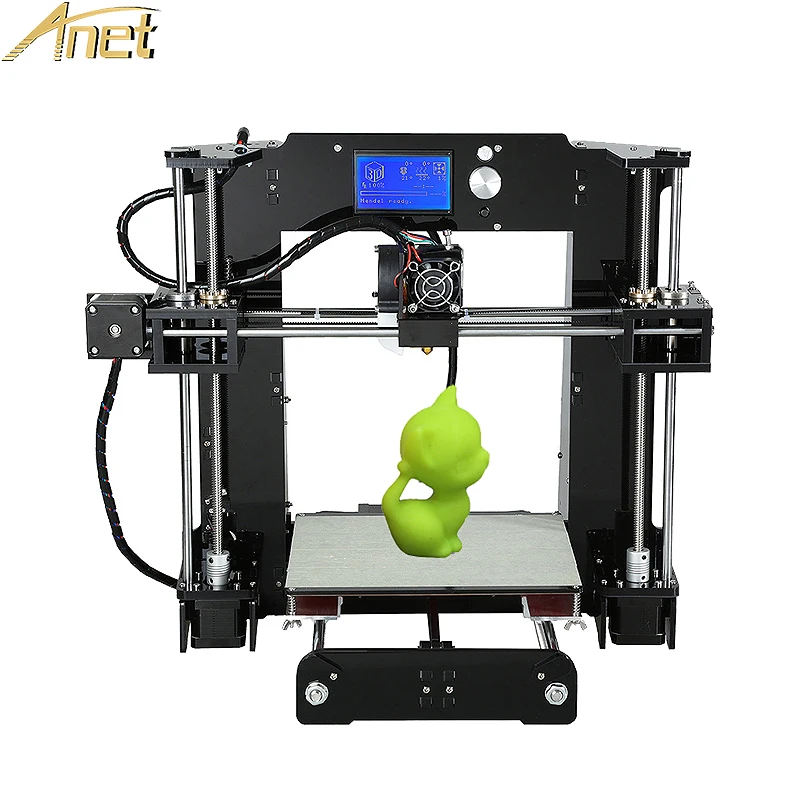

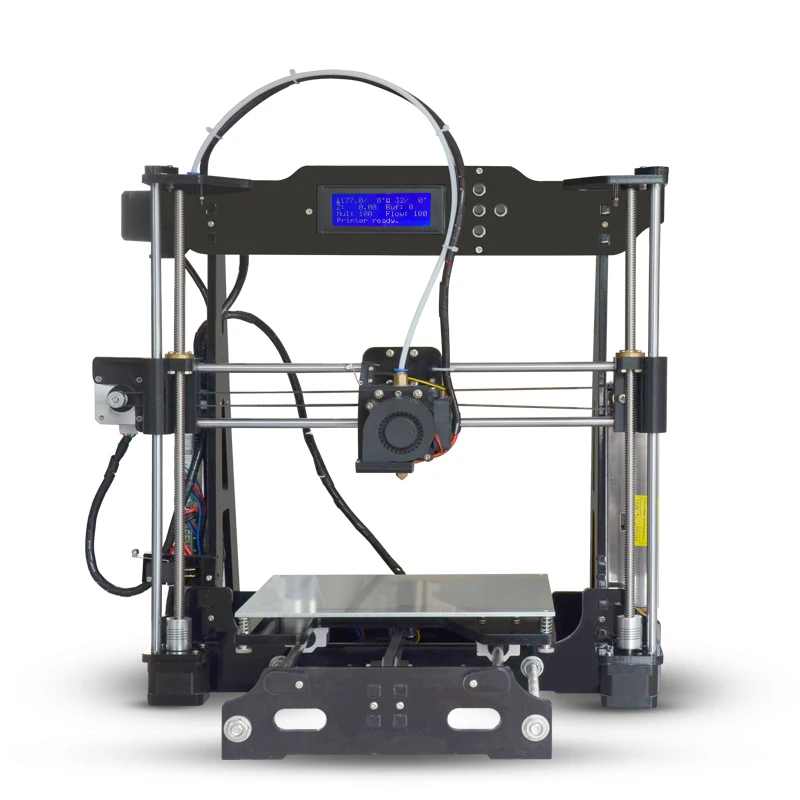

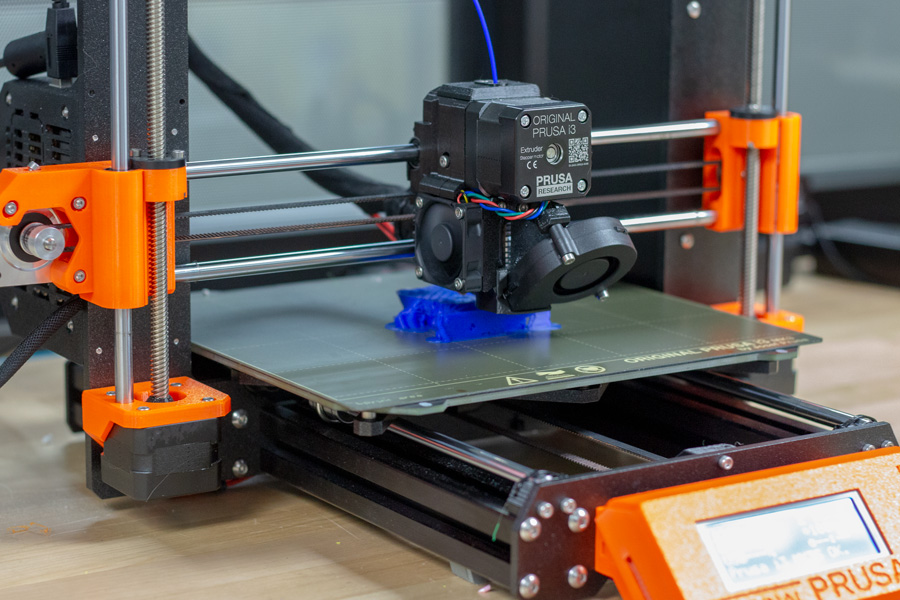

The professional 3D printers featured in our article are basically super-sized versions of ordinary desktop 3D printers. They almost all use extrusion 3D printing technology (FFF) and work the same way as regular desktop printers.

Our “largest 3D printers” selection does not include construction 3D printers, which fit into a different category.

Handpicked related content

If these large scale 3D printers (XXL) are too big, check out our other selections:

- Large format 3D printers (XL)

- Large volume 3D printers (L) for desktops/benchtops

- Large resin 3D printers (L)

Large scale 3D printers (XXL): 2022 selection

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. | |

|---|---|---|---|---|---|

| Modix This brand is a certified partner from our network. | BIG-Meter | 1010 × 1010 × 1010 mm39.76 × 39.76 × 39.76 in | Israel | $ 11,50011 690 €10,201 £1,714,144 ¥ | Buy |

| CreatBot | F1000 | 1000 × 1000 × 1000 mm39.37 × 39.37 × 39.37 in | China | $ 29,99930 494 €26,610 £4,471,531 ¥ | Buy |

| BigRep | BigRep ONE v4 | 1005 × 1005 × 1005 mm39.57 × 39.57 × 39.57 in | Germany | $ 30,00030 000 €26,611 £4,471,680 ¥ | Quote |

| 3D Platform | 400 Series WORKBENCH XTREME | 1000 × 1500 × 700 mm39.37 × 59.06 × 27.56 in | United States | $ 49,99950 823 €44,351 £7,452,651 ¥ | Quote |

| Tractus3D | T3500 | ⌀ 1000 x 2100 mm | Netherlands | $ 59,00049 900 €52,335 £8,794,304 ¥ | Quote |

| The Industry | MAGNUM | 1500 × 1200 × 1200 mm59. 06 × 47.24 × 47.24 in 06 × 47.24 × 47.24 in | Sweden | $ 135,000129 990 €119,750 £20,122,560 ¥ | Quote |

| MASSIVit 3D | Massivit 10000 | 1420 × 1110 × 1500 mm55.91 × 43.7 × 59.06 in | Israel | upon request | Quote |

| Modix This brand is a certified partner from our network. | MAMA | 2000 × 5000 × 1000 mm78.74 × 196.85 × 39.37 in | Israel | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Build volume | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|

| Modix This brand is a certified partner from our network. | BIG-Meter | 1010 × 1010 × 1010 mm39.76 × 39.76 × 39.76 in | 1030.3 L | Israel | $ 11,50011 690 €10,201 £1,714,144 ¥ | Buy on Modix |

| CreatBot | F1000 | 1000 × 1000 × 1000 mm39.37 × 39.37 × 39.37 in | 1000 L | China | $ 29,99930 494 €26,610 £4,471,531 ¥ | Buy on CreatBot |

| BigRep | BigRep ONE v4 | 1005 × 1005 × 1005 mm39.57 × 39.57 × 39.57 in | 1015.08 L | Germany | $ 30,00030 000 €26,611 £4,471,680 ¥ | Get a quote |

| 3D Platform | 400 Series WORKBENCH XTREME | 1000 × 1500 × 700 mm39.37 × 59.06 × 27.56 in | 1050 L | United States | $ 49,99950 823 €44,351 £7,452,651 ¥ | Get a quote |

| Tractus3D | T3500 | ⌀ 1000 x 2100 mm | 1649.34 L | Netherlands | $ 59,00049 900 €52,335 £8,794,304 ¥ | Get a quote |

| The Industry | MAGNUM | 1500 × 1200 × 1200 mm59. 06 × 47.24 × 47.24 in 06 × 47.24 × 47.24 in | 2160 L | Sweden | $ 135,000129 990 €119,750 £20,122,560 ¥ | Get a quote |

| MASSIVit 3D | Massivit 10000 | 1420 × 1110 × 1500 mm55.91 × 43.7 × 59.06 in | 2364.3 L | Israel | upon request | Get a quote |

| Modix This brand is a certified partner from our network. | MAMA | 2000 × 5000 × 1000 mm78.74 × 196.85 × 39.37 in | – | Israel | upon request | Get a quote |

Overview of the best large scale professional 3D printers

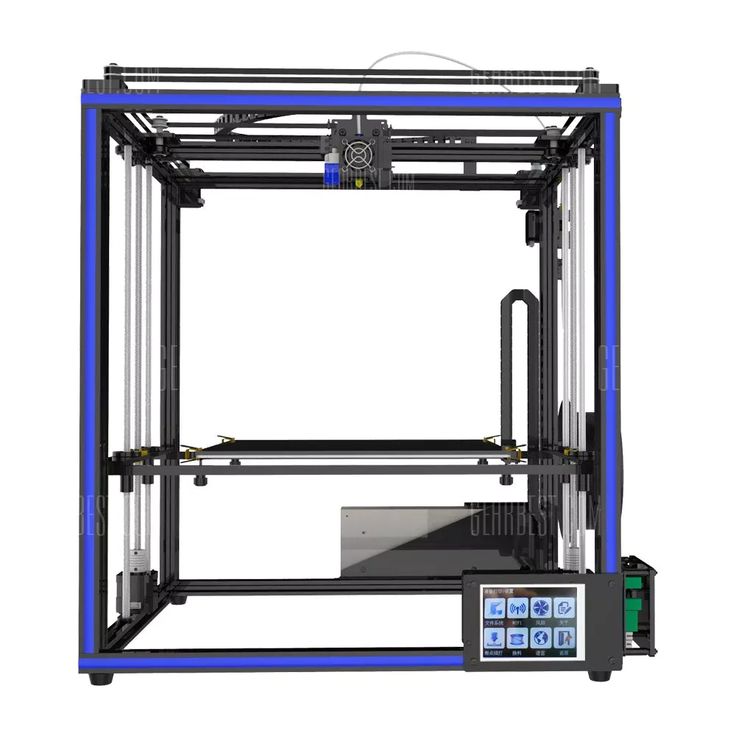

The Modix BIG-Meter offers over one cubic meter of build volume. As all Modix printers do, the BIG-Meter is delivered as a self-assembly kit, which contributes to the printer’s relatively low price point.

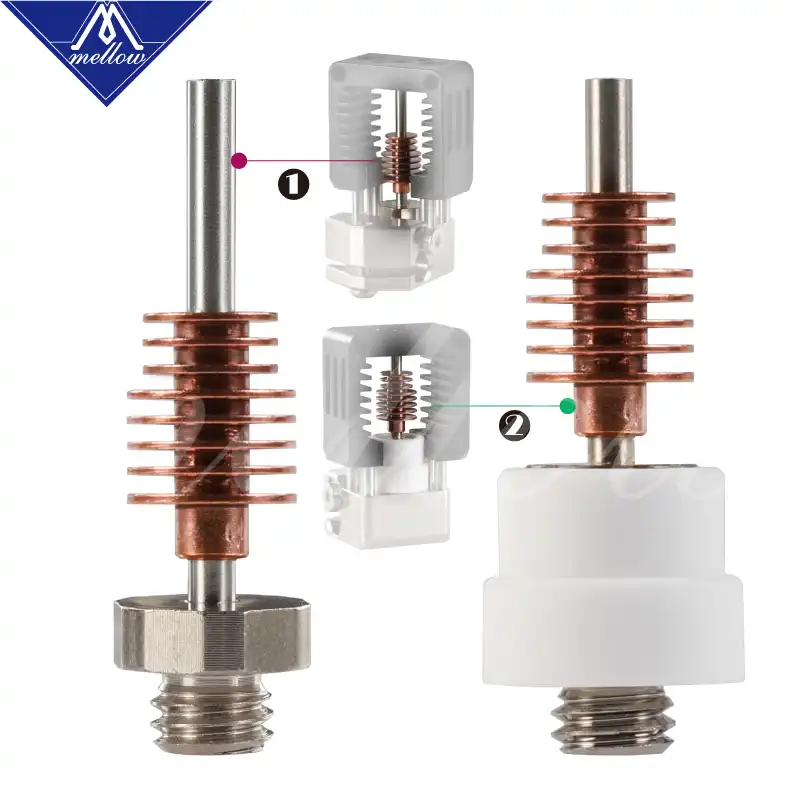

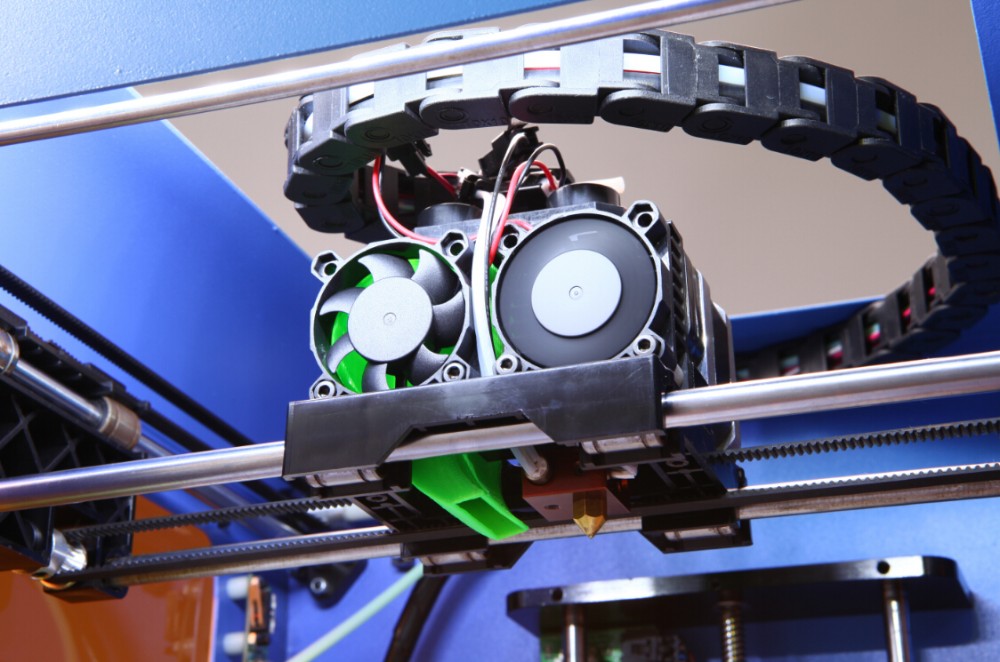

This large scale 3D printer comes with a dual extruder (E3D Aero and E3D Volcano print heads), full automatic bed leveling (bed tile and bed mapping), a Wi-Fi controller, and a range of industrial-grade components. The print bed heats up to 120°C.

The print bed heats up to 120°C.

Buy on Modix Get a quote Add to comparison

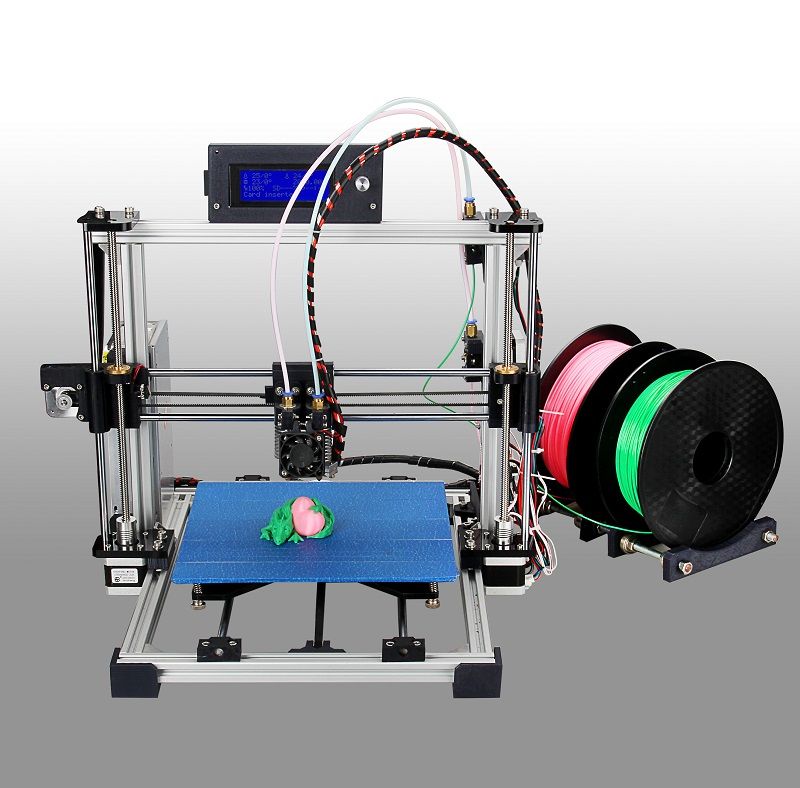

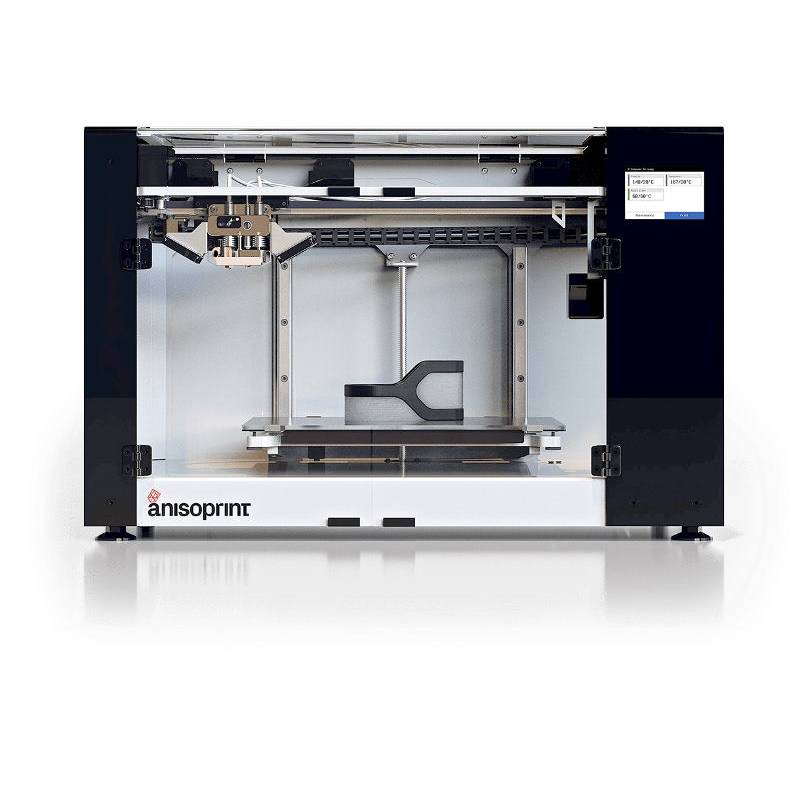

The F1000 from CreatBot offers a full cubic meter of fully enclosed and heated (60°C) build volume. There’s also a filament chamber that can hold two spools of up to 5kg each and heat up to 45°C or 65°C.

Its dual nozzles are able to heat up to 420°C, while the print bed heats up to 100°C. Compatible materials range from standard PLA and ABS to PETG and carbon fiber-filled and flexible materials.

Buy on CreatBot Get a quote Add to comparison

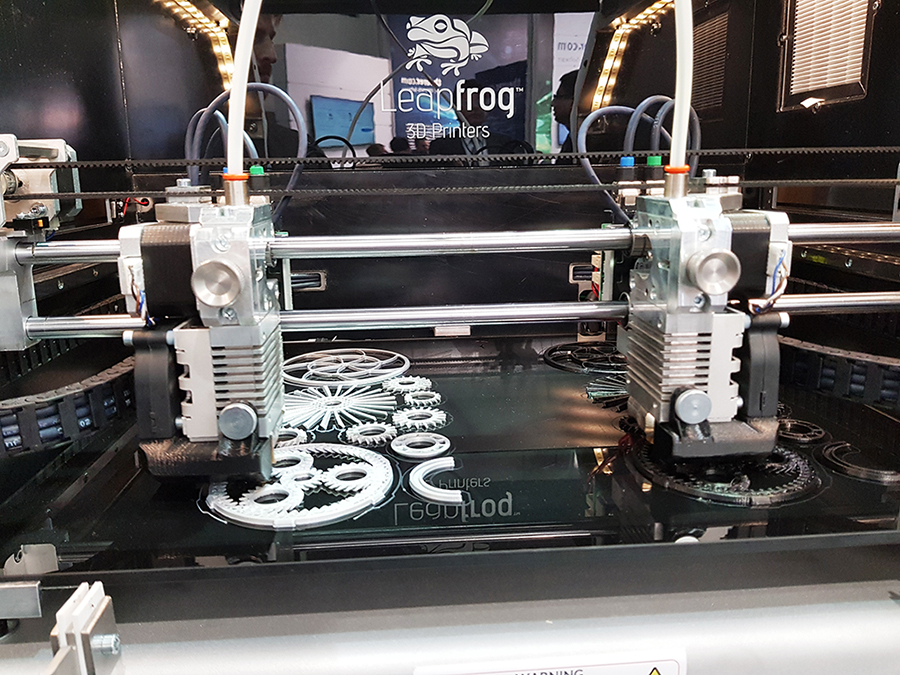

The BigRep ONE, currently in its third generation of upgrades and updates, is one of the only large-sized 3D printers to provide independent dual extrusion (IDEX). IDEX can cut production times in half thanks to duplication or mirror modes.

The printer’s large touchscreen grants access to the webcam and allows users to resume prints even after a power outage. The filament holder is able to hold multiple spools of up to 8kg.

Contact manufacturer Get a quote Add to comparison

This large format 3D printer with dual extrusion is customizable. Various extruders are available, and it’s possible to add an enclosure. The enclosure can be heated and/or include an air filter as well.

Various extruders are available, and it’s possible to add an enclosure. The enclosure can be heated and/or include an air filter as well.

It’s possible to choose from two different control systems; with Wi-Fi or with Ethernet connectivity. The automatic leveling probe touches over 400 points on the print bed to ensure optimal calibration.

Contact manufacturer Get a quote Add to comparison

The T3500, a huge delta 3D printer, offers a massive build size that can 3D print to an exact scale of 1:1 up to 2.1 meters high.

The large-scale Tractus3D T3500 can 3D print exotic materials with its hot-end extruder capable of reaching up to 300°C. This 3D printer features a heated bed and can be equipped with an optional dual extruder.

Contact manufacturer Get a quote Add to comparison

The Industry MAGNUM is a very large format 3D printer by The Industry (previously called BLB Industries), a manufacturer based in Sweden. This XXL 3D printer offers a build volume of 2. 16m³ and comes with a set of nozzles ranging from 2 to 8mm in diameter. The MAGNUM is based on the company’s previous model, the BLB Industries THE BOX.

16m³ and comes with a set of nozzles ranging from 2 to 8mm in diameter. The MAGNUM is based on the company’s previous model, the BLB Industries THE BOX.

Contact manufacturer Get a quote Add to comparison

The Massivit 10000 is an industrial large format 3D printer produced by MASSIVit 3D. MASSIVit 3D is a 3D printer manufacturer based in Israel. This 3D printer offers a build volume of 1420 x 1110 x 1500 mm.

Contact manufacturer Get a quote Add to comparison

Modix has nicknamed their printer “Personal Car Factory”, a quick way to indicate how big the MAMA (Modular Additive Manufacturing Assembler) system really is. It’s equipped with a high-speed pellet extruder, and is also capable of 3D printing with spools of filament.

This huge FFF 3D printer isn’t available yet.

Contact manufacturer Get a quote Add to comparison

Applications for large scale 3D printing

3D printing furniture

The largest 3D printers can be used to 3D print furniture in one go. This includes tables, chairs, and even bathtubs. 3D printing furniture can also generate unique, complex pieces that would be difficult to create otherwise.

This includes tables, chairs, and even bathtubs. 3D printing furniture can also generate unique, complex pieces that would be difficult to create otherwise.

Hence, customized furniture is becoming more and more accessible thanks to extra-large 3D printers.

The BigRep One is in action. Source: QMES3D printing large prototypes

The professional large-scale 3D printers featured in our article can also be used to 3D print large prototypes. This enables businesses to test out their products before actually launching production. Industrial designers and engineers are able to perform more revisions in significantly less time.

They can test their future products extensively while at the same time reducing the production-to-market time.

3D printing production series

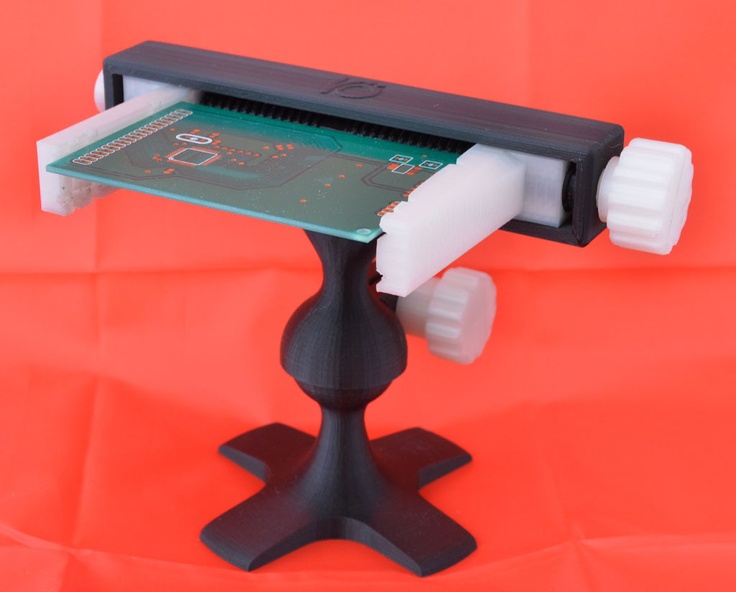

Large-scale 3D printers don’t have to exclusively 3D print large objects and prototypes. Their huge build platform also enables 3D printing big series of smaller objects.

Customized large scale 3D printers

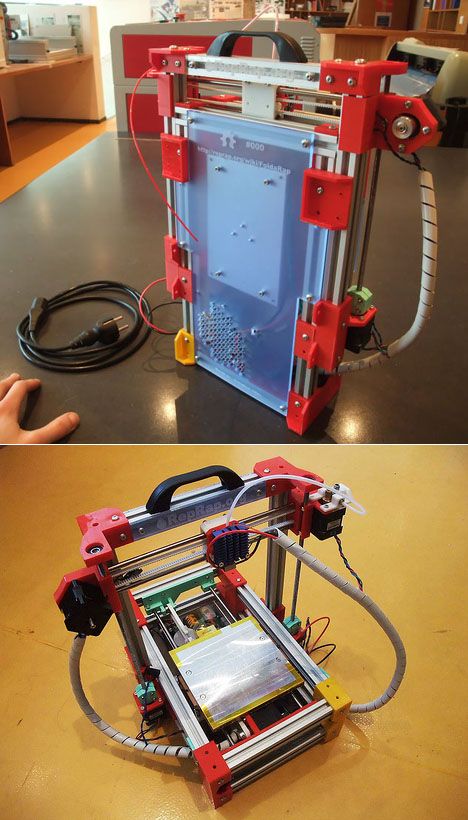

There are several manufacturers that mainly offer tailored solutions rather than standardized 3D printer models. Tobeca, for instance, is a French team that builds 3D printers from scratch and is based entirely on their customers’ needs and requirements.

US-based Erectorbot also provides on-demand builds, although they do have a lineup of standard models. Then there’s Colossus, a company in Belgium that constructs 3D printers within shipping container-like structures. CNC Barcenas, a Spanish manufacturer, also offers tailored, large-scale 3D printers with a range of options to choose from.

THE TOP 10 LARGEST 3D PRINTERS

0Shares

Recently, Mike broke the news about Branch Technology’s C-Fab project for the future of architecture. While that is primarily based on a Kuka arm device, I started to think about some of the other large-sized 3D printing projects in the making and, more specifically, about the 3D printers behind them. While most people generally associate 3D printing with small size objects, the truth seems to be quite different. In fact, there seem to be two diametrically different concurrent trends in the industry. One is towards printing with the finest resolutions and the other is aimed at printing the largest sizes possible.

While that is primarily based on a Kuka arm device, I started to think about some of the other large-sized 3D printing projects in the making and, more specifically, about the 3D printers behind them. While most people generally associate 3D printing with small size objects, the truth seems to be quite different. In fact, there seem to be two diametrically different concurrent trends in the industry. One is towards printing with the finest resolutions and the other is aimed at printing the largest sizes possible.

While they are fewer, numerically, the large size 3D printers seem to draw more interest. So, I figured that, to continue our Top Ten series, we should go find out exactly which are the ten largest 3D printers in the world. This time it is a “real” top ten as I counted close to 20 3D printers with build sizes of around 1 cubic meter and above. It is also based on an objective criteria: build size capability. The only high profile project missing from our list is Dr. Behrokh Khoshnevis’s Contour Crafting, pictured above, as it proposes a process more than a specific 3D printer.

Behrokh Khoshnevis’s Contour Crafting, pictured above, as it proposes a process more than a specific 3D printer.

So, if you are thinking of starting that new 3D printed boat project (like my friends here in Sicily at LivreaYacht), or concrete doghouse and furniture (like my new friends at ConcretePrinter), these are some of the machines you might want to look at and confront with.

2.6 – 3.1 cubic meters / 94 – 112 cubic feet (available for service)

Norway’s Norsk Titanium (NTi) is currently in the process of opening a metal 3D printing facility in the United States, which will feature the company’s Direct Metal Deposition technology. DMD relies on a plasma arc to weld titanium wire directly onto a substrate until it reaches near-net-shape and NTi’s system is capable of 3D printing parts up to 120 x 120 x 180 cm in size, though the maximum length possible they say is 215 cm (that’s 4′ x 4′ x 5.9′ or 7′).

3.696 cubic meters (3,696 Liters) / 130.52 cubic feet (available for purchase)

The Exerial will have a double chamber working volume which will measure 3. 168 liters, making it one of the biggest 3D printers in the world. ExOne uses its own binder jetting technology to work primarily with metals, ceramics and sand, which is used exclusively for serial production of sand cores and molds. On top of its size, the Exerial system is 3-4 times the speed of the next largest machine from ExOne, the S-Max.

168 liters, making it one of the biggest 3D printers in the world. ExOne uses its own binder jetting technology to work primarily with metals, ceramics and sand, which is used exclusively for serial production of sand cores and molds. On top of its size, the Exerial system is 3-4 times the speed of the next largest machine from ExOne, the S-Max.

4 x 2 x 1 m: 8 cubic meters / 282 cubic feet (available for purchase)

The largest industrial machine currently on the market is voxeljet’s VX4000, which uses the company’s binder jetting technology primarily to 3D print sand casts as large as 4 x 2 x 1 meters (a volume of 8 cubic meters),

9 cubic meters / 317 cubic feet (available for projects/studies/research)

Designed by Enrico and Riccardo Dini, this 3D printer uses a binder jetting process. It deposits layers of a particular artificial sandstone and then creates the construction layer by applying a binder. Compared to other cement 3D printers it offers even greater geometrical freedom.

112 cubic meters / 368 cubic feet (available for purchase)

Sciaky’s largest available system is the EBAM 300, which uses a high power electron beam gun to melt a 3 mm thick titanium filament to near net shape, with standard deposition rates ranging from 7 to 20 lbs. per hour.

The KamerMaker was one of the very first large-scale 3D printers to make headlines. It was also the first to use RepRap FFF-type technology to build a house on the canal in Amsterdam. DUS Architects and Fiction Factory, the companies behind it, have just added a second KamerMaker – with twice the original print volume – to speed up construction. The first KamerMaker was already printing at 240 mm/s.

Cylindrical, 8-10 meters / 26-32 ft tall (in development)

Ever since it started making 3D printers, WASP’s founder Massimo Moretti has had the dream of creating a house 3D printer which can construct habitats using soil and minimum energy on location. To do this, the company has built progressively larger delta 3D printers with special extruders. When it will be completed, the GigaDelta model will be 12 meters tall.

When it will be completed, the GigaDelta model will be 12 meters tall.

25 cubic meters / 930 cubic feet (available for service)

You may recognize the the BAAM (Big Area Additive Manufacturing) machine from Cincinnati Incorporated for its use in 3D printing cars. The BAAM printer was designed specifically to 3D print the Strati car for Local Motors, with help and technology licensed from Oak Ridge National Laboratory. The size and speed allow large parts to be made quickly using thermoplastic materials, which makes the process particularly low-cost. It also has open architecture for material vendors, which means that it can offer more alternatives. And BAAM is in the process of getting even bigger, as Cincinnati works on their next version, nicknamed Bertha.

288 cubic meters / 10,170 cubic feet (available for purchase on demand)

Slovenian company BetAbram produces, upon request, a series of three house printers that can 3D print habitable structures from a CAD file. The machines can print layers of 25 cm, but are working up to even thicker layers for added speed. Prices start at just €12,000 for the basic P3 model. The company is working on 3D printing a two-story house at some point this summer.

The machines can print layers of 25 cm, but are working up to even thicker layers for added speed. Prices start at just €12,000 for the basic P3 model. The company is working on 3D printing a two-story house at some point this summer.

2,466 cubic meters / 87,120 cubic feet (available for service)

When discussing large-sized 3D printers, the largest one by far is that created by Winsun, in China, to build furniture, houses, and even five stories buildings. It uses recycled concrete from construction waste and the process is, thus, significantly more eco-sustainable than traditional construction. Here, it is definitely worth noting that there is some controversy about the company’s technology as it relates to Dr. Khoshnevis’s own technology, with the USC professor claiming IP theft.

Correction: This post previously misrepresented the specs of the Exerial 3D printing system from ExOne to be slightly smaller, as well as the availability of the machine. The article has since been updated to more accurately reflect ExOne’s largest machine, now available for purchase.

The article has since been updated to more accurately reflect ExOne’s largest machine, now available for purchase.

Davide Sher

Davide was born in Milan, Italy and moved to New York at age 14, which is where he received his education, all the way to a BA. He moved back to Italy at 26 and began working as an editor for a trade magazine in the videogame industry. As the market shifted toward new business models Davide started working for YouTech, the first iPad native technology magazine in Italy, where he discovered the world of additive manufacturing and became extremely fascinated by its incredible potential. Davide has since started to work as a freelance journalist and collaborate with many of Italy’s main generalist publications such as Corriere della Sera, Panorama, Focus Italy and Wired Italy: many of his articles have revolved around the different applications of 3D printing.

interviews with the developer of industrial FDM installations

Rapid prototyping

Experts recommend

3D printers

Science and education

Author: Viktor Naumov

Author: Viktor Naumov

Discovery 3D Printer: brand history | Technology and equipment line | Benefits of 3D printing with pellets | Applications and implementation examples

Today, many companies use the additive manufacturing solutions available on the market as complementary tools. More and more users are considering introducing 3D technologies into the production process of their enterprises, which is why the industry is actively adapting to new demands.

More and more users are considering introducing 3D technologies into the production process of their enterprises, which is why the industry is actively adapting to new demands.

Some manufacturing sectors require large models and parts that are often difficult to produce with traditional methods. In this sense, large-format 3D printing plays a fundamental role in the creation of such structures, providing lower costs and faster production times.

One company developing such solutions is the Discovery 3D Printer . The equipment of this brand for 3D printing of large products is used by enterprises and organizations of various industries, including railway transport and aviation. We bring to your attention an interview of 3dnatives.com about Discovery 3D Printer solutions with one of the equipment developers.

Find out more about large-format additive manufacturing: 3D printer catalog, tasks, case studies, and useful materials on the Discovery 3D Printer website in Russian

3DN: Please tell us about yourself and your role in additive manufacturing.

– My name is Francisco Barcenas and I am the Director of R&D and Innovation at CNC Bárcenas / Discovery 3D Printer. My main responsibilities include the design and development of large-scale additive plants, as well as the research and testing of new materials, which we carry out in close cooperation with our suppliers. Among them is SABIC, a world leader in the development of special materials for large-scale 3D printing (LFAM). I also advise our clients on 3D modeling for additive manufacturing, lead innovative projects and consult on our 3D printing technologies.

Francisco Barcenas

3DN: What is Discovery 3D Printer and when was it founded?

– Discovery 3D Printer is the division responsible for 3D printing solutions of CNC Bárcenas, founded in Valdepeñas (Ciudad Real, Spain) in 2009. The company also specializes in the production of CNC industrial equipment. The Discovery 3D Printer is the result of many years of intense in-house research, development and innovation, culminating in a contract with BSH Group, our first customer in the industrial sector, specifically their plant in Montagnana, Zaragoza. We still continue to cooperate as suppliers in various technological fields.

We still continue to cooperate as suppliers in various technological fields.

In 2020, we partnered with Gaggenau, an innovative BSH Group company based in Lipsheim, France, that manufactures custom CNC machines for its R&D lab. One of the main features of our company is that we provide customized solutions, including combining different technologies (FDM, FGF and post-processing by milling) in one piece of equipment.

iQB Technologies is the exclusive distributor of Discovery 3D Printer in Russia. Contact our experts: we will select the equipment and help you implement large-scale 3D printing in your company!

3DN: Explain what your technology is based on? What large format solutions have you developed?

– In 2016, we launched the Discovery 3D Printer, a large-format FDM machine. We continued to improve the performance of the printer until we finally created the 2020 version of the printer, a high-performance machine with a print volume of up to 1cc. m. This solution is designed to produce small and large parts at high resolution and speed, as well as using virtually any filament available on the market.

m. This solution is designed to produce small and large parts at high resolution and speed, as well as using virtually any filament available on the market.

In 2017, we introduced the Super Discovery 3D Printer, an innovative equipment that has no analogues in Europe. It uses polymer pellet direct extrusion technology, also known as FGF, to create large objects at high speed. This solution reduces the cost by using consumables in the form of strips. This equipment was developed for the Navantia shipbuilding company, which over the past few years, as part of its strategic Shipyard 4.0 initiative, has introduced the most innovative technological solutions on the market. We also continue to work closely with Navantia on a number of projects (in fact, we are their official supplier of additive manufacturing solutions). And, as I said, we now offer completely customized solutions that combine different technologies and print volumes.

3DN: What is the competitive advantage of 3D printing with pellets? And what are the limitations of this technology?

Let me tell you a few benefits. For example, our technology allows you to create very large parts in a short time and at a lower cost than when using a filament. In addition, the possibility of using a huge range of thermoplastics, including technical ones, is very interesting. This opens up a wide range of applications, such as mold making, which offer great advantages over traditional processes.

Our Super Discovery 3D Printer is available in Standard, Compact, Hybrid and as a 3D printing and post-processing system (Workstation). It allows you to flexibly, quickly and cost-effectively produce large parts - molds, tooling, small series of original or spare parts and functional prototypes using high performance materials reinforced with fibers and minerals. All these materials comply with the regulations, including fire safety, in force in each industry.

All these materials comply with the regulations, including fire safety, in force in each industry.

In the specific field of R&D and innovation, they can be an ideal basis for developing or improving new materials for additive manufacturing according to market requirements, as well as for testing mechanical, physico-chemical, technological and other properties. An important factor is the environmental friendliness of our solutions.

As for the limitations, I'd rather talk about the specific characteristics of this technology. For example, sometimes you need to change the approach to 3D modeling, and in some cases you need to apply post-processing to polish or coat surfaces. As you know, there are no universal solutions in the field of additive technologies, so we decided to focus on a large format using standard thermoplastic, and, if necessary, technical materials.

3DN: What industries might be interested in your solutions? Can you name any of the clients?

“I don't think there is any manufacturing industry that can't take advantage of large format 3D printing. We work with clients from almost all sectors. In addition to BSH and Navantia, we have partnered with AIRBUS for molds and tooling, and with Hitachi ABB Power Grids for parts with dielectric properties well above standard. In the construction industry, I can name Willy Naessens Group, and CAF Group is one of our most representative customers in the field of ground transportation.

We work with clients from almost all sectors. In addition to BSH and Navantia, we have partnered with AIRBUS for molds and tooling, and with Hitachi ABB Power Grids for parts with dielectric properties well above standard. In the construction industry, I can name Willy Naessens Group, and CAF Group is one of our most representative customers in the field of ground transportation.

Subway train components printed on an additive Super Discovery 3D Printer (CAF project). This 1300 x 2500 x 1000 mm build chamber printer is the perfect answer to new needs in large format 3D printing

I would also like to note that Discovery 3D Printer solutions are successfully used by several universities, technology and research centers. For example, we have a very close relationship with the Faculty of Mechanical Engineering of the University of Leuven (KU LEUVEN). In Spain, we have been collaborating for several years with the R&D and Innovation Department of the University of Cadiz.

3DN: Can you highlight any additive manufacturing project involving Discovery 3D Printer?

– We are very pleased with the agreement with UROVESA, a leading Spanish company in the sector of civil and military special vehicles. But in particular I would like to highlight our cooperation with the Department of Design of Lightweight Polymer Structures at the Brandenburg University of Technology (b-tu). For many months we have been working on an innovative project for the production of wind turbine blades. The university already has our Super Discovery 3D Printer Workstation, which combines FGF technology with a milling system.

In the course of work, it was possible to fully fulfill the client's task, namely, to apply 3D printing for the fast and economical production of molds for autoclaves at high temperature and pressure, as well as other large parts using high-quality materials. The dimensions and characteristics of the solution were fully consistent with the original project. It is important to note that the Super Discovery 3D Printer Workstation was selected through an open tender in Germany, in which any company could take part.

It is important to note that the Super Discovery 3D Printer Workstation was selected through an open tender in Germany, in which any company could take part.

Employees of Brandenburg University of Technology and Super Discovery 3D Printer Workstation

We are very proud of this achievement, because we managed not only to outperform other manufacturers in terms of technical characteristics and low production costs. We have received very positive feedback for our proactive and collaborative approach throughout the entire project management cycle, from the first commercial contact to the completion of the delivery to Brandenburg and subsequent technical support. I also want to add that due to the current situation with the pandemic, this was the first fully digital project, without any physical interaction before delivery.

3DN: A few final words for our readers?

– We ask companies and research centers to contact us and express their interest or concerns about large-format industrial 3D printing. I am sure that we will be able to help in the implementation of research, development and innovation projects, in the introduction of new production processes, which will become an important component of additive manufacturing in the future.

I am sure that we will be able to help in the implementation of research, development and innovation projects, in the introduction of new production processes, which will become an important component of additive manufacturing in the future.

What do you think of the technology developed by Discovery 3D Printers? Leave a comment below or on our social media pages. Subscribe to the blog newsletter and be the first to know the latest 3D technology news!

Source: 3dnatives.com Author: Amelia H. Photo © Discovery 3D Printer

Article published on 09/23/2021, updated on 03/04/2022

The world's largest 3D printer printed a boat

Men don't have to bother with gifts now. It will be enough to order a boat that a 3D printer can print.

The world's largest 3D printer is located at the University of Maine in the USA. In 72 hours, the polymer device printed a boat over 7 meters long and weighing 2. 26 tons. Thus, the printing process immediately broke 3 world records, which were successfully recorded by representatives of the Guinness Book of Records:

26 tons. Thus, the printing process immediately broke 3 world records, which were successfully recorded by representatives of the Guinness Book of Records:

1. The largest prototype of a polymer 3D printer;

2. Largest 3D printed solid object;

3. The largest 3D printed boat.

But at this point, the employees of the Center of Excellence and composites stop at going. They claim that this 3D printer can print and more global objects, up to 30 m long, 7 m wide and 3 m high. Performance super 3D printer is 226 kg of polymers per hour.

See also: Transformer bed that solves the problem of territory division

It is worth noting that the prototype 3D printer turned out to be expensive pleasure. To create the entire installation and put it into operation, spent about $2.5 million. The bulk of the money was allocated by the US Army. Later on she plans to work closely with the company to create mobile shelters for soldiers, as well as bridges. Thus, the army will become one of main customers. The company received financial support in the amount of $500,000 from the Maine Institute of Technology.

Thus, the army will become one of main customers. The company received financial support in the amount of $500,000 from the Maine Institute of Technology.

The aim of this project was the idea of using 3D printing in shipbuilding. The printed boat was named "3Dirigo" and have already tried it in the pool. Soon the ship will set sail. It is worth noting that about $40 thousand was spent on its printing.

US Senator Angus King noted that the printing of the 3Dirigo polymer boat was truly a great event in the field of technology, because it opens up many new opportunities. In addition, Angus joked that the first great event for the university was admission at 1965 year of the famous writer Stephen King.

And we recall that in April 2019 in Israel for the first time it was possible to print a living heart on a 3D printer. They made it from human fat cells, which they turned into stem cells of the cardiovascular muscle. The size of the printed heart was about 2.5 cm.

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).