Ultem 3d printing filament

Ultem 9085 3D Printing FIlaments | Aerospace Grade Materials

$78.00 – $440.00

4 interest-free payments with Learn More

ThermaX™ PEI 9085 is a premium filament made using ULTEM™ 9085 resin from Sabic. This resin is FAA-approved for FST applications (Flame/Smoke/Toxicity) and meets FAR 25.853 and OSU 65/65 standards.

[yith_wcwl_add_to_wishlist]

SKU: Select options above Brand: ThermaX™ Category: PEI (Ultem™) Family

- Description

- Reviews

- Questions & Support

We manufacture this ultra-performance 3D printing filament using ULTEM 9085 PEI (polyether imide) resin from Sabic. Filaments made from ULTEM 9085 resin offer the ability to create parts with excellent properties at elevated temperatures due to a high glass transition temperature (Tg) of 186°C.

PEI is an amorphous, high-performance polymer which combines excellent thermal properties, exceptional dimensional stability, inherent flame retardancy, and good chemical resistance.

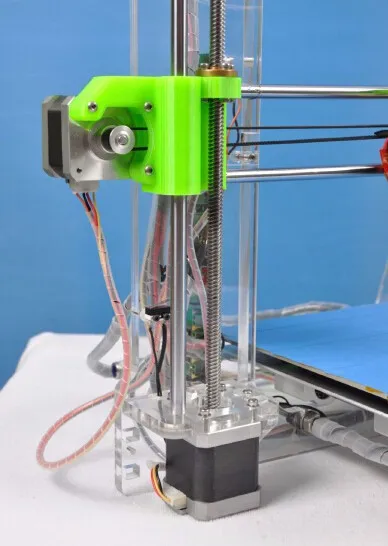

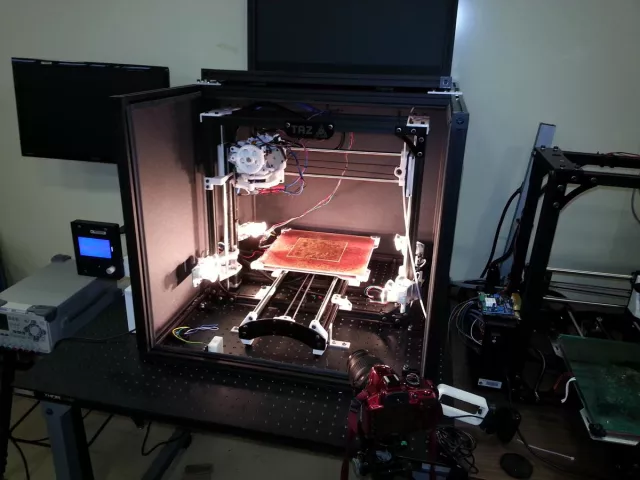

Gearbox HT2™ 3D Printer:

Print industrial-grade parts using our ULTEM PEI and more with the new Gearbox™ HT2 High-Temp 3D Printer.

Extruder Temp

350-380°C

Bed Temp

140-160°C

Heated Chamber

Recommended

Nozzle Specs

No special concerns

Bed Adhesion

Nano Polymer Adhesive

Polyimide Tape

Layer Height

No special concerns

Drying Specs

120°C for 4 hours

Supports

Break-Away Support

Benefits of PEI 9085 Include:

- High thermal properties, with a Tg of 186°C

- Inherently flame-resistant with low smoke evolution and low smoke toxicity

- Long-term hydrolytic stability

- Excellent dimensional stability, low heat creep sensitivity, and a very low, uniform coefficient of thermal expansion create highly reproducible part-to-part dimensions

- Exceptional strength and modulus, even at elevated temperatures

- Good resistance to a broad range of chemicals, include automotive fluids, fully halogenated hydrocarbons, alcohols, and aqueous solutions

- Stable dielectric constant and dissipation factor over a wide range of temperatures and frequencies

Typical Applications of ULTEM 9085 PEI:

Aerospace:

The excellent balance of flame retardancy, low smoke emission, and low smoke toxicity of ULTEM 9085 makes it an excellent candidate for aerospace and aircraft applications. ULTEM 9085 meets FAR 25.853 and OSU 65/65 with low toxicity, smoke, and flame evolution. Ultem resins are found in applications such as personal service units, oxygen panels and components, ventilation system components, connectors, cable ducts, latches, hinges, food tray containers, door handles, and interior cladding parts.

ULTEM 9085 meets FAR 25.853 and OSU 65/65 with low toxicity, smoke, and flame evolution. Ultem resins are found in applications such as personal service units, oxygen panels and components, ventilation system components, connectors, cable ducts, latches, hinges, food tray containers, door handles, and interior cladding parts.

Automotive & Transportation:

ULTEM resins provide automotive manufacturers with a high performance, chemically resistant, thermally-stable, cost-effective alternative to metal that is strong enough to replace steel in some applications yet light enough to replace aluminum in others. For applications like transmission components, throttle bodies, ignition components, sensors, and thermostat housings.

Electronics:

ULTEM resin may be an excellent material choice for today’s demanding electrical applications, including connectors, MCB components like housings, shafts and levers, hard disk drive internals, FOUPs, BiTS, PCBs, MCCB internals, Plenum devices, LCD projector internals, fuel cell components, and many other applications.

Filament Specifications:

1.75mm and 2.85mm +/- 0.05mm in diameter

Recommended Print Settings:

- Extruder: 350-380°C

- Bed Temp: 140-160°C

- Bed Prep: Nano Polymer Adhesive or 3DXTECH Polyimide Tape gives us the best results

- Other: No cooling fan with print speeds of 16mm/s as a starting point

- Heated Chamber: Recommended, a chamber helps reduce warping and improves layer adhesion

- Supports: ThermaX HTS High-Temp Support works ideal for complex, high-temp materials just like this.

- Drying Instructions: 120°C for 4 hours.

Annealing 3D Printed Parts:

If needed, parts printed using ULTEM may be annealed in a hot-air oven to reduce any printed-in stresses which may be present in the part. Printed-in stresses may occur in any plastic and may result in lower than expected mechanical properties. If this is an issue with your part, you can follow the simple 5-step ramp up/down process for annealing the ULTEM parts.

- Step 1: Place printed parts in cool, room-temp oven.

- Step 2. Set temp to 250°F and allow to stabilize for 1 hour.

- Step 3: After 1 hour at 250°F, increase oven temp to 300°F and allow to stabilize 1 additional hour.

- Step 4: After 1 hour at 300°F, reduce heat back to 200°F and allow to stabilize for 30 minutes.

- Step 5: After 30 minutes, turn off oven heat and allow printed parts to return to room temp inside the oven as it cools.

ULTEM™ is a registered trademark of Sabic Innovative Plastics.

3DXTECH manufactures this filament using ULTEM™ 9085 PEI resin.

Questions?

Send us a message and we'll reach out as soon as we can!

Please enable JavaScript in your browser to complete this form.Name *

Business / Organization

Email *

Phone

What can we help you with? *

Newsletter Signup

- Sign me up for the 3DXTECH newsletter

ULTEM 3D Printers and Filament Guide

The continued expansion of 3D printing into industrial sectors is thanks not only to larger and faster 3D printers but also tougher materials. One of those materials is PEEK. PEEK is incredibly strong and high temperature resistant and has a cousin called ULTEM or Polyetherimide (PEI). ULTEM shares many of the same favorable characteristics. Due to its adhesive properties and chemical stability, 3D printing enthusiasts may better recognize ULTEM by its chemical name of polyetherimide, or PEI, as that’s how it’s named as a bed material used on some FFF/FDM printers.

One of those materials is PEEK. PEEK is incredibly strong and high temperature resistant and has a cousin called ULTEM or Polyetherimide (PEI). ULTEM shares many of the same favorable characteristics. Due to its adhesive properties and chemical stability, 3D printing enthusiasts may better recognize ULTEM by its chemical name of polyetherimide, or PEI, as that’s how it’s named as a bed material used on some FFF/FDM printers.

ULTEM Introduction

ULTEM was developed in the 1980s by Joseph Wirth at General Electric’s Plastics Division, which was acquired in 2007 by SABIC. Compared to PEEK, ULTEM has a lower impact strength and useable temperature, but it’s also significantly cheaper. And just because it isn’t quite as strong as PEEK does not mean it’s a slouch. ULTEM’s tensile strength is 15,200 psi and it has a flexural modulus of 480,000 psi. It has very high heat resistance, maintaining most of its physical properties in temperatures as high as 170°C. Additionally, it has a high dielectric strength and can go through thousands of cycles in a steam-based sterilization autoclave without degradation. Its strength-to-weight ratio is also quite similar to that of aluminum and it can be machined with conventional metalworking tools.

Its strength-to-weight ratio is also quite similar to that of aluminum and it can be machined with conventional metalworking tools.

Those mechanical and thermal properties are ideal for a number of demanding applications, from aerospace to medical to electrical. Indeed, ULTEM holds several aerospace certifications and is FDA compliant. In planes and rockets, ULTEM is used in ventilation systems, latches and hinges, and cable ducts. Medical professionals and research scientists often use instruments made from the material, and electrical component manufacturers use ULTEM in connectors, insulation parts, and chip test sockets.

ULTEM / PEI Material Types

Because of its very high glass transition temperature of 217°C (for comparison, PLA has a glass transition temperature of 60°C), working with the material requires more specialized hardware than what’s found in most 3D printers. The extruder has to reach at least 350°C and the bed must reach 150°C; an enclosed and heated build chamber is also necessary to maintain dimensional accuracy.

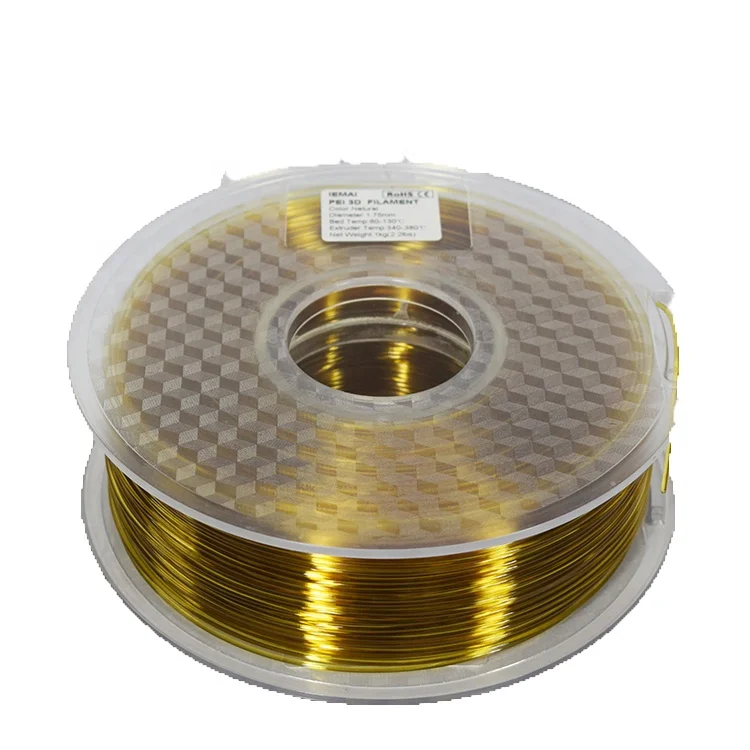

There are two ULTEM material types, the ULTEM 1010 (resin material) and the ULTEM 9085 (filament material). Both material types come with different applications and different print settings. SABIC recently introduced a new series of more new high performance PEI materials that are based on the ULTEM 1010.

ULTEM 1010

Properties

- High tensile strength. This material has the highest tensile strength of all FDM filaments. This results in strong and durable parts.

- High thermal stability. With its excellent thermal stability and heat resistance this material can also withstand autoclaving (steam sterilisation for medical parts).

- NSF 51 food-contact certification, the only FDM material that has this certification.

- Biocompatible (ISO 10993/USP Class VI certifications).

Applications

Due to its food-contact and bio-compatibility certifications, ULTEM 1010 is a very suitable option for applications within the food industry and medical industry. You can think of production tools that come in contact with food and medical devices like surgical guides, fixtures and custom apparatus.

You can think of production tools that come in contact with food and medical devices like surgical guides, fixtures and custom apparatus.

Other industries where ULTEM 1010 is used are the aerospace and automotive industries. Due to its high strength and thermal stability, this material can be used in semi-structural components and out-of-cabin aerospace applications.

Recommended printer settings

- Extruder Temperature (all metal extruder necessary): 370 – 390°C

- Print Bed Temperature: 120 – 160°C

- Print bed adhesion: Perf board, Kapton tape or Lightly sanded FR4

- Heated Enclosure: YES, this is required, the printing of ULTEM performs best in a hot build environment

- Printing speed: 20-30 mm/s

ULTEM 9085

Properties

- Very high strength-to-weight ratio. ULTEM 9085 offers comparable impact strength to metal parts like aluminium but can be made much lighter.

- High thermal resistance.

ULTEM 9085 has a heat deflection temperature of 167°C.

ULTEM 9085 has a heat deflection temperature of 167°C. - Inherently flame retardant. FST-compliant and certified for aircraft components.

- Chemical resistance. Resistant to a wide range of chemicals (e.g. alcohols, automotive fluids & aqueous solutions).

Applications

The properties of ULTEM 9085 make it an ideal for aerospace and automotive applications, providing high-performance parts and a lightweight alternative to metal. The most important property of ULTEM 9085 must be the high strength-to-weight ratio. Because this is extraordinary high for a plastic based material, its applications can be found in the aerospace and automotive industries. Applications of ULTEM 9085 are found in places where the weight of an object significantly has an effect on the cost of operation but object-strength is of the utmost importance. Examples of this can be found in aircrafts where weight of the aircraft directly correlates to the amount of fuel consumed.

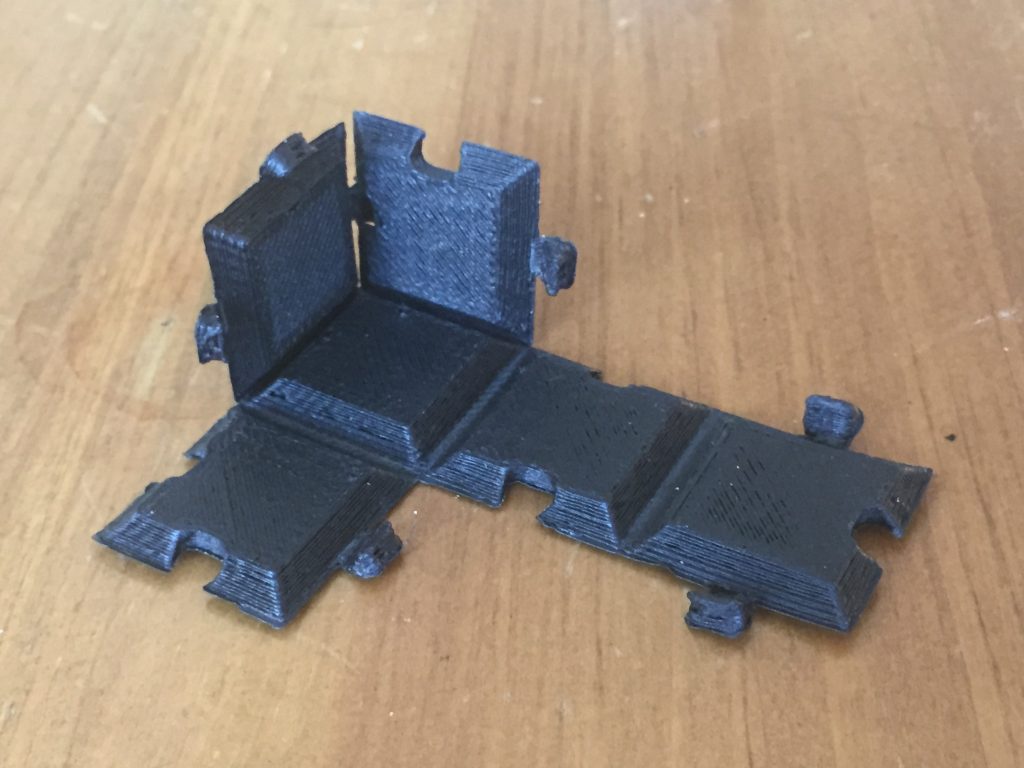

Besides these industrial applications, ULTEM 9085 can also be used to 3D print interior components, ductwork or electrical enclosures.

Recommended printer settings

- Extruder Temperature (all metal extruder necessary): 350 – 390°C

- Print Bed Temperature: 130 – 160°C

- Print bed adhesion: Perf board, Kapton tape or Lightly sanded FR4

- Heated Enclosure: YES, this is required, the printing of ULTEM performs best in a hot build environment

- Printing speed: 20-30 mm/s

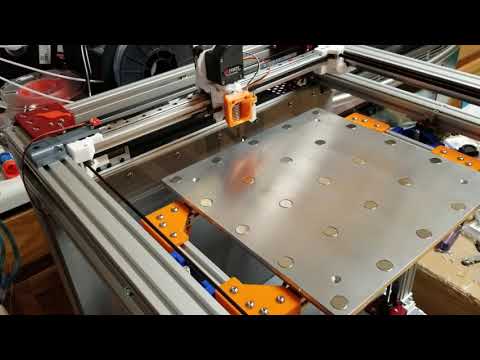

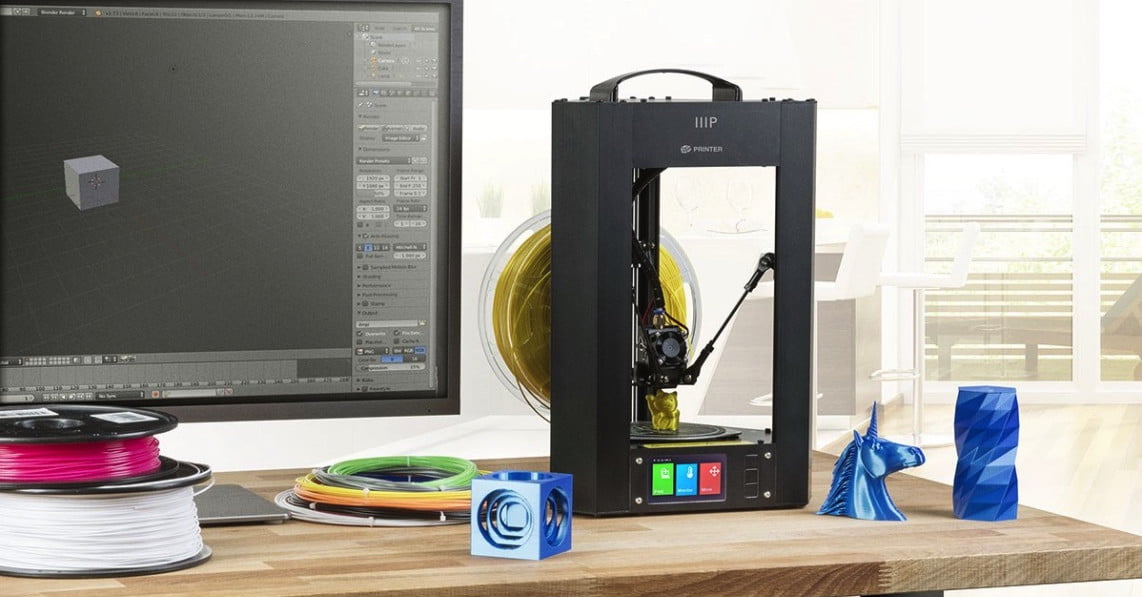

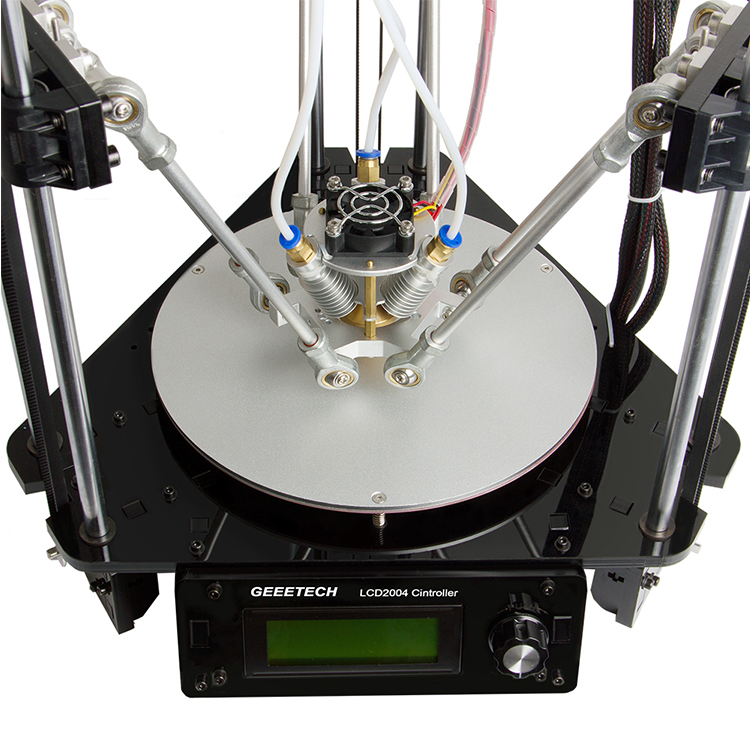

ULTEM 3D Printers

For some time, only Stratasys made 3D printers that could handle ULTEM, but more manufacturers are now producing industrial-grade 3D printers. One of those companies is Tractus3D. Their T850P machine comes with all the bells and whistles an engineer should expect from an industrial 3D printer: high-temperature extrusion, closed print chamber, and high-quality components. Here are the tech specs:

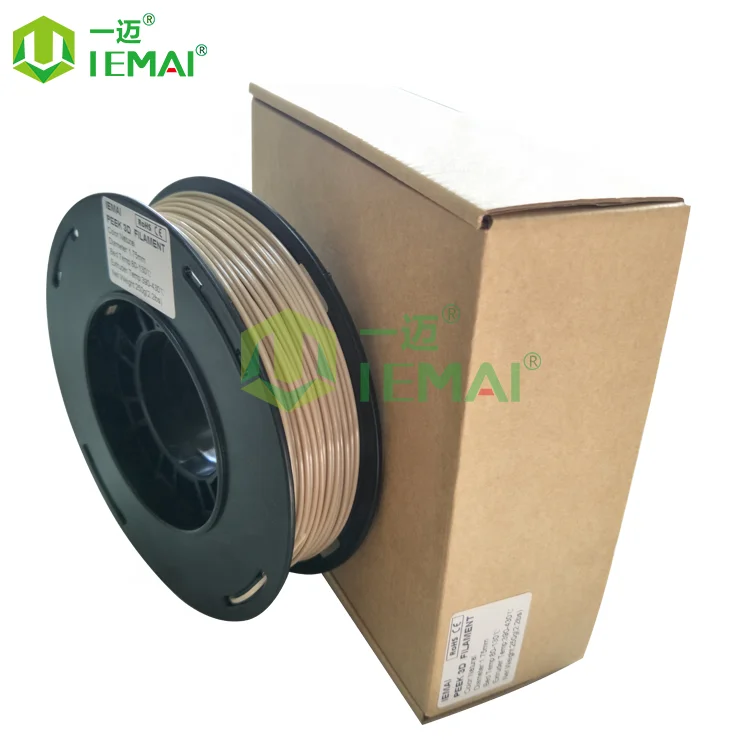

THERMAX™ PEI, ULTEM™ 9085

ThermaX™ PEI 3D Filament made with ULTEM™ 9085 PEI

We manufacture this high performance 3D printing filament using ULTEM™ 9085-PEI (polyether) resin. ULTEM™ 9085 Resin filaments enable the creation of parts with excellent properties at elevated temperatures due to its high glass transition temperature (Tg) of 186°C. PEI is an amorphous, high performance polymer that combines excellent thermal properties, exceptional dimensional stability, inherent fire resistance and good chemical resistance.

ULTEM™ 9085 Resin filaments enable the creation of parts with excellent properties at elevated temperatures due to its high glass transition temperature (Tg) of 186°C. PEI is an amorphous, high performance polymer that combines excellent thermal properties, exceptional dimensional stability, inherent fire resistance and good chemical resistance.

Product attributes include:

- High thermal properties; (Tg) 186°C

- Self-extinguishing with low smoke emission and low smoke toxicity

- Long term hydrolytic stability

- Excellent dimensional stability (low creep sensitivity and low, uniform coefficient of thermal expansion) and very reproducible part sizes

- Exceptional strength and modulus even at elevated temperatures

- Good resistance to a wide range of chemicals such as automotive fluids, fully halogenated hydrocarbons, alcohols and aqueous solutions

- Stable dielectric constant and dissipation factor over a wide range of temperatures and frequencies

Typical Applications for ULTEM™ PEI:

Aerospace: Excellent balance of fire resistance, low smoke production, and low smoke toxicity of ULTEM™ 9085 makes it an excellent candidate for aerospace and aviation applications. ULTEM™ 9085 meets FAR 25.853 and OSU 65/65 with low toxicity, smoke and flame. Ultem™ resins find applications in areas such as personal service devices, oxygen panels and components, ventilation system components, connectors, cable ducts, latches, hinges, food containers, door handles and interior cladding parts.

ULTEM™ 9085 meets FAR 25.853 and OSU 65/65 with low toxicity, smoke and flame. Ultem™ resins find applications in areas such as personal service devices, oxygen panels and components, ventilation system components, connectors, cable ducts, latches, hinges, food containers, door handles and interior cladding parts.

Cars / vehicles: Ultem™ resins provide automotive manufacturers with a high performance, chemical resistant, heat resistant, cost effective alternative to metal that is strong enough to replace steel in some applications and light enough to replace aluminum in others. For applications such as transmission components, throttle bodies, ignition components, sensors and thermostat housings,

Electrical / Electronics: ULTEM™ resin can be an excellent material choice for today's demanding electrical applications including connectors, MCB components such as enclosures, shafts and arms, hard drive internals, FOUPs, BiTS, PCBs, MCCB internals, Plenum devices, LCD projector internals, fuel cell components and many other applications.

Filament specification:

- Diameter: 1.75 mm (+/- 0.05 mm)

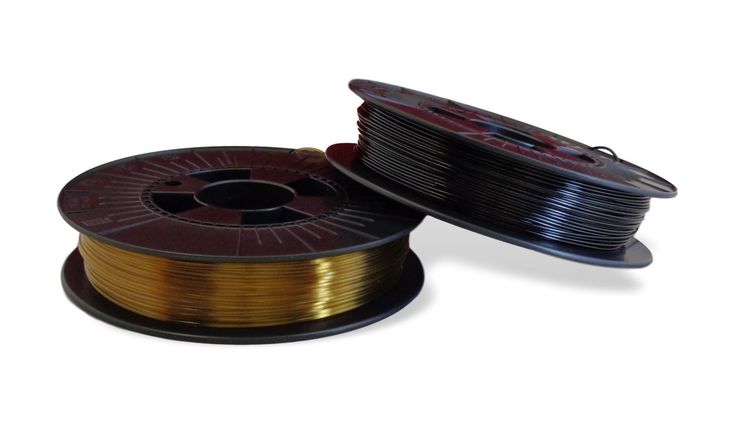

- Colors: natural (light brown) and black

Recommended printing conditions:

- Extruder temperature: 350 - 380°C (all-metal extruder)

- Bed temperature: 140 - 160 ° C

- Bed preparation: PEI tape, polyimide tape, lightly sanded FR4 or perforated board.

- Other: no cooling fan, print speed 1000mm/min (starting point)

- Drying instructions: Please see the following instructions when you want to dry this thread, HERE.

Printed Part Annealing: If necessary, ULTEM™ printed parts can be annealed in a hot air oven to reduce any printed stresses that may be present in the part. Printed stresses can occur in any plastic and can result in lower than expected mechanical properties. If this is a problem with your part, then you can follow a simple 5 step increase/decrease process to anneal ULTEM™ parts.

Step 1: Place the printed parts in a cool, room oven.

Step 2. Set temporary temperature to 250°F and let it stabilize for 1 hour.

Step 3: After 1 hour at 250°F, increase oven temperature to 300°F and allow to stabilize for 1 more hour.

Step 4: After 1 hour at 300°F, reduce heat to 200°F and allow to stabilize for 30 minutes.

Step 5: Turn off the oven after 30 minutes and let the printed pieces return to room temperature inside the oven as it cools.

ULTEM™ is a registered trademark of Sabic Innovative Plastics.

3DXTECH manufactures this filament from ULTEM™ 9085 PEI resin.

Charpy Impact

Bend

Tension Along Layers

Tension Across Layers

Compression

₽

This product is currently not available, see similar

Go to the storeThis product is no longer for sale, see similar ones

Link copied, share it

Or send via social networks

91. 86 ₽ More expensive than average, slightly

86 ₽ More expensive than average, slightly

Reliable seller - 100%

You can safely buy, DFORCE 3 d printer Store

- On the site for more than 5 years

- High overall rating (5917)

- Customers satisfied with communication

- Items as described

- Ships quickly

- for the last 3 months

Prices from other sellers from 1235.61 ₽

1 236 – 1 601 ₽

TPU 3D printing filament Black Flexible 1.75 mm 0.5 kg filament roll plastic filament for 3D printer

color printing material 1 rating1 order

Reliability – 100%

Seller AWTECH Store

In the store in the store

1 414 ₽

ABS threads for 3D printer 1.75 mm 1 kg materials for printing 3D Plastic threads Green

1 Access

1 price 9000

Reliability - 55%

Seller Northcube Store

In the store to store

Found 47 similar products

-5

%

2 979 -3 743 ₽

Container for drying thread 3D, SUCCE 3d printers, fast delivery

2

1

The reliability of the seller 0%

1 591 ₽

Thread for the 3D printer Pla Crystal, 1. 75 mm, 500 g, brilliant plastic threads for 3D printing

75 mm, 500 g, brilliant plastic threads for 3D printing

0

0

The reliability of the seller is 89%

-10

%

1 414 ₽

ABS thread for a 3D printer 1.75 mm 1 kg materials for printing 3D PLANS BROWS

1

1

The reliability of the seller 55%

832.93 ₽

5m pcl 3d filament pen random filament color for sl-300a 3d printing bubble free pens 1.75mm consumable for children

0

0

Reliable seller 100%

Filament for pla rainbow silk 3d printer, 1.75 mm, g, 4 rolls/set, 1 kg, 3d printing material, sublimation gradient filaments

1

10

%

1 414 ₽

ABS thread for 3D printer 1. 75 mm 1 kg materials for printing 3D Plastic threads for printing violet

75 mm 1 kg materials for printing 3D Plastic threads for printing violet

0

0

The reliability of the seller 55 %

-9

%

₽ 9000 ABS ABS threads For a 3D printer 1.75 mm 1 kg printed materials 3D plastic threads for printing jade green0

0

The reliability of the seller 55 %

9000 -7%

1 489 ₽

9000 ABS for 3D printer printer 1 .75 mm 1 kg printing materials 3d plastic printing filament rose red0

0

The reliability of the seller is 55%

11.72 - 98.60 ₽

Strong -resistant 3D threads PLA PLA 3D prints 3D printing material for 3D Press 3D Printer

3

6

Teleplifier Teleplification seller 28%

-11

%

1 414 ₽

ABS filament for 3d printer 1. 75 mm 1 kg printing materials 3d plastic filaments for coffee

75 mm 1 kg printing materials 3d plastic filaments for coffee

1

5 0

5

incomplete data

3 340 -4 629 ₽

Box for drying thread 3D, thread storage holder, sublimation box for storage of thread for 3D printer

2

0

Reliability of 0%

-4 -4

%

Incomplete data

1 921 ₽

1 kg, 1.75 mm wood filament, 3d printer filler, 3d printing pens, high quality 3d printing supplies, wholesale

0

0

The reliability of the seller 0 %

-27

%

1 466 ₽

TRONXY 3D thread 1 kg/roll 1.75 mm PLA PLAT PLAC Black 3D prints 3D Prints Assessoers

0

1

The reliability of the seller 68 %

-10

%

814. 32-1 875 ₽

32-1 875 ₽

3D printer PLA 1 kg/500G/250g materials for printing-plastic filler, 9Colors on the choice of

18

6

The reliability of the seller is 89 %

-0.9

%

3 426 ₽

Soft threads for a 3D printer, flexible thread 1.75/3.00 mm for a 3D printer Makerbot Reprap Mendel Up 1 kg

0

0

Reliability of the seller 100%

2 287 ₽

Spring Steel Velist PRUSA I3 MK3 PEI for updating the 3D printer i3 MK3 ULTEM 1000 9000.

0

Reliable seller 100%

-1

%

2011 – 3 137 ₽

Vigorous new 235x23 5 mm/9.25 "powder-coated double-sided steel plate w/ultem base) ender-3/5 3d printable

0

0

Seller Reliability 89%

1 661 ₽

voron pei ultem sheet for 3d printer, x mm, building plate, double sided golden hardened steel sheet 5 00005

0

The reliability of the seller 89%

1 630-2 547 ₽

FALSHFORGE CREATOR PRO 3D-printing ULTEM PEI STROW STELLENT OF STELLENCE OPLEME OF STELLENCE OPLE COMPLE COMPLED ADDOUSE

3

1 9000 9000 9000) -0. 6

6

%

1 071 – 3 013 ₽

Pla crystal black 1.75 mm 1 kg/500 g/250 g0005

Seller Reliability 89%

20pcs/lot 3d printer filament 20 colors 3d printing pen plastic filament wire 1.75mm printer consumables 3d filament pen abs 909005

1

Reliability of the seller 85%

-3

%

0002 The reliability of the seller is 100 %

-11

%

881.89 -2 073 ₽

PLA Black crystal 3D DIY PRICE PROMICARY 500 g/250 g shining 3D printed PLA plastic threads

2

1

The reliability of the seller is 89 %

-3

%

107.56 -135.83 ₽

5 m/10 m Pla ABS 3D fiber threads of 1. 75 mm different colors. Different colors for 3D printed hand, consumables for refueling for refueling material

75 mm different colors. Different colors for 3D printed hand, consumables for refueling for refueling material

5

7

The reliability of the seller is 100 %

-10

%

1 414 ₽

ABS 3D printer 1,75 mm 1 kg printed materials 3D plastic threads Orange

1

1

The reliability of the seller 55%

-8

%

1 414 ₽

ABS 3D printer 1.75 mm 1 kg Printed Plastic Plastic threads Black

1

2

The reliability of the seller 55% 55%

-43

%

2 999 – 3 171 ₽

pla sunlu filament 1. 75 mm 5 rolls of fillers for 3d printer pla 3d printing materials 5 pcs/set

75 mm 5 rolls of fillers for 3d printer pla 3d printing materials 5 pcs/set

2

8

Seller Reliability 65% .02 mm

5

5

Reliability of the seller 89%

1 298 – 4 290 ₽

Energy with ULTEM powder coating (PEI) Textured/smooth PEI spring steel plate 377x370 mm for 3D printer Ender-5 Plus

1

Reliability of the seller 89%

9000 3 446-4 445 ₽ 9000 ₽ 9000 ₽ 9000Esun 3d Filler Drying Box Filler Storage Holder Dry Filament Measure Filament Weight for 3d Printer Parts

6

3

100% Seller Reliability

-4

%

716.41 ₽

TPU 3d thread flexible color: yellow, thread color 0.5 kg 1. 75 mm dimensional accuracy 0.02 mm no bubbles color full printing material

75 mm dimensional accuracy 0.02 mm no bubbles color full printing material

0

0

Reliability% of the seller

Incomplete data

1 190 ₽

Magnetic sticker for cr10 ender, ultem(pei) applied plate + magnetic base for 3d printer stable build plate

0

0

0100 -6

%

1 416 – 2 229 ₽

pla sunlu filament for 3d printer, pla filament, rainbow materials, 3d filaments 1.75 mm, 1 kg, measurement accuracy +/-0.02 mm

4

5

The reliability of the seller 55 %

-9

%

805.35 -2 240 ₽

PLA 3D silk black thread 1.75 mm 250 g/1 kg 3D 3D seal Silky shiny threads sublimation supply materials

3

1

Reliability of the seller 89%

943. 26-1 320 ₽

26-1 320 ₽

Thermal-resistant 0.2 mm PEI ULTEM for 3D printer Voron, assembly plate for 3D printer 120x12 0/310x31 0/350x350 mm

0

0

9000-15

%

2 035 ₽

Tronxy 3D thread Printer 1kg/TPU Rolon 1.75 mm Flexible thread 3D prints 3D X5SA PRO XY -2 Pro spare parts

3

68%

-10

%

761.91 ₽

Petg 3D printer of thread 1.75 mm 250 g/roll 3D Plastic print 3D Printer 3D handle DIY Print Sublimation materials

0

0

Reliability

20 colors pla filament 5m 1.75mm 3d pen normal luminous filament for 3d printing pen refilled refill consumables material

0

1

0005

%

1 414 ₽

ABS thread for 3D printer 1. 75 mm 1 kg materials for printing 3D Plastic thread blue

75 mm 1 kg materials for printing 3D Plastic thread blue

0

0

Reliability of the seller 55 %

9015%

1 414 ₽

Filament for abs 3d printer 1.75 mm, 1 kg, printing materials, plastic filament for 3d printing, gold %

2 188 ₽

Northcube 3d printed silk pla filament 3d printer filament 1.75mm 1kg-like silk series pink color filament

0

0

g, plastic wire for 3d printer 1.75mm, pla 0.25kg/roll, 3d printing material, dimensional accuracy

1

1

1 500 – 2 511 ₽

AW 1.75mm 3d Printer Filament, Pla Wood Effect 3d Printer Filament, 1kg, 3d Printing Materials, Fast Shipping

1

1

Seller Reliable 100%

-0. 8

8

%

81.36 ₽

Aokin 3d printer filament, 10 meters, pla filament 1.75 mm for 3d printer, extruder, pen, accessories, colored filaments, printing materials

0

Reliability of the seller 89%

-3

%

1 261 - 5 668 ₽

Energy double side with powder coating/Smooth Ultem (PEI) Steel printing sheet build plates 241x254 mm for PRUSA MK3 MK3S 3D

2

3 9000

The reliability of the seller 89%

- 12

%

648.83-1 358 ₽

Energy Amber List PEI ULTEM for PRUSA I3 MK3 241x254x0.2/0.125 mm, 3D printer Platfrom, PLS

0

Sales of Selia%

-5

%

Silk pla 3d printer filament 1.