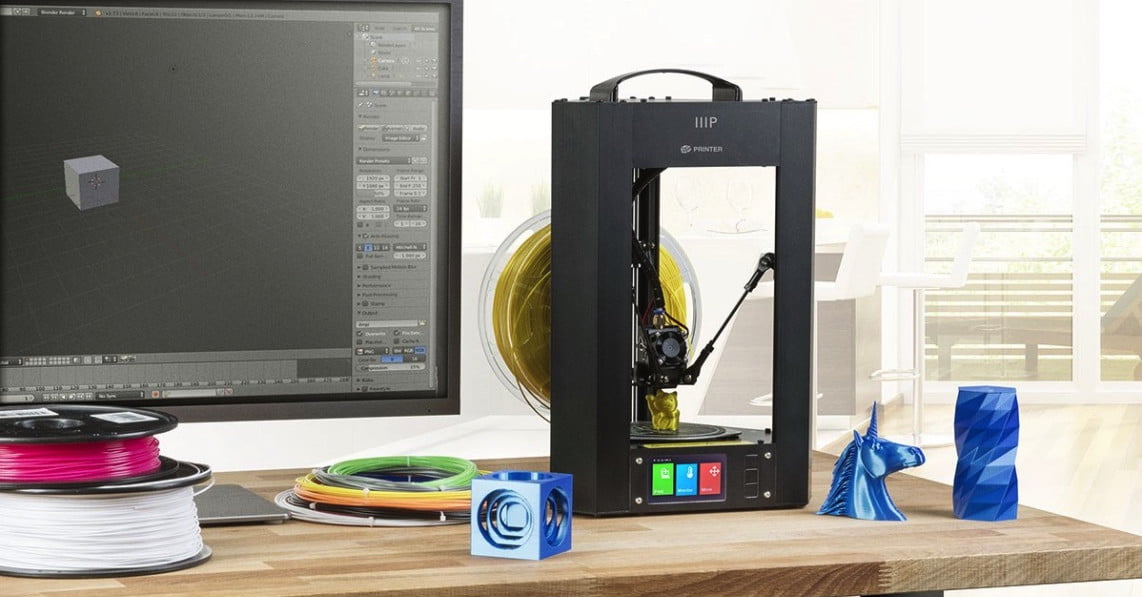

Dual hotend 3d printer

The 9 Best Dual Extruder 3D Printers for Multi Material Printing – Clever Creations

Dual-extruder 3D printers are an excellent solution for multi-color and multi-material 3D printing. You don’t need to swap out filaments for a color change or limit yourself to printing with only a single material at a time. In a dual extrusion printing process, you get two entirely separate extruders for printing with multiple filaments.

If you decide to buy a dual extruder 3D printer, you’ll encounter terms like IDEX system, dual print-head system, and more. It can get quickly confusing to select the right printer for your needs, and you might end up getting one that is not the best fit for you.

In this article, we’ve created a list of the best dual extruder 3D printers that are available for you to buy right now and sorted them into different categories to make your buying decision a little bit easier.

Read on to understand more about these machines and how to choose the best dual extruder 3D printer for your needs.

| Dual Extruder 3D Printer | Category | Type | Price (~) | Best Offer |

|---|---|---|---|---|

| Sovol SV02 | Best under $500 | Single hot end | $359 | Sovol3D |

| Flashforge Dreamer | Best under $500 | Dual hot end | $449 | Flashforge |

| TENLOG TL-D3 Pro | Best under $1000 | IDEX | $699 | Amazon |

| Flashforge Creator Pro 2 | Best under $1000 | IDEX | $649 | Flashforge |

| QIDI Tech i-Fast | Best prosumer | Dual hot end | $2299 | Amazon |

| Ultimaker S3 | Best prosumer | Dual hot end | $4725 | MatterHackers |

| BCN3D Sigma D25 | Best professional | IDEX | $3995 | MatterHackers |

| Raise3D Pro 3 | Best professional | Dual hot end | $5249 | MatterHackers |

| Ultimaker S5 | Best professional | Dual hot end | $6355 | MatterHackers |

What is a Dual Extruder 3D Printer?

A dual extruder 3D printer is a machine that has two extruders, as the name suggests. These extruders can be used to print with different colors or different materials simultaneously. This way, you don’t have to swap out filaments every time you want to change the color of your print.

These extruders can be used to print with different colors or different materials simultaneously. This way, you don’t have to swap out filaments every time you want to change the color of your print.

You can also use dual extruders to print with multiple materials at the same time, for example, printing with both ABS and TPU filaments in a single 3D print. This opens up a lot of possibilities for interesting prints that wouldn’t be possible with a single extruder printer.

In this article, we’ve covered three types of different dual extrusion 3D printers: Single hot end setup, Dual hot end extrusion, and Independent Dual Extruder system (IDEX).

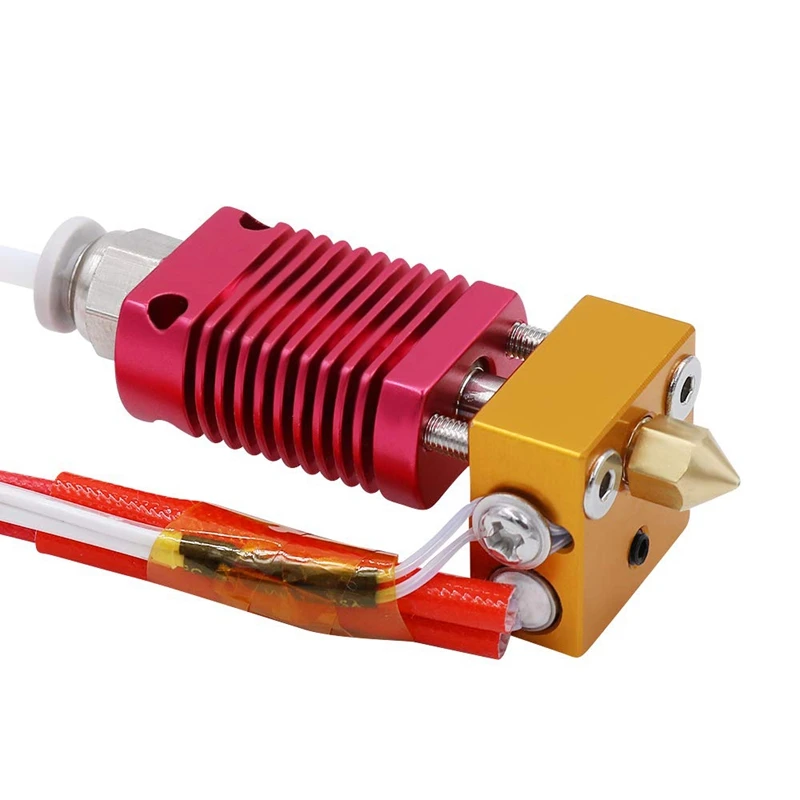

The single hot end setup is the least complex. It gives you the benefits of dual extrusion 3D printers without actually having a second print head or a complex motion system.

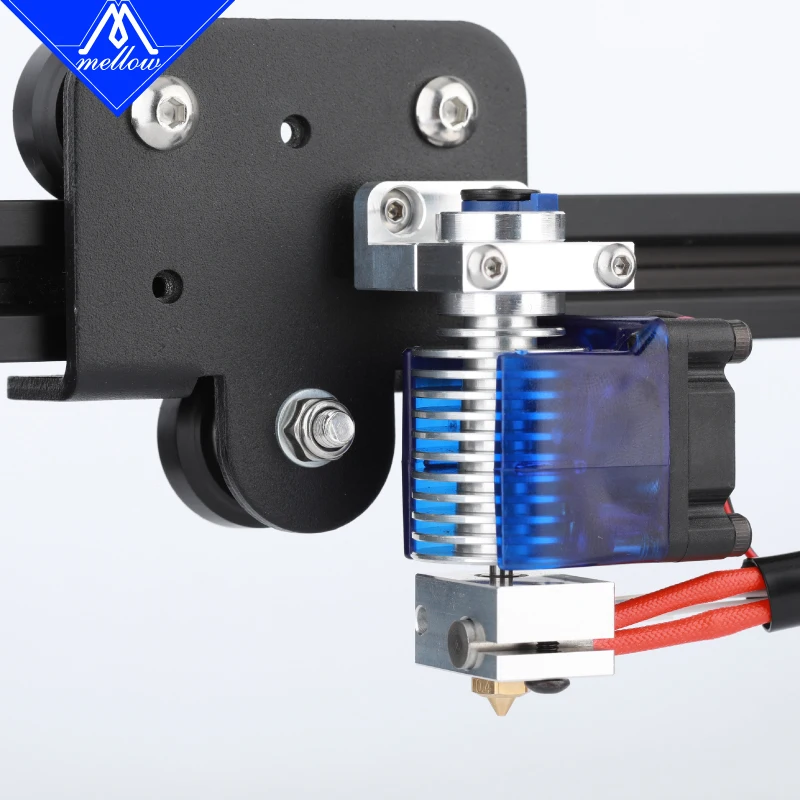

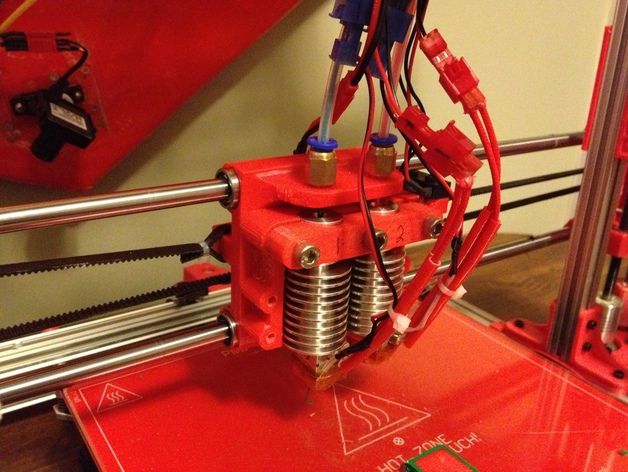

The dual hot end setup incorporates a second print head next to your primary hot end, and both hot ends move together. You can assign different materials for each hot end, effectively giving you the capabilities of printing with two 3D printers, albeit on a single print bed.

You can assign different materials for each hot end, effectively giving you the capabilities of printing with two 3D printers, albeit on a single print bed.

One of the best and the most practical applications of dual extruders is the IDEX style of 3D printer. These printers have two independent print heads that can be controlled and moved separately. This gives you a lot of control over the printing process and opens up a lot of possibilities for complex prints.

What is the Benefit of a Dual Extruder 3D Printer?

A dual extruder 3D printer triumphs over the regular single extruder 3D printer in many ways. You do not need to swap out any filaments mid-print for any color changes, leading to a faster print speed.

You can print with multiple materials simultaneously with a dual extruder printer. You can use one print head to print the outer shell of the model, while the secondary hot end will print the infill with a more robust material. Similarly, you can use filaments with different colors to print a colorful model.

IDEX printers give you the added benefits of printing modes. You can print multiple objects simultaneously with the duplication mode and print a mirrored version of your design with the mirror print mode. It leads to increased productivity and is useful for 3D printing larger batches of objects.

The last and probably one of the most popular benefits of dual extruder 3D printers is their ability to print soluble supports. You can use PVA or HIPS filament in your secondary extruder to print water dissolvable supports. It gives you the freedom to print complex objects and significantly saves post-processing time, as it takes away the need to remove supports manually.

The Best Dual Extruder 3D Printers

Sovol SV02

Best under $500

Check Price

AmazonSovol3D

The Sovol SV02 is an excellent budget dual extruder 3D printer. It features a Y-shaped, two-in, one-out single print head. It is a clever way to carry out multi-filament printing without adding too many extra 3D printer costs.

The SV02 has a decent printing volume and a dual Z-axis design for better printing accuracy. Its textured glass bed helps with first-layer adhesion and makes the removal of prints easier.

Its mainboard features TMC 2208 stepper drivers for a silent 3D printing process. You also have the option to install a BLTouch auto-leveling sensor as an upgrade, taking away the need for manual bed leveling.

Additionally, you can buy a mixing hot end that lets you mix two different colors simultaneously. This feature gives a lot of room for fun experimentation and creative 3D prints.

The SV02 is an excellent fit for schools to print colorful educational models and for beginners and amateurs users who want to experiment with dual extruder 3D printing without breaking the bank.

Standout Features

- 2-in-1-out hot end

- Optional color mixing

- Dual Z-axis

Technical Details | |

|---|---|

| Build volume | 280 x 240 x 300 mm |

| Dual extrusion setup | Single hot end |

| Max hot end temperature | 260°C |

| Bed leveling | Manual |

| Connectivity | SD Card or Data Cable |

| Compatible materials | PLA, TPU, HIPS, ABS, PETG, WOOD |

What We Like

- Lightweight hot end

- Silent 3D printing

- Can mix two colors

Could Be Better

- Inconsistent print quality

- Occasional filament jams

Find Sovol SV02 at

AmazonSovol3D

Flashforge Dreamer

Best under $500

Check Price

AmazonFlashforgeMatterHackers

The Flashforge Dreamer is one of the most popular dual extruder 3D printers in the market that comes with some elegant features for easy multi-material 3D printing. It comes fully assembled, and you can get started with 3D printing on it within 30 minutes of unboxing the printer.

It comes fully assembled, and you can get started with 3D printing on it within 30 minutes of unboxing the printer.

With the Dreamer, you get two print heads with a direct-drive setup that can help you print a wide variety of materials with ease. The fully enclosed design prevents any harmful 3D printer fumes from leaving the printer and aids considerably with printing ABS. It includes an aluminum heated print bed for a more even heat distribution on the print surface.

The dual extruder design does result in a slight reduction in the build volume of the 3D printer, however, and you get a relatively small print area for the price. Some users also find the bundled FlashPrint slicing software limiting in terms of features.

Nonetheless, considering that the Dreamer is primarily aimed towards beginners, it does an excellent job in the user convenience and accessibility department. It is a good choice for educational institutes and amateur 3D printer users who want a plug-n-play solution for their multi-color and multi-material printing needs.

Standout Features

- Fully enclosed print chamber

- Aluminum build plate

- Wi-Fi connectivity

Technical Details | |

|---|---|

| Build volume | 230 x 150 x 140 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 240°C |

| Bed leveling | Assisted Manual |

| Connectivity | USB cable, SD card, Wi-Fi |

| Compatible materials | PLA, TPU 95A, ABS, PETG |

What We Like

- Stable printing area

- Beginner-friendly

- Plug-n-play functionality

Could Be Better

- Small build volume

Find Flashforge Dreamer at

AmazonFlashforgeMatterHackers

TENLOG TL-D3 Pro

Best under $1000

Check Price

Amazon

The Tenlog TL-D3 Pro is a rare dual extruder 3D printer to feature an IDEX system under $1000. It has two independent extrusion systems that move independently and let you print in mirroring print modes and duplicating modes.

It has two independent extrusion systems that move independently and let you print in mirroring print modes and duplicating modes.

You get a linear rail precision guide on the X-axis to support the IDEX system and a sturdy metal frame to deliver accurate printing quality. The tempered glass heated print bed gives excellent bed adhesion, and the silent motherboard with TMC 2208 and TMC 2225 stepper drivers delivers a quiet 3D printing experience.

The Tenlog TL-D3 Pro is a great dual extruder 3D printer that provides a unique mix of features at an affordable price. If you’re someone who has the need for batch 3D printing in a semi-professional setup, or you want an IDEX 3D printer on a budget, the TL-D3 Pro is a solid option.

Standout Features

- Multiple printing modes

- X-axis linear rail

- IDEX system

Technical Details | |

|---|---|

| Build volume | 300 x 300 x 350 mm |

| Dual extrusion setup | IDEX |

| Max hot end temperature | 300°C |

| Bed leveling | Manual |

| Connectivity | SD card, USB 2. 0 0 |

| Compatible materials | TPU, PVA, PLA, ABS, HIPS, WOOD, PETG, FLEXIBLE |

What We Like

- Easy to assemble

- Silent 3D printing

- Wide material compatibility

Could Be Better

- Open-frame design

Find TENLOG TL-D3 Pro at

Amazon

Flashforge Creator Pro 2

Best under $1000

Check Price

AmazonFlashforgeGeekbuyingAliExpress

While the aforementioned Flashforge Dreamer is suited for beginners and amateur users, the Flashforge Creator Pro 2 is aimed more towards the professional user base. The Creator Pro 2 is a fully enclosed 3D printer with a similar level of user convenience, but now with an upgraded independent dual extruder (IDEX) system.

The Flashforge Creator Pro 2 has multiple printing modes that let you print mirrored designs, duplicate your models for faster 3D printing, and even print with soluble support materials for complex and intricate 3D designs. The heated print bed and the enclosed design further expand the material compatibility of the printer, letting you print with PLA, ABS, HIPS, and PVA.

The heated print bed and the enclosed design further expand the material compatibility of the printer, letting you print with PLA, ABS, HIPS, and PVA.

The Flashforge Creator Pro 2 is a superb dual extruder 3D printer for industry professionals and hobbyists alike. You get a robust build quality, an IDEX system, ease of use, and excellent printing, all for a relatively low cost. In our book, it’s the best dual extruder 3D printer under $1000

Standout Features

- Fully enclosed design

- Residue scraping

- Easy to use touchscreen

Technical Details | |

|---|---|

| Build volume | 200 x 148 x 150 mm |

| Dual extrusion setup | IDEX |

| Max hot end temperature | 240°C |

| Bed leveling | Manual |

| Connectivity | SD Card |

| Compatible materials | PLA, ABS, PVA, PETG |

What We Like

- Affordable IDEX printer

- Excellent print quality

- Great support team

Could Be Better

- Small printing volume

- Lacks air filters

Find Flashforge Creator Pro 2 at

AmazonFlashforgeGeekbuyingAliExpress

QIDI Tech i-Fast

Best prosumer

Check Price

AmazonGeekbuying3DPrintersBay

The QIDI Tech i-Fast is not for the masses and is instead more positioned as a premium 3D printer for prosumers. For almost $2300, you get a printer that comes with many high-end features and a large build volume (uncommon in dual-extruder 3d printers) to accommodate a wide variety of 3D designs.

For almost $2300, you get a printer that comes with many high-end features and a large build volume (uncommon in dual-extruder 3d printers) to accommodate a wide variety of 3D designs.

Its heated print chamber measures 330 x 250 x 320 mm and is fully enclosed. For better printing with high-end materials like Nylon, Polycarbonate, and PolyPropylene, it can be heated up to 60°C. The motion system is fully supported with high-quality precision linear rails, and it has a dual Z-axis setup for increased accuracy.

The QIDI Tech i-Fast is a feature-packed dual extruder 3D printer for professional use case scenarios and printing high-end prototypes. Despite its high price, it still offers excellent value compared to similar printers in this price range. If you’re planning on adding an industrial machine to your workflow, the i-Fast is likely to be a perfect choice for your prototyping needs.

Standout Features

- Heated build chamber

- Extra all metal print-heads

- Large build volume

Technical Details | |

|---|---|

| Build volume | 330 x 250 x 320 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 300 °C |

| Bed leveling | Manual |

| Connectivity | Wi-Fi, USB and SD Card |

| Compatible materials | PLA, Nylon, TPU, PETG, ABS, PC, Wood, CF |

What We Like

- Quiet 3D printing

- Prints ABS very well

- Retractable hot ends

Could Be Better

- Manual bed leveling

- Limited firmware support

Find QIDI Tech i-Fast at

AmazonGeekbuying3DPrintersBay

Ultimaker S3

Best prosumer

Check Price

MatterHackers

The Ultimaker S3 is feature-packed and one of the best dual extruder 3D printers by Ultimaker. It is for professional users who want a high-quality, compact printer that consistently delivers excellent print quality.

It is for professional users who want a high-quality, compact printer that consistently delivers excellent print quality.

With the Ultimaker S3, you get a modest build volume of 230 x 190 x 200 mm. This is enough for most typical 3D prints but can be a limitation if your needs involve creating larger multi-color or multi-material objects.

The dual extruders on the Ultimaker S3 have swappable print cores that let you print with advanced materials if you need to. Over 200 materials are tried and tested on the S3, making it one of the most compatible dual extruder printers in terms of filaments.

Additional features include a 4.3-inch touchscreen with an easy-to-use UI, an onboard camera for remote monitoring, and an automatic bed leveling system to give you perfect bed adhesion and first layers every time.

The Ultimaker S3 is a premium 3D printer, and at a price point of over $4000, it is undoubtedly not for primary hobby purposes. The features it provides and the materials it supports are more geared towards industrial prototyping and end-component solutions for industries. If you’re someone who fits in that bracket, the S3 is a good choice for your 3D printing needs.

If you’re someone who fits in that bracket, the S3 is a good choice for your 3D printing needs.

Standout Features

- Swappable print cores

- Onboard camera

- Automatic bed leveling

Technical Details | |

|---|---|

| Build volume | 230 x 190 x 200 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 280 °C |

| Bed leveling | Automatic |

| Connectivity | Wi-Fi, Ethernet, USB |

| Compatible materials | PLA, ABS, PETG, NylonX, TPU, PVA, PP, PC |

What We Like

- Excellent print quality

- Professional software support

- Wide material compatibility

Could Be Better

- Limited build volume

- Expensive replacement parts

Find Ultimaker S3 at

MatterHackers

BCN3D Sigma D25

Best professional

Check Price

MatterHackers

Improving on the R17 and R19 Sigma’s series of independent dual extruder (IDEX) 3D printers, BCN3D’s new Sigma D25 is a professional-grade 3D printer that comes in a new light gray color and with a desktop-sized footprint. It features an independent extruder system, letting you print with multiple print modes and enhance your productivity.

It features an independent extruder system, letting you print with multiple print modes and enhance your productivity.

The Sigma D25 includes stainless steel, precision linear rails on the X-axis, and a robust Z-axis designed for durability and maximum print accuracy. For better bed adhesion, its new aluminum heated build plate comes with a silicon thermal pad to evenly heat its area.

It also includes a new set of custom-made E3D hot ends coupled with Bondtech extruders that support a wide variety of materials and deliver a consistent 3D printing performance. The filament spools are neatly tucked within the printer frame itself, protecting them from any external debris and giving the printer a clean look.

BCN3D Sigma D25 aims to deliver the highest dual extrusion 3D printing in a clean-looking, easy-to-use package. The large build volume, IDEX system, and interface make it suitable for batch printing, print farms, and educational purposes.

Standout Features

- IDEX setup

- Built-in filament holders

- Large build volume

Technical Details | |

|---|---|

| Build volume | 420 x 300 x 200 mm |

| Dual extrusion setup | IDEX |

| Max hot end temperature | 300°C |

| Bed leveling | Manual |

| Connectivity | SD card, Wifi, Ethernet |

| Compatible materials | PLA, PVA, PET-G, TPU, PP, PA |

What We Like

- Easy to use interface

- Great build quality

Could Be Better

- Manual bed leveling

- Limited Z-height

Find BCN3D Sigma D25 at

MatterHackers

Raise3D Pro 3

Best professional

Check Price

MatterHackers

The Raise3D Pro 3 is one of the flagship 3D printers by the Raise3D team. It builds upon the previous generation of the Pro 2 series of industrial 3D printers. Its improvements lie with its new dual extruder setup, interchangeable hot end, and airflow system to give you great 3D printing results every time.

It builds upon the previous generation of the Pro 2 series of industrial 3D printers. Its improvements lie with its new dual extruder setup, interchangeable hot end, and airflow system to give you great 3D printing results every time.

The Pro 3 comes with a large build volume of 300 x 300 x 300mm. That volume is fully enclosed to isolate the print area from the external environment. Additionally, it includes a HEPA filtration system to keep away potantially unhealthy 3D printer fumes.

Its automatic bed leveling minimizes the calibration time required, resulting in improved productivity. The built-in ‘EVE intelligent assistant’, too, is a unique feature with the Pro 3 designed to locate and resolve any issues and give helpful feedback to the user.

The Raise 3D Pro 3 is for professional users who need a robust, large-sized 3D printer that lets you execute multi-material 3D printing on an industrial scale. You can use it to carry out batch 3D printing with advanced materials and end-use components without hassles.

Standout Features

- Airflow manager

- Interchangeable hot ends

- EVE Smart assistant

Technical Details | |

|---|---|

| Build volume | 300 x 300 x 300 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 300°C |

| Bed leveling | Automatic |

| Connectivity | Wi-Fi, LAN, USB port |

| Compatible materials | PLA, ABS, HIPS, PC, TPU, TPE, PETG, ASA, PP, PVA, Nylon |

What We Like

- Professional build quality

- High repeatability

- Auto bed leveling

- Large filament compatibility

Could Be Better

- Large investment

Find Raise3D Pro 3 at

MatterHackers

Ultimaker S5

Best professional

Check Price

AmazonMatterHackers

The Ultimaker S5 is the bigger brother of the Ultimaker S3, but with a larger build volume to utilize the benefits of dual extrusion 3D printing fully. It is similar to the S3 in many aspects, but the additional upgrades and add-ons make it an automated industrial-level 3D printer.

It is similar to the S3 in many aspects, but the additional upgrades and add-ons make it an automated industrial-level 3D printer.

The S5’s large build volume of 330 x 240 x 300 mm is suitable for big-sized objects, and it can be fully enclosed with an optional air management system to maintain a stable temperature in the printing area. This makes it more suitable as a Nylon 3D printer or to work with other high-temperature filaments.

To expand this 3D printer further, you can add a material station that takes up to six materials and automatically choose the required material for the current print without any user intervention.

The swappable print cores, retracting nozzles, and automatic bed leveling are the same as the S3, delivering a predictable and high-quality 3D printing experience each time.

The Ultimaker S5 is an excellent printer for industrial environments and can be upgraded to fulfill even more complex needs. It is our top pick for the best dual extruder 3D printer for professionals.

Standout Features

- Large build volume

- Additional upgrades

- Swappable print cores

Technical Details | |

|---|---|

| Build volume | 330 x 240 x 300 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 280°C |

| Bed leveling | Automatic |

| Connectivity | Wi-Fi, Ethernet, USB |

| Compatible materials | PLA, ABS, PETG, NylonX, TPU, PVA, PP, PC |

What We Like

- Wide material compatibility

- Premium components

- Reliable

Could Be Better

- Pricy upgrades

Find Ultimaker S5 at

AmazonMatterHackers

What to Look For When Buying a Dual Extruder 3D Printer

Dual extruder type

When you consider buying a dual extruder 3D printer, you’ll come across technologies such as the IDEX system, double hot ends, and a single Y-shaped hot end.

The IDEX system lets you simultaneously 3D print with two independently driven extruders and a hot end setup.The advantages of an IDEX system are the multiple printing modes that you get with it. You get to duplicate and mirror your models, effectively resulting in increased productivity.

If you look at the single hot end setup, you’ll notice that the hot end is much lighter, and you do not lose any printing area to a second print head. The downside, though, is that this setup is more likely to run into issues, as a single print head is used for multiple materials at a single time.

The most common and relatively more accessible dual extrusion system is double hot ends. You get two individual hot-ends and extruders, and each hot end can be configured to print a single material with maximum efficiency. However, two hot ends next to each other occupy extra space, cost more, and do not increase productivity like the IDEX system.

If you want a printer for maximum productivity and are looking to run it into print farms or to run multiple batches of prints, the best dual extruder 3D printer for you is an IDEX one. In contrast, the dual hot end setup is more suitable for conventional dual extrusion 3D printing, where you do not need to print many parts.

In contrast, the dual hot end setup is more suitable for conventional dual extrusion 3D printing, where you do not need to print many parts.

Printing modes

While the single nozzle and the dual hot ends styles let you print with multiple materials and soluble supports, printing modes are truly available only on the IDEX style of dual extruder 3D printers.

There are four printing modes that come with dual extruder 3D printers – Mirror, duplication, soluble supports, and multi-material mode. The mirror mode lets you print symmetrical mirrored objects, and you can print the part and its inverse simultaneously. For example, shoes, gloves, and other things come in a couple but are symmetrically opposite.

Another helpful model is the duplication mode, which helps carry out batch prints. In duplication mode, both the hot ends repeat the same movements and produce identical copies of the original design. It drastically improves your productivity rates and is suitable for print farms.

The soluble supports and the multi-material modes are similar and not just available in the best dual extruder 3D printers; any dual extruder printer can do them. While the primary nozzle is used for the main filament, you can use the secondary nozzle with either soluble supports or a differently colored material.

Print Volume

The dual extruder design reduces the printing volume of any 3D printer due to the extra space the secondary extruder takes up. This results in a smaller printing volume on the Y-axis in dual extruder printers compared to a single extruder setup.

When you use print modes, too, you’ll realize that the print area is reduced considerably due to the second extruder’s size in mirror mode. Hence, in the case of dual extruder printing, it becomes more crucial to look at the actual printing volume that you’ll get.

If you need a bigger print size, you should look at the Raise3D Pro 3, Ultimaker S5, and the BCN3D Sigma D25. These printers come with a large print volume that gives you more freedom to take full advantage of their dual extrusion capabilities.

Print Speed

Even with the addition of a second hot end on the motion system, the printing speeds of dual extruder 3D printers are relatively unaffected. Powerful stepper motors and a rigid frame can compensate for the added weight of the hot end.

Almost all of the 3D printers in this list can comfortably print at around 60-100 mm/s of printing speeds, while travel speeds go up to 200 mm/s. These speeds give you a good balance between print quality and lead times.

If you consider the other benefits of dual extruder 3D printers, you’ll realize that the printing modes lead to a considerable increase in overall productivity. The ability to print with two print heads simultaneously easily triumphs the faster printing speeds of any other 3D printer.

Filament Compatibility

Ensuring that your 3D printer is compatible with many filaments is one of the primary things you need to consider while buying any 3D printer. More so with dual extruder 3D printers due to their second print head.

The second print head is helpful for printing soluble supports. If you’re getting a dual extruder printer specifically for printing with soluble filaments such as PVA and HIPS, you should check whether or not it is compatible with these materials.

Every printer in this list is equipped to print with these materials. And some of the dual extruder 3D printers like the Ultimaker S3, S5, Raise3D Pro 3 go beyond and let you swap your print heads for printing with specific materials, thus increasing their material compatibility.

Enclosure

A 3D printer enclosure plays a crucial role with dual extruder 3D printers. The isolated printing area on enclosed 3D printers lets you print with tricky materials such as ABS filament and keeps 3D printing fumes within the printer body itself.

Aside from the Sovol SV02 and the Tenlog TL-D3, all other dual extruder 3D printers come with at least a partially enclosed design. And with the Creator Pro 2, you get the benefits of both; you can choose to keep the printer open on the top while printing with PLA and fully enclose it when you want to print with ABS.

The Ultimaker S5 goes a step beyond its airflow management system, however, the QIDI Tech i-Fast is the only dual extruder 3D printer on the list with an actively heated build chamber. This ensures that you get the best print quality and that the printer is compatible with a wide variety of materials.

Warranty

Warranty is often an overlooked factor when buying dual extruder 3D printers. You need to carefully evaluate the warranty conditions and everything that is covered within it. Some manufacturers offer a warranty on specific components for a short while, while the best dual extruder 3D printers tend to get comprehensive coverage of any manufacturing defect in the printer.

In this list, all the dual extruder 3D printers have at least a 12 months warranty period that covers any manufacturing defect from the company’s end.

FAQ

Are dual extruder printers faster?

Even the best dual extruder 3D printers are not necessarily faster than any other 3D printer. However, the dual extrusion process leads to an overall increase in productivity due to the ability to print multiple copies at the same time.

However, the dual extrusion process leads to an overall increase in productivity due to the ability to print multiple copies at the same time.

Can dual extruder printers print with soluble filaments?

Yes, all of the dual extruder 3D printers in this list are capable of printing with soluble filaments.

How many extruders can a 3D printer have?

Most 3D printers have a limit of two extruders. However, depending on the electronics capabilities and general hardware setup, some 3D printers can have up to four or five extruders.

What is the advantage of a dual extruder printer?

The dual extruder setup allows for printing with multiple materials, which leads to an increase in productivity. Additionally, dual extruder printers are compatible with a wider range of filaments.

Do dual extruder printers have an enclosed build area?

No, dual extruder printers do not necessarily have an enclosed build area as it is not necessary for their operation. However, some dual extruder printers do come with a partially or fully enclosed design.

However, some dual extruder printers do come with a partially or fully enclosed design.

Can you 3D print multiple objects at once?

Yes, dual extruder 3D printers can print multiple objects at once provided that they have the necessary build volume. However, the print quality may not be as good as if you were to print them one at a time.

What is the average price of a dual extruder 3D printer?

Dual extruder 3D printers generally cost more than single extruder 3D printers. However, the price difference is not as significant as it used to be and there are a number of excellent dual extruder 3D printers in the market at a wide range of prices.

You can find a good one, like the Flashforge Creator Pro 2, for around $650. The best dual extruder 3D printers, however, cost multiple thousands of dollars.

How do you print multiple filaments?

To print multiple filaments, you need to have a dual extruder 3D printer with two extruders. The filaments are then loaded into the extruders and the printer will print with both filaments simultaneously.

Conclusion

Dual extruder 3D printers let you print with multiple materials simultaneously, and that too with ease. Especially with the IDEX style of printers and the multi-material capabilities, you get the added benefits of various printing modes that increase your overall productivity and are great for the batch style of prints.

From the list, the best dual extruder 3D printer that stands out on the top is the Flashforge Creator Pro 2. It gives you the benefits of the IDEX system, is fully enclosed, and has broad material compatibility while still being affordable and accessible for professionals and hobbyists alike. Its only downside is a relatively small print volume.

If print area is your main criteria, you should consider the QIDI Tech i-Fast and the BCN3D Sigma D25 for their large print chambers in decent footprint size. These are professional dual extruder 3D printers with advanced features, excellent print quality, and great for industrial prototyping needs.

Let us know your thoughts on the list, and if you have anything else to add, feel free to comment below.

Dual Extrusion 3D Printers | MatterHackers

Whether you need to 3D print with two different colors, two different types of filament or support material for 3D prints that have complex geometries or overhangs, this collection of 3D printers fit the bill. Dual extrusion 3D printers can take advantage of the second material to create a scaffolding for the main 3D print, allowing for much more complex designs using PVA from a variety of manufacturers like Ultimaker, E3D, 3DFuel and more. Creators are also able to 3D print with an additional color or even another type of filament at the same time for endless possibilities.

Guides & Articles

How to Succeed with Quantum Dichromatic PLA Filament

Follow this guide for tips and tricks on how to get the best results when 3D printing with Quantum Dichromatic PLA filament.

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How To Build A Successful Makerspace

Find out the necessary components to create an effective space for your maker community.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

Tech Breakdown and How to Succeed: Ionic Hybrid Support Material

Supporting engineering-grade filament has been difficult without a support material dedicated to higher temperature 3D printing. Ionic aims to solve that.

How To Succeed with OBC 3D Printing Filament

From Dow Chemical, OBC combines flexible and rigid into one unique material with properties of both.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

How to Succeed with LayerLock Powder Coated PEI Build Plates

Powder coated PEI steel sheets are a great alternative build surface for strong bed adhesion. Here's how you can succeed using this durable build plate.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

How to Succeed when 3D Printing with Polycarbonate Filament

Follow these helpful steps to start successfully printing with this extremely tough, professional grade material.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

Why 2 extruders in a 3D printer? / Habr

Good afternoon everyone! In this article, we would like to talk about the issue that torments many customers when choosing a 3D printer with 2 extruders. Namely, which is better? What is more stable? Which 3D printer to choose? Why do dual extruder 3D printers alone cost significantly less, and what is the difference between them?

A bit of theory

First of all, let's start with the fact that by printing with 2 extruders (or 2-component printing), we mean the ability to print with 2 materials, for example, PLA (base material) and PVA (temporary support material removed chemically, using water in this case ).

It is possible to print in two different colors. But in practice this has not received any great distribution. The printing of complex models with dissolvable supports is in demand.

Therefore, you need to decide for yourself why you need a 3D printer with two extruders? For most tasks, it is enough to use a 3D printer with 1 extruder.

The use of a dual extruder 3D printer is a must when printing complex 3D models with dissolvable supports. Usually such 3D printers are chosen by manufacturing companies for printing geometrically complex prototypes or owners of 3D printers with 1 extruder who understand that they cannot realize with a 3D printer with 1 extruder.

But do all 3D printers with 2 extruders have the same capabilities? Or is it that differences in design, and, accordingly, in price, are of decisive importance?

Let's consider various solutions for 3D printing with 2 materials on the 3D equipment market.

To implement this function, manufacturers use the following solutions:

Solution No.

1

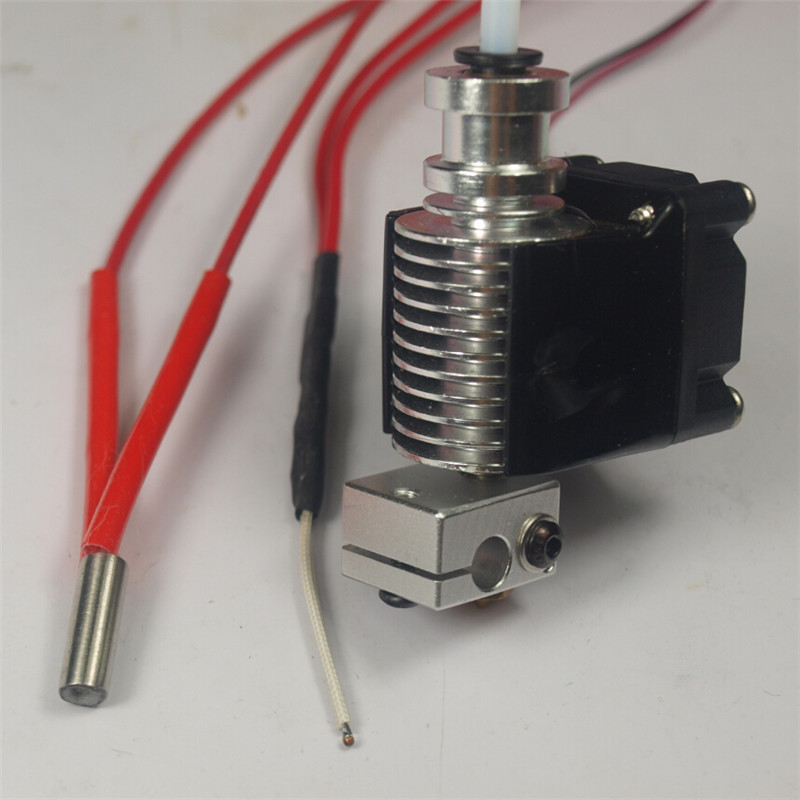

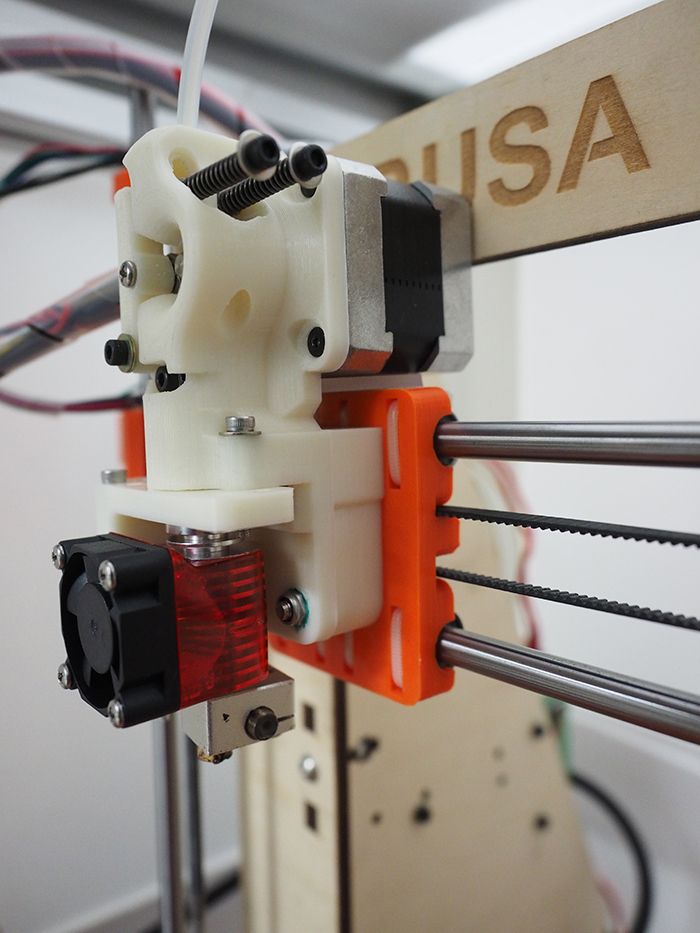

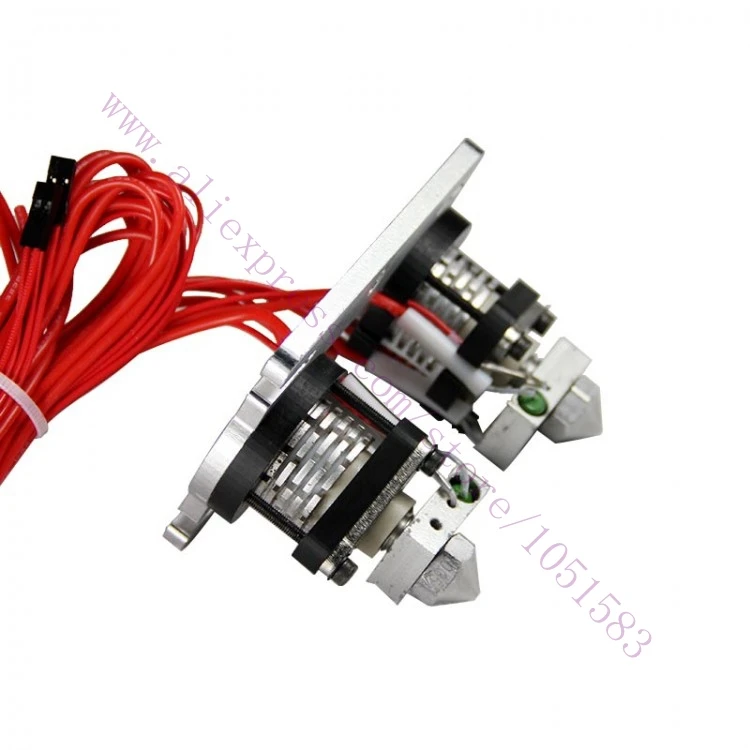

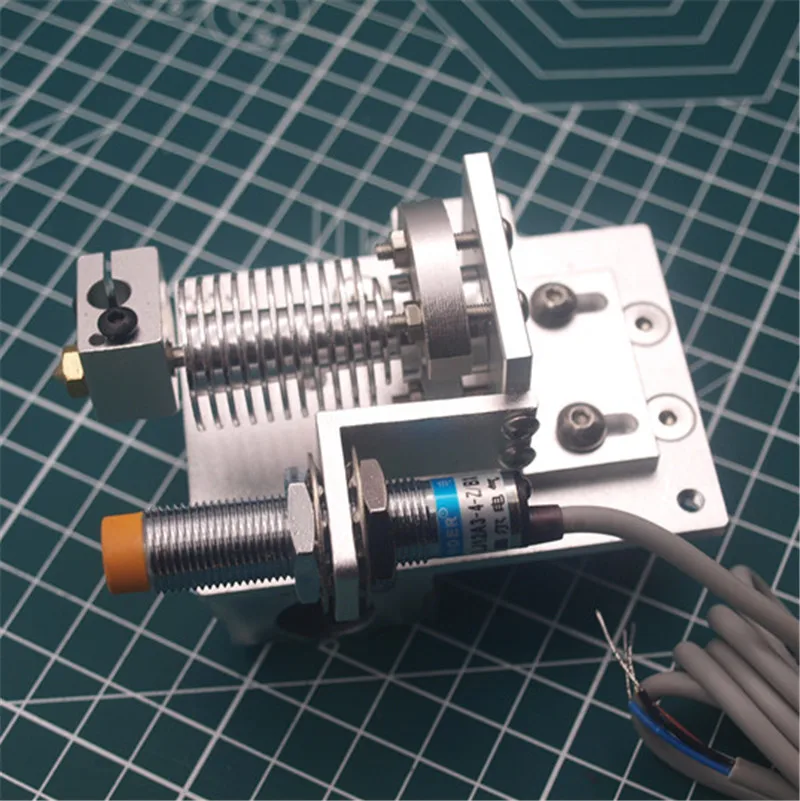

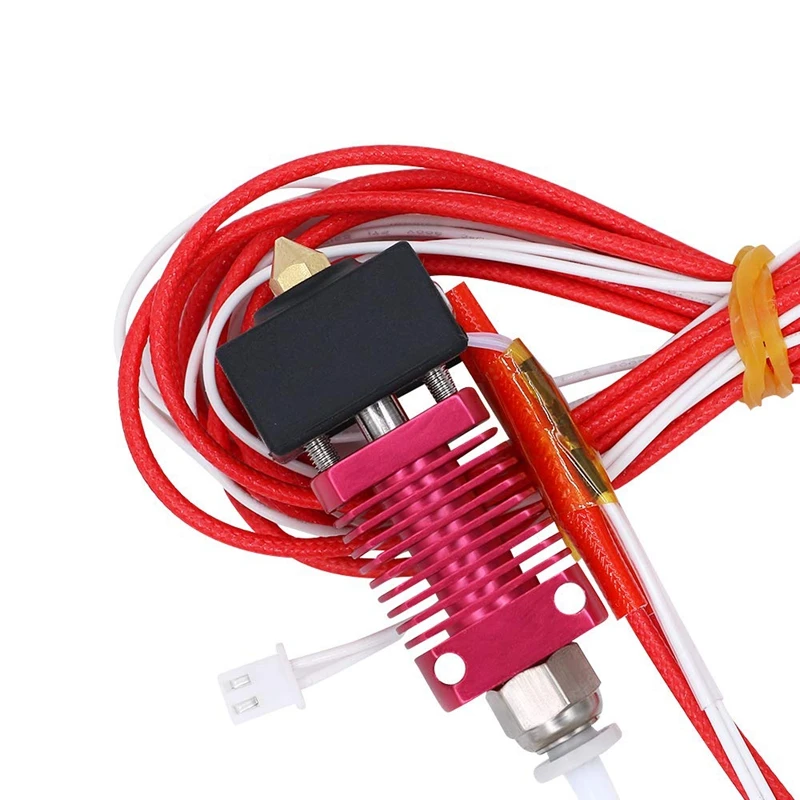

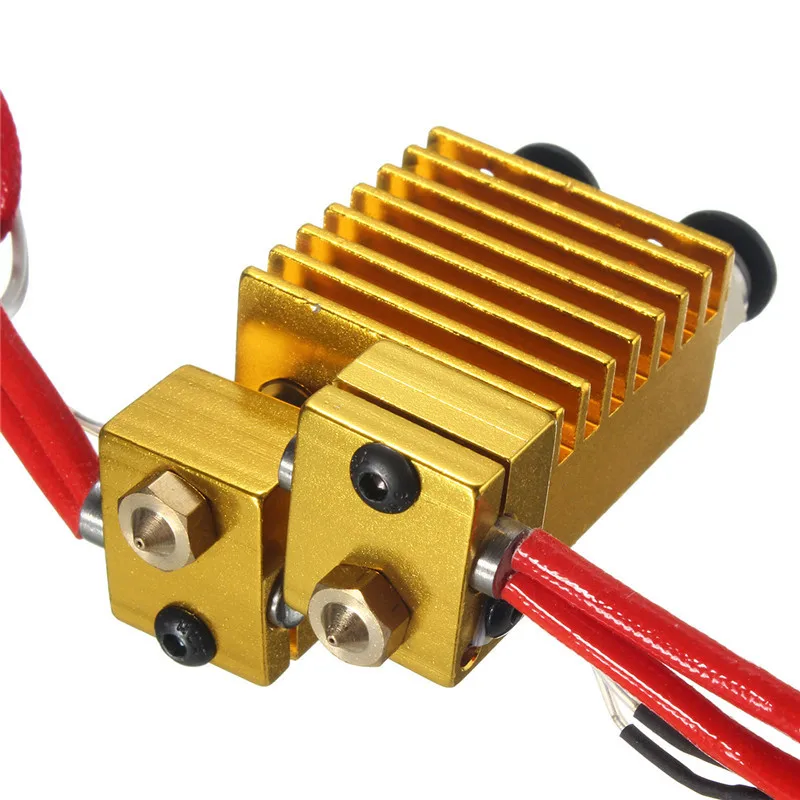

1 Use of 2 static extruders. As a rule, these are 2 hot-ends with two independent material feed motors. There are many options. But all of them, to one degree or another, repeat the decisions on the Makerbot Replicator 2, released in 2012.

There are several technical solutions, but they all have a common list of disadvantages and features.

Disadvantages :

1) Be sure to align both nozzles horizontally with respect to the 3D printer desktop. In other words, the nozzles of each hotend should be at the same height, ideally with an error of no more than 0.1 mm.

2) Using a utility tower (or similar) to clean the inactive nozzle from plastic drips (drop formation) before switching to the active mode for printing. Consider an example: if nozzle #1 prints a model with blue plastic, then in order for nozzle #2 to start printing white, the printer first needs to print the 1st layer of the tower with nozzle #2 to remove the remaining plastic, and only then move it to print the base model ( see picture). And so every switch. This greatly (at times) slows down the print speed, relative to the same model but when printing in 1 color. Moreover, there is a possibility of the collapse of the utilitarian tower (the layer did not fit well, or peeled off from the desktop) and, as a result, the marriage of the entire project.

And so every switch. This greatly (at times) slows down the print speed, relative to the same model but when printing in 1 color. Moreover, there is a possibility of the collapse of the utilitarian tower (the layer did not fit well, or peeled off from the desktop) and, as a result, the marriage of the entire project.

3) No guaranteed result. Due to the complexity and imperfection of the extruder architecture. Large marriage rate. A nozzle that is currently inactive can leak plastic and ruin the part.

Advantages:

1) Low cost solution

2) Simplicity of design, as a result - high maintainability.

This variant has the lowest price and the lowest overall performance. The complexity of the settings, to obtain a high-quality result, makes this implementation option a testing ground for experiments at home. In a more or less intensive implementation of projects, this option is quite problematic.

Decision No. 2

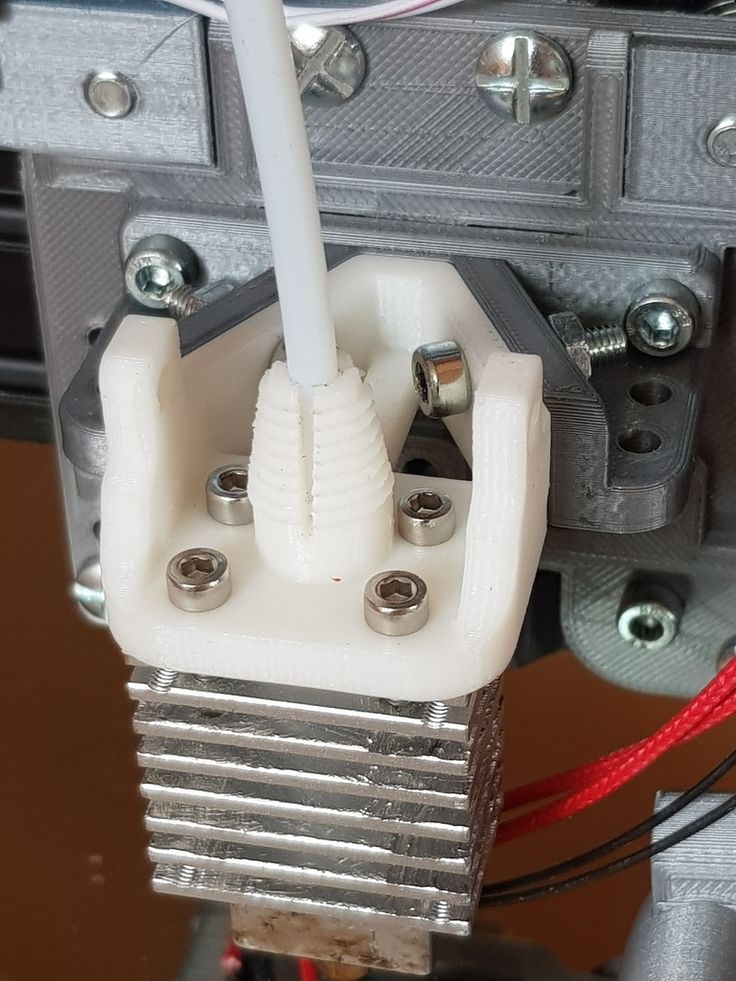

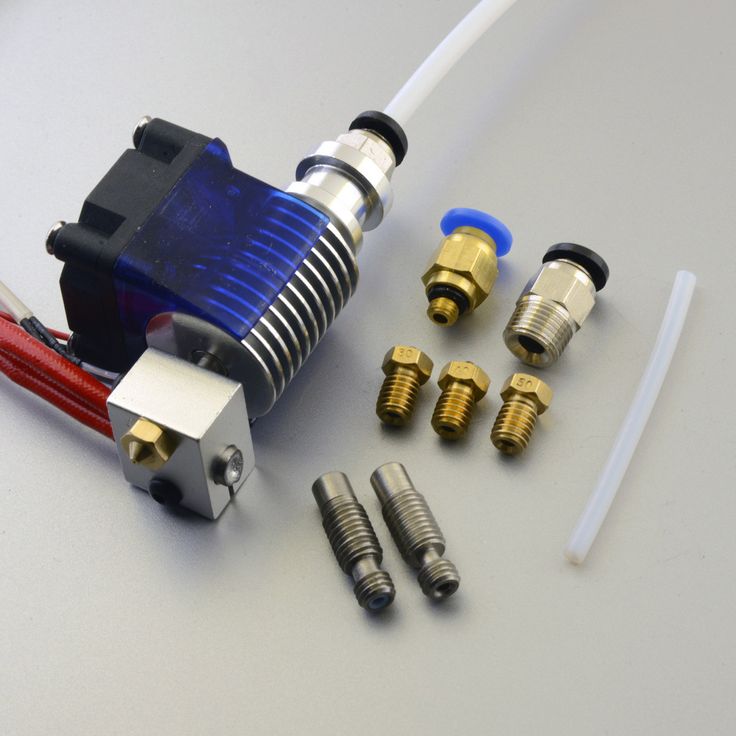

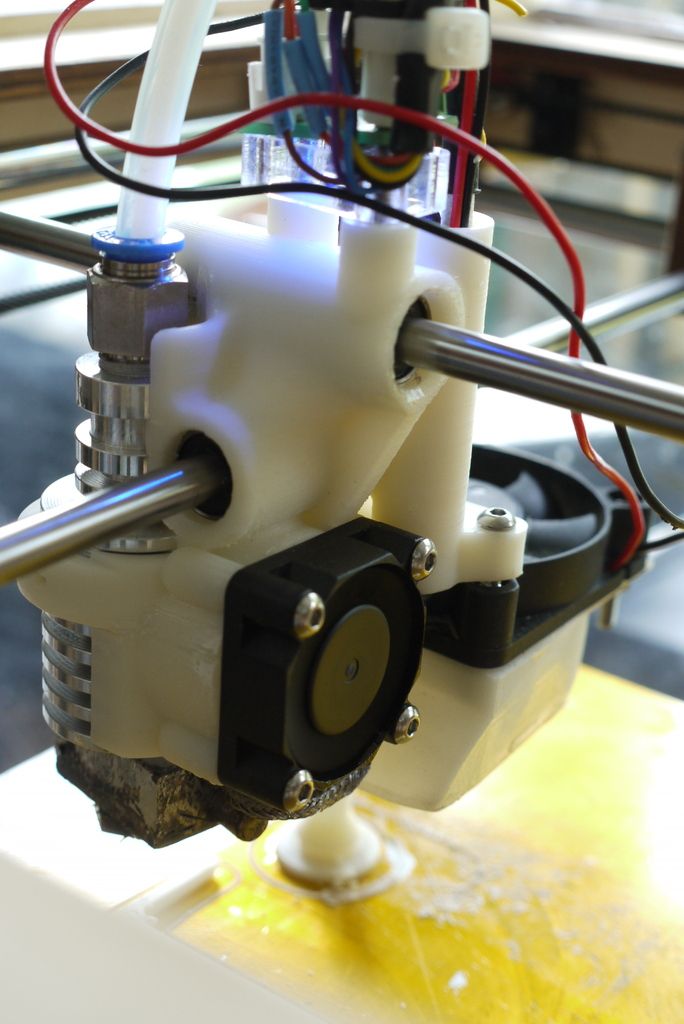

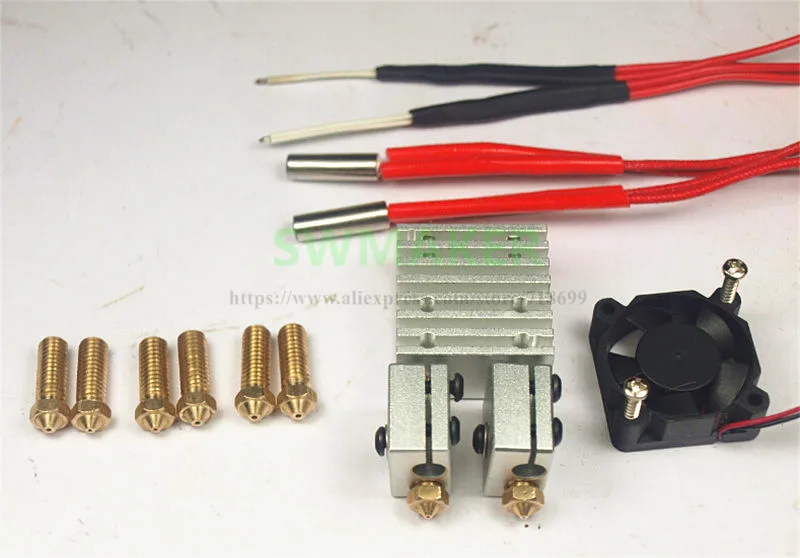

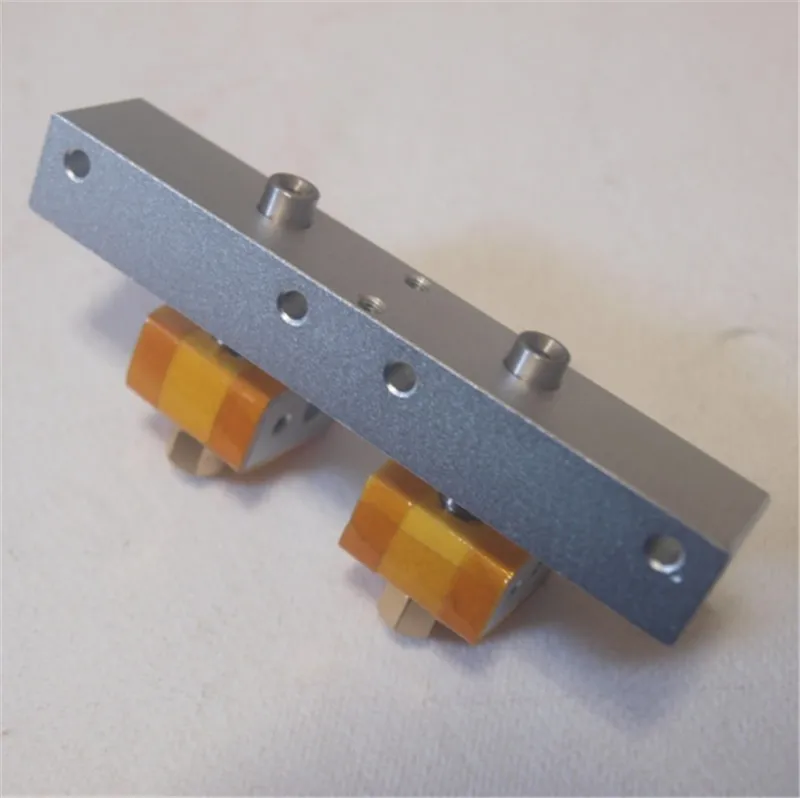

Using a Diamond type extruder. This type of extruder uses a single nozzle, and a radiator(s) (or cooling module) with multiple internal plastic passages.

This type of extruder uses a single nozzle, and a radiator(s) (or cooling module) with multiple internal plastic passages.

Basically, this extruder is used for printing different colors. But this, as we already know, has not received much distribution in reality. Printing with solvent material will be somewhat difficult. Firstly, the base material and support material have different operating temperatures. This will cause some difficulties for quality printing.

And in any case, this design has almost the entire list of disadvantages, like the first option.

Only there is no point about the alignment of the nozzles - here it is one.

Disadvantages :

1) There remains the need to use a utility tower (or equivalents) to clean the nozzle from plastic drips (drop formation) before switching to another material. This "tower" is visible in the photo. This greatly (at times) slows down the print speed, relative to the same model, but when printing in 1 color. Here it will still probably take time to change the temperature of the nozzle, when changing the base material to supports. Or the possibility of poor-quality printing will greatly increase.

Here it will still probably take time to change the temperature of the nozzle, when changing the base material to supports. Or the possibility of poor-quality printing will greatly increase.

2) There is no guaranteed result. Due to the complexity and imperfection of the extruder architecture. Large marriage rate.

3) This type of extruder is equipped with Bowden-scheme plastic feeding. This entails difficulties (more often even the impossibility of printing with flexible plastics)

The advantages have also disappeared.

Such a solution is quite expensive. And it has a complex structure.

Advantages:

1) Better print quality than #1.

As a result, in the variant of printing with two materials with dissolvable supports, there are no special advantages over the first solution. But this option has a higher price.

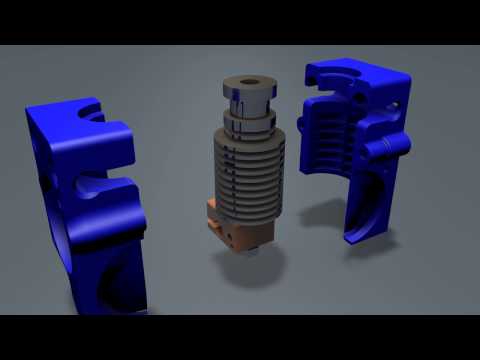

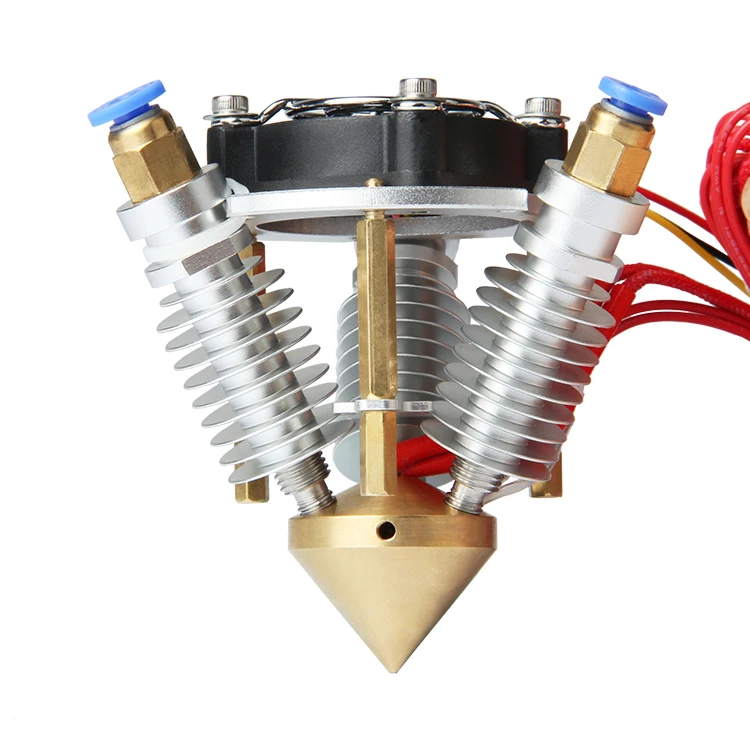

Solution #3

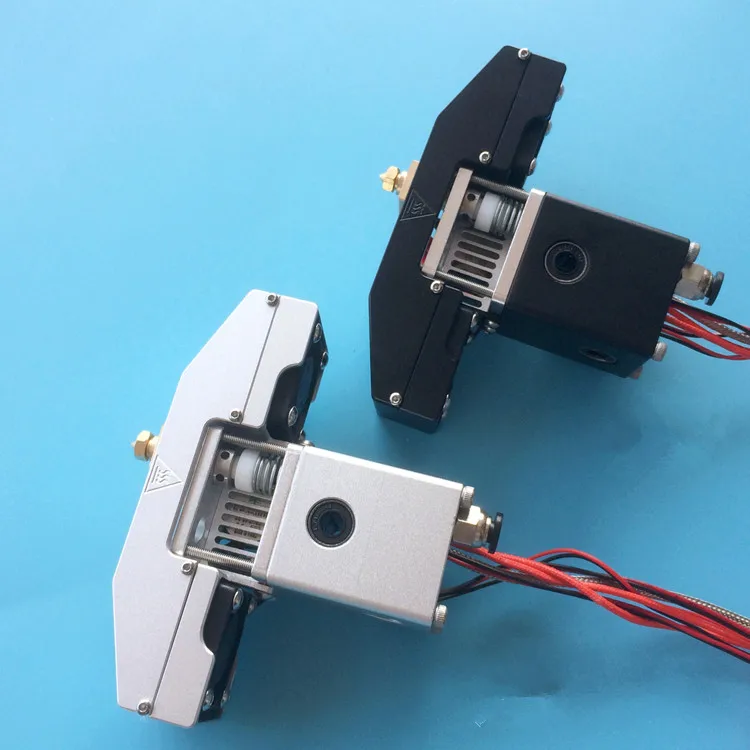

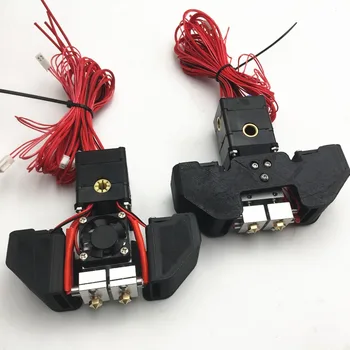

Extruder designs where the currently inactive nozzle rises to avoid problems. The most famous today, among serial printers, is the JetSwitch circuit.

The most famous today, among serial printers, is the JetSwitch circuit.

Rotating nozzle system from PICASO 3D. There is one plastic feed motor, which facilitates the design.

The main feature is that one of the nozzles that is active at the moment is lowered to the working level by means of a rotary mechanism. The second is closed at this time, and no molten plastic flows out of it.

Advantages:

1) High print quality

2) There is no need to build a utilitarian "tower". Therefore, the switching time between extruders is short. The speed of printing with two materials is MUCH faster than that of options 1.2. Below is a comparison table from PICASO 3D.

Disadvantages :

1) A rather complicated design, and as a result, a high price.

There are several other types of extruders with lifting nozzles. All of them are united by one thing - a much higher print quality with two materials than the "classic" option No. 1. Yes, they all have a higher price, but the print quality is drastically different.

1. Yes, they all have a higher price, but the print quality is drastically different.

Terminals

The conclusions are as follows - by purchasing an inexpensive design, you save money, but spend many times more time on setup and printing itself. With the remaining risk of marriage, which reduces all efforts to zero. At the same time, the print result will still be worse than that of designs with lifting nozzles.

If you need a high quality result and the printing time of complex models is critical, then it makes sense to choose a model with lifting nozzles:

1) PICASO 3D Designer X PRO

2) Raise3D Pro2

3) Ultimaker 3

Creality Ender 3 Dual Extruder Options - All Your Best Options (& Pro/V2)

Contents

- Creality Ender 3

- Ender 3 Dual Extruder Options

- Mosaic Palette 2 / Pro 9014 Project

- Cyclops Hot End

- Proper Printing Mod for Ender 3 Dual Extruder

- Upgrading Ender 3 to Dual Extruder: Pros and Cons

- Before Installing Dual Extruder on Ender 3

- Be Confident and Safe!

- Get ready to roll up your sleeves

- Q&A

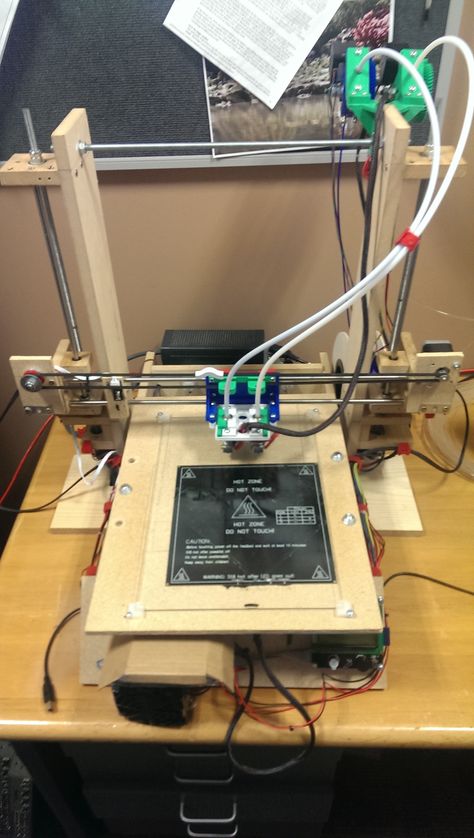

Creality Ender 3

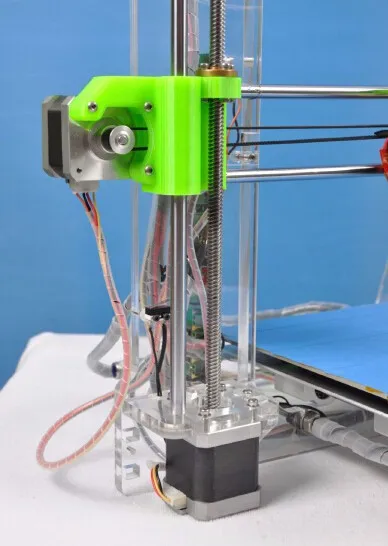

Creality's Ender 3 series is one of the most popular budget 3D printer lines on the market today, and if you own one, chances are you already know why. In addition to being unbeatable in price, they are easy to use, reliable and powerful enough for their range.

In addition to being unbeatable in price, they are easy to use, reliable and powerful enough for their range.

What's more, their openness makes them easy to modify, an ideal feature for today's craftsmen. One of the most popular upgrades for the Ender 3 is the upgrade to a dual extruder as this line only comes with a single extruder as standard.

It's easy to see why dual-extruder Ender 3 versions are popular. The ability to print with more than one type or color of filament at the same time makes prints superior and unique. Not to mention, using a stronger filament along with the main filament creates more reliable projects with less post-processing required.

The cost difference must also be taken into account. Installing a dual extruder on your Ender 3 will cost significantly less than buying a similar printer with a dual extruder already installed.

Standard dual extruder 3D printers typically cost around $600, which is three times the price of a standard Ender 3.

So how do you install a dual extruder on an Ender 3? What should I pay attention to before starting work? And what are the dual extruder options for which Ender 3 models?

Ender 3 Dual Extruder Options

The open source developer community for Ender 3 is huge, and there is no shortage of people with great ideas for modifying and upgrading Ender 3 printers with laser engravers, better bezels, and even advanced touch screens.

In this regard, it is quite understandable that you cannot immediately understand which printer is right for you. So here we take a look at some of the best and most reliable dual extruder Ender 3 mods you can check out today.

Mosaic Palette 3 / Pro

Price: $599-$799

While technically more of an honorable mention than a true Ender 3 dual extruder, the Mosaic Palette 3 and Palette 3 Pro are by far the easiest way to use the Ender 3 to create multi-color prints without the need for active modification of the printer.

This is great news if you're unsure or for some other reason don't want to pick up Ender 3 tools, but still want to make prints using different colors and filaments.

Mosaic Palette models act as automatic switches, like changing the orientation of a railroad line to direct certain trains or uncoupled wagons in different directions. The Mosaic Palette models act as changers that swap up to eight different filaments per print and automatically manage each one.

Mosaic palette 3 1

The disadvantage is the cost. Priced around $700, these are not cheap machines. But if you're not very handy and have the money, this is the easiest way to hook up what you might call a "multi-extruder" to your Ender 3.0003

Project Chimera

Project Chimera, named after the Greek concept of animal fusion rather than ideological improbability, is the first great example of a DIY dual extruder that was designed for the Ender 4 but is still compatible with all Ender 3 models

Modification of the Chimera Project Ender 3 dual extruder, originally designed for the Ender 4.

A standard dual extruder that is quite cheap to manufacture, the Chimera Project sits on a mount that you will have to print yourself. While this sounds like an extra step, don't discount how great it is to use your 3D printer to make your own custom modification parts.

Precautions and recommended equipment are laid out in such a way that even the most humble of beginners can easily figure out how it all works.

Regardless of your DIY experience, you'll need everything to run this Ender 3 & 4 Dual Extruder if you follow the instructions carefully and carefully.

Cyclops Hot End

Cyclops Hot End is the spiritual brother of Chimera. They can both be used with the same print fixture and both can alternate between different colors and filament types during the printing process. The Cyclops gets its name from the fact that it looks like a single extruder but has all the features of a dual extruder.

In addition to standard printing with multiple filaments, it can also mix filaments together. Although it looks more like a "filament control system" than a standard dual extruder, it does all the features you'd expect.

Although it looks more like a "filament control system" than a standard dual extruder, it does all the features you'd expect.

Instructions and files, as well as some assembly and usage tips, can be found here for free. This Cyclops seems like a reliable and very easy way to convert your Ender 3 into a dual extruder, unlike true Cyclopes, whose implied lack of depth perception probably makes them a lot less formidable than mythology would have it.

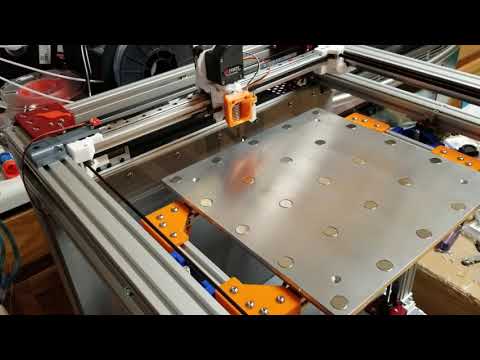

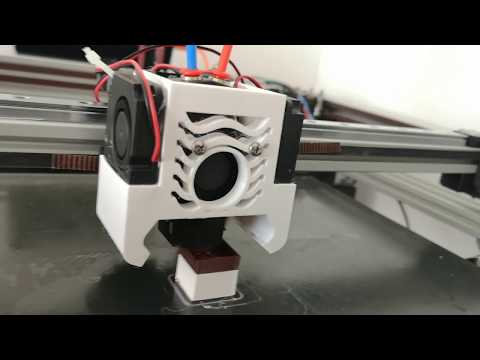

Ender 3 Proper Printing Dual Extruder Mod

Proper Printing has developed a unique dual extruder design that does not require a second servo. Instead, this very interesting and surprisingly clever design relies on a spring mechanism that allows the two extruders to switch smoothly, working like a dolly.

The extruders move in a slanted V shape, with only the active extruder parallel to the assembly, while the other, unused, is tilted to the side. This allows extruders to be used with the same servo instead of each one wasting time just waiting for their turn.

This minimizes assembly volume loss by saving space and parts in the design.

Known as "The Rocker" and available as printable files for as little as $3 on their site here, this is an absolute steal for something no Ender user should be without.

While it is claimed to work on any stock Ender 3 model (i.e. out of the box and without modification), it is not clear if it will work well with other 3D printers or more modern Creality Ender models.

Although since the $3 price is just files and instructions, you are free to experiment and tweak to see if The Rocker works with other 3D printers if you are confident and tech savvy enough to do so.

You can even change the design yourself if it doesn't work right away with the model you have in mind - that's the beauty of modifications!

Upgrading an Ender 3 to a Dual Extruder: Pros and Cons

Upgrading an Ender 3 to a Dual Extruder may seem pointless. One is more than two, which means it's better. But like most things related to 3D printers, it's not as easy as it sounds.

But like most things related to 3D printers, it's not as easy as it sounds.

Dual extruders have a lot of advantages, but that doesn't mean there aren't any disadvantages. While not a one-way modification (meaning you can go back to a single extruder if you want), installing an Ender 3 dual extruder only to find out later that it wasn't worth the hassle would be a waste of time, money, and effort on your part. sides.

Equipping your Ender 3 with a dual extruder comes with some downsides that, depending on your desired goals, may not be worth the effort. So keep these points in mind before deciding whether or not to take out your toolbox.

Printing with several types of threads/filaments at once.

Multicolor prints are much easier and take less time because you don't have to constantly change filaments during the printing process.

You can strengthen prints with dissolvable threads such as HIPS and PVA to improve the surface quality.

Upgrading/modifying single extruder printers is often cheaper than buying dual extruder printers.

Twin extruders are bulky and difficult to handle and operate for beginners.

Not necessary if printing in one color is enough for you.

A lot more maintenance, care and cleaning is required to keep the dual extruder clean and functioning well.

Smaller build area due to larger extruder requiring more space.

Basically, a dual extruder requires a lot more work and maintenance to be used reliably than a single extruder. If you're aiming for reinforced and/or multicolor prints, then upgrading your Ender 3 with a dual extruder is a fantastic idea.

On the other hand, if you're happy with monochrome prints or you're not sure you can handle maintenance, it's best to stick with one extruder.

However, if you're willing to put in the effort and still believe you need a dual extruder on your Ender 3 despite all of these shortcomings, we'll help you move on.

Before Installing Dual Extruder on Ender 3

Ender 3 models come with single extruders by default. However, as we have already seen with the options for adding laser engravers, these are highly modifiable machines. This means that with enough knowledge and effort, you can equip your Ender 3 with a dual extruder.

However, as we have already seen with the options for adding laser engravers, these are highly modifiable machines. This means that with enough knowledge and effort, you can equip your Ender 3 with a dual extruder.

Be confident and safe!

There is no official dual extruder extension for the Ender 3, so you'll have to put on your DIY hat. Remember that you will be dealing with mechanical parts that can get very hot, so make sure everything is turned off and unplugged before starting work.

Also, remember that you are working with moving mechanical parts and will manipulate them in ways they are not designed for, such as adding an extension cable to a standard outlet. Therefore, take the utmost care to protect yourself and the machine during operation. Always double-check equipment and instructions before starting work to move forward as confidently and safely as possible.

Because the Ender 3 is a modded model, you can be sure that you will be very careful when upgrading your model. Removal and replacement of parts must be done with care to ensure the correct operation of each element. An incorrectly installed extruder can fail or fail in the middle of printing, increasing the risk of clogging, failure, and even fire.

Removal and replacement of parts must be done with care to ensure the correct operation of each element. An incorrectly installed extruder can fail or fail in the middle of printing, increasing the risk of clogging, failure, and even fire.

Get ready to roll up your sleeves

Any third party modification of the device will require effort and know-how beyond what you will find in the instructions on the box. Mods done with user guidance and good explanation will be much more reliable than random selection of any old mod, but they all require at least some work on your part.

These mods are often much more complicated than just buying a new part and screwing it in, so read the instructions carefully and test before you actually start using your new mod. Attention to detail and precision in operation are a must before you're ready to plug in and start printing.

The main difficulty when installing your own dual extruder on the Ender 3 or any other 3D printer is the need for an additional servo.