What do i need for 3d resin printing

What Do You Need For Resin 3D Printing? – Gorilla Output

This post may contain affiliate links, which means that we get commissions for purchases made through such links, at no additional cost to you. As an Amazon Associate we earn from qualifying purchases.

You should know all the materials you need for resin 3D printing if you wish to start exploring the world of resin 3D printing. That is why we have put this post together to share our knowledge and expertise on the requirements for resin printing.

What do you need for resin 3D printing? You need a resin 3D printer and resin material. You also need safety accessories, like goggles, a respirator mask, and gloves. You may also need paper towels or a pallet knife to make your resin 3D printing easier. What’s more, you should think of the accessories you would need for post-processing. These include isopropyl alcohol and a UV curing machine (or sunlight, if you like), among others.

There are many things you need for resin 3D printing beyond just the resin material and a 3D resin printer. Some of these materials are basic requirements, while some others will make resin printing easier and/or safer for you. As you read on, we will show you everything you need for resin 3D printing and explain what each one does.

The Basic Things You Need for Resin 3D Printing

The two basic needs for resin 3D printing are a 3D printer and resins. Resin is the basic material for creating 3D parts. The printer, on the other hand, is the machine that helps harness the resin to create your desired 3D part. If you have these two things, you can print your resin 3D models, but you may need some accessories to make the process easier and safer.

Resin 3D Printer

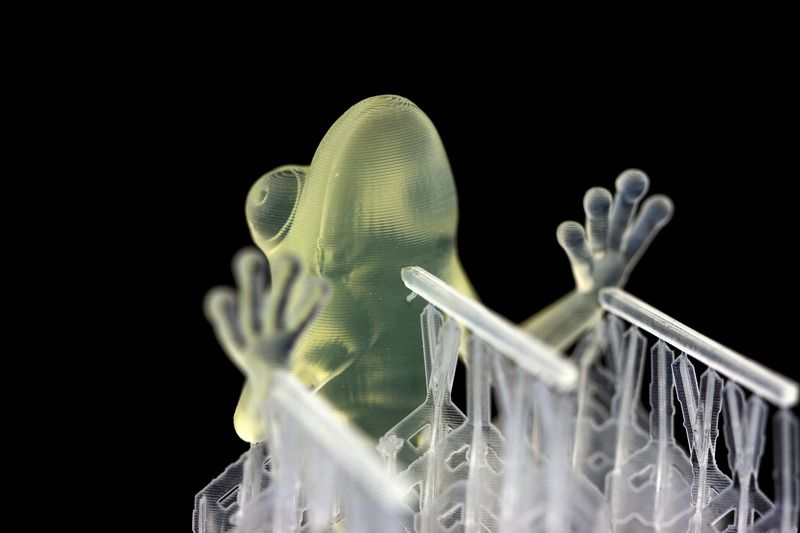

A resin 3D printer uses liquid resins, rather than filaments or powder, to print 3D models. There are different types of resin printers, but stereolithography (SLA) printers are the most popular. The SLA happens in a “tank” as the printer spreads the resin layer by layer, starting with the first layer on the printer’s platform. Successive layers are spread on the one before it.

Successive layers are spread on the one before it.

Types of Resin 3D Printers

There are three common types of resin 3D printers. These three types use resin but they employ different mechanisms to solidify resin parts. The 3 common resin printer types are:

- SLA (Stereolithography) 3D printers, which makes use of laser beams

- LCD 3D printers, which use the LED lights of LCD panels

- DLP (Digital Light Processing) 3D printers, which light flashes from a projector

Resin

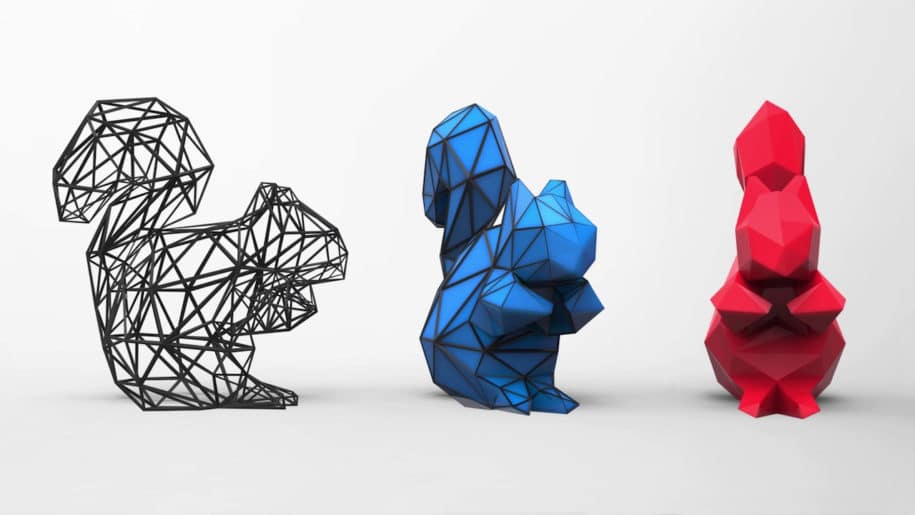

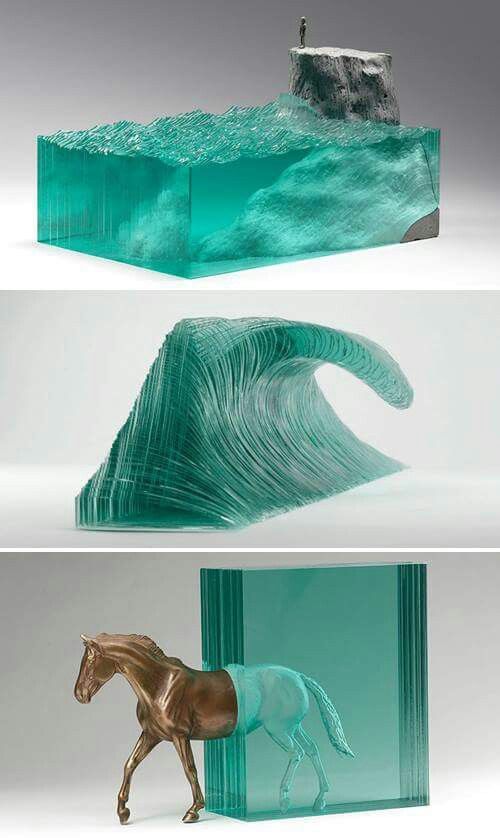

Resin is the basic material for printing resin 3D models . This photopolymer material, which comes in liquid form, cures when exposed to light to create solid 3D parts. There are different resin types and models for various applications. Entry-level resins are cheaper but they don’t offer as much quality as high-end resins, which usually cost more.

Ultimately, resin materials provide higher quality and print models with higher details and accuracy than FDM printers. They also provide smoother results than 3D models created with filament or powder materials.

They also provide smoother results than 3D models created with filament or powder materials.

✅ Video – You NEED these to 3D Print with Resin (Short Version)

Before you read on, watch this video to get a basic overview of what we will be talking about. It shows you the different accessories one by one and even demonstrates how to use them. The sections after this video categorize the accessories by what they do and give a more detailed explanation of each accessory.

Safety Accessories for Resin 3D Printing

Goggles, respirator masks, and gloves are the three vital safety accessories for resin printing. Goggles will protect your eyes, the respirator mask will protect your lungs, and the gloves will protect your skin, particularly your hands. You shouldn’t undertake the resin printing process without these three accessories.

You shouldn’t undertake the resin printing process without these three accessories.

Resin can cause skin irritations and the fumes can get into your eyes and lungs too. So you’ve got to use adequate protection to keep yourself safe while the printing process is ongoing. Let’s take a good look at these three safety accessories:

Goggles

The fumes from standard printing resin are not safe for the eyes. These fumes or even resin itself should never come in direct contact with the eyes. If they do, they can cause quick harm to the eyes. That’s why you need goggles to keep your eyes safe. Some people manage to print 3D resin parts without goggles, but it’s not a safe practice. If you can’t get goggles, you can use regular safety glasses as an alternative.

Respirator Mask

Masks are very important for the protection of your lungs. Resin and its fumes can have two effects on your lungs. Firstly, it can cause quick damage when you inhale too much while printing. Secondly, the effects of minor exposure from time to time can accumulate over years and cause chronic lung damage and respiratory problems. In addition to a mask, you should make sure to print your 3D resin in a well-ventilated area.

Secondly, the effects of minor exposure from time to time can accumulate over years and cause chronic lung damage and respiratory problems. In addition to a mask, you should make sure to print your 3D resin in a well-ventilated area.

Gloves

While handling resin, you should avoid direct contact at all costs to prevent skin irritation. A pair of nitrile gloves should come in handy here. Some people claim that resin does not irritate their skin, but they don’t understand the type of irritant that resin is. You can touch resin several times with no irritation whatsoever. But with increasing exposure, your skin will eventually react. And from the first time your skin reacts, it won’t stop reacting.

Other Resin 3D Printing Accessories

To make your resin 3D printing easier, you need a paint scraper or pallet knife for print removal and paper towels to absorb spills. You also need a dedicated toothbrush to remove excess resins from the finished print. What’s more, you may also need an FEP film and a good filter.

A lot goes into resin 3D printing and that’s why it costs a bit more than other 3D printing technologies. You not only need more consumables for resin printing, but you also need more accessories to help facilitate the process. You should be aware of these requirements before you dabble into resin 3D printing.

Here’s a closer look at the different accessories that can make your 3D resin printing easier:

Paint Scraper or Pallet Knife

After you finish printing your 3D part, you must remove it gently from the printer’s build plate without damaging the newly printed model. Since these models are usually still quite delicate, it’s best to use an extra-wide knife, such as a paint scraper or pallet knife, to remove them. That way, you wouldn’t stress or damage the model while getting it out of the printer.

Paper Towel

You need paper towels to absorb spills during printing. You can use any type of cleaning material, but paper towels do the best job for cleaning resins. Make sure to buy this in bulk because resins are quite messy and can quickly cause permanent stains if left uncleaned. What’s more, it’s better to use pantry paper towels rather than those sold in drugstores.

Make sure to buy this in bulk because resins are quite messy and can quickly cause permanent stains if left uncleaned. What’s more, it’s better to use pantry paper towels rather than those sold in drugstores.

Toothbrush

You should have dedicated toothbrushes for your resin 3D printing. They are ideal for brushing off excess resins from finished prints. You can also use them to remove dust from the surface of your 3D part after sanding. Make sure you get a toothbrush with soft bristles, as hard bristles can damage prints.

Filter

You don’t need filters during printing but they can help you save waste after printing. If there are leftover resins in your printer vat, you can filter them to remove cured resins. Dispose of the cured resin and store the uncured resins for later use.

You have two options; you can get a permanent filter or buy disposable filters from time to time. Both options work well. But permanent filters need thorough washing after each use. Disposable filters, on the other hand, are to be disposed of after each use but that’s not so environmentally friendly because they can’t be recycled.

Disposable filters, on the other hand, are to be disposed of after each use but that’s not so environmentally friendly because they can’t be recycled.

FEP Film

FEP films are transparent, double-layered foils that you can insert into the rack linked to your printer’s tank. This film creates a clear way for UV radiation to cure resins while printing is still ongoing. This makes the entire process faster without affecting the model’s strength or accuracy.

Accessories for Resin 3D Print Post-ProcessingThe accessories for post-processing resin 3D prints include IPA (Isopropyl alcohol) to wash off excess resins and an ultrasonic cleaner that will help clean the printed part automatically. A UV light source is also very important for curing your 3D print. You can cure your 3D part with sunlight but you would need a solar-powered turntable to facilitate even and effective UV curing.

Let’s examine the different post-processing accessories one by one:

Isopropyl Alcohol (IPA) & Pickle Bucket

IPA will help wash excess resins away from your printed part. You may need a pickle bucket where you will pour IPA and dunk the printed part in it. As you do this, all the extra resins on the surface of your printed part will wash off.

You may need a pickle bucket where you will pour IPA and dunk the printed part in it. As you do this, all the extra resins on the surface of your printed part will wash off.

Ultrasonic Cleaner

An ultrasonic cleaner will come to your rescue if you don’t want to wash your resin print manually. This machine is designed to clean resin prints automatically. You will have to add IPA and put your finished print in the machine. Then, switch it on and let it run for about 5 minutes. Some ultrasonic cleaners have a timer, so you can set the time it would run for.

UV Light Source

If you are not curing your 3D resin with sunlight, you would need a source of UV light. For this, you can use a UV lamp or torch. But for high-quality results, you can purchase a UV curing machine. These machines allow you to set your preferred UV wavelength and heat levels. So you can use custom curing settings for different applications.

Solar-powered Turntable

Solar-powered turntables are originally for displaying objects but you can also use them for post-processing your resin prints. If you are curing your resin 3D part under sunlight, you would need to rotate the model for even curing. That way, the UV light will touch all sides of the model regardless of the direction of sun rays. Without a turntable, only a side will receive UV rays and that will cause uneven curing.

If you are curing your resin 3D part under sunlight, you would need to rotate the model for even curing. That way, the UV light will touch all sides of the model regardless of the direction of sun rays. Without a turntable, only a side will receive UV rays and that will cause uneven curing.

Wash & Cure Box

This is an optional post-processing accessory but if you get it, it will make your work easier. These machines are all-in-one stations that will wash your resin print and cure the resins for you. This reduces the need for manual input in post-processing resin prints.

Related Questions

How Much Resin Do I Need For 3D Printing?

A 1-liter resin bottle should be enough to print about 120-140 small board game figures, assuming the figures are about 1 inch tall. This should give you an idea of how much resin you need to print your model, considering the size. But not to worry, most SLA printers have in-built slicer software that estimates how much resin you need to print your design.

Modeling software for 3D prints usually gives information on how much resins your 3D part will require before you start printing. As such, there is little to no chance that you will run out of resins midway during printing.

How Long Does Resin Printing Take?

3D resin printing can take as little as 30 minutes or as long as one week or more. Factors that determine this include the size and complexity of your model and the print resolution. The type of printer you are using also plays a vital role. Generally, SLA resin printers are the fastest for highly detailed resin printing. But then, there are cheap printers and high-end printers. High-end printers, though more expensive, tend to be faster.

We have a comprehensive that answers the question, “How fast is a resin 3D printer?“. You can read it for more details.

What Are The Dangers Of 3D Printing?

The major dangers of 3D resin printing stem from the fact that resin is a toxic material. It gives off fumes that could be toxic to the eyes and lungs. And it causes skin irritation too. What’s more, resins are not friendly to the environment and ecosystem, particularly sea animals.

It gives off fumes that could be toxic to the eyes and lungs. And it causes skin irritation too. What’s more, resins are not friendly to the environment and ecosystem, particularly sea animals.

To mitigate the toxic effects of resins, make sure to protect yourself with gloves, goggles, and ventilator masks while handling resin. Also, make sure to cure excess resins before disposal. And dispose of them appropriately as designated by local authorities for non-degradable materials.

Conclusion

It’s exciting to be able to print highly detailed 3D prints with resin from your workshop or home. But to do this successfully, you must have the right tools, materials, and accessories. So far, we have listed 16 such materials in this post. We hope that you find this list helpful as you embark on your resin 3D printing.

What Do I Need for Resin Printing? More Than You Think!

Curtis Satterfield, Ph.D.

Share on facebook

Share on twitter

Share on linkedin

Share on email

Resin printing is great for producing parts with high levels of detail. Unlike FDM printing a resin part isn’t ready as soon as the printer finishes.

Unlike FDM printing a resin part isn’t ready as soon as the printer finishes.

To get started with resin printing you will need; a resin printer, resin, a way to wash your prints, a way to cure your prints, extra printer consumables, and personal protective equipment.

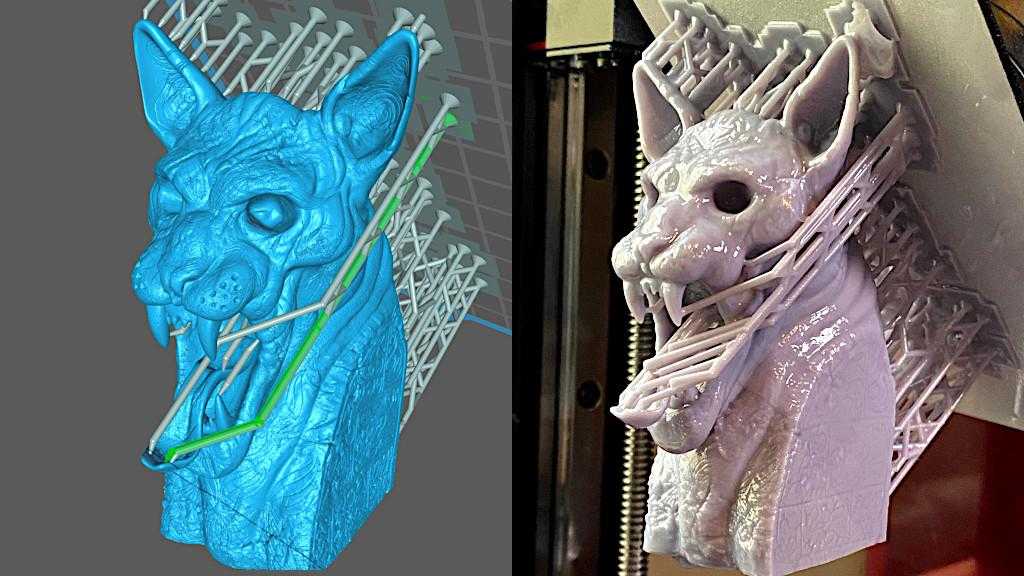

There are several steps to a successful resin print including post processing. After the print comes out of the printer it must be washed, cured, and have the supports removed. I’ve detailed each step below with suggested items you can use to ensure successful printing. We will examine the steps for 3D resin printing in the next section. The rest of the article will cover each step of the process and the items you will need for each step.

Steps for Resin Printing

After a print finished on a resin printer it needs to go through a few steps before it’s ready for use.

- Print your 3D model on your resin printer

- Remove the Print from the build plate

- Wash the model in isopropyl alcohol to remove residual resin

- Cure the print with a UV source.

- Remove Supports

- Clean up any marks left on the print from the supports

The process is straight forward, but you will need extra equipment that didn’t come with your printer. This is the recommended process from most printer manufacturers. I like to remove the supports after the wash step and before curing. In my experience this makes the supports much easier to remove are less likely to leave scars on the print. For more information on how to get started with resin 3D printing check out my article here.

Printing Your Resin Model

Items needed for this step (Amazon links):

- Resin Printer – I recommend the Elegoo Mars Pro 2 as a great first resin printer.

- Resin

- Respirator

- Nitrile Gloves – So many gloves.

- Lint free disposable shop towels

- Paint strainer funnel

Recommended consumables to keep on hand:

- FEP film (size dependent on your printer)

- Extra Resin Vats (printer dependent)

- LCD Panel (printer dependent)

- Build Plate (printer dependent)

We’ll start with the obvious items you will need. A 3D resin printer and some resin. There are several consumer grade resin printers available today starting around $250. The printers will usually come with the printer and all the components the printer will need to work. Some will come with a small tool kit that includes plastic scrapers and a few sets of nitrile gloves.

A 3D resin printer and some resin. There are several consumer grade resin printers available today starting around $250. The printers will usually come with the printer and all the components the printer will need to work. Some will come with a small tool kit that includes plastic scrapers and a few sets of nitrile gloves.

What the printers don’t come with is everything else you need print. One of the big things they don’t come with are personal protective equipment. It’s important to understand that resin is toxic. You need to avoid breathing the fumes or getting it on your skin. Wear a respirator approved for use with organic compounds and wear nitrile gloves when working with the resin.

If you don’t plan to use your printer for a while, I recommend returning the unused resin from the vat to the resin bottle. You will need to use a paint strainer funnel to ensure no hardened bits of resin get back in the bottle. Your kit may have come with one or two funnels, but I recommend ordering more to have on hand. They are made of thin material and can easily be damaged.

Your kit may have come with one or two funnels, but I recommend ordering more to have on hand. They are made of thin material and can easily be damaged.

You should also keep extra FEP film on hand. The FEP film will last a long time if well cared for but FEP is a consumable and will need to be replaced. I also recommend getting at least one spare resin vat. This will allow you to swap between two different resin types without the need to clean the vat each time.

The LCD panel in your resin printer is also a consumable. The LCD screen that is used for the actual printing part will eventually die and need to be replaced. If you’re not in a hurry you can wait until your screen dies and order a new one. If you want to be proactive you should order a spare to keep on hand, so you don’t lose any printing time.

If well cared for the build plate should last you a long time. It will eventually wear out and need to be replaced. If your prints stop sticking to the build plate, try sanding it with 400 grit sandpaper. If any of the screws or the connection between the plate and the Z-carriage become damaged, you will need to replace the build plate.

If your prints stop sticking to the build plate, try sanding it with 400 grit sandpaper. If any of the screws or the connection between the plate and the Z-carriage become damaged, you will need to replace the build plate.

Washing Your Resin Print

Items needed for this step (Amazon links):

- Cleaning solution

- Container for washing

- Pickle Jar or

- Ultrasonic cleaner or

- Print wash machine

- Respirator

- Nitrile Gloves

- Lint free disposable shop towels

The first step after removing your resin print from the build plate is to wash the print. This can be achieved by dunking your print into a container of isopropyl alcohol. A popular method is to buy a plastic pickle jar with a sealable lid. Put your alcohol in the container, drop in the print, and shake for 30 seconds. Let the print soak in the alcohol for about 10 minutes.

There are also machines that can wash the print for you. Another popular option is to use an ultrasonic cleaner. Do not put isopropyl alcohol in an ultrasonic cleaner! Fill the ultrasonic cleaner with water then place your alcohol and print in a Ziplock bag. Seal up the bag and set the bag in the ultrasonic cleaner. Many people have found success using heated ultrasonic cleaners.

Another popular option is to use an ultrasonic cleaner. Do not put isopropyl alcohol in an ultrasonic cleaner! Fill the ultrasonic cleaner with water then place your alcohol and print in a Ziplock bag. Seal up the bag and set the bag in the ultrasonic cleaner. Many people have found success using heated ultrasonic cleaners.

3D printer manufactures also make devices that will wash and cure your print as well. Anycubic sells the Wash and Cure station and Elegoo sells the Mercury Plus. Both machines will keep the cleaning solution moving over the print.

Source: Anycubic.comThere are several alternatives to using isopropyl alcohol to clean your prints. I use Mean Green in an ultrasonic cleaner and it does a great job. I have also read about success with acetone, but you must be careful! Acetone will eat your print if you leave it for too long! No matter what method you use to wash your prints you will need to experiment with cleaning times to find what works best for each resin type you use.

Once the print comes out of the wash, I recommend scrubbing it with a toothbrush in warm water. Depending on your cleaning solution, you may not need to use a toothbrush. Again, you will need to experiment and find out what works best for you.

Curing Your Print

Items needed for this step (Amazon links):

- UV Light Source

- Sunlight or

- UV Light or

- Print curing machine

- Nitrile Gloves

The most cost-effective way to cure your print is to place it outside in direct sunlight. You can achieve better results by placing the print in a clear container filled with water. Place this container in the sun for 15-20 minutes. If the print still feels sticky or uncured leave it for another five minutes and check again.

But what happens if it’s raining or night-time when your print is ready to cure? You can use a UV light source to cure your prints. You can find an inexpensive UV curing light and turntable kit on Amazon for this purpose. I recommend building a box around the turntable lined with tin foil to help distribute the light.

You can find an inexpensive UV curing light and turntable kit on Amazon for this purpose. I recommend building a box around the turntable lined with tin foil to help distribute the light.

On the more expensive side you can use a purpose build curing machine. The wash and cure machines we talked about in the previous section can cure your prints as well. If you have the budget, I highly recommend using a curing machine. It will make your post processing much easier.

Elegoo Mercury Plus Courtesy of Elegoo.comRemoving Supports from Your Print

Items needed for this step (Amazon links):

- Nitrile Gloves (if removing pre-cure)

- Flush Cutters (if removing post-cure)

Most manufacturers recommend removing the supports from your print after curing. I have tried both ways and I prefer removing the supports after washing but before curing. I remove the supports after rinsing them in warm water. The warm water helps soften the supports and they usually pop right off.

The warm water helps soften the supports and they usually pop right off.

If you remove the supports after curing, you will need a pair of flush cutters to snip the plastic away. Snip as close as you can to the print to reduce the amount of sanding you will need to do.

Cleaning Up the Print

Items needed for this step (Amazon links):

- Fine grit sandpaper or

- Fine grit sanding sticks

- Respirator

The last step is to clean up any areas where the supports left marks on the print. This should be minimal if you removed the supports before curing. If not, you will need some sandpaper or sanding sticks. Using a fine grit sandpaper 400 or above, gently remove any points left from the supports. Let it dry and sand flush with the surface. Be sure to wear a respirator while sanding!

If you printed with a transparent resin your print will look scuffed and dusty at this point. You can use a clear coat to help bring back the transparency of the resin. The clear coat will fill in the gaps from the printing and sanding process providing a clean finish.

You can use a clear coat to help bring back the transparency of the resin. The clear coat will fill in the gaps from the printing and sanding process providing a clean finish.

If you printed with an opaque resin and plan to paint your print, I recommend using an acrylic primer first. This will help any paint stick to the model and will cover up any areas you had to sand.

Personal Protective Equipment

You will go through gloves very quickly when working with your printer. To save money I recommend getting a thick pair of nitrile gloves like the ones I use (Amazon link). It can be a bit cumbersome at first because the gloves are not as thin. You can also use a simple pair of cleaning gloves. Now that I am used to the thicker gloves, I no longer need the disposable gloves.

Remember to store your respirator in a Ziplock bag when not in use to prolong the filter life. And if you opt for reusable nitrile gloves clean them off after each use to avoid resin build up.

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- SLA Overview

- SLA Standard Resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Biocompatibility class I vs biocompatibility class IIa

- Cast SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products –

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

The stereolithography prints plastic parts with high resolution, good fine detail and smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries:

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning.

SLA 3D Printing Resin Overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface.

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (ABS equivalent)

Tough resin was developed for models that need to withstand high loads and be durable.

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes.

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance.

Pros:

Cons:

Flexible Resin

Rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips.

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping.

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models.

Durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough tough resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness.

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o C, but has poor impact strength and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity.

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs

Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A biocompatible)

0114

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

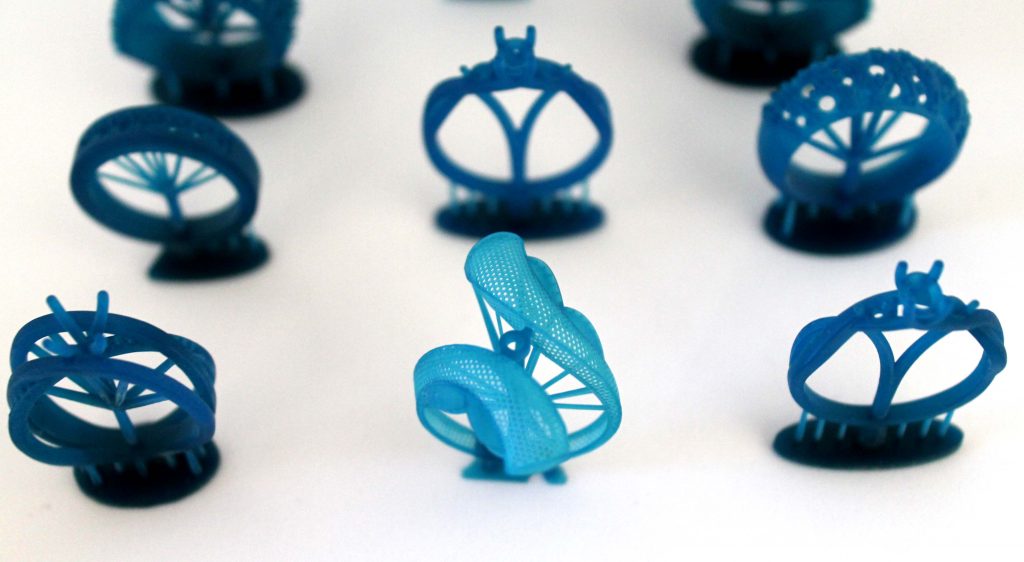

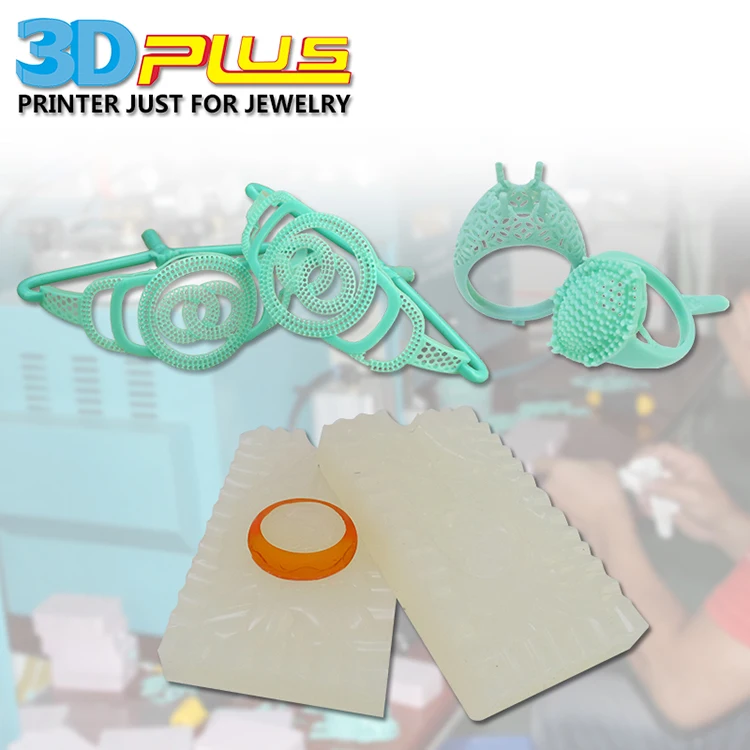

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resins

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.

Cast resin allows you to get the finished product directly from design to precision casting with just one 3D printed part. It is suitable for making jewelry and other small and complex components.

Pros:

Cons:

Ideal for: investment casting, jewelry making

SLA/DLP 3D printer catalog

Photopolymers from FormLabs

Post-Processing SLA/DLP 3D Printing Article

Well, that's all we have! We hope this article was useful for you!

You can order Formlabs SLA 3D printers or ask your questions and find out the status of your order, you can

- Email: [email protected]

- By phone: 8(800)775-86-69

- Or on our website: http://3dtool.ru

-

Don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

In contact with

Printing miniatures on a photopolymer 3D printer

Material source Epoxy Fairy (epoxy resin)

To be honest, I bought the printer out of laziness. Well, I'm tired of sculpting, pouring and cutting with pens and pens, I want to take a model, pour polymer and print for myself.

Well, I'm tired of sculpting, pouring and cutting with pens and pens, I want to take a model, pour polymer and print for myself.

I feel that at the moment when I decided that 3D printing is easy, the god of epoxy choked on a bagel, and then called the god of 3D printing and together they laughed at me like a homer. And then they opened a plant for the production of lip-rolling machines, knowing for sure that as long as I was alive, they would never go bankrupt.

My article is primarily for those who are just thinking of buying this miracle car, I want to tell my impressions of a simple layman for the same for mere mortals. What do you need to be prepared for. Since I have a photopolymer printer (the one that prints from liquid resin), I'm talking about it. Although some of the statements work for other models.

- 1. First, you need to understand why you need a printer. Printing all sorts of gear squiggles is one thing. Print dolls, jewelry and anything subtle or something else.

From this, the printer model and the amount of gold from your pocket vary greatly.

From this, the printer model and the amount of gold from your pocket vary greatly. - 2. Before buying, you should study offers from different sellers, because the same model can cost differently. But! Somewhere in the kit there is resin, somewhere consumables, somewhere nothing, and the fourth seller is generally a scammer.

- 3. Printing settings for different resins, for different colors and even pieces of different size and detail - attention - different! Some printers supply these settings right away with the instructions, but basically you will have to empirically look for it yourself - or on the forums, if you're lucky. don't think

like me,that you just pressed the button and away you go - you have to mess around to find the right ones. And there are so many of them!

- 5. Do not believe the labels on the packages.

Curing time and other settings may not be correct for your particular printer.

Curing time and other settings may not be correct for your particular printer. - 6. Stock up on consumables - look for replacement films, alcohol, filters, etc. in advance. For example, there are no films on mine yet and I don’t know what to do when this one fails.

- 7. For the photopolymer printer, you still need a lamp, which will do additional illumination - so that your product becomes truly solid. Because the printer is only nominal fast printing.

- 8. And you also need something where to wash parts from liquid polymer - I bought a two-in-one thing from my own manufacturer - curing and washing. But I haven't used it yet - I'll tell you about it later.

- 9. Need good programs for cutting parts , for creating supports and more. This whole matter will also have to be studied in some detail.

- 10. It must be understood that some models on the Internet may be skewed and not printed due to construction problems - this will also have to be studied.

What we have left: printing on such a printer is quite a complicated process. To create something interesting, you need to study a lot of additional materials - and this is just printing finished models. It’s not that I don’t look at the modeling itself, I quickly run away if it starts to peer at me.

My second modelHowever, if you are willing to spend your valuable time searching and studying - or if you have a helper / magic wand / loading material into the brain as in a matrix - then this is quite interesting and entertaining. It's worth it, as agent K said ...

Material source EpoxyFairy (epoxy resin)

Related videos and reviews

Common beginner mistakes. I will explain how to win a 3D printer

If you have already tried to print on 3D printers, then probably nothing good happened the first time.